Patents

Literature

135 results about "Metallic color" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A metallic color is a color that appears to be that of a polished metal. The visual sensation usually associated with metals is its metallic shine. This cannot be reproduced by a simple solid color, because the shiny effect is due to the material's brightness varying with the surface angle to the light source. In addition, there is no mechanism for showing metallic or fluorescent colors on a computer without resorting to rendering software which simulates the action of light on a shiny surface. Consequently in art and in heraldry one would normally use a metallic paint that glitters like a real metal.

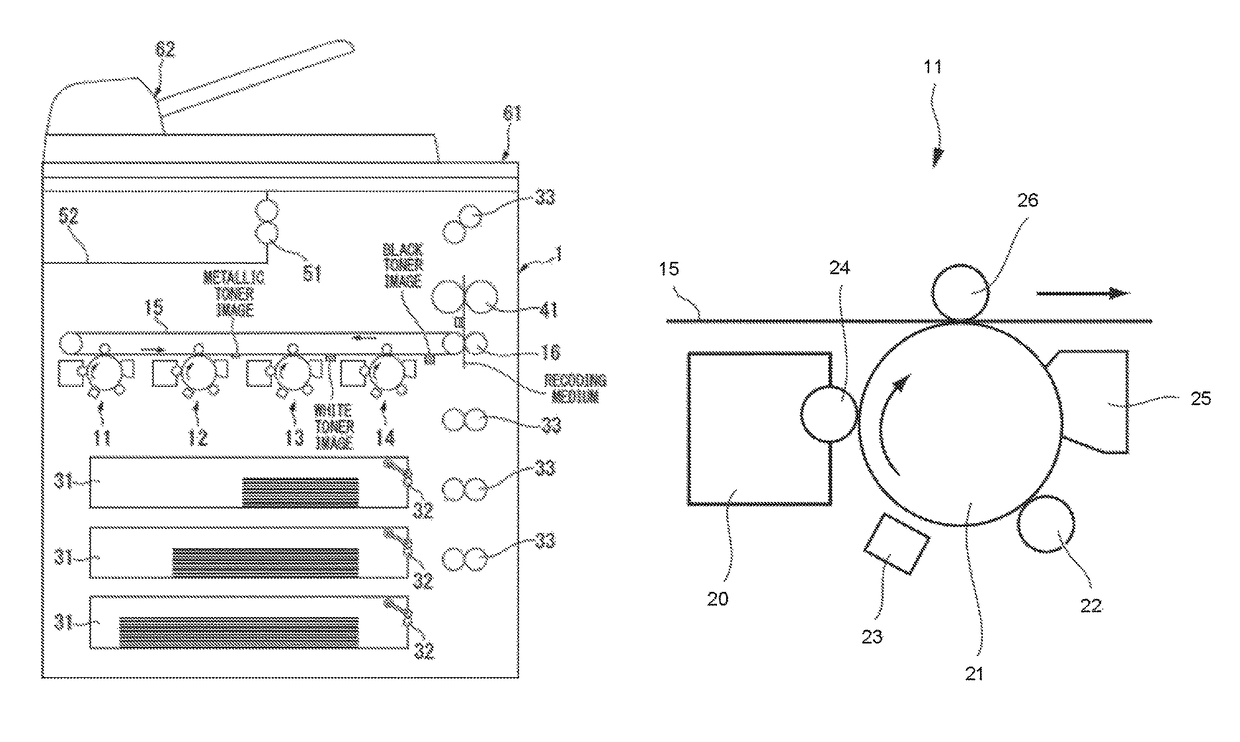

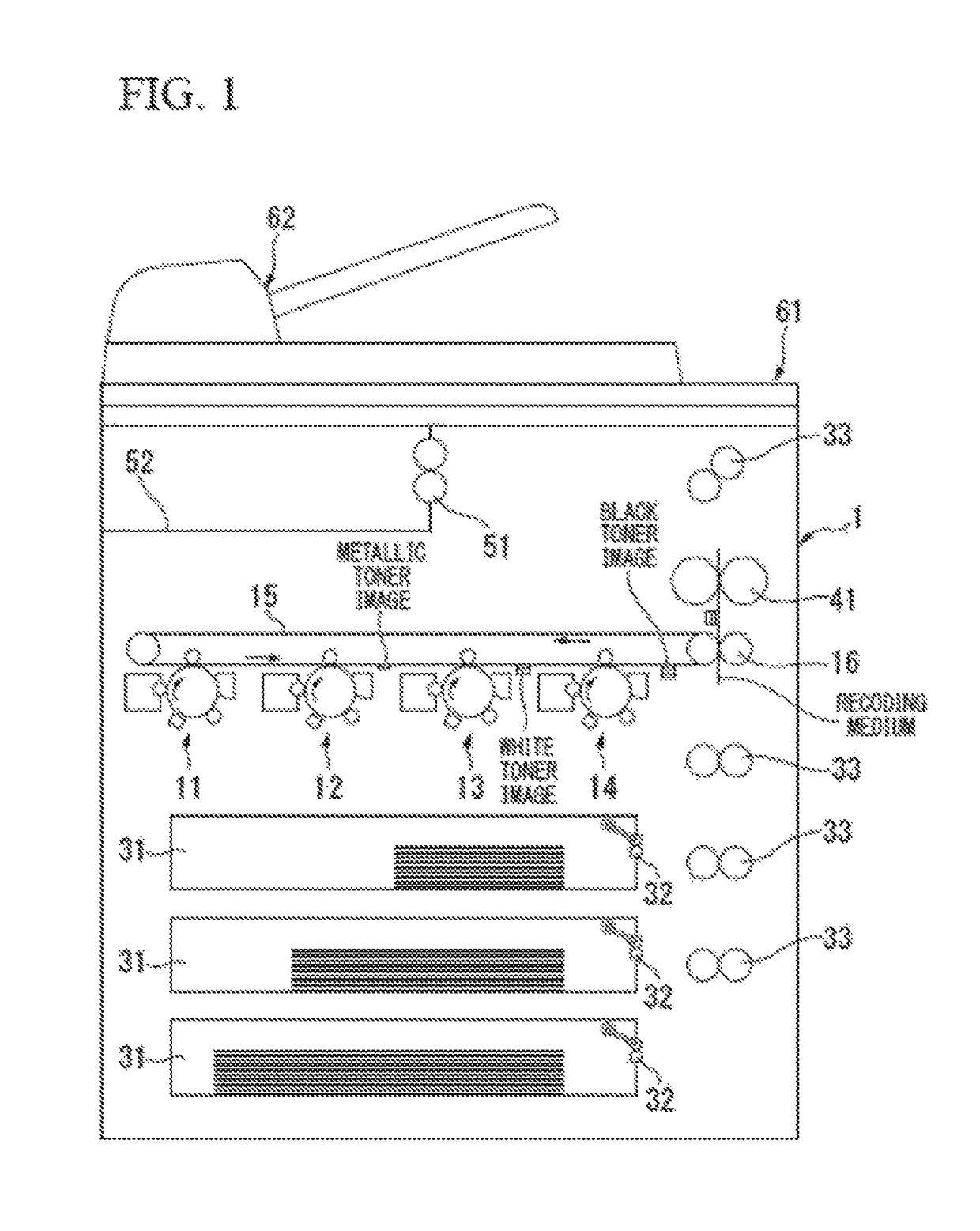

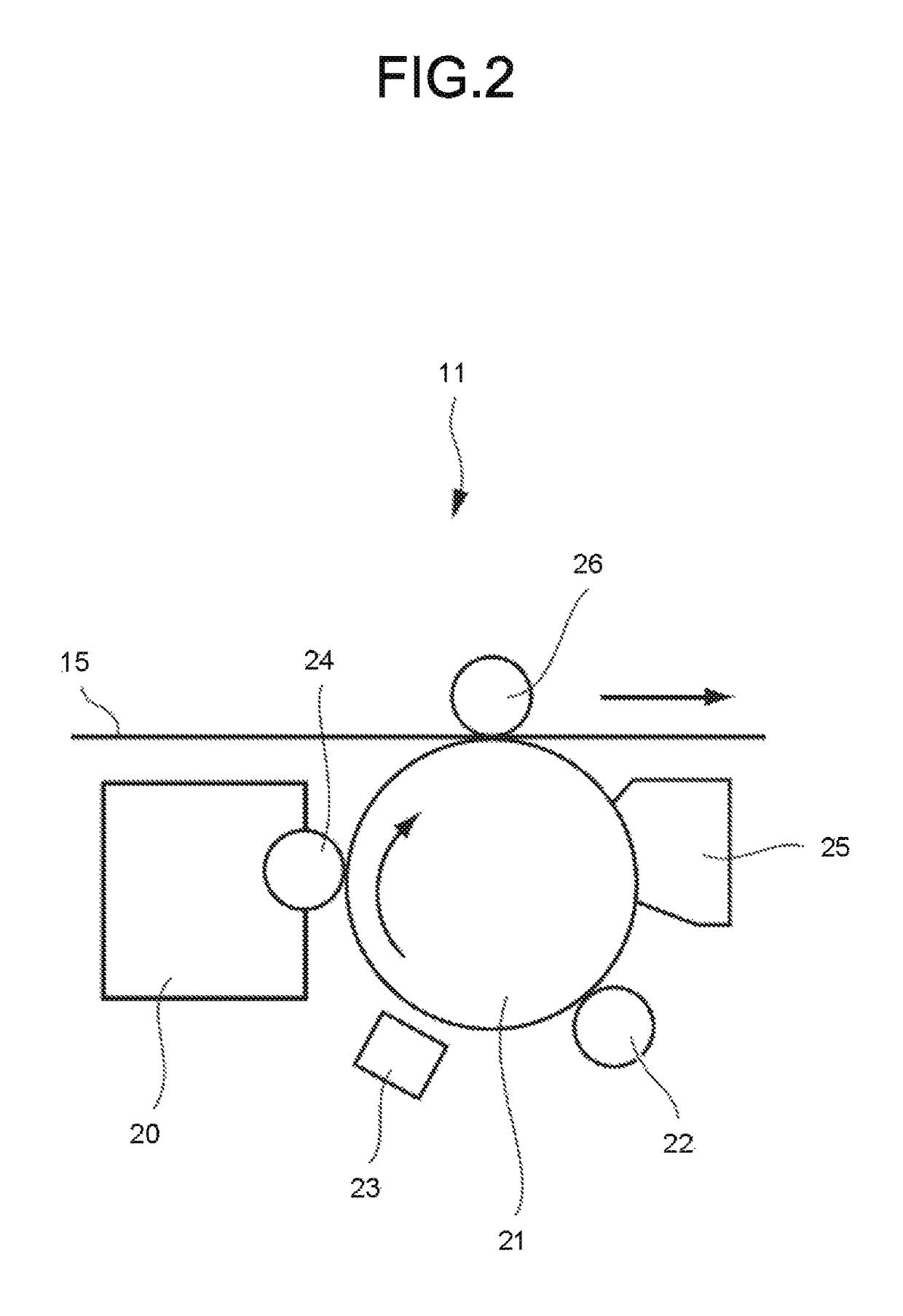

Metallic color image forming apparatus and metallic color image forming method

In accordance with one embodiment, an image forming apparatus forms a metallic toner image with the toner having metallic color tone. The plurality of developing sections includes either or both of a developing section for forming a black toner image with the black toner and a developing section for forming a white toner image with the white toner. The plurality of developing sections is provided with one or more than two developing sections for forming a metallic toner image with the toner having metallic color tone.

Owner:KK TOSHIBA +1

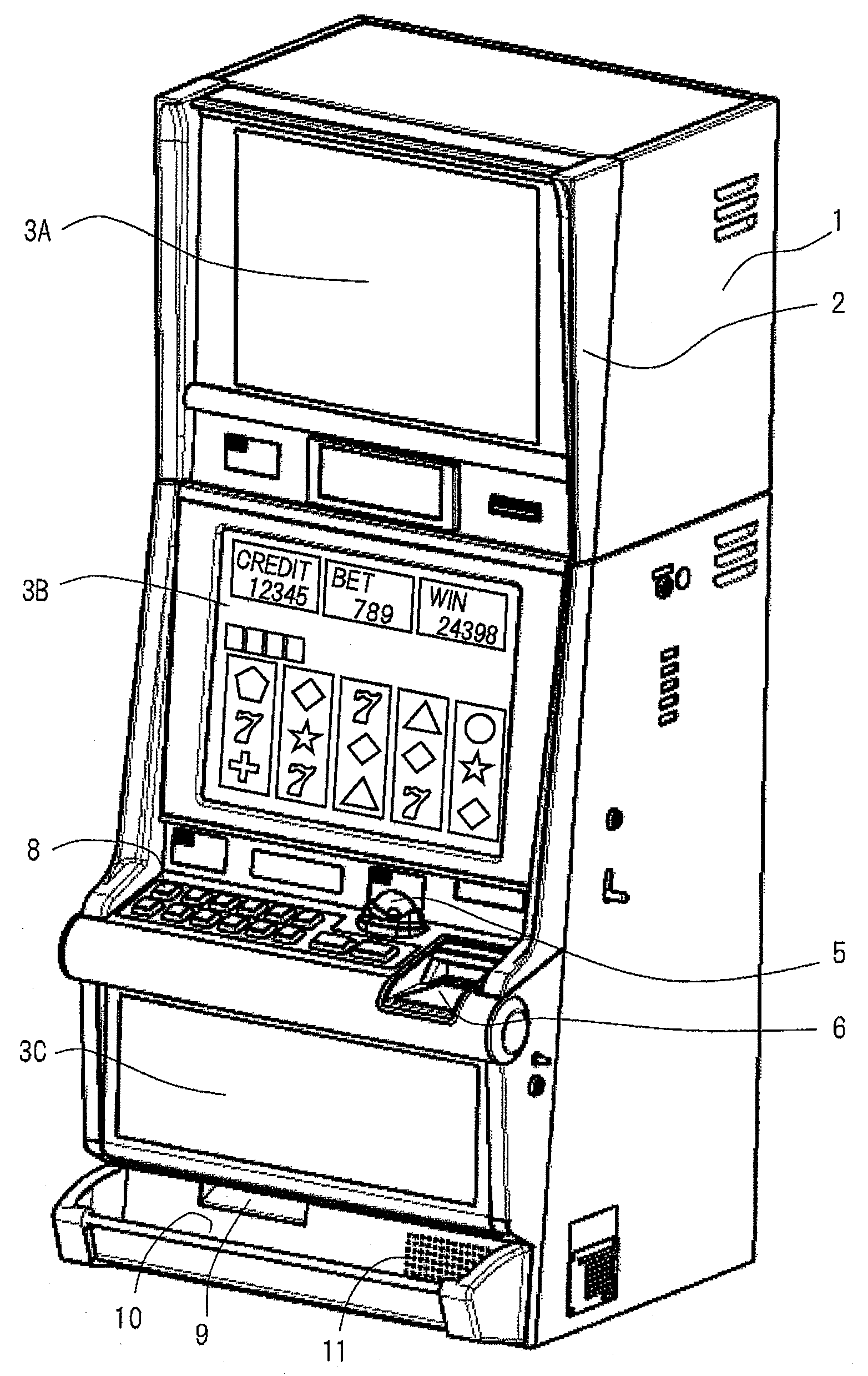

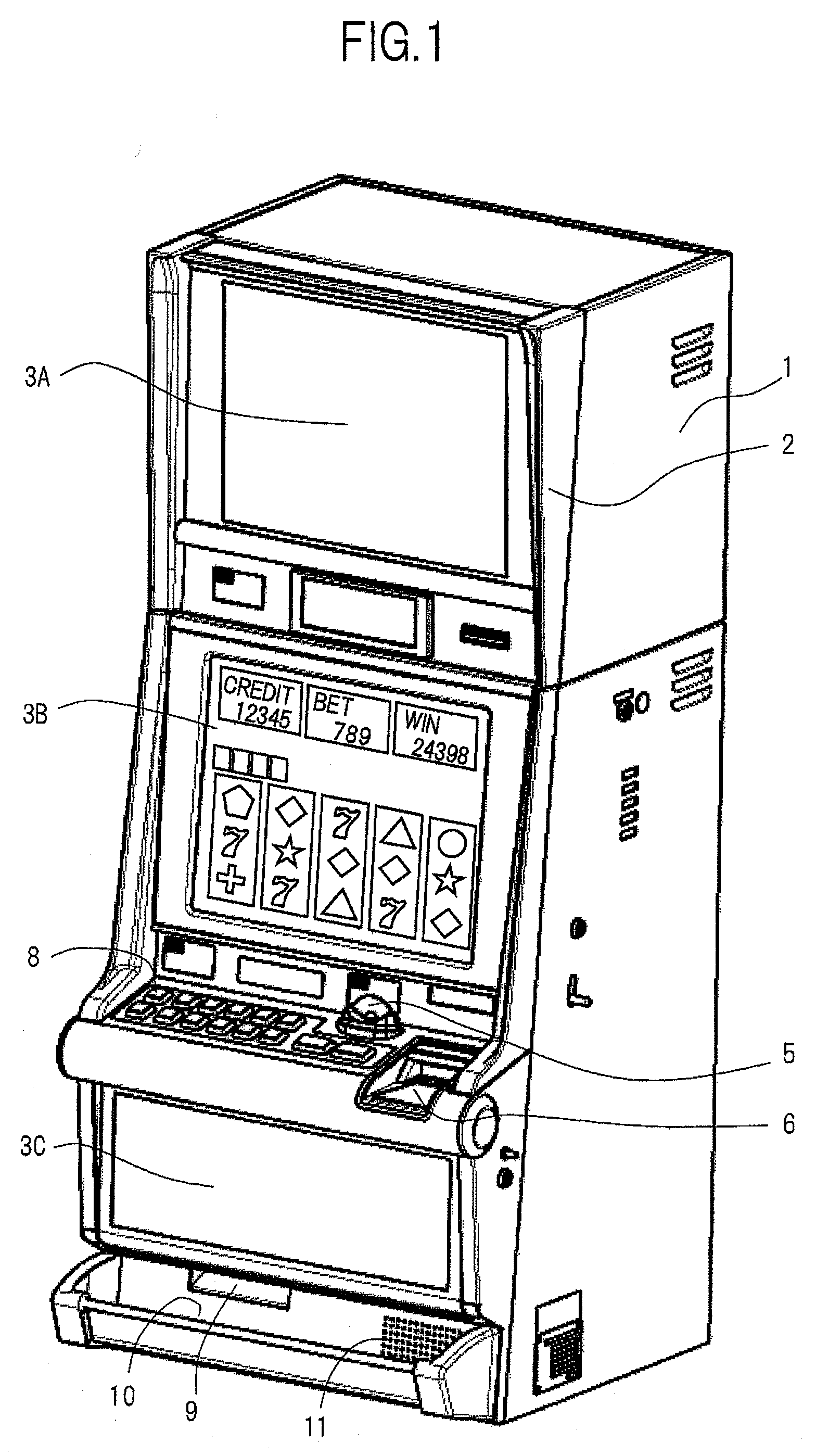

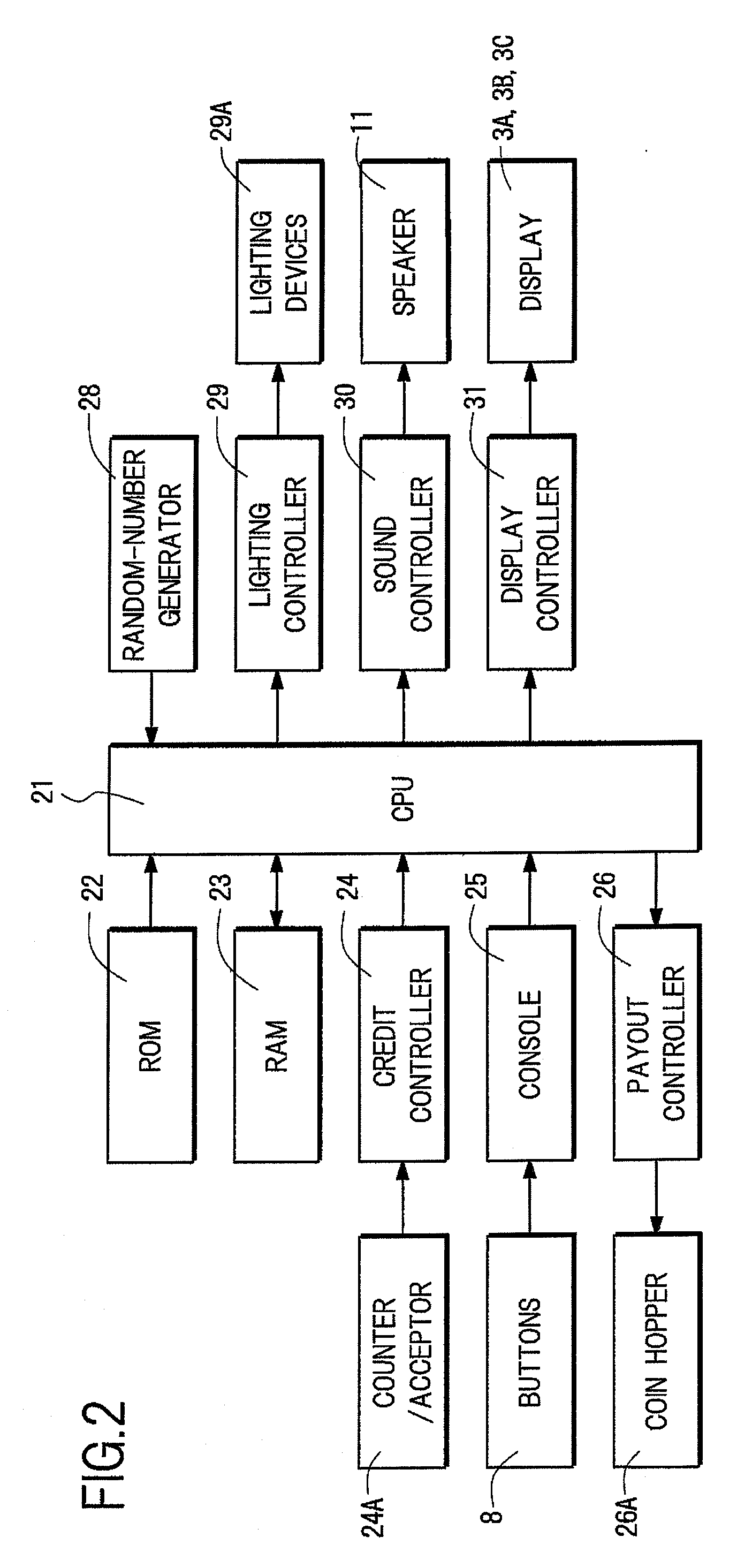

Gaming machine and method for displaying symbols

InactiveUS20090054129A1Increase probabilityReliably noticeApparatus for meter-controlled dispensingVideo gamesGraphicsMetallic color

A gaming machine comprises a display unit that displays video reels using computer graphics. Symbols are moved and stopped on each video reel. A game controller unit selects a type of symbols and an arrangement of symbols at random, and provides a player with an award if a winning combination appears on a payline in the arrangement of symbols and the player has placed a bet on the payline. A display controller unit causes the display unit to move symbols on each video reel, and then stop symbols in the arrangement. The display controller unit further causes the display unit to change a symbol of the selected type to a special symbol while moving symbols. Special symbols appear in a prominent form, e.g., in a background color complementary to a background color of other symbols, or in a metallic color, or in a blinking, flashing, or sparkling pattern.

