Patents

Literature

149results about How to "Does not affect physical properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Aqueous flame-retardant and thermal-insulated coating and preparation method thereof

InactiveCN101671523AGood weather resistanceSimple preparation processCoatingsThermal insulationEmulsion

The invention discloses an aqueous flame-retardant and thermal-insulated coating and a preparation method thereof, relates to a building coating, and provides a building thermal-insulated coating integrating flame-retardant property, thermal-insulated property and decorative function. The coating consists of emulsion, a fire retardant, titanium, hollow glass beads, water and assistants, with the respective mass parts being 35-40, 20-30, 15-20, 5-10, 19-21 and 11-15. The coating uses fire retardants of inorganic type, phosphorus type and nitrogen type and utilizes synergistic action among different fire retardants to achieve the retardant effect with less amount and without influencing the physical properties of the coating layer; better thermal-insulated effect can be achieved when the thickness of the coating layer is about 1mm through obtaining thermal insulation property by reducing thermal conductivity, thermoconvection and thermal radiation through the glass beads; and the thermal-insulation and flame-retardant properties of the coating are reflected by that the heat conduction coefficient is not more than 0.090 w / (m.k), and the oxygen index is not less than 28.0 percent.

Owner:XIAMEN UNIV +1

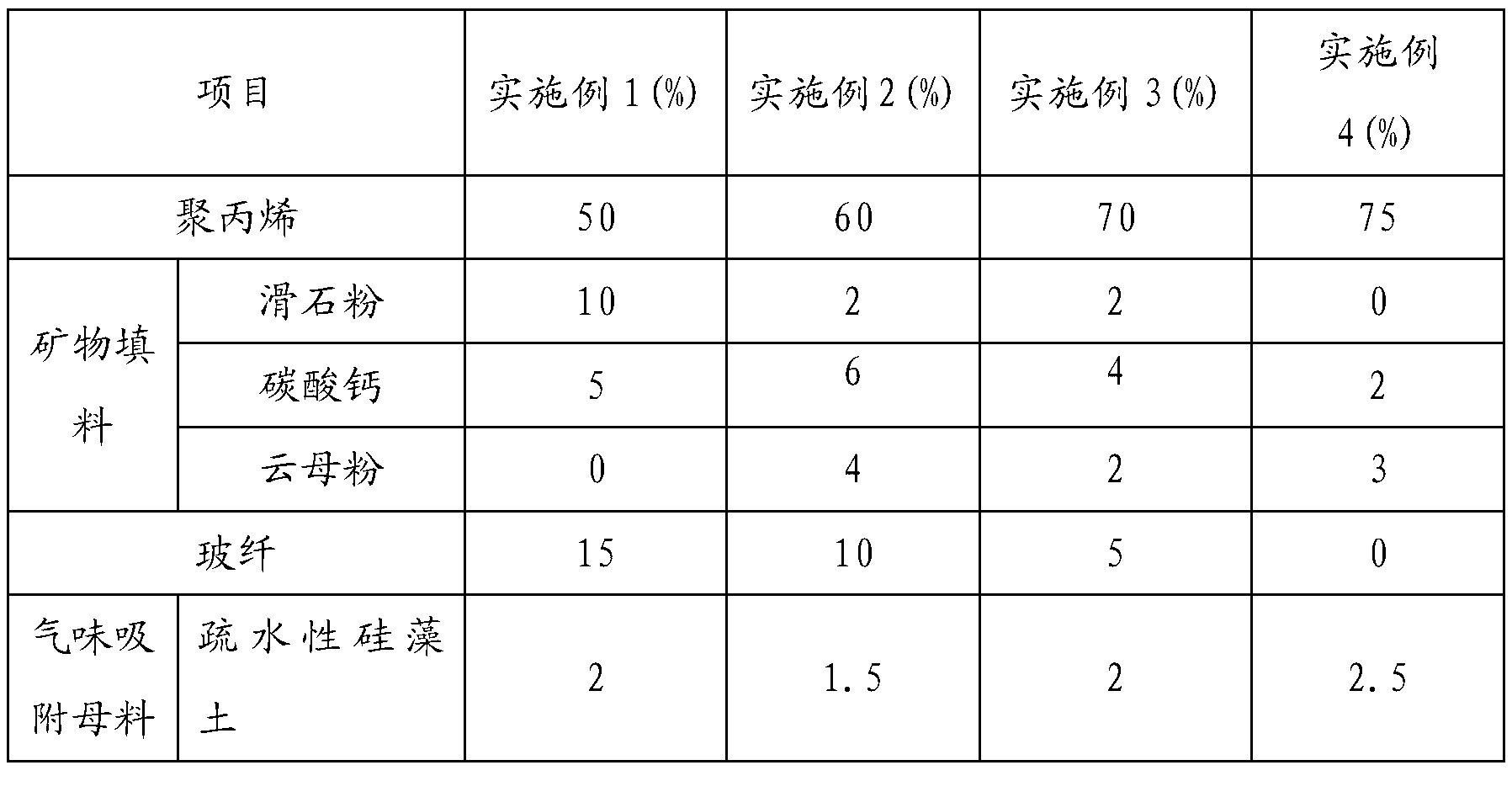

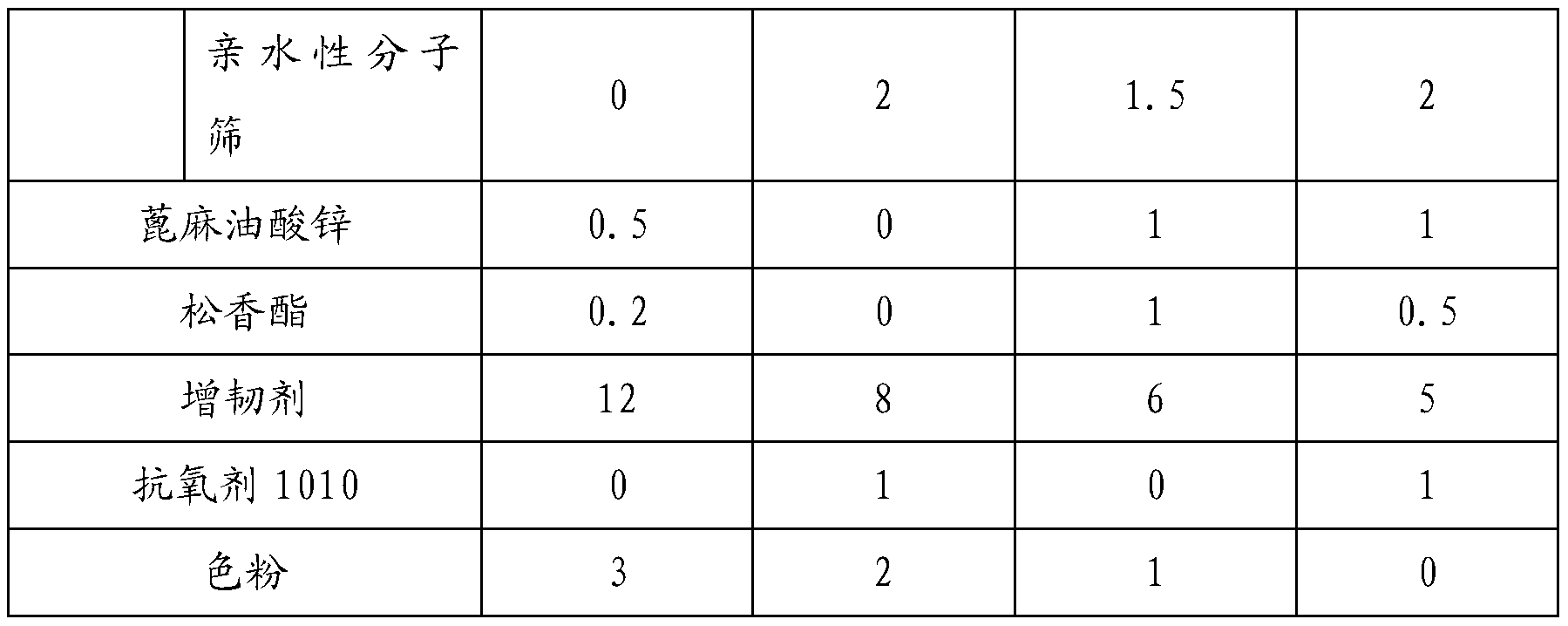

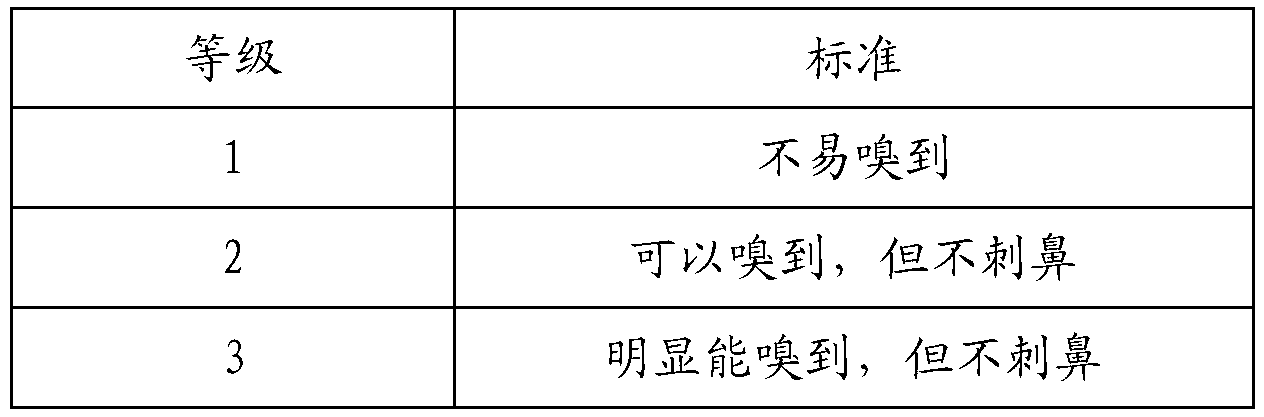

Low-smell vehicle polypropylene composite material and its preparation method

The invention discloses a low-smell vehicle polypropylene composite material and its preparation method and is characterized in that the low-smell vehicle polypropylene composite material comprises the following components: by weight, 50-85% of polypropylene resin, 5-25% of a mineral filler, 0-20% of glass fiber, 0.6-4.5% of a smell absorption masterbatch, 0-1.5% of zinc ricinoleate, 0-2% of abietate, 5-15% of a flexibilizer, 0-1% of an anti-oxidant 1010, 0-5% of a toner, and other auxiliary agents. The polypropylene is one or a combination of co-polypropylene or high-crystallized homo-polypropylene with the crystallization degree being 50%-70%. The mineral filler is one or more of powdered steatile, calcium carbonate or mica powder. The anti-oxidant 1010 is tetra[beta-(3,5-di-t-butyl-4-hydroxyphenyl)propionate]pentaerythritol ester. The composite material provided by the invention has excellent comprehensive properties and has a characteristic of low smell grade.

