Patents

Literature

202results about How to "Not easy to jam" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

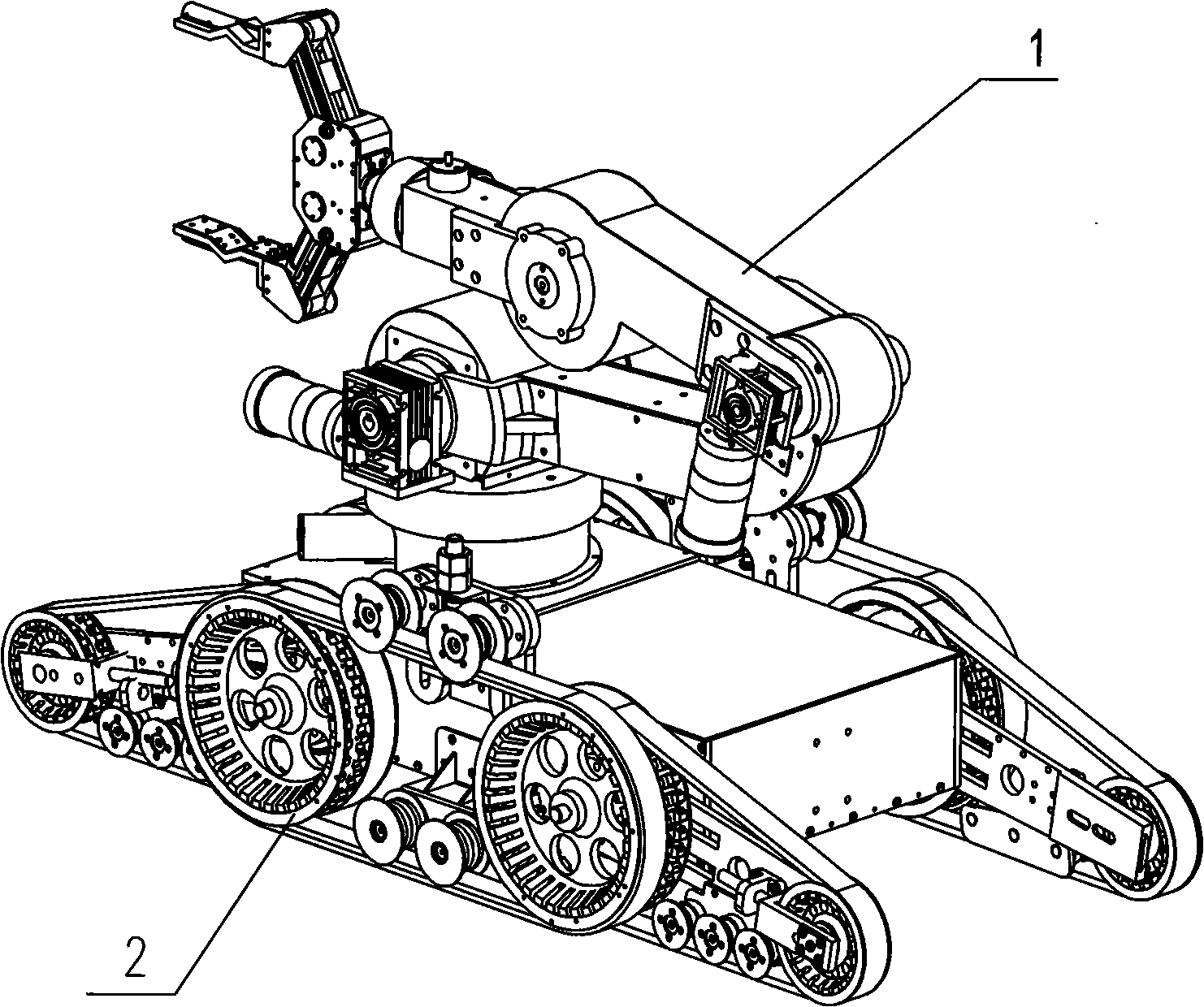

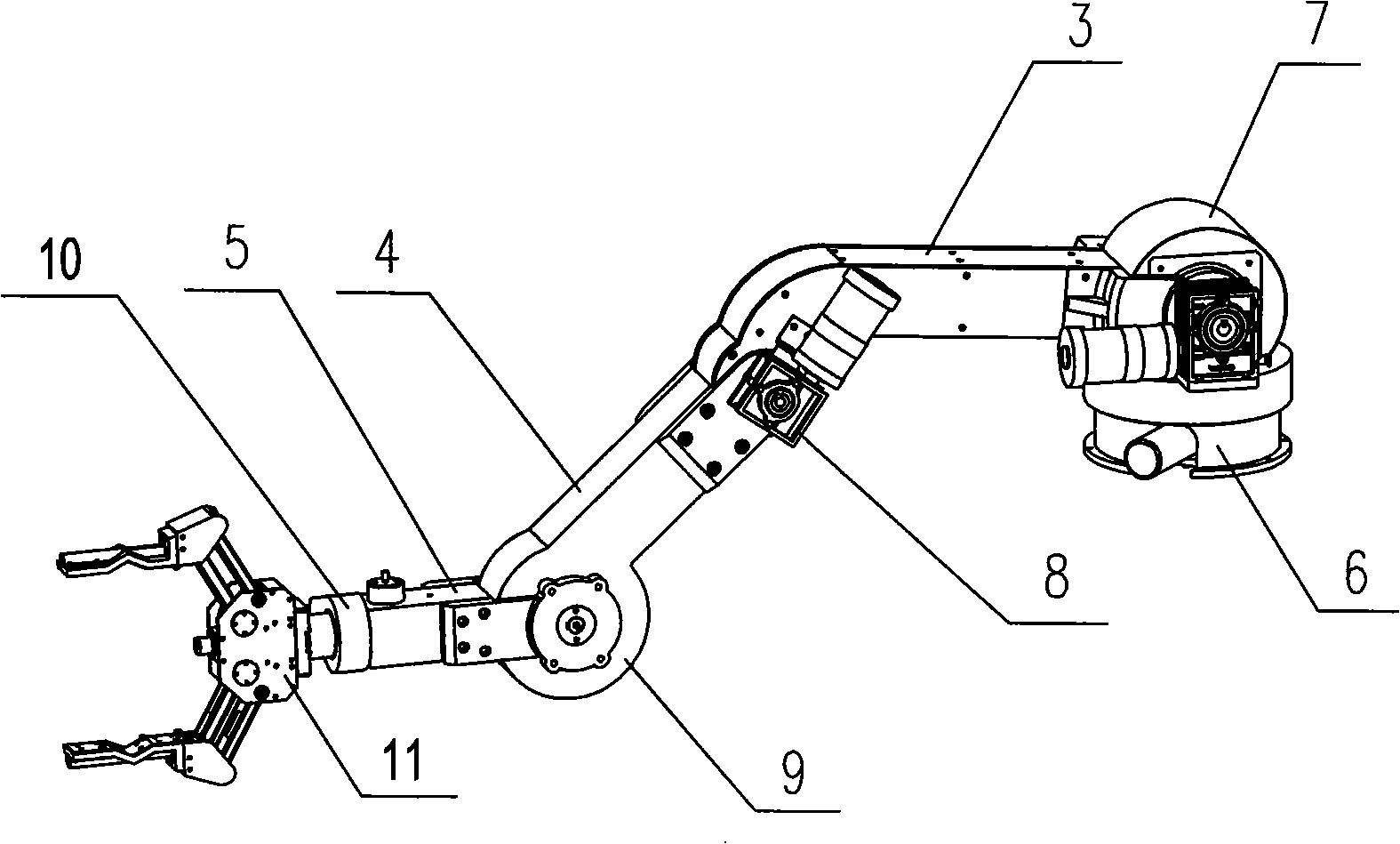

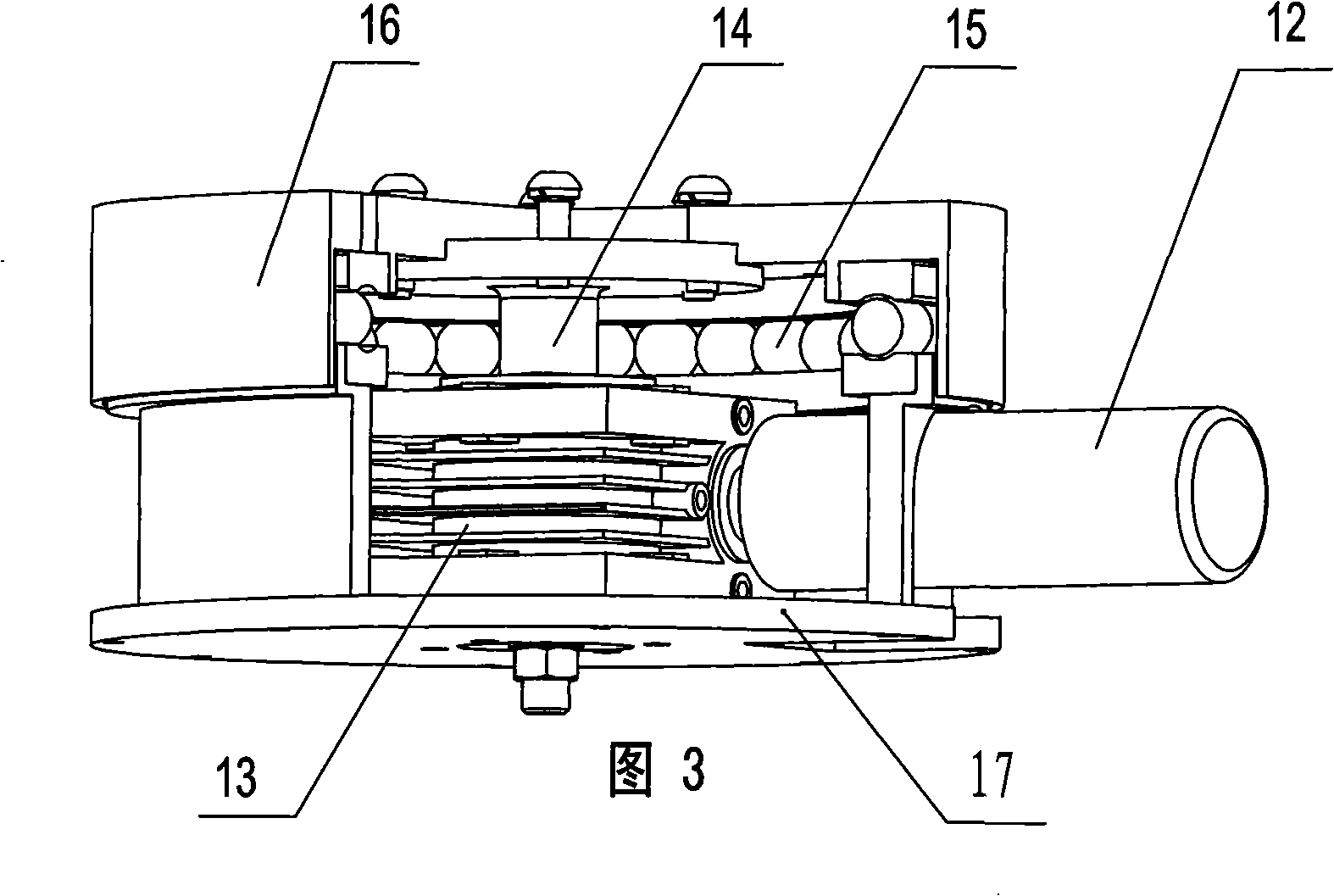

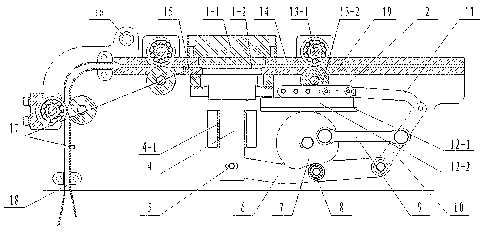

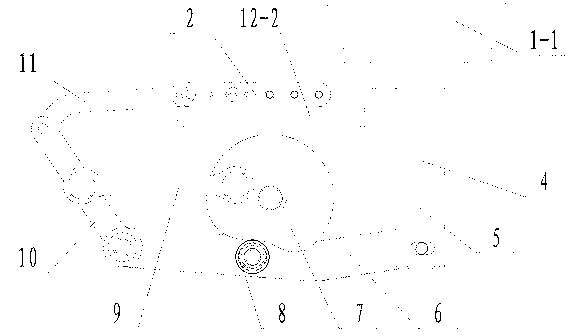

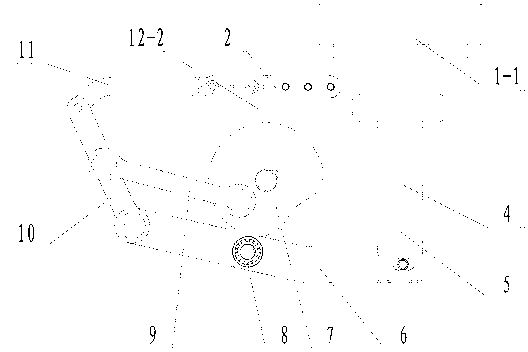

Crawler type multi-arm rod mobile robot

InactiveCN101279618AIncrease flexibilityAdaptableEndless track vehiclesManipulatorWorking environmentHigh intensity

The invention relates to the robot field, which provides a pedrail type movable robot with multiple arm links and consists of an arm working device and a pedrail type walking device. The invention can realize normal movable driving on a plurality of complicated road surfaces and finish a plurality of human hand bionic actions. The robot of the invention can substitute for human to work under a plurality of complicated, dangerous and abominable working environments, and has the advantages of strong adaptability, good flexibility, high intensity, etc.

