Patents

Literature

131results about How to "Fast punching" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

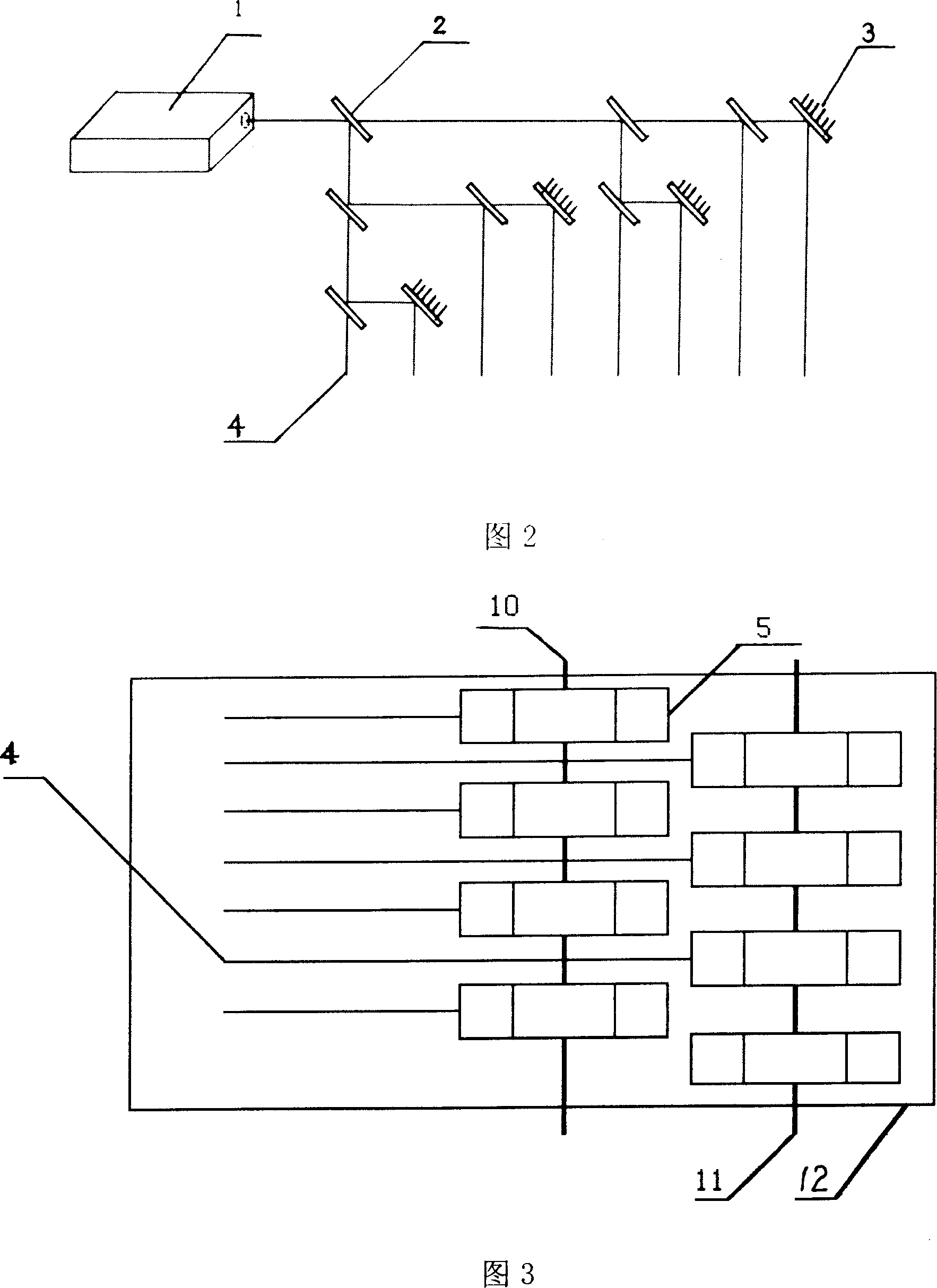

Cigarette tipping paper laser boring method and apparatus

InactiveCN101462204AAnti-counterfeitingBeautiful and changeable appearanceMetal working apparatusLaser beam welding apparatusPunchingRepeat pattern

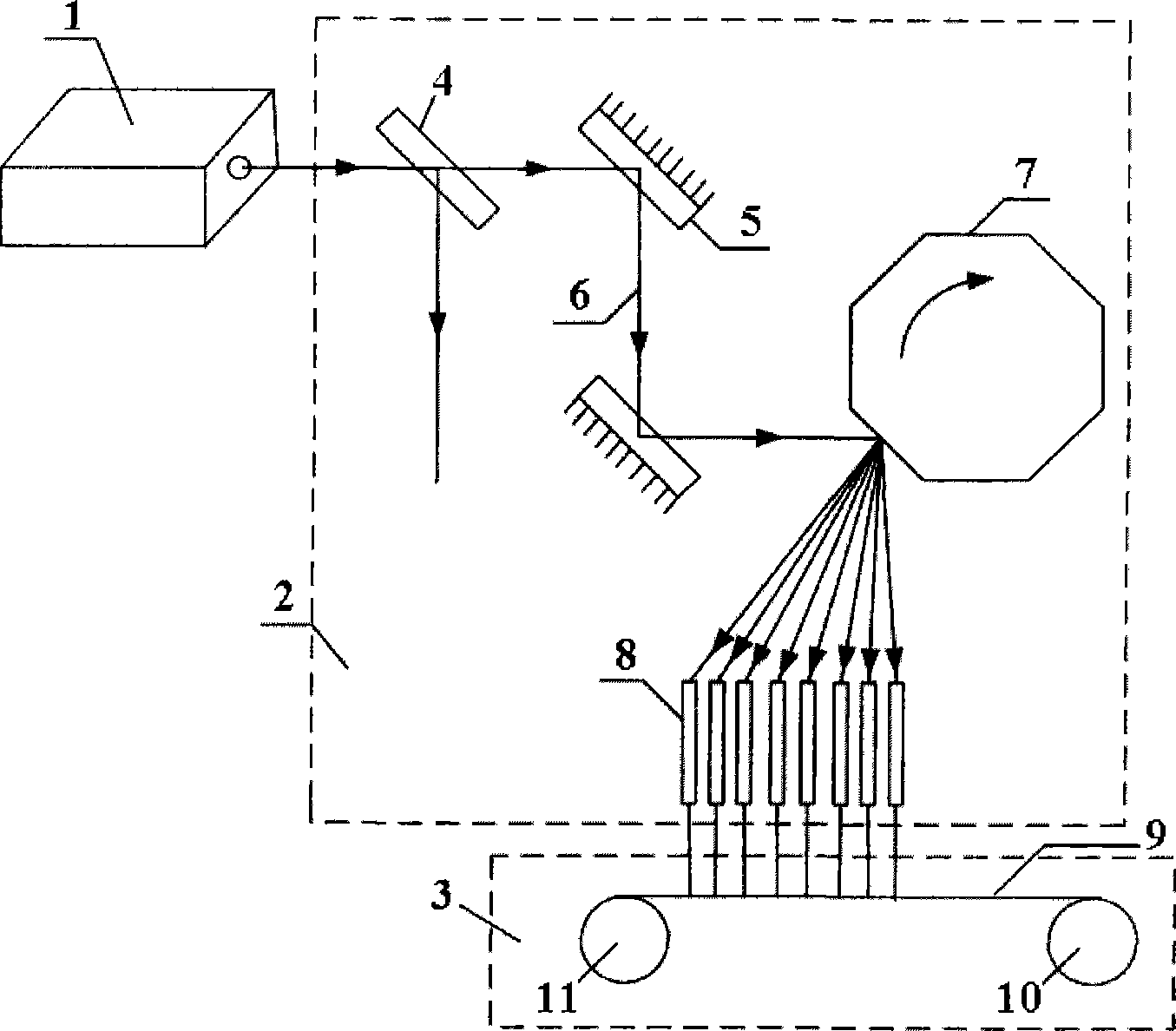

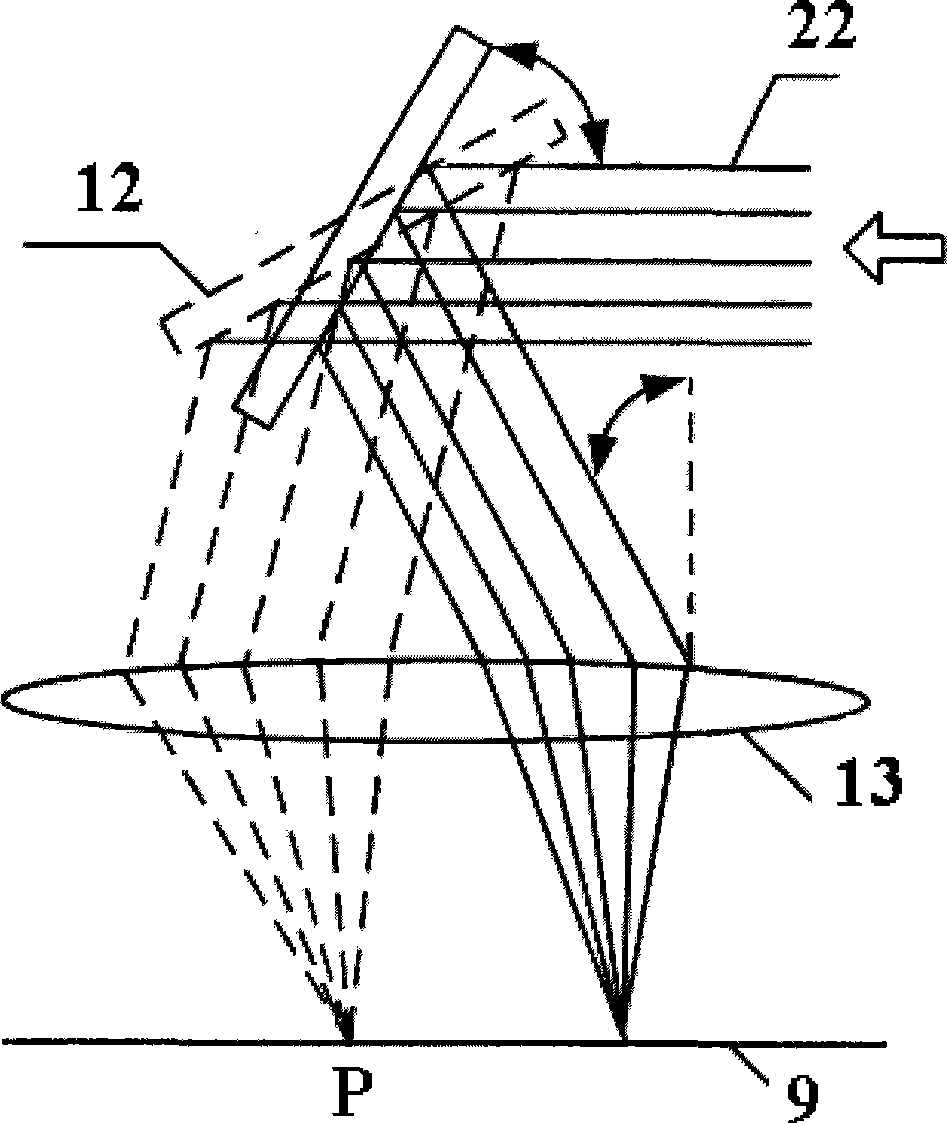

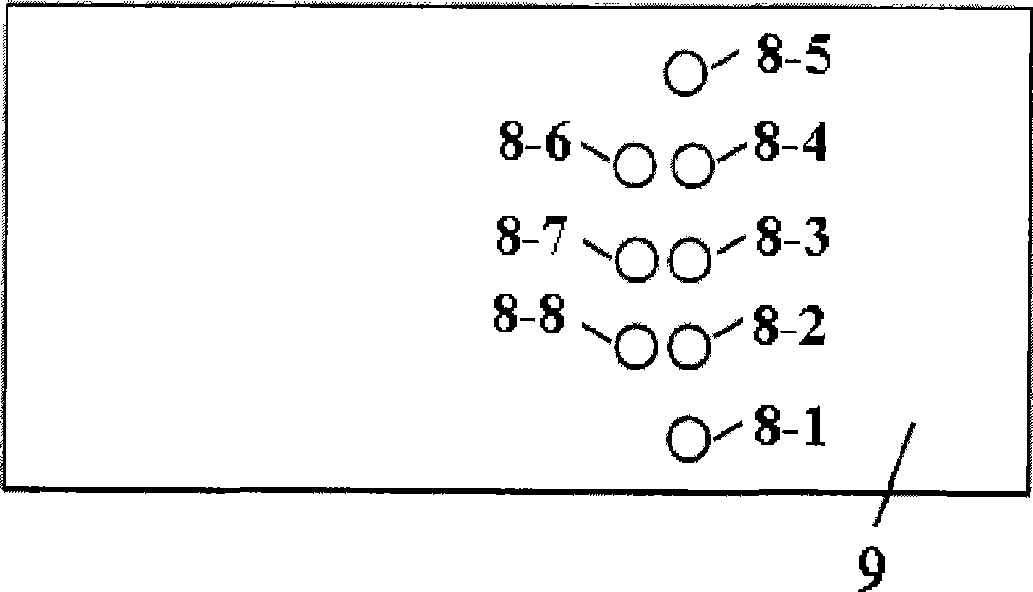

The invention provides two methods and equipment for laser punching of cigarette tipping paper. One is a rotary multi-prism punching method and equipment; and the other one is a vibrating mirror punching method and equipment. The methods and the equipment can utilize optical equipment to focus laser output by a laser; and punch pores (15) which are distributed in a single-row or multi-row curve or repeated pattern on the surface of continuously-moving tipping paper (9), such as pores (15) distributed in triangular, jagged, rhombic, trapezoidal, sine or cosine arrangement. The methods can carry out high-speed curve punching on the tipping paper, has the punching speed which is the same as linear punching speed and has good machining efficiency and good product quality; and the equipment has a simple structure, long service life, stable operation and high utilization efficiency of laser energy.

Owner:HUAZHONG UNIV OF SCI & TECH

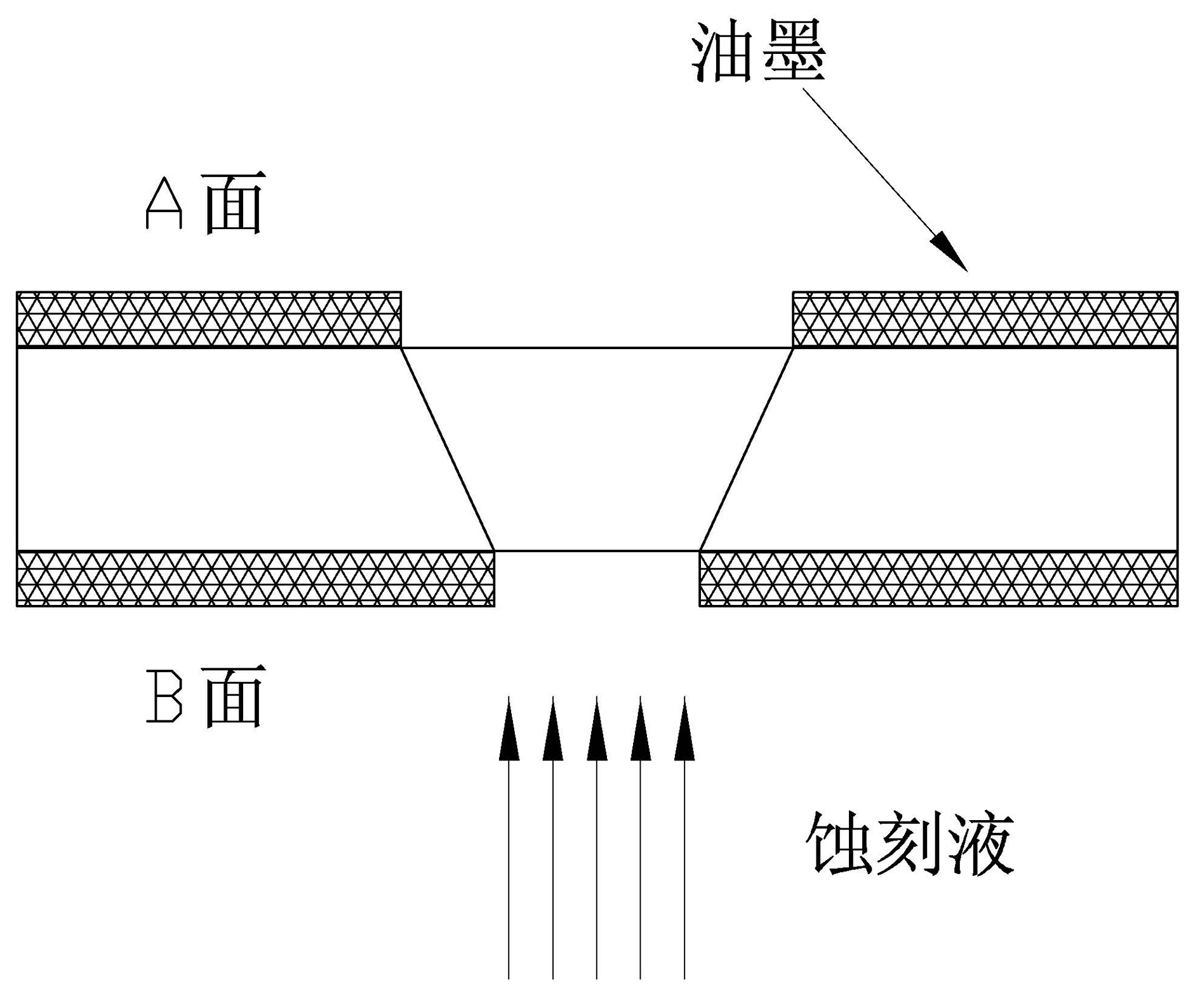

Etching method of metal micro-holes

InactiveCN101913065AEffective protectionImprove protectionLaser beam welding apparatusEtchingMachining process

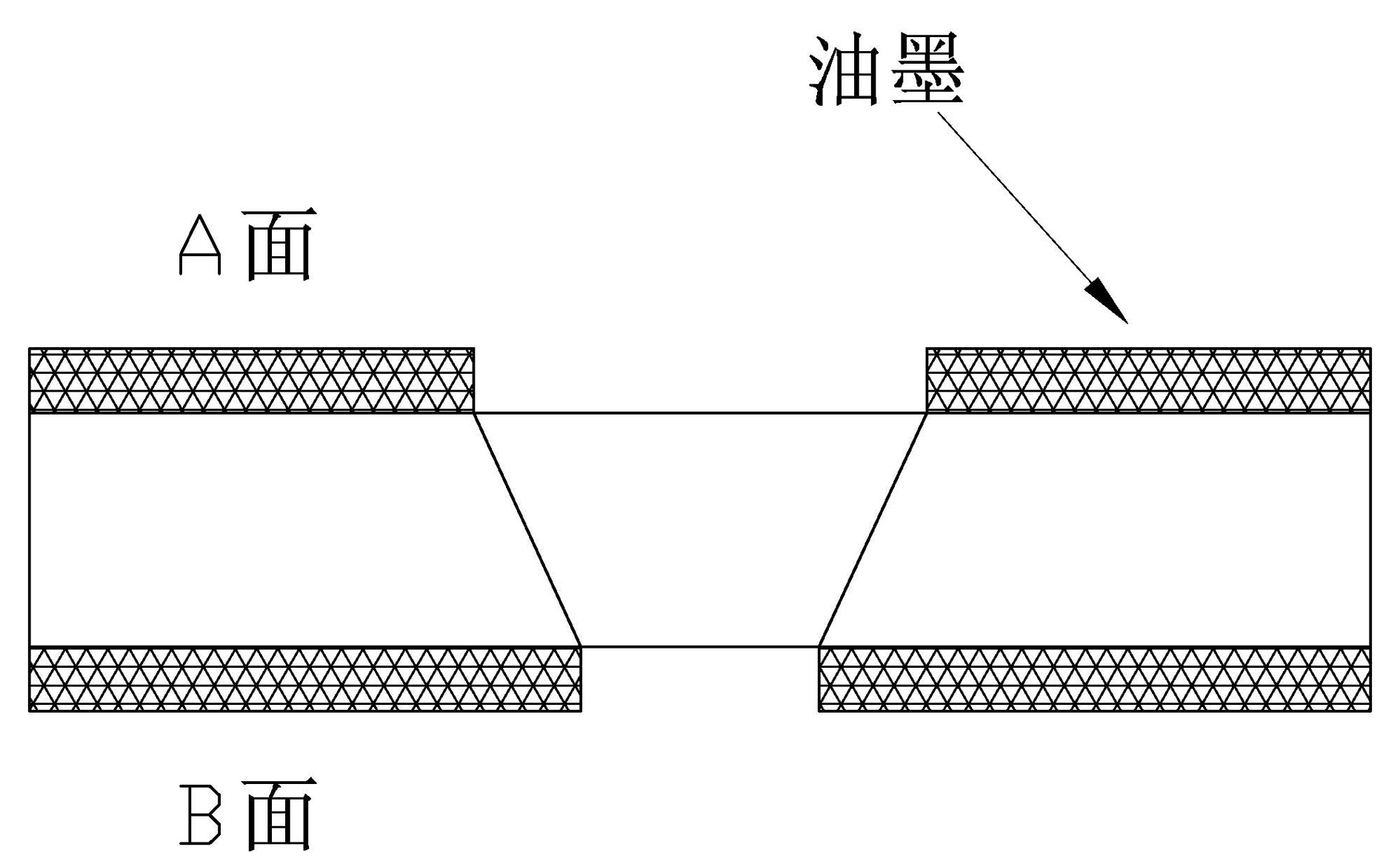

The invention relates to an etching method of metal micro-holes, which comprises the following processing process steps: process step 1) spraying oil: uniformly spraying an ink layer on a metal workpiece, and leading the thickness of sprayed oil to meet the minimum requirement of avoiding the ink layer after laser perforation from shedding; process step 2) laser perforation: using laser to perforate on the metal workpiece, and leading the perforated hole diameter to be smaller than the finally formed hole diameter; and meeting the requirement of avoiding the laser energy from damaging an ink coating; and process step 3) chemical etching: using etching solution to respectively carry out etching by times from two sides of the workpiece, and leading the diameters at two ends of the hole to meet the finally formed hole diameter. The etching method of the metal micro-holes can process the micro-holes with the diameter of 0.2mm-0.5mm of 3D curved surfaces and stainless steel sheets with the thickness of 0.4mm-1.0mm which can not be processed by the traditional process, and eliminate burrs during the processing process.

Owner:叶淦波

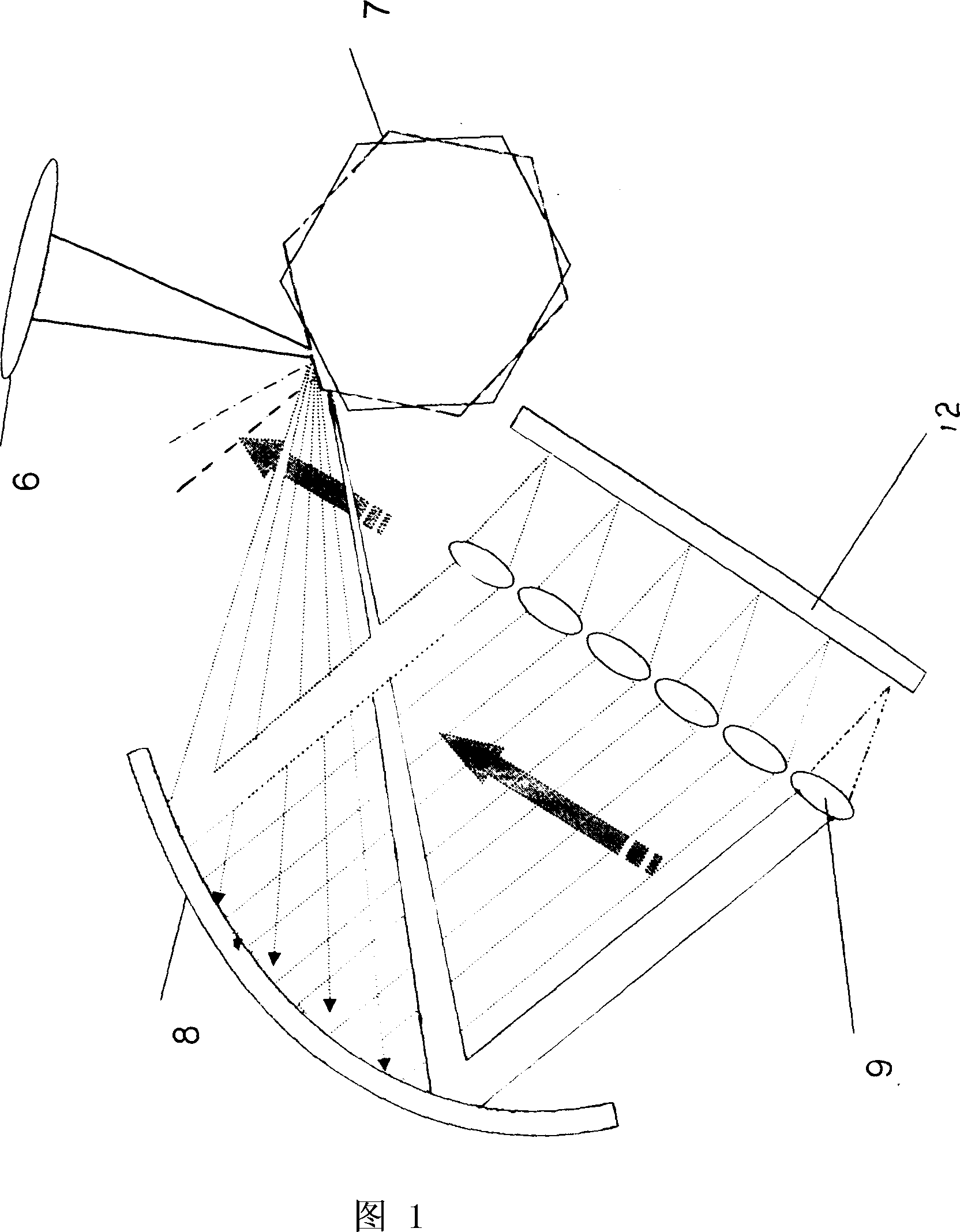

Laser method and device for boring dense micropore on leather

InactiveCN1995399AAccelerateSimple structureLeather clicking/perforating/clickingLaser beam welding apparatusPhysicsPrism

The invention discloses a dense micropore laser punching method and device of leather, which comprises the following parts: laser, rotary prism and integral punching head with reflector and focal lens, wherein the integral punching head can punch micropore continuously, which is divided into multiple pulse laser beam; the continuous laser outputs laser, which reflects scanning laser within certain angle into parallel laser within certain space; the parallel laser is focused into pulse focal array, which can punch hole on the leather.

