Metallic fog-brightening water based treatment agent and preparation method thereof

A technology for metallic texture and mist washing and brightening, applied in the field of surface treatment of artificial leather and synthetic leather, can solve the problems such as the inability to fully meet the needs of consumers, the metal texture mist washing and brightening treatment agent has not been reported, and the hidden dangers of human health, etc. The effect of high thermal adhesion, delicate and soft hand feeling, and strong leather feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

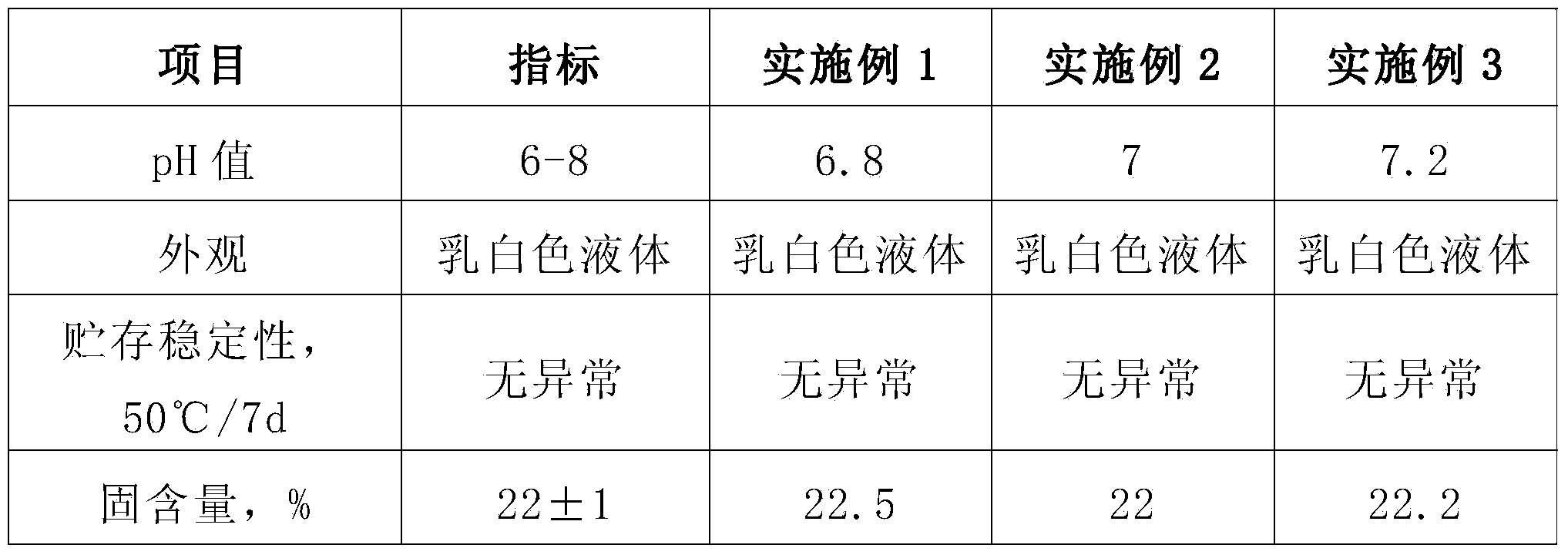

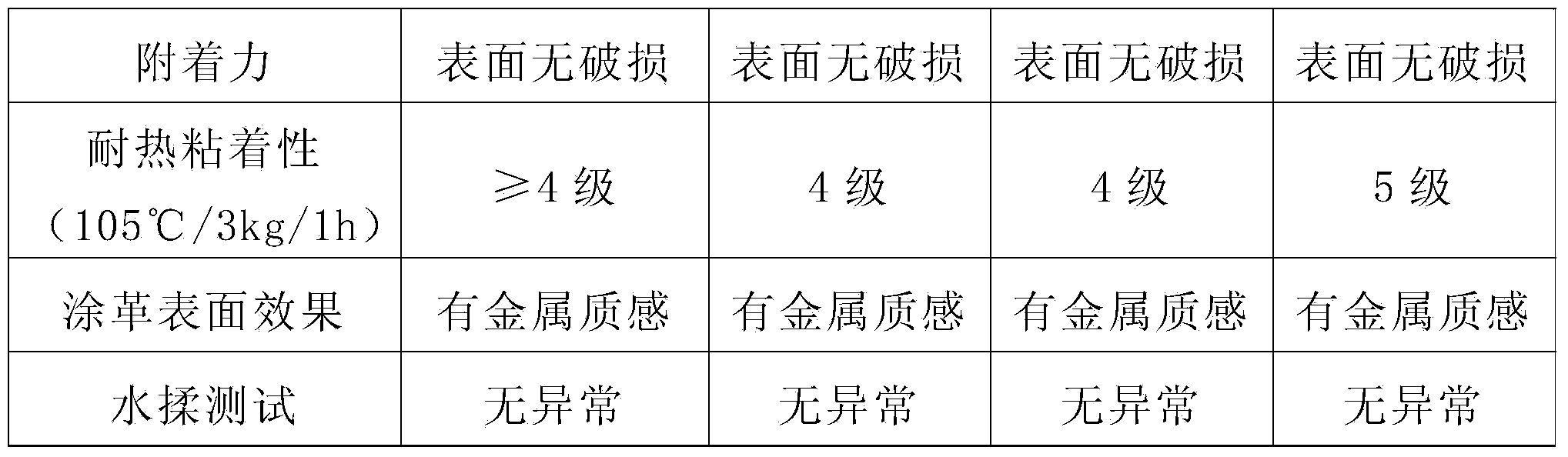

[0020] Example 1. Put 45kg of water-based polyurethane resin KT723 (produced by Hefei Ketian Chemical Co., Ltd.) in a stainless steel container with a volume of 200L on the disperser, then add 0.2kg of water-based wetting and dispersing agent BYK192 and 1kg of water-based defoamer BYK025, Mix and stir at 800 rpm; then add 7kg of silica matting powder FK-100 and 2kg of PTFE wax powder 0103, stir for 20 minutes at 1500 rpm, and then add 0.2kg The wetting and leveling agent TEG O270, 7kg of ethylene glycol butyl ether and 36kg of ordinary tap water are stirred evenly at 1000 rpm and then filtered with a 200-mesh filter cloth; finally, the filtered mixture is put into a clean In a 200L container, add 1kg of water-based associative thickener RM2020 while stirring, and the viscosity of the system reaches 1200cps. After stirring evenly, you can get a water-based treatment agent for metal texture mist washing. The test results of its technical performance are shown in Table 1.

Embodiment 2