Owner:北京中泰恒通科技有限公司

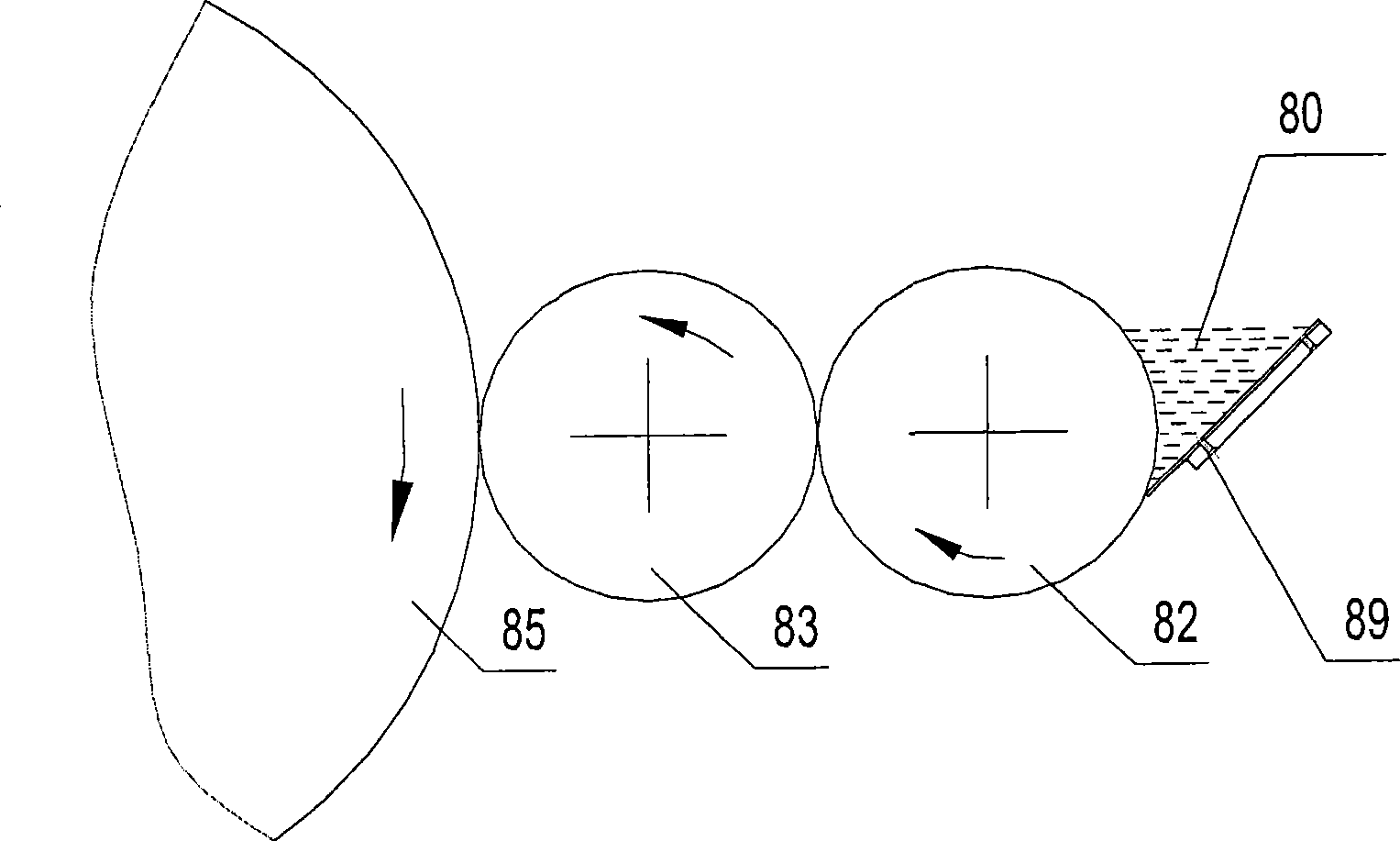

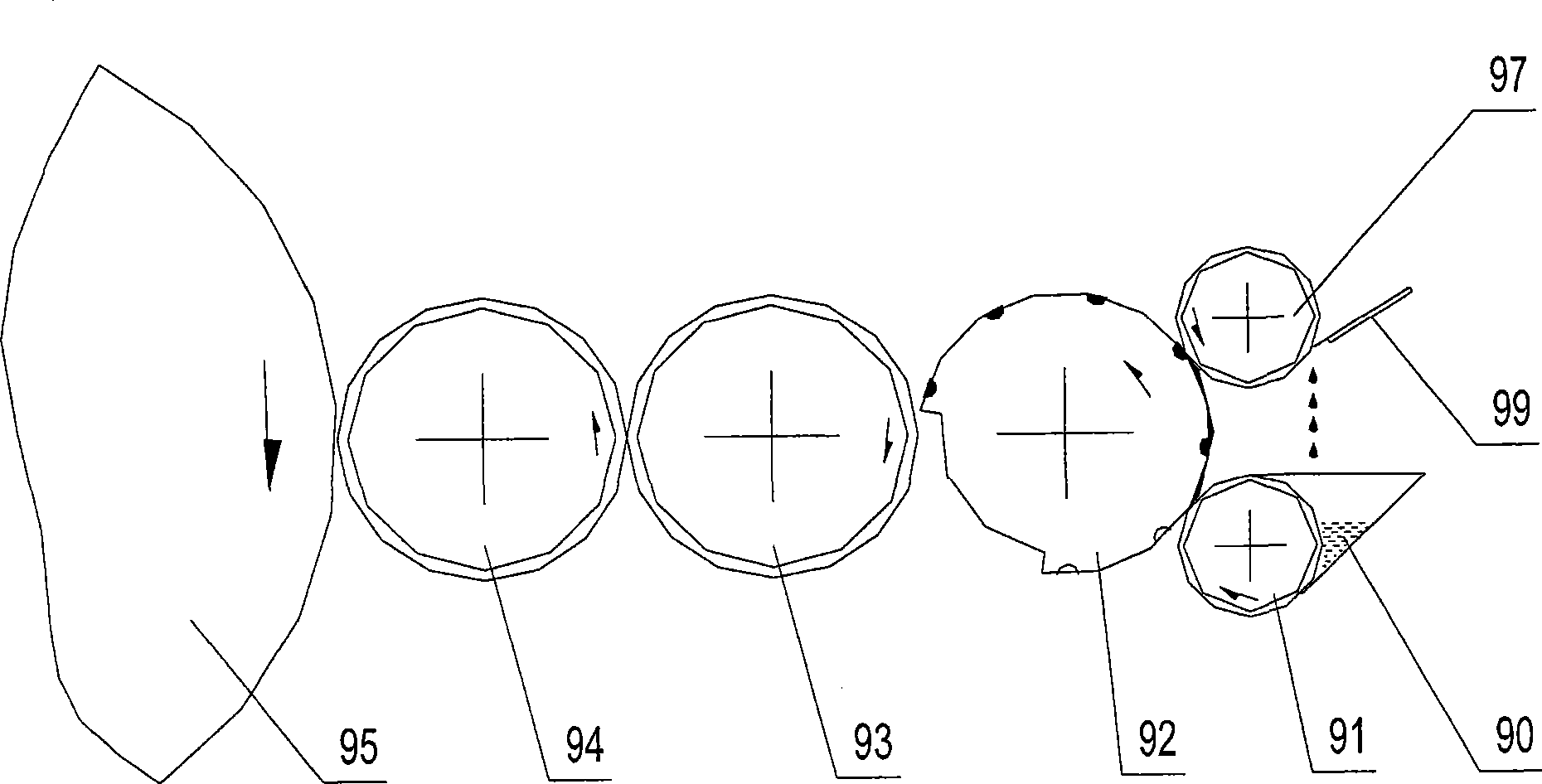

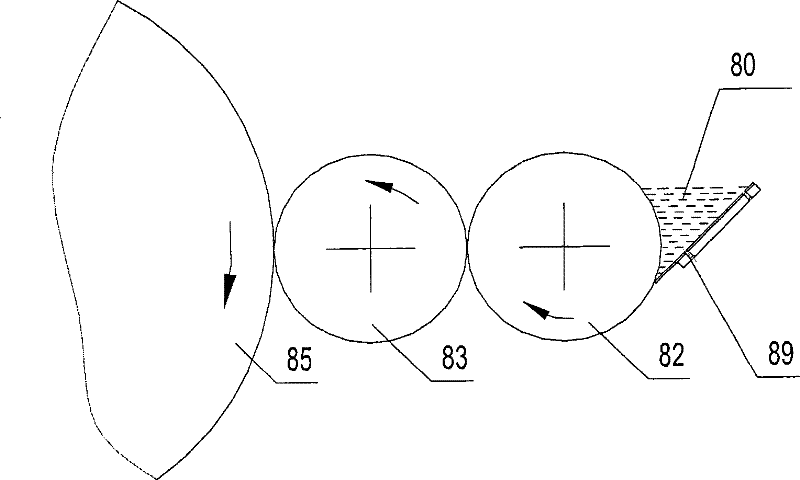

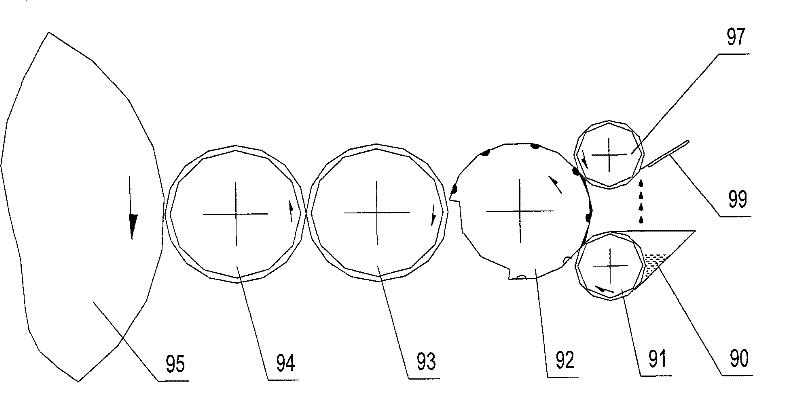