Owner:WENZHOU ADVANCED MFG TECH INST OF HUAZHONG UNIV OF SCI & TECH

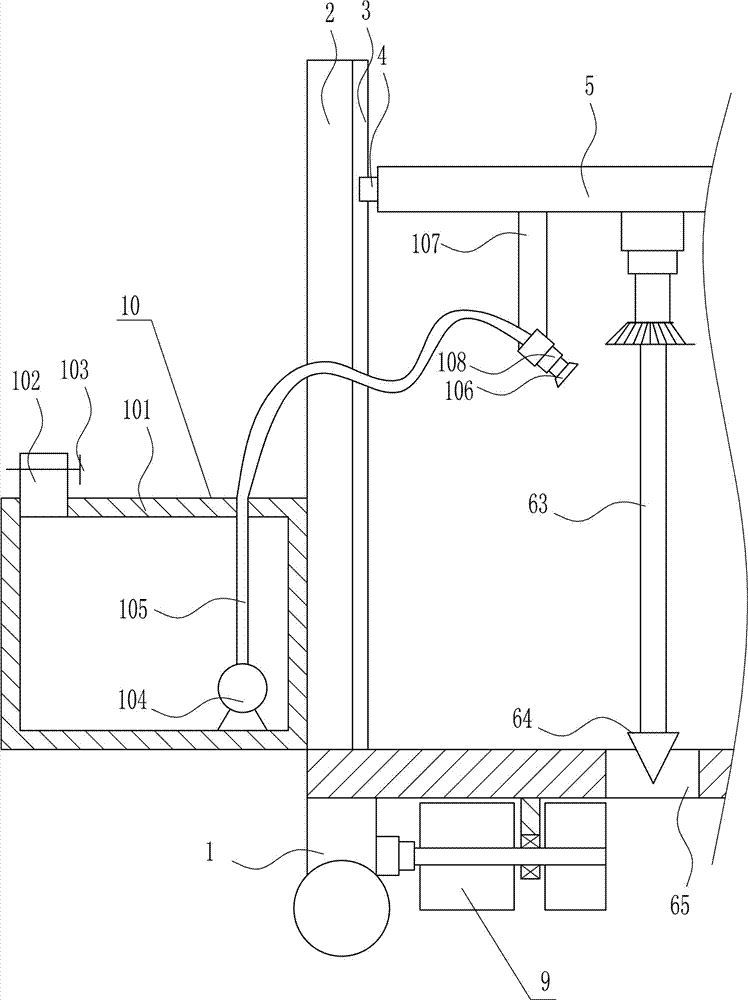

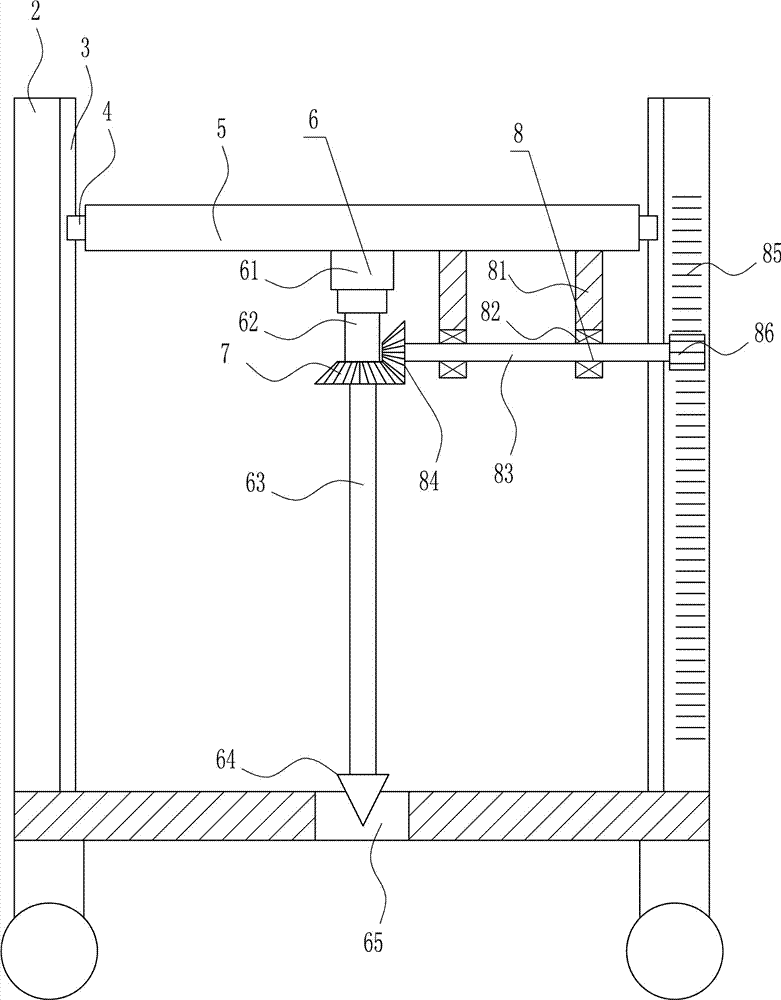

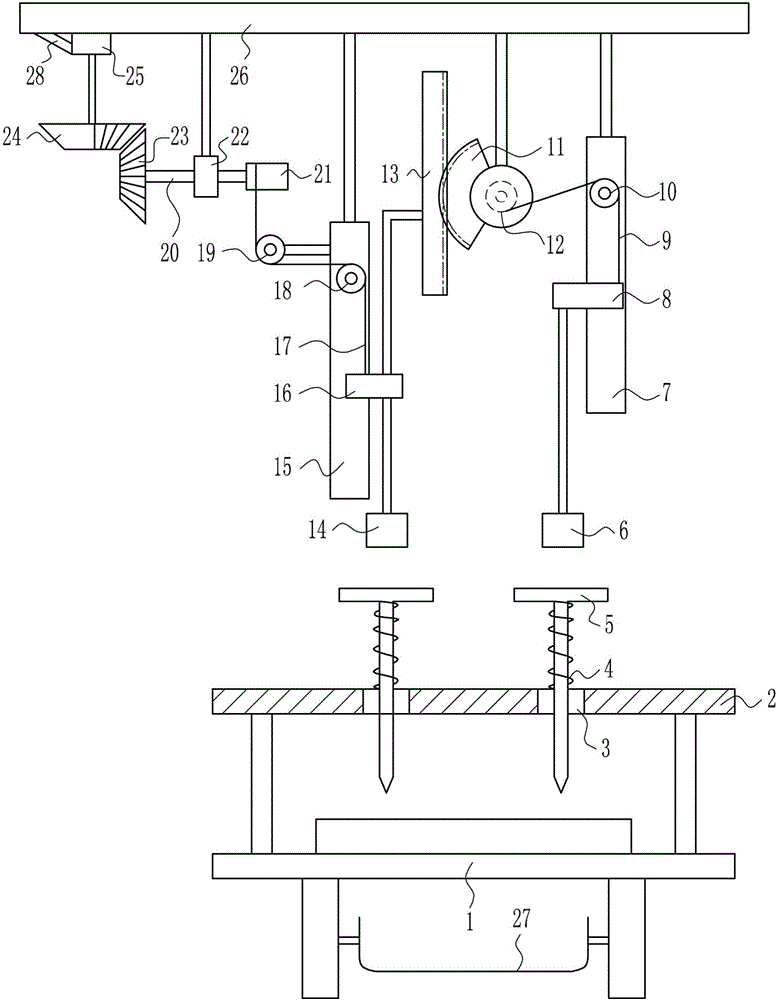

Perforating device for monitor installation

InactiveCN107503682APrevent affecting the punching effectExtended service lifeDerricks/mastsCleaning using liquidsEngineering

Owner:吴义锖

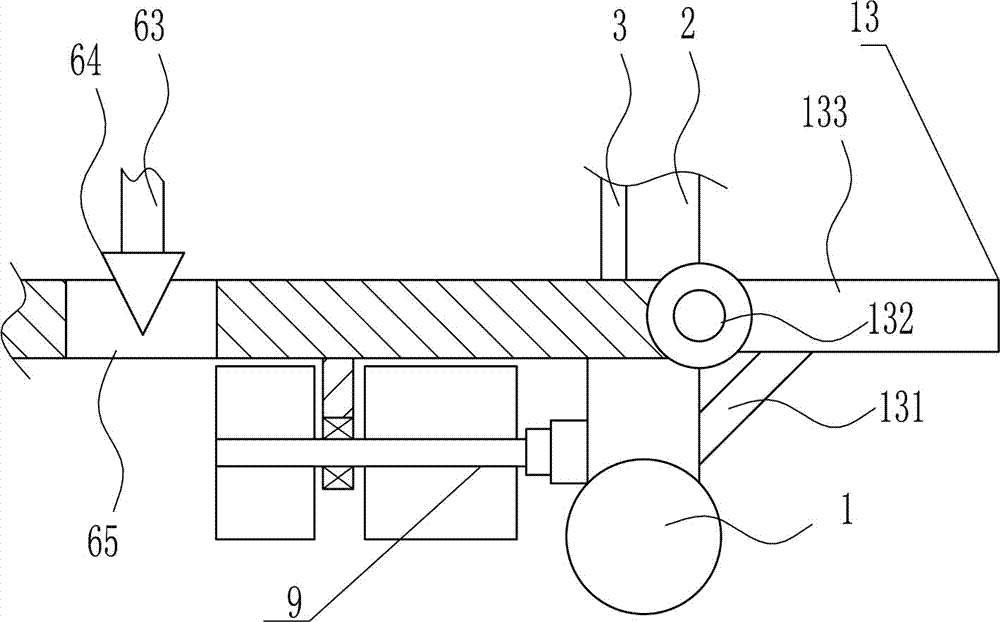

Sand cone method subgrade compaction degree detection rotary excavating and soil taking device

The invention provides a sand cone method subgrade compaction degree detection rotary excavating and soil taking device. The device comprises a device frame, a rotary excavating drill bit, a drill bit sleeve, a soil sample collecting sleeve, a motor driving device and an operation handle. The overall soil sample collecting sleeve is annular, the drill bit sleeve is located over the soil sample collecting sleeve, and an annular hollow part of the soil sample collecting sleeve communicates with the drill bit sleeve so that a hollow cylindrical cavity capable of allowing the rotary excavating drill bit to move up and down can be formed. The upper half portion of the inner wall of the soil sample collecting sleeve is in an open shape, and an opening serves as a soil throwing outlet. A sealing cover is arranged at the upper end of the drill bit sleeve. The bottom of the rotary excavating drill bit is provided with alloy tooth heads, and a spiral lifting sheet is arranged over the alloy tooth heads. The sand cone method subgrade compaction degree detection rotary excavating and soil taking device has the advantages of being simple in structure, high in excavating efficiency, capable of collecting all soil samples and convenient to use.