Owner:SUZHOU SUNWAY POLYMER

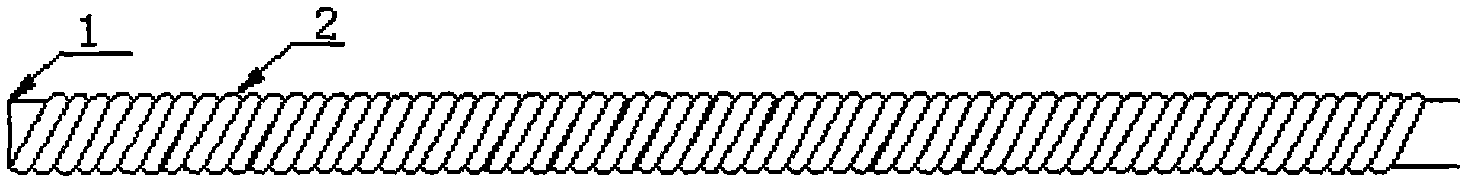

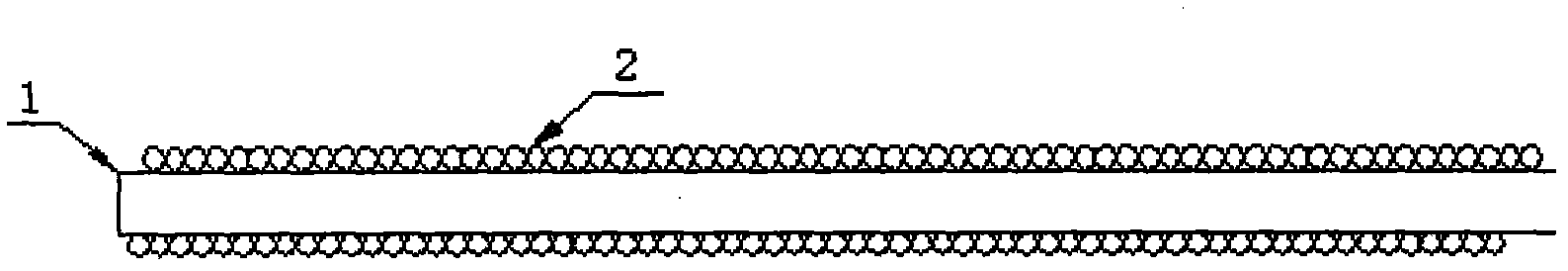

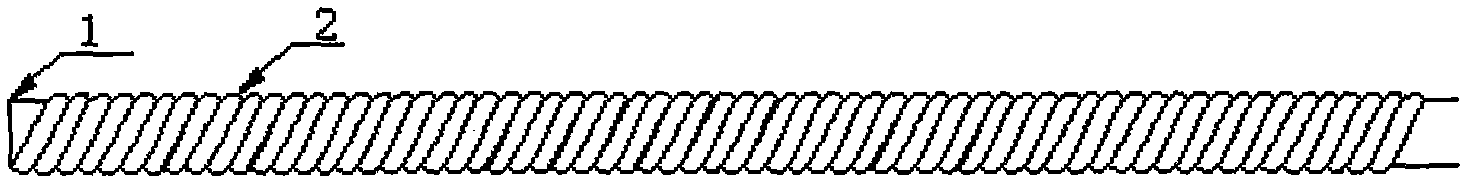

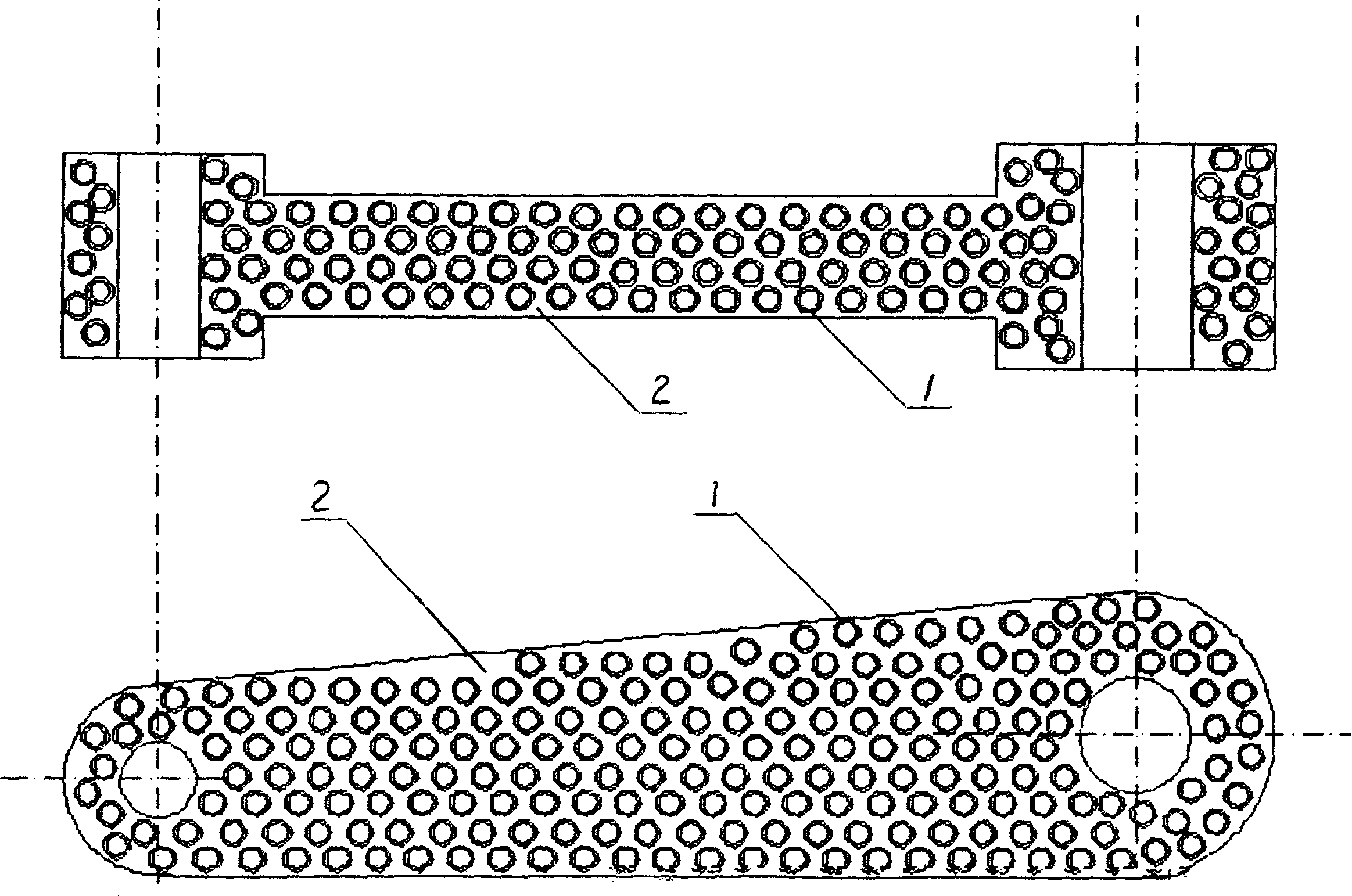

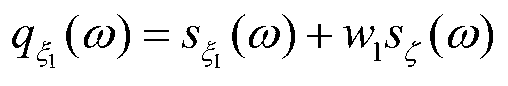

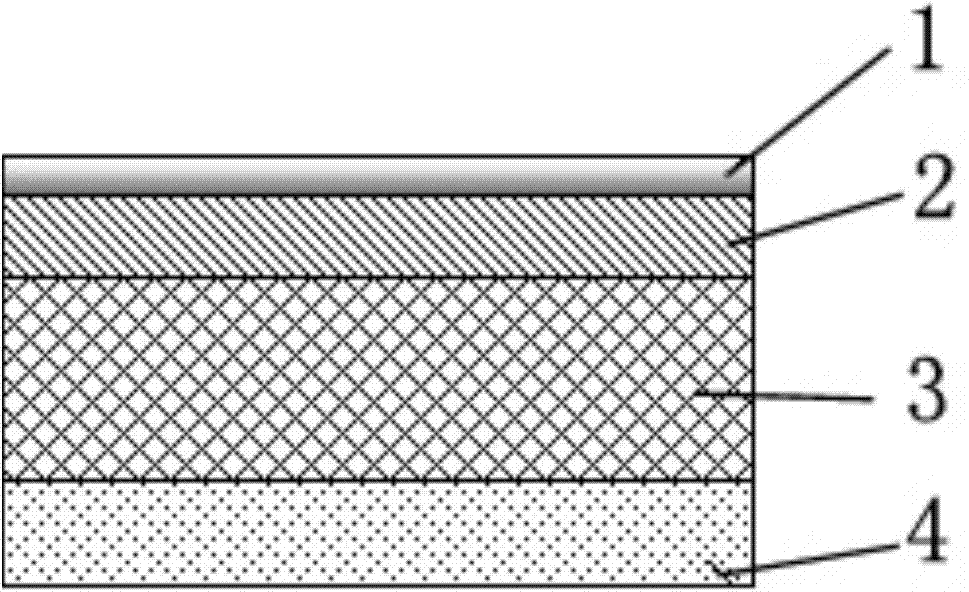

Intravascular stent with improved developing performance and method for improving developing performance of intravascular stent

ActiveCN102429750AImprove the development effectIncrease flexibilityStentsSurgeryStress distributionInsertion stent

The invention provides a method for improving the developing performance of an intravascular stent and an intravascular stent with improved developing performance, and particularly provides an intracranial vessel stent. According to the invention, at least one layer of wire (2) made of a developing material is integrally wound on a stent wave rod (1) of the stent. By adopting the stent, accurate positioning under medical image equipment during and after surgery can be ensured, and the wound developing rod (2) is positioned at an unstressed or hardly-stressed position on the stent without influencing the expansion and stress distribution of the stent, so that the service life of the stent is not shortened, and the expected application effect of the stent is not influenced.

Owner:MICROPORT NEUROTECH SHANGHAI

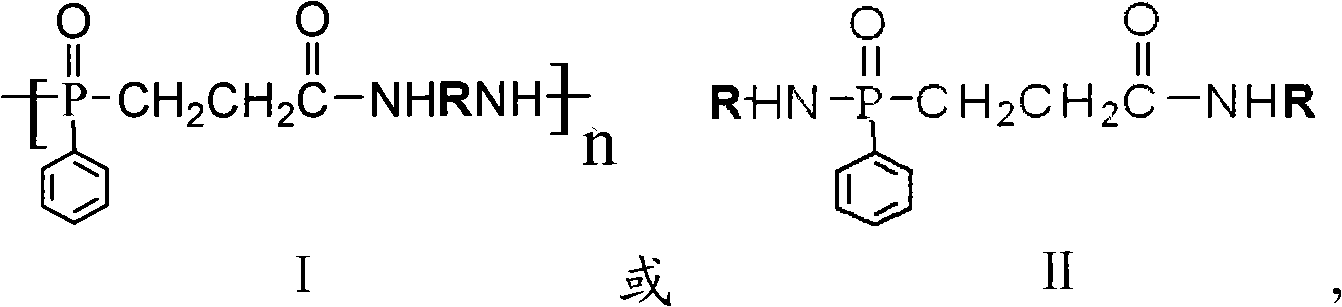

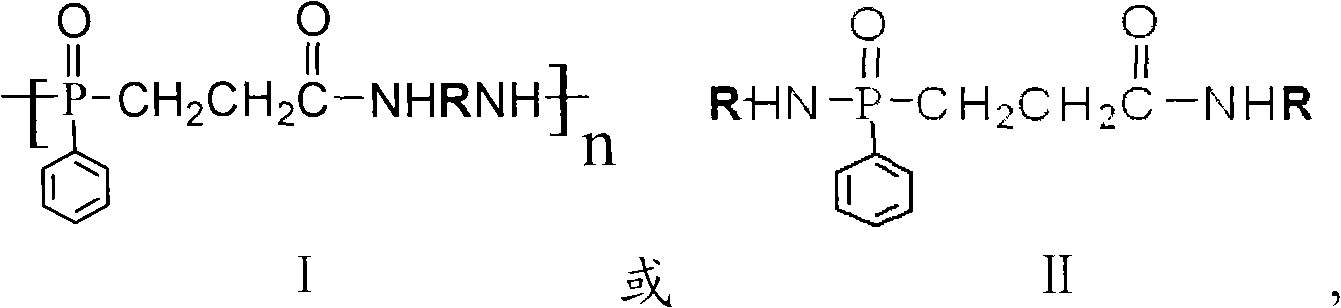

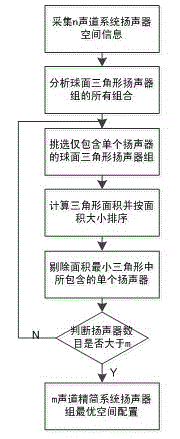

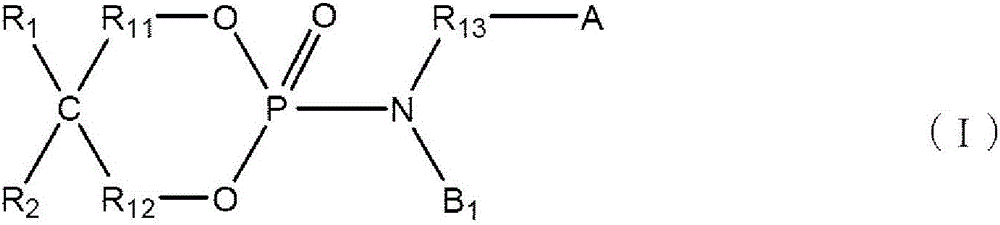

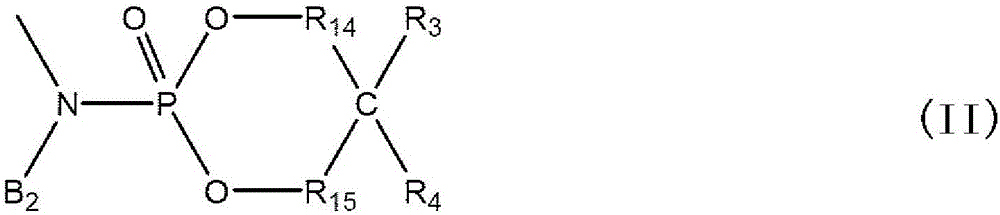

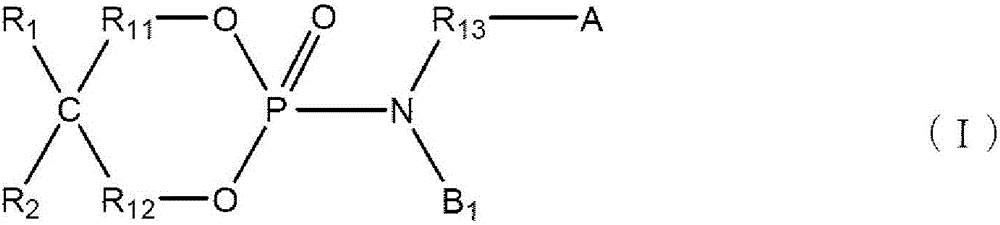

P-N collaborative type flame-retardant compound and preparation method thereof

ActiveCN101665515AStable physical and chemical propertiesImprove flame retardant performanceGroup 5/15 element organic compoundsPhosphinic AcidsPolyamide

The invention relates to a P-N collaborative type flame-retardant compound and a preparation method thereof. The flame-retardant compound comprises a structural unit as the below formula, wherein, n is not less than 1 and R represents aromatic radical or straight-chain or branched-chain hydrocarbyl containing 1-8 C atoms. The method comprises the following steps: leading carboxyl ethyl(phenyl)phosphinic acid and a compound containing active amine to be directly reacted under the heating condition and the nitrogen protection condition or be reacted in an organic solvent, then cooling a reaction system, carrying out purification treatment, drying and then forming a target product. The compound has the advantages of stable physical and chemical performances, high flame-retardant performance, safety, environmental protection, good compatibility with polymer base materials, diverse technologies, and simple and easy preparation, thereby being applicable to manufactures with various scales for production. The compound can be widely used in polyesters and polyamides, as well as epoxy resin, glass fiber reinforced resin, paints (water-soluble and oil-soluble) and the like.

Owner:河南森远科技有限公司

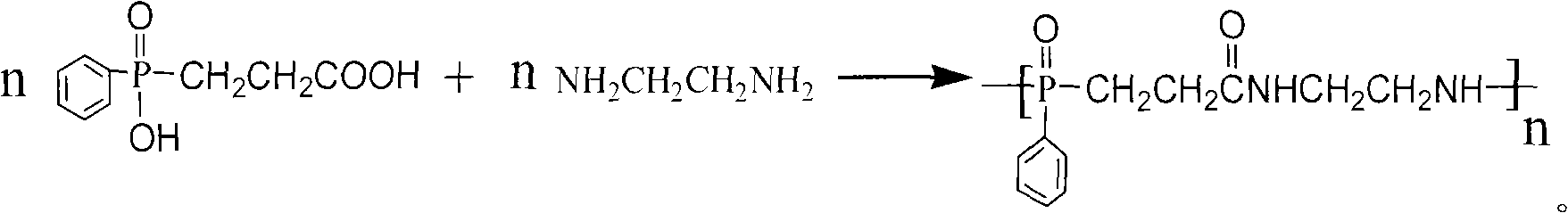

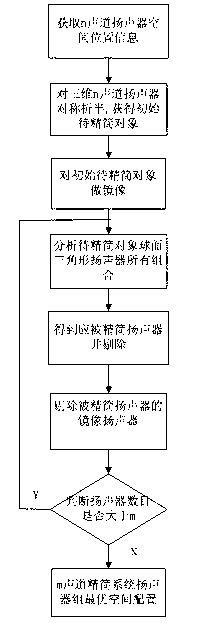

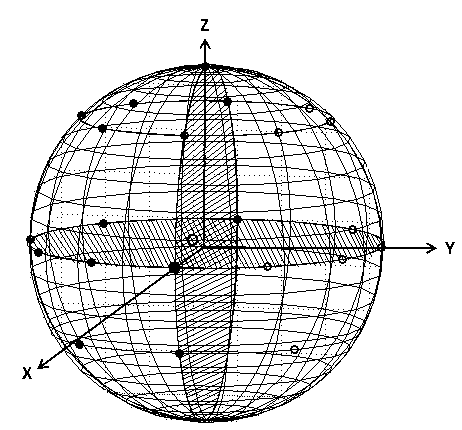

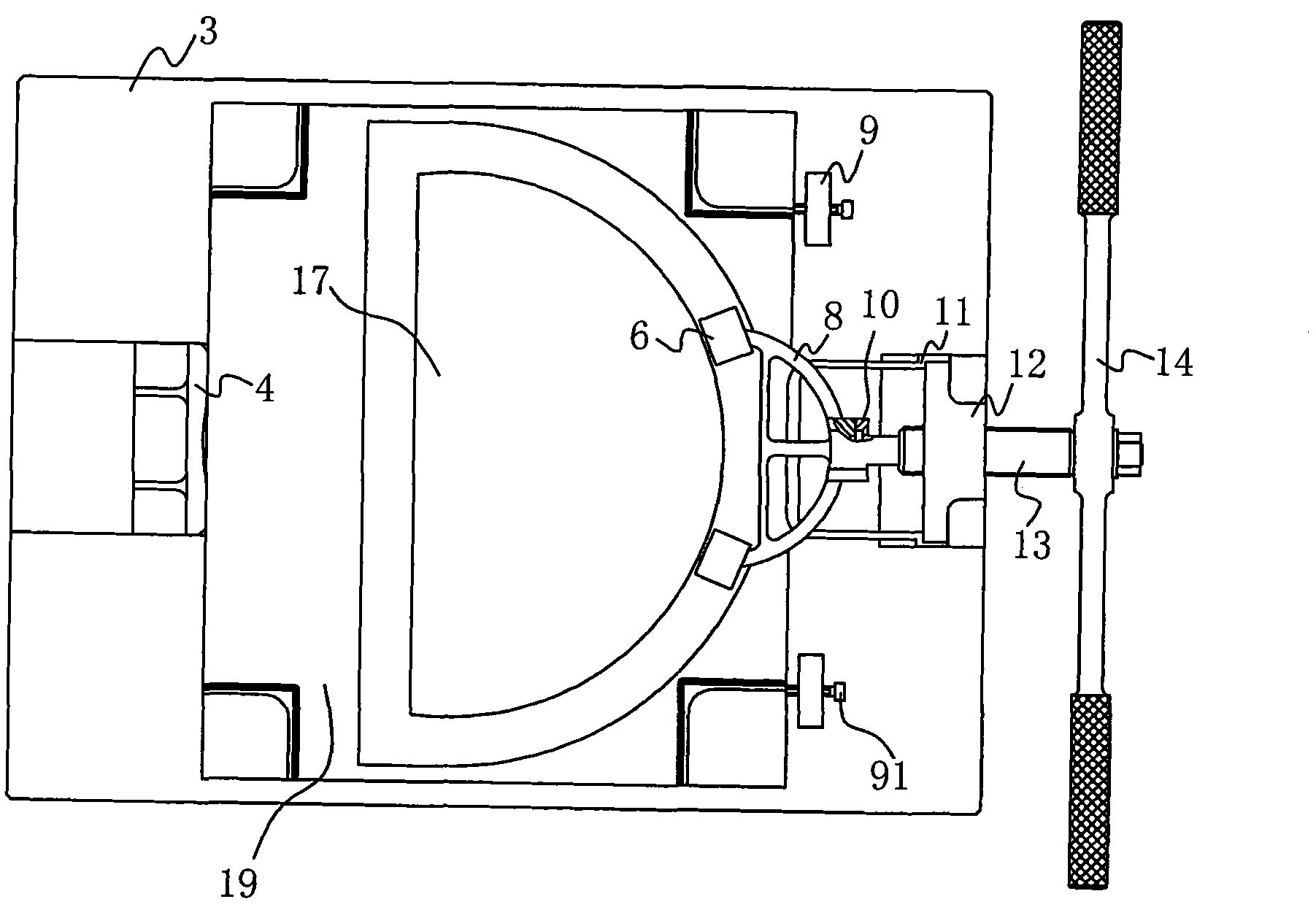

Simplifying and laying method for loudspeaker groups of three-dimensional multi-channel audio system

ActiveCN102883246ADoes not affect physical propertiesLoudspeaker spatial/constructional arrangementsEngineeringLoudspeaker

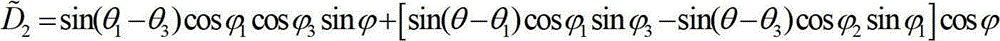

A simplifying and laying method for loudspeaker groups of a three-dimensional multi-channel audio system comprises the following steps of: collecting the space position information of all loudspeakers in a three-dimensional n-channel audio system before simplifying; analyzing all the combinations of spherical triangle loudspeaker groups and selecting the spherical triangle loudspeaker groups only comprising a single loudspeaker respectively; removing the single loudspeaker in the loudspeaker group with the minimum spherical triangle area; judging whether the number of the current loudspeakers to be simplified is greater than m; when the number is greater than m, continuously executing the simplifying process; otherwise, stopping iteration until the number is m, so as to obtain the optimum layout of the space positions of the loudspeaker groups of the simplified m-channel system. With the technical scheme provided by the invention, the physical properties of sound at a sound listening center point can be ensured in the simplifying process.

