Glaze for metal product surface and firing method thereof

A technology for metal products and glazes, which is applied to the firing process of the glaze layer on the surface of metal products, can solve the problems of color glaze fading and peeling, lack of transparency of the enamel, and inability to reflect the texture of precious metals, and achieves good gloss and enhances appreciation. The effect of stability and high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

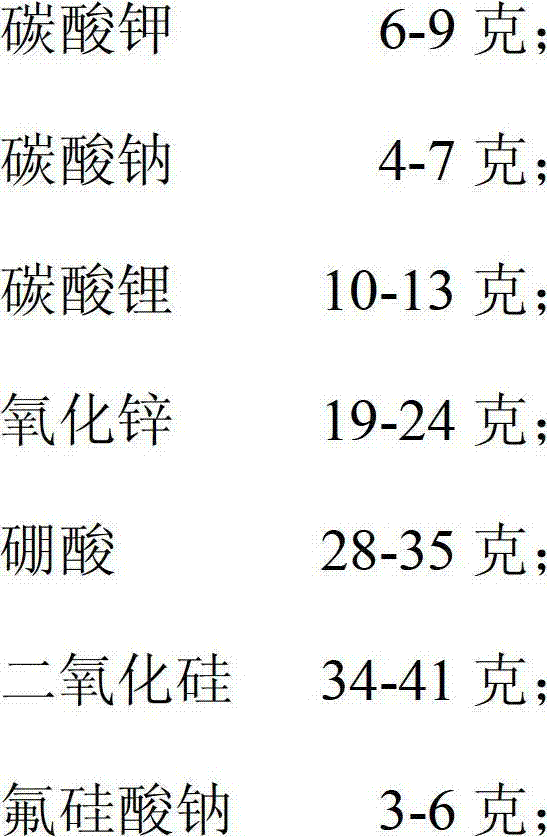

[0036] Embodiment 1-5: Taking gold products as green bodies

[0037] The method of firing the glaze on the surface of gold products is as follows: 1) Weigh the raw materials according to the ratio in Table 1; 2) Mix and stir the raw materials evenly and then heat to make a frit; then add water and grind it finely to become Glaze slurry; 3) Apply glaze slurry to the precious metal body by traditional glazing method, dry it and put it in a high-temperature furnace for firing; the furnace temperature is evenly heated from room temperature for 3-5 hours to 800-900 degrees Celsius. Glazes are obtained on the surface of gold objects.

[0038] Table 1: Components and contents of Examples 1-5 (unit: gram)

[0039]

Embodiment 6-10

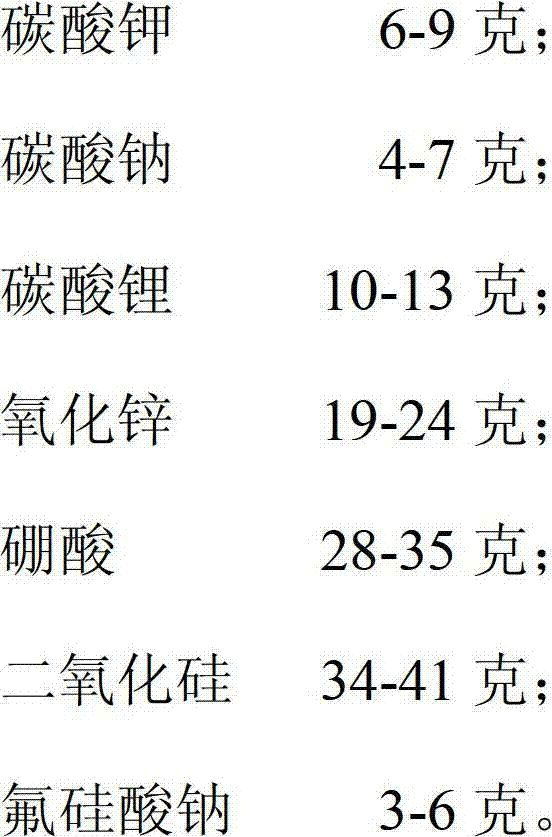

[0040] Embodiment 6-10: Taking silver as the green body

[0041] The method of firing the glaze on the surface of silver products is as follows: 1) Weigh each raw material according to the ratio in Table 2; 2) Mix and stir the raw materials evenly and then heat to make a frit; then add water and grind it finely to form a frit Glaze slurry; 3) Use the traditional glazing method to apply glaze slurry to the precious metal body, dry it and put it in a high-temperature furnace for firing; the furnace temperature is evenly heated from room temperature for 3-5 hours to 700-800 degrees Celsius. Glaze is obtained on the surface of silver products.

[0042] Table 2: Components and proportions of Examples 6-10 (unit: gram)

[0043]

[0044] potassium carbonate

Embodiment 11-15

[0045] Embodiment 11-15: Taking pure copper as the green body

[0046] The method of firing the glaze on the surface of pure copper products is as follows: 1) weigh the raw materials according to the ratio in Table 3; 2) mix and stir the raw materials evenly and then heat to make a frit; then add water and grind it finely, Become a glaze slurry; 3) Use the traditional glazing method to apply glaze slurry to the precious metal body, dry it and put it in a high-temperature furnace for firing; the furnace temperature is evenly heated from room temperature for 3-5 hours to 900-1000 degrees Celsius . Glaze is obtained on the surface of pure copper products.

[0047]

Example 1

Example 2

Example 3

Example 4

Example 5

potassium carbonate

6

6

9

8

7

Sodium carbonate

4

4

7

6

5

lithium carbonate

13

13

10

11

12

19

24

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com