Owner:HEBEI ROAD & BRIDGE GROUP +1

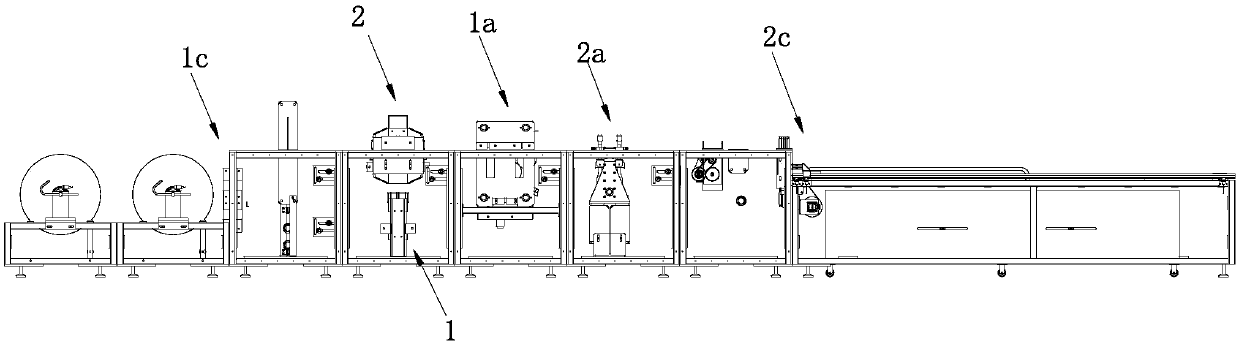

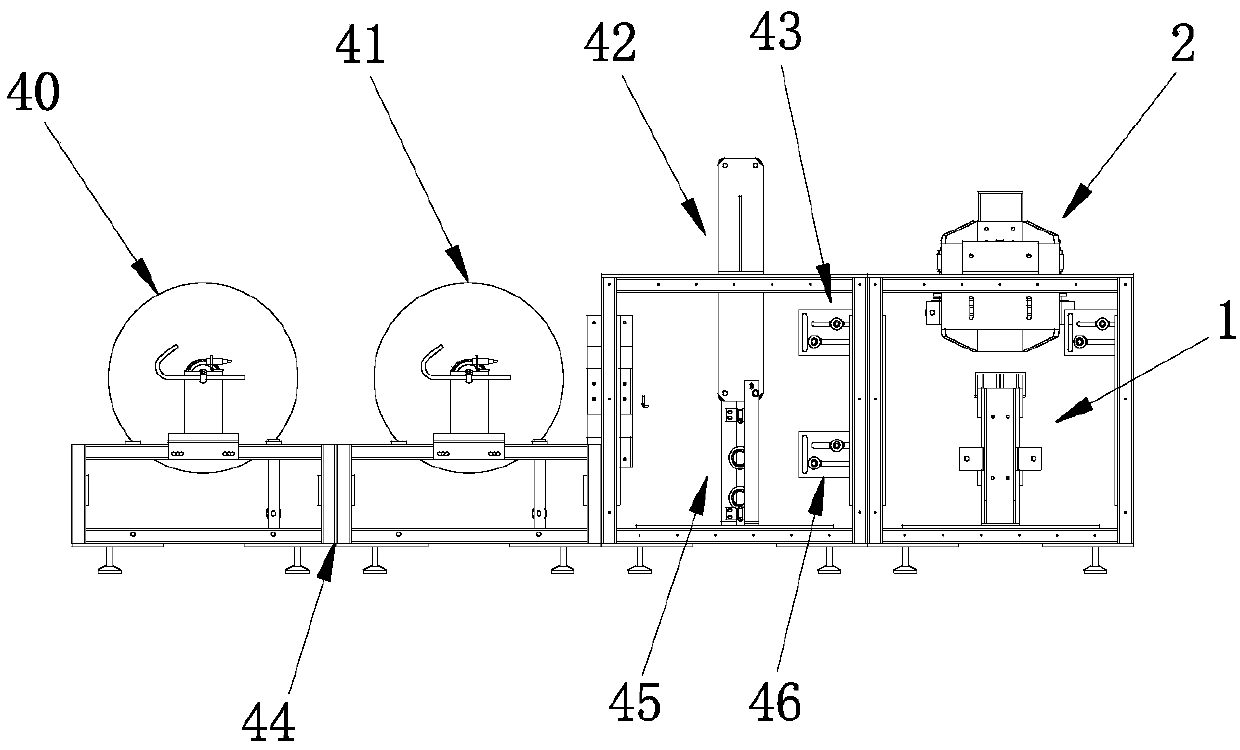

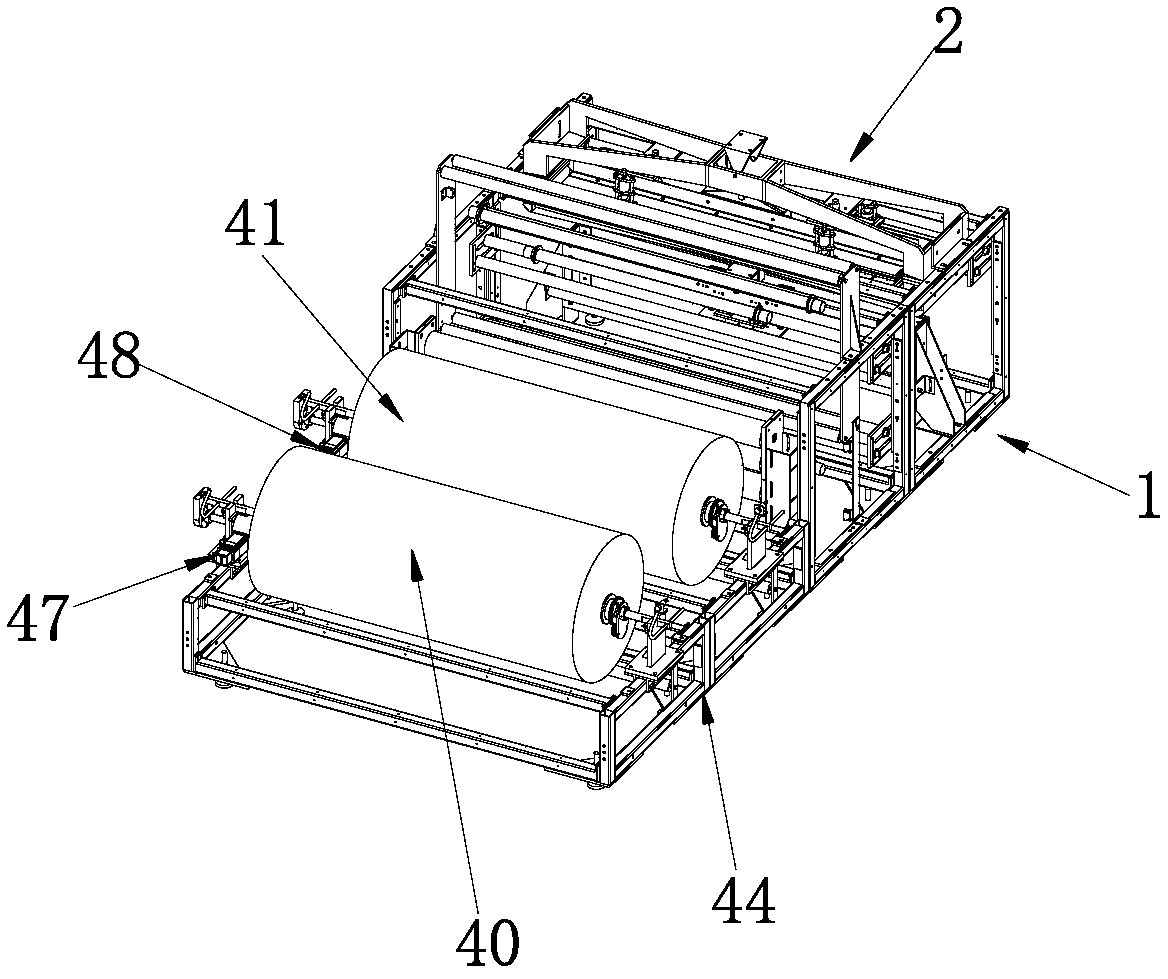

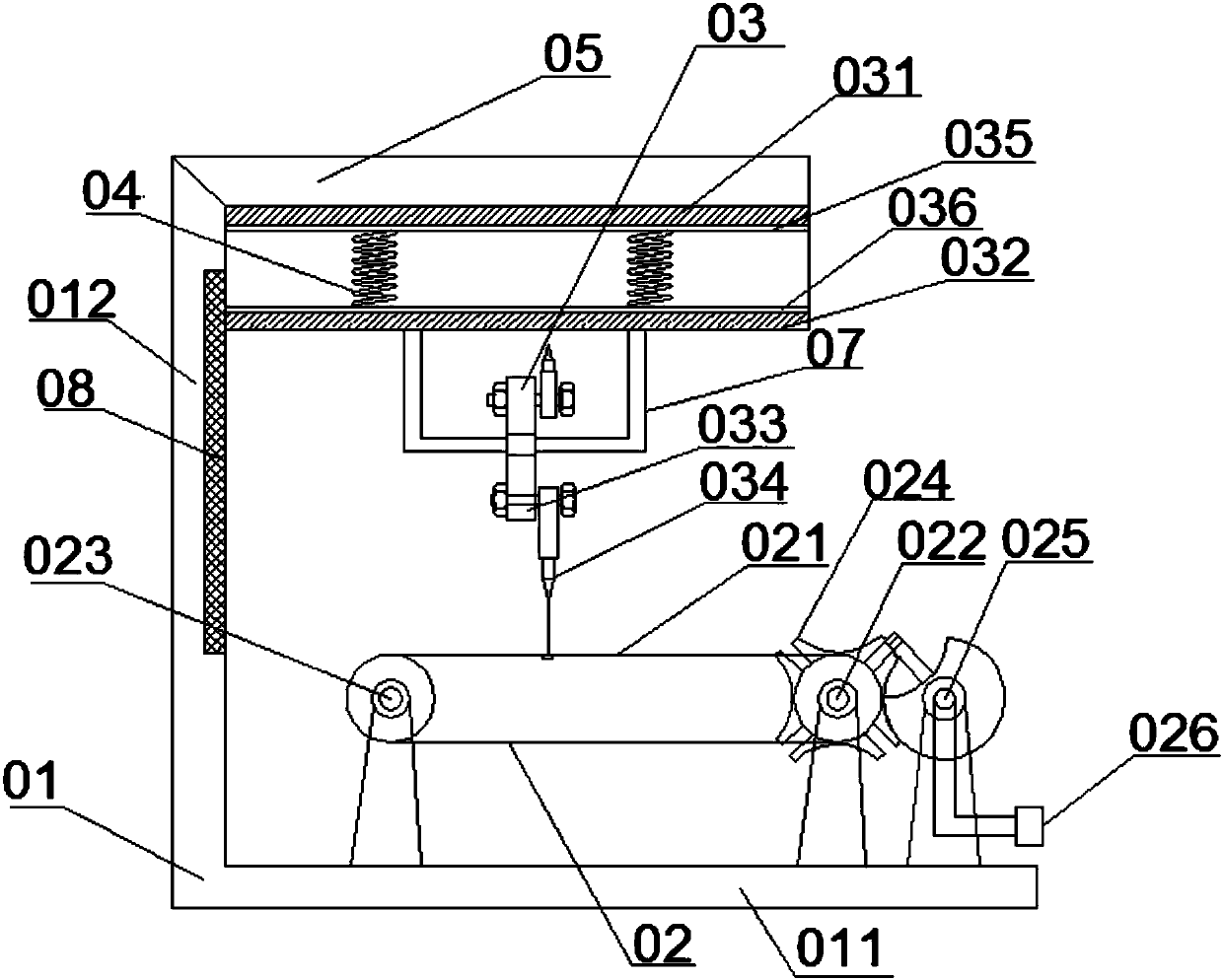

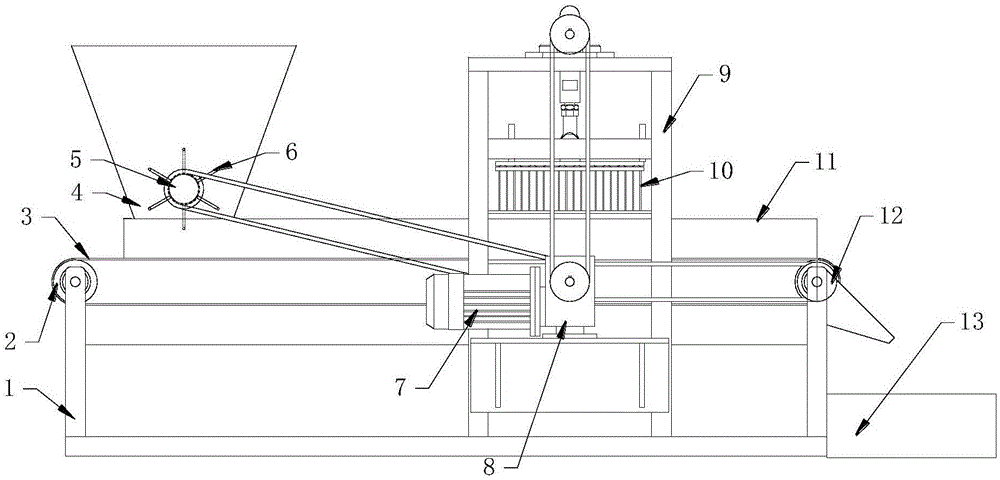

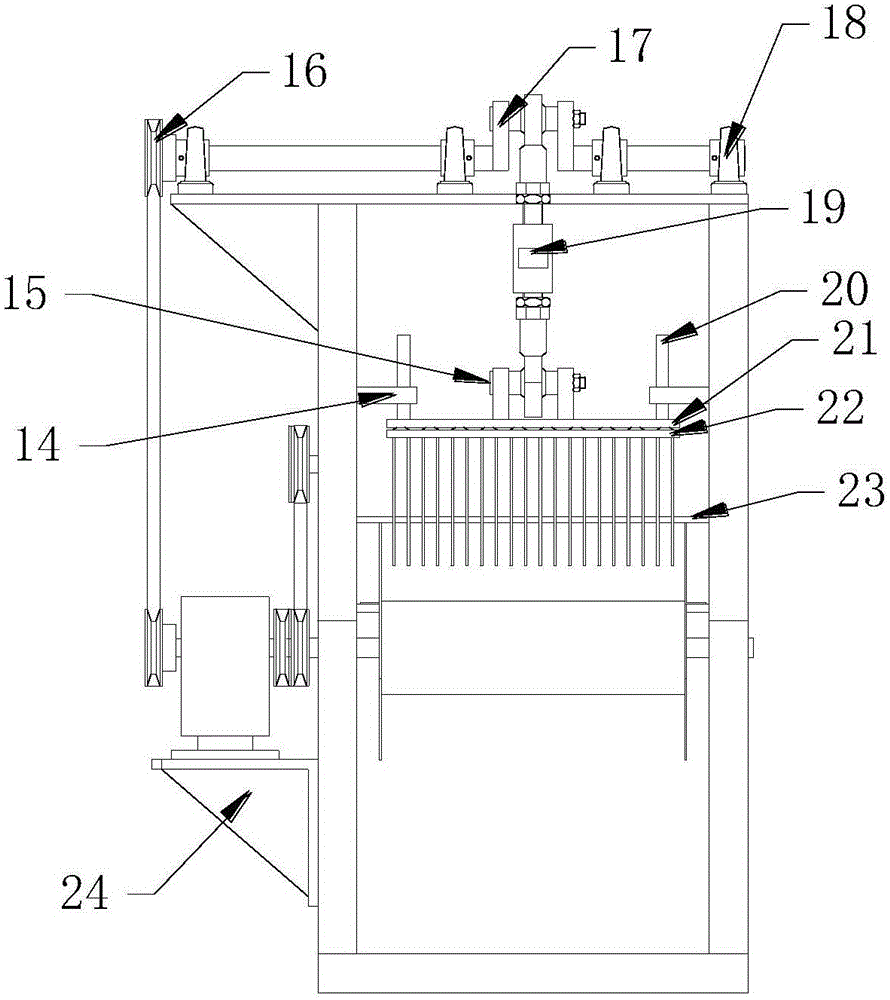

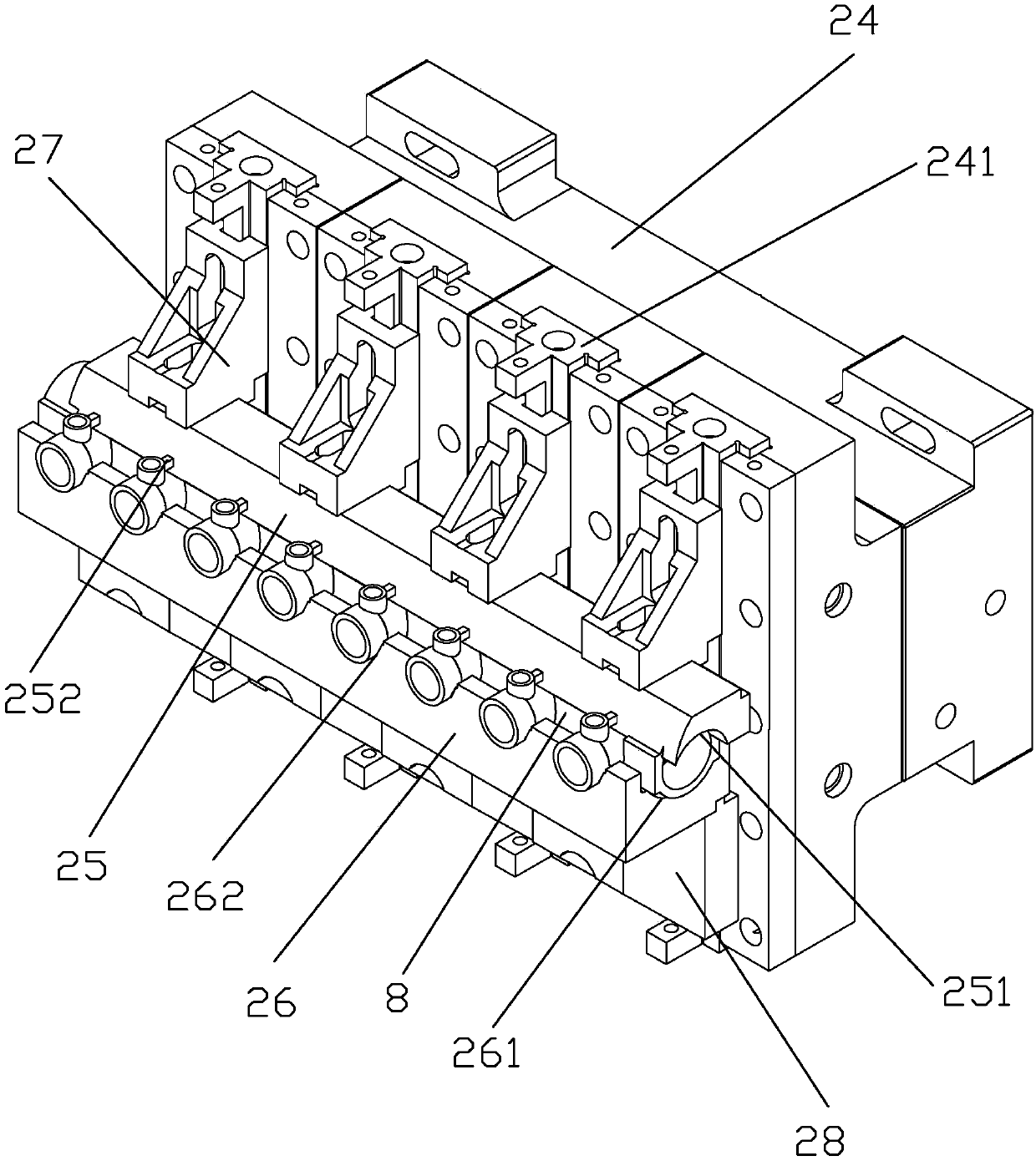

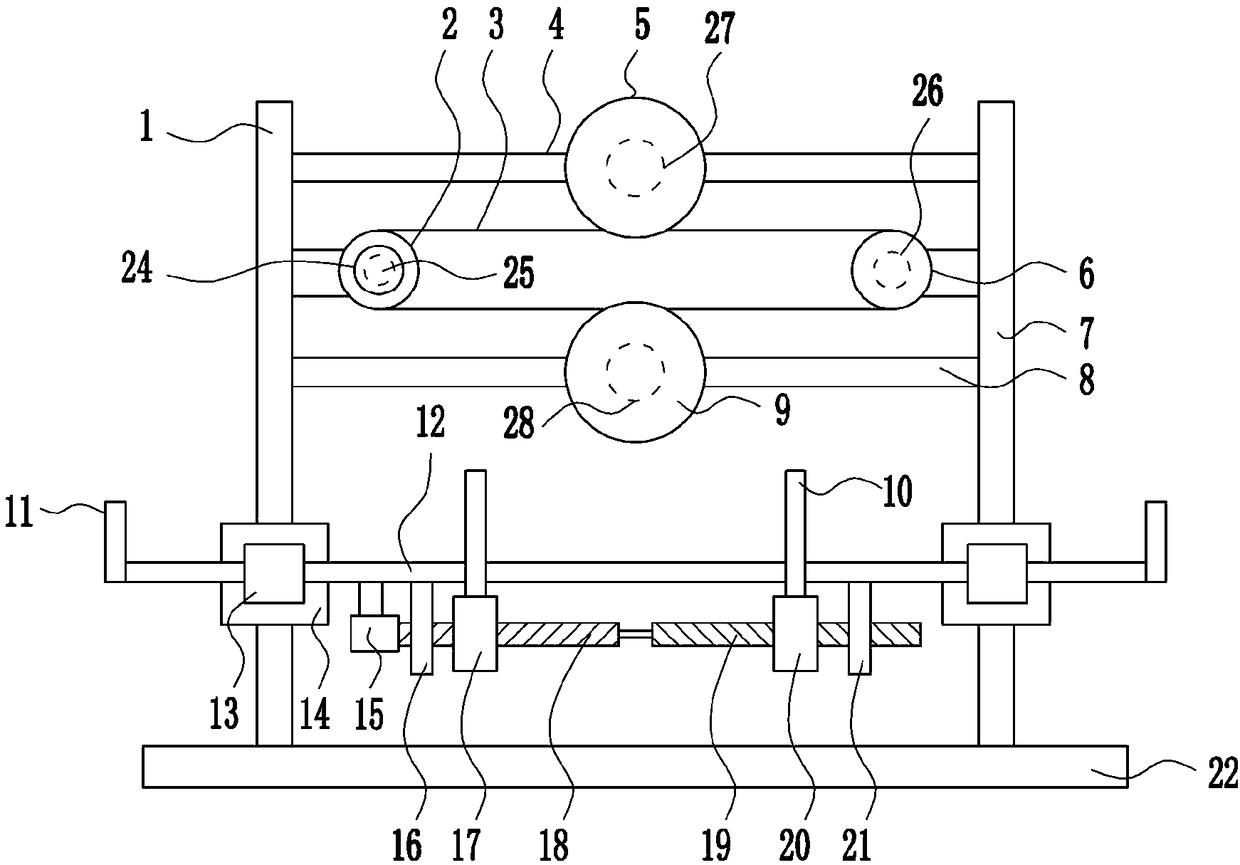

Intelligent production line of medical surgical gown

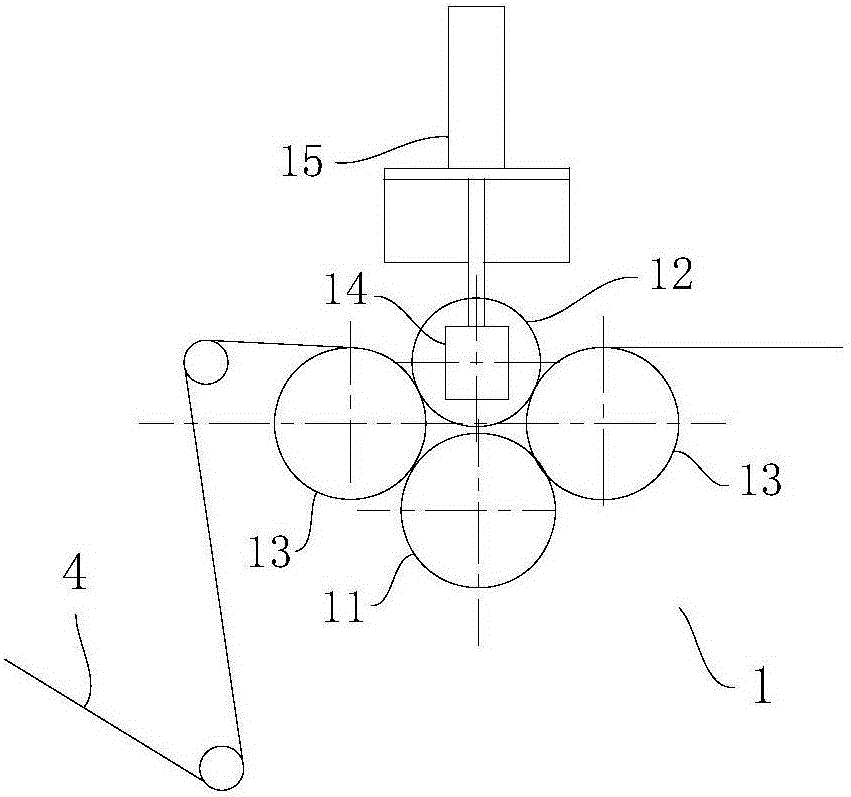

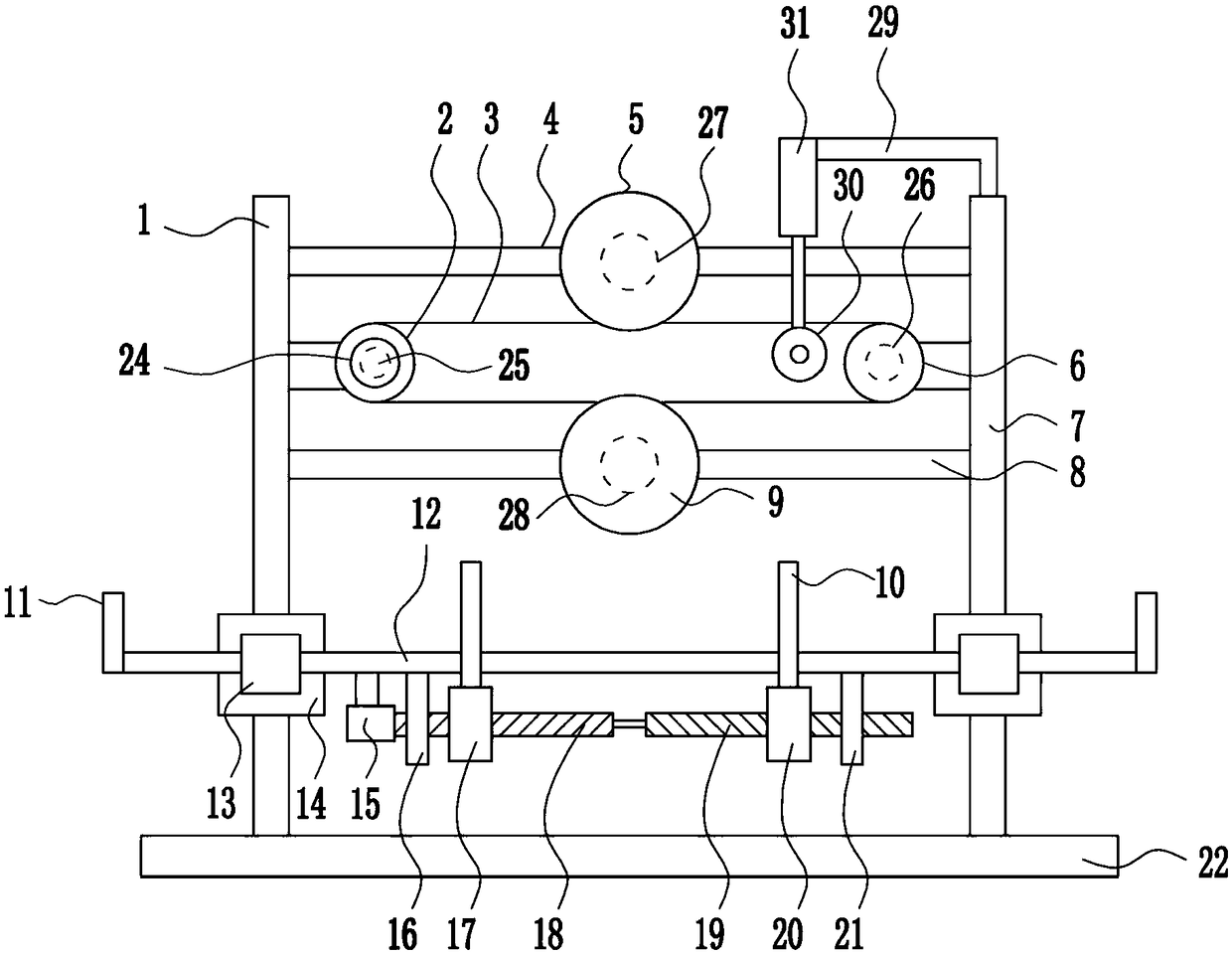

ActiveCN109567293AIncrease productivityImprove product qualityLamination ancillary operationsLaminationProduction linePunching

The invention discloses an intelligent production line of a medical surgical gown, which is characterized by comprising a feeding device, a punching device, a compounding device and a cutting and collecting device, wherein the feeding device, the punching device, the compounding device and the cutting and collecting device are sequentially disposed on a frame along the moving direction of an upperlayer nonwoven fabric and a lower layer nonwoven fabric. According to the intelligent production line, the punching device, the compounding device and the cutting and collecting device are connectedtogether, and the punching, compounding, cutting and collecting of the surgical gown can be automatically completed, thereby improving the production efficiency and quality of the surgical gown.