Owner:NANJING BEIDOU INNOVATION & APPL TECH RES INST CO LTD

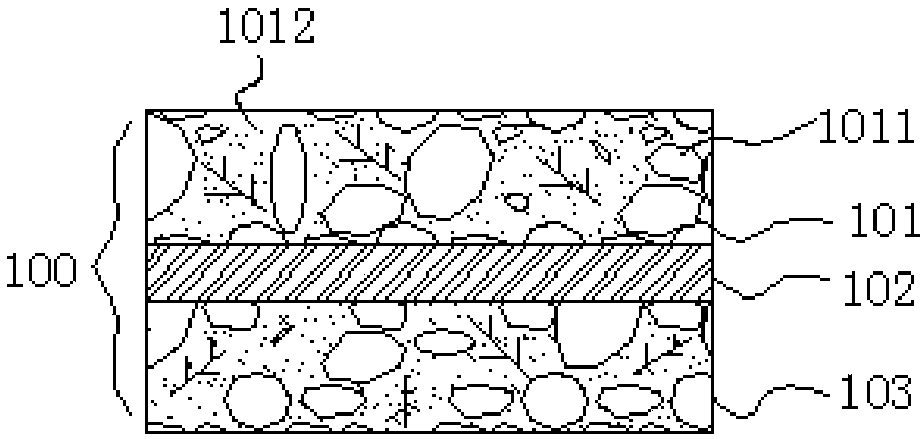

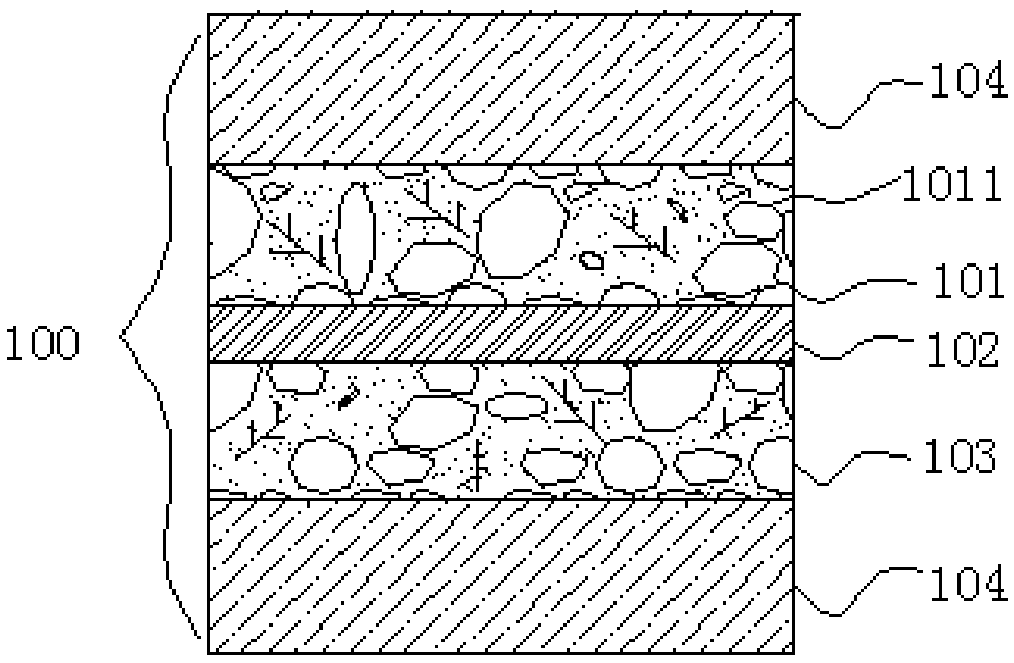

Close-pore foamed metal element with hollow ceramic and method for preparing the same

InactiveCN1843664AUniform microstructureControllable microstructureGearingCylindersMicro structureMetallurgy

The invention relates to a hollow ceramic ball sealed foam metallic element which is produced by uniformly dispersing hollow ceramic balls in fused metallic liquid and molding liquid in mould. Said invention comprises hollow ceramic balls (1) and metallic base (2). First adding preheated hollow ceramic balls into fused metallic liquid; uniformly distributing said balls via mixing decreasing temperature or / and adding thickener; pouring it into mould to be cooled and shaped. The invention has simple process, while the final foam metallic element has controllable micro structure and complex shape. And it can be directly used with few following process.

Owner:HEFEI UNIV OF TECH

Flame retardant and flame retardant polyurethane resin composition

ActiveCN105683337AImprove flame retardant performanceExcellent anti-fog propertiesFireproof paintsPolyurethane elastomerPolyol

Owner:DIAHACHI CHEMICAL INDUSTRY CO LTD

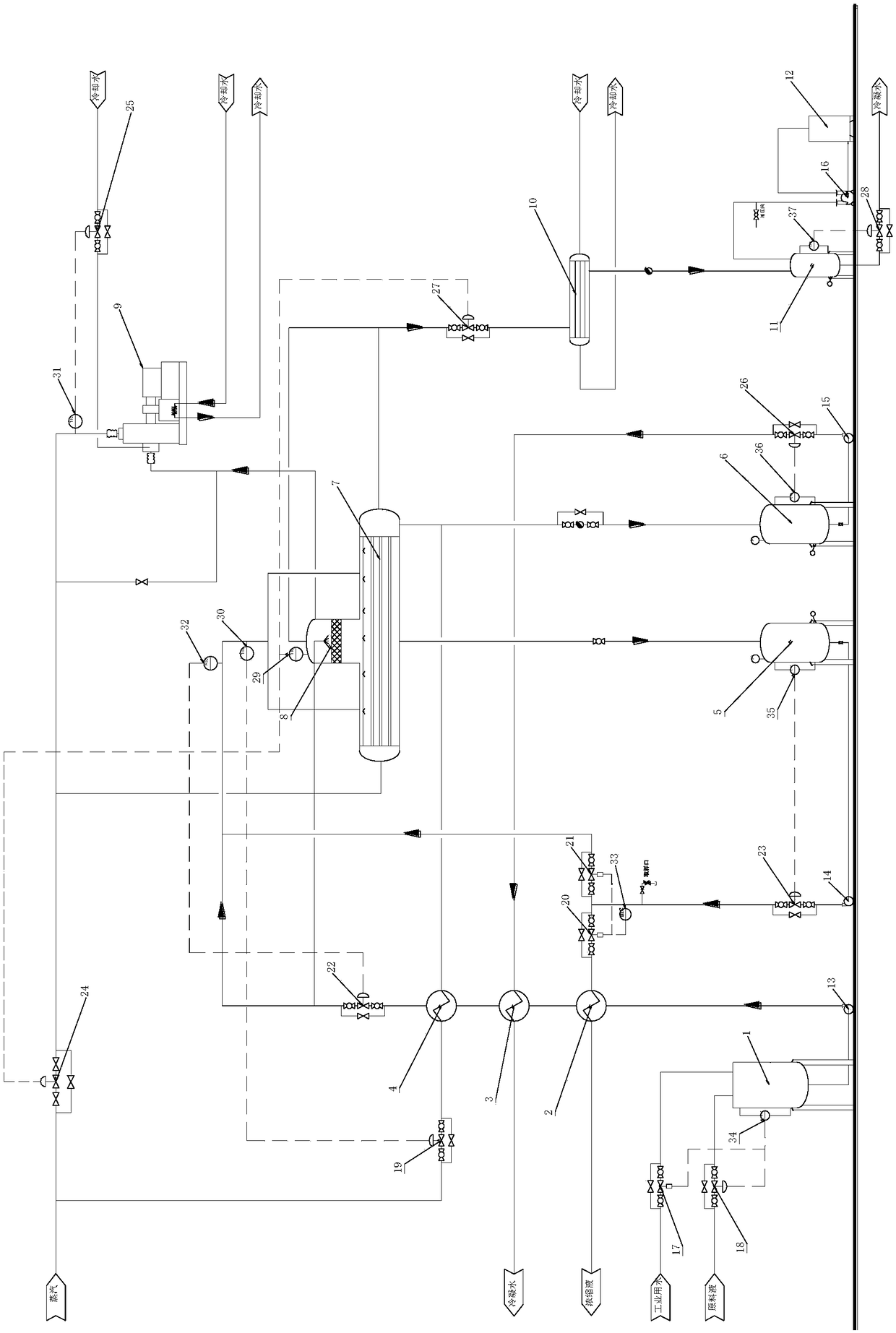

Energy-saving high-efficiency MVR evaporation and concentration system

InactiveCN108159719AExtreme utilizationReduce usageEvaporator accessoriesSteam condensationLiquid storage tank

The invention discloses an energy-saving high-efficiency mechanical vapor recompression (MVR) evaporation and concentration system. Through the system, stable and continuous operation can be realized,and the efficiency of an evaporation process is high. The system comprises a raw material tank, preheating devices, a horizontal tube falling film evaporator, a silk screen defoaming device, a condensate liquid storage tank, a concentrated liquid storage tank, a steam compressor and a vacuum system which are connected through pipelines, valves and related pumps; the bottom of the raw material tank is connected with the inlet of a feeding pump, and is connected with the inlet of the horizontal tube falling film evaporator through the multi-stage preheating devices; the silk screen defoaming device is arranged at the top of the horizontal tube falling film evaporator; the bottom of the horizontal tube falling film evaporator is connected with the concentrated liquid storage tank; the tube pass of the horizontal tube falling film evaporator is connected with the condensate liquid storage tank; steam condensate water is connected with the preheating devices through the condensate liquid storage tank; the vacuum system comprises a water-ring vacuum pump, a vacuum condenser, a vacuum condensation liquid storage tank and a circulating water tank; and the discharge of pressure and non-condensable gas in the tube pass of the horizontal tube falling film evaporator is completed through feedback regulation of a pressure transmitter and a control valve.

Owner:NANJING UNIV OF TECH

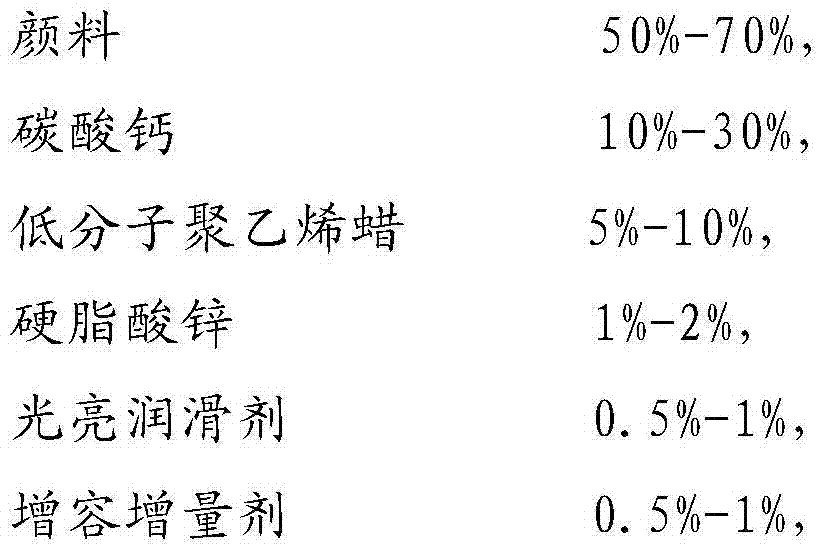

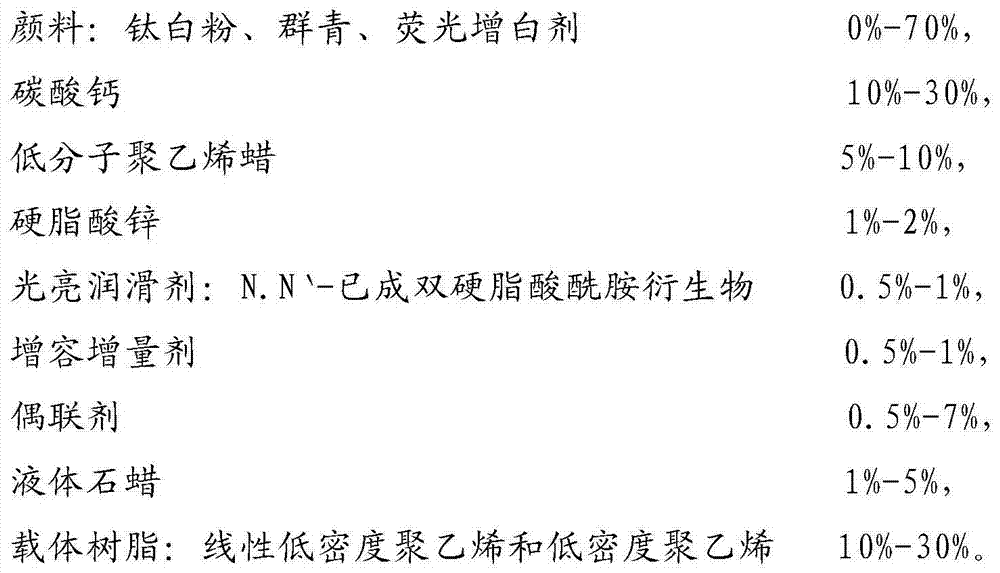

High-concentration polyolefin calcium carbonate filled white master batch and preparation method thereof

The invention discloses a high-concentration polyolefin calcium carbonate filled white master batch which comprises a pigment, calcium carbonate, additives for plastics, and a carrier resin, wherein the additives for plastics comprises low-molecular polyethylene wax, zinc stearate, a brightening and lubricating agent, a compatibilizing and extending agent, a coupling agent and liquid paraffin. The high-concentration polyolefin calcium carbonate filled white master batch comprises the following components in percentage by weight: 50-70% of pigment, 10-30% of calcium carbonate, 5-10% of low-molecular polyethylene wax, 1-2% of zinc stearate, 0.5-1% of brightening and lubricating agent, 0.5-1% of compatibilizing and extending agent, 0.5-7% of coupling agent, 1-5% of liquid paraffin and 10-30% of carrier resin. The filled white master batch has the advantages of small addition amount, high tendency to dispersion, high whiteness, strong covering power, low cost and the like. The invention also discloses a preparation method of the high-concentration polyolefin calcium carbonate filled white master batch.