Owner:KONAMI GAMING

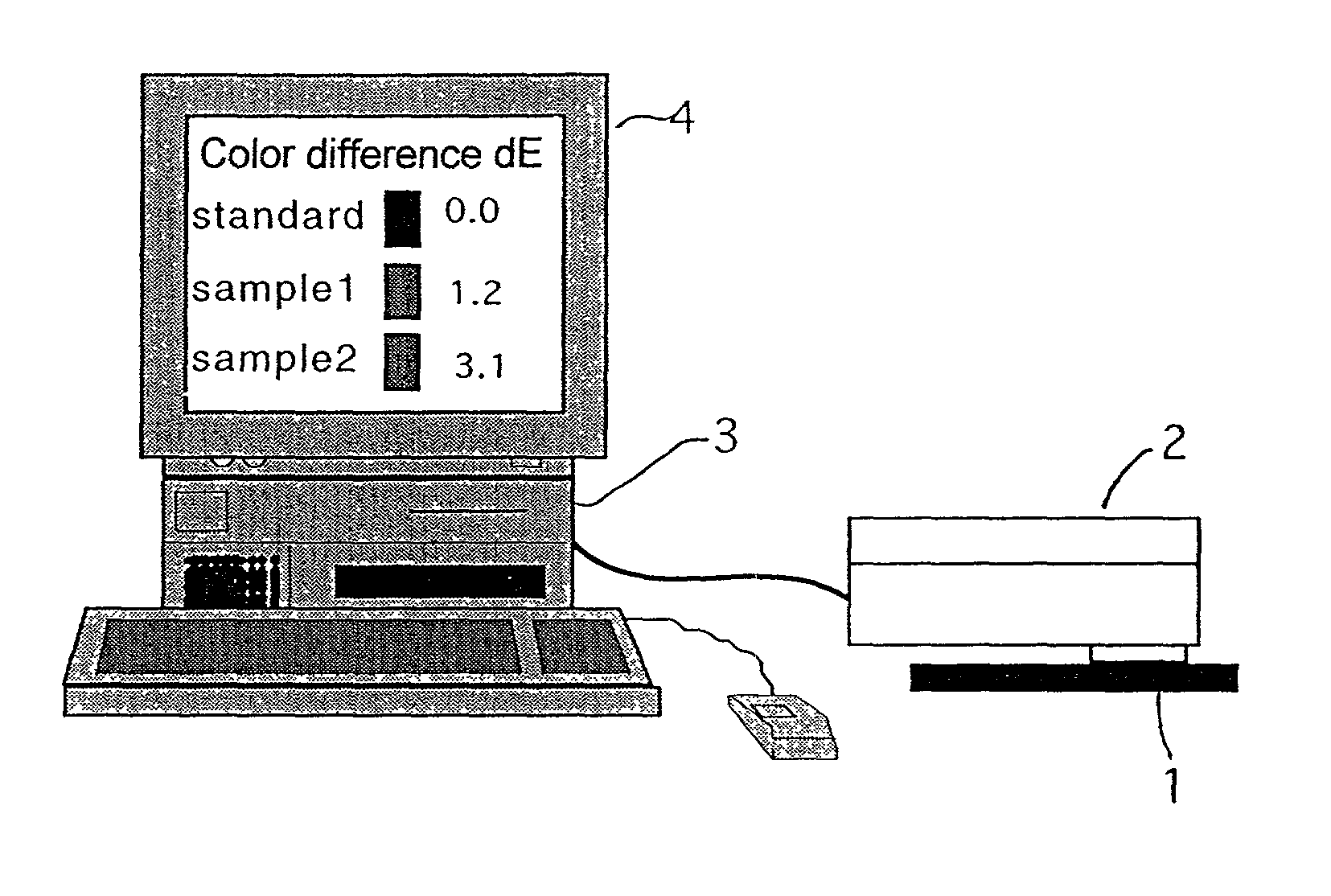

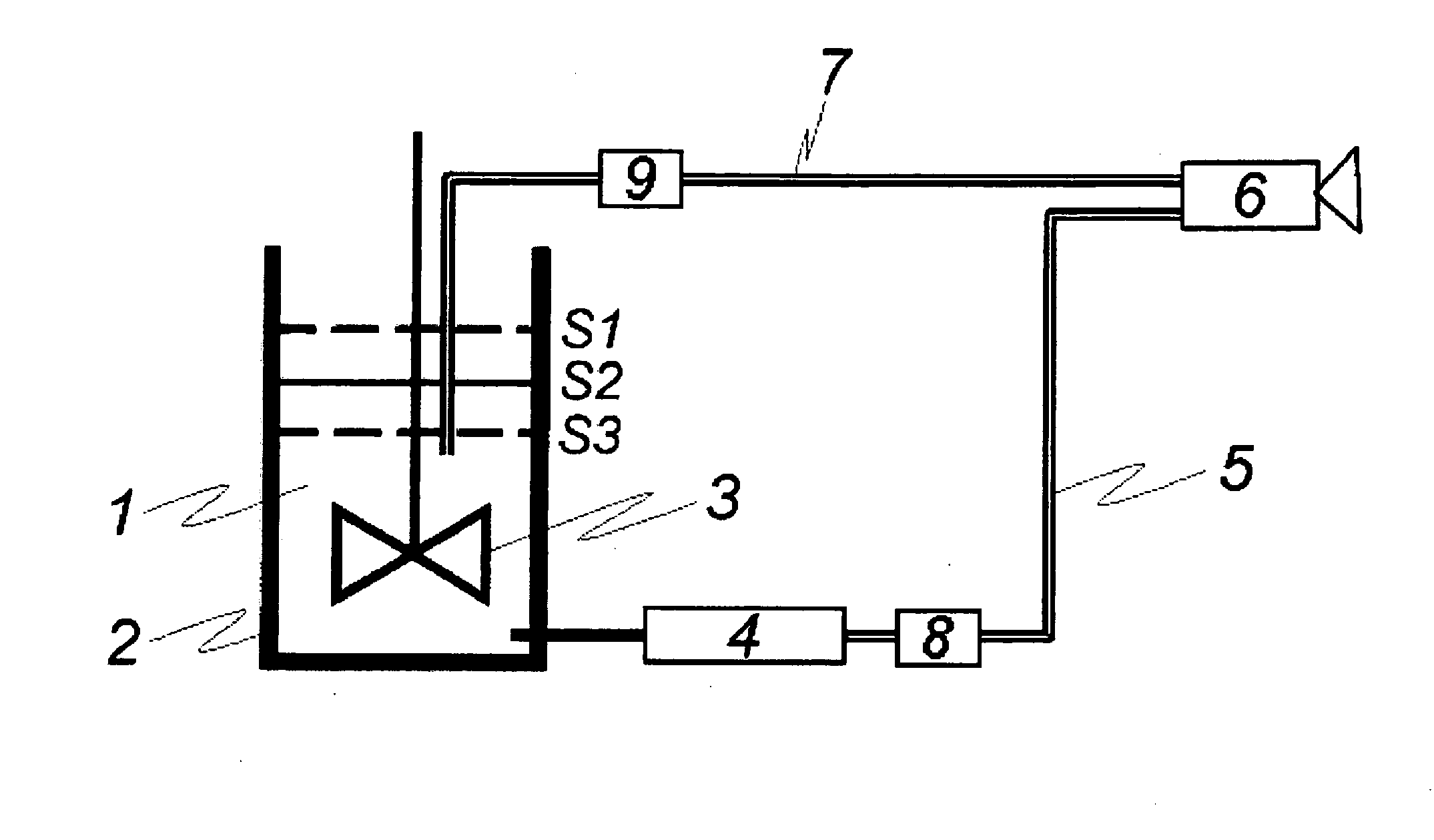

Method for quickly retrieving approximate color of metallic paint color

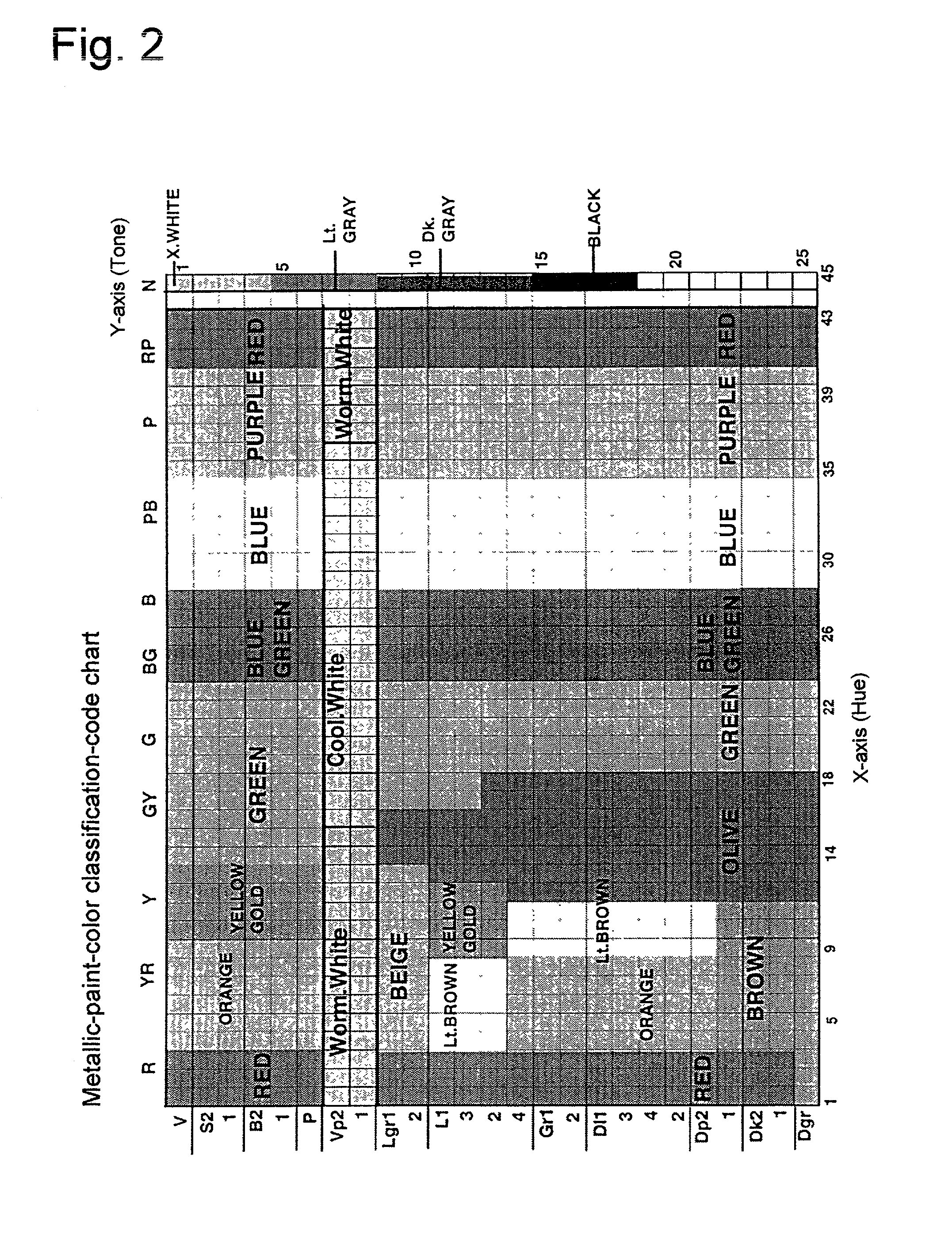

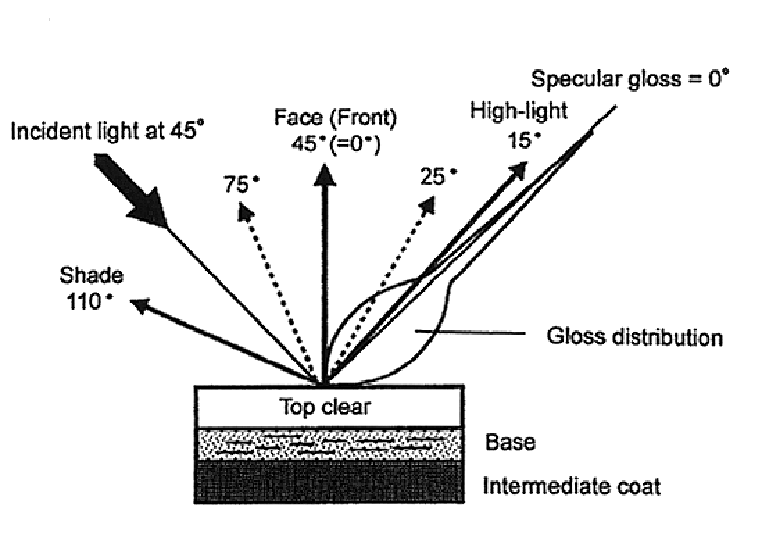

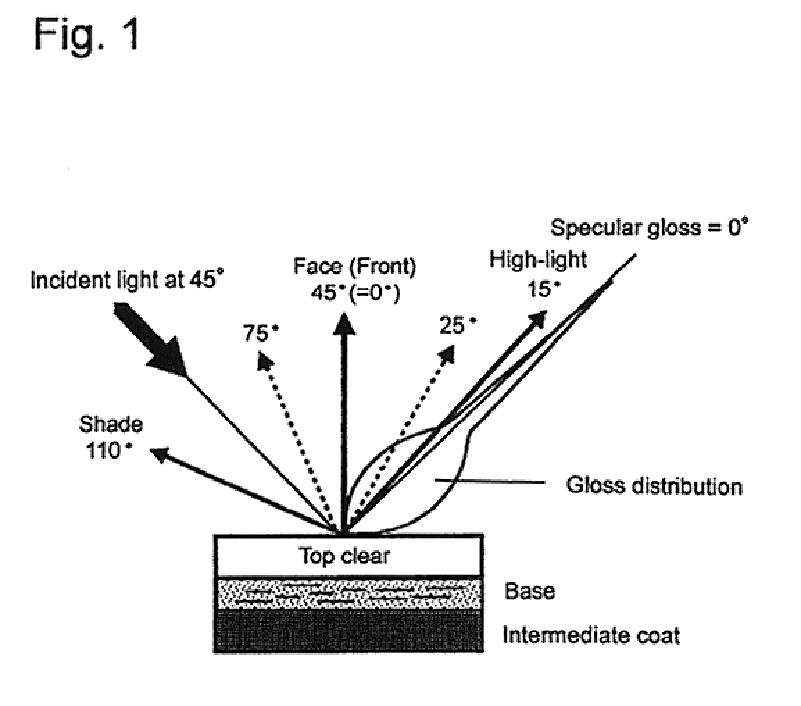

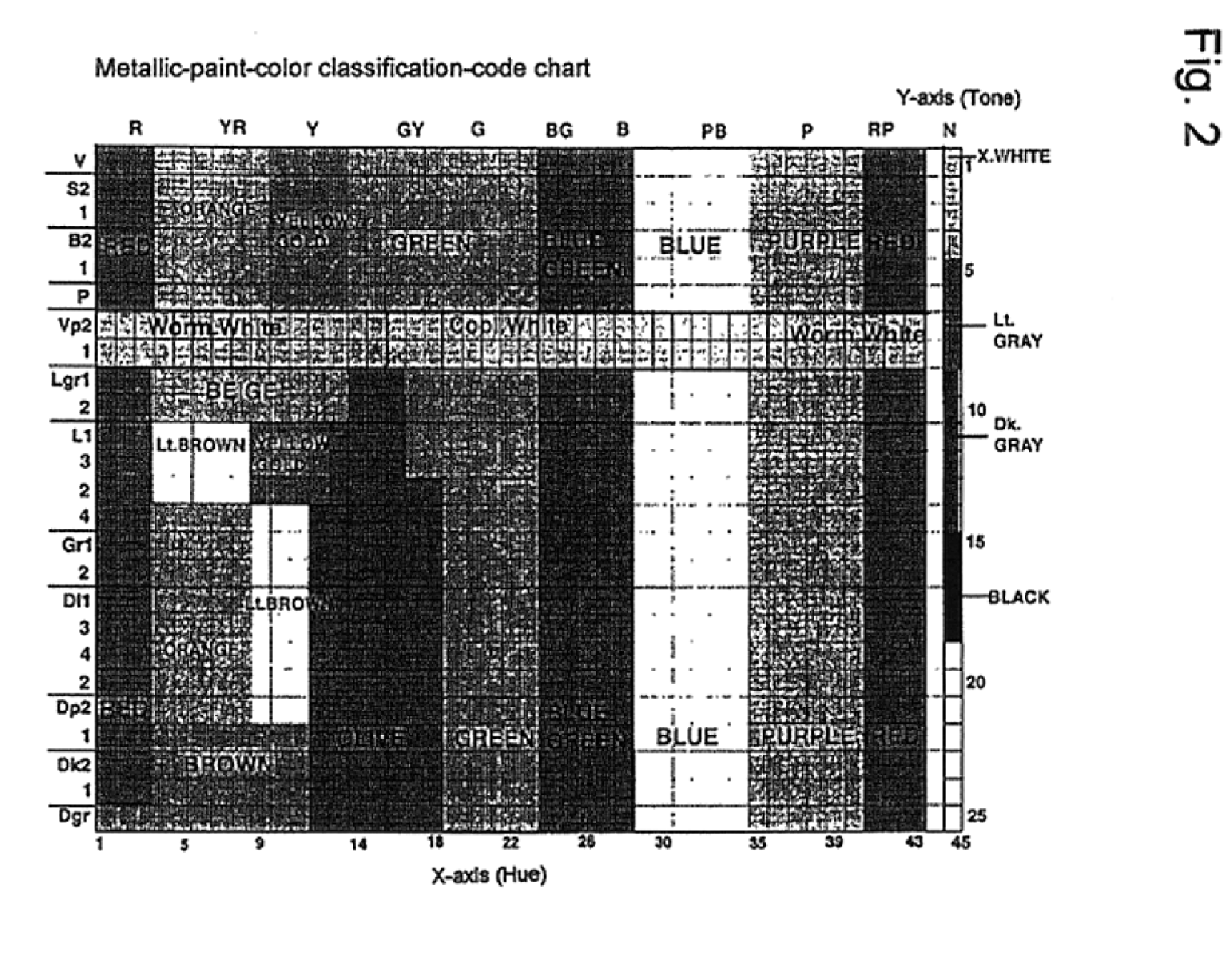

The following procedures are included: a procedure (1) for measuring a metallic paint color by a multi-angle spectrophotometer and storing the multi-angle colorimetric value Lab* of the paint color, a color classification code to which the paint color belongs, and a computer graphic image in a memory of a computer and a procedure (2) for calling a metallic paint color to be retrieved (this is referred to as the metallic paint color concerned) from the memory by using a paint color name as a keyword. Moreover, in the case of a new color not stored in the memory, the color is measured by a multi-angle spectrophotometer and stored in the memory in accordance with the procedure (1). A screening function (3) is included which previously narrows down paint colors whose approximate colors will be computed by using color classification codes when computing an approximate color of the metallic color concerned.

Owner:KANSAI PAINT CO LTD

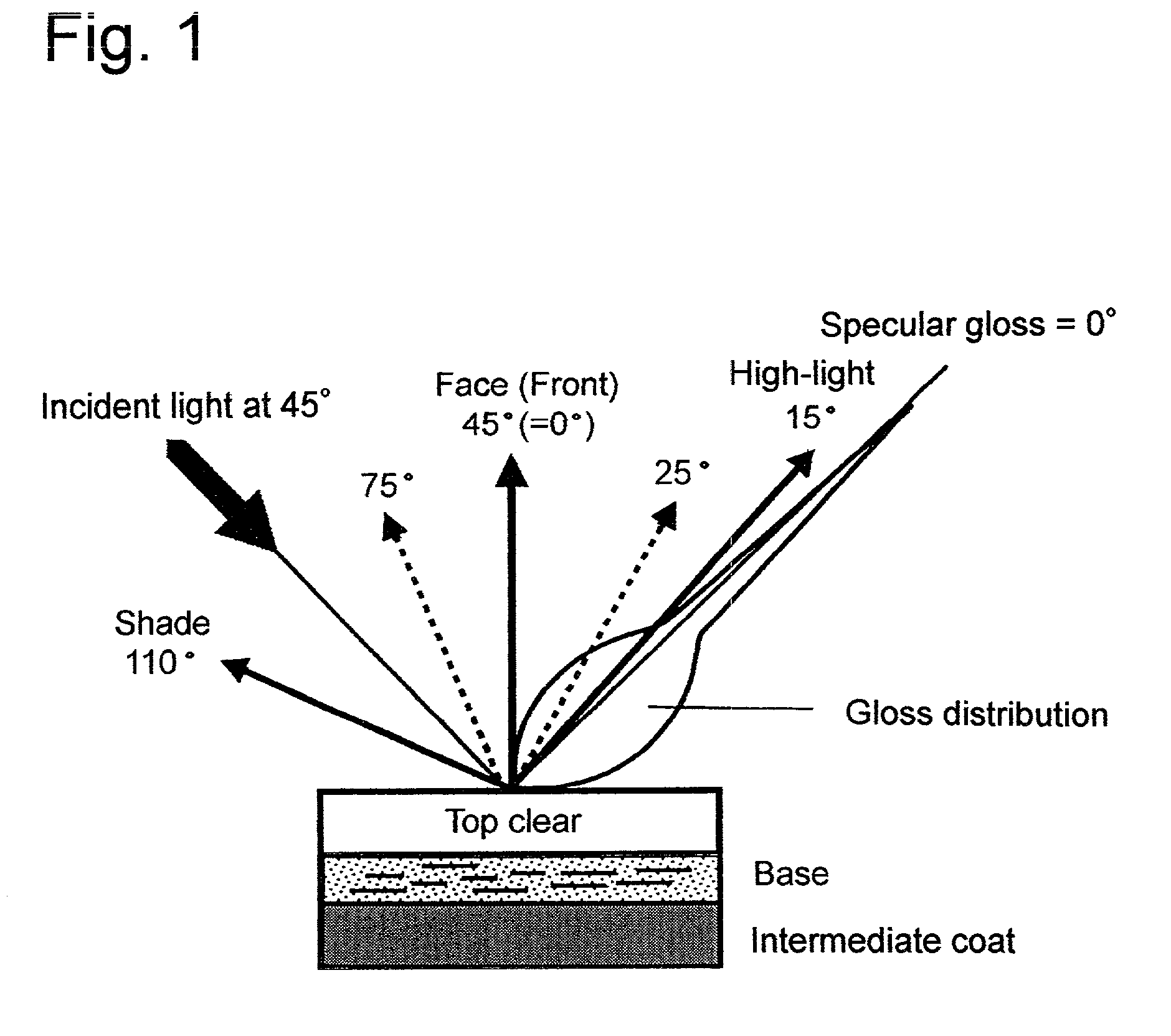

Process for the production of multi-layer coatings in light metallic color shades

InactiveUS20060068116A1High pigment contentPretreated surfacesPaints with free metalsHueBrightness perception

A process producing multi-layer coatings in light metallic color shades, comprising the successive steps: (1) applying a 5 to 20 μm thick base coat layer to a pre-coated substrate, (2) applying a clear coat layer onto the base coat layer, (3) jointly curing the base coat and clear coat layers, wherein the base coat layer is applied from an unmodified water-borne metallic base coat having a ratio by weight of pigment to resin solids of 0.3:1 to 0.45:1, wherein the pigment content consists 60 to 100% by weight of at least one non-leafing aluminum pigment with a platelet thickness over 100 to 500 nm and 0 to 40% by weight of at least one pigment different from aluminum pigments, wherein the pigment(s) different from aluminum pigments are selected in such a way that the multi-layer coating obtained exhibits a brightness L* (according to CIEL*a*b*, DIN 6174), of at least 80 units.