Owner:INST OF INTELLIGENT MFG GUANGDONG ACAD OF SCI

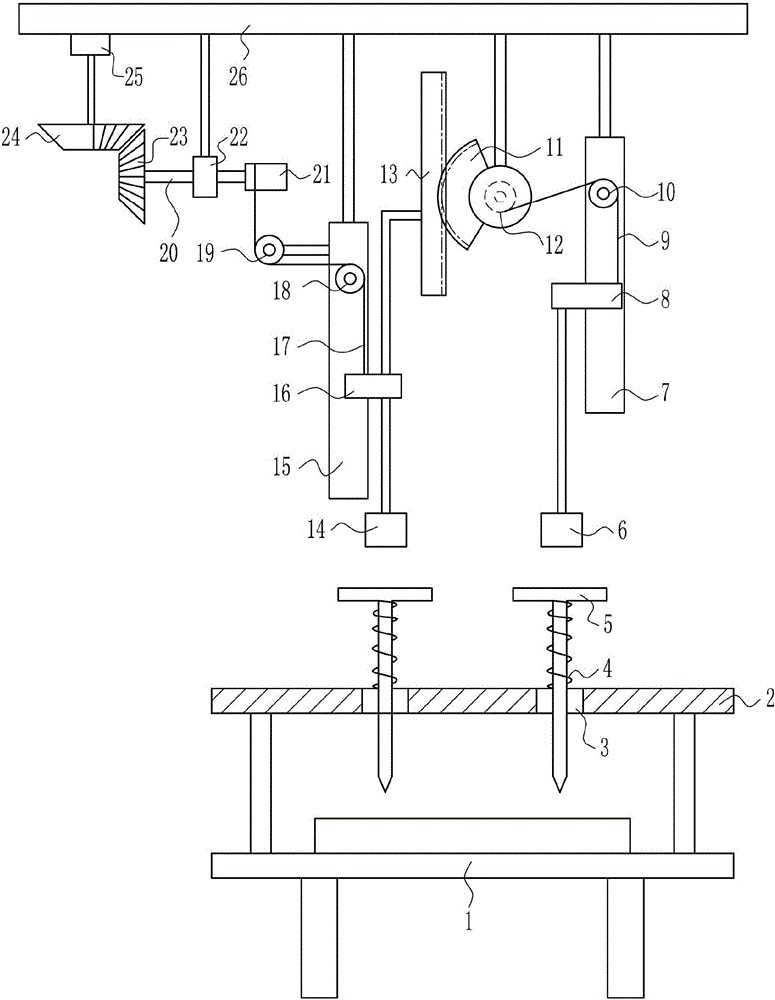

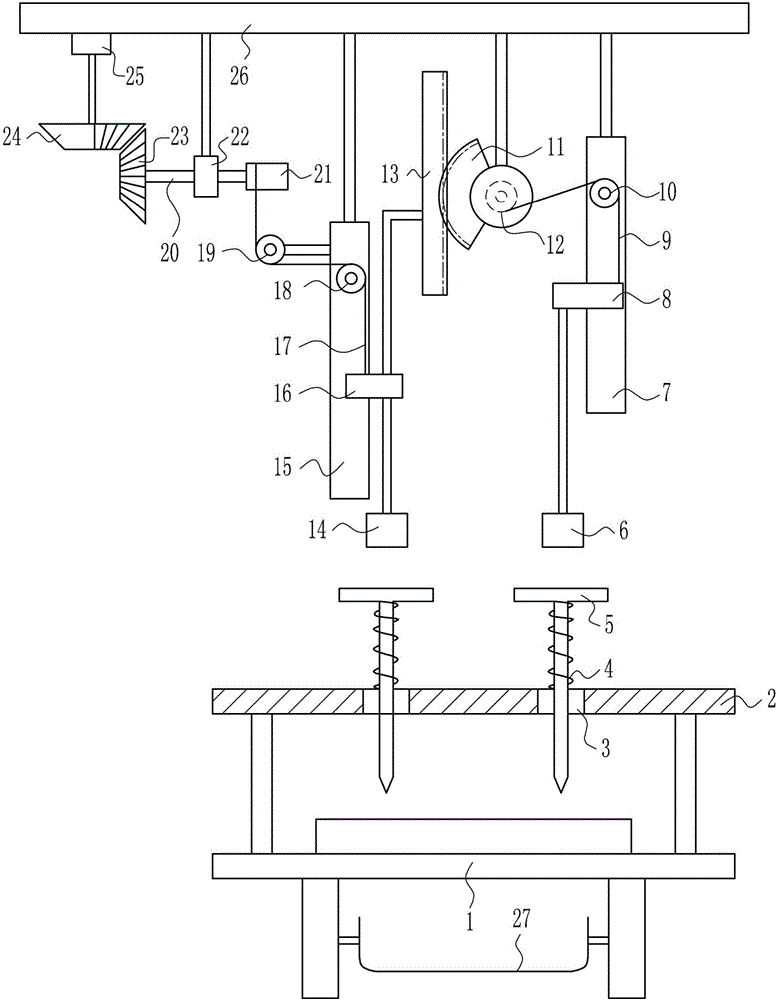

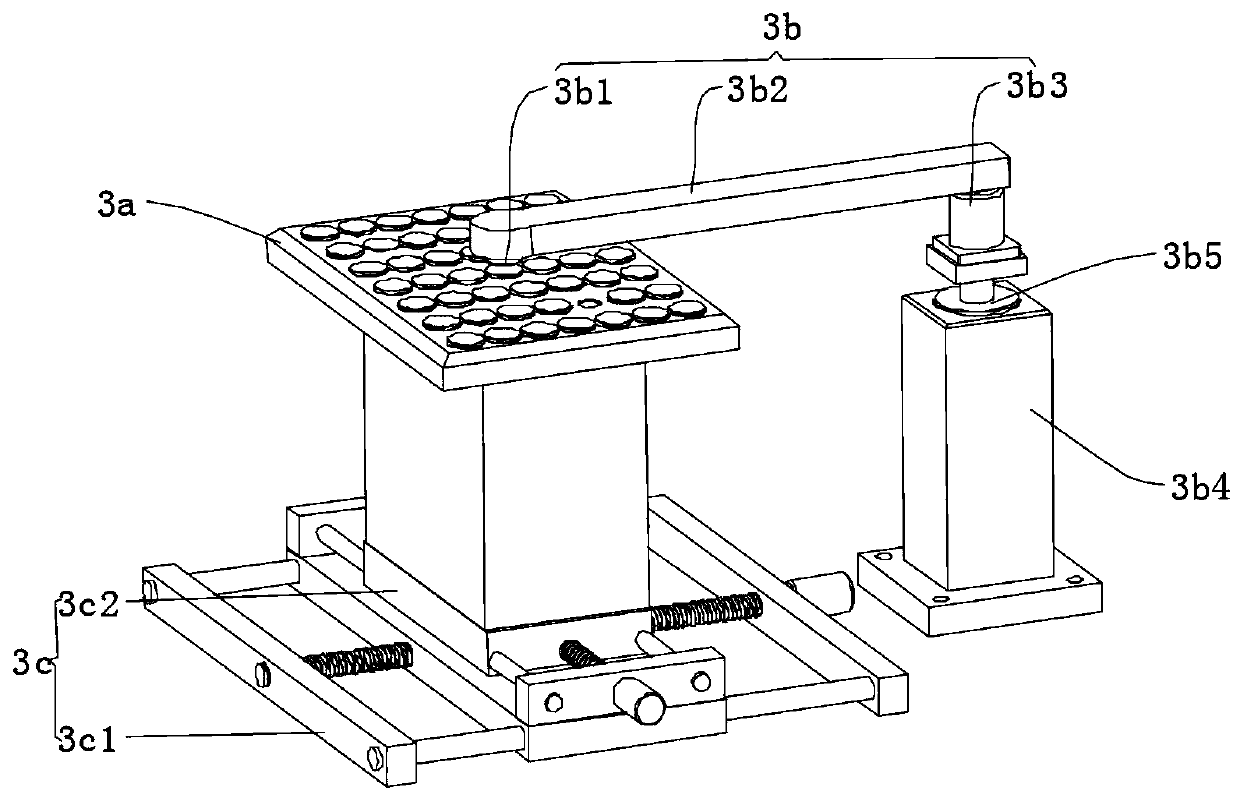

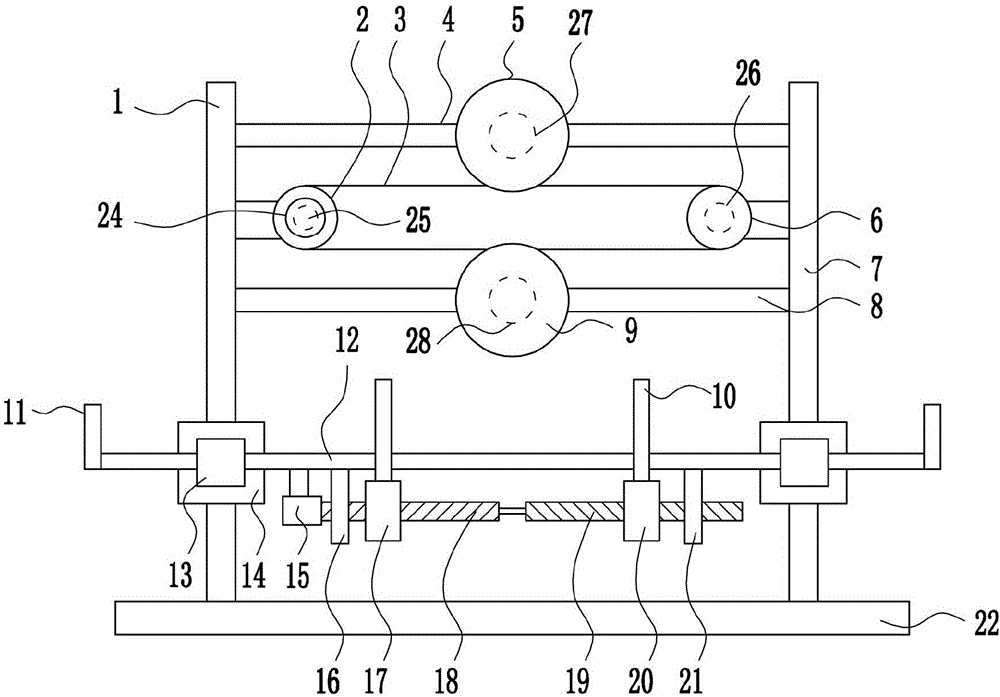

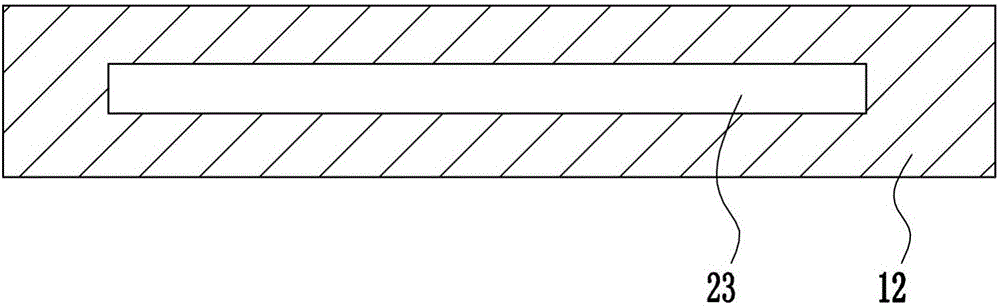

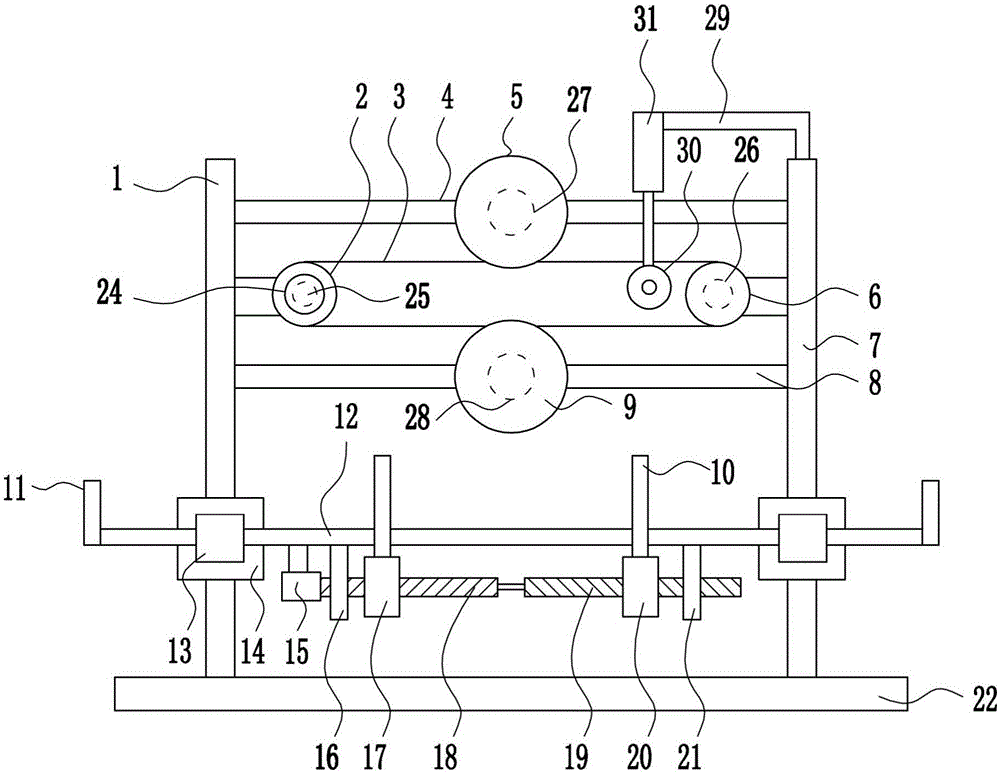

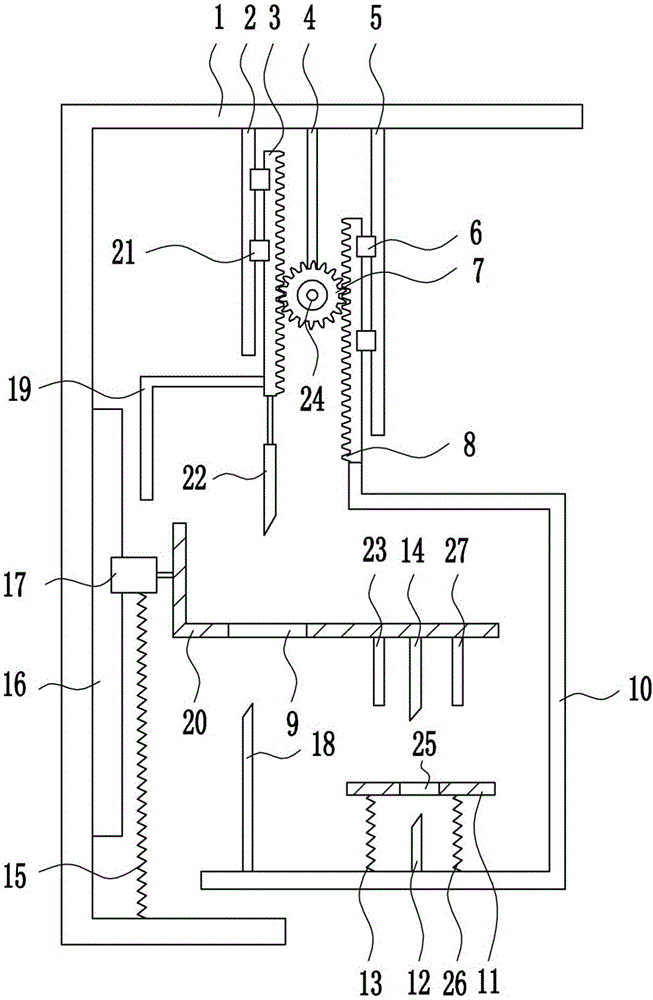

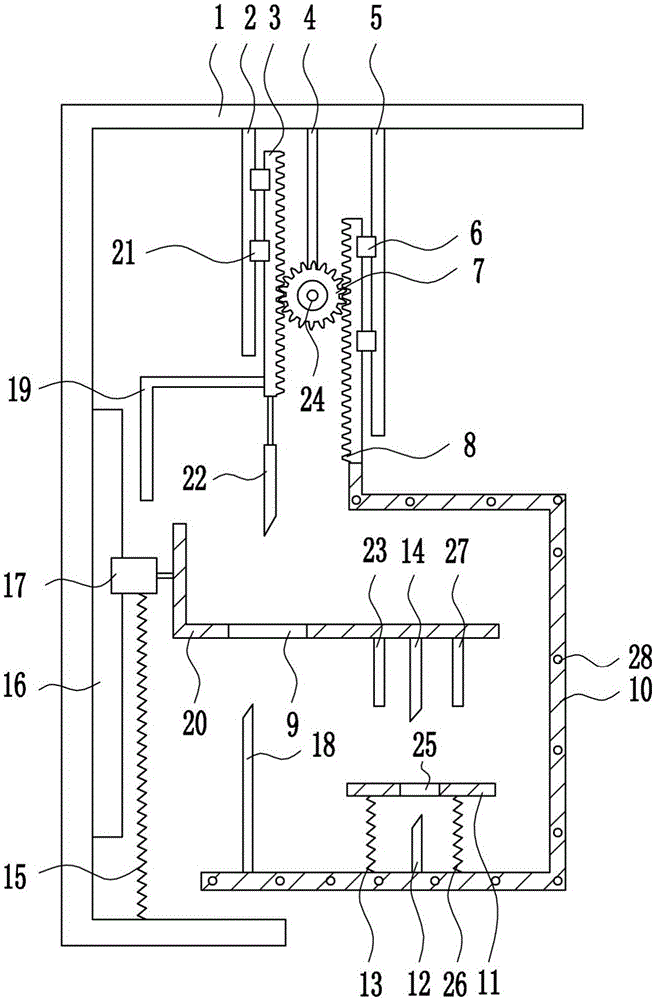

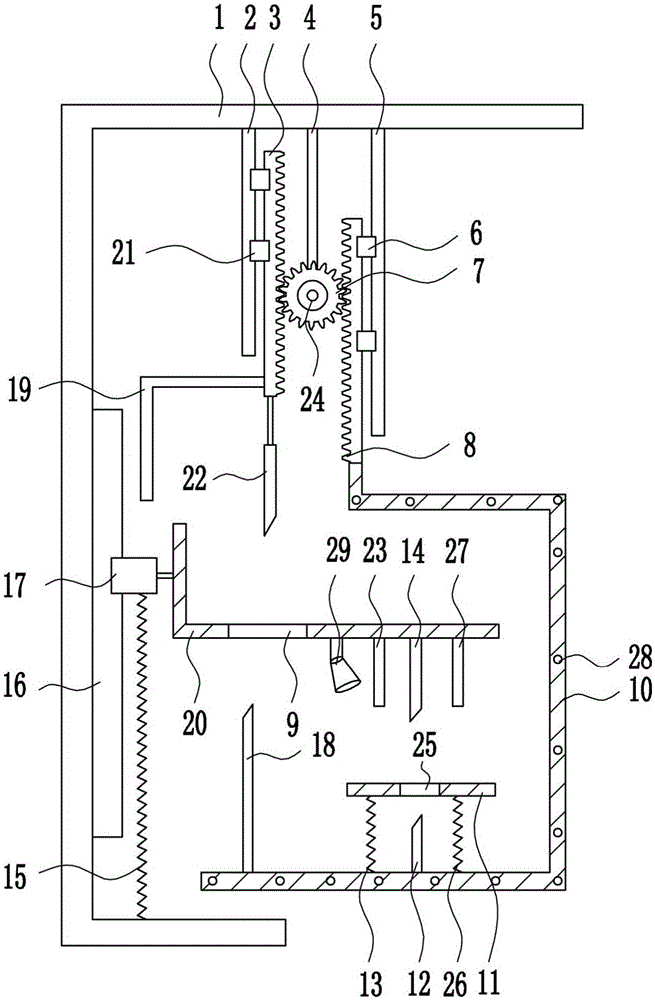

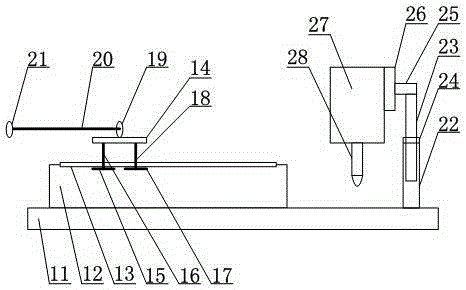

Vamp perforating device for shoe making

InactiveCN106174890AImprove aestheticsIncrease drilling speedShoemaking devicesDesign improvementEngineering

The invention relates to a perforating device, in particular to a vamp perforating device for shoe making. The technical problem to be solved by the invention is to provide the vamp perforating device for shoe making, with the advantages of high perforating speed, good perforating effect and long service life. In order to solve the technical problems, the invention provides such vamp perforating device for shoe making. The vamp perforating device for shoe making comprises a perforating worktable, a guiding plate, springs, perforating rods, a first pressing block, a first sliding rail, a first slide block, a first pull rope, a first roller, a sector gear, a first wire reeling wheel, a rack, a second pressing block, a second sliding rail, a second slide block, a second pull rope, a second roller, a third roller, a rotating rod, a second wire reeling wheel, a bearing base, a first bevel wheel, a nicked bevel wheel and a rotating motor. The vamp perforating device for shoe making achieves the effects of high perforating speed, good perforating effect and long service life; through design improvements, the perforating speed of the vamp perforating device for shoe making becomes very high, but the perforating effect is not changed thereby.

Owner:温州市日翔鞋业有限公司

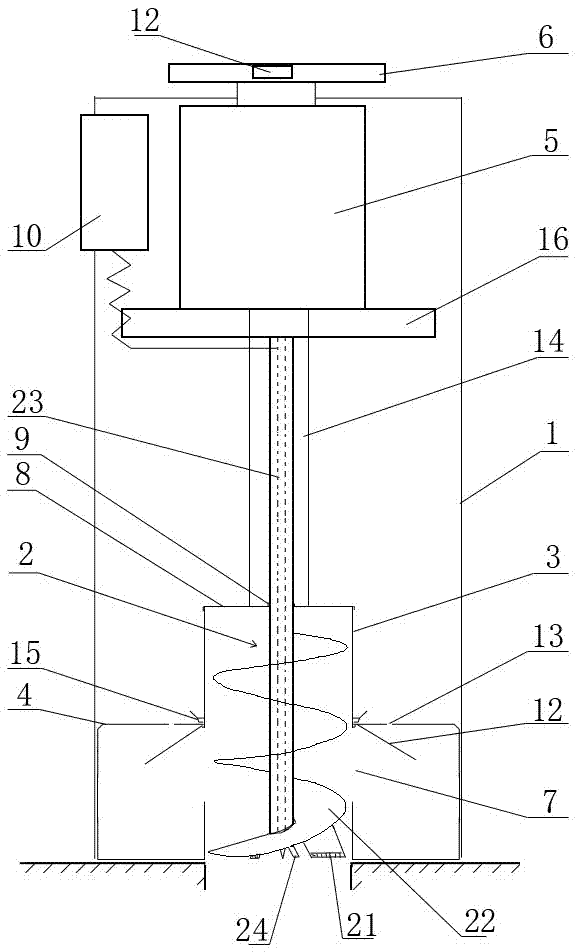

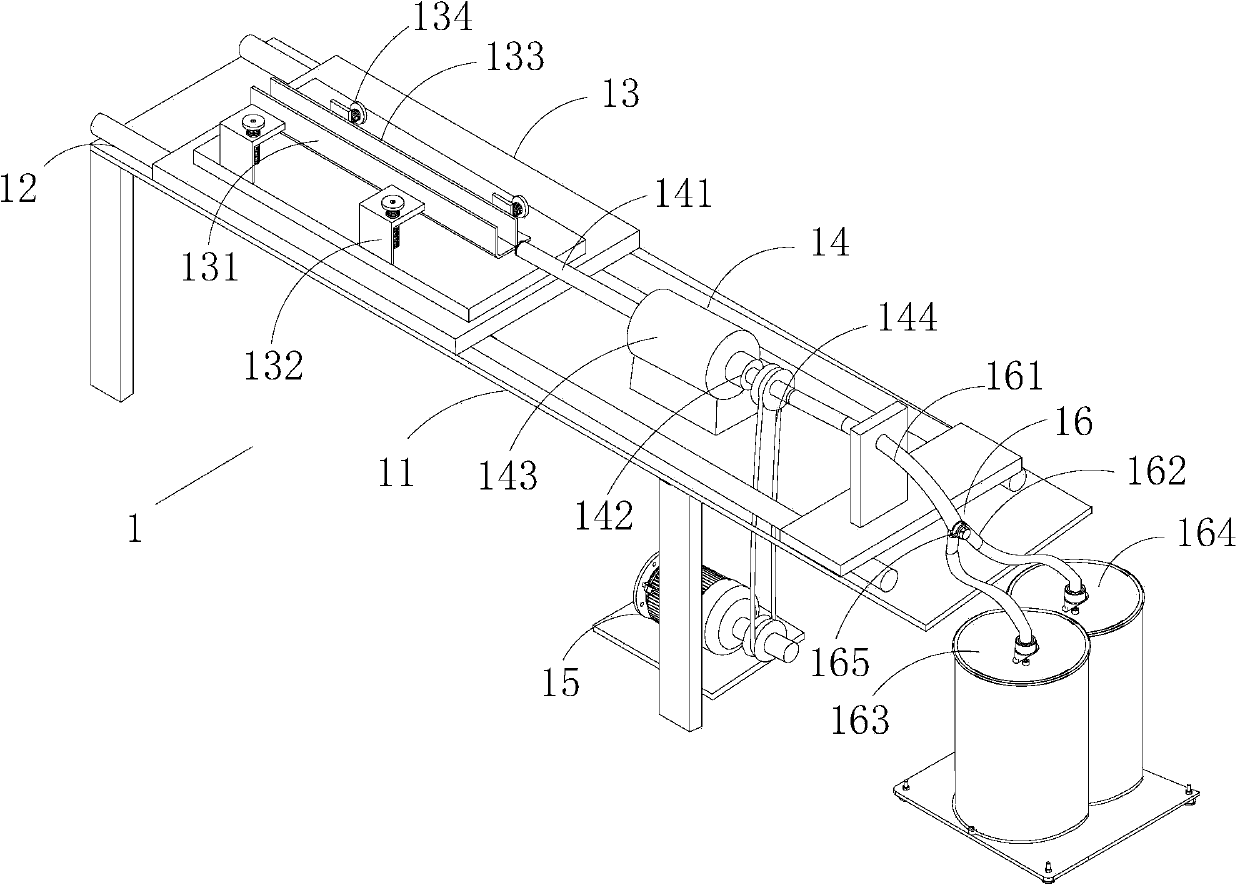

Molding system for sponge pipe

The invention discloses a molding system for a sponge pipe. The molding system comprises a punching system, a peeling system and a control system, wherein the punching system comprises a punching system bracket, a guide rail, a fixed seat assembly, a hollow punching drilling tool assembly and a power assembly; the guide rail is arranged on the punching system bracket; the fixed seat assembly can move along the guide rail; the hollow punching drilling tool assembly is opposite to the fixed seat assembly; the power assembly drives the hollow punching drilling tool assembly; the peeling system comprises a peeling bracket, a peeling guide rail, a peeling tool assembly, a shaft rod transmission supporting seat, a shaft rod locking supporting seat and a positioning shaft rod; the peeling guide rail is arranged on the peeling bracket; the peeling tool assembly is arranged in the middle of the peeling guide rail; the shaft rod transmission supporting seat is arranged at the front end of the peeling tool assembly and can move along the peeling guide rail; the shaft rod locking supporting seat is arranged at the rear end of the peeling tool assembly and can move along the peeling guide rail; the positioning shaft rod is arranged on the shaft rod transmission supporting seat, can penetrate through the peeling tool assembly by mechanical transmission and is positioned on the shaft rod locking supporting seat. By the adoption of the molding system for the sponge pipe, a longer sponge through hole can be punched without compression of sponge, bad situations such as deformation and distortion of an inner hole of the sponge can be avoided, and the molding system is high in punching speed and low in sponge loss.

Owner:东莞市樟木头雅丰海绵制品加工厂

Board punching device

InactiveCN108340446AEasy to fixEasy to useStationary drilling machinesBark-zones/chip/dust/waste removalPunchingEngineering

The invention relates to a punching device, in particular to a board punching device. the board punching device is high in punching speed, and an operator is not prone to being hurt. The board punching device comprises a hollow bottom plate, supporting legs, first sliding blocks, a containing plate, a 7-shaped plate and the like; the supporting legs are arranged at the four corners of the bottom of the hollow bottom plate, sliding grooves are formed in the left and the right of the top of the hollow bottom plate, the first sliding blocks are arranged in the sliding grooves in a sliding manner,the containing plate is arranged on the tops of the first sliding blocks, an opening is formed in the containing plate, the 7-shaped plate is arranged on the right of the hollow bottom plate, and a left and right moving device is arranged on the top inside the 7-shaped plate. Through the left and right moving device, the position of the punching device is adjusted, through the punching device, the board is punched, a fixing device is arranged, and therefore when the board is punched, the board is more stable, and the effects that the punching speed is high, and the operator is not prone to being hurt are achieved.

Owner:余明强

High-property T iron punching device for loudspeaker

ActiveCN110834108AMaximize punching spaceGuaranteed qualityDrilling/boring measurement devicesMetal working apparatusEngineeringLoudspeaker

The invention relates to the technical field of T iron machining, and provides a high-property T iron punching device for a loudspeaker. The high-property T iron punching device comprises a base and further comprises a controller, a loading mechanism, a punching mechanism and a discharging mechanism. The loading mechanism comprises a placing table and a first absorbing assembly, the punching mechanism comprises a rotating disc, a driving assembly and a drilling assembly, the discharging mechanism is arranged on the other end of the top of the base in a through manner to discharge drilled T iron, the discharging mechanism comprises a conveying belt and a second absorbing assembly, the second absorbing assembly is slidingly arranged beside the rotating disc, the conveying belt is arranged onthe end, away from the top of the placing table, of the base, and the first absorbing assembly, the driving assembly and the second absorbing assembly are electrically connected with the controller.According to the loudspeaker high-property T iron punching device, the T iron punching operation space is maximized, the punching efficiency is improved, the yield is increased, meanwhile, it can be effectively ensured that the T iron is not damaged by too large drilling strength, and the T iron quality is ensured.

Owner:嘉兴尚乐机电股份有限公司

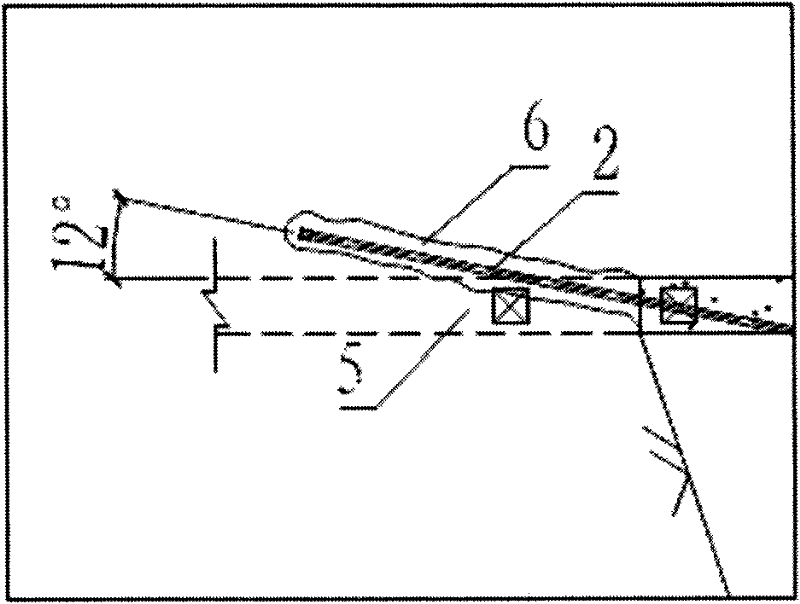

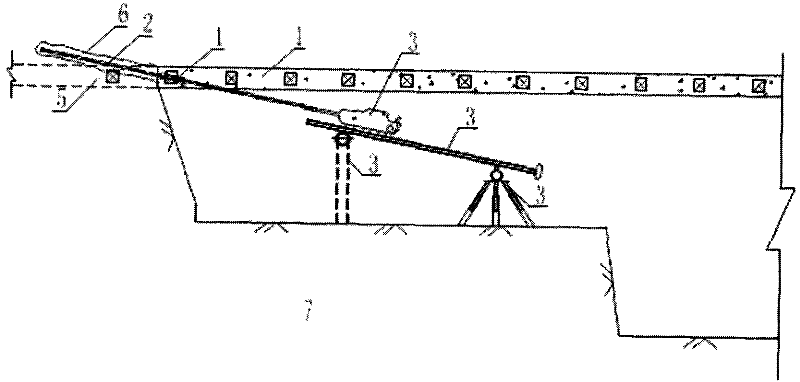

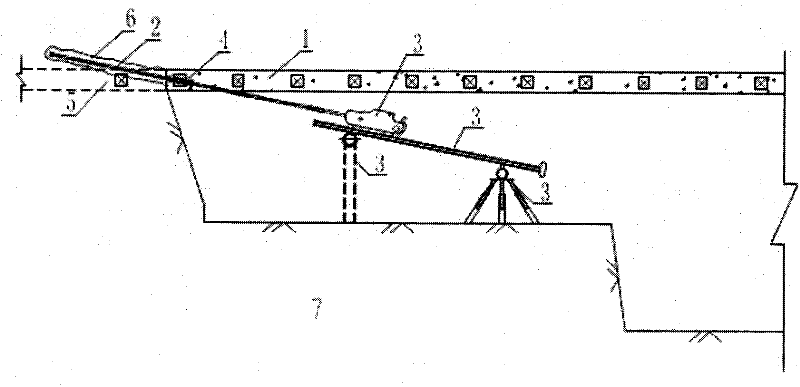

Advanced hole-forming method of sand gravel boulder layer

The invention provides an advanced hole-forming method of a sand gravel boulder layer, comprising the following steps of: during construction, welding a preserved orifice pipe on a former hinged grille according to the design; after spraying concrete on the former hinged grille, splicing a guide tail type heavy pneumatic drill on steps of a tunnel and then mounting a self-advancing hollow groutedbolt on a drilling machine after the splicing is finished; starting the drilling machine and adjusting the height and the angle of the guide tail type heavy pneumatic drill according to the preservedposition; and after all preparations are finished, starting drilling, separating the self-advancing hollow grouted bolt from the guide tail type heavy pneumatic drill after the drilling depth reachesthe requirement and forming a hole. The advanced hole forming method provided by the invention has the characteristic of great impact and drill rod rotating torque and can be used for respectively adjusting the impact energy, the drill rod rotating speed and the torque; the drilling speed is high, thus one hole can be formed within about 2 minutes after the mounting is in place; and the advanced hole forming method ensures that the equipment used in the method has light weight, high mounting in-place and displacing speed, reasonable overall dimension and small occupied space and is not easy to cause the phenomenon of clamping the drill rod in the sand gravel layer and is low in cost and especially suitable for narrow operation places in the pit.

Owner:RANKEN RAILWAY CONSTR GROUP

Tailoring carton rapid punching device

The invention relates to a punching device, in particular to a tailoring carton rapid punching device. According to the technical scheme, the tailoring carton rapid punching device is provided and is high in punching speed. In order to achieve the above technical aim, the tailoring carton rapid punching device comprises a lifting frame, a top plate, a first strut, a second strut, a third strut, a fixed pulley, a sliding rail, a sliding block, a cam, a winding wheel, a rotating motor, a contact wheel and the like; and the top plate is arranged above the base plate, the lifting frame, the first strut, the second strut and the third strut are sequentially arranged on the bottom of the top plate from left to right, the fixed pulley is arranged at the bottom end of the second strut, the sliding rail and a guide rod are arranged on the left side of the third strut, the sliding rail is located above the guide rod, and the sliding block is arranged on the sliding rail. The tailoring carton rapid punching device has the effects of being high in punching speed, high in punching efficiency, simple in device operation, long in service life of the device and high in strength of the device; and in addition, strengthening ribs are arranged.

Owner:中山市永隆纸箱有限公司

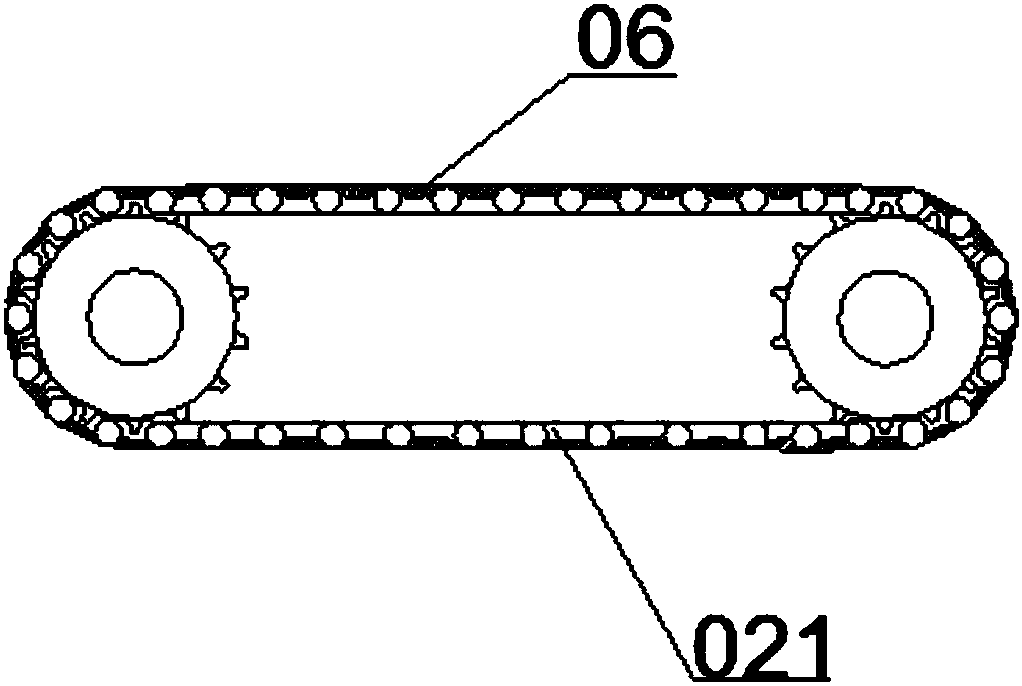

Thermal perforating device for plastic film

InactiveCN106078905AAdjustable widthWide range of perforation thicknessMetal working apparatusTransport systemPlastic film

The invention discloses a thermal perforating device for a plastic film. The thermal perforating device for the plastic film comprises a needle roll, a rubber roll and film supporting rolls, wherein the needle roll is a hollow roll; a plurality of needle components are arranged on the surface of the needle roll in the radial direction; a heating assembly is arranged inside the needle roll; heat is conducted to the needle components; the rubber roll is opposite to the needle roll; and the rubber roll and the film supporting rolls form a plastic film winding and conveying system. An unwinding device and a winding device are respectively arranged in the front and at the rear of the perforating device, the unwinding device is provided with a complete plastic film unwinding roll, a complete plastic film is fed into the perforating device and passes through space between the rubber roll and the needle roll of the perforating device, hot melting perforating is realized by the heated needle components on the needle roll, the winding device is provided with a perforated plastic film winding roll, and the plastic film which is perforated by the perforating device is wound on the winding roll. The thermal perforating device for the plastic film is simple in structure and easy to operate, a perforating density adjustment range is large, the plastic film is perforated by hot melting, penetration rate of holes is high, the film is not pulled during perforating, and therefore, the physical properties of the film are not affected.

Owner:湖南圣华节水科技股份有限公司

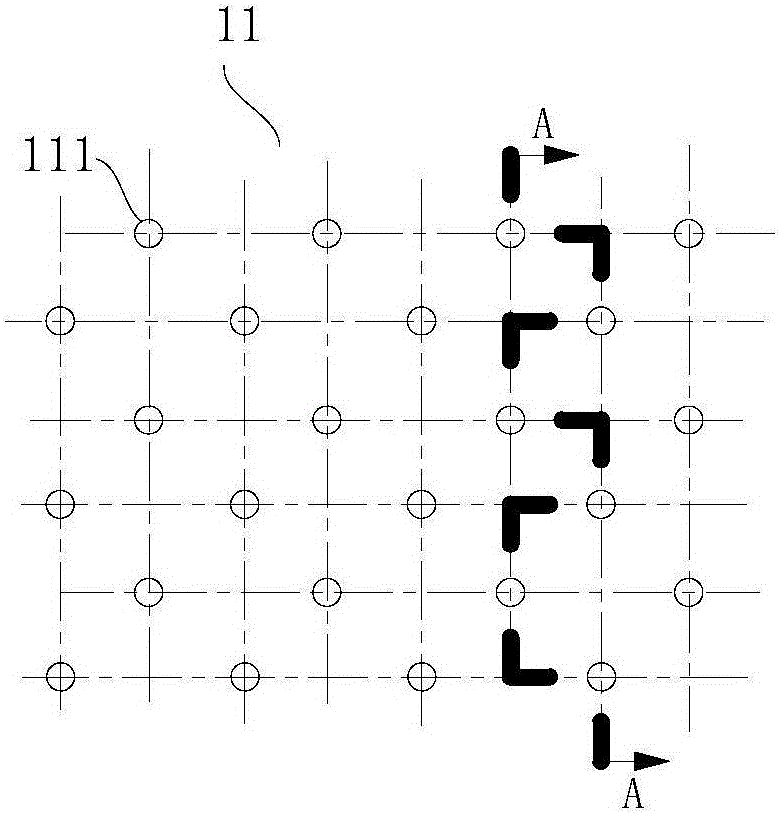

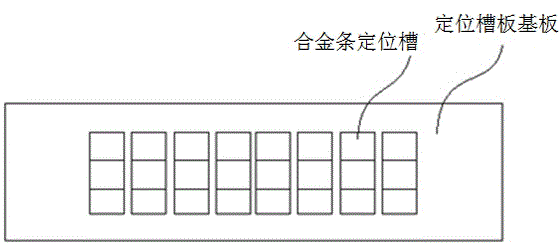

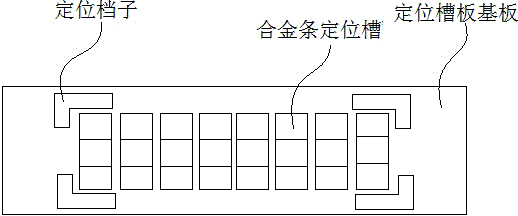

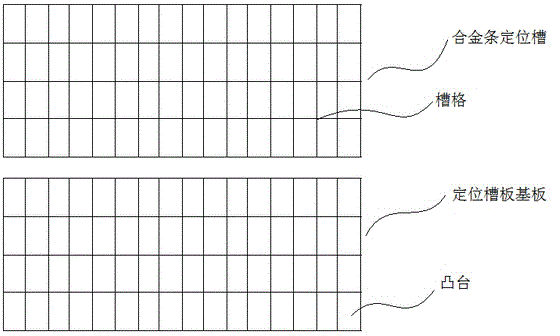

Single-face bonding method suitable for hard alloy strips in hard alloy hard-face machining process and application

ActiveCN104976201APrecise processing sizeHigh speedFastening meansWelding apparatusAdhesive beltAlloy

The invention provides a single-face bonding method suitable for hard alloy strips in a hard alloy hard-face machining process and application. A locating groove plate for bonding is scientifically designed, the hard alloy strips are placed on the locating groove plate, the hard alloy strips are bonded through punched single-face adhesive tape, and the hard alloy strips or blocks are fixed through spot welding; and then the adhesive tape is placed on a steel surface of a to-be-machined component, and through spray welding, bead weld and grinding, the steel surface is machined into a hard surface. According to the method, the aim that a large number of hard alloy strips are bonded at a time is simply and easily achieved, the bonding efficiency is greatly improved, and the conditions that due to manual operation, the bonding angles are different, and the bonding intervals are uneven are avoided; the bonding precision is improved, and wear resistance of the product hard surface can be effectively ensured and improved; and the method can be well applied to the aspect of hard-face machining of centering guides or TC bearings of drilling tools or screw drilling tools.