Owner:SHANGHAI YUCHENG POLYMER MATERIAL CO LTD

Polyurethane waterproof moisture-permeable film and preparation method thereof

ActiveCN111019332AGood compatibilityImprove moisture absorption performancePolymer chemistryInorganic filler

The invention discloses a polyurethane waterproof moisture-permeable film and a preparation method thereof. The polyurethane waterproof moisture-permeable film is prepared from the following raw materials in parts by weight: 25-45 parts of polyurethane resin, 52-75 parts of an organic solvent, 0.5-2 parts of a pore-forming agent and 0.1-1 part of an inorganic filler. The method comprises the following steps: step 1, physical blending: adding a pore-forming agent into a polyurethane resin solution, stirring, adding the inorganic filler, continuously stirring, adding the organic solvent, uniformly stirring, and cooling to obtain a mixed solution; and 2, preparing a film, namely pouring the mixed solution obtained in the step 1 onto a planar medium, scraping a film on the planar medium by using a scraping tool, and drying to form a film, thereby obtaining the polyurethane waterproof moisture-permeable film. According to the invention, the problem of poor performance of a commercially aviable waterproof and moisture permeable film can be solved, the moisture permeability and the water pressure resistance of the polyurethane waterproof moisture-permeable film are effectively improved, the waterproof and moisture permeable performance of the polyurethane waterproof moisture-permeable film can be regulated and controlled, and the breaking strength, the elongation at break and other mechanical strength are excellent.

Owner:ZHEJIANG HUAFON SYNTHETIC RESIN

Volatile organic solvent-free UV spraying finish coat

ActiveCN102031055ANo pollution in the processImprove efficiencyPolyurea/polyurethane coatingsEpoxy resin coatingsPolyesterOrganic solvent

The invention relates to the technical field of coatings, in particular to a volatile organic solvent-free ultraviolet (UV) spraying finish coat. The finish coat comprises 20 to 35 percent of N-vinyl caprolactam, 10 to 20 percent of 1,6-hexamethylene diacrylate, 5 to 12 percent of trimethylolpropane triacrylate, 1 to 3 percent of active amine, 2 to 5 percent of 1173 initiator, 1 to 3 percent of benzophenone, 20 to 30 percent of epoxy acrylic resin, 5 to 12 percent of polyester acrylic resin, 5 to 10 percent of polyurethane acrylic resin, 0.1 to 0.6 percent of acrylic leveling agent and 0.1 to0.5 percent of Tego410 leveling agent. The materials are added at different time and are controlled at different stirring revolutions to prepare the finished product. The finish coat is low in viscosity, suitable for spraying, does not contain a volatile organic solvent at all, and is environmentally-friendly.

Owner:东莞大宝化工制品有限公司

Glass fiber reinforced environment-friendly nylon composite material and preparation method thereof

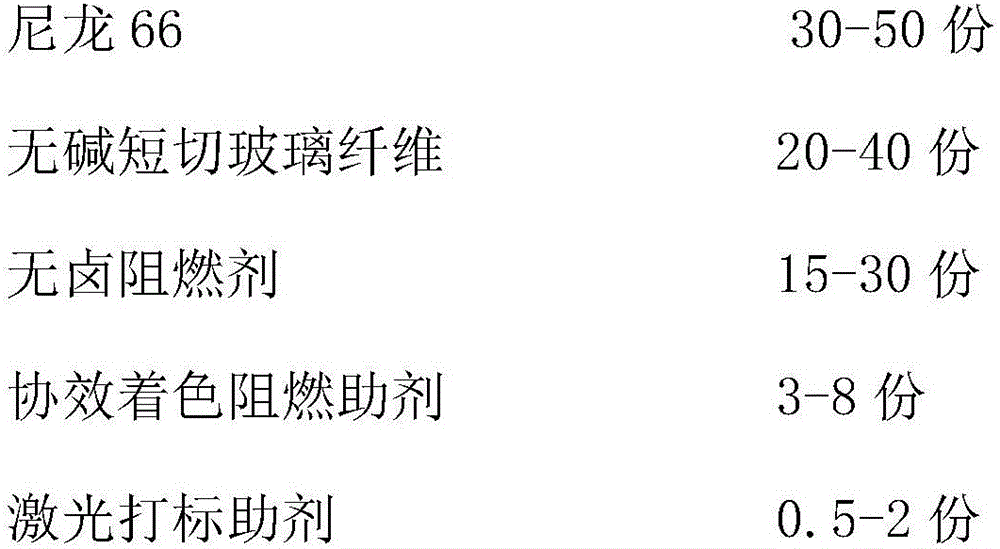

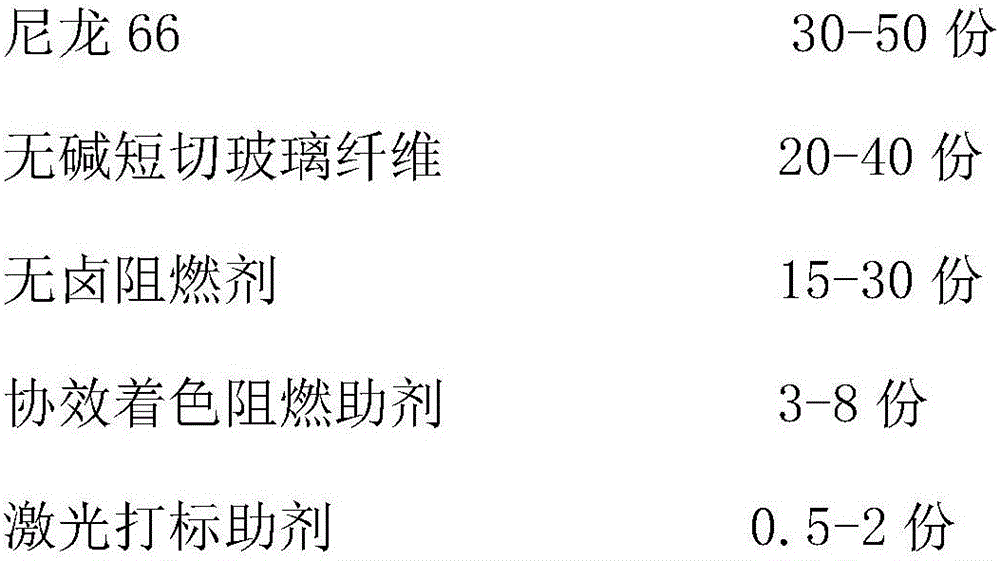

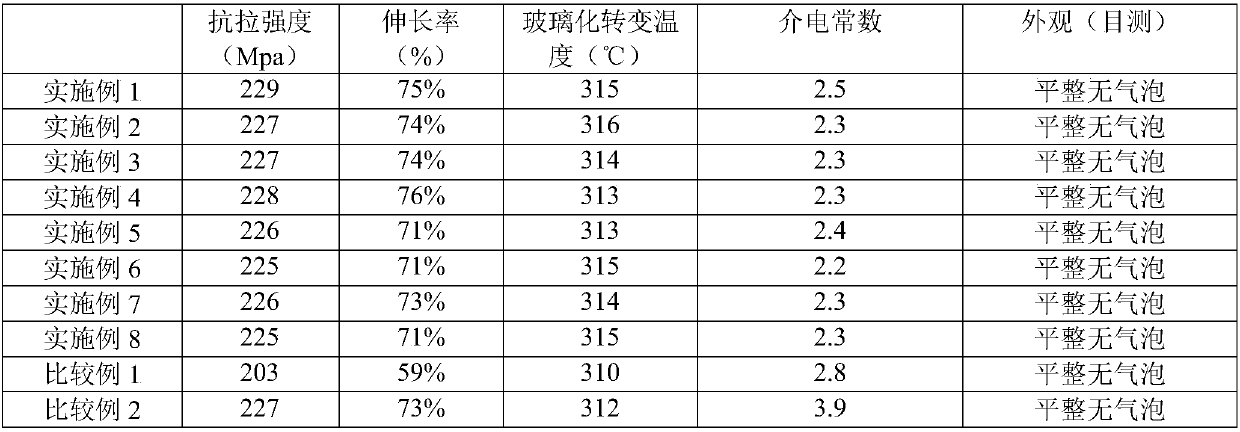

Belonging to the technical field of modified polyamide, the invention relates to a glass fiber reinforced, easy dyeing, laser marking, halogen-free, environment-friendly and flame retardant nylon 66 composite material and a preparation method thereof. The composite material comprises the following raw materials by weight: 30-50 parts of nylon 66, 20-40 parts of alkali-free short glass fiber, 15-30 parts of a halogen-free flame retardant, 3-8 parts of a synergistic coloring flame-retardant additive, 0.5-2 parts of a laser marking additive, and 0.5-1.5 parts of other additives, i.e. a compound of a silane coupling agent, an antioxidant and a dispersant. The composite material is mainly used in bearing covers, electrical junction boxes, row plug-in pieces and the like in automobiles, machinery, electrical and electronic appliances and other industries, and can be applied to components and parts with high requirements for environmental protection and safety, flame retardance, laser marking, intensity and color.

Owner:NANJING JULONG SCI&TECH CO LTD

Flame-retardant silica gel for synthetic leather and preparation method thereof

InactiveCN107254177ADoes not affect physical propertiesImprove flame retardant propertiesHydrogenSilica gel

The invention discloses flame-retardant silica gel for synthetic leather. The flame-retardant silica gel consists of the following raw materials in parts by weight: 100 parts of vinyl polysiloxane, 5-10 parts of white carbon black, 0.15-0.8 part of an inhibitor, 0.3-0.8 part of a platinum catalyst, 5-10 parts of diatomite and 11-12 parts of hydrogen-containing silicone oil. The invention further discloses a preparation method of the flame-retardant silica gel for the synthetic leather. The flame-retardant silica gel for the synthetic leather is completely environment-friendly and can pass REACH detection; a used flame retardant cannot affect the physical properties of products, also has good flame resistance and can automatically extinguish when on fire.

Owner:广东省良展有机硅科技有限公司

High-adhesion low-dielectric polyamide film and preparation method thereof

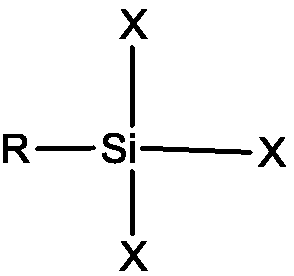

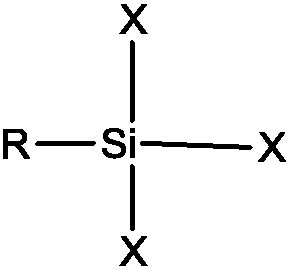

The invention relates to a low-adhesion low-dielectric polyamide film and a preparation method thereof. The low-adhesion low-dielectric polyamide film is characterized by being prepared from, by weight, 1.5-2.5% of fluorinated siloxane grafted modification silicon dioxide pellets, wherein the structural formula of the fluorinated siloxane is shown in the specification, X is any one of Cl or methoxyl, ethyoxyl or alkyl with the carbon number being 1-10; R is fluorine-containing alkyl with the carbon number being 1-20. The obtained polyamide film has the high adhesion strength and low dielectricconstant and is suitable for the field of micro-electronics and aerospace.

Owner:WUXI CHUANGCAI OPTICAL MATERIALS

Vacuum aluminium plating film with high adhesion to aluminium and its production method

InactiveCN101143499ADoes not affect physical propertiesImprove adhesionSynthetic resin layered productsElastomerPolyolefin

The invention discloses a vacuum aluminum film, which has a high adhesion to an aluminum as well as its production method. A corona layer is blended up with an isotactic polypropylene and / or a copolymer polypropylene, and a polyolefin elastomer which can be melted with the polypropylene and an anti-adherent. A middle layer group comprises the isotactic polypropylene. A heat layer group consists of polypropylene or isotactic polypropylene. The invention enhances the adhesion of the aluminum layer through adding polar polymer material into the film corona layer. The testing result of the aluminum layer adhesion of the vacuum aluminum flow extension film provided by the invention is larger than 1.0 Newton, while the testing result of the aluminum layer adhesion of a general vacuum aluminum flow extension film is only 0.6 Newton at most. The invention can be widely used for printing, compositing and packaging areas, and has an excellent barrier property for water vapor and oxygen.