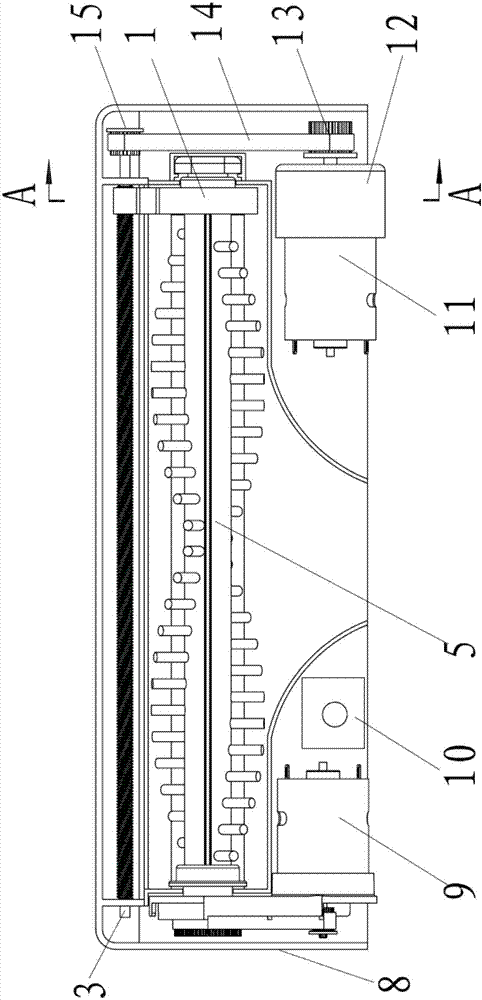

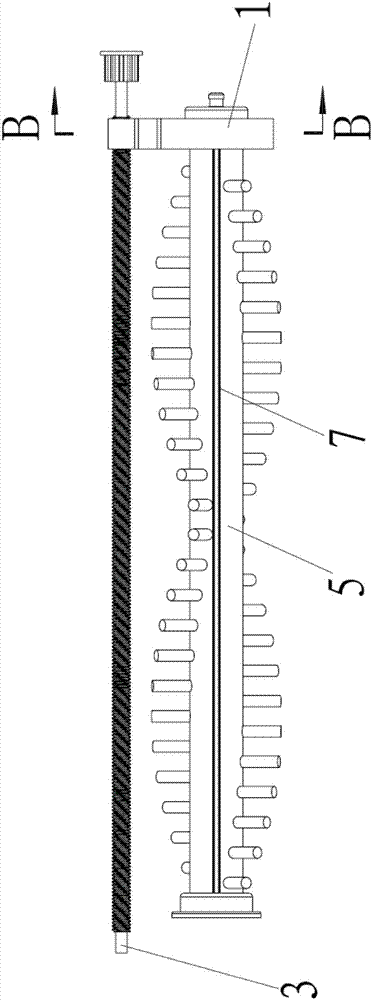

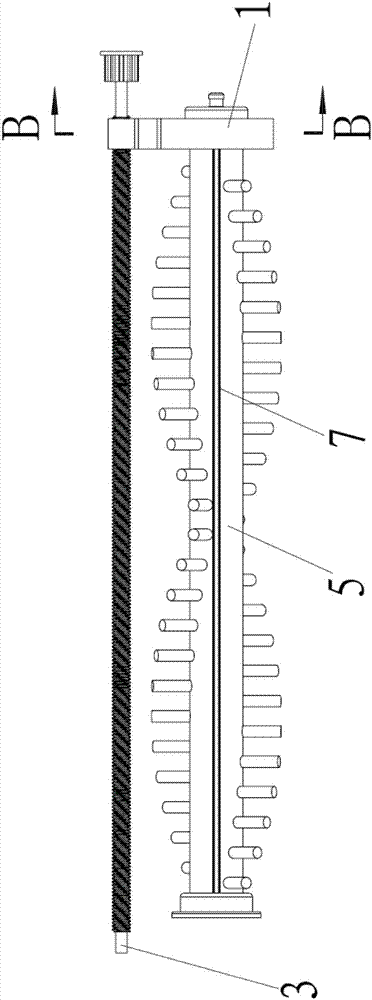

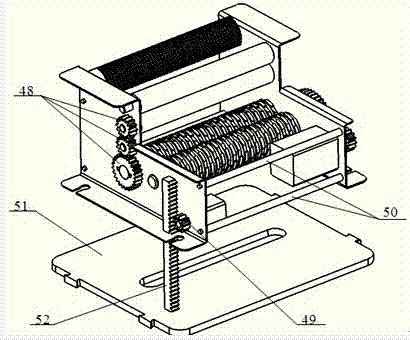

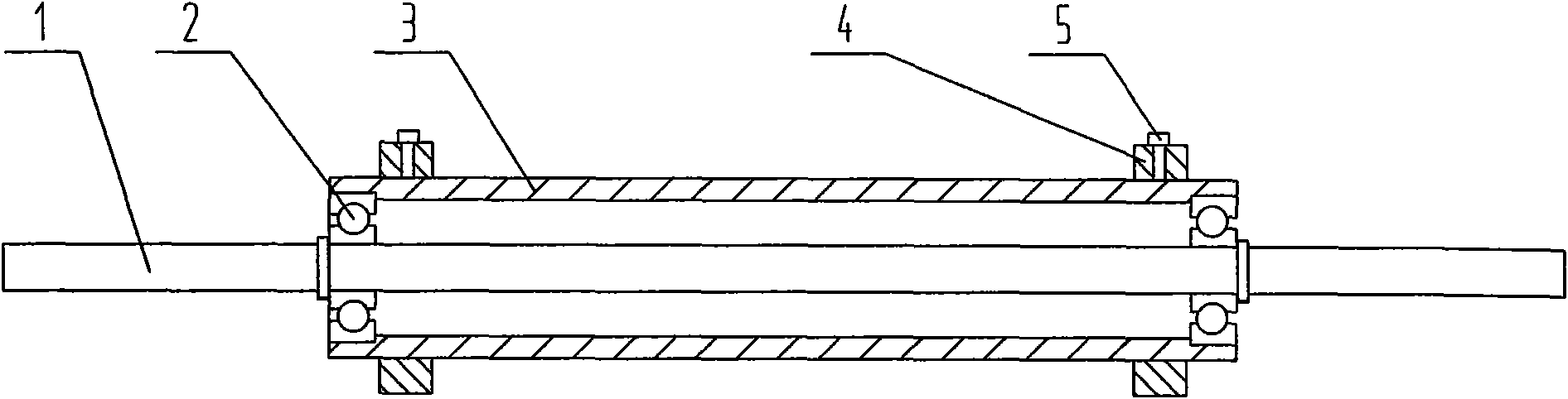