Owner:株洲金韦硬质合金有限公司

Efficient hardware sheet punching device

ActiveCN106583785AConvenient punching workImprove work efficiencyStationary drilling machinesFeeding apparatusPunchingEmbedded system

The invention relates to a punching device, in particular to an efficient hardware sheet punching device and aims at achieving the technical purpose of providing the efficient hardware sheet punching device high in punching efficiency, high in punching speed and high in practicability. To achieve the above technical purpose, the efficient hardware sheet punching device is provided and comprises a left frame, a first belt wheel, a flat belt, a first connecting rod, a third belt wheel, a second belt wheel, a right frame, a second connecting rod, a fourth belt wheel, a stop block and the like. The right side of the top of the base is connected with the right frame. The first connecting rod is connected between the upper portion of the right side of the left frame and the upper portion of the left side of the right frame. The third belt wheel is connected to the middle portion of the first connecting rod. The third belt wheel is connected with a third drill rod. The efficient hardware sheet punching device achieves the effects of the high punching efficiency, the high punching speed and the high practicability, and when punching work needs to be conducted on a hardware sheet, the work efficiency of the whole hardware sheet punching work can be improved by using the device.

Owner:东莞松柏电子五金有限公司

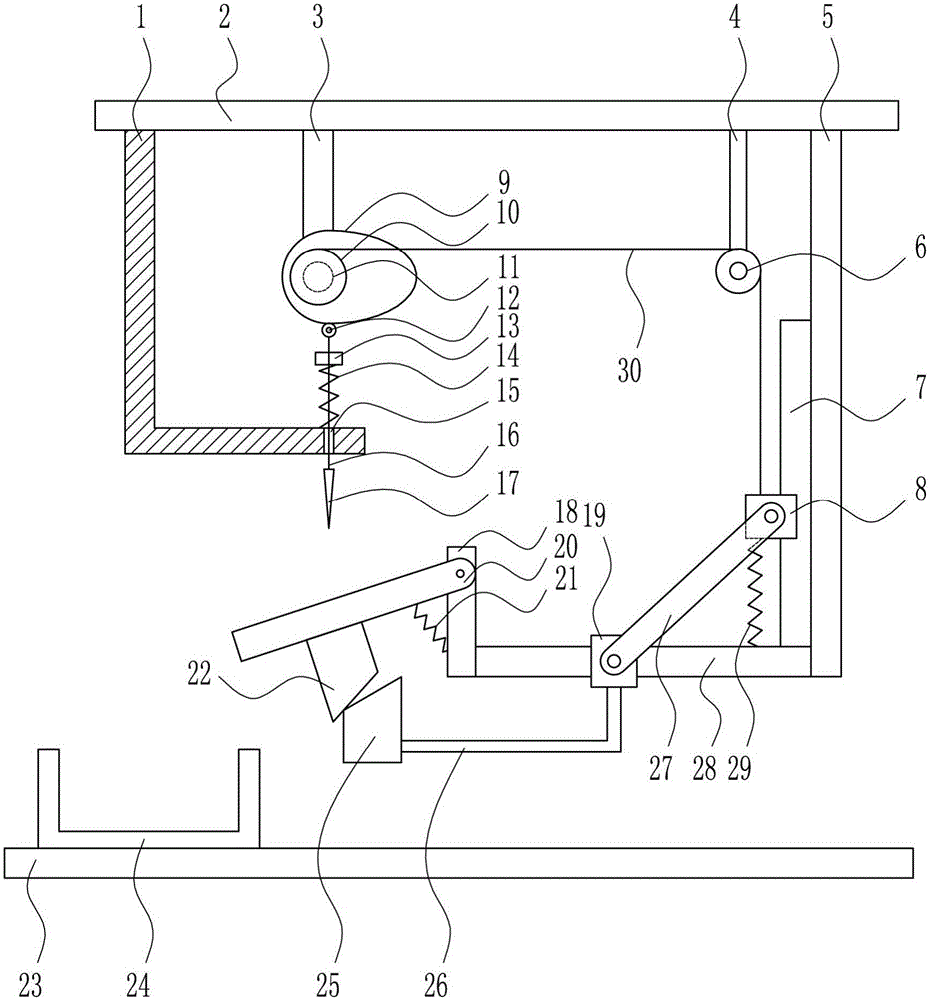

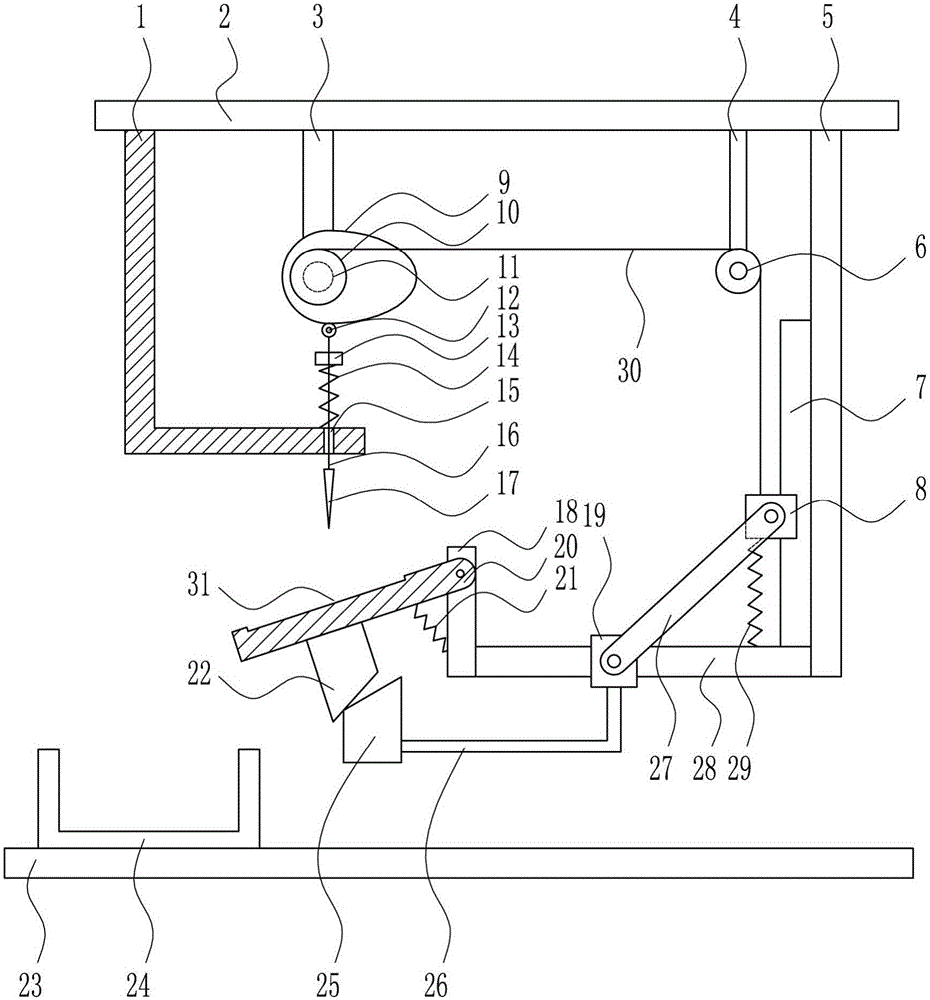

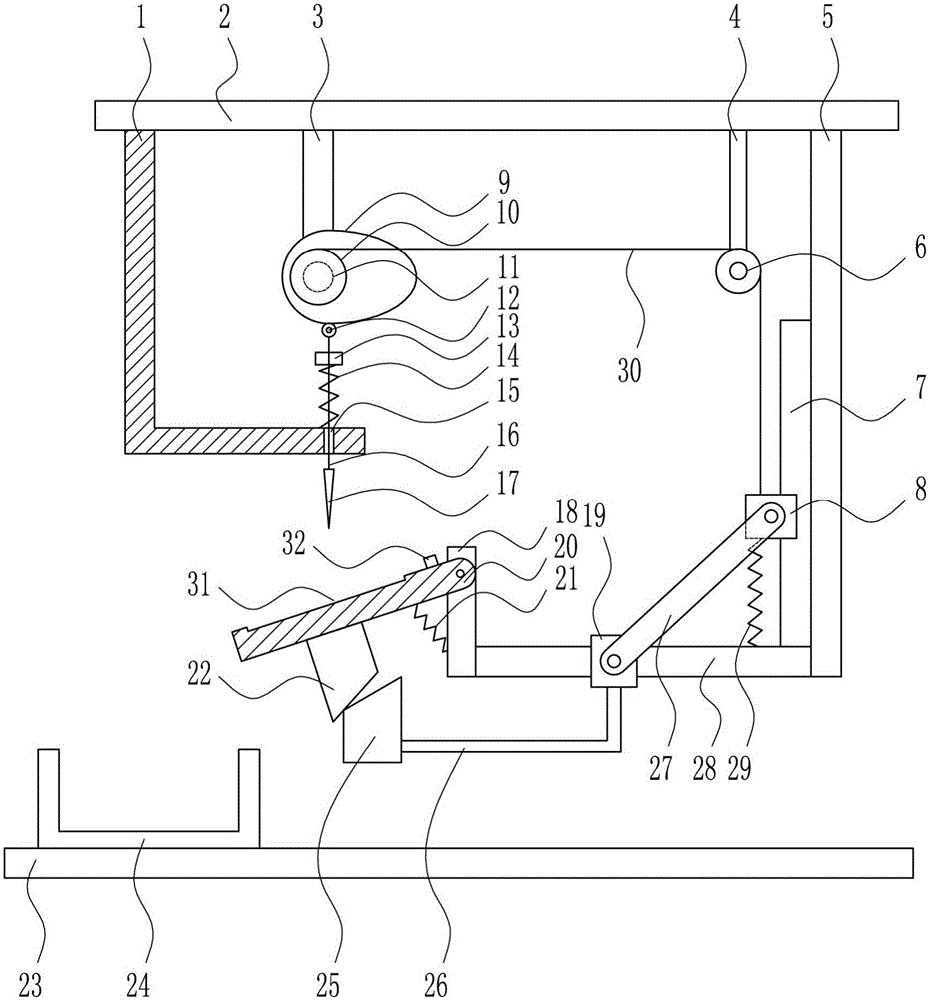

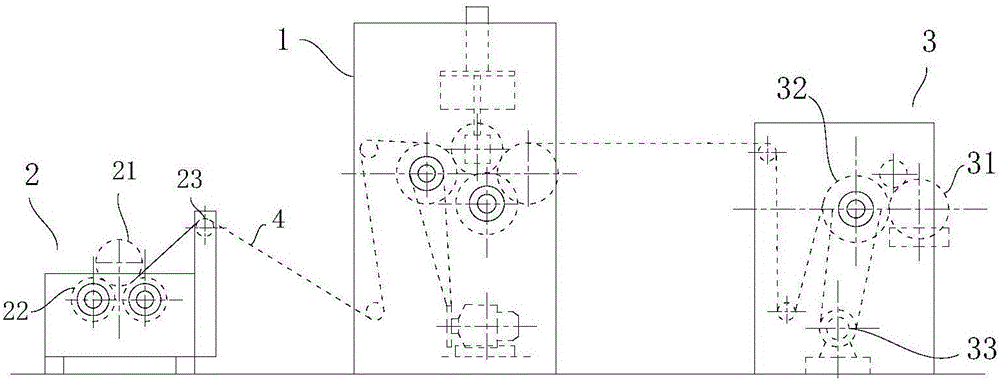

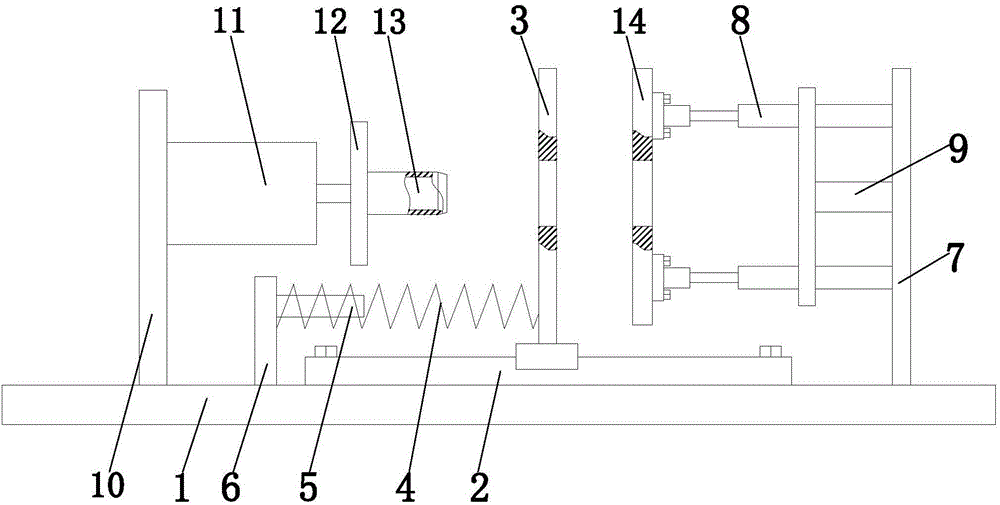

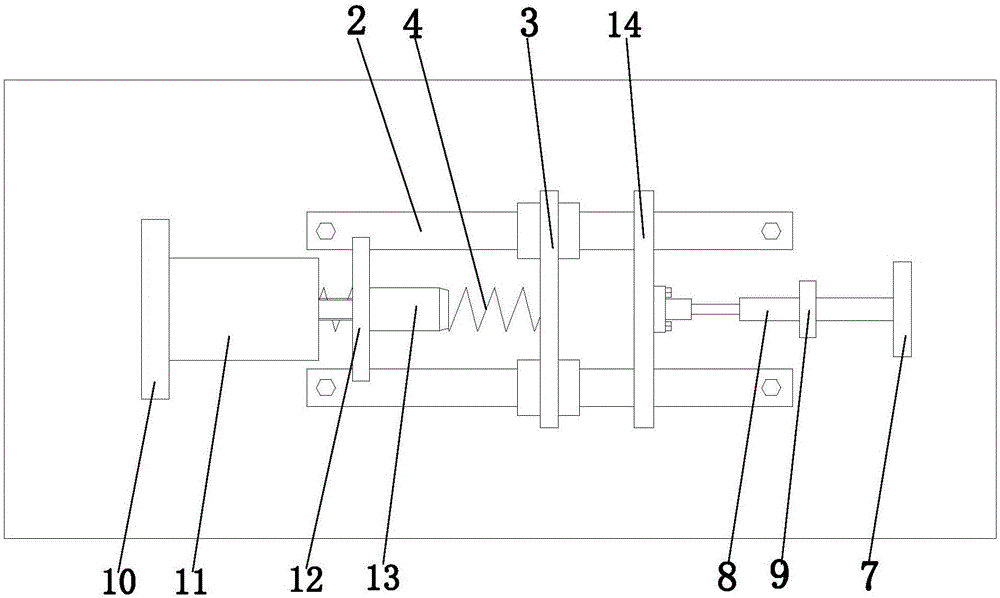

Rapid punching device for shoebox for shoemaking

The invention relates to a punching device, in particular to a rapid punching device for a shoebox for shoemaking. The invention aims to solve the technical problem of providing the rapid punching device for the shoebox for shoemaking which is high in punching efficiency. For solving the above technical problem, the rapid punching device for the shoebox for shoemaking is provided. The rapid punching device comprises a support, a first slideway, a first rack, a first connection rod, a second slideway, second sliding blocks, a gear, a second rack, a second connection rod, a placement plate, a second electric drill, a first spring, a first electric drill, a second spring, a third slideway, a third sliding block, a third electric drill, a first pushing rod and the like, wherein the first slideway, the first connection rod and the second slideway are sequentially arranged on the top in the support. According to the rapid punching device, the shoe box on an L-shaped support rod are punched through a fourth electric drill and the third electric drill, and the shoe box on the placement plate is punched through the first electric drill and the second electric drill, so that punching speed is enhanced.

Owner:浙江芙蓉印务有限公司

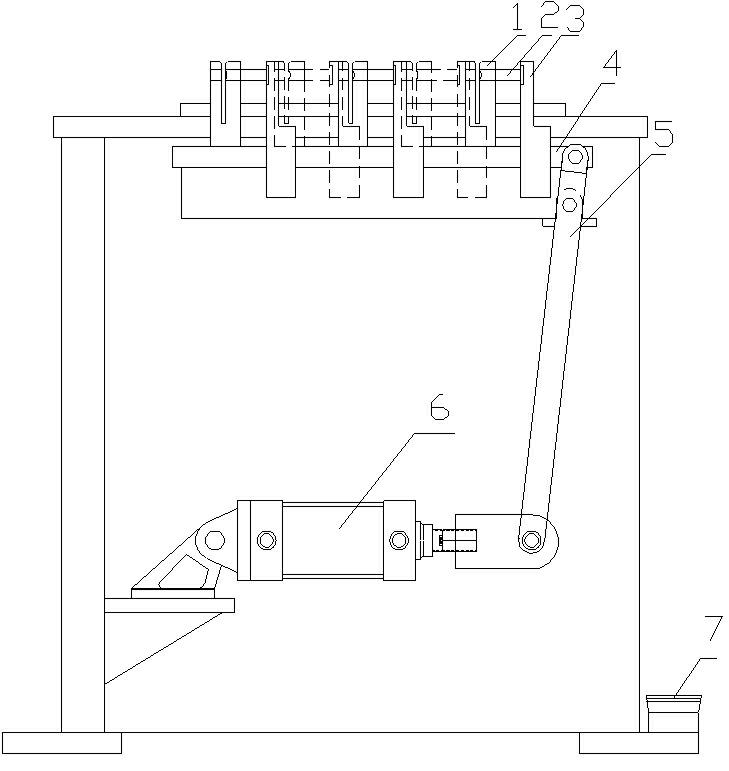

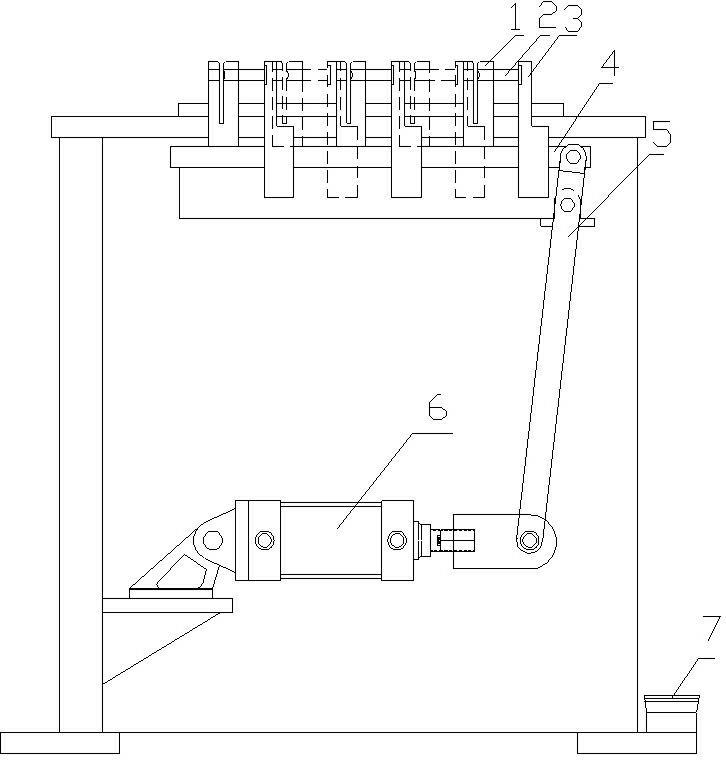

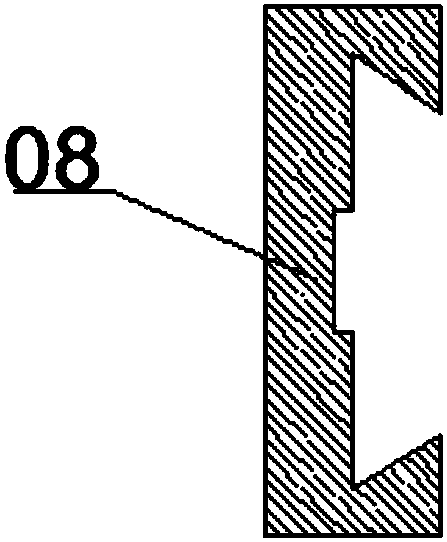

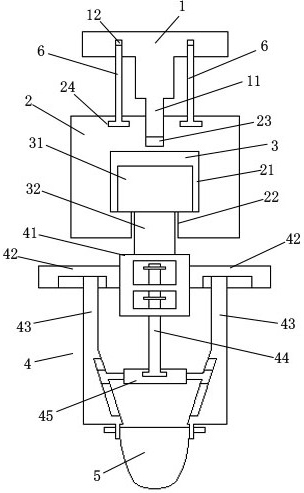

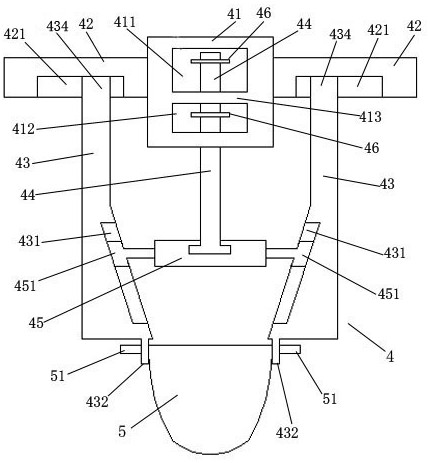

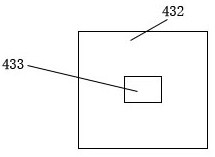

Perforating device of lead acid storage battery shell

The invention discloses a perforating device of a lead acid storage battery shell. A cylinder (6) is installed at the bottom of a machine frame (7). The piston rod of the cylinder (6) is connected to one end of a lever (5). The other end of the lever (5) is connected to a mould sliding block (4). The mould sliding block (4) is movably installed on the top of the machine frame (7). A set of mould movable blocks (3) is installed on the mould sliding block (4). A perforating cutter (2) is installed on each mould movable block (3). A set of mould fixed blocks (1) is installed on the top of the machine frame (7). Guide holes are arranged on the mould fixed blocks (1). The guide hole of each mould fixed block (1) corresponds with one perforating cutter (2). According to the perforating device of the lead acid storage battery shell disclosed by the invention, the device is used for integrally locating and perforating at one time in a lever manner; the process is reliable and rapid; and the direct push perforating manner by locating one by one of a membrane cylinder is avoided, therefore, the device has the advantages of less burrs after perforating a product, higher consistency, simplified process and low cost.