Owner:EI DU PONT DE NEMOURS & CO

Method for quickly retrieving approximate color of metallic paint color

The following procedures are included: a procedure (1) for measuring a metallic paint color by a multi-angle spectrophotometer and storing the multi-angle colorimetric value Lab* of the paint color, a color classification code to which the paint color belongs, and a computer graphic image in a memory of a computer and a procedure (2) for calling a metallic paint color to be retrieved (this is referred to as the metallic paint color concerned) from the memory by using a paint color name as a keyword. Moreover, in the case of a new color not stored in the memory, the color is measured by a multi-angle spectrophotometer and stored in the memory in accordance with the procedure (1). A screening function (3) is included which previously narrows down paint colors whose approximate colors will be computed by using color classification codes when computing an approximate color of the metallic color concerned.

Owner:KANSAI PAINT CO LTD

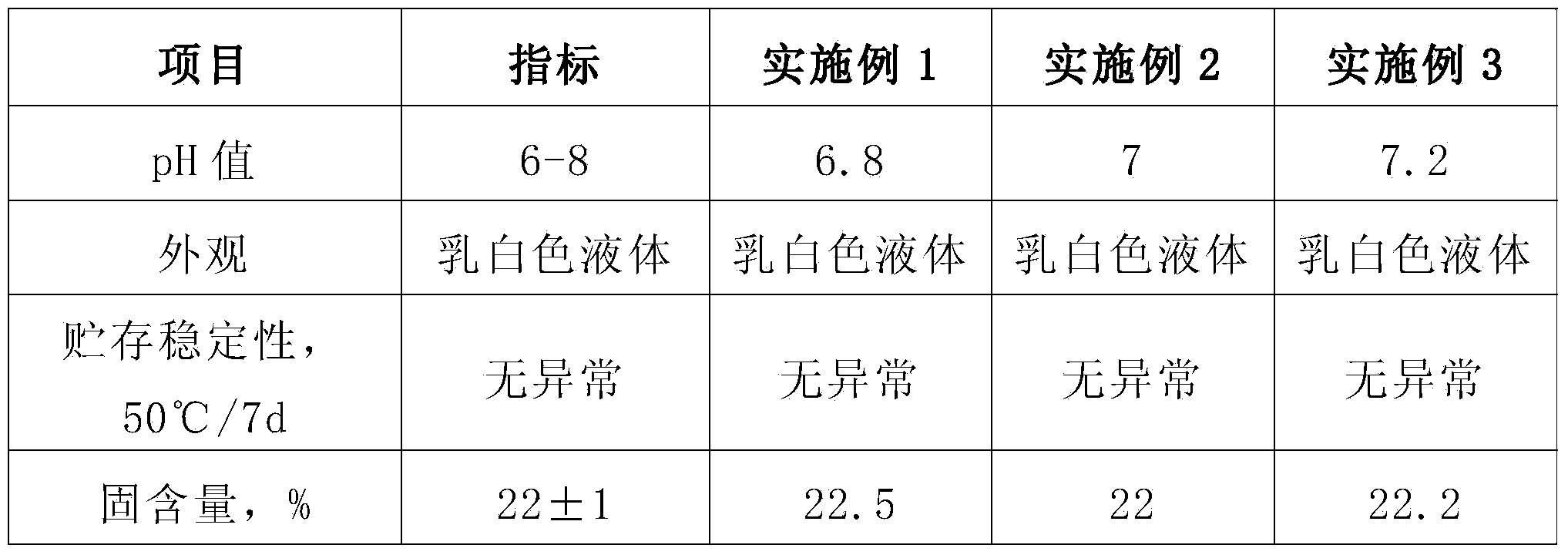

Metallic fog-brightening water based treatment agent and preparation method thereof

The invention discloses a metallic fog-brightening water based treatment agent and a preparation method thereof. The preparation method comprises the steps: adding a wetting dispersant and a defoaming agent into waterborne polyurethane resin for mixing and stirring; then adding extinction powder and polytetrafluoroethylene wax powder, performing high-speed stirring for 20 minutes, adding a cosolvent, a wetting leveling agent and water, uniformly stirring the materials and performing filtration; adding a thickening agent into a mixture obtained by filtration, and adjusting the viscosity to 800-1,500 cps to obtain the metallic fog-brightening water based treatment agent. The metallic fog-brightening water based treatment agent disclosed by the invention is extremely high in haze and blackness; after being washed in water, the bottom of a trench and the top of leather are obviously different in glossiness, certain layering impression and high flocking impression are achieved; due to vision observation, the surface of the leather has a certain metallic color, so that the color is natural and soft. The product is prepared from a waterborne material, is safe and non-toxic and is a green and environment-friendly treatment agent.

Owner:LANZHOU SCISKY AQUEOUS POLYMER MATERIAL CO LTD

Water based ink having metallic luster adapted for direct-filling in ball-point pen

InactiveUS6083311AEasy to writeHigh viscosityOther chemical processesInksWater basedWater dispersible

PCT No. PCT / JP98 / 00676 Sec. 371 Date Nov. 10, 1998 Sec. 102(e) Date Nov. 10, 1998 PCT Filed Feb. 18, 1998 PCT Pub. No. WO98 / 40441 PCT Pub. Date Sep. 17, 1998Disclosed is water based ink having metallic luster adapted for a direct-filling ball-point pen, which is used by being directly filled into the tube, said ink comprising, based on the total amount of the ink composition, 1% to 20% by weight of a metallic color pigment comprising metallic powder and a color pigment adsorbed thereon, 0.1% to 1.0% by weight of a water-soluble or water-dispersible polymer agent which imparts pseudo-plasticity, and water, thereby providing ink satisfactory in beauty and luster and excellent in aging stability and writing properties.

Owner:PILOT PEN CO LTD

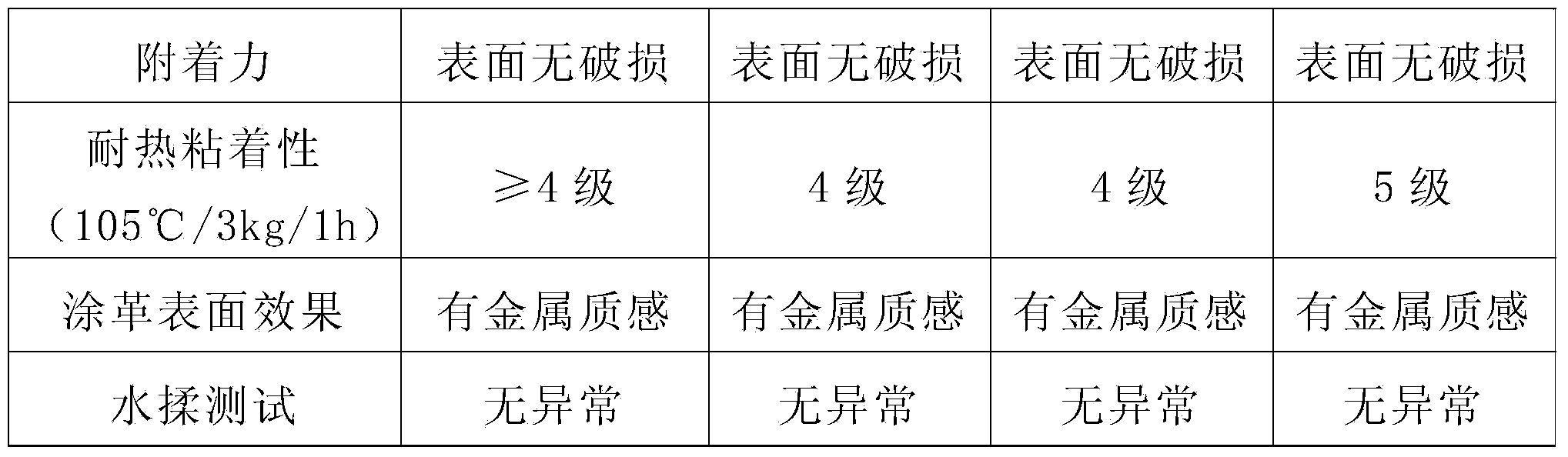

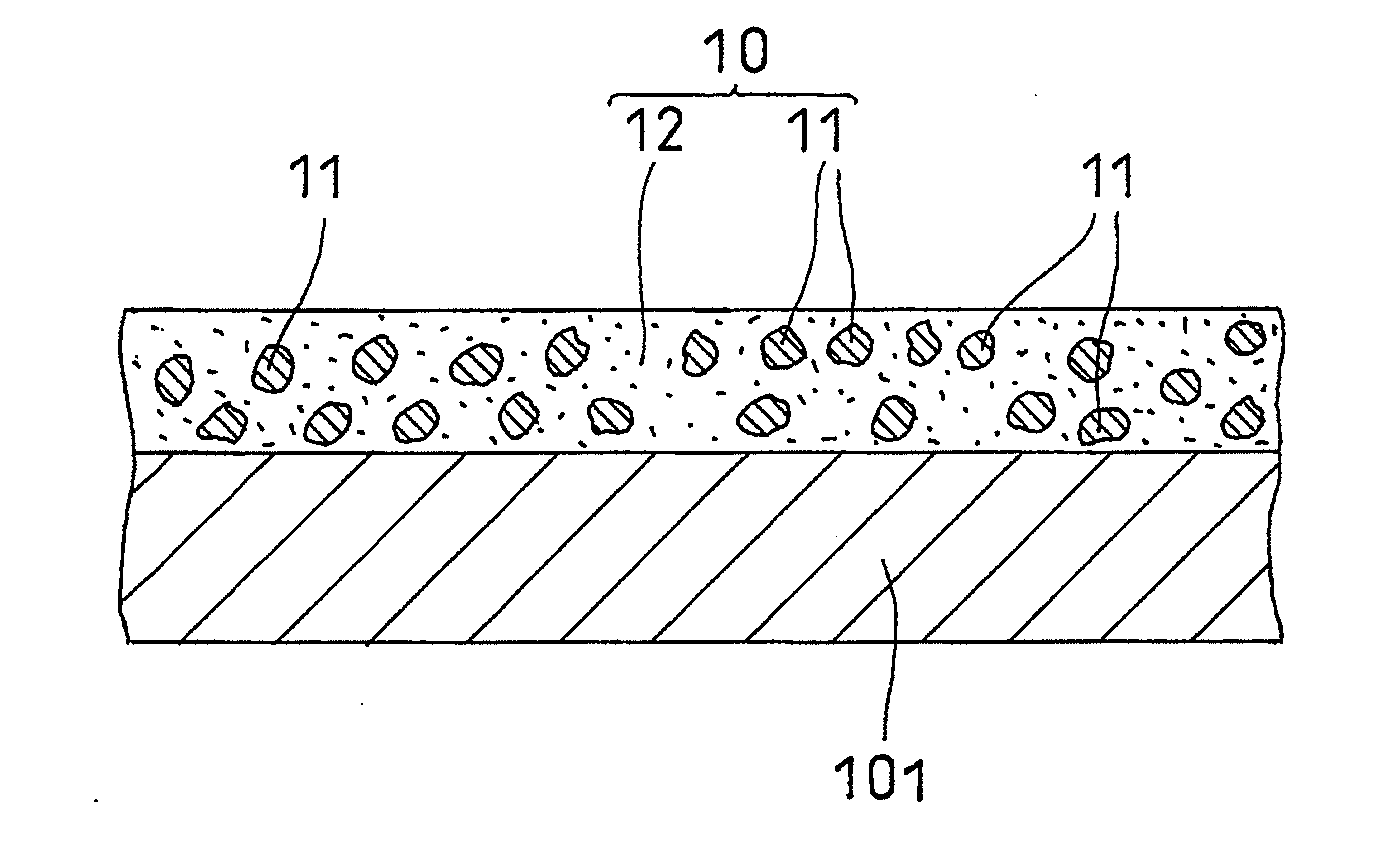

Decorative film and method for forming the same

InactiveUS20110236672A1Desirable metallic shineLow millimeter wave damping rateMaterial nanotechnologyLayered productsOrganic filmRadar