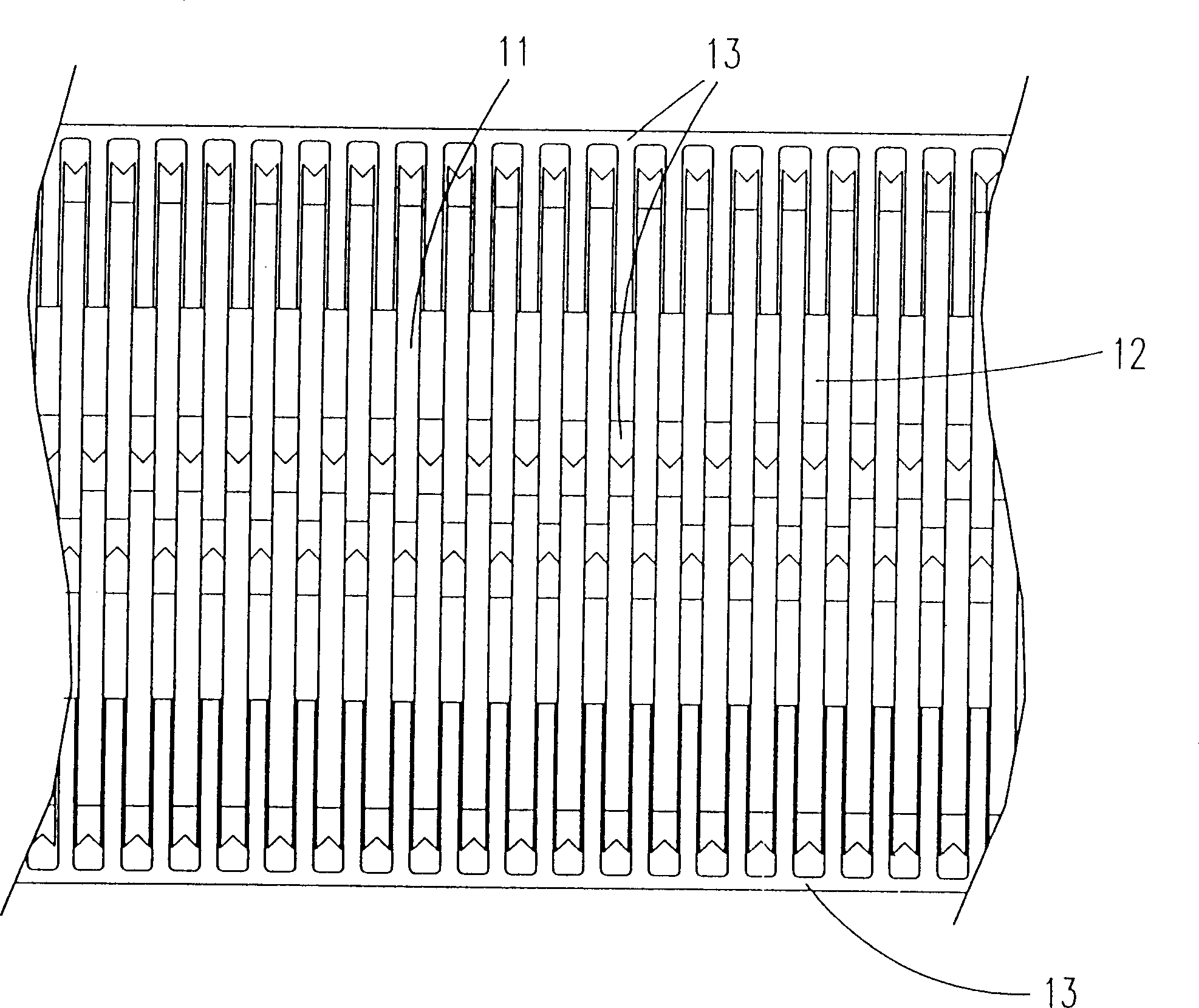

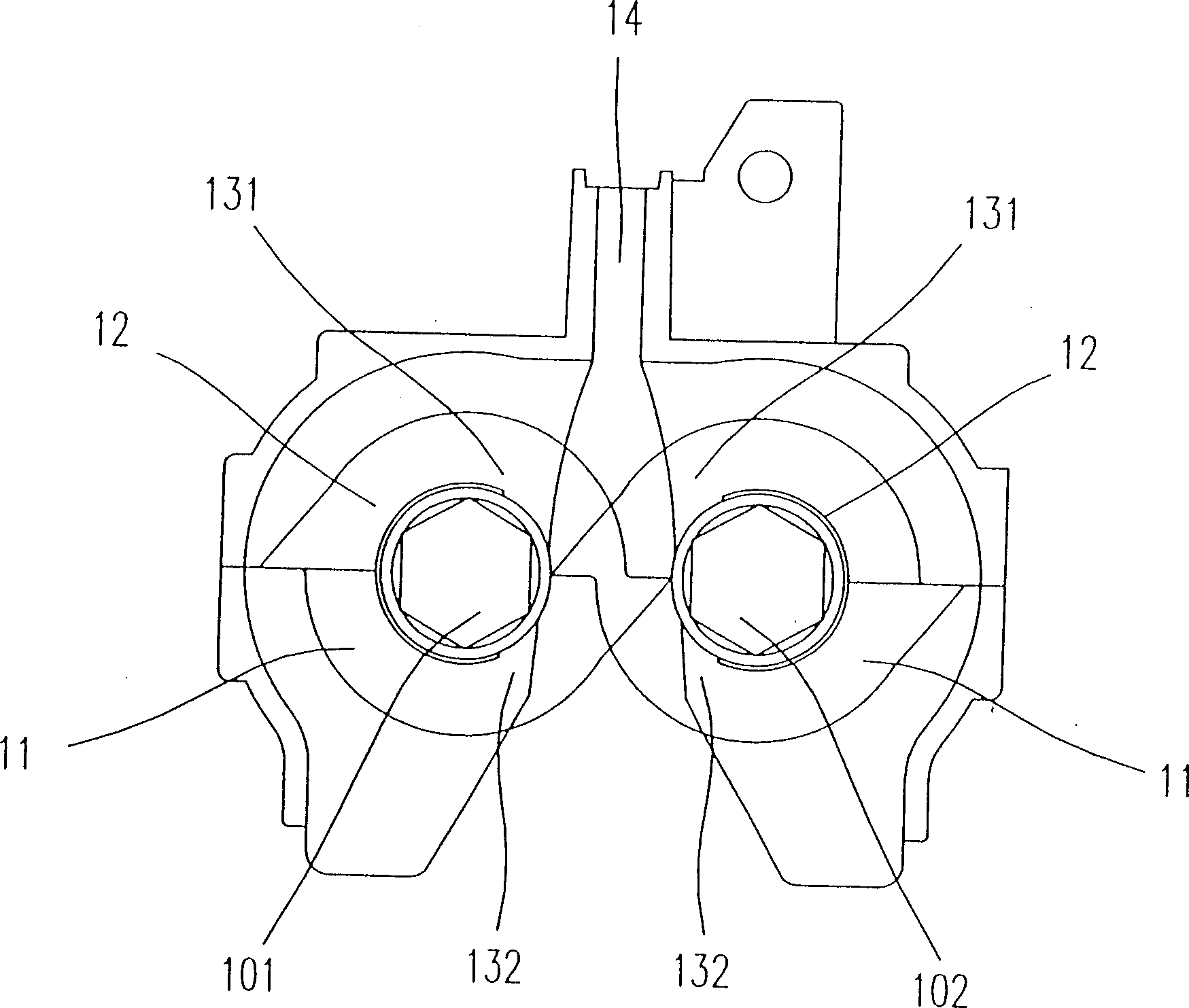

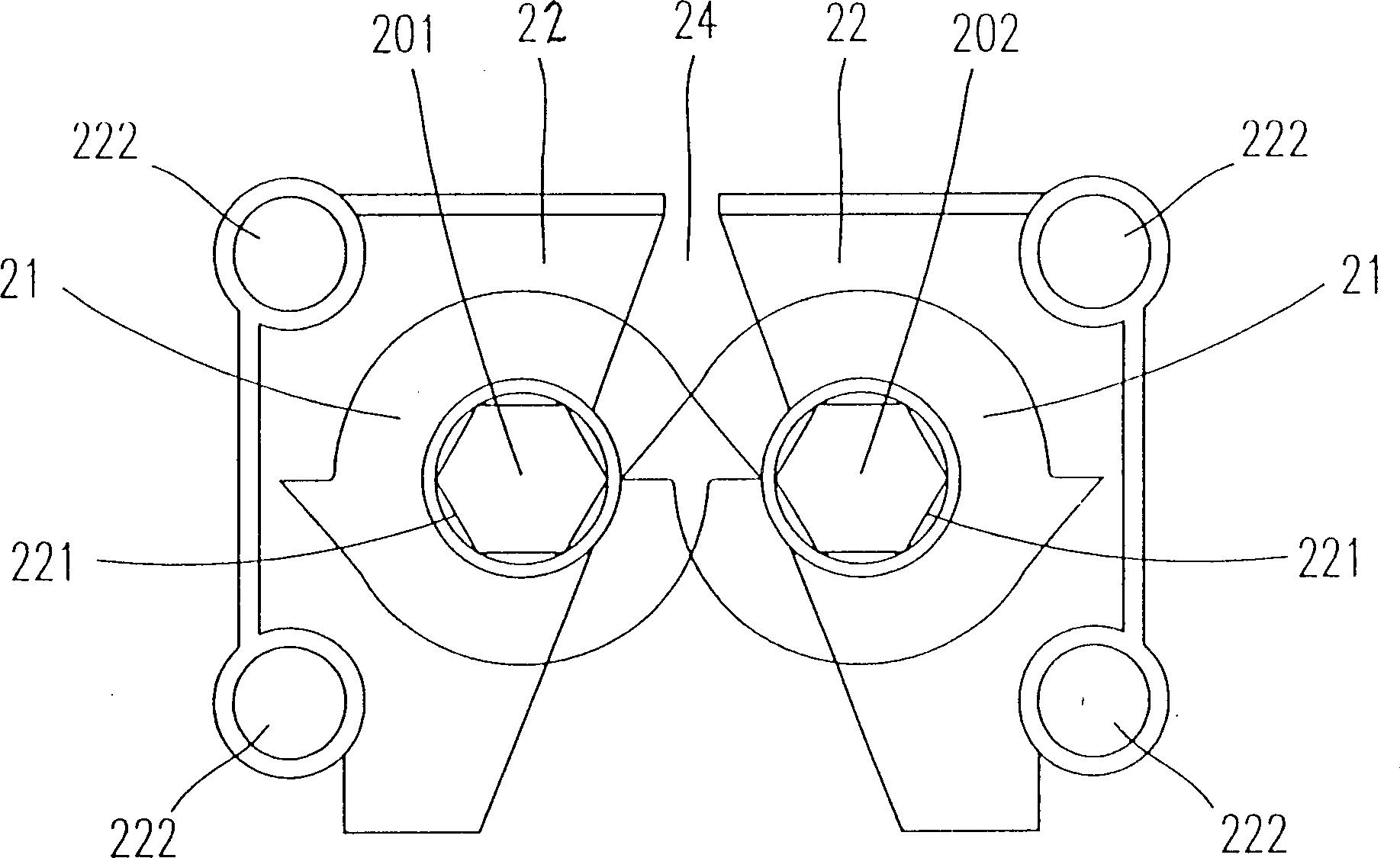

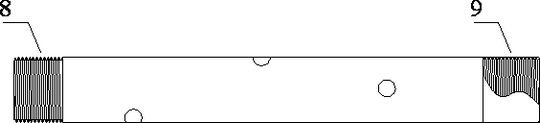

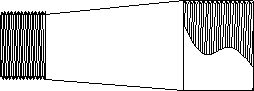