Owner:安徽双津实业有限公司

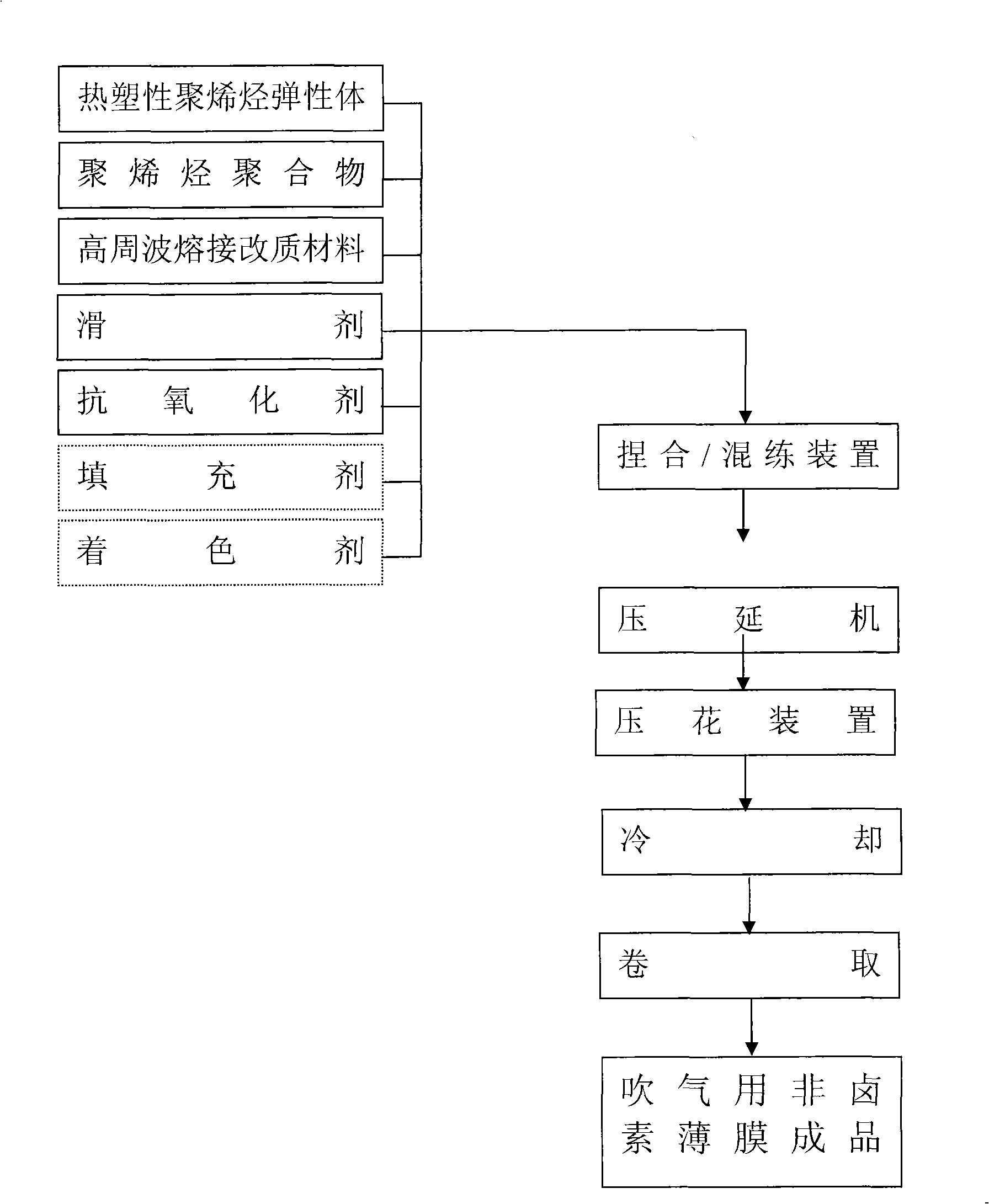

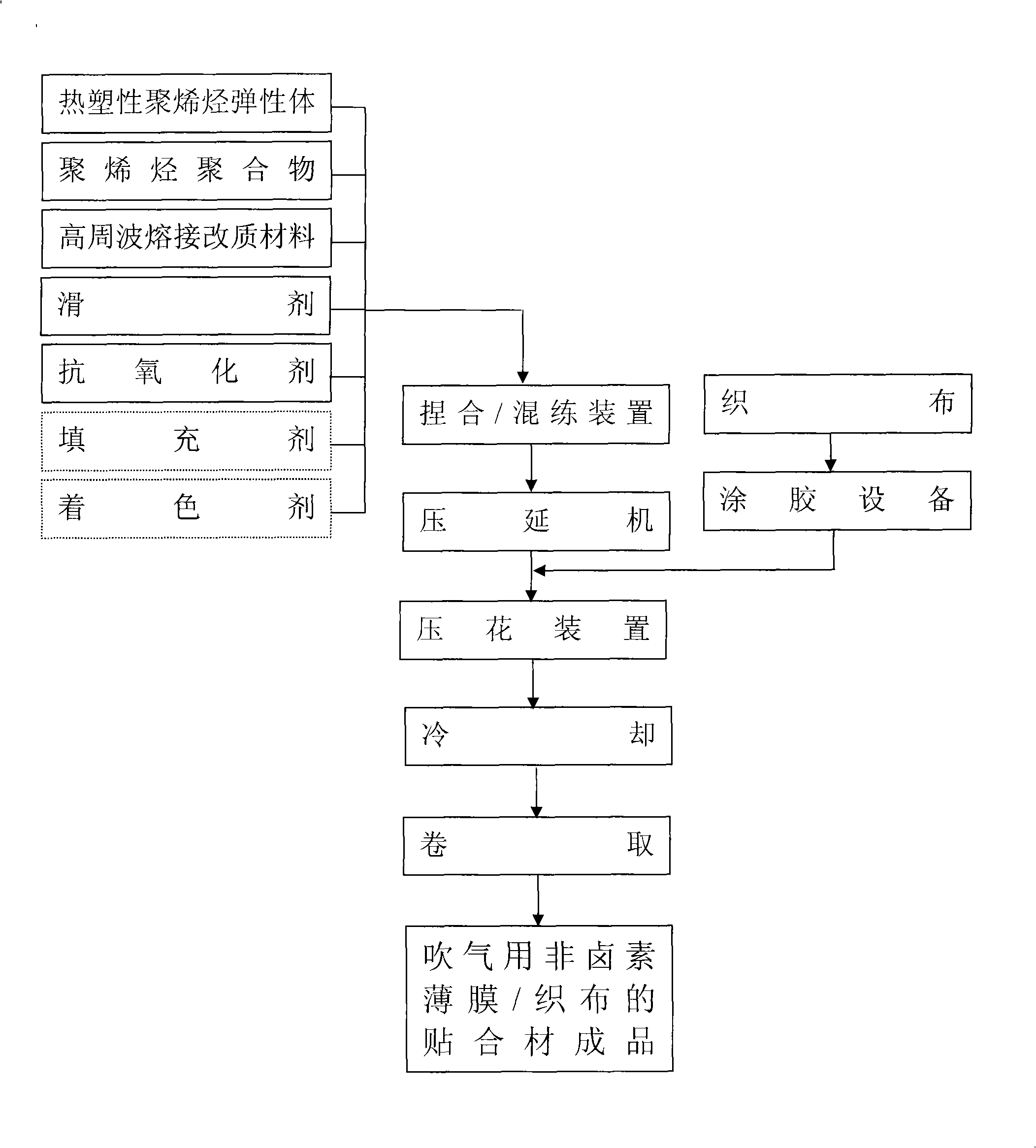

Non-halide thin film for aeration and preparation thereof

The invention provides a non-halogen film for inflation and the preparation thereof. The film is made from 20-80 phr (parts per hundred of resin) of thermoplastic polyolefine elastomer, 80-20 phr of polyolefine polymer, 1-50 phr of high-frequency weld modifier, 0.1-5 phr of lubricant, 0.1-5 phr of antioxidant, 0-50 phr of bulking agents and 0-15 phr of colorant. The preparation of the film is as follows: subjecting a batch mixture to a mixing / mulling device for gelatination, uniformly mixing, making a hot-melting adhesive film by using a calendering machine, cooling and coiling to obtain the no-halogen film for inflation. The film is environment-friendly, free of halogen, recoverable and suitable for high-frequency welding, has similar property to the polyvinyl chloride (PVC) film; and is used to replace the conventional PVC film for inflation.

Owner:CHINA GENERAL PLASTICS

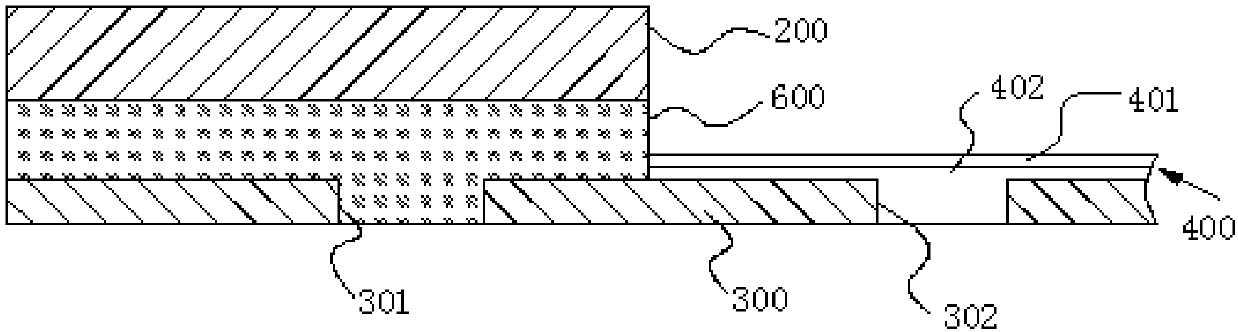

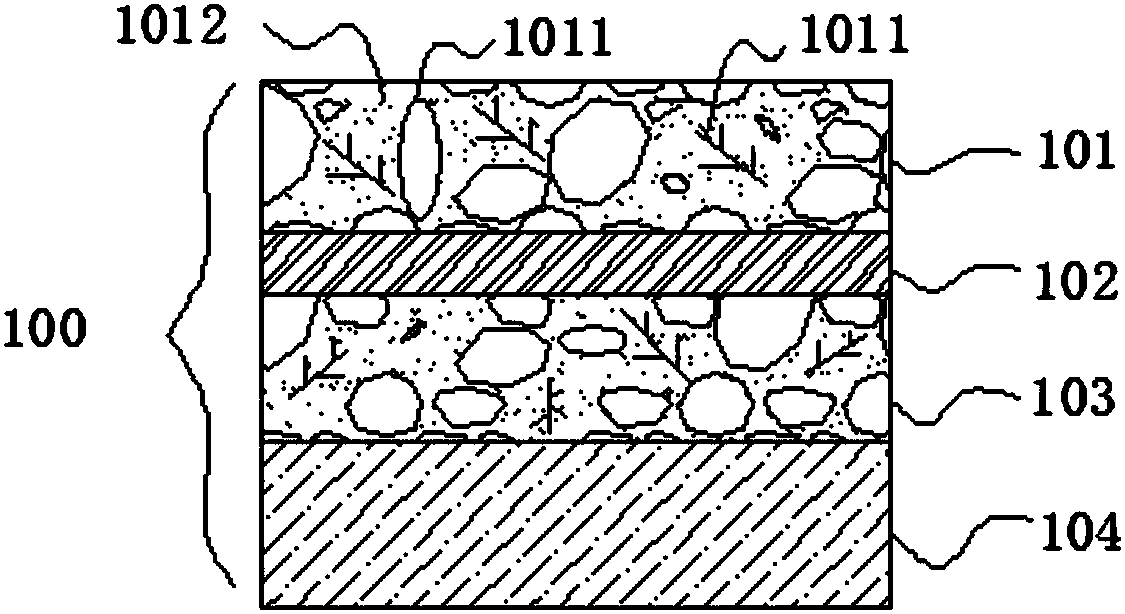

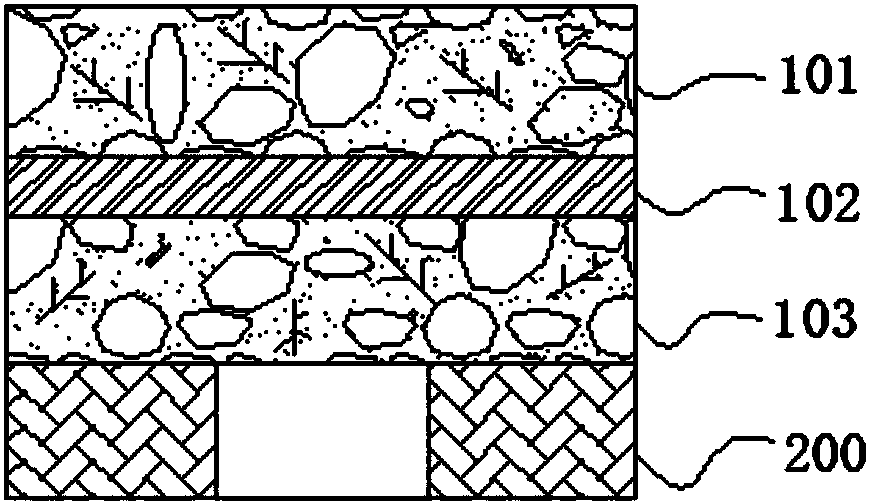

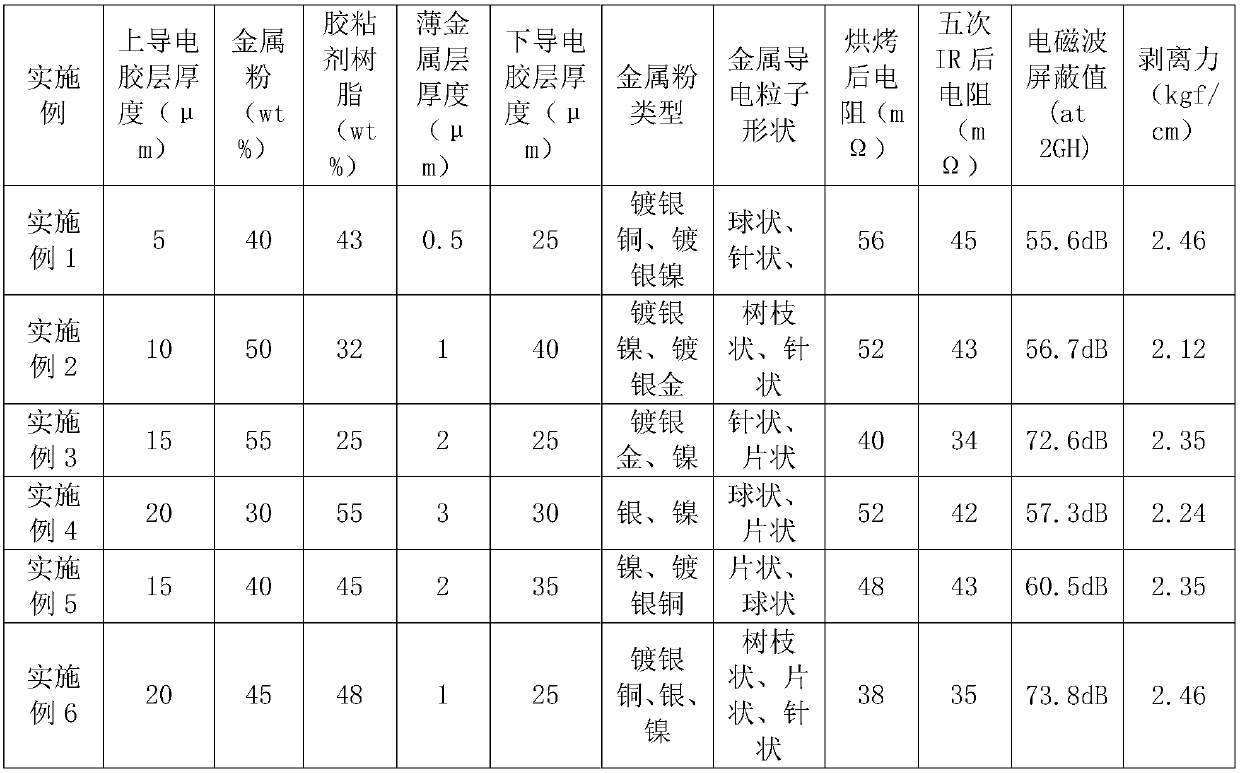

Multilayer anisotropic puncture type conductive fabric adhesive and FPC reinforcing shielding structure using same

PendingCN109890124ARealize the effect of direct connectionAchieve groundingNon-insulated conductorsPrinted circuit detailsAdhesiveElectromagnetic shielding

The invention discloses a multilayer anisotropic puncture type conductive fabric adhesive and an FPC reinforcing shielding structure using the same, wherein the conductive fabric adhesive comprises anupper conductive adhesive layer, a lower conductive adhesive layer and an ultra-thin conductive fabric layer formed between the upper conductive adhesive layer and the lower conductive adhesive layer; the thickness of the upper conductive adhesive layer is 15-25[mu]m, and the thickness of the lower conductive adhesive layer is 35-45[mu]m; the upper and lower conductive adhesive layers comprise metal conductive particles, wherein the metal conductive particles are at least two kinds of a tree branch shape, a chain shape, a needle shape, a slice shape and a sphere shape, and particle sizes of the metal conductive particles are 40-100[mu]m; and the thickness of the ultra-thin conductive fabric layer is 5-15[mu]m. According to the adhesive, the characteristics of an extremely good grounding effect and an electromagnetic shielding effect, high electrical property, excellent bonding strength, excellent tin soldering property, excellent reliability, excellent flame resistance and the like can be achieved by combining with a reinforcing material and an EMI film under the condition that the FPC does not have a reserved grounding hole, and in addition, the production process can be reduced,and the production cost can be lowered.

Owner:KUSN APLUS TEC CORP

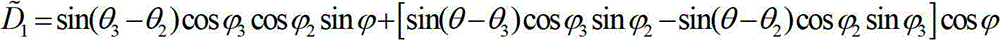

Method for reducing and streamlining three-dimensional multiple sound channel audio system speaker group by half

ActiveCN103220601ADoes not affect physical propertiesImprove efficiencyStereophonic circuit arrangementsVocal tractMirror image

The invention discloses a method for reducing and streamlining a three-dimensional multiple sound channel audio system speaker group by half. Mirror images are arranged to be symmetrical according to original speakers, and n speakers in a three-dimensional n sound channel audio system are streamlined into m speakers in a three-dimensional m sound channel audio system by means of half-reducing method. The method for reducing and streamlining the three-dimensional multiple sound channel audio system speaker group by half comprises the following steps: obtaining spatial location information of each speaker in the three-dimensional n sound channel audio system before half reduction and streamlining; reducing the speakers in the three-dimensional n sound channel audio system by half before the streamlining by means of the symmetrical surface, and obtaining original objects to be streamlined; conducting mirror image allocation on the speakers; analyzing all combinations of a triangular speaker group in objects to be streamlined, and analyzing speakers, obtaining speakers and rejecting speakers which should be streamlined; and rejecting mirror image points of the rejected streamlined speakers, judging whether the sum of the current speakers to be streamlined is larger than m, wherein a simplification process is continuously executed if the sum of the current speakers to be streamlined is larger than an-m, otherwise, iteration is finished, and obtaining optimal spatial location distribution of the m sound channel streamlined system speaker group.

Owner:NANJING BEIDOU INNOVATION & APPL TECH RES INST CO LTD

High temperature and high voltage resistant cable

InactiveCN105427921AImprove high temperature resistanceImprove anti-aging propertiesPower cables with screens/conductive layersInsulated cablesPolyolefinElectrical conductor

The invention belongs to the field of cables, and particularly relates to a high temperature and high voltage resistant cable. The cable comprises a conductor and a sheath layer externally wrapping the conductor, the sheath layer is orderly composed of an insulating layer, a mica belting layer, a low-smoke halogen-free flame retardant polyolefin inner jacket, a woven shielding layer, a low-smoke halogen-free flame retardant polyolefin outer jacket and an outer sheath from inside to outside; material of the insulating layer and material of the outer sheath both are modified fluoroplastic for cables, and the modified fluoroplastic for cables comprises the following constituents in parts by weight: 60-80 parts of polytetrafluoroethylene, 10-20 parts of wear-resistant agent, 5-10 parts of fire retardant, 7-16 parts of plasticizer, 5-9 parts of filler, 1-3 parts of antioxidant, 1-3 parts of paraffin oil, 0.1-0.2 parts of ratproof master batch and 0.1-0.2 parts of temite preventing master batch. The structure above can perform multi-angle protection for the cable, and can effectively reduce influence of high temperature and high voltage generated when conducting the conductor or outside severe environment on service life of the cable.