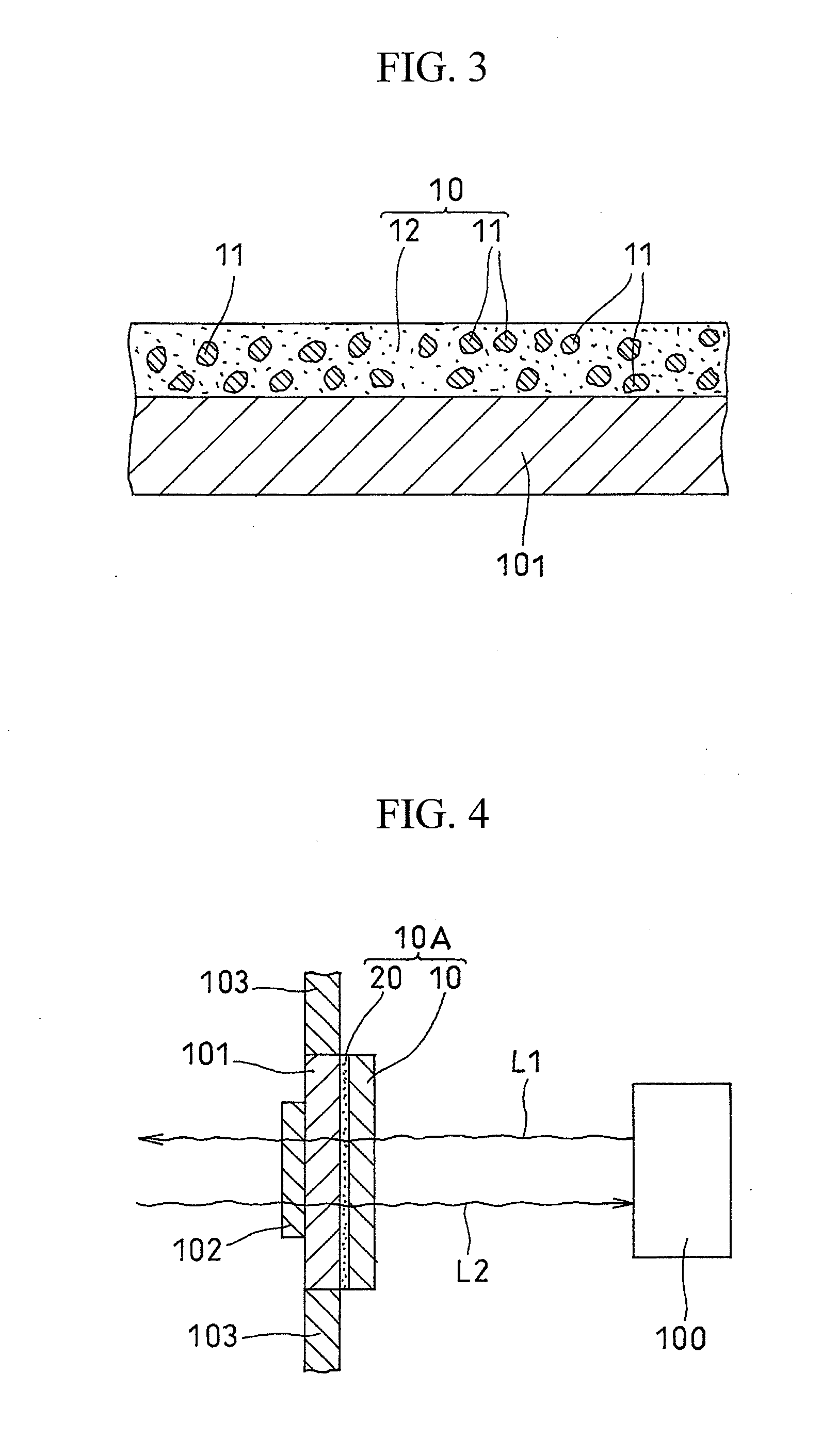

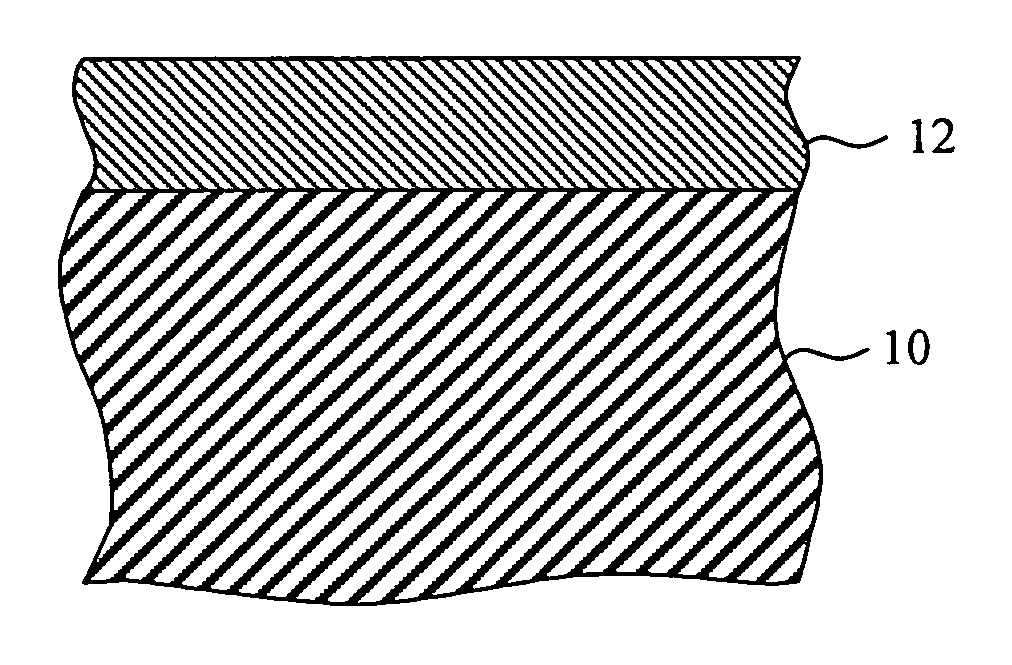

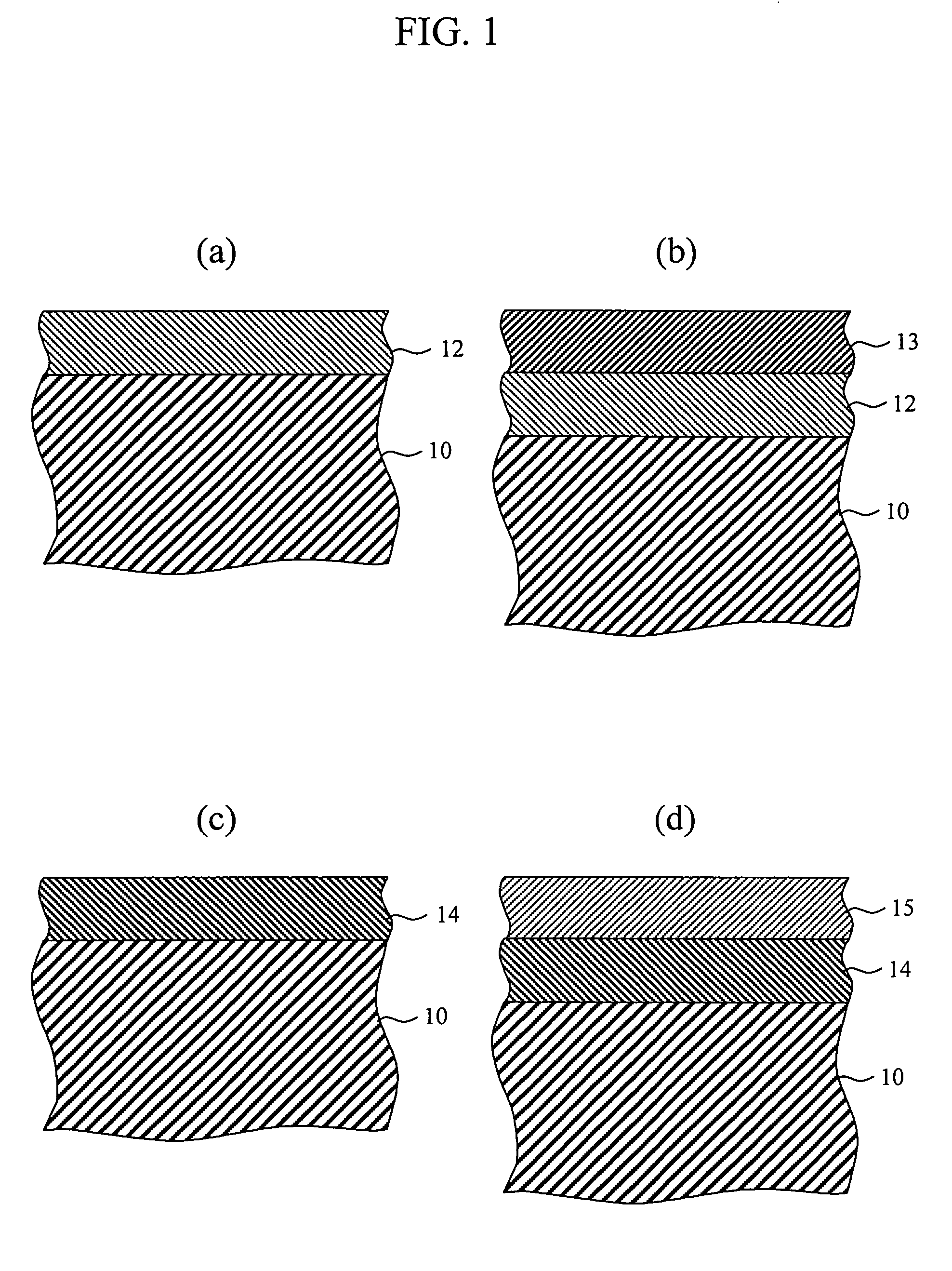

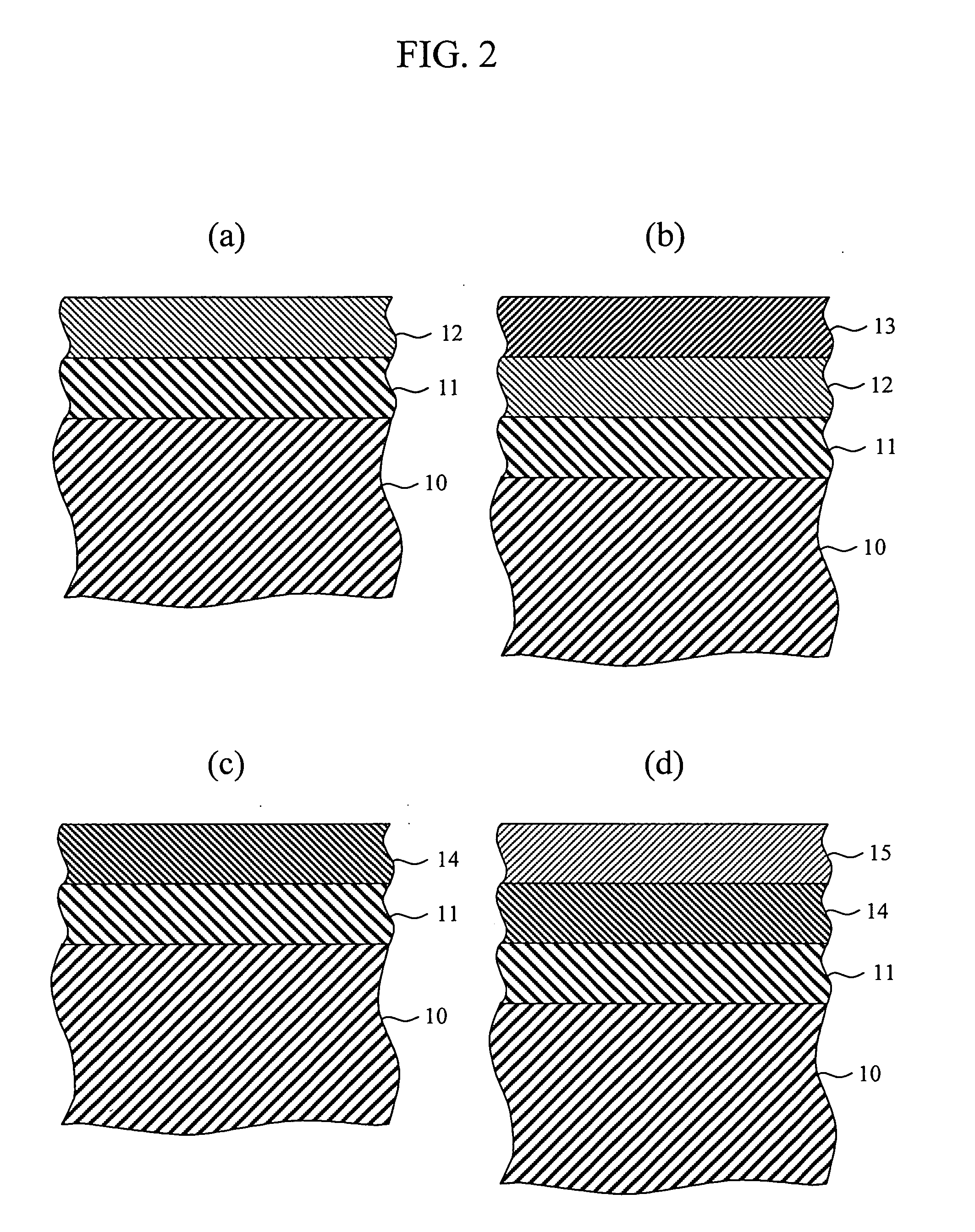

The present invention relates to a decorative film formed on the surface of a resin substrate positioned within a radar device path and a method for forming the same. The present invention provides a decorative film that can be formed with high yield and efficiency without highly accurate film thickness regulation and is excellent in terms of radiowave transmission performance and appearance design, with a metallic color tone, and to provide a method for forming the same. Such method is a method for forming a decorative film 10 on the surface of a resin substrate 101 positioned within a radar device path, wherein a decorative film 10 comprising an organic film 12 in which metal nanoparticles 11 are dispersed is formed by producing an organic material comprising a solvent in which metal nanoparticles 11 (to which organic molecules are coordinated) are dispersed, applying the organic material to the surface of a resin substrate 101, and volatilizing the solvent.

Owner:TOYOTA JIDOSHA KK

Molded article located in the beam path of radar device, and method of manufacturing the same

InactiveUS20050031897A1Large radio transmission lossEasy to peelAntenna adaptation in movable bodiesVacuum evaporation coatingOxide ceramicRadar

A molded article located in the beam path of a radar device has only a slight amount of radio transmission loss and has a metallic color. The molded article comprises a substrate and a layer of ceramic material with which the external surface of the substrate is coated. The ceramic material includes nitride ceramics, oxide ceramics, carbide ceramics, and mixtures thereof. The ceramic material includes titanium nitride and / or aluminum nitride.

Owner:TOYOTA JIDOSHA KK

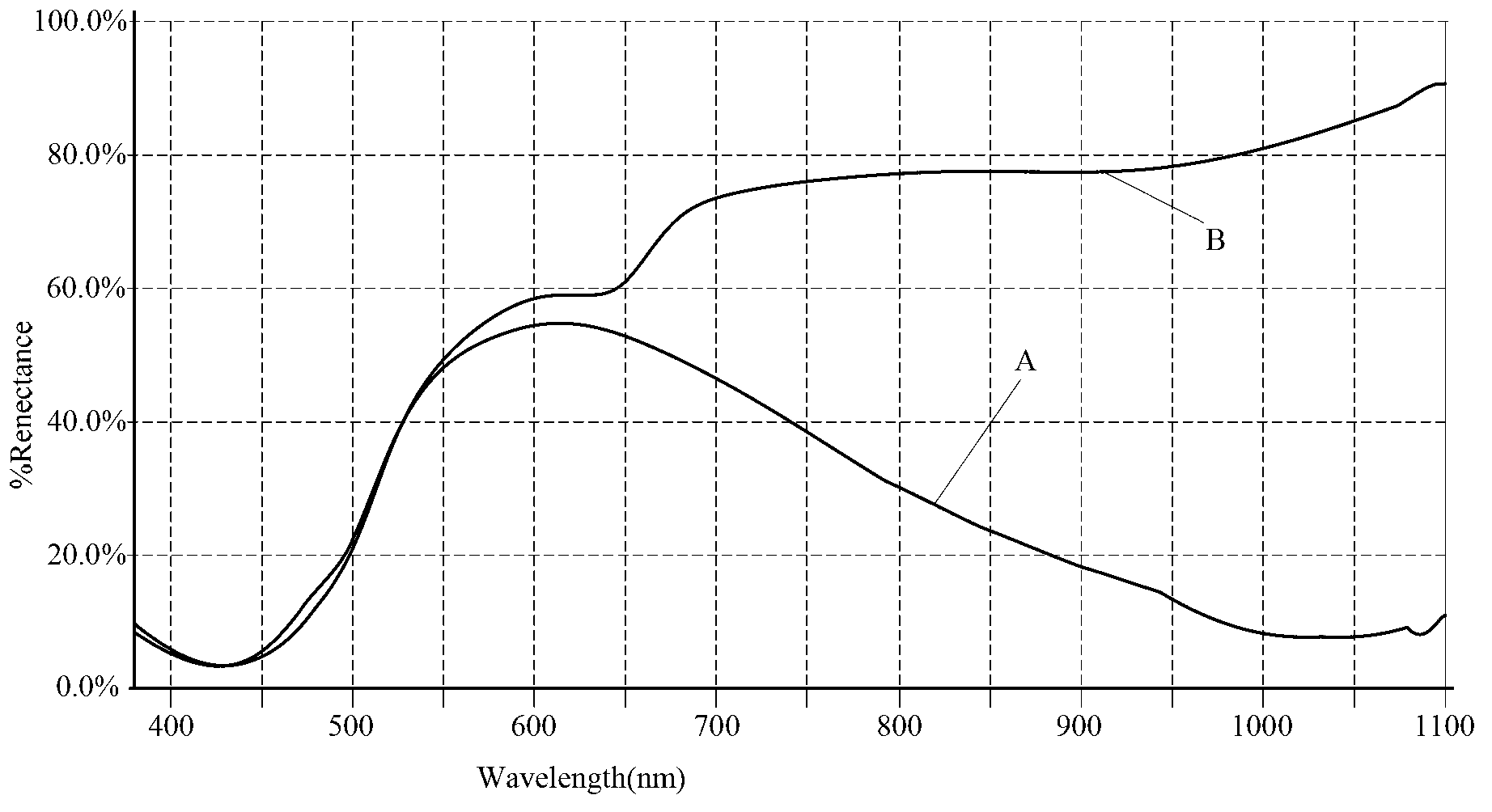

Metallic effect printing ink with infrared characteristic

The invention relates to a metallic effect printing ink with infrared characteristic. According to the metallic effect printing ink with infrared characteristic, the infrared characteristic means that absorption characteristic is displayed within the near infrared spectrum. The printing ink comprises an infrared absorption material which is 1 to 15% of the total weight of the printing ink; and the reflectivity of the metallic effect printing ink is is less than 30% at the maximum absorption wavelength in a near infrared region. The metallic effect printing ink provided by the invention not only has the characteristics of metallic color and luster and flicker but also has the characteristic of infrared absorption; and an anti-counterfeit mark printed by the metallic effect printing ink shows public counterfeiting resisting means and professional counterfeiting resisting means. The invention also provides application of the metallic effect printing ink with the infrared characteristic in making of safety products with the anti-counterfeit mark by constituting suitable printing ink together with other printing inks.

Owner:CHINA BANKNOTE SECURITY PRINTING TECH RES INST CO LTD +1

Method for producing multi layered coating film

InactiveUS20090004398A1Inhibit aggregationSuppress prevent skinningOrganic dyesSpecial surfacesSolubilityEmulsion

A method for producing a multi layered coating film by applying an intermediate coating composition on an article to form an intermediate coating thereon; applying a metallic color base coating composition on the intermediate coating to form a metallic color base coating thereon; and applying a clear coating composition on the metallic color base coating to form a clear coating thereon. The metallic color base coating composition is waterborne and contains an acryl emulsion resin; a water dispersion of a hydrophobic melamine resin having an average particle size within a range of from 20 to 300 nm; a luster color pigment; and an organic alcohol solvent having a solubility in water within a range of from 0.01 to 5.0 wt % and a boiling point within a range of from 160 to 200° C.

Owner:NIPPON PAINT CO LTD

Waterborne base coat compositions having a light metallic color

A waterborne base coat having a light metallic color and containing 0.5 to 2 wt.-% of poly(meth)acrylic acid thickener and 2 to 7 wt.-% of non-ionically emulsified EVA copolymer wax with a drop point of the wax portion of 80 to 110° C., the wt.-% in each case calculated as solids and relative to the solids content of the waterborne base coat.

Owner:AXALTA COATING SYST IP CO LLC

Colorful silk jacquard fabric

InactiveCN102286828AGood moisture permeabilityStrong metallic visual effectSwivel-woven fabricsLappet-woven fabricsDesign organizationViscose

The warp yarn of the colorful silk jacquard fabric of the present invention adopts conventional cotton yarn, and the weft yarn adopts greige yarn or colored yarn and colorful yarn, and the greige yarn is one or more of cotton yarn, viscose bright yarn, cotton-type colored yarn, and polyester. The yarn is one or more of cotton yarn, viscose lustrous yarn, cotton colored yarn, polyester, and the cotton yarn count in the warp yarn is between 40S and 80S; in the weft yarn, the British count is 20S~60S. The specification of colorful silk is 70D~180D, the dosage ratio of colorful silk and greige yarn or dyed yarn is 0.5%~50%, more than three kinds of raw materials are used for interweaving, through pattern design, color design, weave design, dyeing and finishing process The comprehensive cooperation of all aspects of technology enables the fabric to have good moisture permeability. Due to the decorative decoration of colorful silk, the fabric has a strong metallic visual effect.

Owner:陆生杰

Treatment method for plastic rubber surface with coloured titanium metal texture

InactiveCN1962950AGood reproducibilitySimple sputtering processVacuum evaporation coatingPretreated surfacesTitanium metalTitanium

The invention discloses a disposing method of plastic surface with colorful titanium metal sense, which comprises the following steps: 1. cleaning the surface of plastic surface; 2. coating a layer of bottom paint with thickness at 5-10um on the plastic surface to display little bright or foggy; solidifying through UV; 3. plating a layer of titanium metal at splashing pattern; 4. adopting plastic of splashed titanium film as anode through anode oxidizing technology and stainless steel as cathode; supplying different voltages in the electrolyte to obtain different colors of colorful metal film.

