Thermal perforating device for plastic film

A punching device and plastic film technology, which is applied in the field of plastic film processing, can solve the problems of low hole penetration rate, low efficiency, and large occupied space, and achieve high hole penetration rate, fast punching speed, and convenient cleaning Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

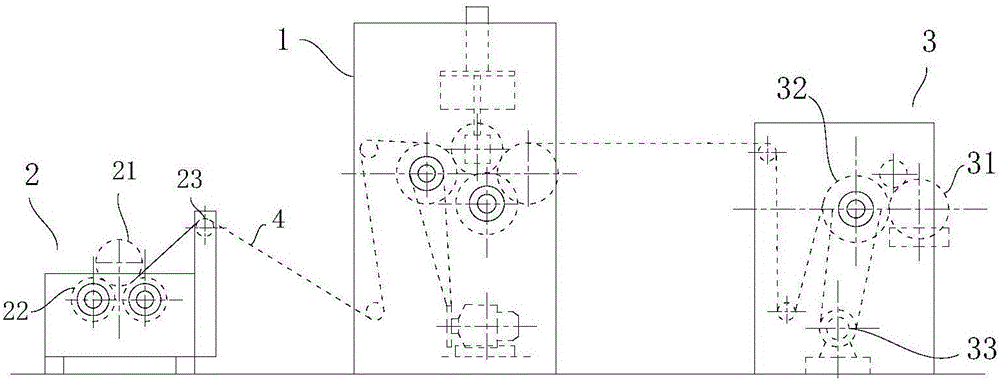

[0032] see figure 1 , the punching device 1 in the illustration also includes a supporting unwinding device 2 and a winding device 3, wherein the unwinding device 2 is used to set the unwinding roller 21 of a complete plastic film, and two sets of unwinding rollers 22 are arranged on it The unwinding roller 21 is supported, and the complete plastic film 4 is introduced into the punching device 1 through the guide roller 23 for punching, and the punched plastic film 4 is led out to the winding device 3, and the winding device 3 is provided with a winding The winding roller 31 of perforated plastic film, the winding roller is connected with a winding driving roller 32 pairs of rollers, and the winding driving roller 32 is connected with the winding motor 33 by a chain transmission mechanism, and the plastic film that completes punching is wound on the Winding on the driving roller 32, and then winding on the winding roller 31.

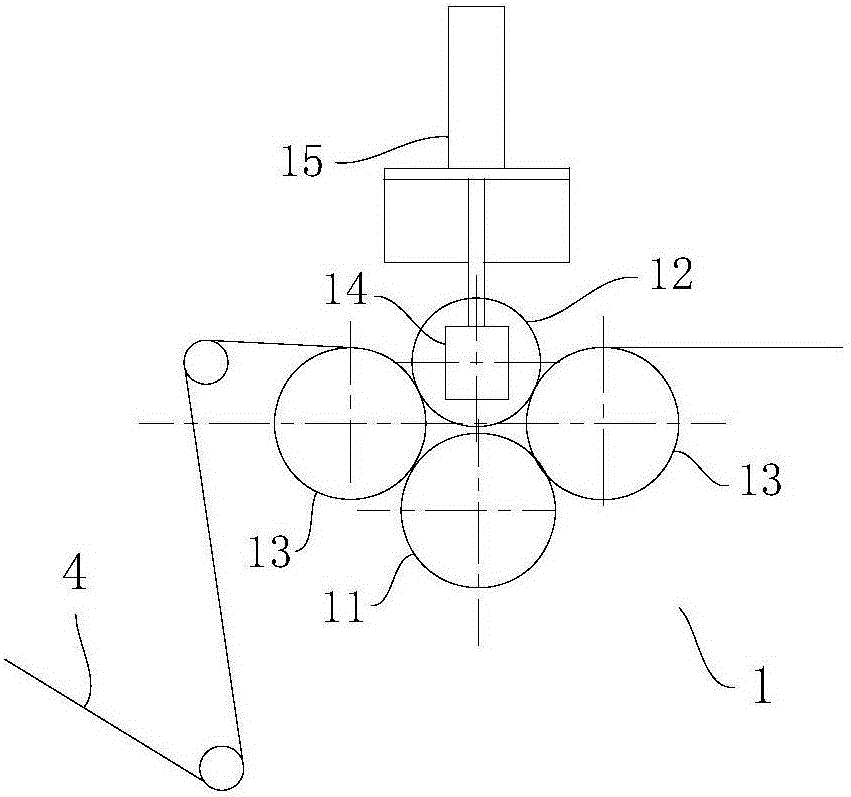

[0033] For details, see figure 2 , The punching...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com