Owner:GUANGDONG ZHONGDE CABLE

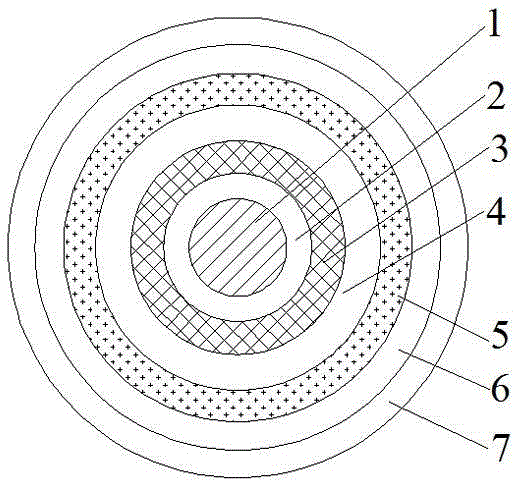

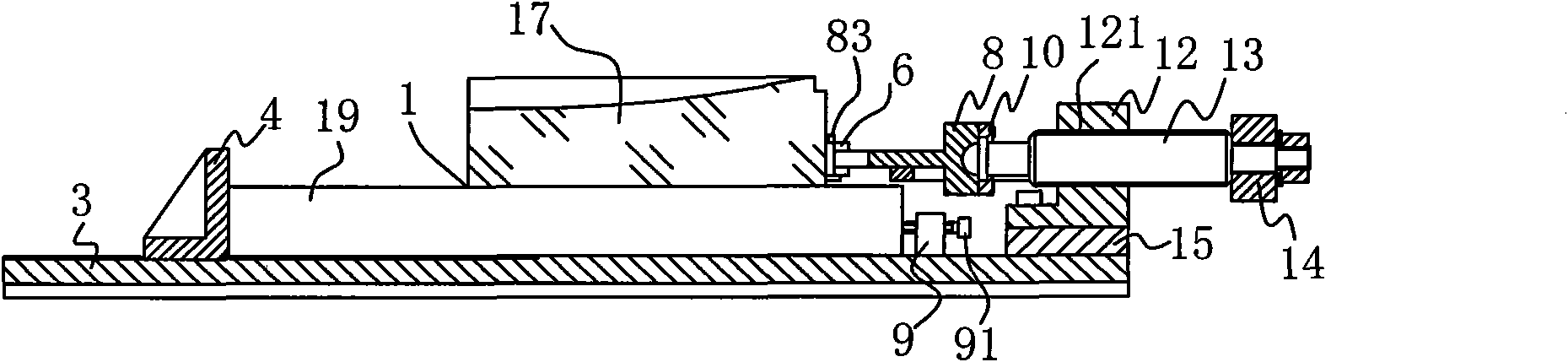

Method and tool for decementing light machine assembly parts

InactiveCN101767323AReduce the risk of stickingEasy to operateMetal-working hand toolsRoom temperatureEngineering

The invention relates to a method and a tool for decementing light machine assembly parts, comprising the following steps: 1) fixing a light machine assembly part 1 to be decemented on a decementing tool; 2) placing the light machine assembly part 1 to be decemented and the decementing tool into a high and low temperature chamber and raising temperature to 60 DEG C to 80 DEG C at constant speed in 30min then keeping the temperature for 30min; 3) opening the door of the high and low temperature chamber, slowly rotating a wrench in the high and low temperature chamber to enable a bucking bar to move leftwards until optical glass breaks away from a framing member; 4) cooling the high and low temperature chamber to room temperature and then taking out optical glass, the framing member and the decementing tool. With the method and tool of the invention, pollution of mirror surface film layer, size distortion and structural damage in the existing technology for decementing the light machine assembly parts are solved. In addition, the method and tool of the invention have the advantages of simple and convenient operation and no influence on physical property of optical elements.

Owner:XIAN MICROMACH TECH CO LTD

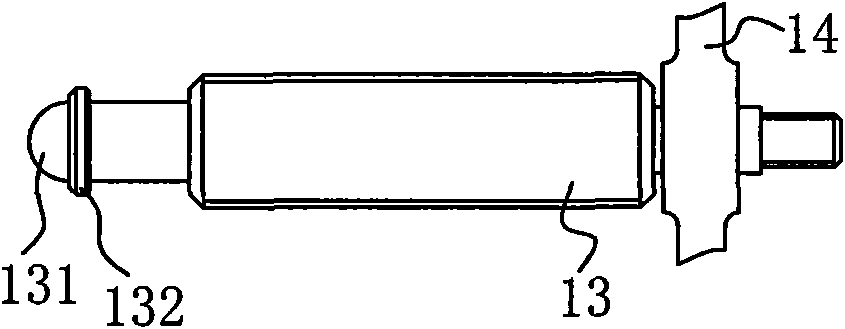

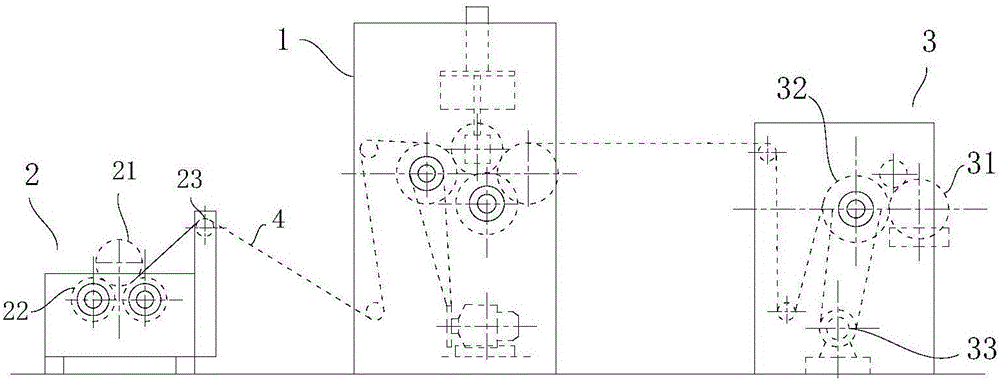

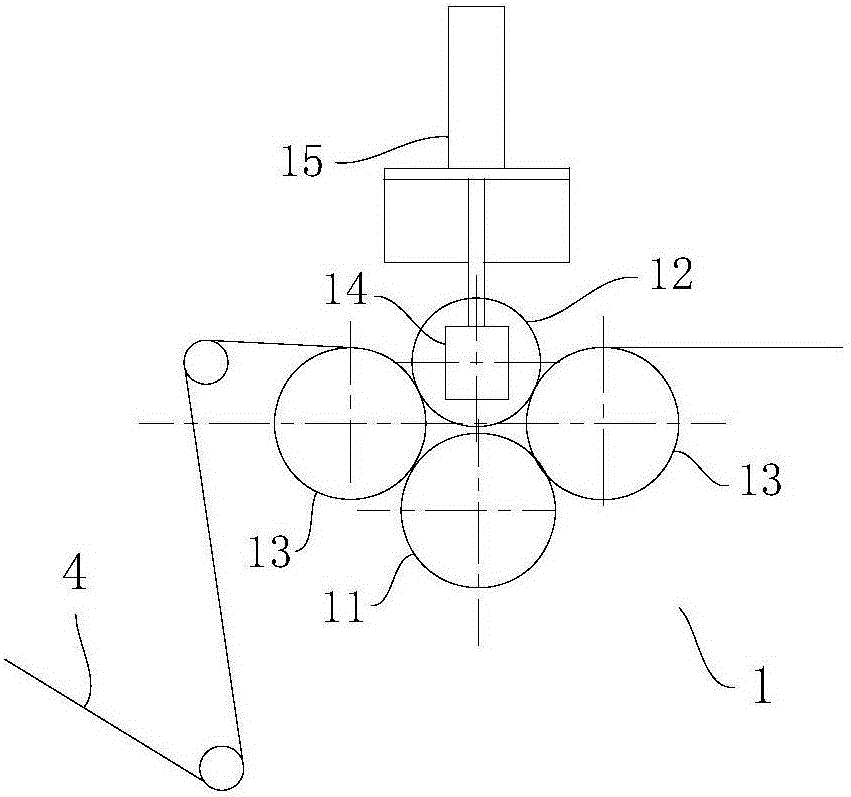

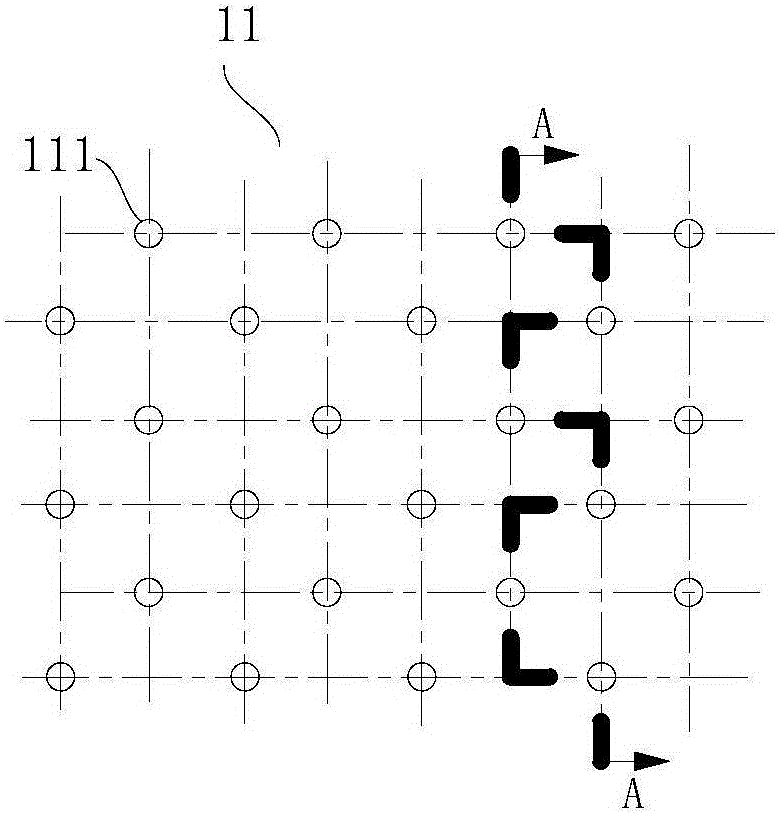

Thermal perforating device for plastic film

InactiveCN106078905AAdjustable widthWide range of perforation thicknessMetal working apparatusTransport systemPlastic film

The invention discloses a thermal perforating device for a plastic film. The thermal perforating device for the plastic film comprises a needle roll, a rubber roll and film supporting rolls, wherein the needle roll is a hollow roll; a plurality of needle components are arranged on the surface of the needle roll in the radial direction; a heating assembly is arranged inside the needle roll; heat is conducted to the needle components; the rubber roll is opposite to the needle roll; and the rubber roll and the film supporting rolls form a plastic film winding and conveying system. An unwinding device and a winding device are respectively arranged in the front and at the rear of the perforating device, the unwinding device is provided with a complete plastic film unwinding roll, a complete plastic film is fed into the perforating device and passes through space between the rubber roll and the needle roll of the perforating device, hot melting perforating is realized by the heated needle components on the needle roll, the winding device is provided with a perforated plastic film winding roll, and the plastic film which is perforated by the perforating device is wound on the winding roll. The thermal perforating device for the plastic film is simple in structure and easy to operate, a perforating density adjustment range is large, the plastic film is perforated by hot melting, penetration rate of holes is high, the film is not pulled during perforating, and therefore, the physical properties of the film are not affected.

Owner:湖南圣华节水科技股份有限公司

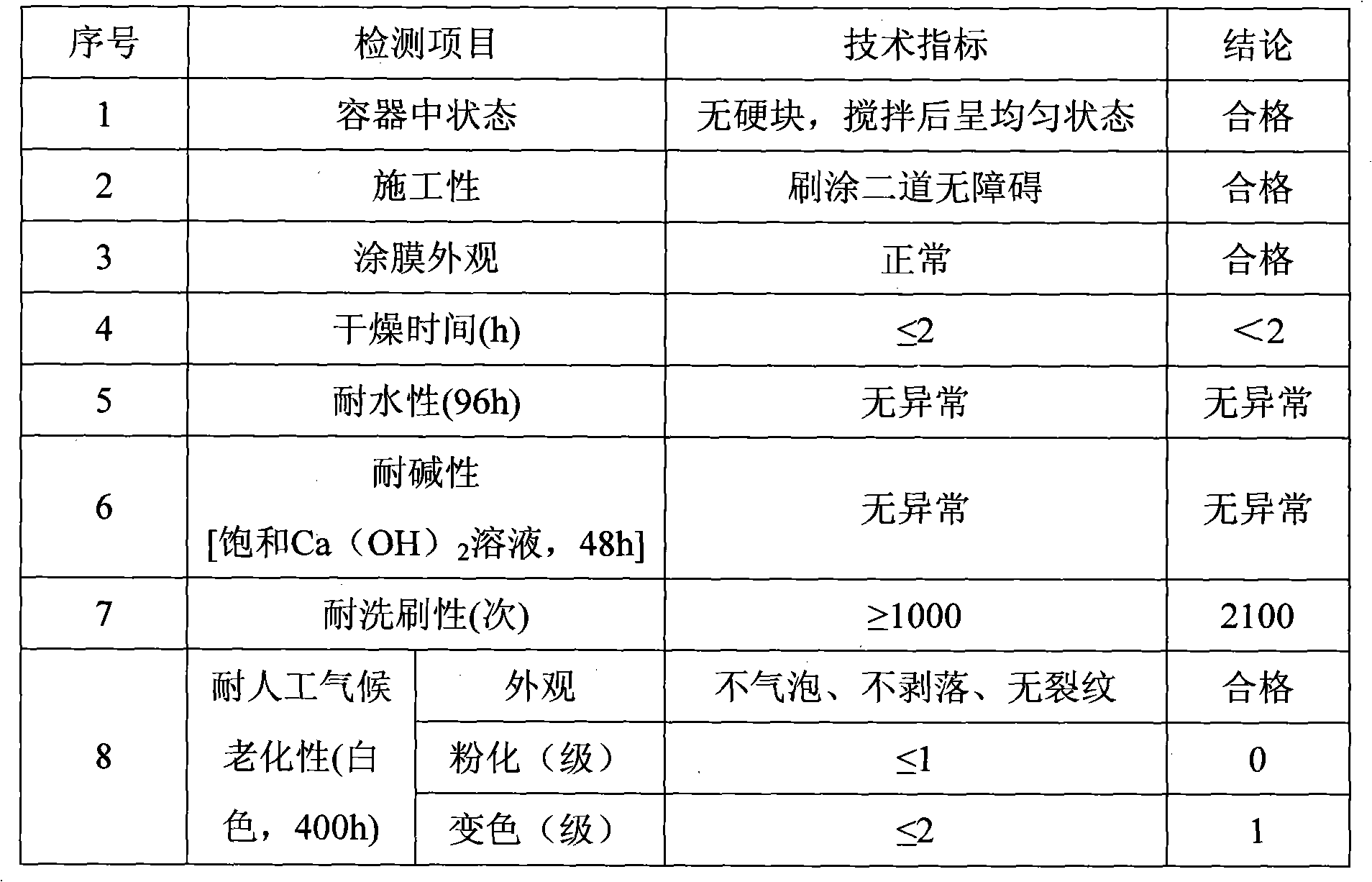

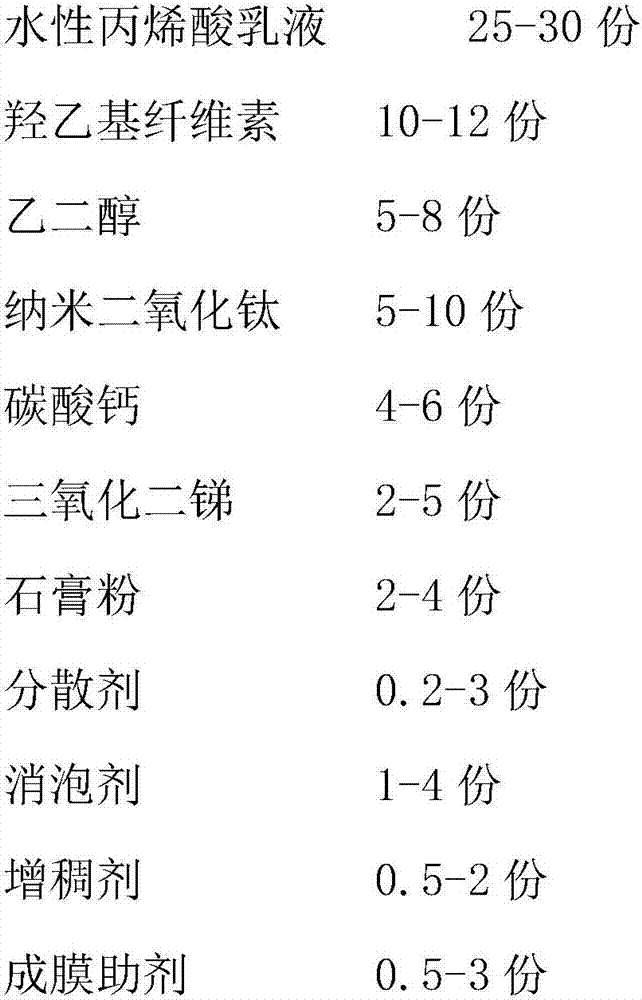

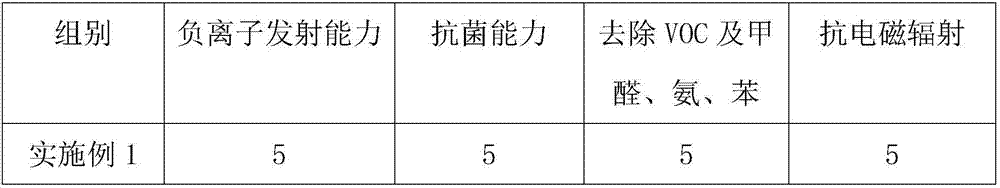

Water-based acrylic acid paint utilizing negative ions to purify air

ActiveCN107201124AImprove dispersion stabilityImprove air qualityCoatingsPigment treatment with organosilicon compoundsActivated carbonSilane coupling

