Laser strengthening process for metal leaf

A laser strengthening, metal blade technology, applied in metal processing equipment, laser welding equipment, manufacturing tools and other directions, can solve the problems of uneven hardness, complex process, difficult temperature control, etc., to achieve automatic processing and production, accurate beam positioning. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

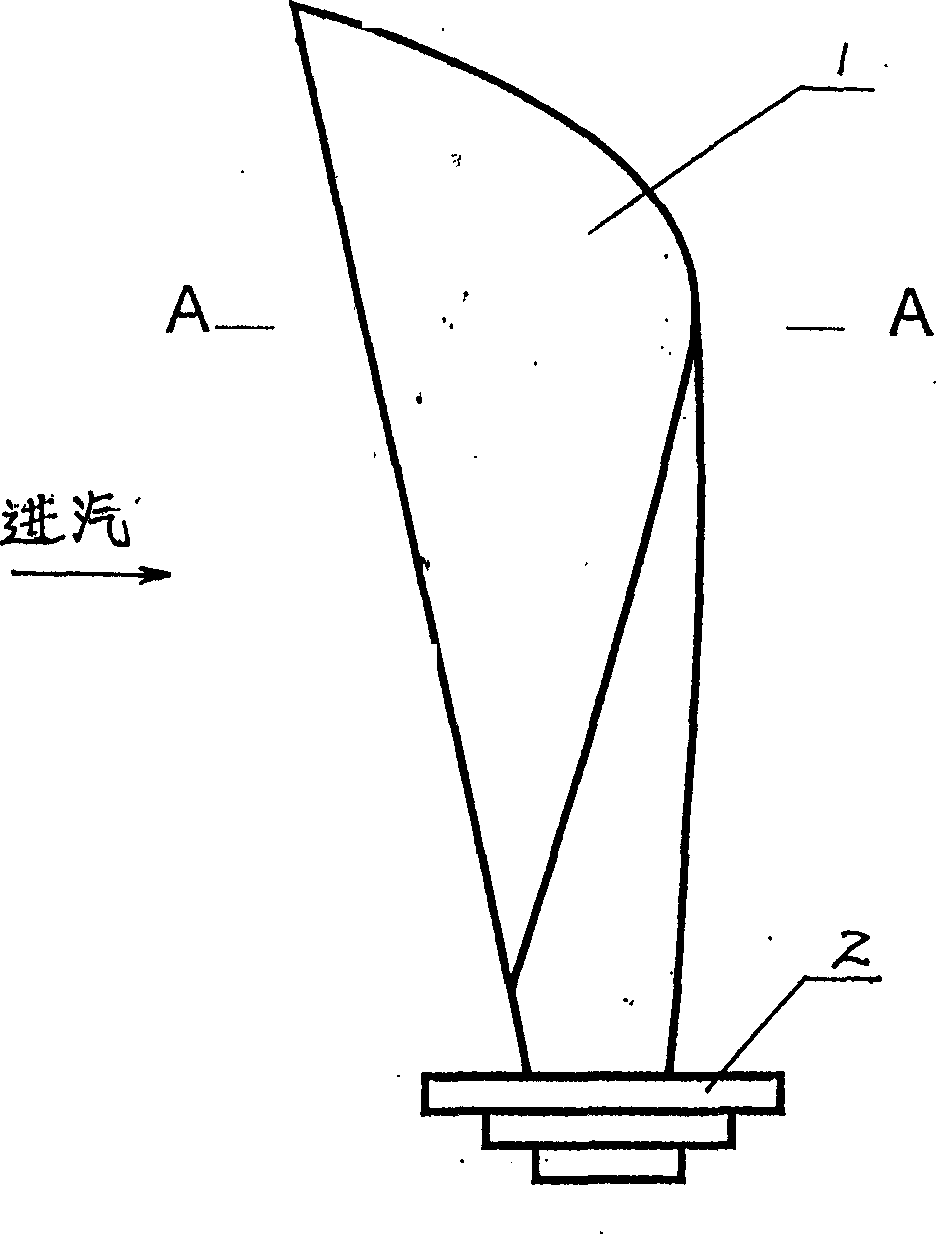

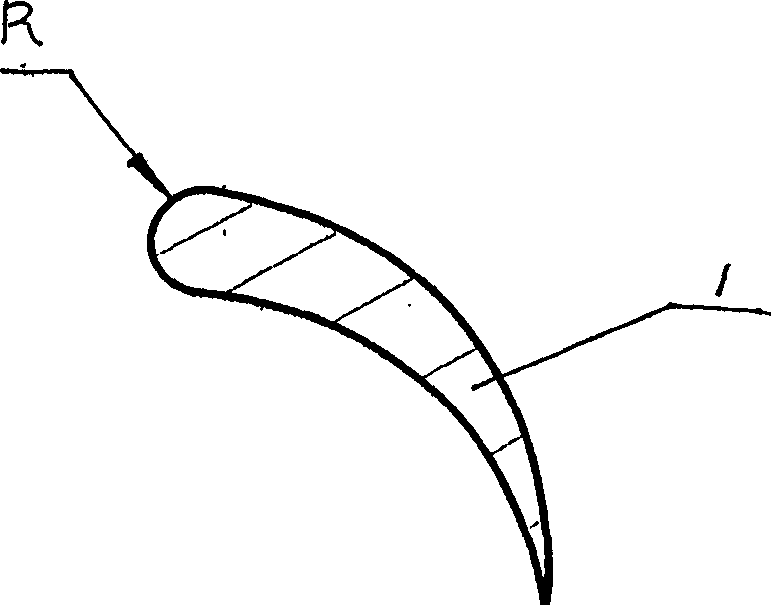

[0014] Combine below Figure 1 ~ Figure 3 The embodiment of the present invention is described in detail. The blade of the embodiment of the present invention is composed of a crown 1 and a root 2, and the material is 2Cr13, in a tempered state. Before the treatment, pre-determine the area