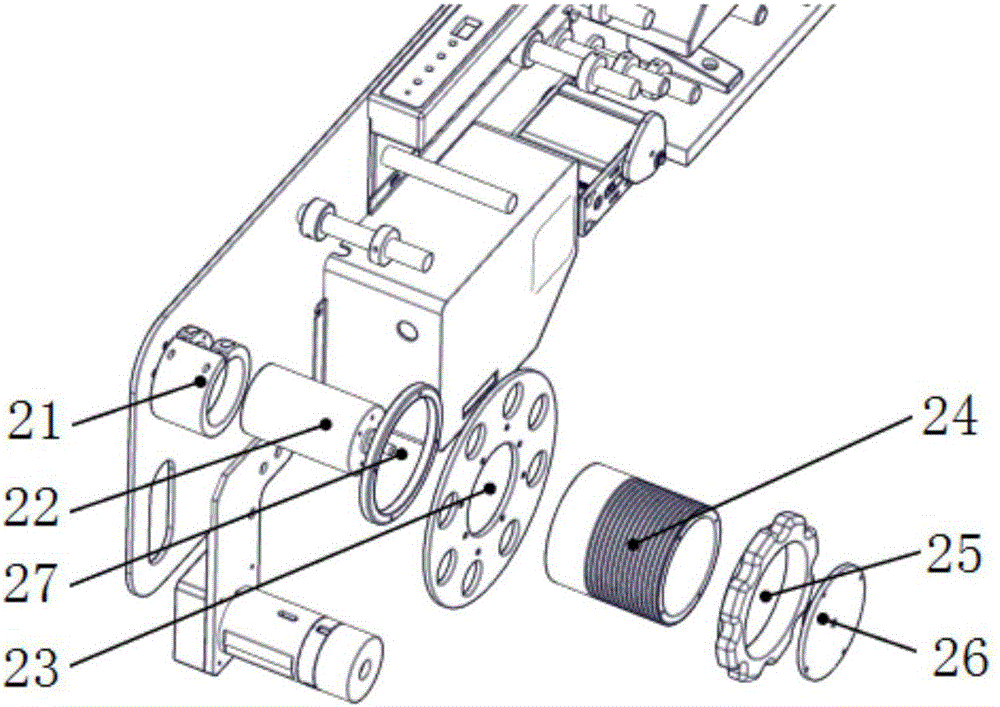

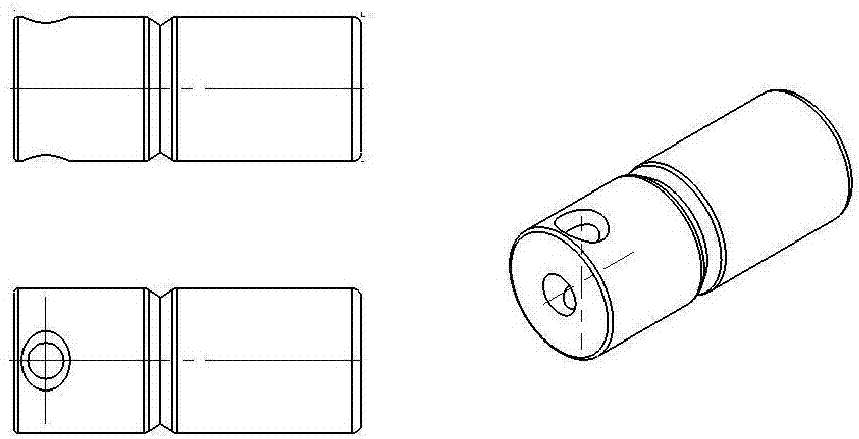

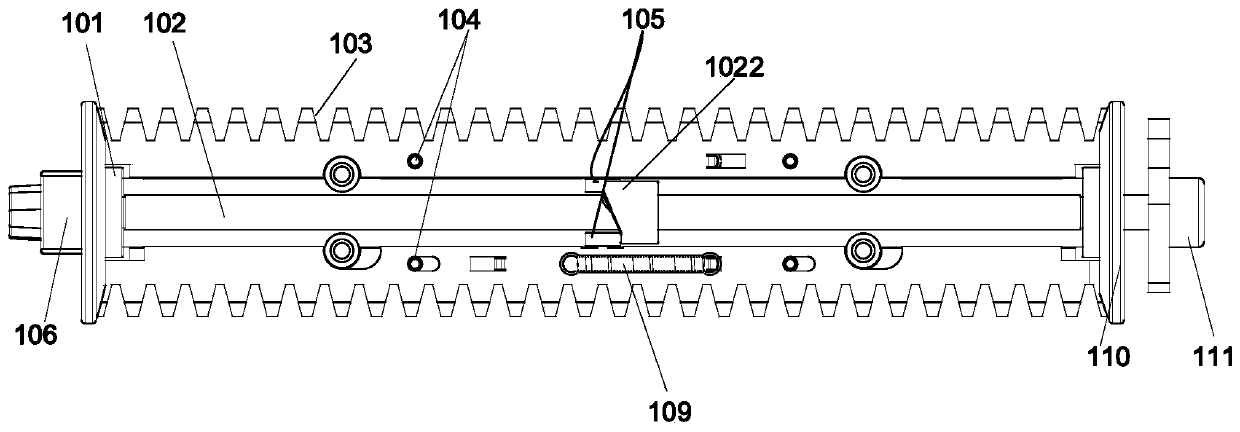

Ink fountain roller, ink distributing unit and ink distributing system of carving photogravure press