Owner:JIANGSU LEOCH BATTERY

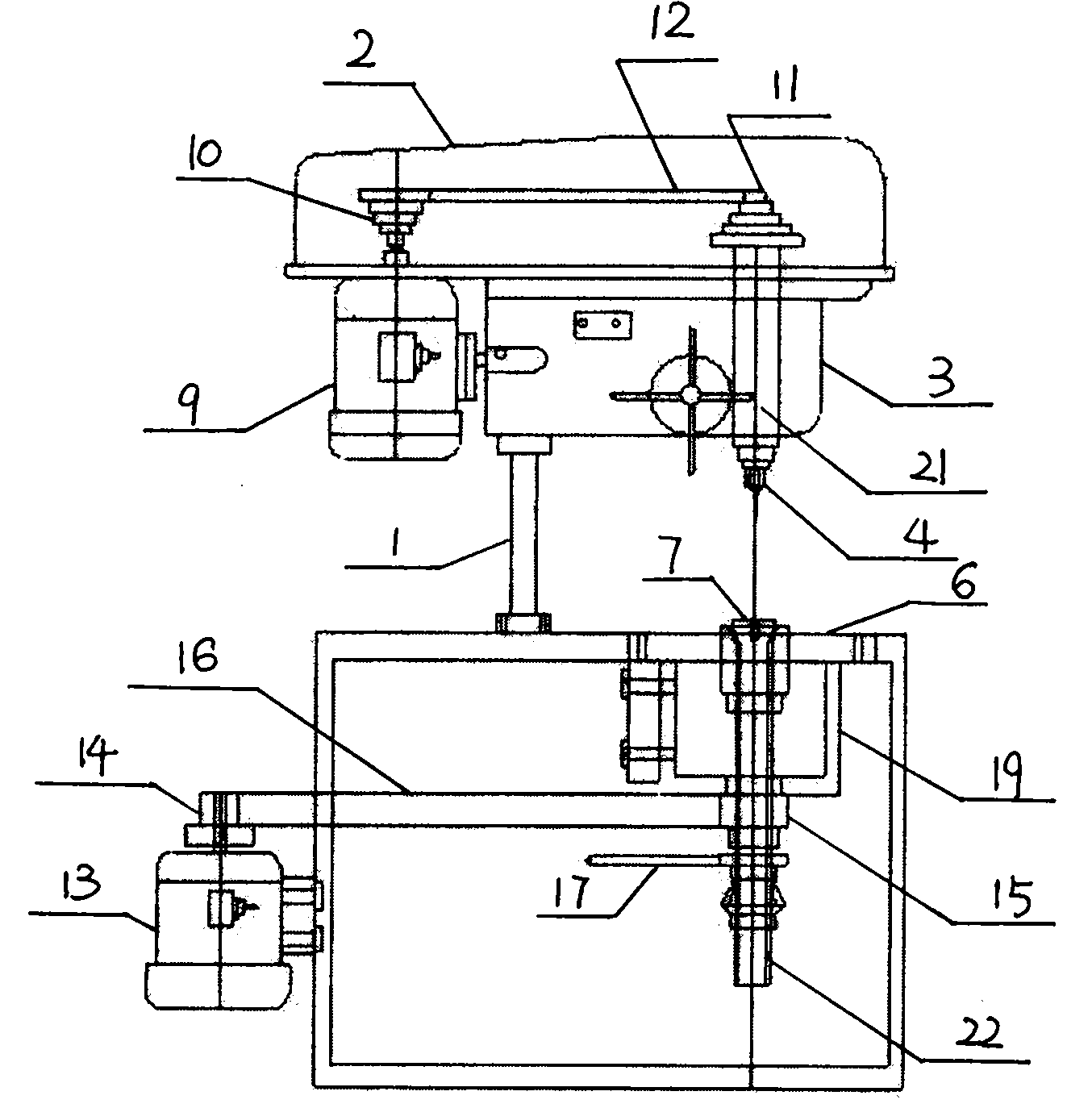

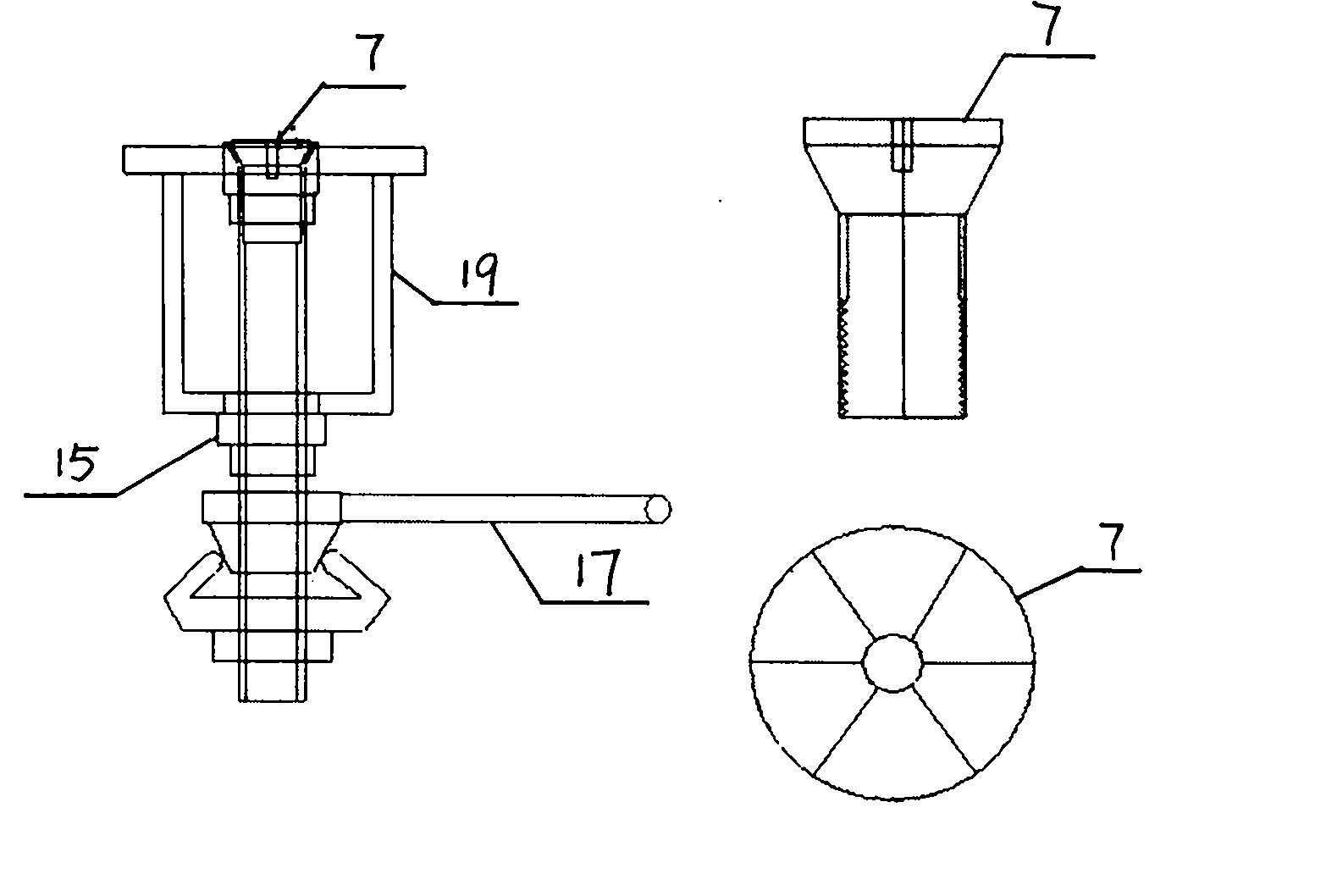

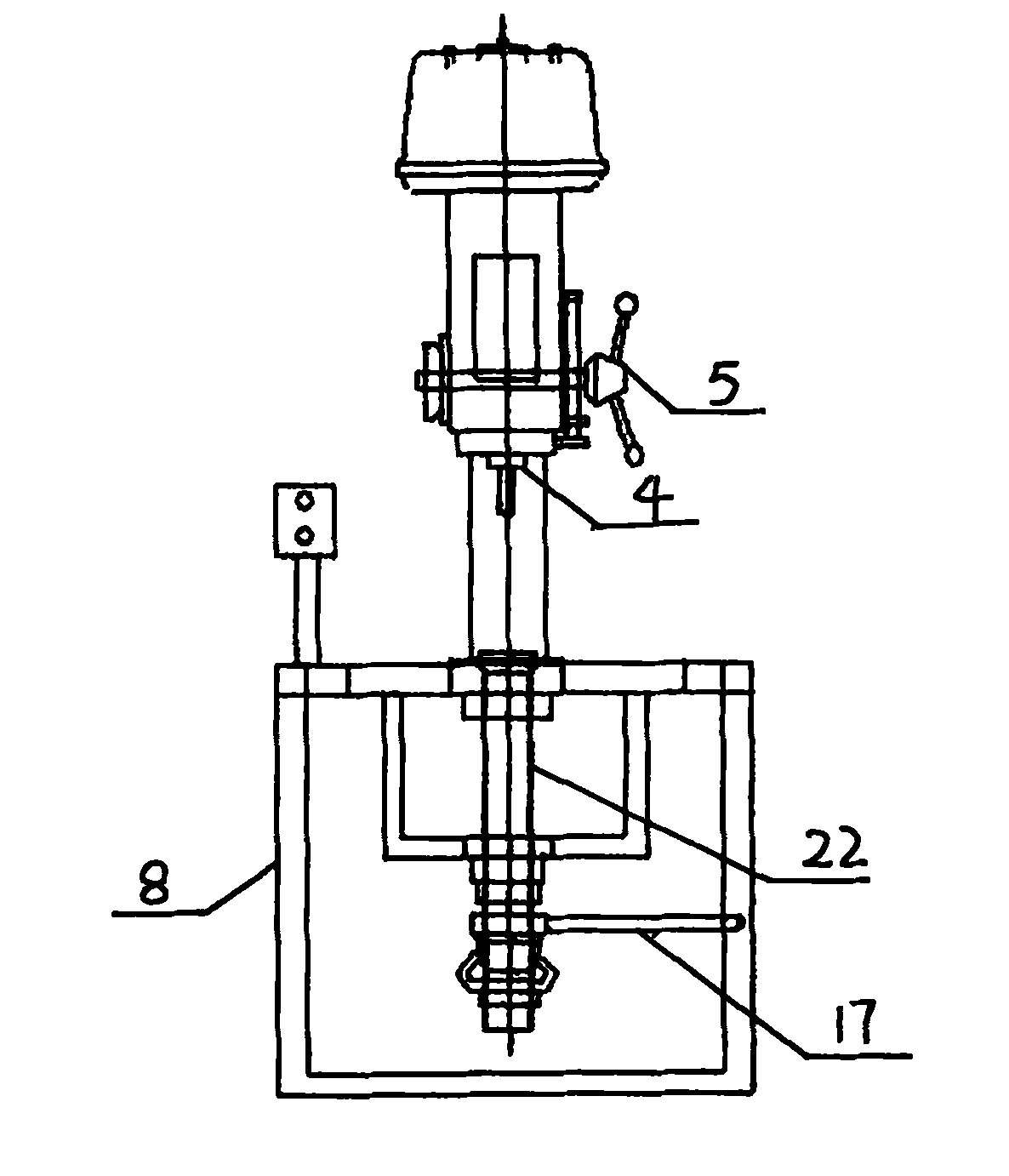

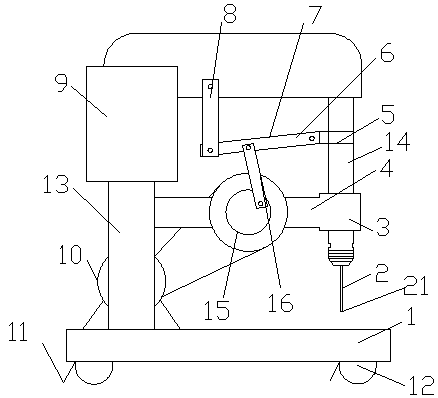

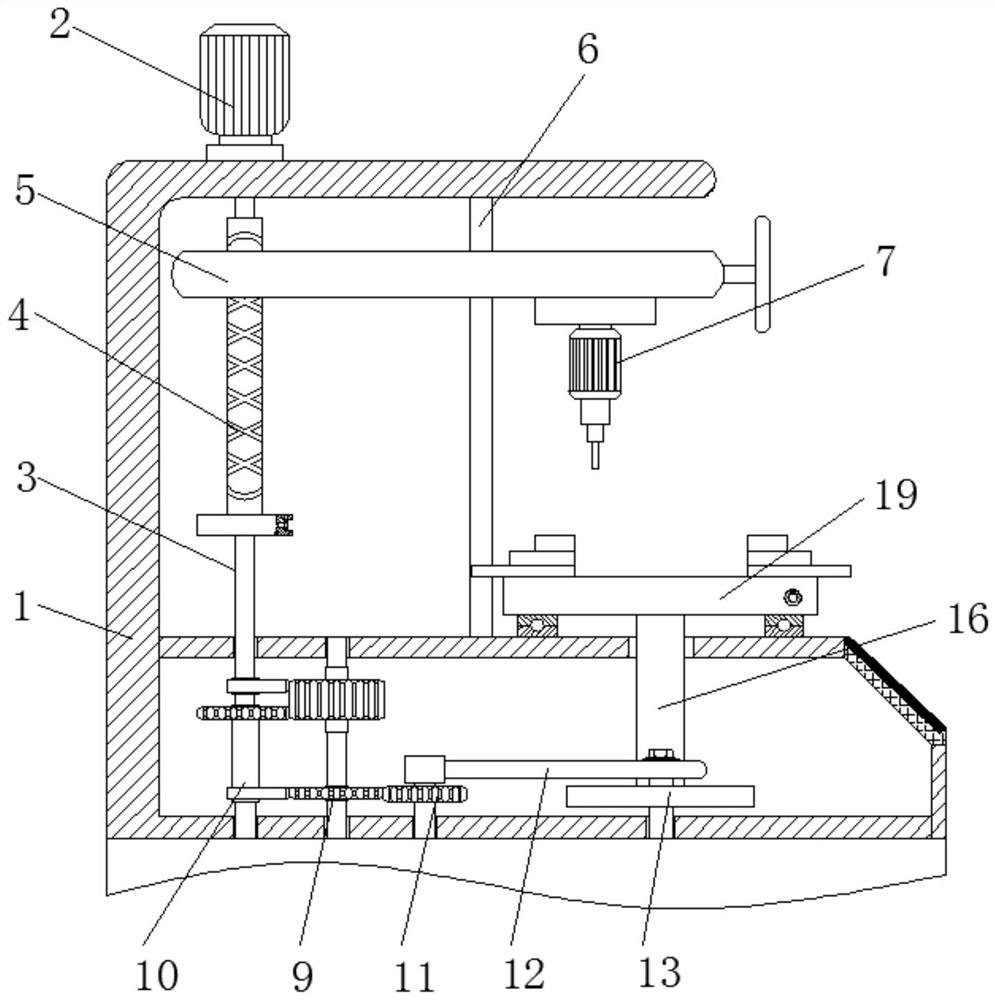

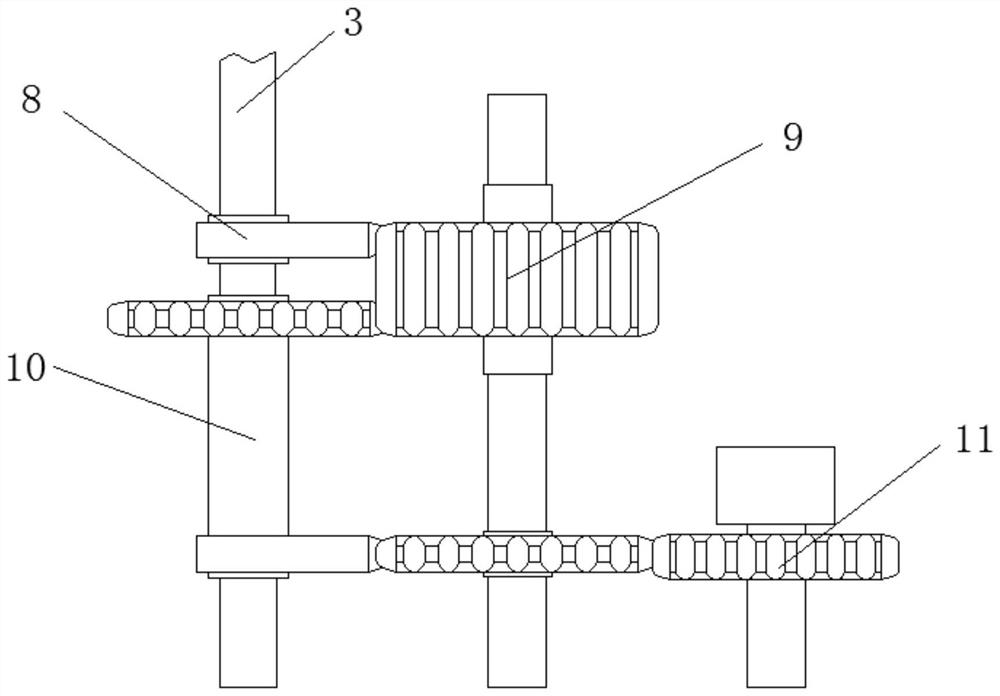

Leftward/rightward rotating punching machine

InactiveCN101982268AFast punchingPrecise punchingLarge fixed membersPositioning apparatusPunchingEngineering

The invention relates to a leftward / rightward rotating punching machine, comprising an upper body, a supporting part and a lower body, wherein the supporting part is connected between the upper body and the lower body. The punching machine is characterized in that the upper body comprises an upper housing, a punching part, a wrench and a power mechanism 1; the punching part comprises a spindle 21, a chuck and a drill; the chuck is positioned at the front end of the spindle 21 and is used for fixing the drill; the wrench is connected with the punching part and is used for pushing the punching part; the power mechanism 1 is connected with the punching part and is used for providing power for rotation of the punching part; the lower body comprises a stage, a spindle 22 and a power mechanism 2, wherein the stage comprises a clamping device; the clamping device is positioned on the stage and is used for clamping the workpiece; the spindle 22 is connected with the clamping device on the stage; the power mechanism 2 is connected with the spindle 22; when the punching machine punches holes, the punching part rotates; and meanwhile, the spindle 22 drives the clamping device to further drive the workpiece to rotate oppositely relative to the punching part.

Owner:JINFANGTONG WELDING EQUIP LUTAI ECONOMIC DEV ZONE

Progressive type hole punching device

InactiveCN106541016AFast punchingAchieve progressive advancementPerforating toolsMetal-working feeding devicesMechanical engineeringEngineering

The invention provides a progressive type hole punching device. The progressive type hole punching device comprises an operation table which is provided with a material conveying pipeline; the material conveying pipeline is provided with a material conveying channel in the axial direction; the upper side wall of the material conveying pipeline is provided with a sliding groove; a movable base is arranged above the material conveying pipeline; a suction piece is arranged below the sliding groove and is connected with the bottom of the movable base through a connecting rod; the operation table is provided with a guiding pipe; a lifting pipe is arranged in the guiding pipe in a sleeved manner; the end portion of the lifting pipe is provided with a connecting pipe; the end portion of the connecting pipe is provided with a fixing plate which is provided with an automatic hole punching machine; and the automatic hole punching machine is provided with an automatic hole punching head which is arranged above the operation table. By means of the progressive type hole punching device, an article is propelled to the position below the automatic hole punching machine, and the automatic hole punching machine can conveniently perform fast hole punching treatment on the article through the automatic hole punching head.

Owner:TIANJIN YUEFENG TECH

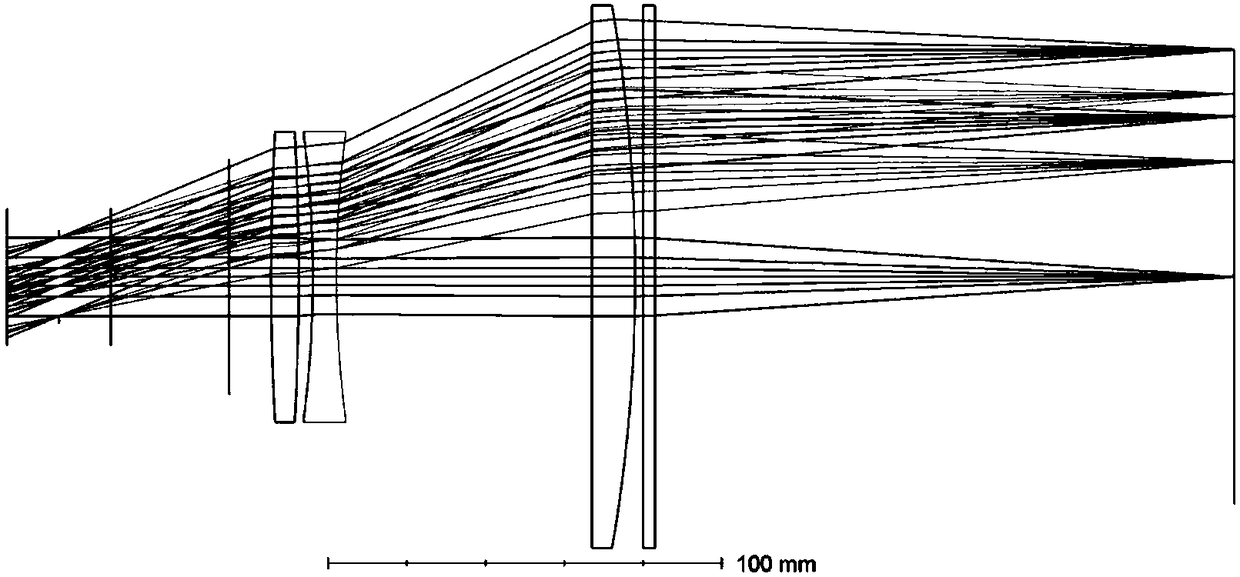

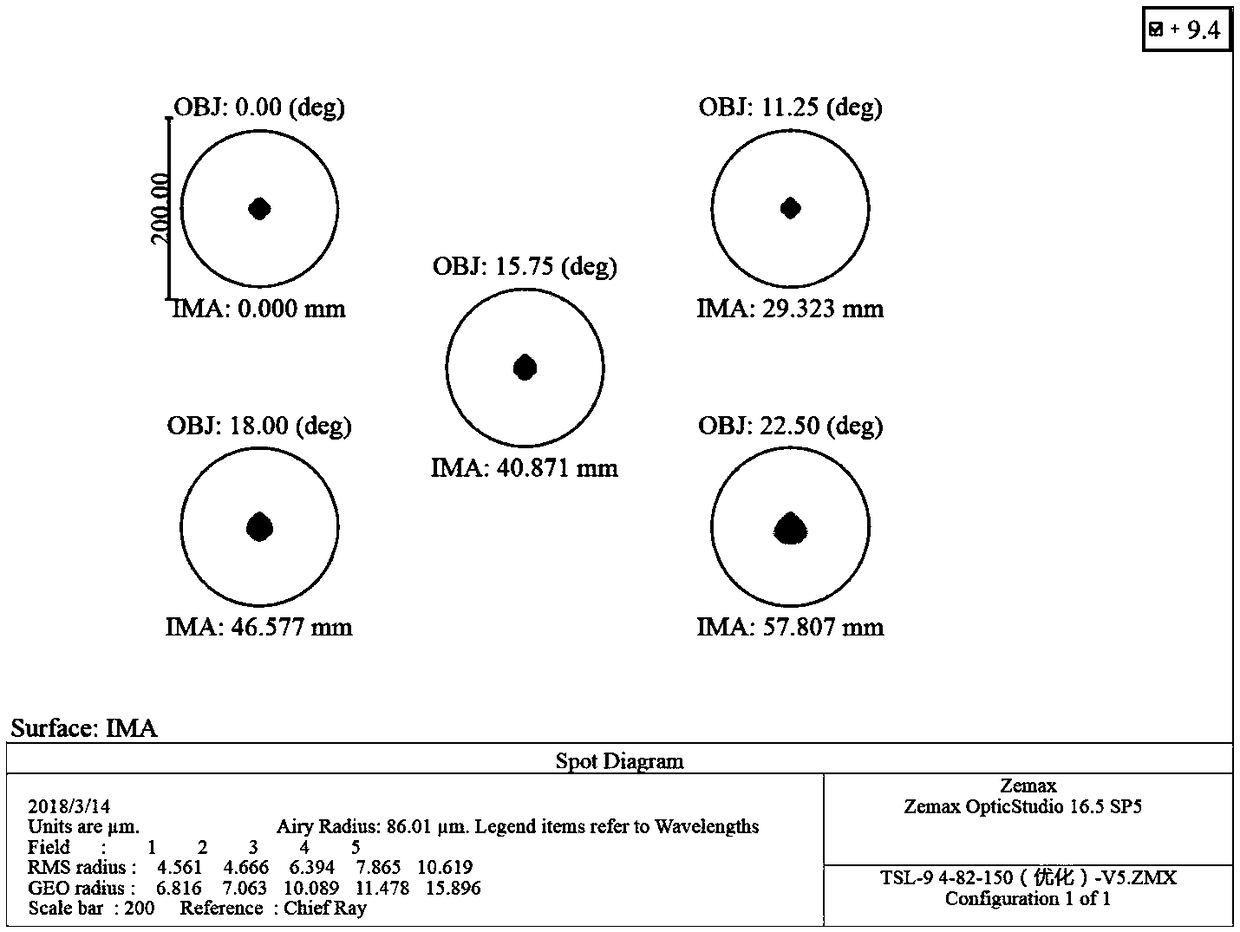

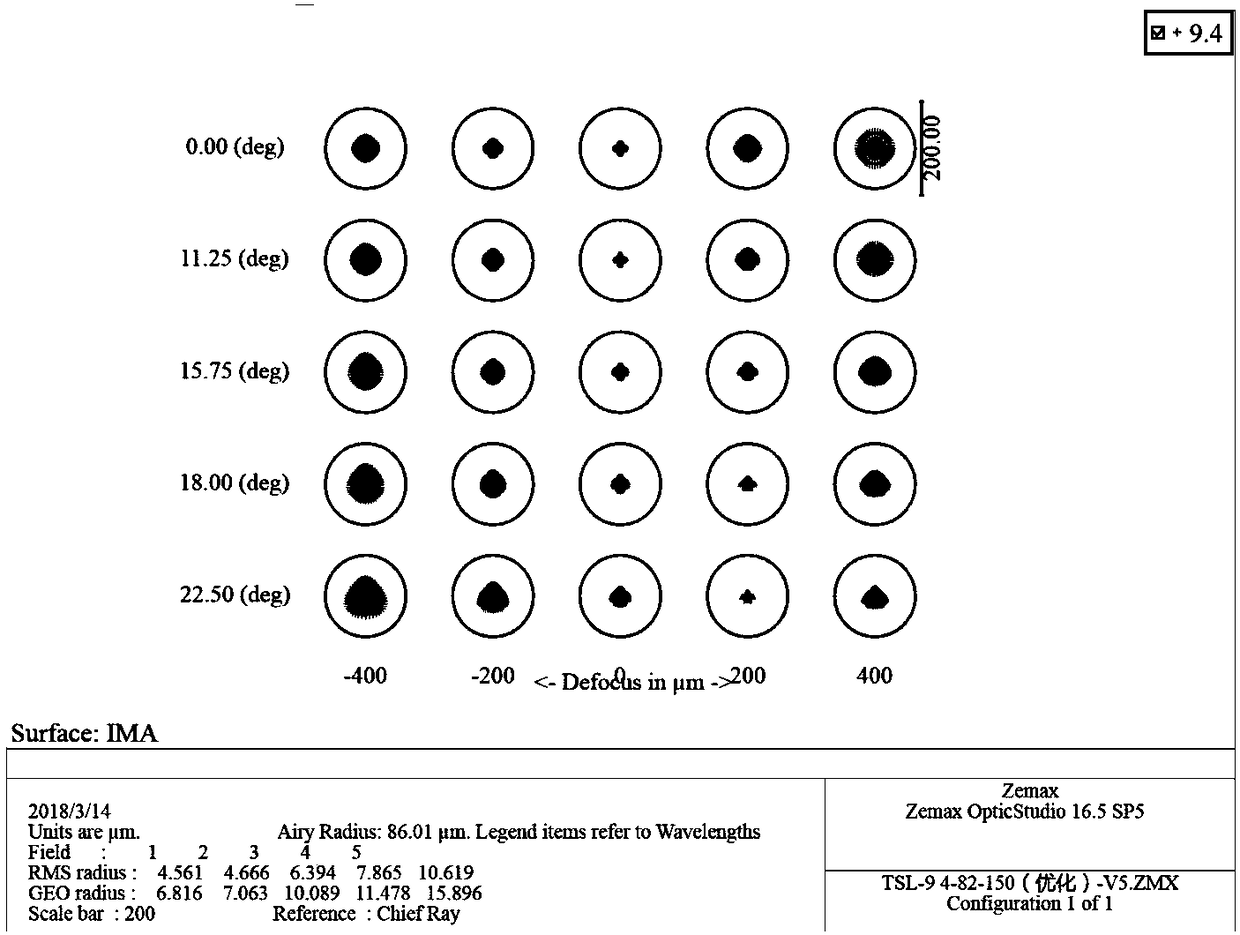

F-theta lens unit

PendingCN108415147AMeet the specific requirements of drilling operationsNo lossOptical elementsCamera lensPhysics

The invention discloses an F-theta lens unit, comprising a first lens, a second lens, a third lens and a window piece arranged sequentially along a light incoming direction. The first lens is a positive lens, the second lens is a negative lens, and the third lens is a positive lens. The F-theta lens unit is applicable to drilling, can meet various drilling requirements, is particularly suitable for the manufacture of small-diameter holes, and is suitable for processing of holes high in roundness and good in size uniformity.

Owner:NANJING WAVELENGTH OPTO ELECTRONICS SCI & TECH CO LTD

Positioning and punching mechanism for packaging cartons

InactiveCN106476322ARealize automatic fast punching functionFast punchingPaper-makingBox making operationsHydraulic cylinderPunching

The invention relates to a positioning and punching mechanism for packaging cartons. The positioning and punching mechanism comprises a bottom plate. Two linear sliding rails are symmetrically installed in the middle of the upper end face of the bottom plate. The upper ends of the two linear sliding rails are provided with a limiting plate. The middle of the limiting plate is provided with a first positioning hole. The back of the limiting plate is connected with a limiting spring. A positioning shaft is sleeved with the left end of the limiting spring. The positioning shaft plays a role in positioning the left end of the limiting spring and prevents the limiting spring from causing the deviation phenomenon. The limiting spring plays a limiting and speed reduction role, and the limiting plate can slowly and stably move on the two linear sliding rails under the effect of external force. The positioning shaft is arranged on a fixing plate. The lower end of the fixing plate is welded to the bottom plate. A vertical plate is installed on the right side of the upper end face of the bottom plate. Two hydraulic cylinders are installed on the side wall of the vertical plate. The positioning and punching mechanism can achieve the automatic and rapid punching function for cartons, and has the advantages of being easy and convenient to operate, high in punching speed, high in punching efficiency, high in working efficiency and the like.

Owner:安徽柳峰包装材料有限责任公司

Packing bag punching equipment

The invention provides a packaging bag punching device, which relates to the technical field of packaging bag punching, including a base, a transmission mechanism, a punching mechanism and a support seat fixedly connected to the top of the base. The transmission mechanism is set on the support seat, and the punching mechanism includes an upper fixed block, a lower moving block, a circular dial and a punching needle arranged on the annular dial, and several elastic parts are arranged between the upper fixed block and the lower moving block , the upper fixed block is fixed on the lower end of the support seat, and the annular needle disc is connected to the lower end of the lower moving block; when punching, the elastic member instantly drives the lower moving block to drive the punching hole on the annular needle disc to punch the packaging bag on the transmission mechanism hole. Through the implementation of this technical solution, it is possible to effectively avoid the phenomenon of rough edges or out-of-roundness in the punching in the prior art, and improve the punching quality of the packaging bag; and it can also produce packaging bags with different apertures at the same time, improving the efficiency of punching the packaging bag .