Owner:MITAC PRECISION TECH CO LTD SHUNDE DISTRICT FOSHAN CITY

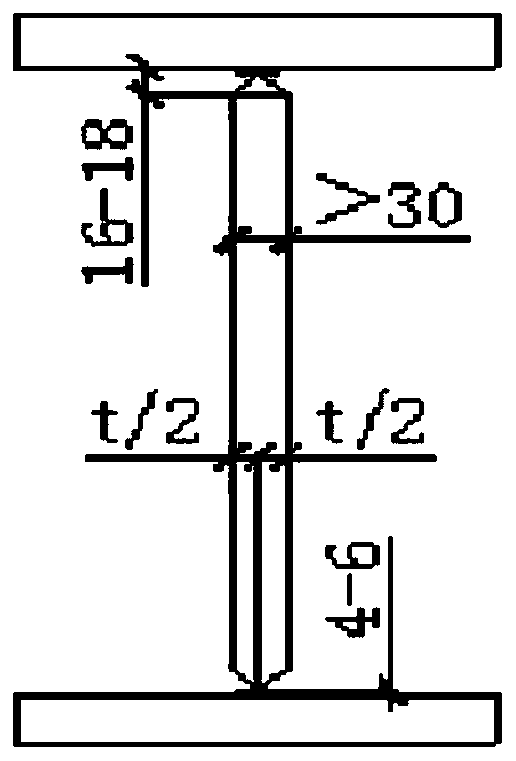

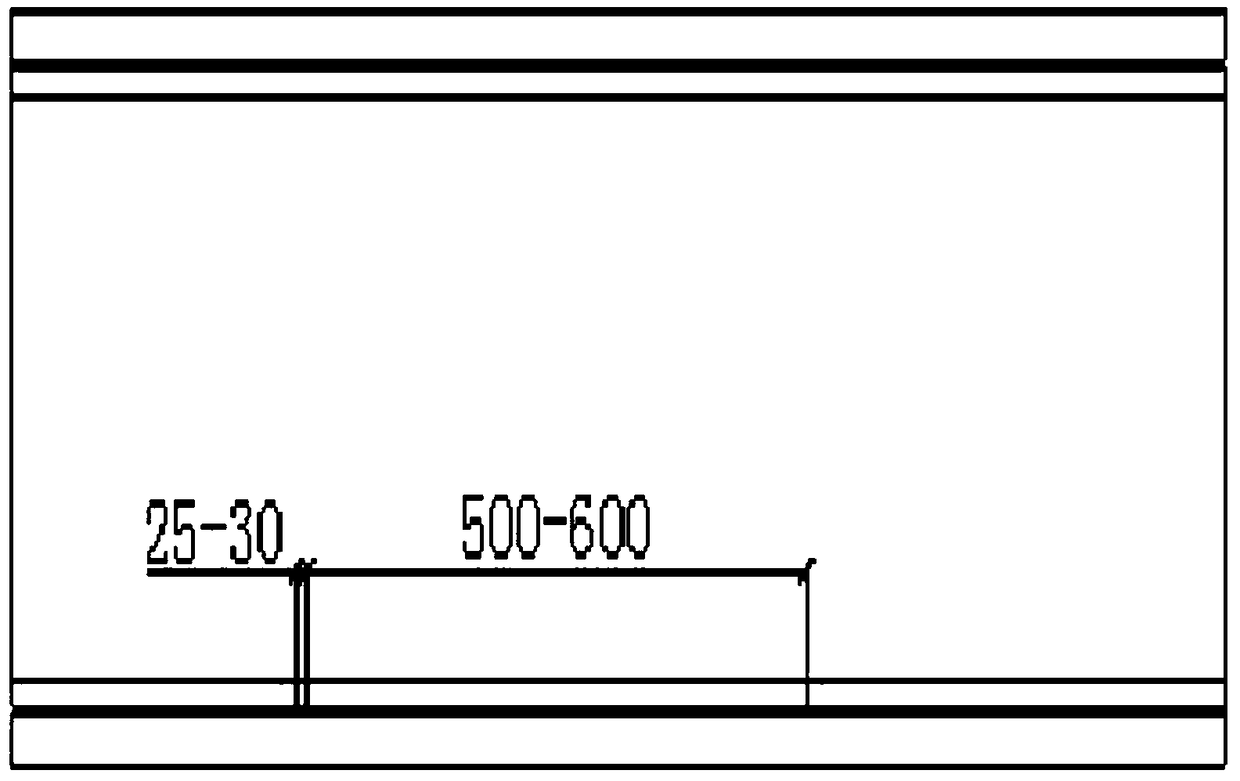

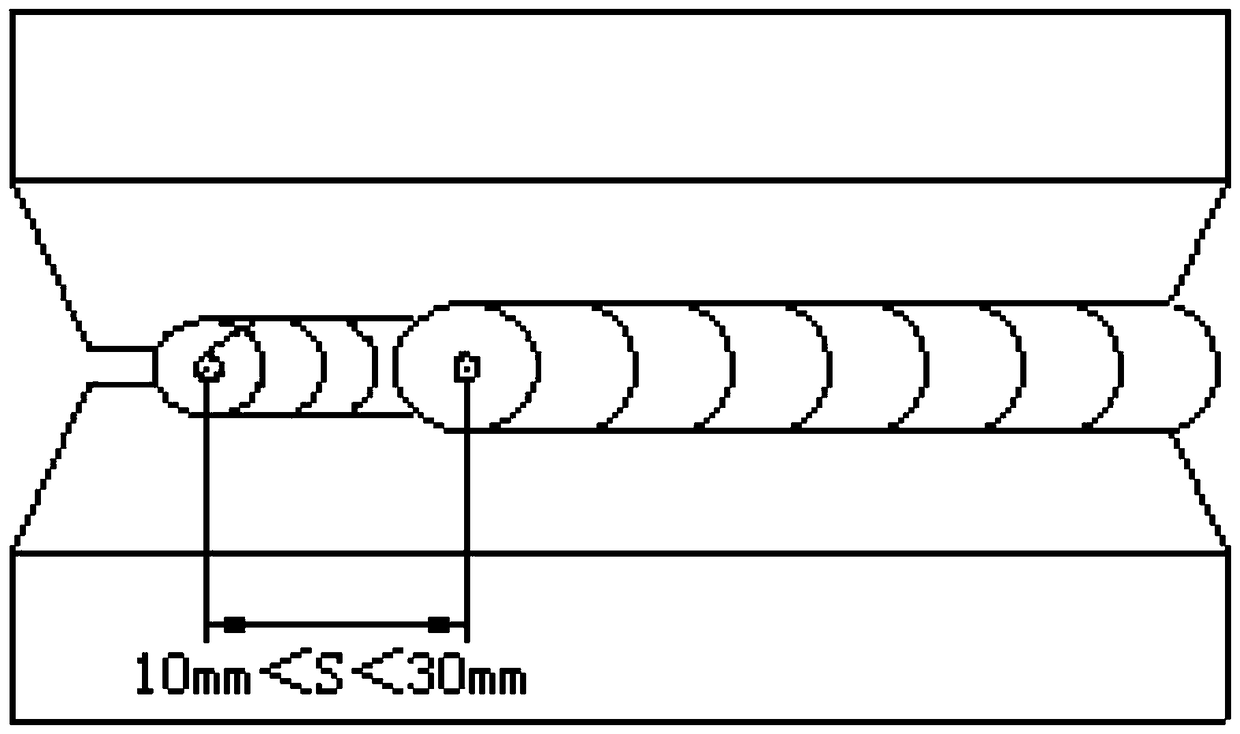

T-shaped double arc welding backing process for medium-thickness plate

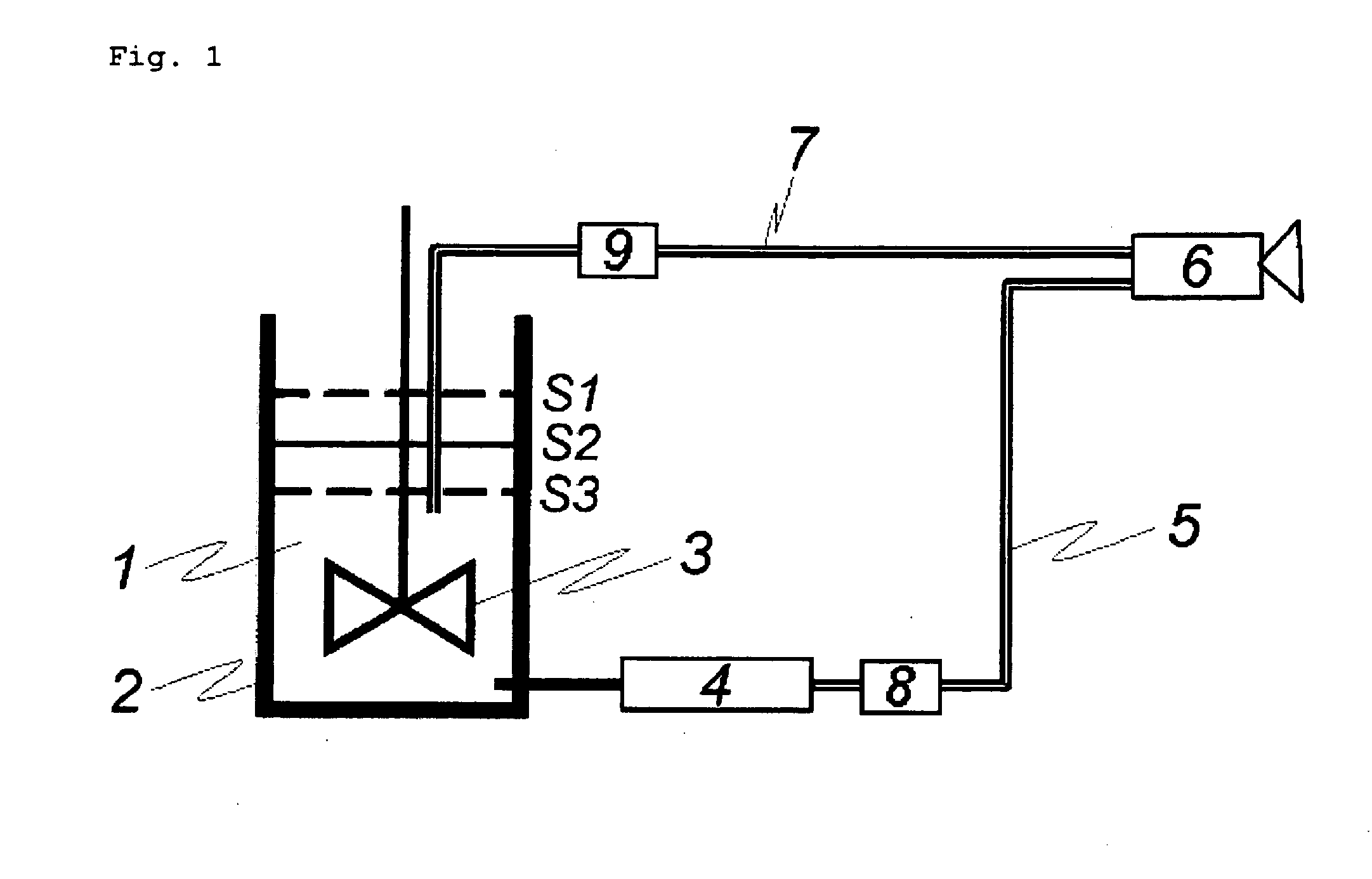

The invention discloses a T-shaped double arc welding backing process for a medium-thickness plate. The T-shaped double arc welding backing process comprises the following steps of (1) the blanking ofan H-shaped steel web is performed, negative 3 mm to negative 5 mm remains, a double-sided K-shaped groove is formed in a full penetration weld, which is greater than 16 mm, of the H-shaped steel web, the groove width is 16 mm to 18 mm, no root face is left in the groove, and the clearance of 4 mm to 6 mm is left; (2) oxide skin, iron rust and other impurities existing within a range of 50 mm onboth sides of the K-shaped groove position of the H-shaped steel web and the full penetration weld position at the middle of a flange are cleared through grinding, and a metallic color is displayed; and (3) the clearance of 4 mm to 6 mm is left during the assembly of the full penetration weld, a backing plate of 5 mm is adopted for controlling the clearance at intervals of 500 mm to 600 mm, a tackwelding point is positioned within 10 mm of the backing plate; the tack welding intervals are consistent with the intervals of 500 mm to 600 mm among the backing plates, the length of the tack welding point is 50 mm, and during the assembly, the full penetration weld is shrunk by 3 mm to 5 mm on the section of the H-shaped steel web. According to the T-shaped double arc welding backing process disclosed by the invention, the double-sided groove is formed in the H-shaped steel web, no root face is left, the clearance of 4 mm to 5 mm is left, the double arc backing welding operation is performed, the air gouging operation is not needed, the welding quality and efficiency are greatly improved, and the production cost is reduced.

Owner:CHANGJIANG & JINGGONG STEEL STRUCTURE GRP CO LTD

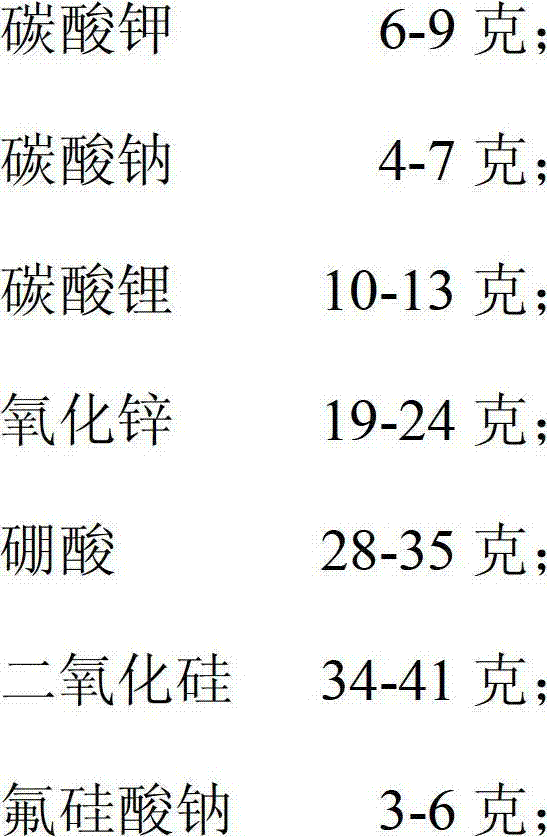

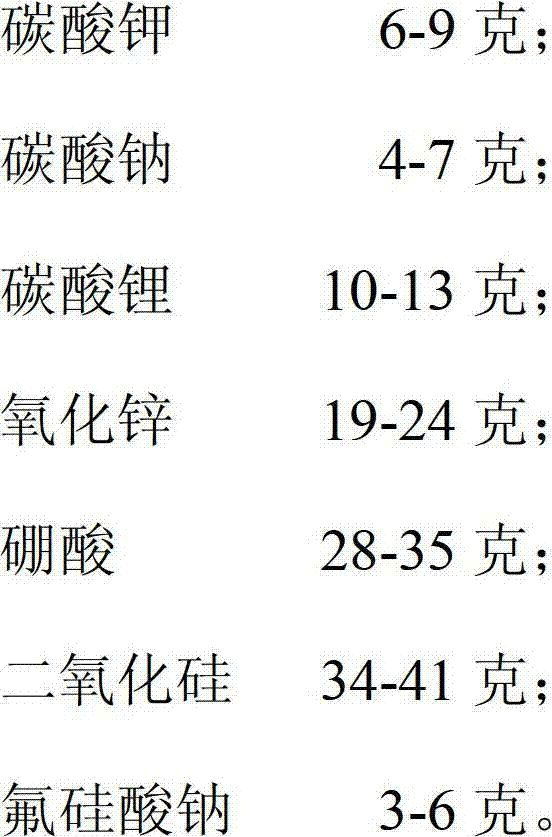

Glaze for metal product surface and firing method thereof

The invention relates to a glaze for a metal product surface and a firing method thereof. The glaze 1) comprises at least one base agent A and 2) may also comprise an assistant B or C, wherein the base agent A comprises 6-9g of potassium carbonate, 4-7g of sodium carbonate, 10-13g of lithium carbonate, 19-24g of zinc oxide, 28-35g of boric acid, 34-41g of silicon dioxide and 3-6g of sodium fluosilicate. The technical scheme has the following advantages: 1. the glaze has favorable acid / alkali resistance, high hardness (up to Hv500-700) and favorable glossiness (70-90%); 2. the fired glaze layer has bright color, and can protect the noble metal vessel from oxidation, thereby enhancing the practicality; the fired glaze layer can also keep the original metallic color and appearance characteristic of the noble metal billet, thereby enhancing the ornamental value; and 3. the raw materials are non-toxic and leadless in the preparation process, thereby satisfying the international safety standard.

Owner:上海渊泉集币收藏品有限公司

Method for preparing coating for hiding surface of orthodontic metallic tooth arc wire

InactiveCN102179353AUniform thicknessCoating color can be adjusted freelyPretreated surfacesSpecial surfacesAlcoholDistilled water

The invention provides a method for preparing a coating for hiding surface of an orthodontic metallic tooth arc wire, which comprises the following steps: (1) preprocessing the surface of the metallic tooth arc wire, ultrasonically cleaning the surface of the metallic tooth arc wire for 10 minutes in acetone, alcohol and distilled water, and removing oil stains; (2) straightening and fixing the preprocessed metallic tooth arc wire by using a mould, lifting and coating the metallic tooth arc wire in a dip-coating solution, wherein the dip-coating solution is stirred for 5-20 minutes at a stirring speed of 100-500 revolutions per minute and a lifting and coating speed is 0.5-5 millimeters per second; and (3) standing the coated metallic tooth arc wire for 15 minutes at room temperature, and then curing for 10-30 minutes at 150-180 DEG C, thereby acquiring a NiTi metallic tooth arc wire with a hidden coating. The method provided by the invention has the advantages that the preparation method is simple, the preparation method is free from being influenced by the shape of the tooth arc wire, the preparation method is environment-friendly, the coating is used for efficiently shielding the metallic color of the metallic tooth arc wire, and the coating has a function of hiding the tooth arc wire.

Owner:NANCHANG HANGKONG UNIVERSITY +1

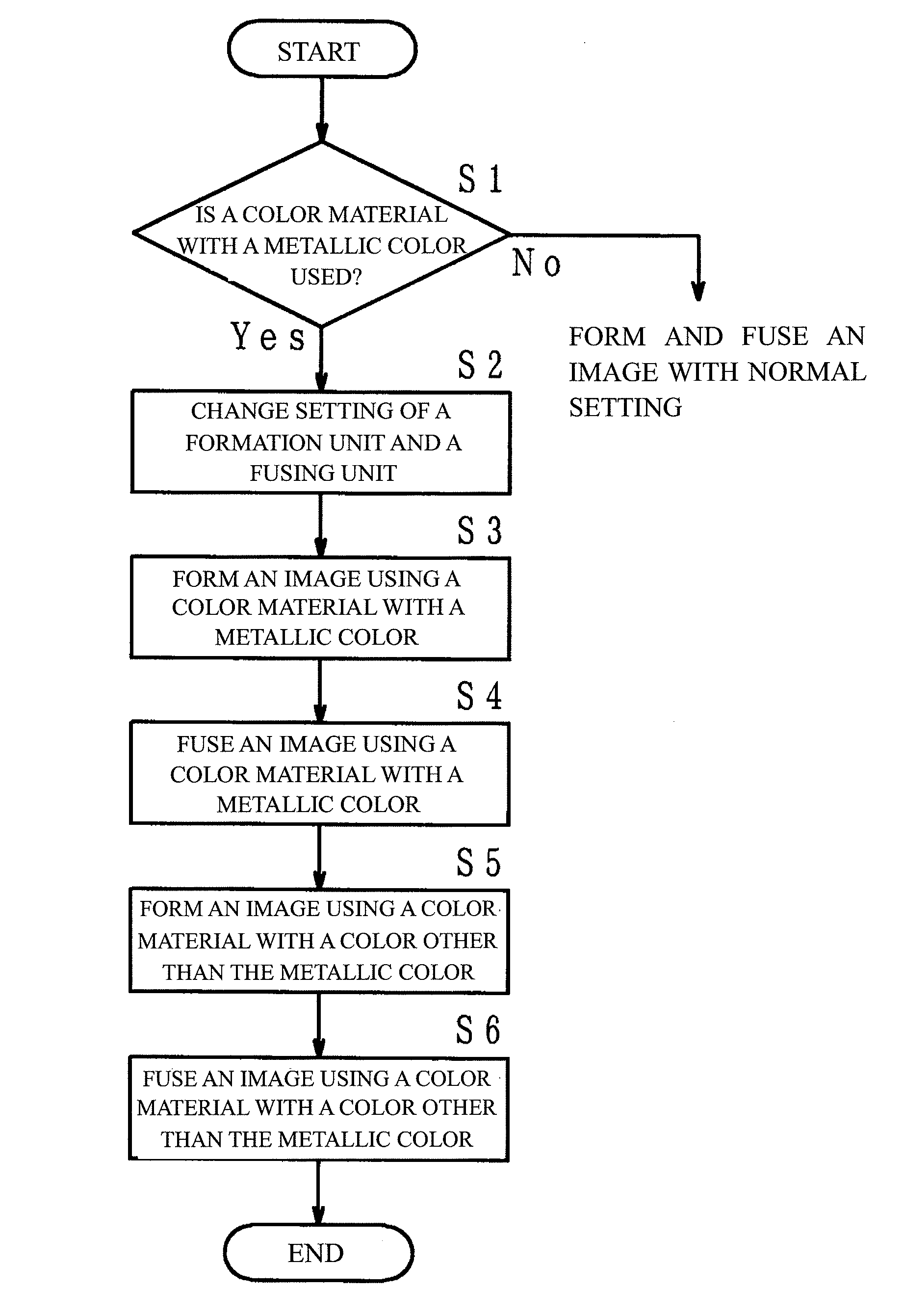

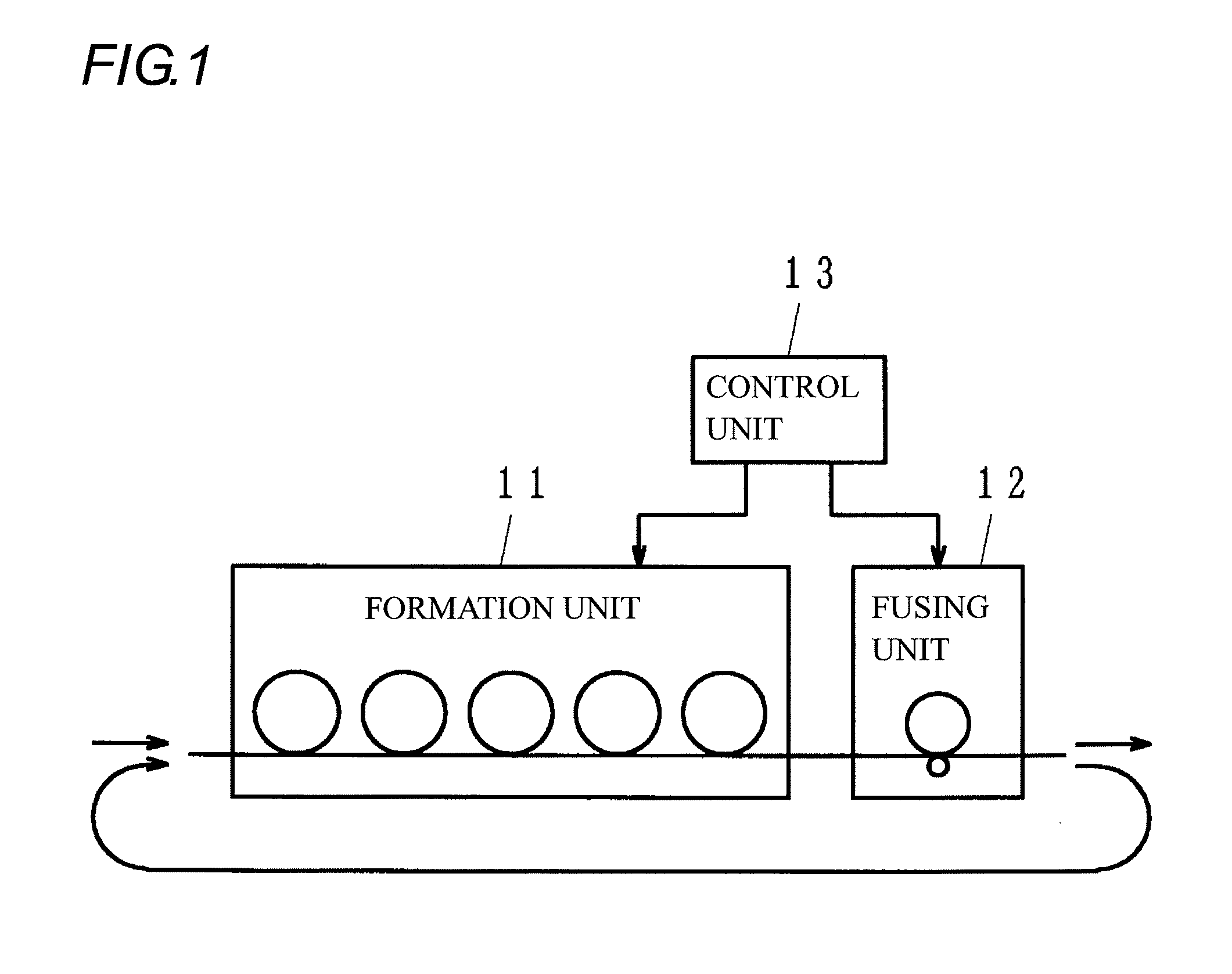

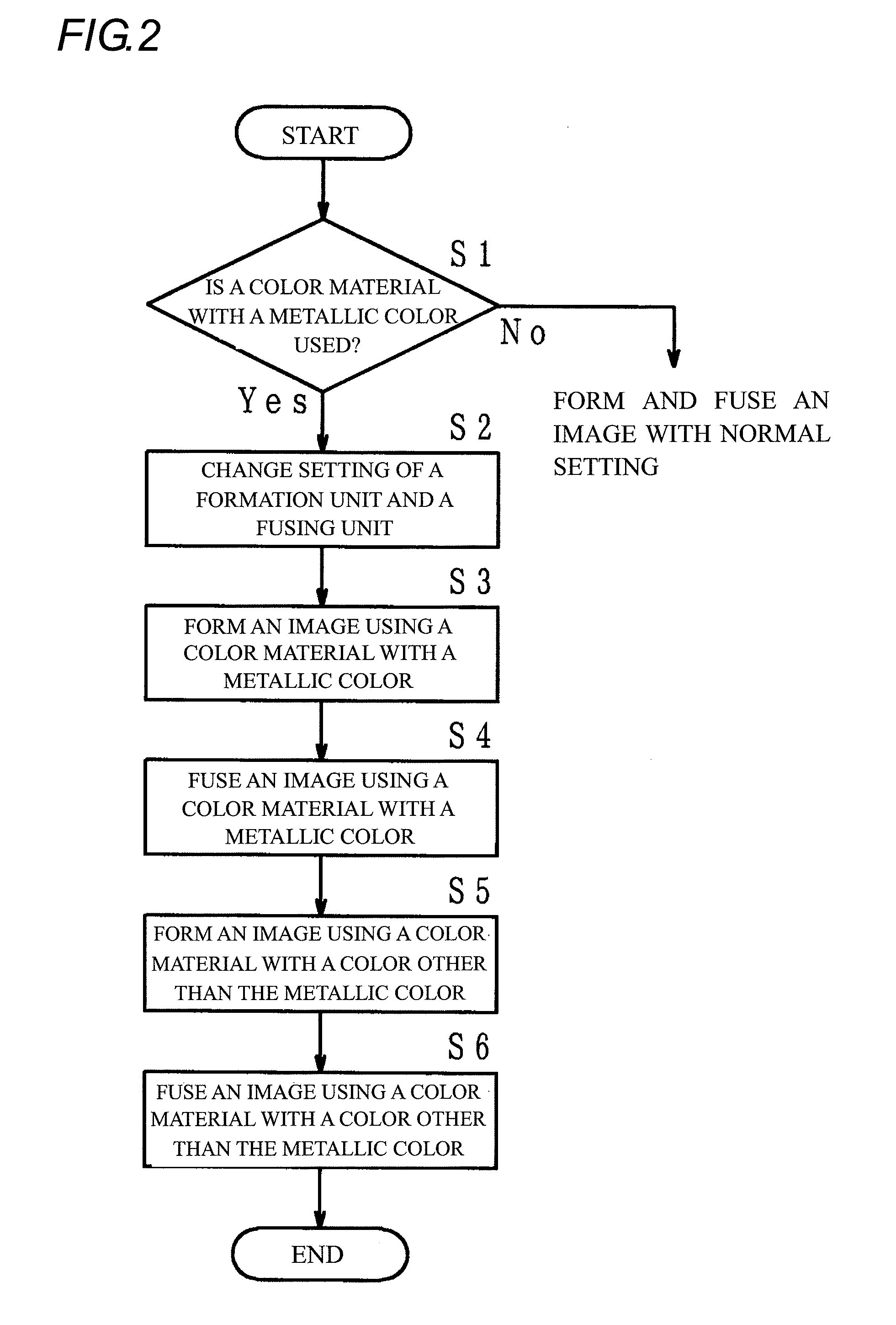

Image forming apparatus and image forming program

There is provided an image forming apparatus including: a formation unit that forms an image using a color material, on a medium; a fusing unit that fixes the image formed on the medium; and a control unit that controls to perform both of a first fusing and a second fusing on the medium, wherein the first fusing is a fixation in which a first image is formed by using a color material with a metallic color and the first image foamed is fixed, the second fusing is a fixation in which a second image is formed by using a color material with another color than the metallic color and the second image formed is fixed, and the first image and the second image are overlapped.