Water-based acrylic acid paint utilizing negative ions to purify air is disclosed. 1-5% by weight of a negative ion paint additive is added into water-based acrylic acid paint. The additive is prepared by modifying negative ion powder and activated carbon powder with a titanate coupling agent. According to the provided water-based acrylic acid paint utilizing the negative ions to purify air, the titanate coupling agent is adopted to modify tourmaline in the negative ion powder and the negative ion powder is composited with the activated carbon powder, and therefore surface hydrophobicity of the tourmaline is improved, the crystal structure of the tourmaline is not destroyed, original physical characteristics of the tourmaline are not influenced, and negative ion release of the tourmaline is improved than negative ion release of tourmaline treated with a traditional silane coupling agent, thus improving air quality.

Owner:湖北佰航建材科技有限公司

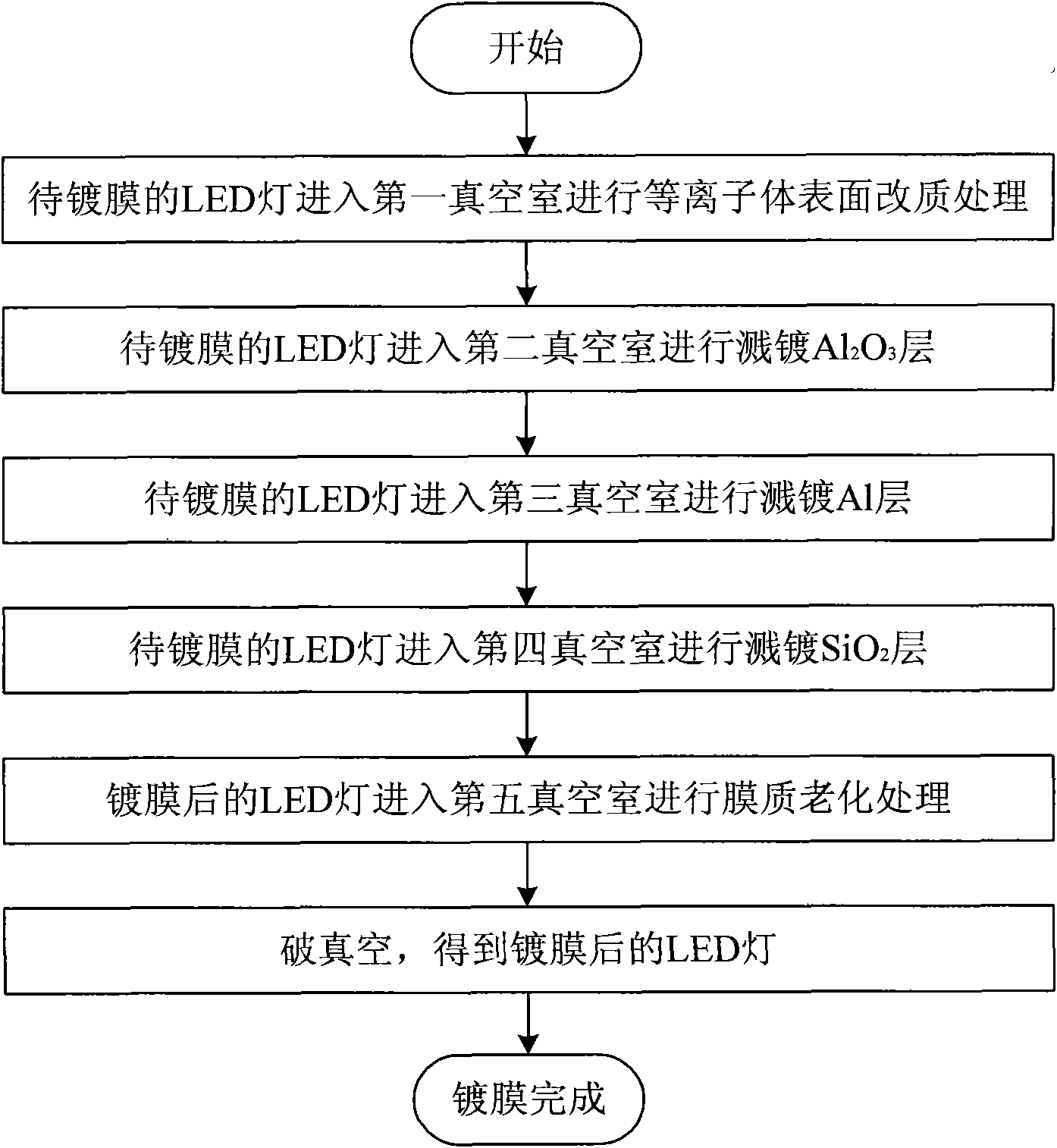

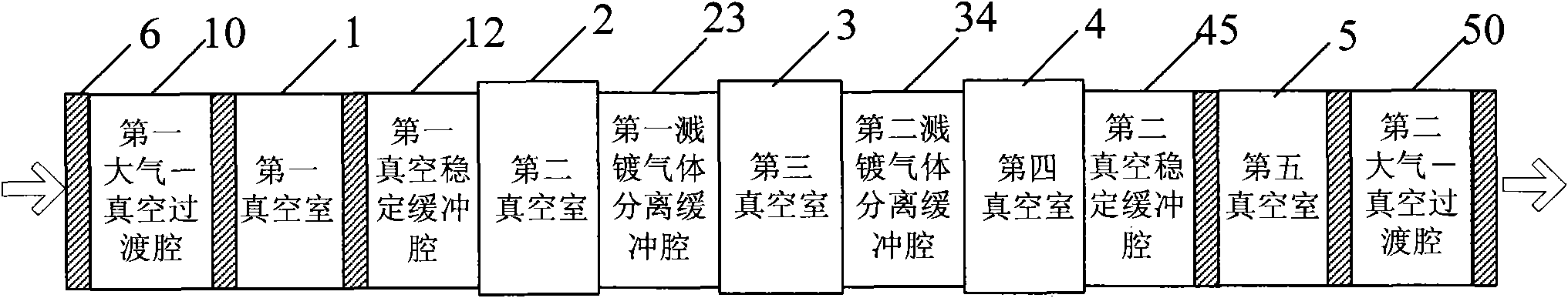

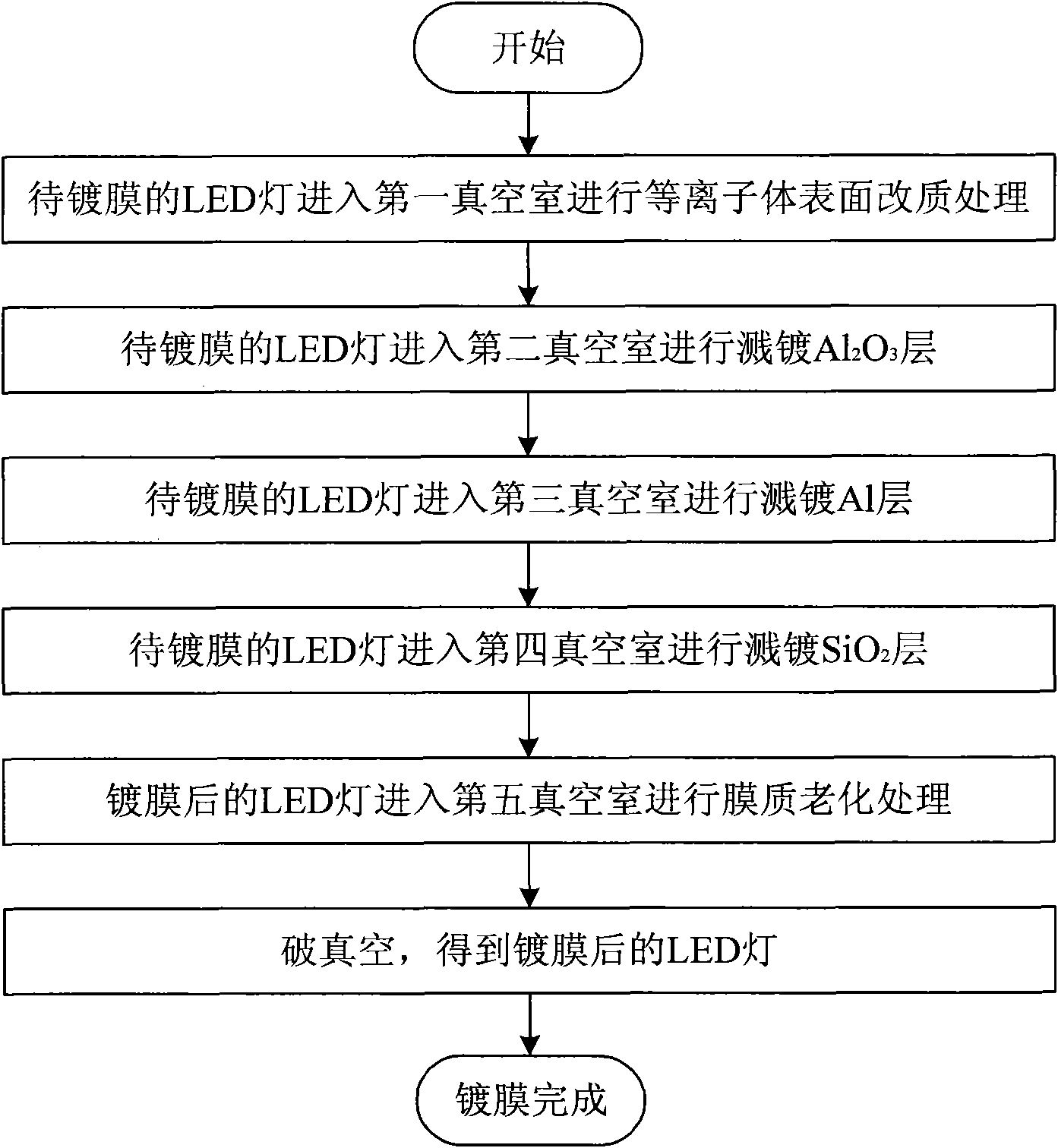

High-reflectivity nano film layer for high-power LED lamps and film coating method thereof

ActiveCN101949003AIncrease productivityHigh product yieldPoint-like light sourceVacuum evaporation coatingHigh resistanceSputtering

The invention discloses a high-reflectivity nano film layer for high-power LED lamps, which contains the three components of Al2O3, Al and SiO2 and is coated on the light reflecting surface of the LED lamp by using vacuum ion magnetron sputtering technology. The invention also discloses a film coating method for preparing the high-reflectivity nano film layer, which sequentially comprises the steps of plasma surface modification treatment, the coating of an Al2O3 layer, the coating of an Al layer, the coating of an SiO2 layer and film aging treatment. The film layer prepared by the method hasthe characteristics of high reflectivity and high resistance to oxidization; and the film coating method has the advantages of once film forming without assembly in the film coating process, applicability to continuous mass industrial production, relatively higher production efficiency and relatively higher product yield.

Owner:SUZHOU RONGRAY NANO COMPOSITE TECH +1

Multi-layer anisotropic conductive adhesive film and manufacturing method thereof

ActiveCN107914435AReduce the ground impedance valueGood anisotropic conductivityElectrical equipmentMetal layered productsAnisotropic conductive adhesiveMetal powder

The invention discloses a multi-layer anisotropic conductive adhesive film. The multi-layer anisotropic conductive adhesive film comprises an upper conductive adhesive layer, a thin metal layer and alower conductive adhesive layer, wherein the thin metal layer is formed between the upper conductive adhesive layer and the lower conductive adhesive layer and is 50-3000 nm thick, and a release filmlayer or a carrier film layer is formed below the lower conductive adhesive layer. The multi-layer anisotropic conductive adhesive film has high conductivity and high electromagnetic wave shielding function. Metal conductive particles contained in the upper conductive adhesive layer and the lower conductive adhesive layer are in various shapes, and the thickness of the thin metal layer is nanoscale; when the conductive adhesive film is conducted, the metal conductive particles tend to flow in multiple directions, and conduction in all directions can be achieved; meanwhile, the metal conductiveparticles can pierce the thin metal layer, the number of the metal conductive particles can be reduced under the same conducting force, metal powder pollution is reduced, and the production cost is reduced.