[0021] Example 2. Put 45kg of water-based polyurethane resin KT723 (produced by Hefei Ketian Chemical Co., Ltd.) in a stainless steel container with a volume of 200L on the disperser, then add 0.2kg of water-based wetting and dispersing agent BYK192 and 1kg of water-based defoamer BYK025, Mix and stir at 900 rpm; then add 5kg of silica matting powder FM-14 and 4kg of PTFE wax powder 0103, stir for 20 minutes at 1800 rpm, and then add 0.2kg The wetting and leveling agent TEGO270, 8kg of ethylene glycol butyl ether and 35kg of ordinary tap water are stirred evenly at 900 rpm and then filtered with a 200-mesh filter cloth; finally, the filtered mixture is put into a clean 200L In the container, add 1kg of water-based associative thickener RM2020 while stirring, and the viscosity of the system reaches 1000cps. After stirring evenly, you can get a water-based treatment agent for metal texture mist washing. The test results of its technical performance are shown in Table 1.

Embodiment 3

[0022] Example 3. Put 44kg of water-based polyurethane resin KT723 (produced by Hefei Ketian Chemical Co., Ltd.) in a stainless steel container with a volume of 200L on the disperser, then add 0.2kg of water-based wetting and dispersing agent BYK192 and 1kg of water-based defoamer BYK025, Mix and stir at 1000 rpm; then add 6kg of silica water-based matting powder FM-14 and 3kg of PTFE wax powder 0103, stir for 20 minutes at 1500 rpm, and then add 0.2kg of wetting and leveling agent TEGO270, 8kg of ethylene glycol butyl ether and 36kg of ordinary tap water are stirred evenly at 900 rpm and then filtered with a 200-mesh filter cloth; finally, the filtered mixture is put into a clean Add 2kg of water-based associative thickener RM2020 to a 200L container while stirring, and the viscosity of the system will reach 1100cps. The test results of its technical performance are shown in Table 1.

[0023] Table 1

[0024]

[0025]

[0026] The metal texture mist washing and brigh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com