Owner:FUJIFILM BUSINESS INNOVATION CORP

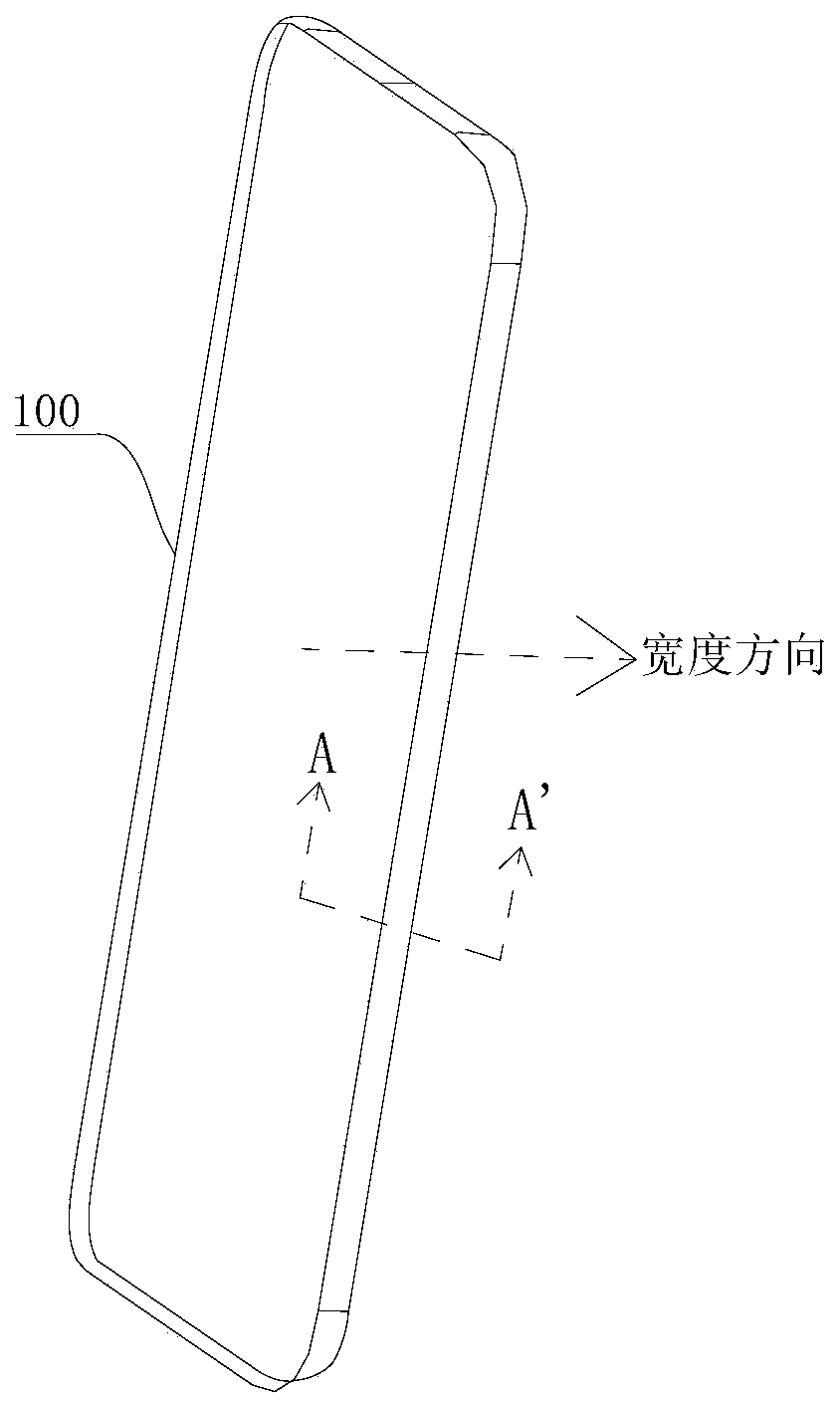

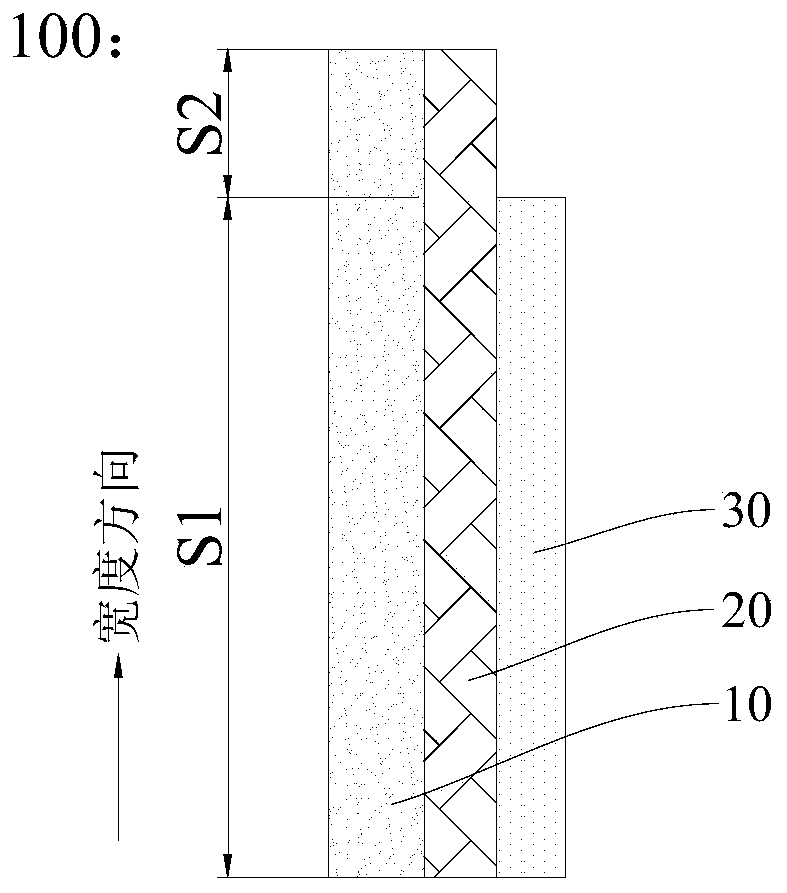

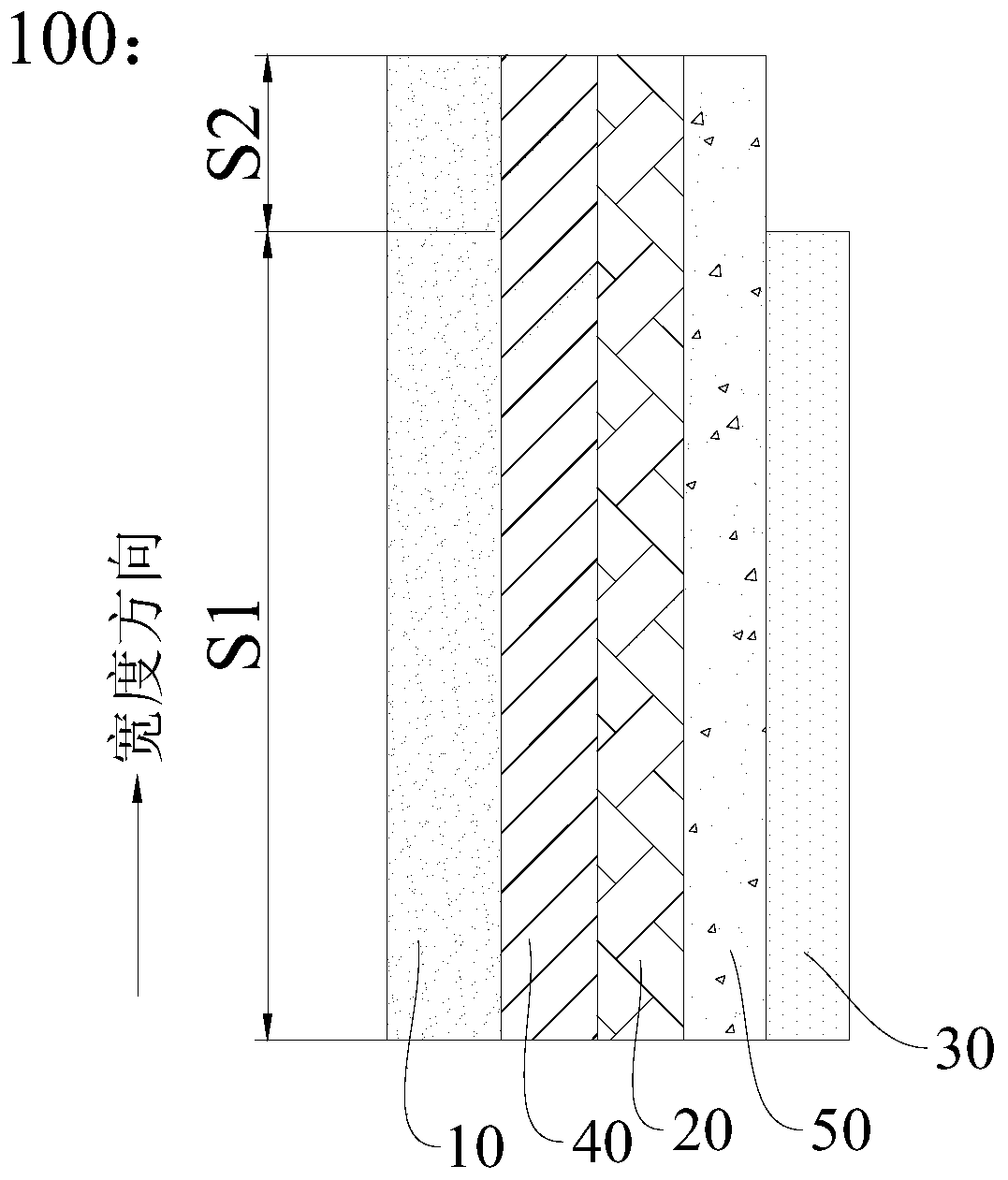

Middle frame, preparation method thereof and electronic equipment

InactiveCN110913614AVisual frivolityElectrical apparatus casings/cabinets/drawersMetal coatingEngineering

The invention provides a middle frame, a preparation method thereof and electronic equipment. The middle frame comprises a plastic base material which is sequentially divided into a first section areaand a second section area in the width direction; a metal coating which is arranged on one side of the outer surface of the plastic base material, and the orthographic projection of the metal coatingon the plastic base material covers the first section area and the second section area; and a transparent colored paint layer which is arranged on the side, away from the plastic base material, of the metal plating layer, and the orthographic projection of the transparent colored paint layer on the plastic base material is overlapped with the first section area. Therefore, the appearance color right corresponding to the first section area of the middle frame is bright and transparent, the bright and transparent color with the metal texture can be presented, and the appearance texture of the middle frame is improved; transparent colored paint is not arranged in the area right corresponding to the second section area, so that the edge of the middle frame is in a bright metal color, the appearance of the middle frame can be decorated, the texture and visual impact of the middle frame are improved, and the middle frame is light and thin visually.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

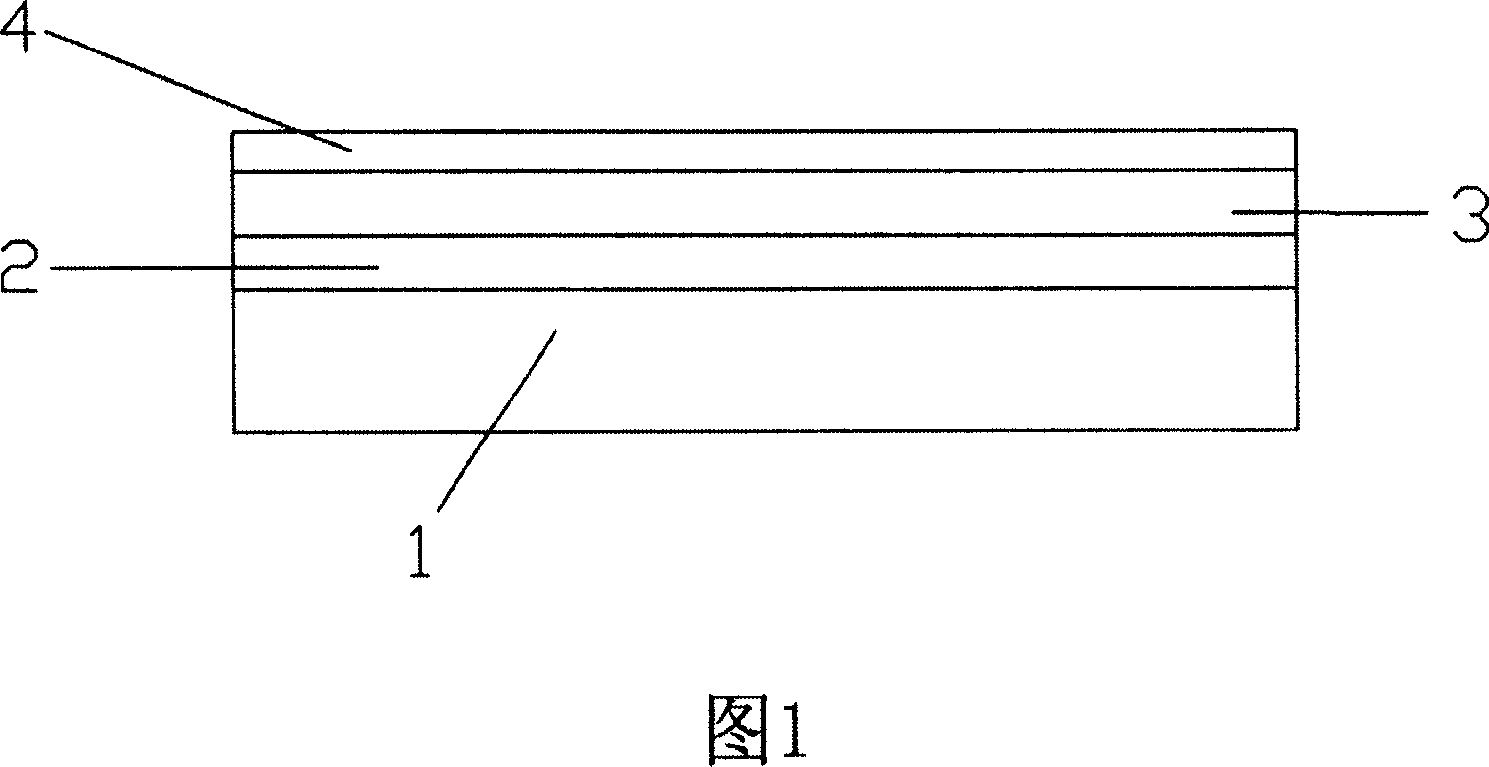

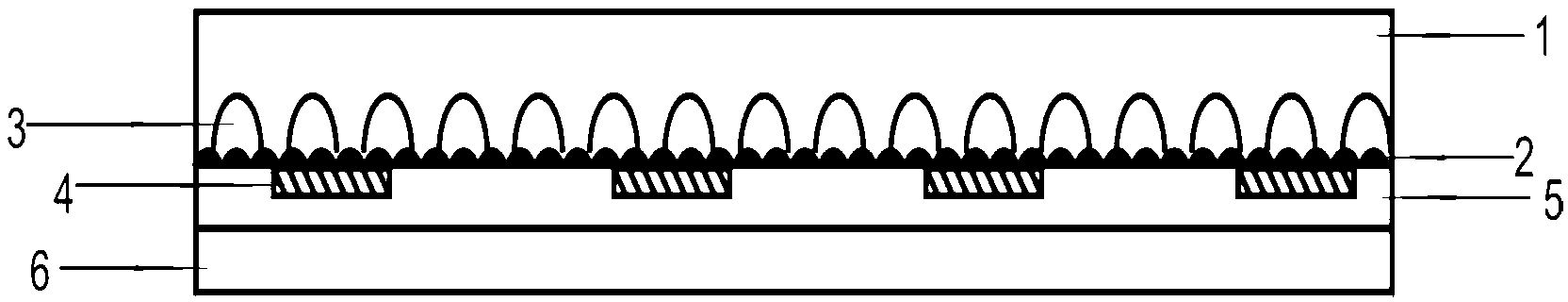

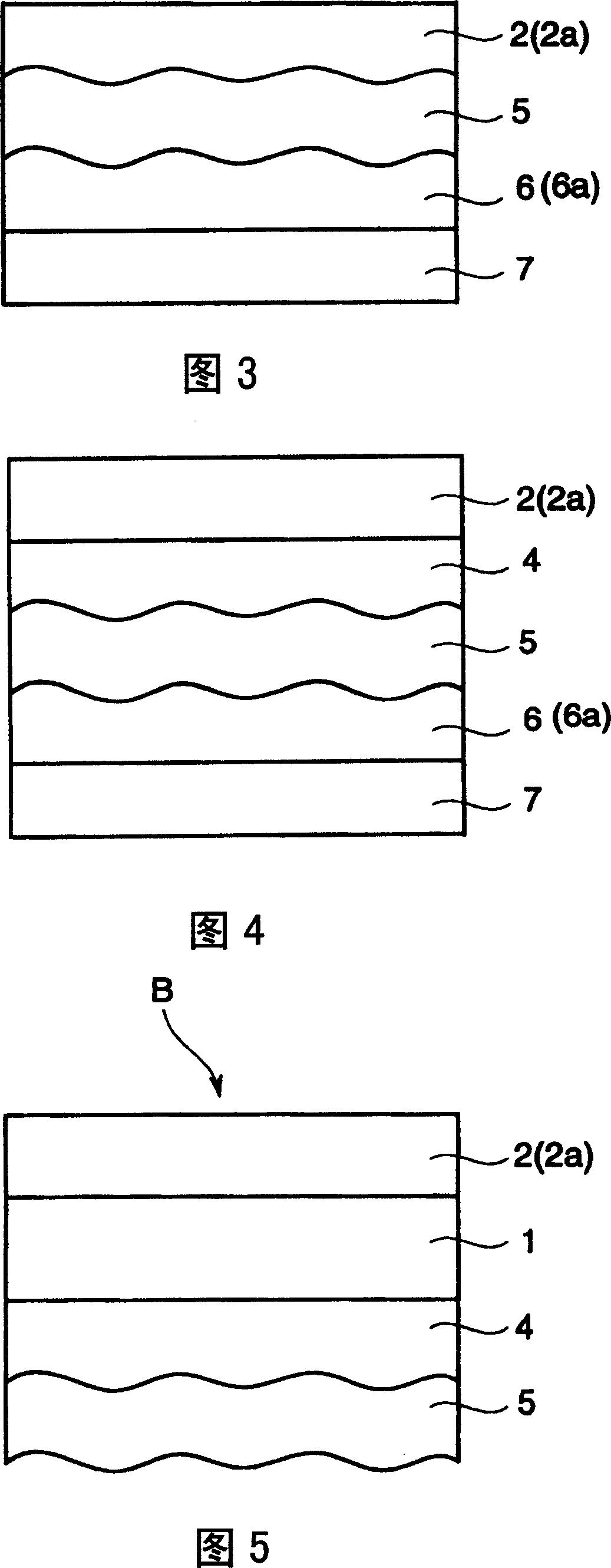

Manufacturing method of metallic glass plate

InactiveCN103273703ASolve the problem of engraving and patterningReduce light pollutionGlass/slag layered productsFlat glassScreen printing

The invention provides a manufacturing method of a metallic glass plate. The product is high-grade decorative electrical household appliance panel glass in a laminated structure. A substrate is float sheet glass (1), a grinding layer (2) and a subtraction splineway brush mark throwing layer (3) are adopted, then the substrate is tempered or hot-bent, and a screen printing local pattern layer (4), a screen printing metallic color surface layer (5) and a screen printing or roller coating back cover protective layer (6) are adopted. With the adoption of the glass plate and the manufacturing method, the process difficulty is simplified, the manufacturing cost is lowered, the adhesion fastness between composite layers is improved, the light pollution of specular reflection is reduced, and a semi-matte nonspecular texture effect of a high-grade decorative stainless steel drawing plate is simulated more perfectly.

Owner:JIANGSU XIUQIANG GLASSWORK CO LTD

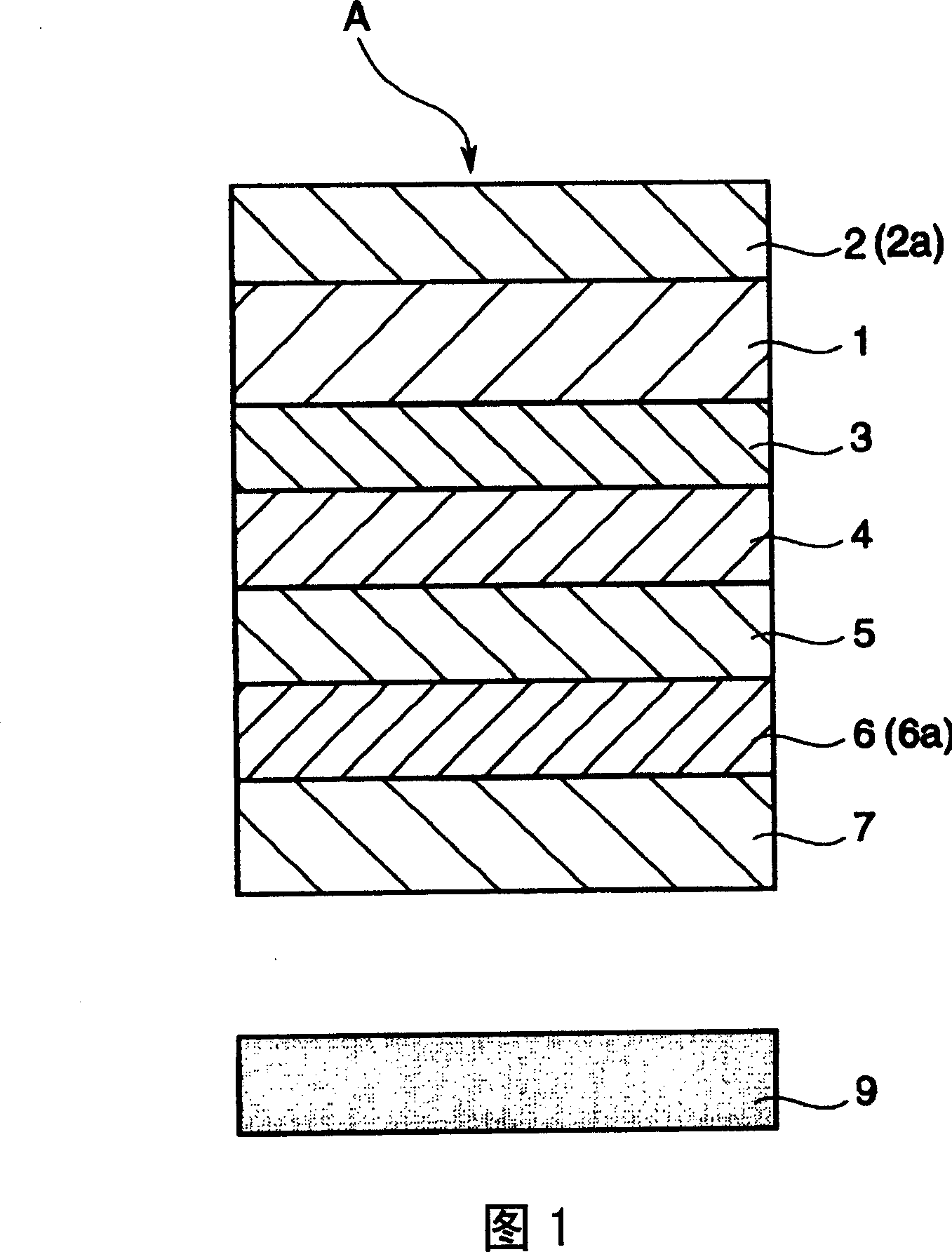

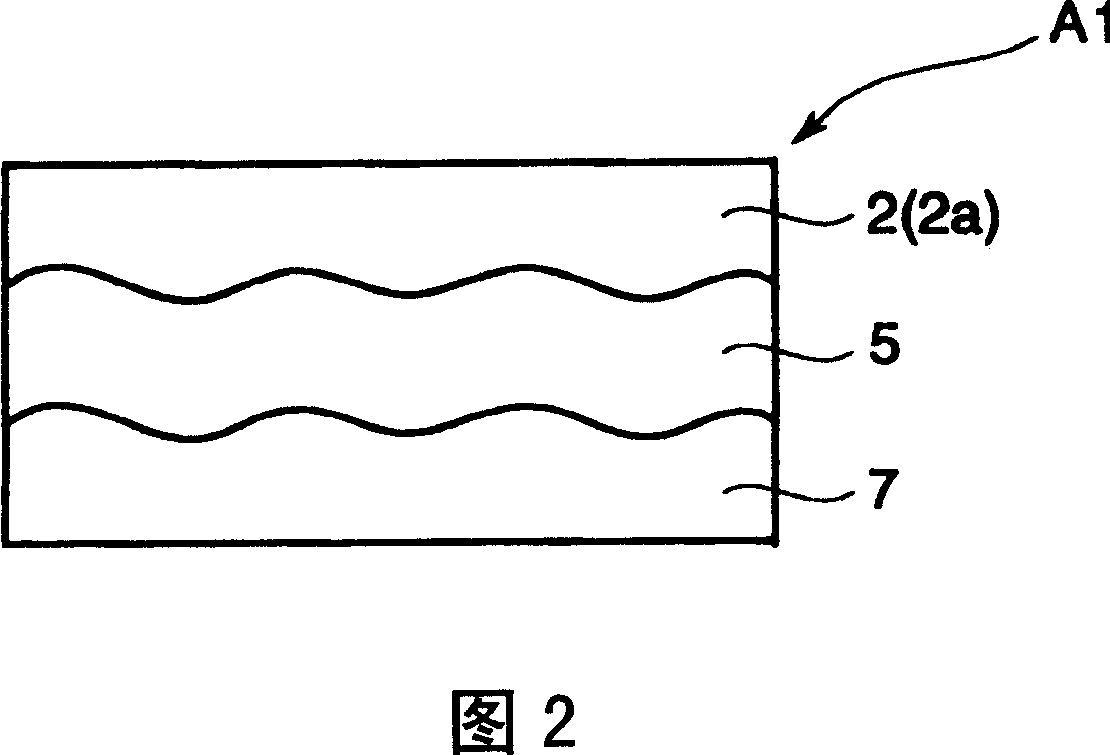

Metal color decorative thin slice and decorative metal plate

InactiveCN1923505AImprove pattern designMetallic colorSynthetic resin layered productsWood veneerPolymer science

The invention relates to a decorate sheet with metallic color. Wherein, it is formed by modified polyolefin resin layer, metal foil layer, and transparent film layer which selects at least one of modified polypropylene, polyethylene and ethene-propone rubber as main component that passed with non-saturated carboxylic acid or non- saturated carboxylic acid derivate, while the extending stress at 5% length is 25-500MPa. Therefore, the inventive sheet will not flow resin at the section in cutting or holing process.