Owner:KUSN APLUS TEC CORP

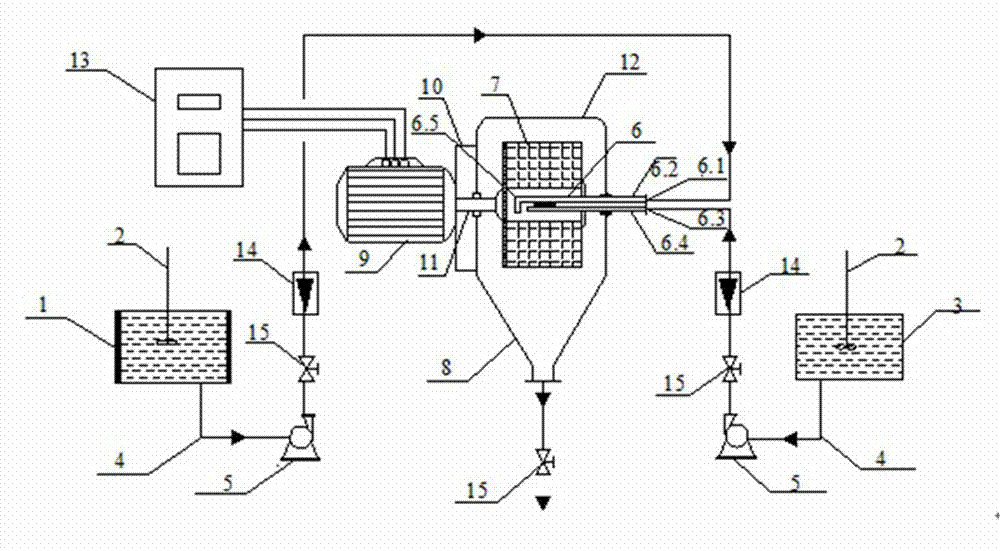

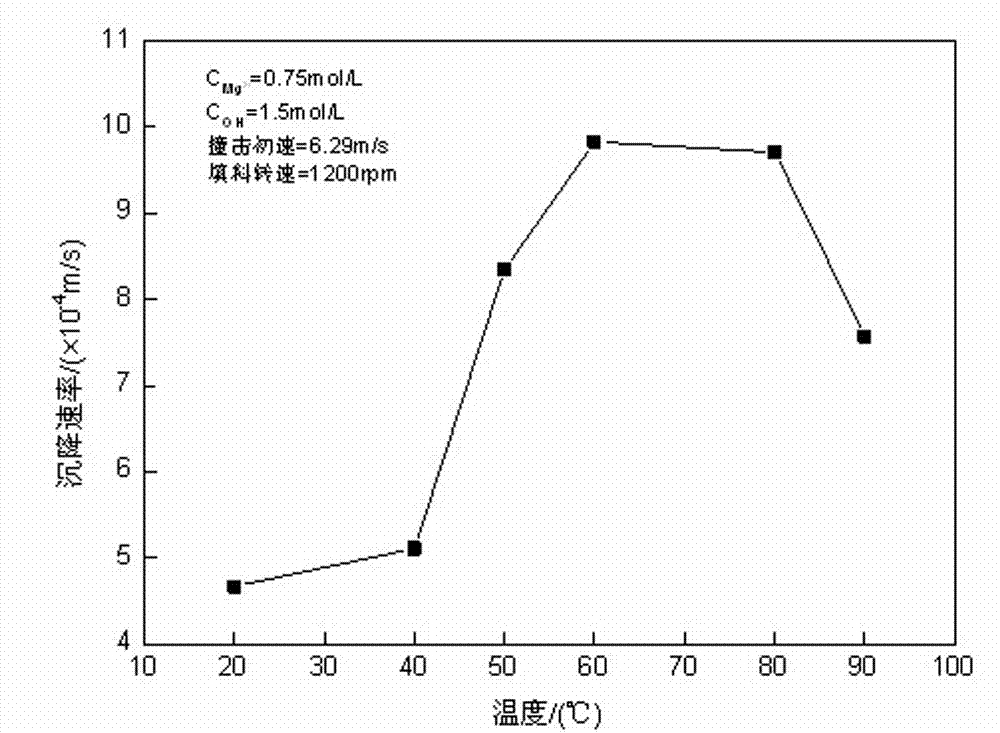

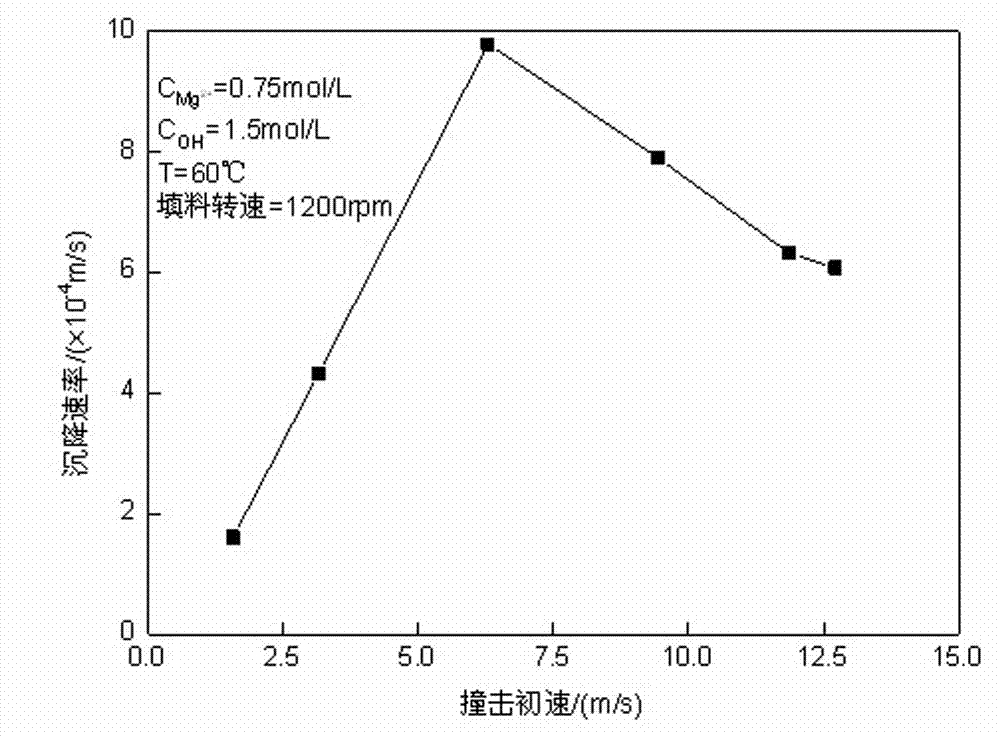

Method and device for synthesizing superfine magnesium hydrate fire retardant

ActiveCN103043689AIncrease contact areaShorten mixing timeMaterial nanotechnologyMagnesium hydroxideChlorideSodium hydroxide

The invention belongs to the technical field of the inorganic chemical industry, specifically relates to a method and a device for synthesizing a superfine magnesium hydrate fire retardant, and aims to solve the problem that existing magnesium hydrate synthesizing methods have respectively different disadvantages. The method comprises the steps that a magnesium chloride solution and a sodium hydroxide solution enter a liquid distributor from a liquid inlet of a supergravity reactor to realize first rapid uniform mixing and reacting, and then the solutions penetrate through a padding layer in a radial direction from inside to outside to realize second rapid uniform mixing and reacting. The device comprises the supergravity reactor, the liquid distributor of the supergravity reactor comprises a liquid inlet pipe I and a liquid inlet pipe II, the liquid inlet I is straight-pipe-shaped, the liquid inlet pipe II is straight-pipe-shaped and is provided with a 90-degree bend at the front end, and nozzles are formed at the front ends of the liquid inlet pipes. The device has the advantages that the structure is simple, the operation is simple and convenient, the device runs stably, the energy consumption is low, the technological design is reasonable, and the mixing efficiency of reactants can be enhanced, so that the product dispersibility is good, the grain size distribution is uniform, and the padding performance and the dispersing performance of the superfine magnesium hydrate fire retardant in a high polymer material are improved.

Owner:ZHONGBEI UNIV

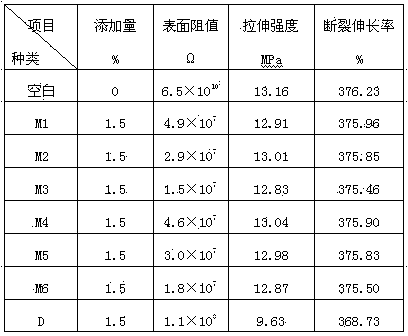

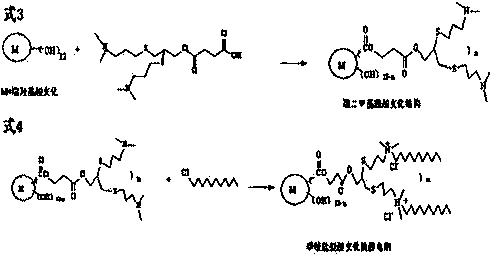

Quaternary ammonium salt hyperbranched antistatic agent and preparation method thereof

InactiveCN103865076AMolecular utilization is highThe surface is highly absorbentPolymer scienceButanedioic acid

The invention relates to the technical field of a high polymer material antistatic agent, and particularly relates to a quaternary ammonium salt hyperbranched antistatic agent. Propargyl alcohol reacts with succinic anhydride so as to obtain a modified monomer R1, the R1 reacts with 3-(dimethylamino)-1-propanethiol so as to obtain a modified monomer R2, the R2 reacts with a hydroxyl-terminated hyperbranched polymer so as to obtain a dimethyl amine-terminated hyperbranched structure, and then the dimethyl amine-terminated hyperbranched structure reacts with alkyl chloride so as to obtain the quaternary ammonium salt hyperbranched antistatic agent. The molecules of the antistatic agent contain more effective active groups, the utilization rate of the molecules is relatively high, the surface water absorbability of the antistatic agent in a substrate is relatively strong, and correspondingly the antistatic agent has a relatively good antistatic effect; the antistatic agent has relatively good compatibility with a medium and very good dispersibility.

Owner:UNIV OF JINAN

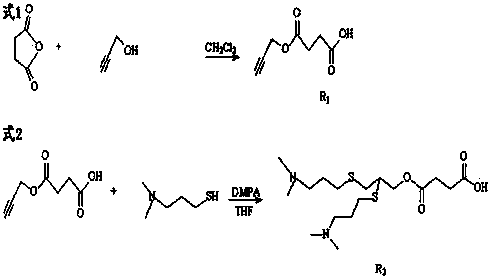

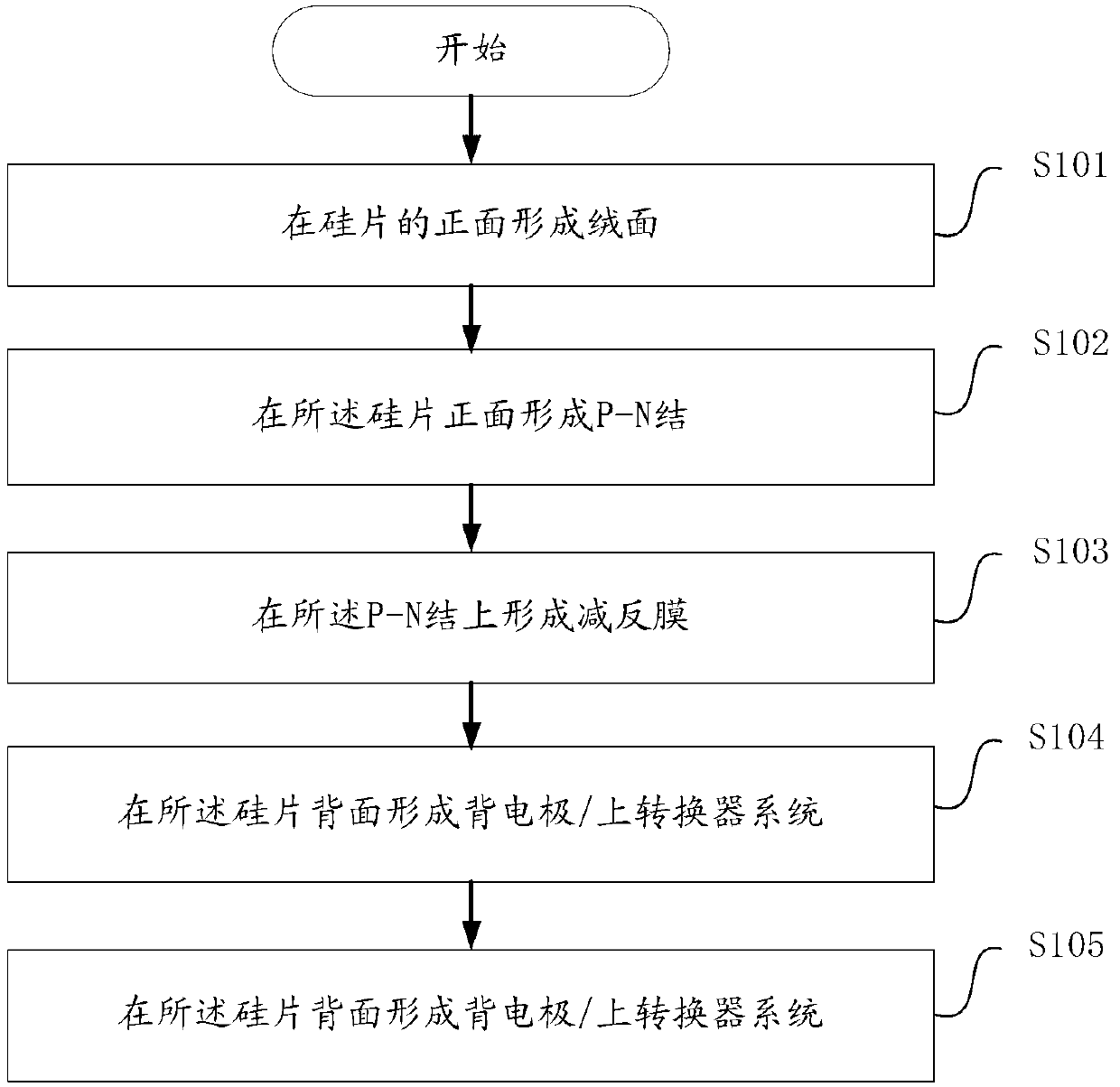

Up-conversion solar cell and preparation method thereof

InactiveCN103346203AAdd lessAdding process is simpleFinal product manufacturePhotovoltaic energy generationElectrical batteryMetal particle

The invention discloses a preparation method for an up-conversion solar cell. The method comprises the following steps of forming a flocking face on the front face of a silicon chip, forming a P-N junction on the front face of the silicon chip, forming an anti-reflection coating on the P-N junction, forming a back electrode / up-converter system on the back of the silicon chip, and forming a positive electrode on the front face of the silicon chip. Correspondingly, the invention further provides the up-conversion solar cell which sequentially comprises the back electrode / up-converter system, the silicon chip, the P-N junction, the flocking face, the anti-reflection coating and the positive electrode from bottom to top. The back electrode / up-converter system is made of electro-conduction slurry containing metal particles, inorganic glass materials, organic carriers and up-conversion materials. According to the preparation method, under the circumstance that the forbidden bandwidth of solar cell base body materials is not changed, by changing the wave length of some photons, the photons which can not be used in photovoltaic conversion originally are utilized, and therefore the photovoltaic conversion efficiency of the solar cell is improved greatly.

Owner:ZHEJIANG ASTRONERGY

Cleaning agent for liquid crystal display screen

InactiveCN108559660ALess corrosiveDoes not affect physical propertiesInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsSodium metasilicatePolyvinyl alcohol

The invention discloses a cleaning agent for a liquid crystal display screen, belonging to the technical field of cleaning agents. The cleaning agent comprises the following raw materials by mass: 5-10% of fatty alcohol polyoxyethylene ether, 2-5% of isomeric alcohol polyoxyethylene ether, 0.2-0.5% of a fluorocarbon surfactant, 3-7% of sodium diisooctyl succinate, 2-5% of sodium dodecyl benzene sulfonate, 1-3% of cocamidopropyl betaine, 2-5% of trans-1,2-cyclohexanediaminetetraacetic acid, 1-3%of sodium polyacrylate, 2-4% of sodium metasilicate, 2-5% of hydroxyethylethylenediamine, 1-3% of polyvinyl alcohol, 3-7% of a solubilizer and 0.5-1% of a corrosion inhibitor, with the balance being deionized water. The cleaning agent of the invention has good ability in dissolving of liquid crystalmaterials, oil stains, dust, etc., and liquid crystal materials, oil stains, dust and the like are emulsified and dispersed in the cleaning agent and are thus separated from a to-be-cleaned surface; and the cleaning agent has good cleaning effect, is free of residues on the surface of a liquid crystal cell and low in corrosivity to liquid crystal display screens, and does not affect the physical properties of liquid crystal display screens.

Owner:安徽全兆光学科技有限公司

Mother material for environment protecting shinny stone granules

A degradable mother material with glittering granules consists of calcium carbonate 85wt%; polyolefin 13wt%, and auxiliary 2wt% containing aluminate coupling agent 0.5wt%, olefin-cracked wax with high melting point 0.2wt%; stearic acid 0.5wt%, iron-ion containing free radical reducing agent 0.1wt%, olefin-cracked wax with high molecular weights 0.2wt%, ethylene stearamide 0.3wt%, plant oil 0.1wt% and alcohol 0.1wt%. Olefin chains are broken by light radiation, oxidation and bacteria degradation. The mother material is mixed with polyolefin and calcium carbonate to increase their physical performance and decrease cost.

Owner:王世杰

VMCPP film with high aluminium layer adhesive force

The invention relates to a VMCPP film with a high aluminium layer adhesive force. A base film is produced by adopting a three-layer co-extrusion tape-casting method. The three layers are a corona layer, an intermediate layer and a heat-sealing layer respectively. Detection results of the aluminum plating adhesive force are higher than 3.0 N / 15 mm that is more than 5 times of the adhesive force of a common aluminum plating film. The thickness ratio of the three layers are that the thickness ratio of the corona layer is 5-30%, the thickness ratio of the intermediate layer is 10-85% and thickness ratio of the heat-sealing layer is 10-30%. By utilization of characteristics of acrylate polymer materials, the adhesion strength of an aluminum layer and polypropylene is enhanced, thus achieving effects of enhancing the adhesive force of aluminum plating layers. The acrylate polymer has good molten miscibility with the polypropylene, and is free of influence on physical properties of the film. In addition, the polarity of the material is in good affinity with aluminum, thus enhancing the adhesive force between the aluminum plating and the corona layer polypropylene.

Owner:安徽双津实业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com