Owner:弘毅天承知识产权股份有限公司

Device for automatically punching chillies

The invention provides a device used for automatically punching chillies. The device comprises a rack, a conveying mechanism, a punching mechanism and a motor, wherein the motor is provided with a speed reducer; the conveying mechanism comprises a conveyor belt, a driven wheel and a driving wheel; the driving wheel and the driven wheel are arranged at the two sides of the rack; the conveyor belt is installed between the driving wheel and the driven wheel; and the punching mechanism is arranged in the middle of the rack and comprises a support frame, a crankshaft, a connecting rod, locating sleeves, directional shafts, a presser, a pin installing plate, punching pins and a punching pin guide plate. The device has a simple structure and a high degree of automation, is convenient to use and can achieve the effects of reducing the dependence of enterprises on workers and effectively reducing the production costs of the enterprises.

Owner:昆明万顺通科工贸有限公司

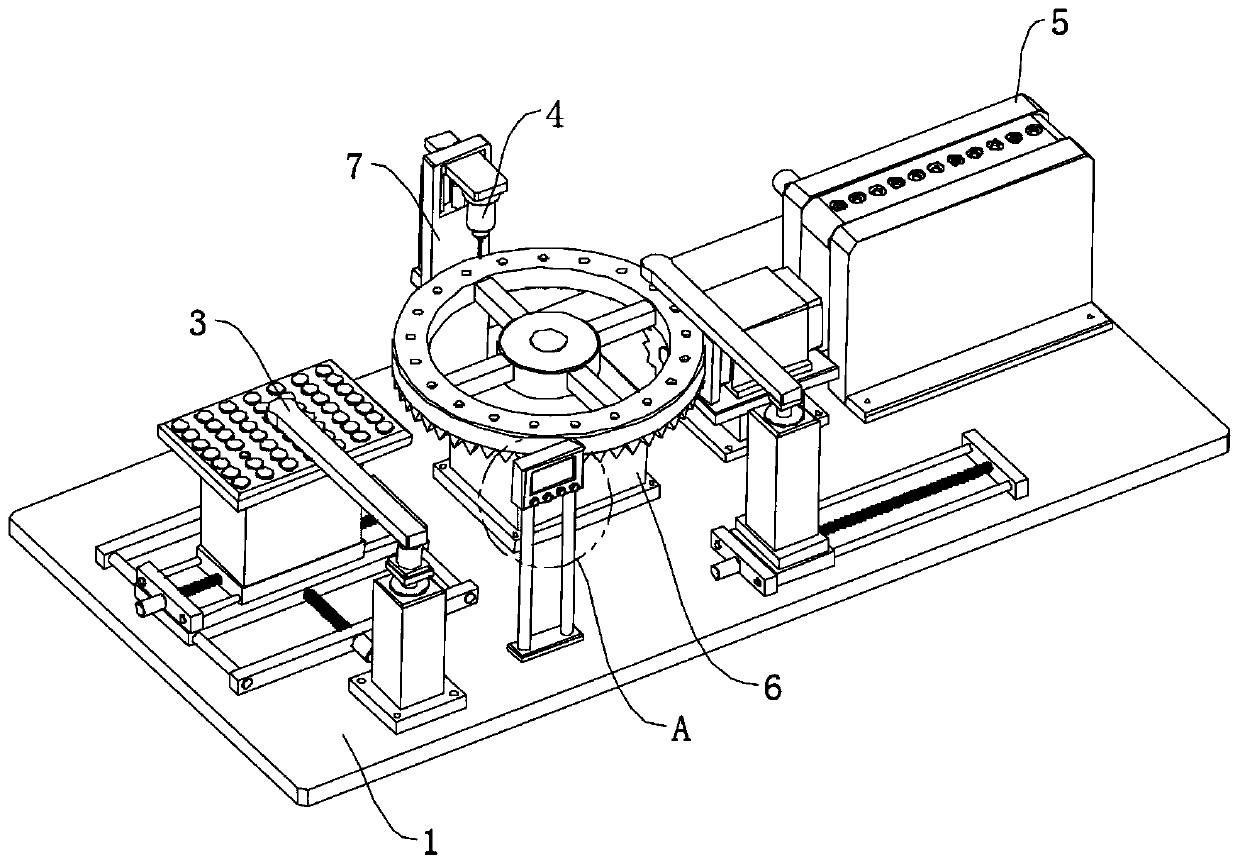

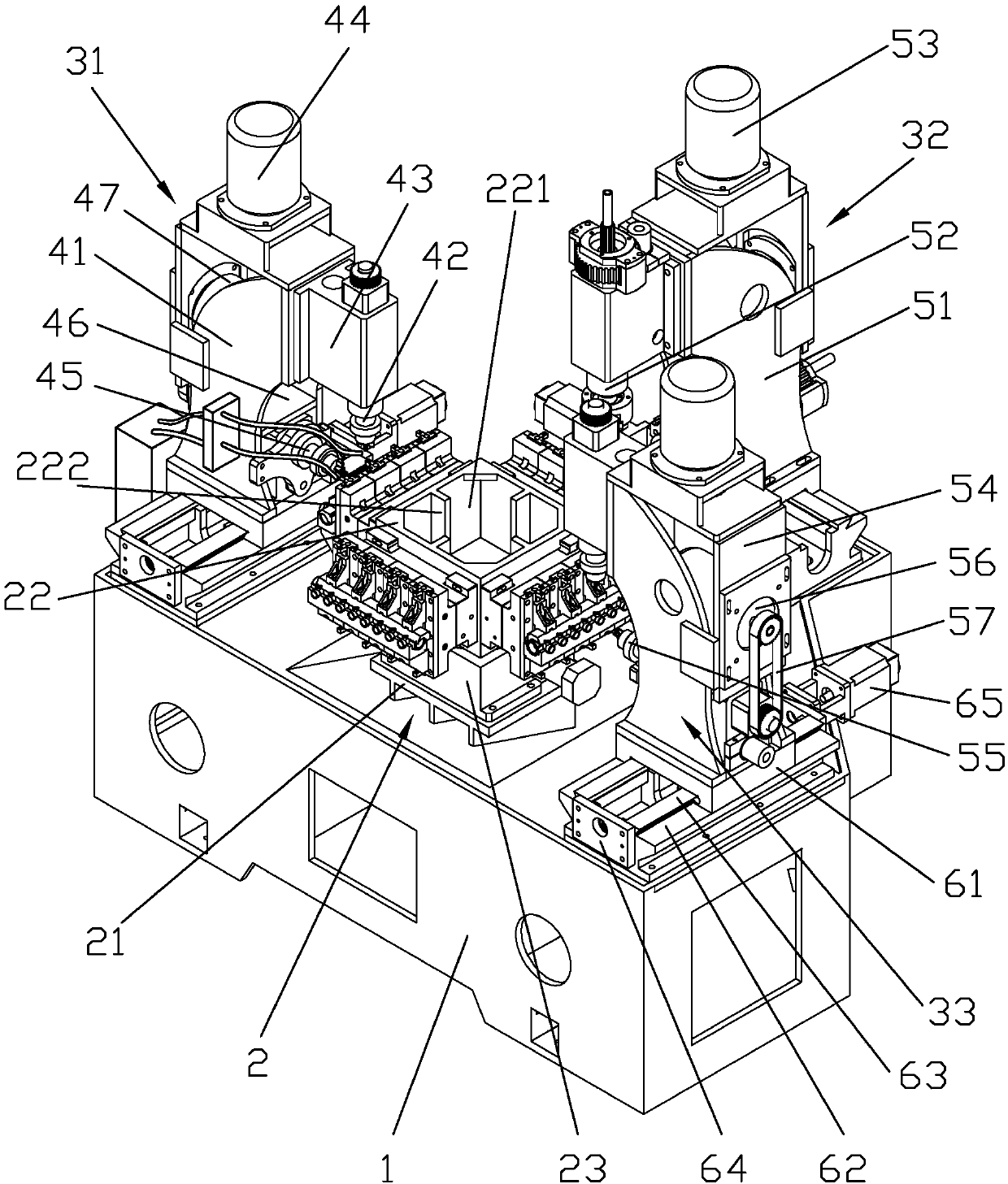

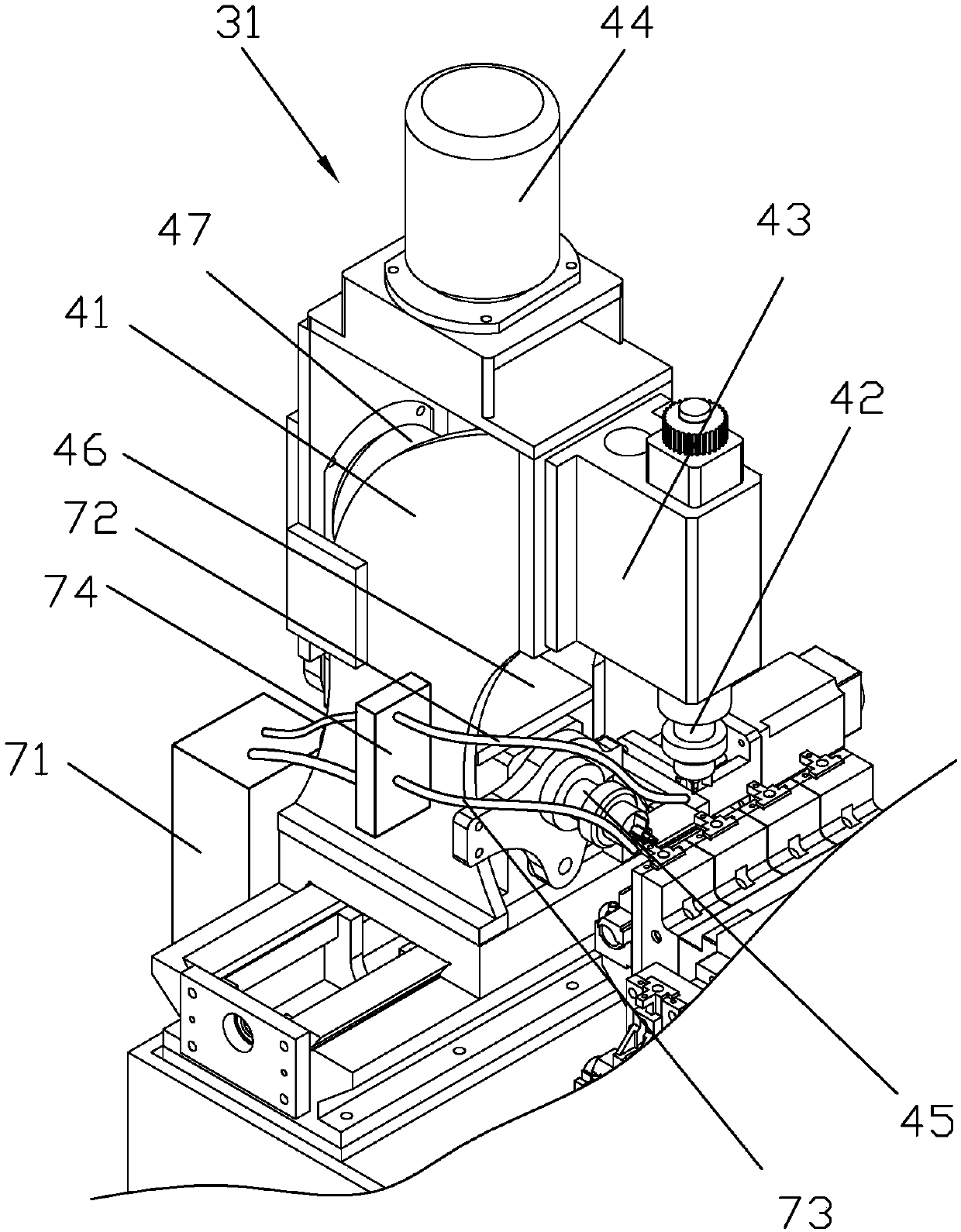

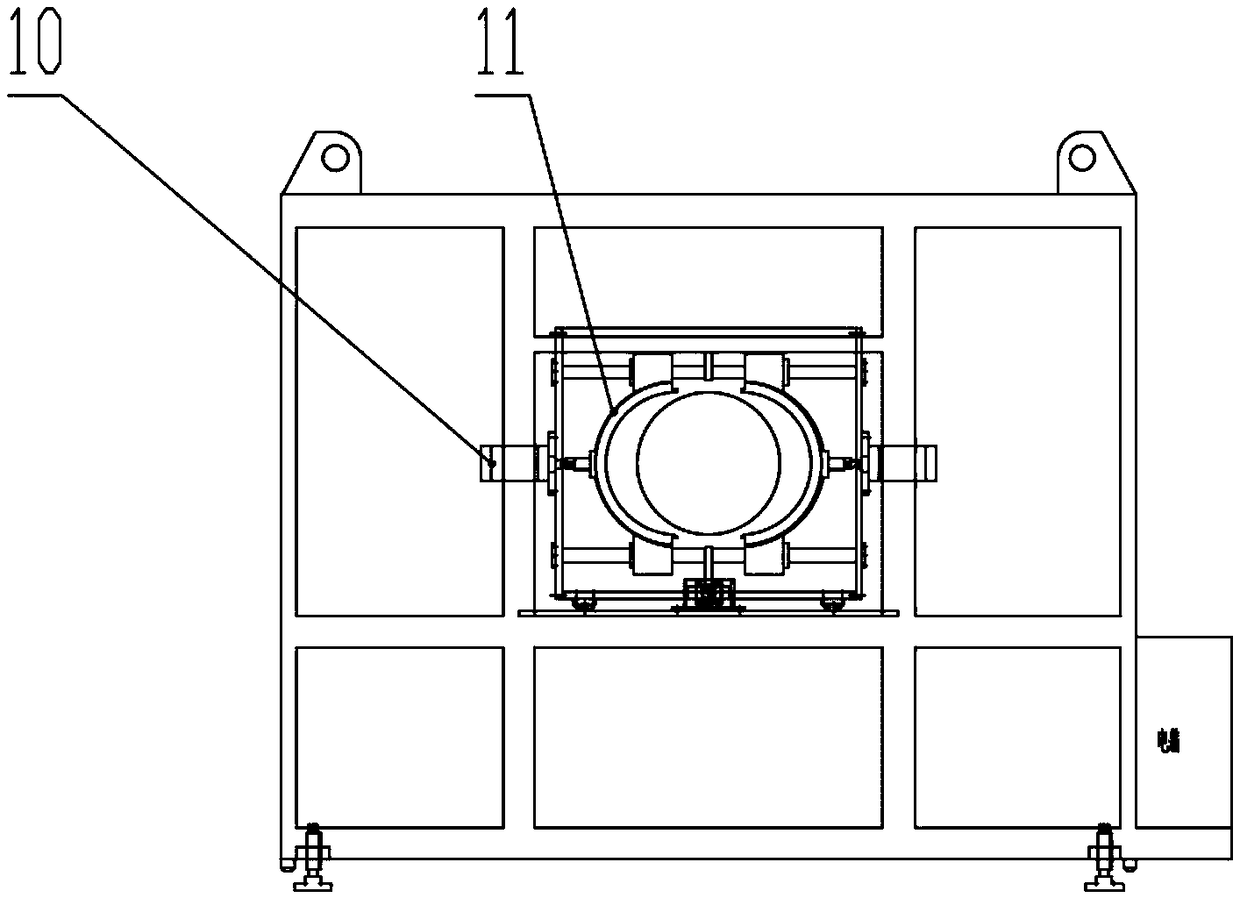

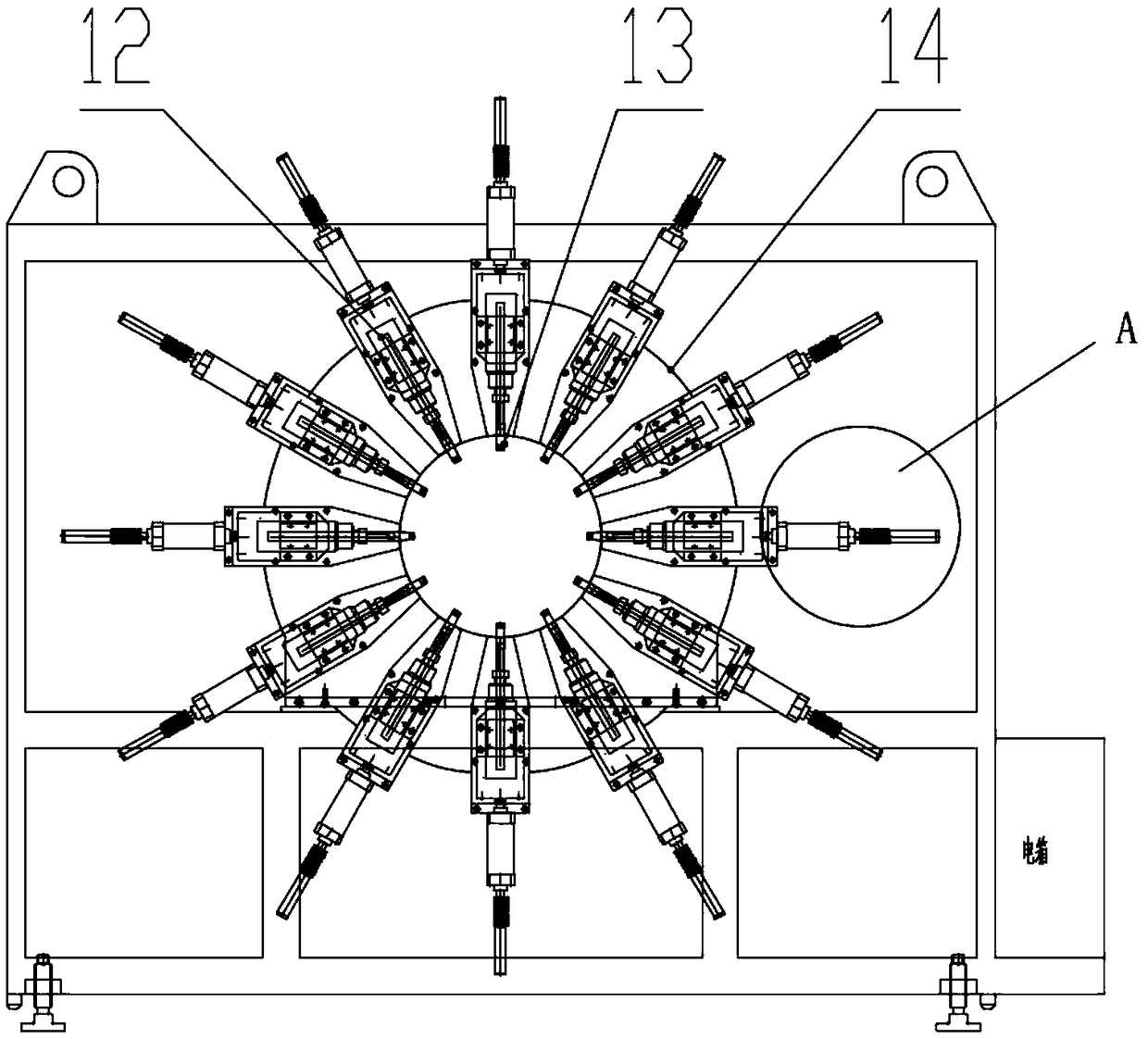

Horizontal-vertical type six-axis disc machine tool for pipe punching

PendingCN107695378AImprove precisionGuaranteed cleanlinessMaintainance and safety accessoriesBoring/drilling machinesPunchingEngineering

The invention relates to the technical field of detection tools, and discloses a horizontal-vertical type six-axis disc machine tool for pipe punching. The horizontal-vertical type six-axis disc machine tool comprises a machine base and a base plate, wherein the base plate is arranged on the top surface of the machine base; a disc base is arranged in the center of the top surface of the base plate; a square box is arranged on the disc base and is connected to the disc base in a rotating mode; a dividing plate is arranged between the square box and the disc base; a dividing motor connected to the dividing plate is arranged on the side surface of the disc base; pipe positioning clamps are arranged on the four side surfaces of the square box and are fixedly connected to the square box throughfixing plates; a drilling mechanism, a longitudinal reaming mechanism and a transverse reaming mechanism are arranged on the positions, located on the left side, the rear side and the right side of the square box, of the base plate correspondingly; and sliding bases are arranged at the bottoms of the drilling mechanism, the longitudinal reaming mechanism and the transverse reaming mechanism and are connected to the base plate in a sliding mode through electric control sliding mechanisms. The horizontal-vertical type six-axis disc machine tool has the advantages that a clamping device does notneed to be replaced in the machining process, continuous punching can be realized, the machining speed can be greatly increased, the working efficiency can be improved, and time and labor can be saved.

Owner:蒋晨

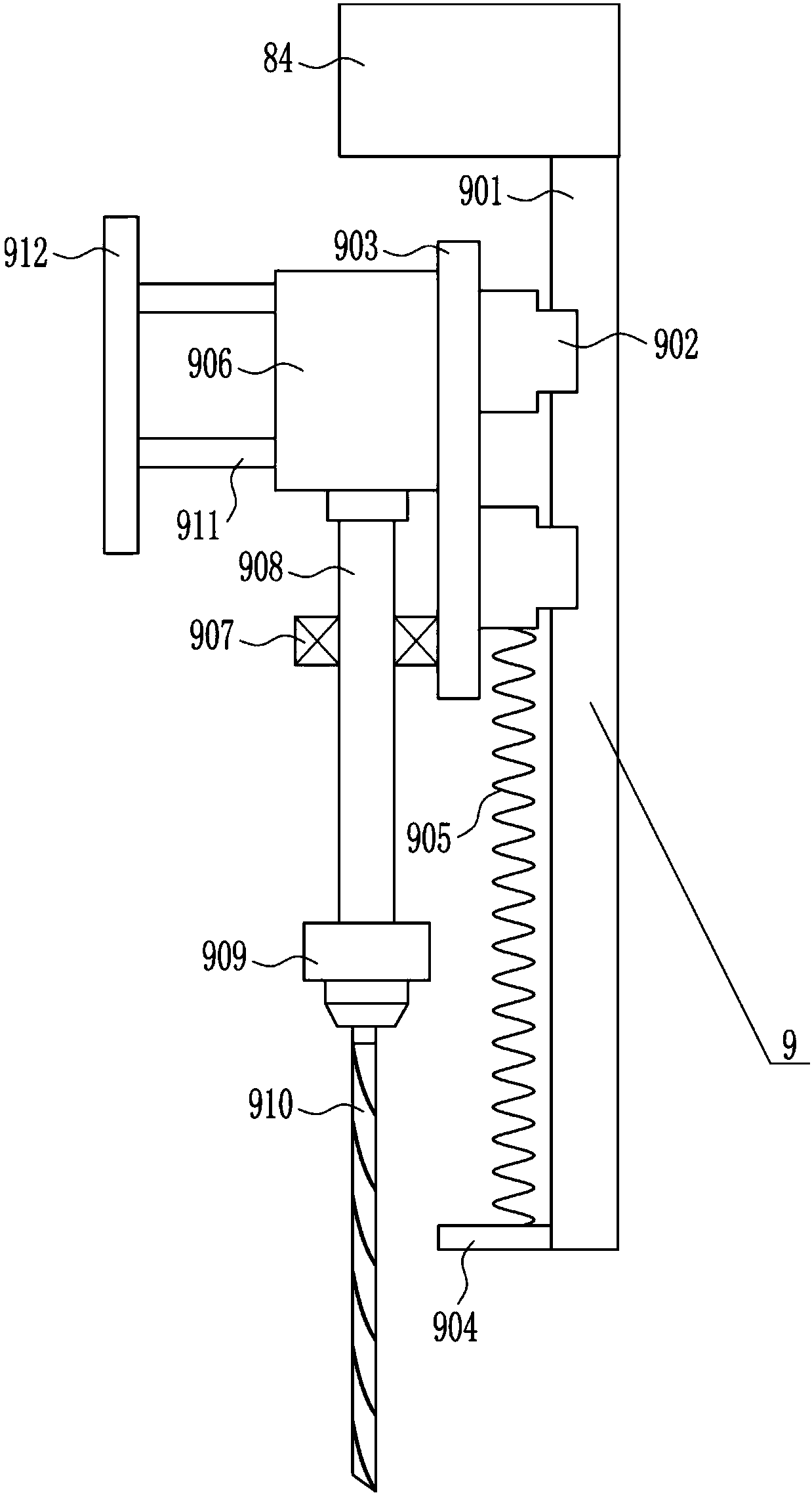

Portable electric drill

InactiveCN107639267ARealize automatic up and down movementReduce labor costsPortable drilling machinesPunchingElectric machinery

The invention discloses a portable electric drill which comprises a base, an electric drill body, a drill motor, a spindle and a drill pit. The electric drill body is fixedly mounted on the base, thedrill motor is arranged on the electric drill body and is in transmission connection with the drill bit through the spindle, a swinging motor is further arranged on the electric drill body and is connected with the spindle through a swinging guide bar mechanism, four sliding devices are respectively arranged at four bottom corners of the base, and the outer surface of the drill bit is coated witha wear-resisting layer which is 1-2mm in thickness. The drill bit moves vertically through cooperative operation of the drill motor and the swinging guide bar mechanism, and full-automatic punching isachieved; compared with traditional manual operations, the operation of the portable electric drill has the advantages that labor cost is saved, punching speed is greatly increased, and production efficiency is greatly improved; a sliding device is additionally arranged on the base, working intensity of porters is reduced by pushing the electric drill to operate in a rolling manner, and the portable electric drill is simple in structure, and convenient for handling.