Owner:角正三郎

Process For Producing Multi-Layer Coatings In Light Metallic Color Shades

ActiveUS20100143705A1High pigment contentReduce transmissionLiquid surface applicatorsLayered productsUltravioletPolyresin

A process for producing multi-layer coatings in light metallic color shades and reducing UV transmission there-through comprising the successive steps of:(1) applying a 10 to 30 μm thick base coat layer to a pre-coated substrate,(2) applying a clear coat layer onto the base coat layer, and(3) jointly curing the base coat and clear coat layers,wherein the base coat layer is applied from an unmodified water-borne metallic base coat having a ratio by weight of pigment to resin solids of 0.3:1 to 0.45:1, wherein the pigment content consists of 90% to 100% by weight of at least one non-leafing aluminum pigment with a platelet thickness over 100 to 500 nm and 0 to 10% by weight of at least one pigment different from aluminum pigments, wherein the pigment(s) different from aluminum pigments are selected in such a way that the multi-layer coating obtained exhibits a brightness L* (according to CIEL*a*b*, DIN 6174), of at least 80 units.

Owner:AXALTA COATING SYST IP CO LLC

Inkjet printing of pearlescent and metallic colours

A method of inkjet printing a colour image including a metallic or pearlescent colour comprising the steps of applying on part of an ink receiver a layer containing a pearlescent or metallic pigment having a volume mean particle size of at least 3.0 pm as measured by laser diffraction; and inkjet printing on part of the layer containing the pearlescent or metallic pigment a layer with a white inkjet ink containing a white pigment having a average particle size between 250 and 400 nm as measured by differential centrifugal sedimentation.

Owner:AGFA NV

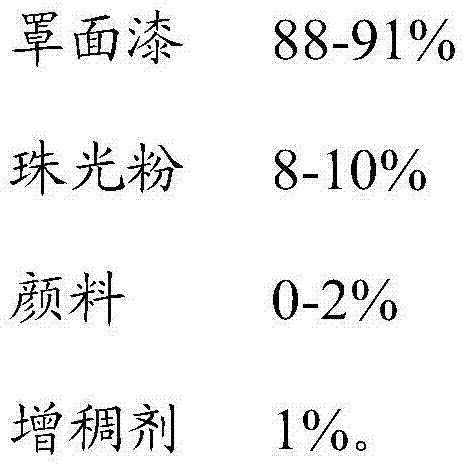

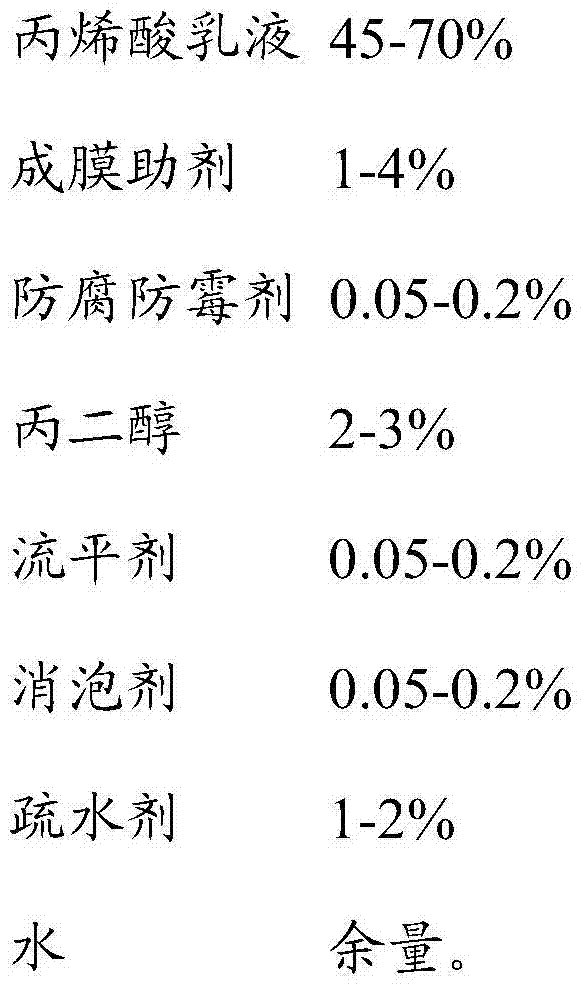

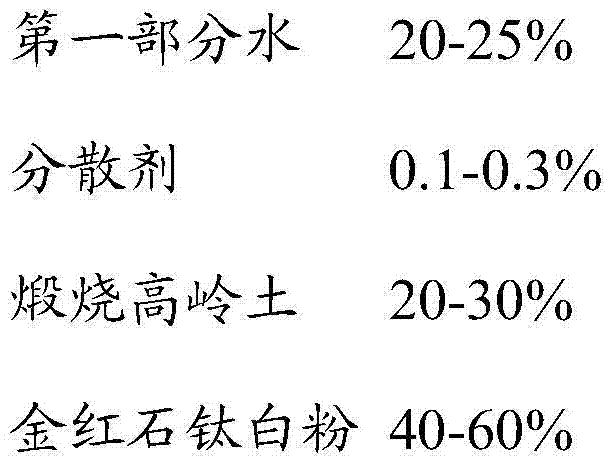

Super-weather-proof water-based metallic paint and preparation method thereof

InactiveCN104725962AIncrease coverageReduce powder contentAntifouling/underwater paintsPaints with biocidesWater basedCalcium silicate

The invention discloses a super-weather-proof water-based metallic paint, and belongs to the field of a water-based paint. The super-weather-proof water-based metallic paint comprises the following components in percentage by weight: 88-91% of finish-coat paint, 8-10% of pearl powder, 0-2% of pigment and 1% of a thickener. The invention further discloses a preparation method of the super-weather-proof water-based metallic paint. The super-weather-proof water-based metallic paint has favorable hiding power, excellent contamination resistance and self-cleaning function, excellent pain film property, high weather resistance, scrubbing resistance, ageing resistance, scratch resistance, rice color, rich metallic color, obvious quality and good gloss effect; the paint is applicable for inner and outer wall surfaces and metal surfaces, calcium silicate board surfaces and other decorative material surfaces, the application scope is wide. The preparation method is easy to implement, the three wastes are avoided during the production process, and so the preparation method is environmentally friendly and safe.

Owner:GUANGZHOU ZUODANSHI PAINT

Colorful silk jacquard pattern face fabric

InactiveCN101307522AGood moisture permeabilityStrong metallic visual effectSwivel-woven fabricsLappet-woven fabricsColoredPulp and paper industry

The invention provides a seven-color yarn jacquard pattern plus material. Chaine adopts conventional cotton yarn and weft yarn adopts blank yarn or colorful yarn or seven-color yarn, wherein, the blank yarn is one or a plurality of cotton yarn, mucilage glue bright yarn, cotton colored spun yarn and terylene, the colorful yarn is one or a plurality of cotton yarn, mucilage glue bright yarn, cotton colored spun yarn and terylene, wherein, the cotton yarn counts in the chaine is between 40 and 80S; the yarns in the weft yarns are converted into Ne between 20 and 60S, the specification of the seven-color yarn is between 70 and 180D, the use amount ratio of the seven-color yarn to the blank yarn or the colorful yarn is between 0.5 and 50 percent, more than three raw materials are interwoven. The plus material has good moisture permeability by the comprehensive coordination of the flower pattern design, the color design, the organization design and the dyeing and finishing technique; the plus material has strong metallic color visual effect due to the setting-off decoration of the seven-color yarn.

