Heat exchange piece and piece type air heat exchanger using same

An air heat exchanger, heat exchange fin technology, applied in heat exchange equipment, heat exchanger types, indirect heat exchangers, etc., can solve the problems of reducing heat exchange efficiency, large volume, heat conduction failure, etc., to eliminate heat exchange Dead point, increase the heat dissipation area, the effect of reasonable structure setting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

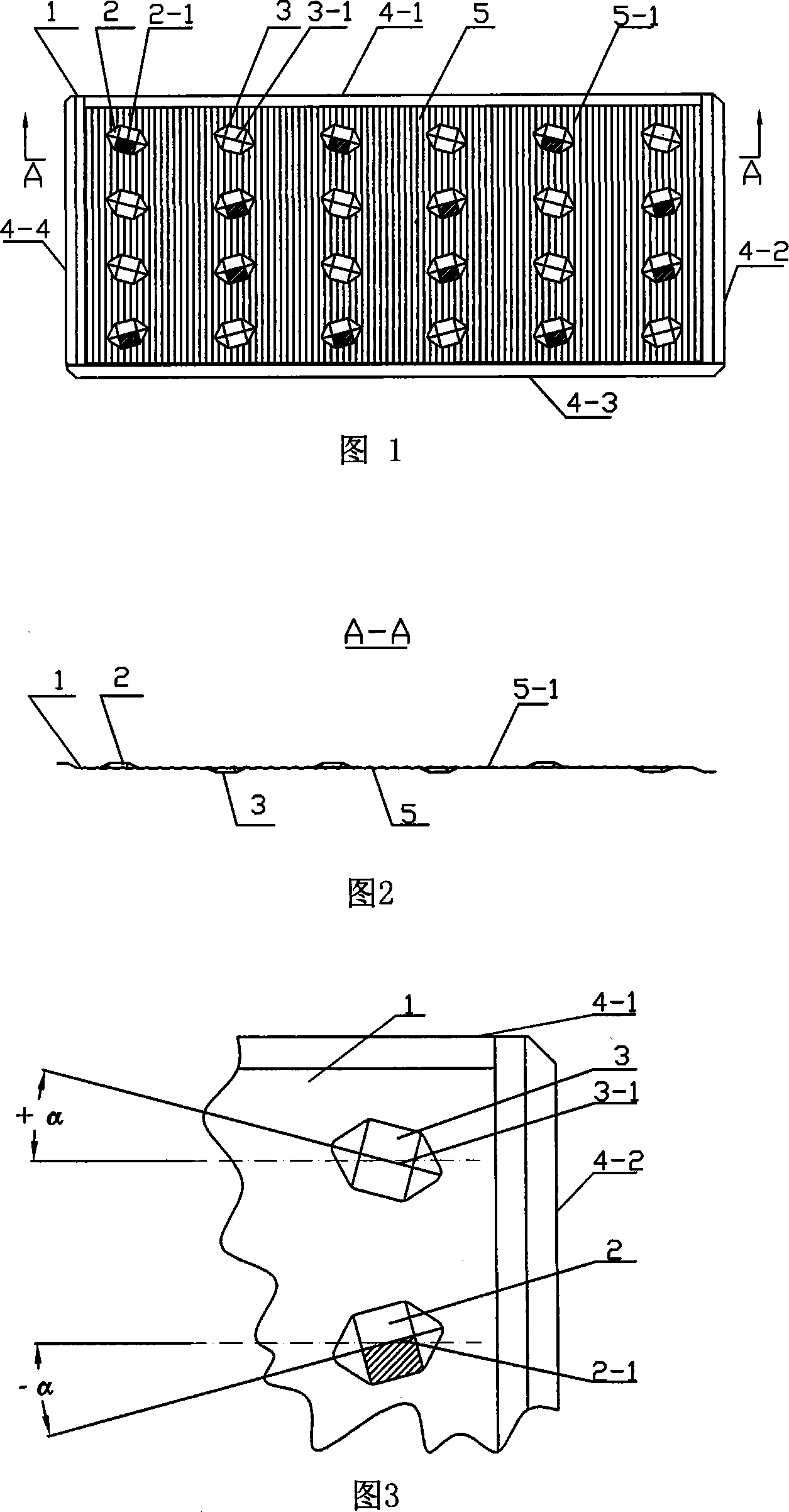

[0030] Fig. 1 is a schematic front view of the heat exchange fin; Fig. 2 is a cross-sectional view of A-A of Fig. 1; Fig. 3 is a schematic diagram of the inclination angle of the central ridge of the convex and concave polyhedron shells in Fig. 1 . Figures 1-3 show a heat exchange fin 1, which is a metal foil molded part composed of a substrate 5 and several convex and concave shell units arranged vertically and horizontally on it, which is characterized in that the convex 1. The concave shell type unit is a convex and concave polyhedral shell 2, 3 symmetrical to the central ridge 2-1, 3-1 respectively, and its central ridge 2-1, 3-1 is connected to the heat exchange fin 1 and the air inlet direction The included angle between the parallel sides 4-1 is +α or -α, and the value of α is 10° to 45°. The dotted line in Fig. 3 is the side 4-1 parallel to the air inlet direction of the heat exchange fin 1 Parallel lines, in this case the alpha value is 15°. The substrate 5 of the he...