Owner:南通豪鼎光伏科技有限公司

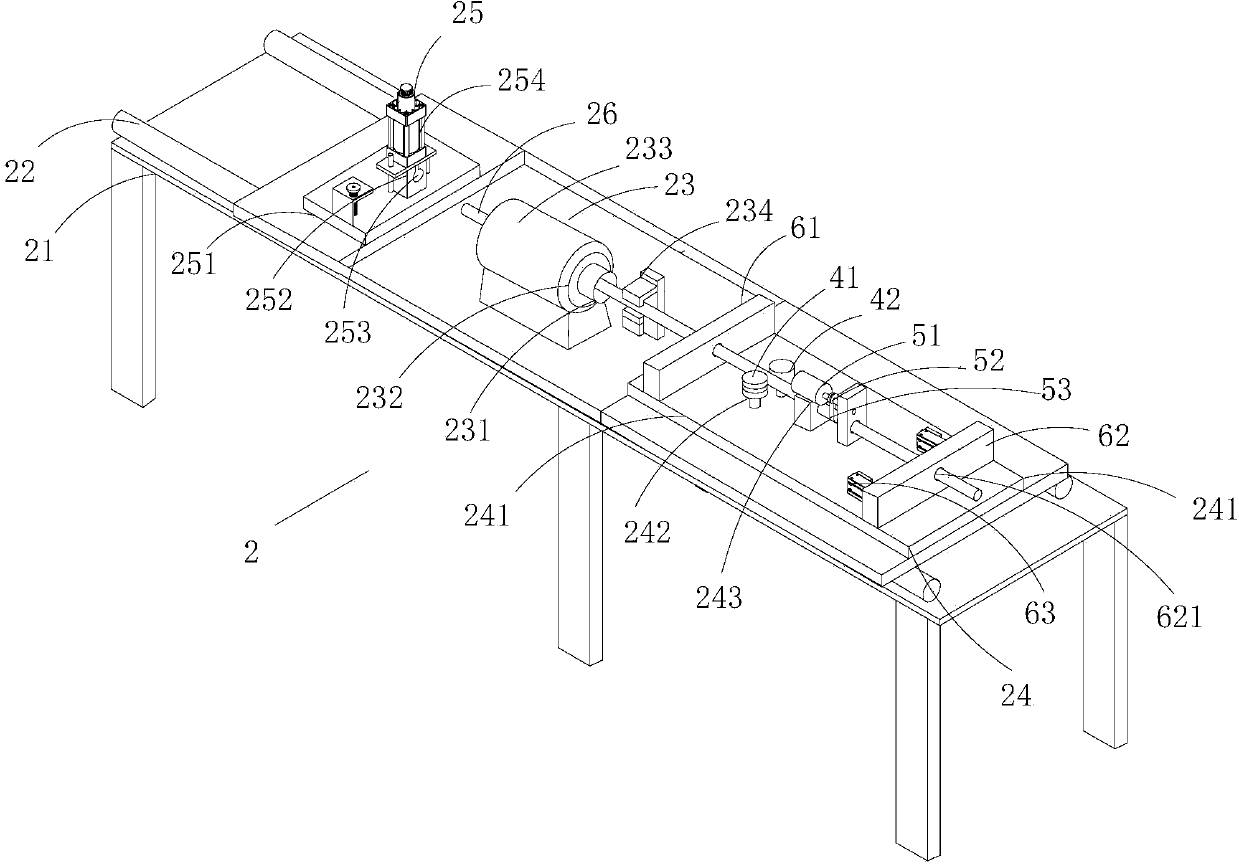

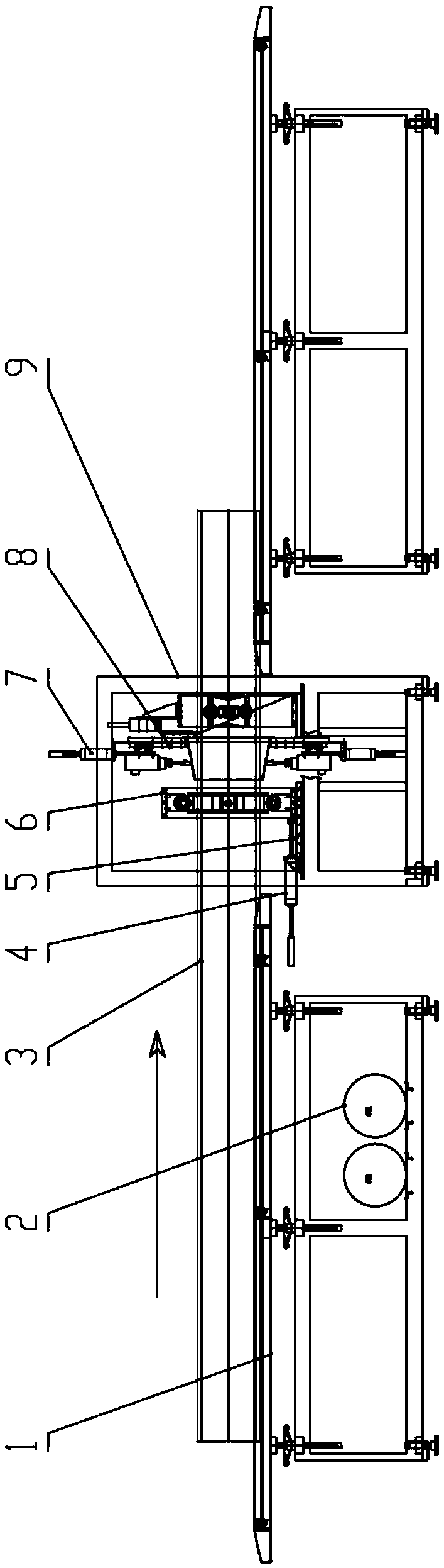

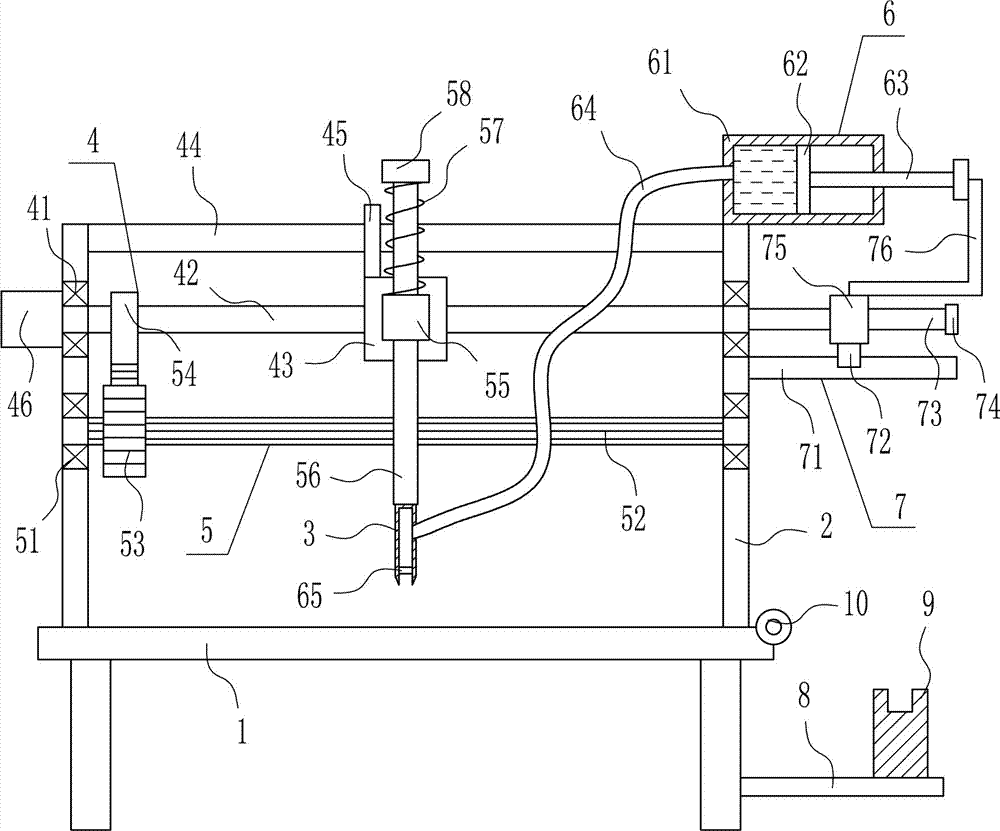

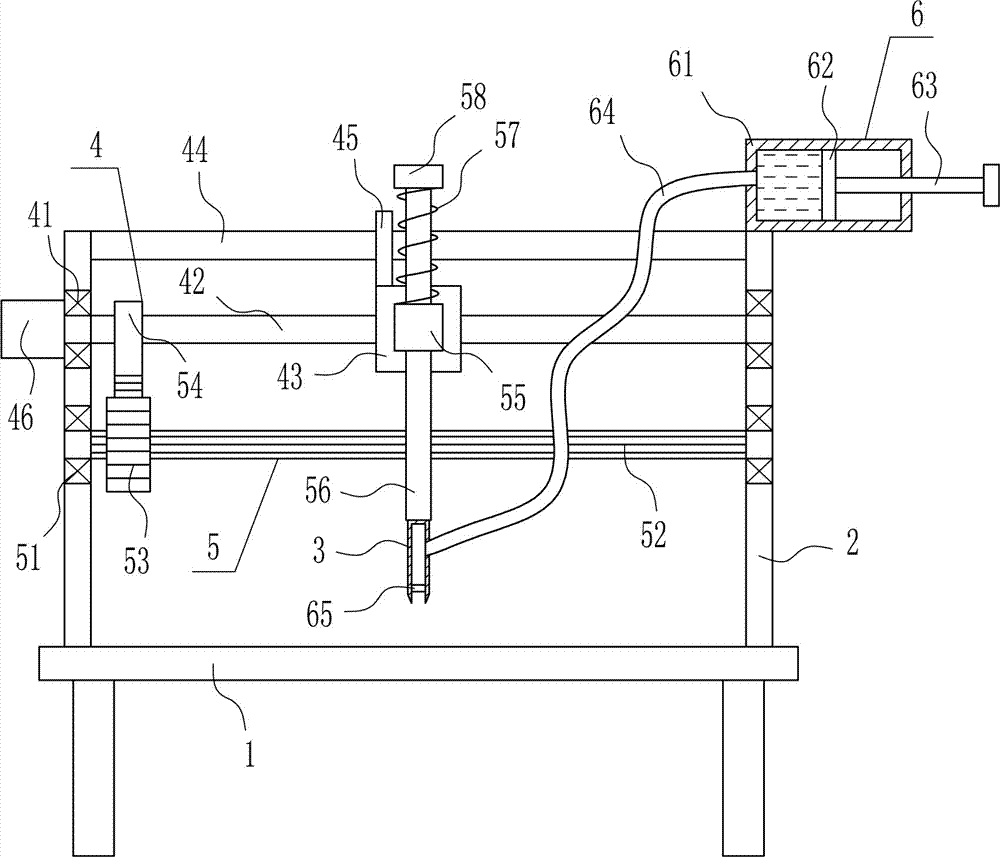

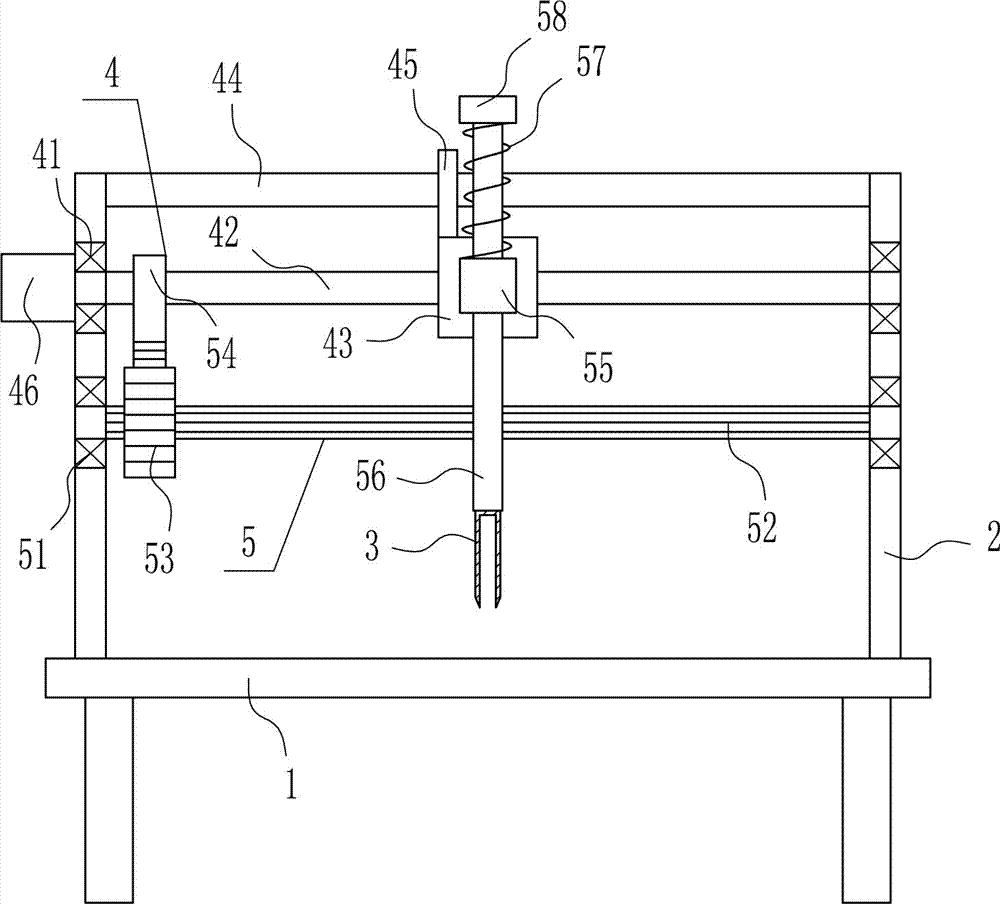

Plastic pipe punching machine

The invention relates to a plastic pipe punching machine. The plastic pipe punching machine comprises a punching device and a machine body located on the two sides of the punching device, wherein a to-be-punched plastic pipe is placed on the machine body, the machine body mainly plays a role of supporting, a plurality of rollers are arranged on the machine body, the plastic pipe is arranged on therollers, so that the plastic pipe can move on the machine body conveniently. The punching device comprises a punching machine frame and a clamping mechanism, a punching mechanism and a pressing mechanism which are arranged on the punching machine frame in sequence, wherein the clamping mechanism is mainly used for clamping the plastic pipe, the punching mechanism is used for punching the plasticpipe, and the pressing mechanism is used for setting the plastic pipe right and clamping the other end of the plastic pipe during punching. The punching machine has the advantages that the automationis realized, the consistency of the axial hole spacing is ensured, the uniformity of each circumference section hole and the hole angle is achieved, the quality of each plastic pipe is guaranteed, andthe hidden danger caused by inconsistent manual punching is eliminated.

Owner:江苏煜宇塑料机械科技有限公司

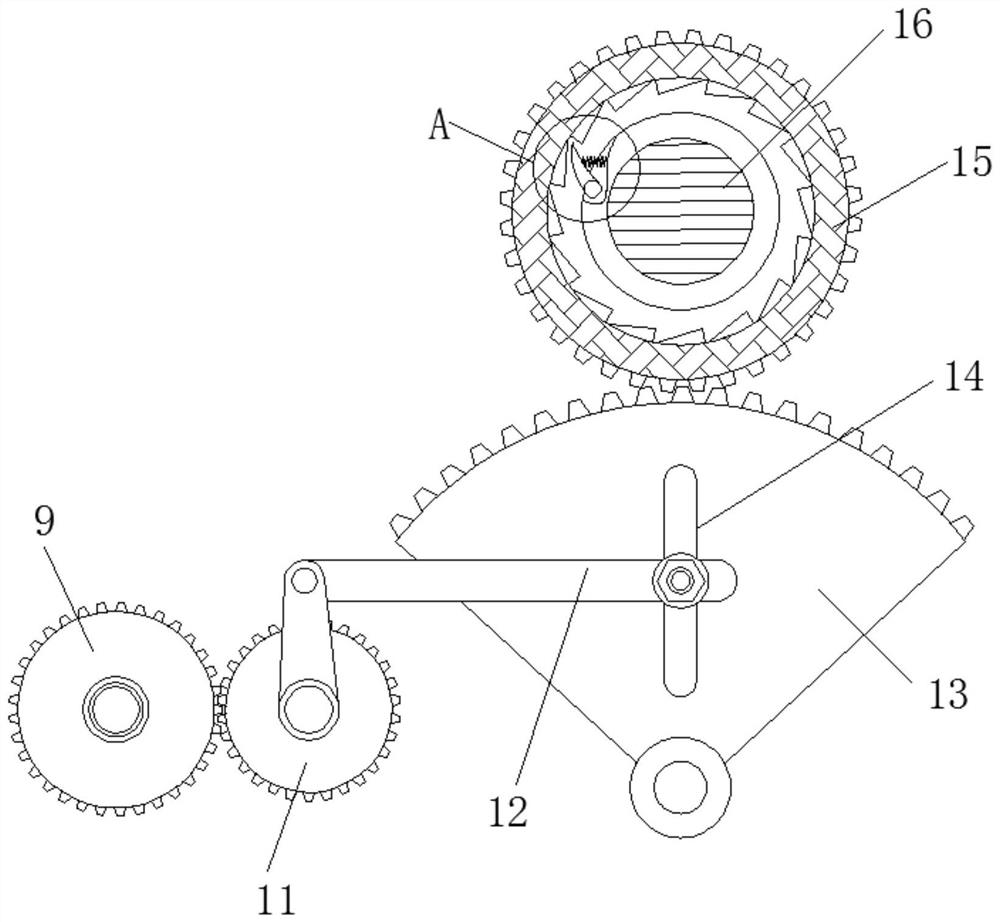

Intelligent continuous equidistant punching device for new material circular plate

InactiveCN112453462AAvoid measuringAvoid punctuationBoring/drilling componentsBoring/drilling machinesRatchetPunching

The invention relates to the technical field of new material punching, and discloses an intelligent continuous equidistant punching device for a new material circular plate. The punching device comprises a support, wherein an adjusting motor is fixedly connected to the top of the support; a rotating shaft is fixedly connected to the bottom of the adjusting motor, and the rotating shaft is sleevedwith a sleeve shaft; a lifting plate is movably connected to the exterior of the sleeve shaft; a guide rod is movably connected to the interior of the lifting plate; a drilling motor is movably connected to the bottom of the lifting plate; a sector gear is fixedly connected to the exterior of the rotating shaft; and a connecting gear is connected to the exterior of the sector gear in an engaged manner. Through cooperative use of the sleeve shaft, the lifting plate, a guide rod, a transmission gear, a connecting rod, a reciprocating gear, a ratchet wheel, a support shaft, a pawl and a limitingspring, the continuous equidistant punching effect is achieved, the troubles of early-stage measurement, point marking and point alignment are avoided, the punching difficulty is effectively reduced,and the punching speed is increased, therefore, the working efficiency and the working quality of punching are effectively guaranteed.

Owner:戚金香

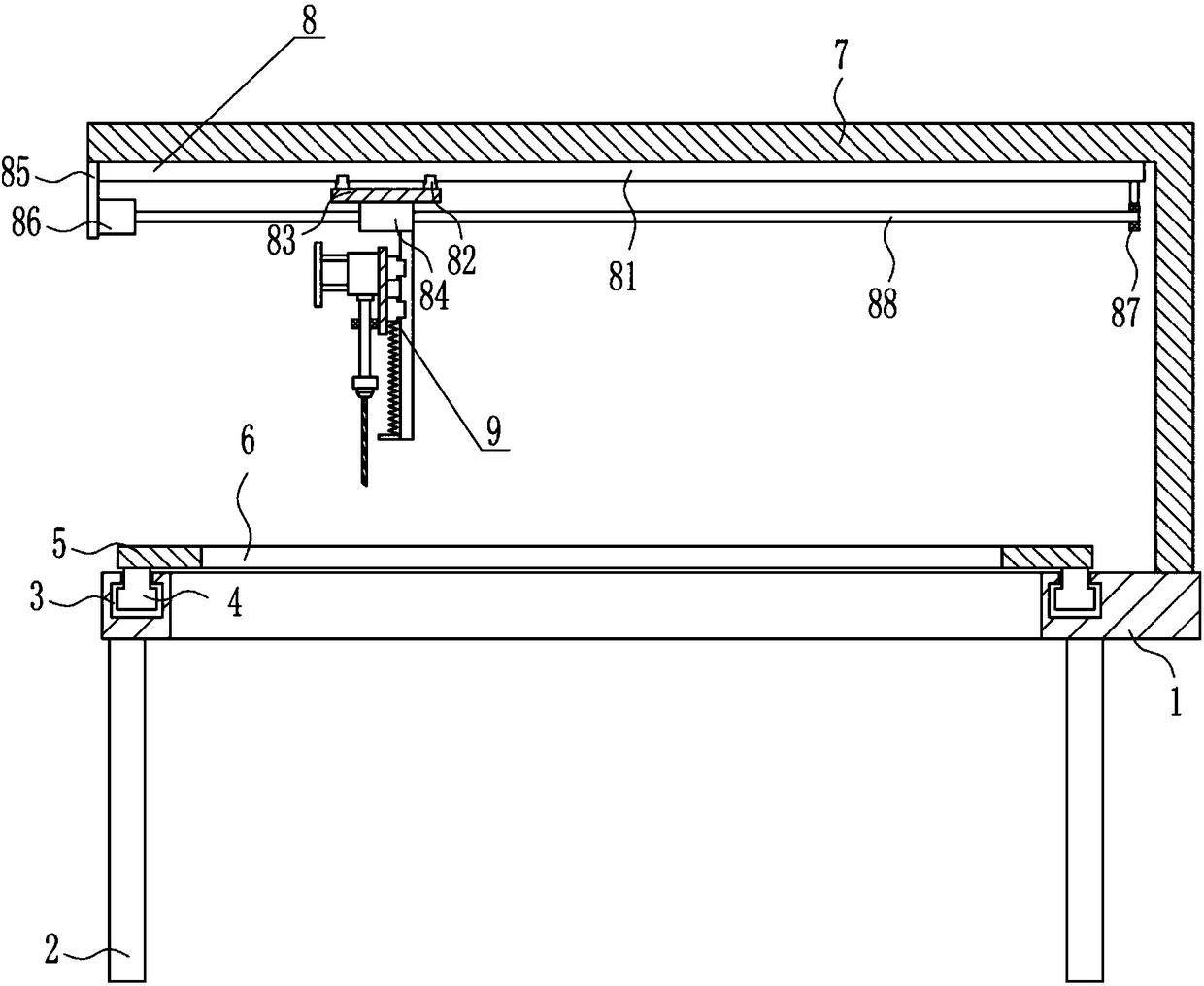

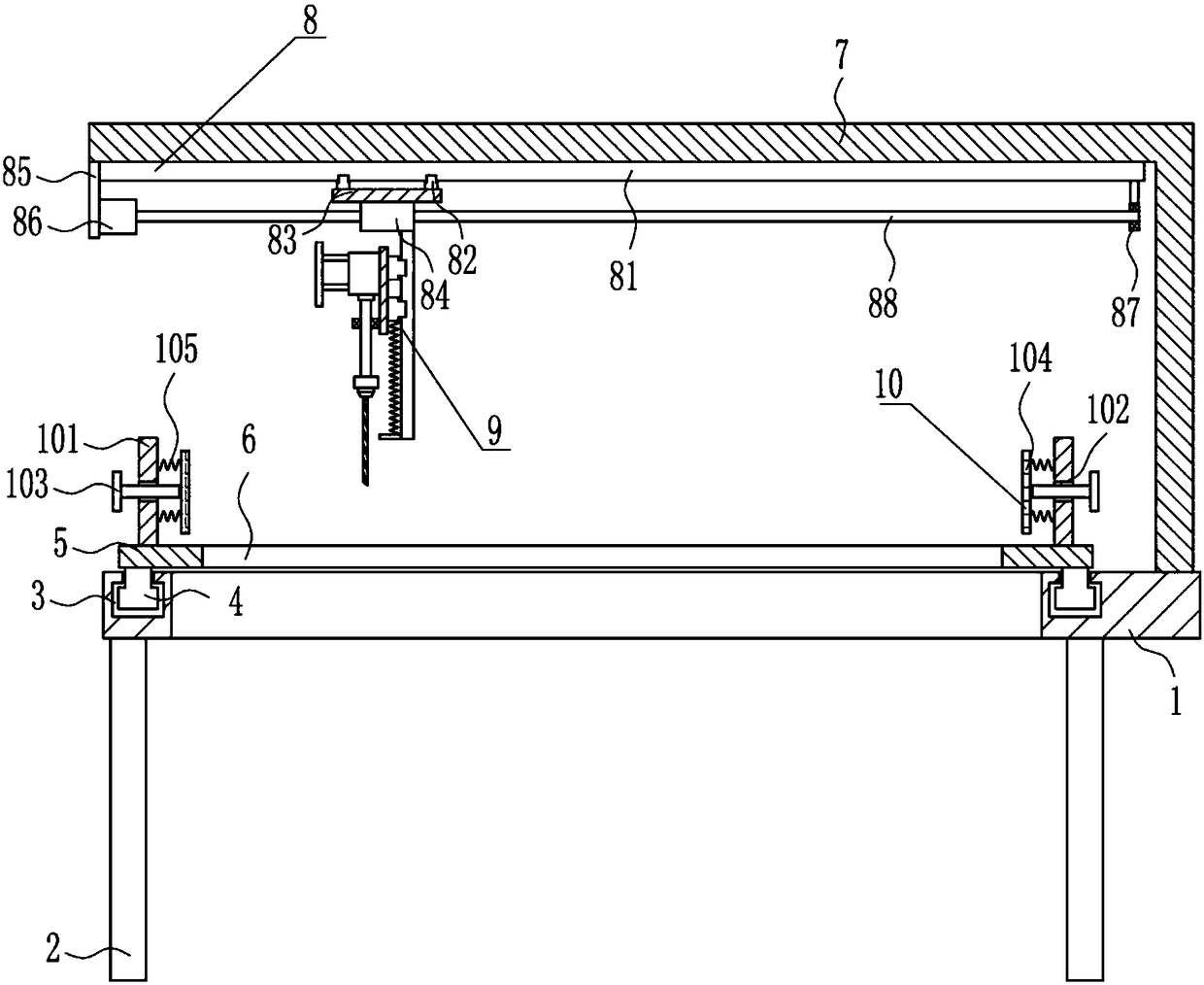

Leather perforating equipment for producing leather shoes

ActiveCN108004353APrevent fallingDoes not affect the effect of subsequent useLeather clicking/perforating/clickingSkins/hides/leather/fur manufacturing apparatusEngineeringOperating table

The invention relates to perforating equipment, in particular to leather perforating equipment for producing leather shoes. The leather perforating equipment for producing the leather shoes aims at achieving the technical effects that the perforating speed is high, perforating is conducted uniformly, and subsequent use of leather is not affected. The leather perforating equipment for producing theleather shoes comprises an operating table and the like. Vertical plates are symmetrically mounted at the left side and the right side of the top of the operating table. A moving device is arranged between the upper portion of the vertical plate at the left side and the upper portion of the vertical plate at the right side. An ascending-and-descending device is arranged between the middle of thevertical plate at the left side and the middle of the vertical plate at the right side. The ascending-and-descending device is connected with the moving device. A perforating head is connected to an ascending-and-descending component of the ascending-and-descending device and located above the operating table. According to the leather perforating equipment, by means of a clearing-away device, theresidual leather in the perforating head can be cleared away, and leather perforating conducted through the perforating head is not affected; by means of a storage base, an operator can place the leather on the operating table better; and the effects that the perforating speed is high, perforating is conducted uniformly, and subsequent use of the leather is not affected are achieved.

Owner:广东辛迪丹顿鞋业有限公司

Telescopic adjusting type vegetable plug seedling field planting puncher

ActiveCN111802025AAdjust operating heightEasy to usePlantingFurrow making/coveringAgricultural engineeringMechanical engineering

The invention discloses a telescopic adjusting type vegetable plug seedling field planting puncher. The telescopic adjusting type vegetable plug seedling field planting puncher comprises an upper holding rod, a connecting box body, a rotary driving mechanism, an upper connecting mechanism, a punching head and a telescopic adjusting screw rod. Through rotation of the telescopic adjusting screw rod,an inserting floating rod of the upper holding rod can be driven to slide up and down in a telescopic floating groove in the middle of the upper end of the connecting box body, so that the operationheight is adjusted, and the use is quite convenient.

Owner:江苏翠源食品科技股份有限公司

A high-efficiency punching device for metal thin plates

ActiveCN106583785BConvenient punching workImprove work efficiencyStationary drilling machinesFeeding apparatusPunchingMetal sheet

The invention relates to a punching device, in particular to an efficient hardware sheet punching device and aims at achieving the technical purpose of providing the efficient hardware sheet punching device high in punching efficiency, high in punching speed and high in practicability. To achieve the above technical purpose, the efficient hardware sheet punching device is provided and comprises a left frame, a first belt wheel, a flat belt, a first connecting rod, a third belt wheel, a second belt wheel, a right frame, a second connecting rod, a fourth belt wheel, a stop block and the like. The right side of the top of the base is connected with the right frame. The first connecting rod is connected between the upper portion of the right side of the left frame and the upper portion of the left side of the right frame. The third belt wheel is connected to the middle portion of the first connecting rod. The third belt wheel is connected with a third drill rod. The efficient hardware sheet punching device achieves the effects of the high punching efficiency, the high punching speed and the high practicability, and when punching work needs to be conducted on a hardware sheet, the work efficiency of the whole hardware sheet punching work can be improved by using the device.

Owner:东莞松柏电子五金有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com