and overlap of the treatment leaf crown 1, and perform numerical control programming according to the shape of the treatment part of the leaves, make the positioning fixture of the leaves, clean the treatment area, and apply alloy light-absorbing paint. The laser spot is a rectangular laser spot of 10mm×2mm, and the inert gas is protected during processing.

[0015] Taking the manufacturing steps of SK / MK56-3 gas turbine blades as an example, the description is as follows:

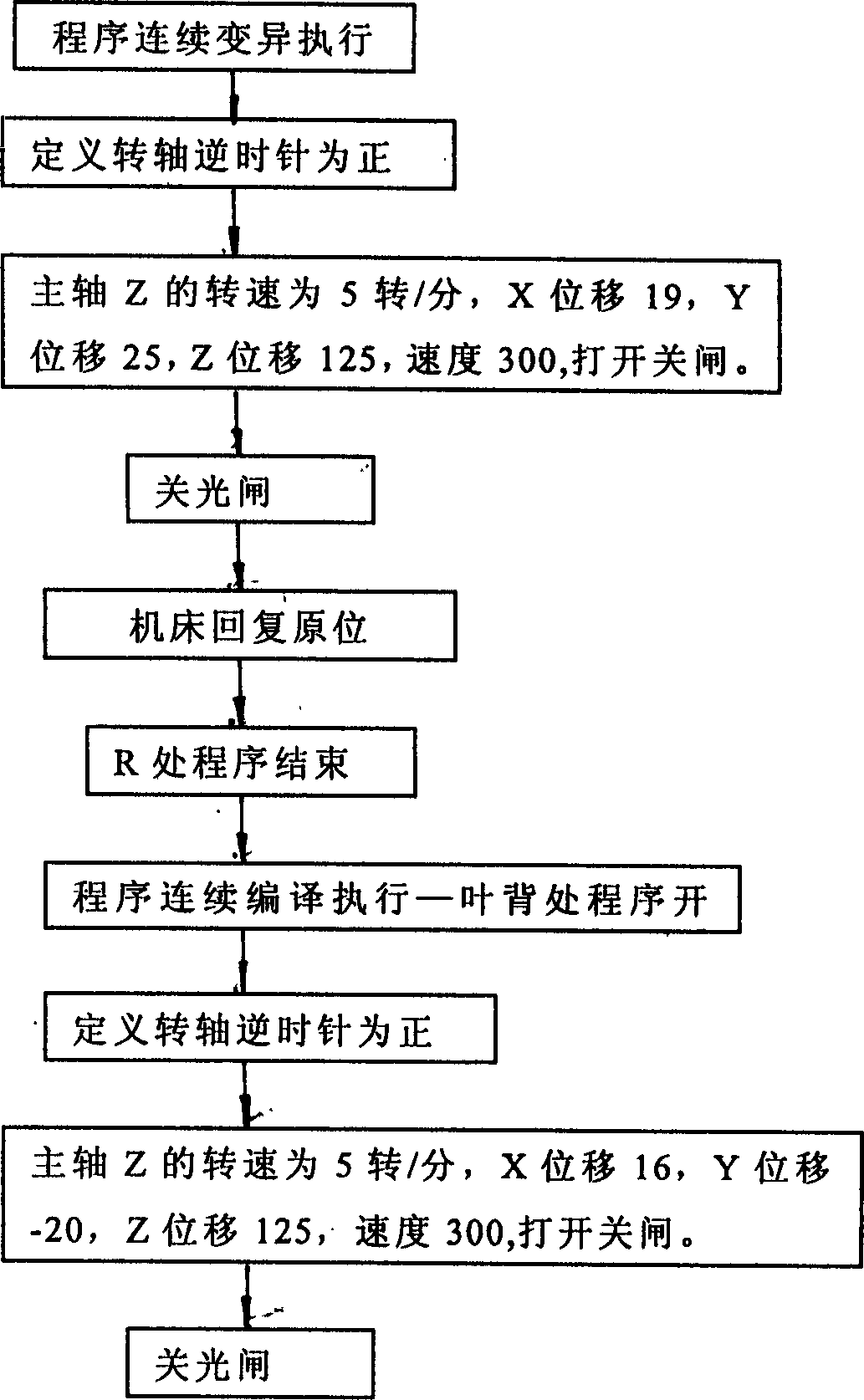

[0016] 1. According to the requirements of the processing area, carry out NC programming according to the blade shape line, the program block diagram is as follows figure 1 As shown, the program code is as follows:

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com