Embodiment 2

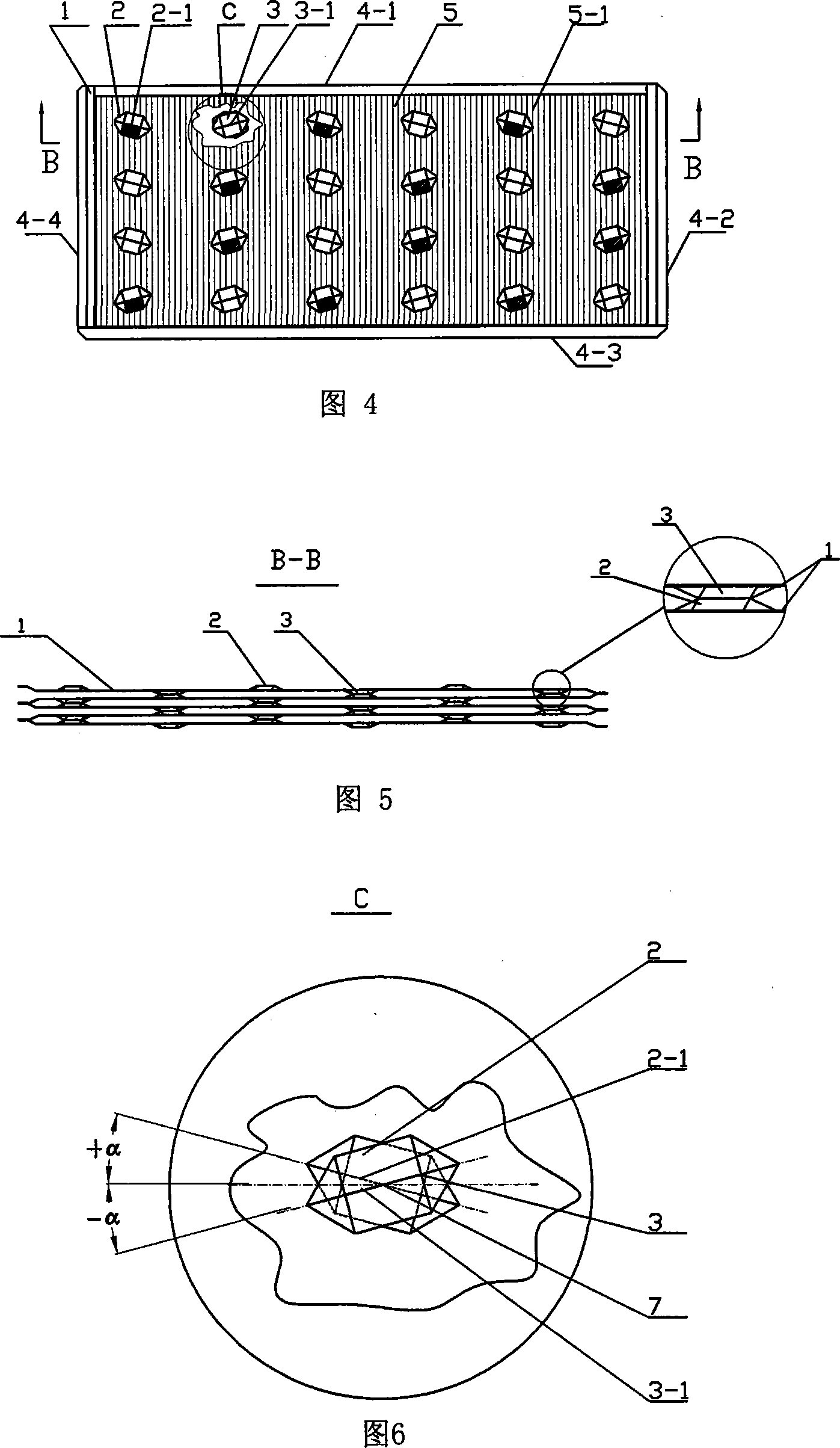

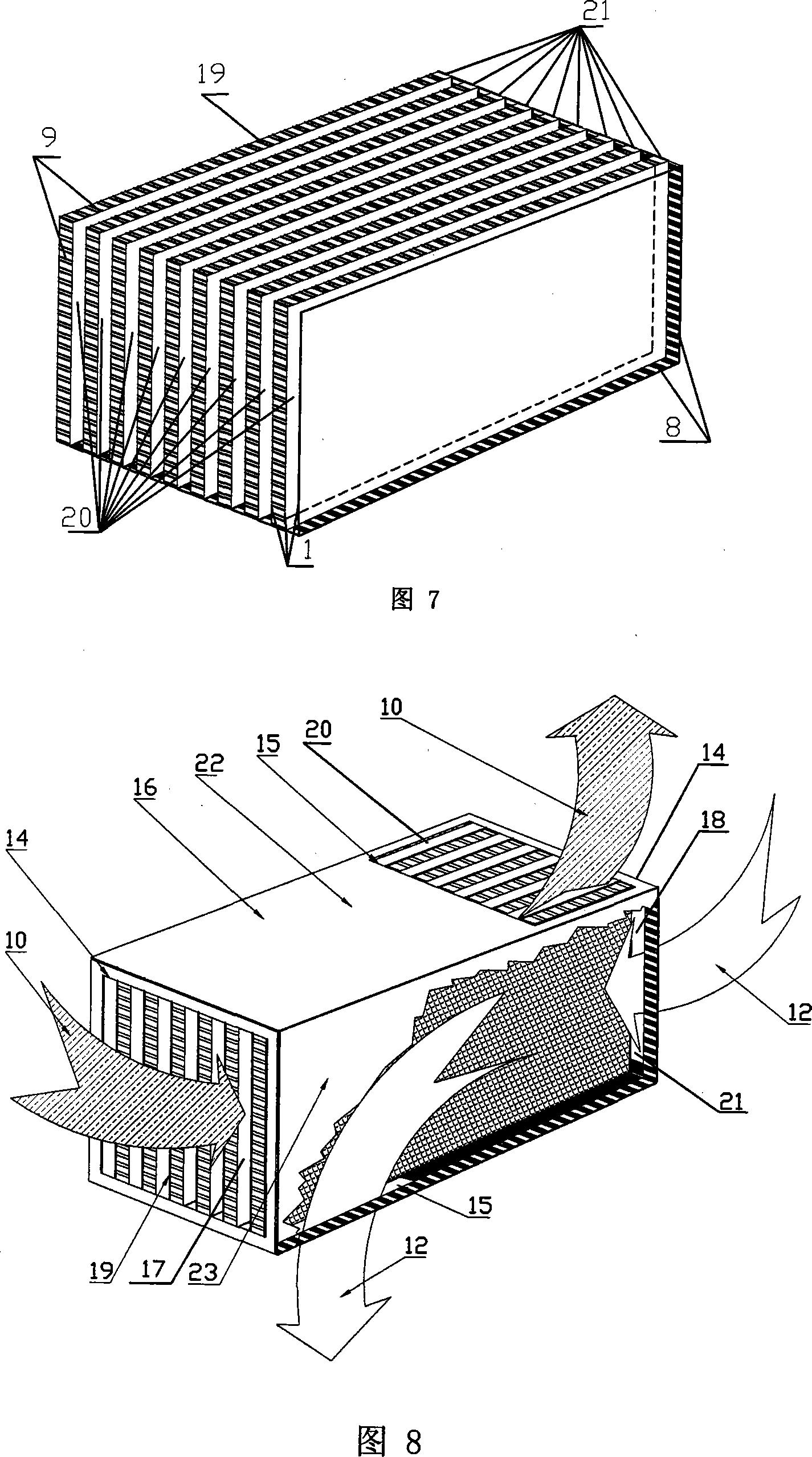

[0032] Fig. 4 is a schematic diagram of the front structure of the convex and concave polyhedral shells of two adjacent heat exchanging fins intersecting against each other; Fig. 5 is a cross-sectional view of B-B in Fig. 4; Fig. 6 is the center of two adjacent heat exchanging fins in Fig. 4 Schematic diagram of the positions of the convex and concave polyhedral shells with intersecting ridges; Fig. 7 is a schematic structural diagram of the sealed connection of the heat exchange fins of the core of the sheet air heat exchanger; Fig. 8 is a schematic diagram of the overall structure and working principle of the sheet air heat exchanger; Fig. 9 is a schematic diagram of the installation structure of the plate-type air heat exchanger installed on the side wall of the electrical cabinet. Fig. 8 shows a plate-type air heat exchanger using the heat exchange fins 1 described in Embodiment 1, which includes a heat exchanger core 19 and a fixing mechanism composed of multiple layers of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com