Owner:JIANGSU GOLDSUN TEXTILE SCI & TECH

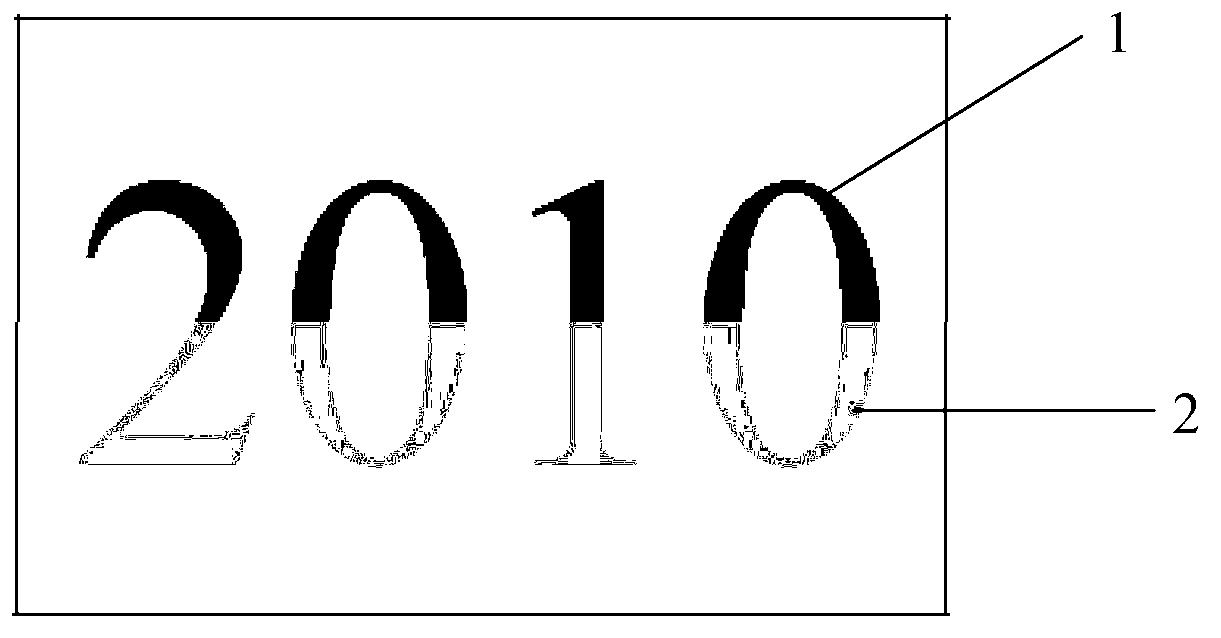

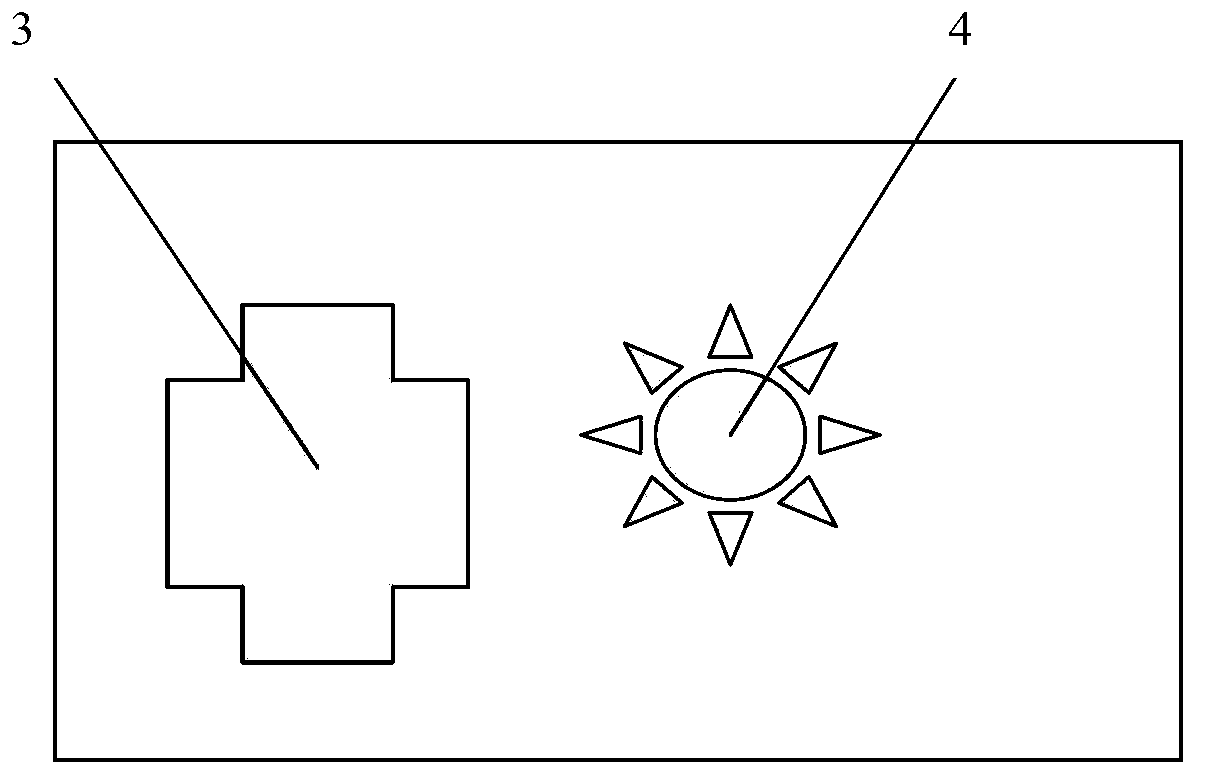

Decorative plastic molded article and manufacturing method thereof

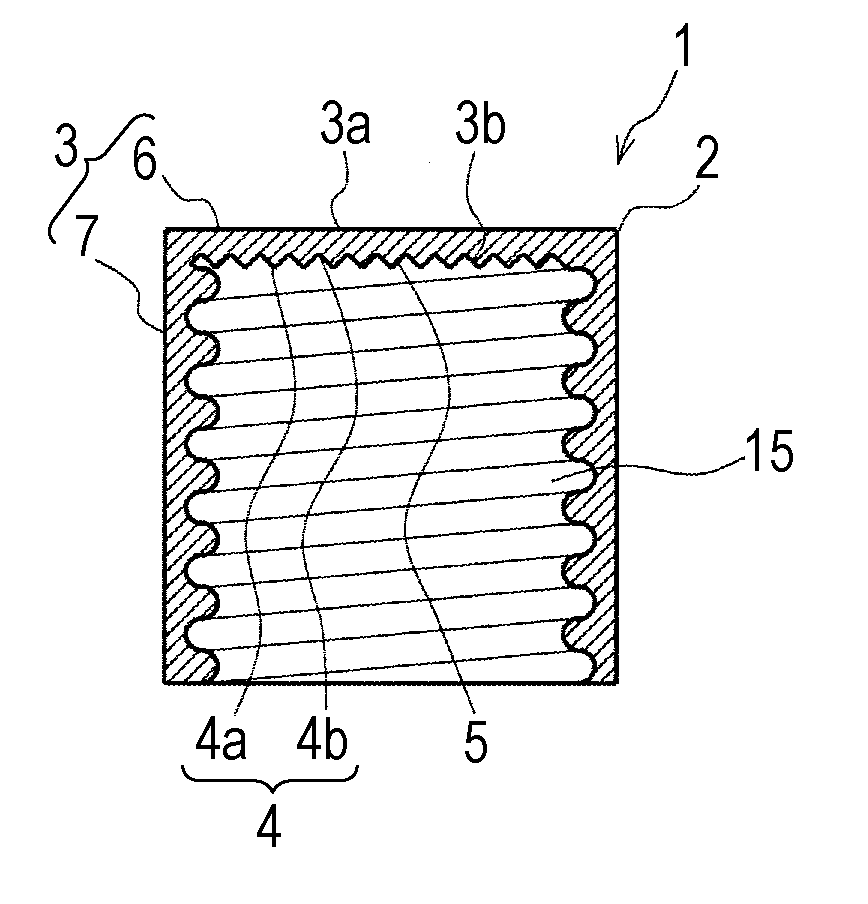

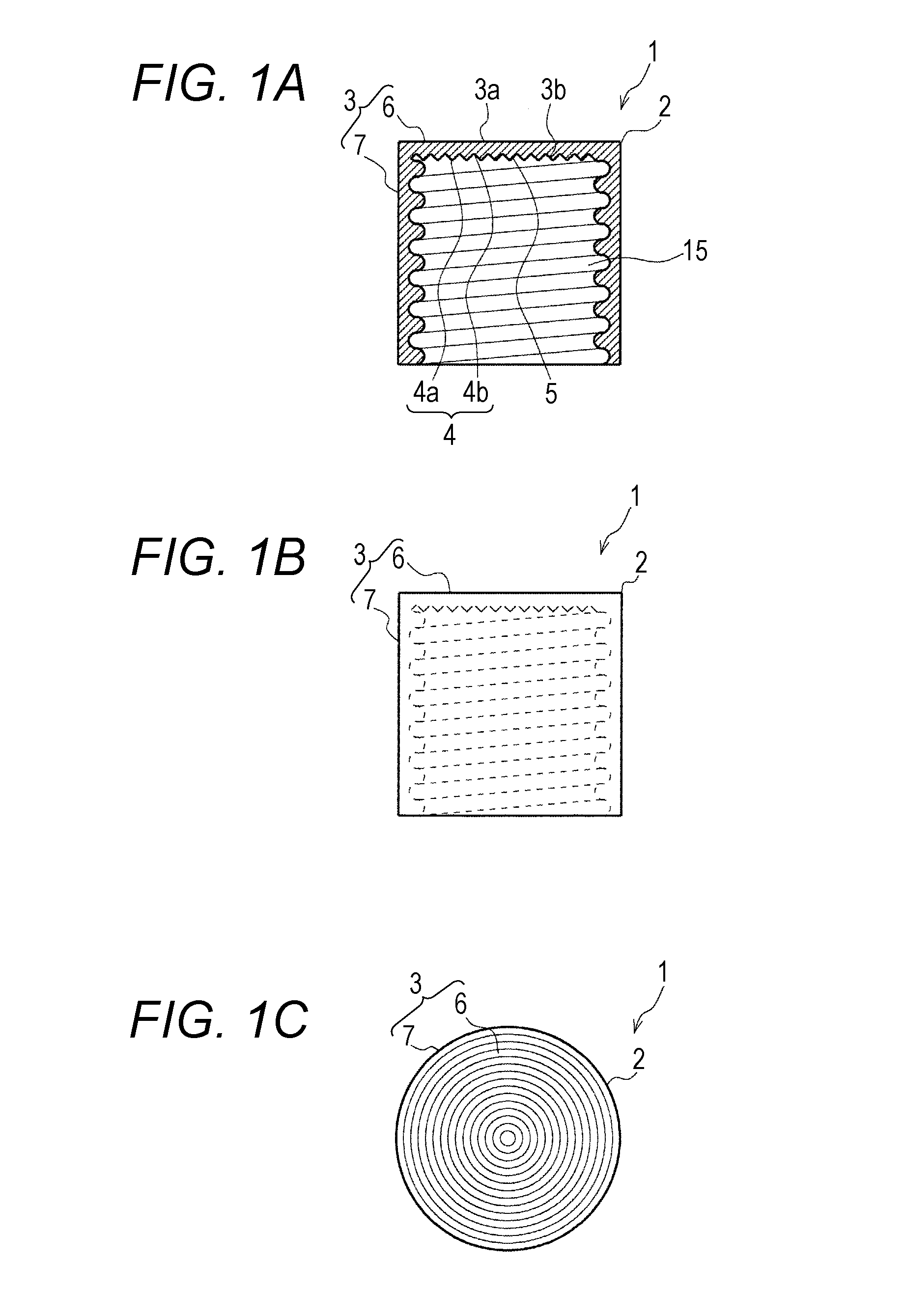

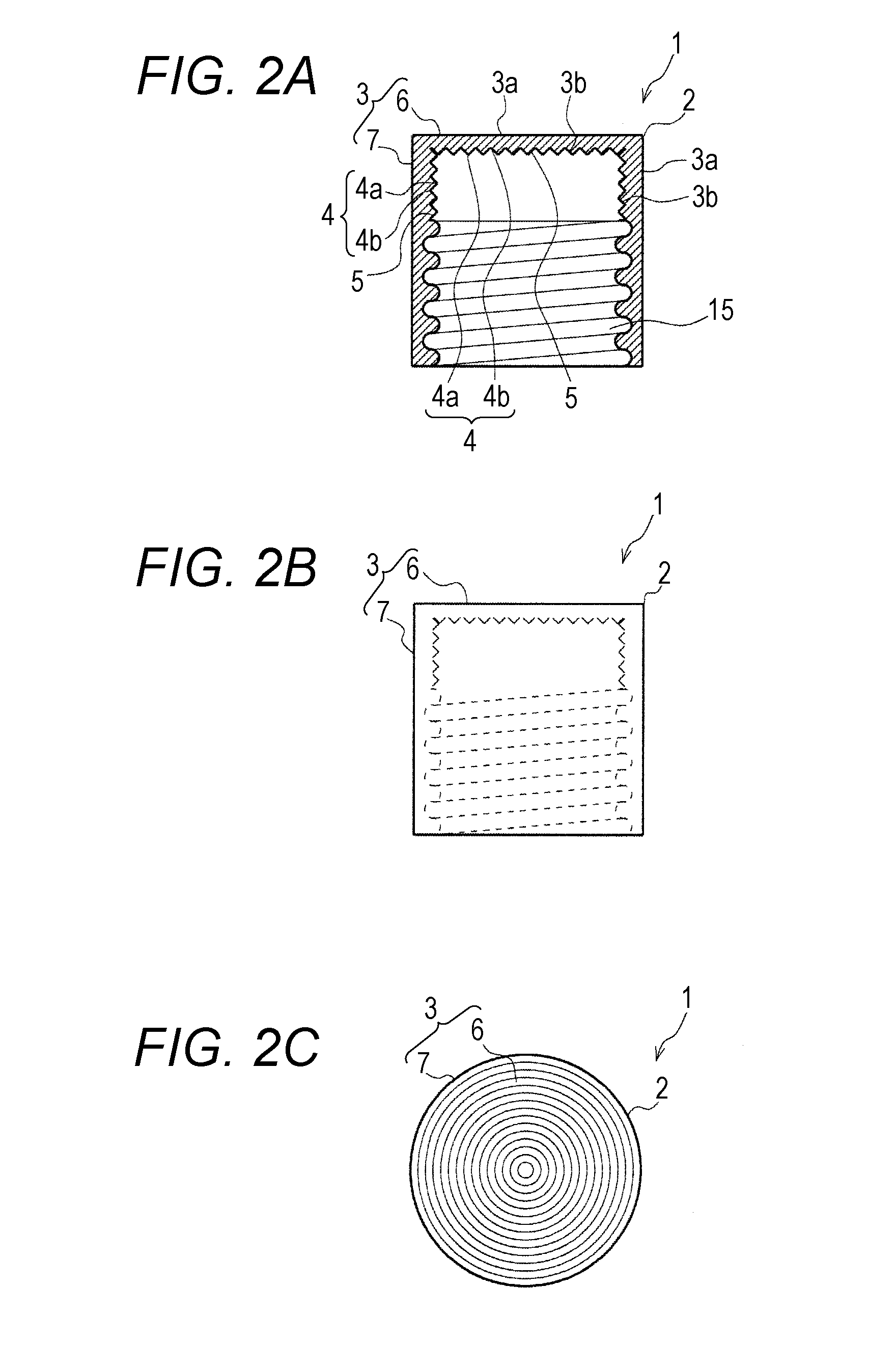

ActiveUS20160178916A1Stable maintenanceIncreased durabilityContainer decorationsLevel indicationsEngineeringMetallic color

A decorative plastic molded article has an outer appearance of metallic color like and a display of a character, a graph or a symbol. A body of the molded article has a plate-like portion; the plate-like portion has a first surface and a second surface; a small concave and convex portion is formed on the second surface; the small concave and convex portion has a plurality of inclined surfaces. The outer appearance of metallic color like is obtained by the total reflection light at the inclined surface and the display of a character, a graph or a symbol is obtained by the transmissive light through a planar transparent portion with shape of a character, a graph or a symbol formed in the small concave and convex portion or the total reflection light at the small concave and convex portion with shape of a character, a graph or a symbol.

Owner:SEIKOH GIKEN

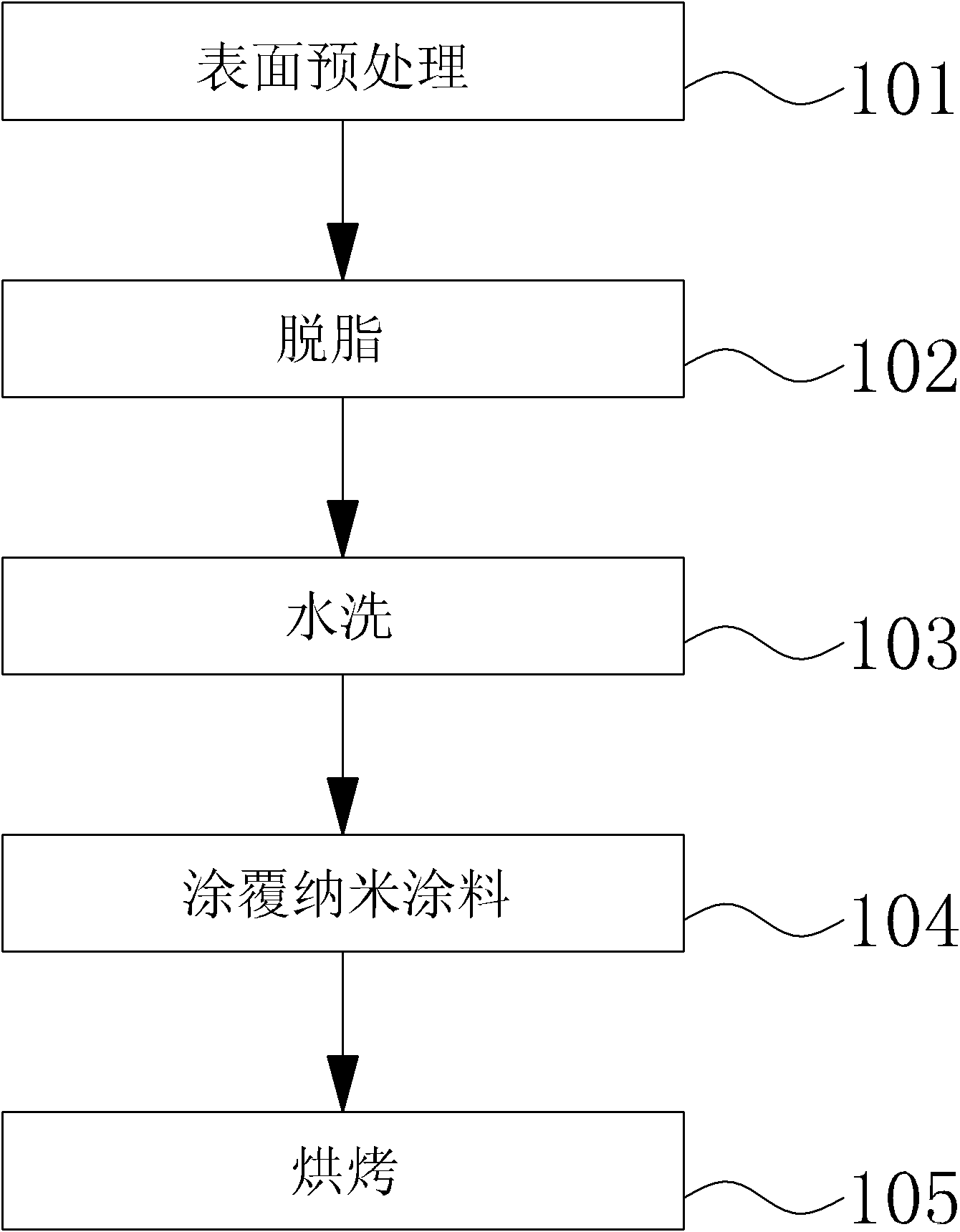

Preparation method of magnesium alloy surface colorless transparent film

InactiveCN102652937AImprove corrosion resistanceIncrease brightnessPretreated surfacesCoatingsIsobutanolEther

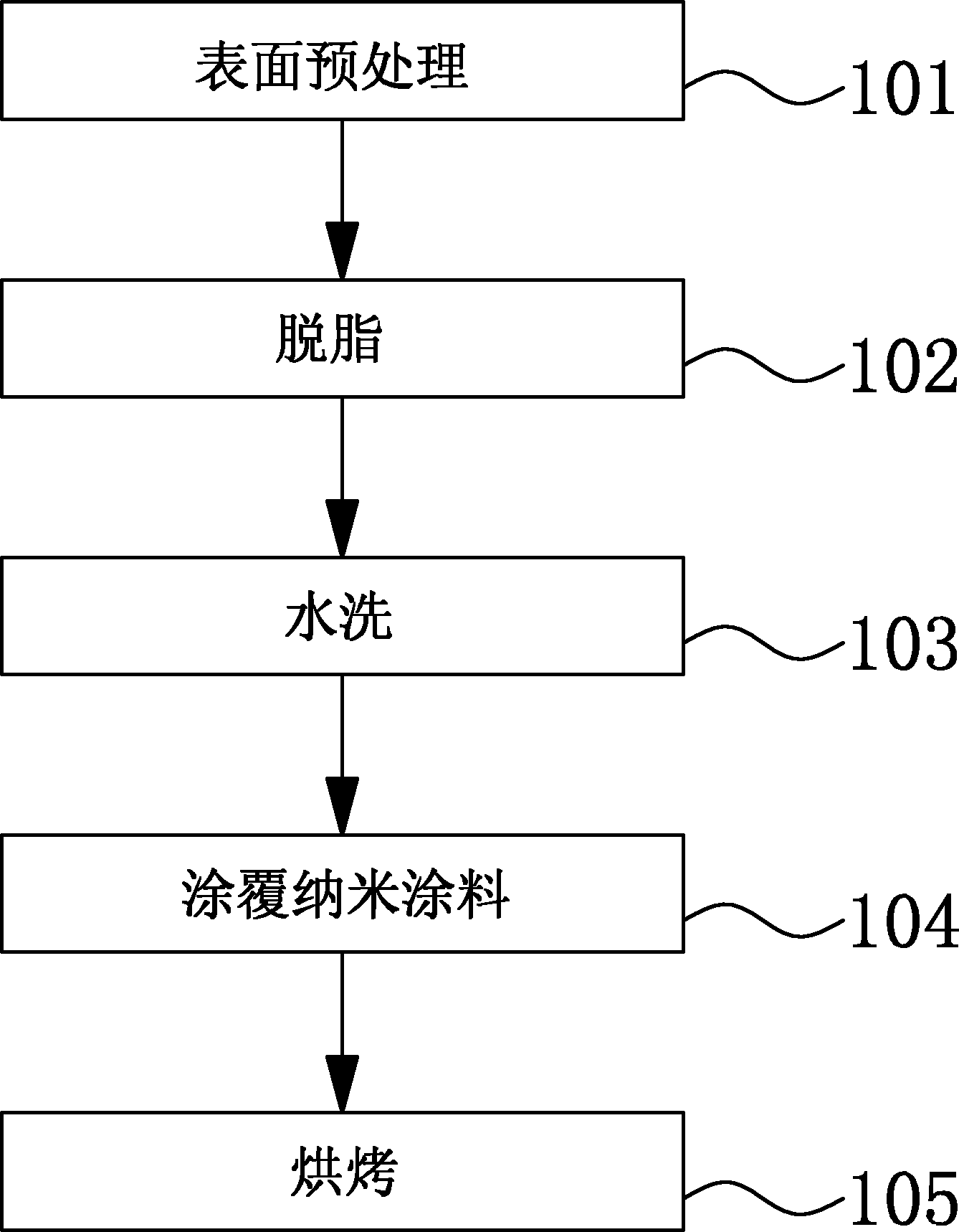

The invention provides a preparation method of a magnesium alloy surface colorless transparent film which is characterized by mainly comprising the following steps: (1) surface pretreatment; (2) degreasing; (3) water washing; (4) application of nano paint; and (5) baking. In the step (4), the nano paint mainly comprises the following components in percentage by weight: 20-50% of isobutanol, 40-70% of ethylene glycol monobutyl ether and 5-20% of nano sol-gel. Compared with the prior art, the preparation method provided by the invention has the advantages of simple technique, less required equipment and low cost; and the magnesium alloy surface colorless transparent film prepared by the method provided by the invention has the advantages of favorable corrosion resistance, high brightness and low ohmic value of the product surface, and can keep the metallic color and luster of the magnesium alloy.

Owner:MITAC PRECISION TECH(KUNSHAN) CORP

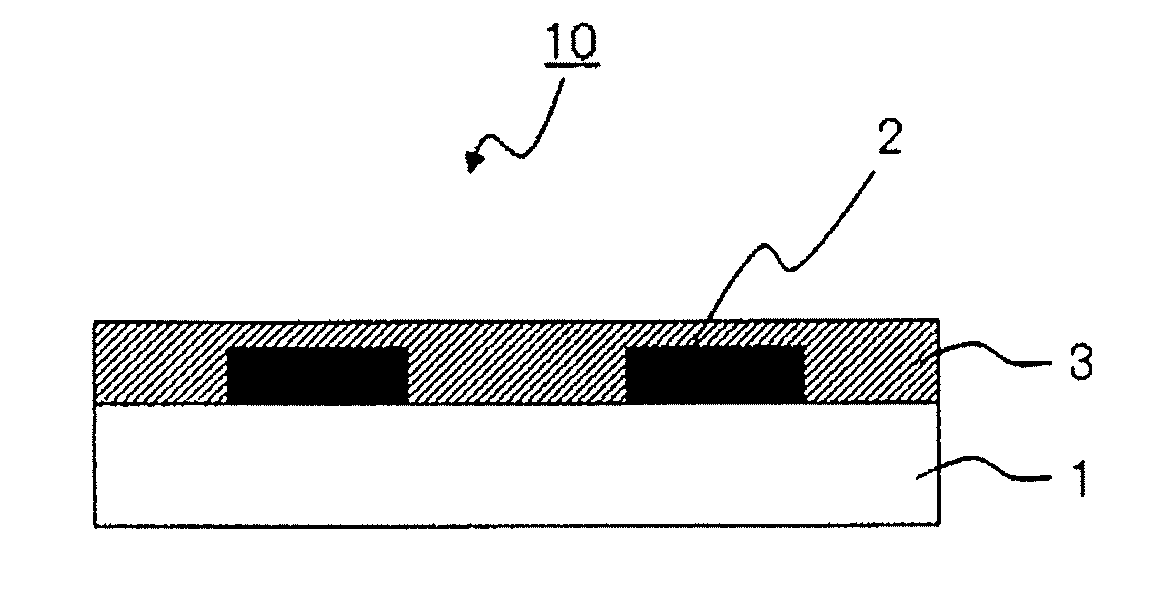

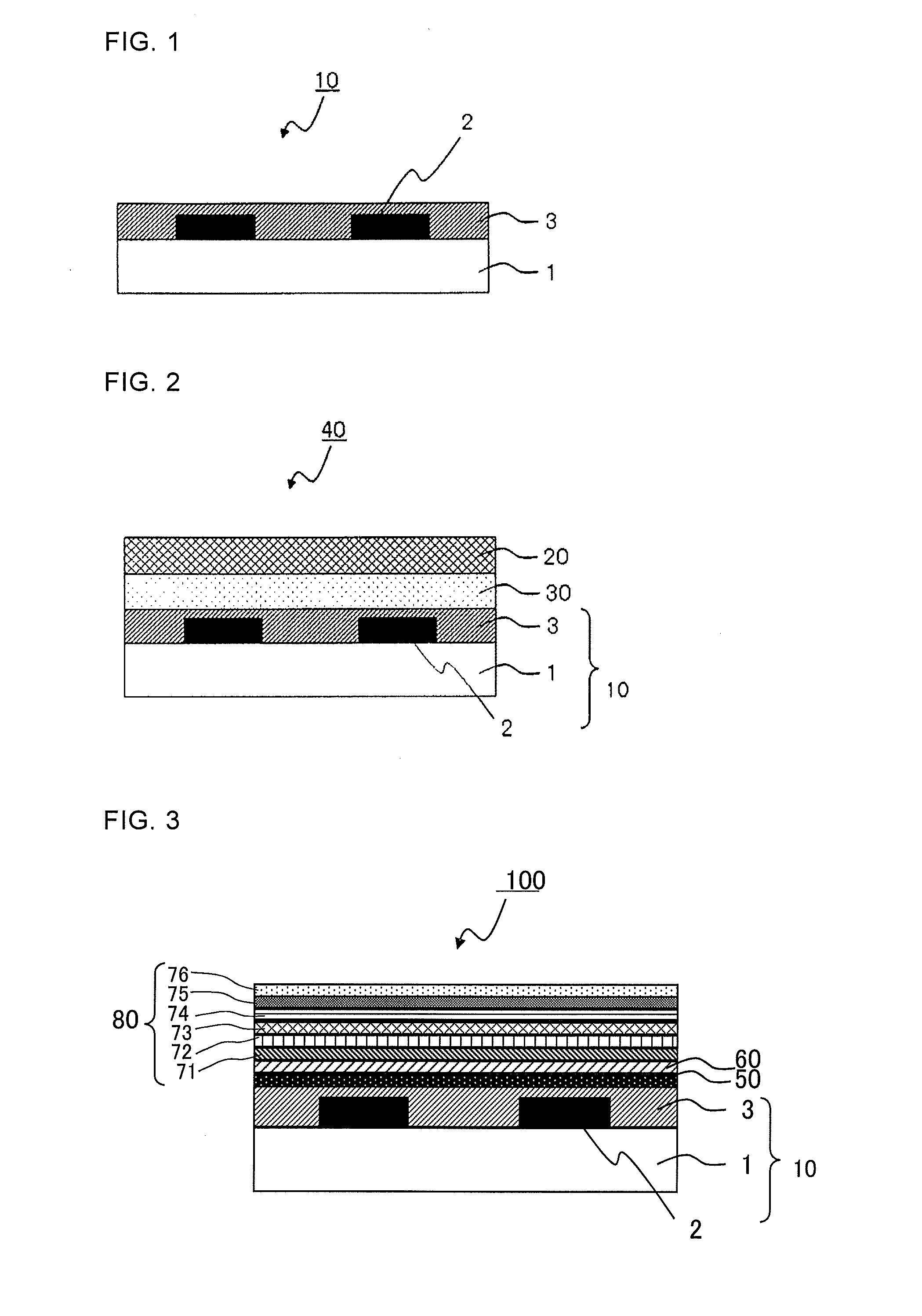

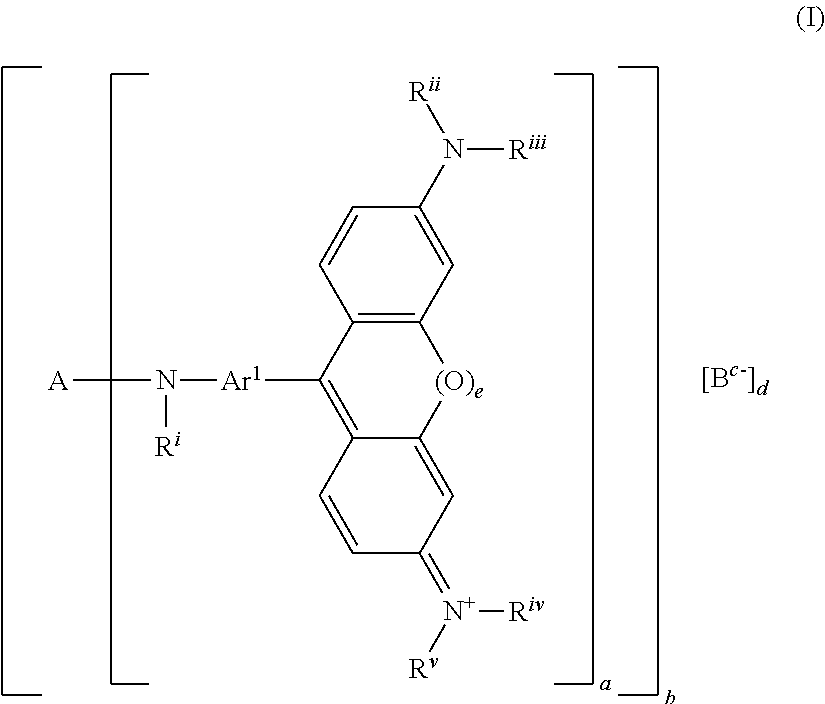

Color material dispersion liquid for color filters, color material, color filter, liquid crystal display device and organic light-emitting display device

ActiveUS20160282530A1Improve heat resistanceIncrease brightnessPyronine/xanthon/thioxanthon/selenoxanthan/telluroxanthan dyesDiaryl/thriaryl methane dyesColor gelDisplay device

Disclosed is a color material dispersion liquid for color filter, which has excellent heat resistance and is able to form a high-luminance coating film. The color material dispersion liquid for color filters includes (A) a color material, (B) a dispersant and (C) a solvent. The color material (A) contains (A-1) a color material represented by the following general formula (I) and (A-2) a metal lake color material of a rhodamine-based acid dye:

Owner:DAI NIPPON PRINTING CO LTD

Color compositions and methods of using the same

InactiveUS20050287091A1Efficient use ofCosmetic preparationsHair cosmeticsReady to useComputer vision

A color composition and a method of using this color composition. The color composition may be used to color various portions of the body, such as hair, lips, face, and the like. The color composition results in a semi-solid material that may by applied using pressure. As such, the color composition may be easily applied. Various embodiments of the color composition result in differing colors and metallic colors. The color compositions may be used such that the same color results even though the color of the underlying substrate is substantially different.

Owner:SPECTRUM ASSOC LLC +2

Material for decorative parts

A lightweight material for decorative parts having a silver metallic color tone is provided. The material includes a sintered body including a main hard phase composed of a solid solution formed of titanium carbonitride and titanium carbide; a main binder phase composed of nickel; a first additive material composed of at least one selected from the group consisting of molybdenum carbide, niobium carbide, tungsten carbide, and tantalum carbide; a second additive material composed of at least one of chromium and chromium carbide; and the balance being incidental impurities. The N content in the sintered body is 2.0% to 6.0% by mass. The color tone of the sintered body satisfies L*=9 to 14, a*=−2 to 3, and b*=−6 to 0, which are values of the L*a*b* color system measured with a spectrophotometric colorimeter.

Owner:SUMITOMO ELECTRIC HARDMETAL CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com