ActiveCN101544098AMolushortNot easy to jamRotary intaglio printing pressPrinting press partsPhotogravurePrinting press

The invention provides an ink fountain roller, an ink distributing unit and an ink distributing system of a carving photogravure press. The ink duct roller is a cavity-die inking roller with quasi-grains at the surface, and the quasi-grains correspond to forme grains; the ink distributing unit comprises an ink fountain, the ink fountain roller, a hook type scraper and an elastic color model roller, wherein the ink fountain roller contacts with ink in the ink fountain, the scraper is arranged at one side of the ink fountain roller, the elastic color model roller is arranged at the other side of the ink fountain roller and is in rolling transmission with the ink fountain roller; and the ink distributing system also comprises a gravure roller and an impression roller. The ink fountain roller of the ink distributing unit transmits ink grains which correspond to the gravure grains and have different thicknesses to the color model roller to form basso-relievo-shaped quasi-grain ink; the basso-relievo-shaped quasi-grain ink is transmitted into the gravure grains on the gravure roller; and the gravure roller and the impression roller mutually press to carry out printing. The invention has short ink path, easily ensures the accuracy of ink distribution and easily maintains the printing adaptability without ineffective circulation for the ink.

Owner:CHINA BANKNOTE PRINTING & MINTING

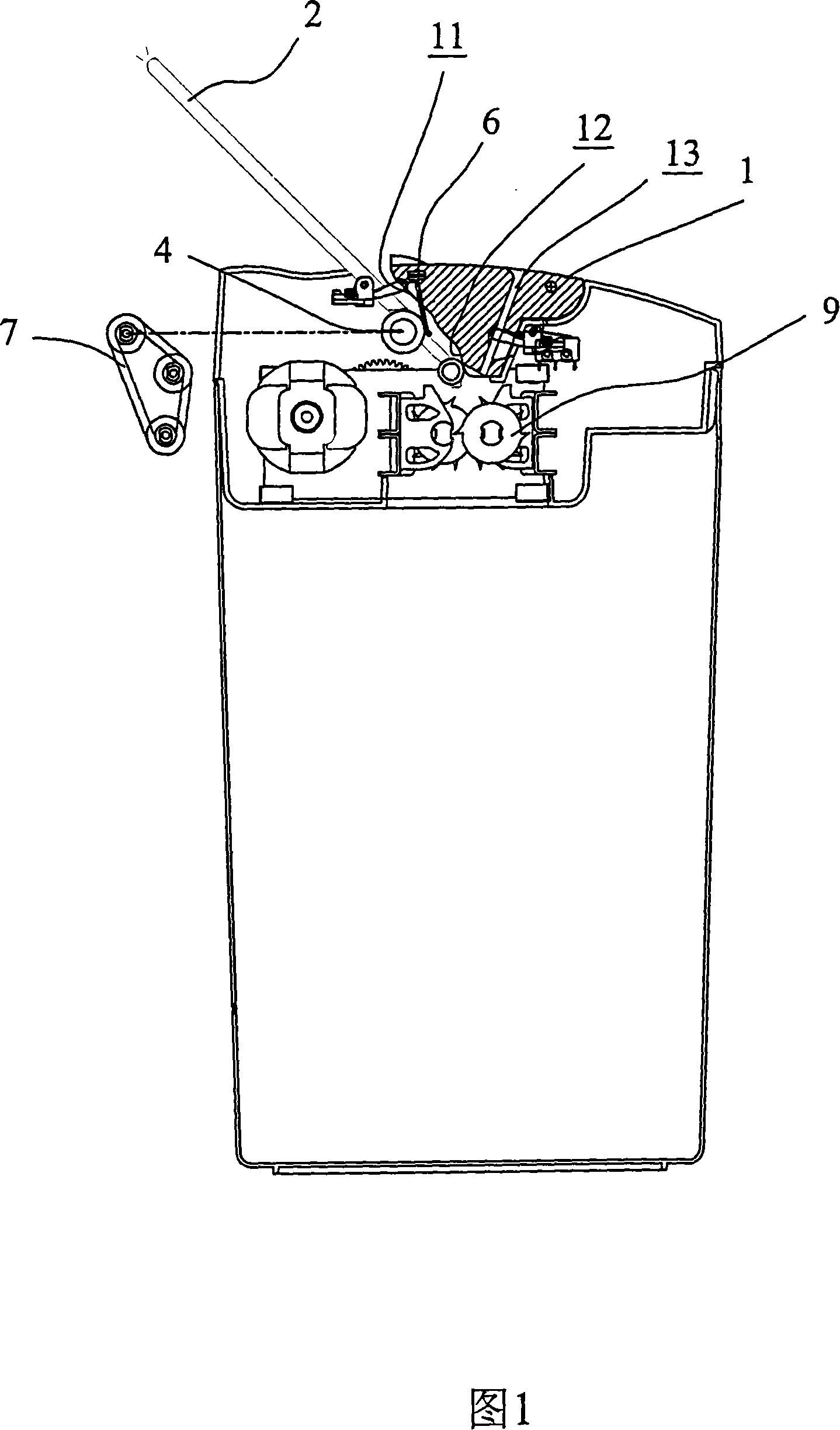

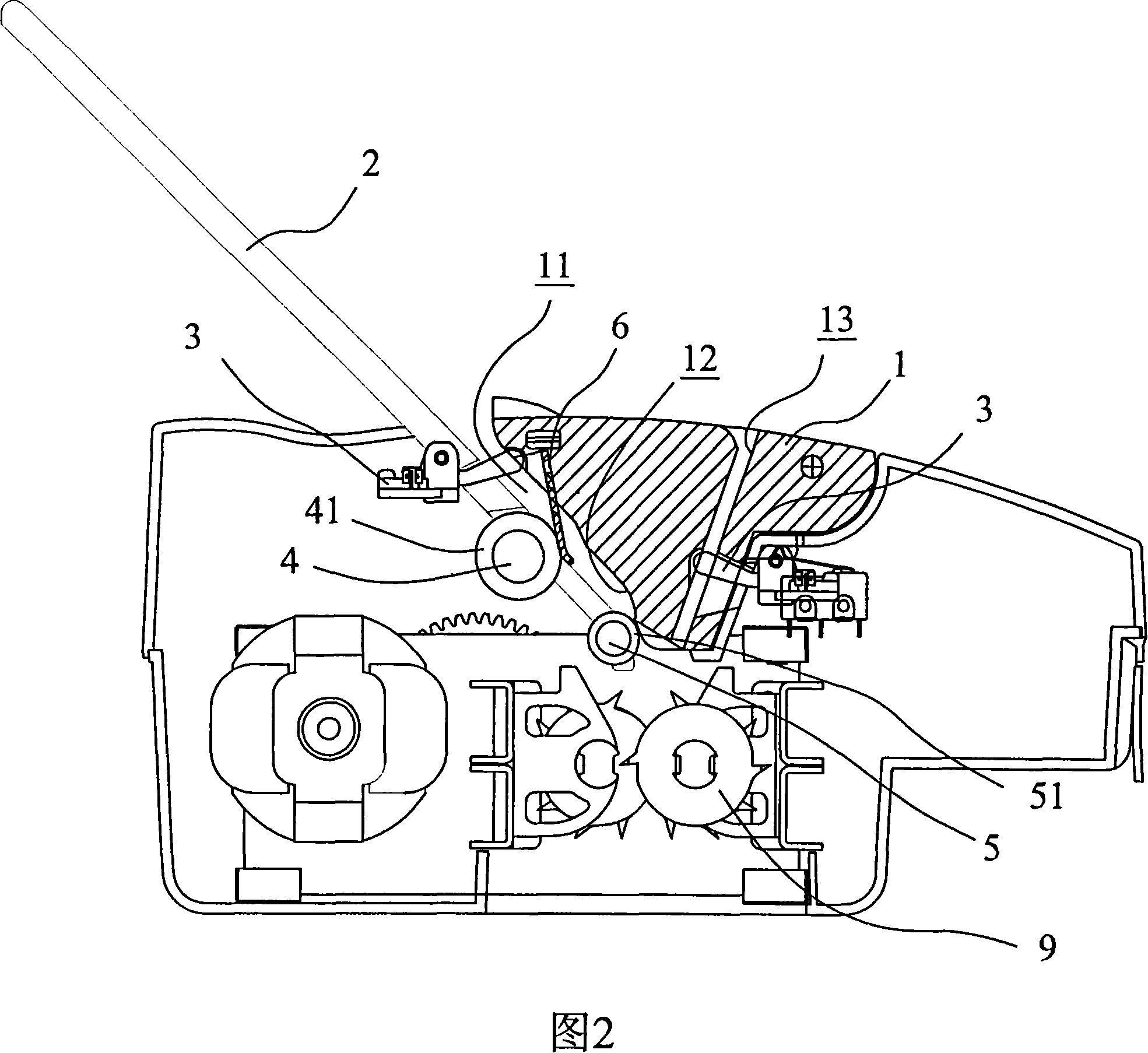

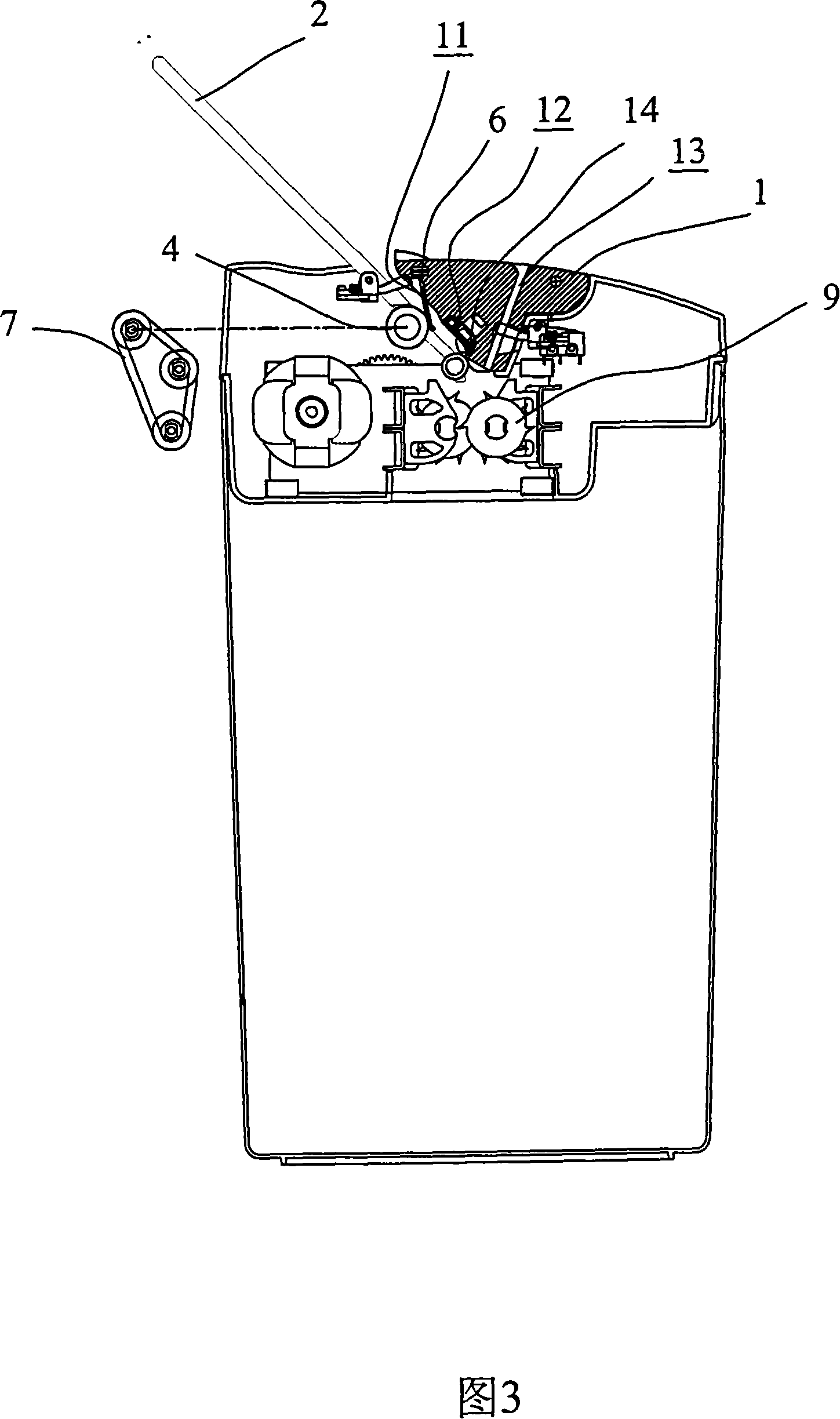

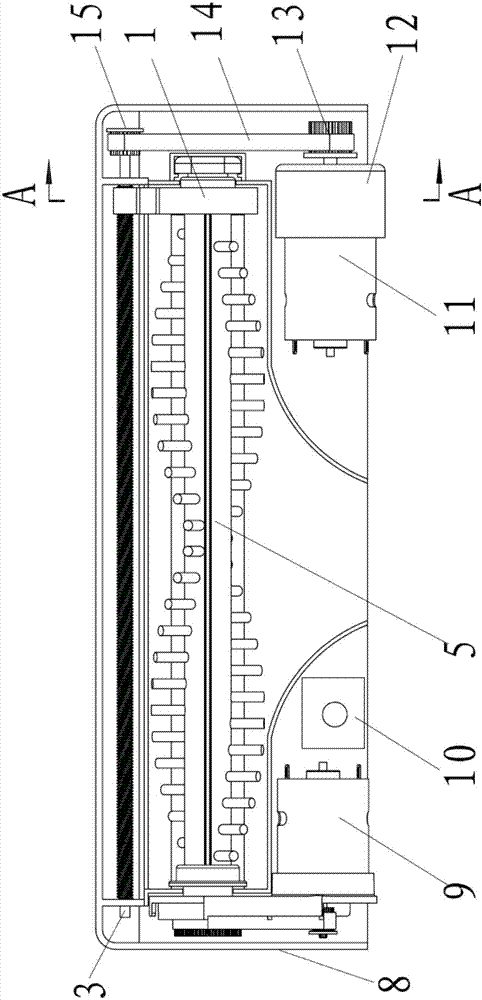

Automatic stamping mechanism based on copper stamp

ActiveCN103129193AMake up for the defect of low service lifeLow failure rateStampingFailure ratePulp and paper industry

An automatic stamping mechanism based on a copper stamp structurally includes a paper feeding channel, a paper outlet channel, a paper conveying driving mechanism, a stamping mechanism and a control management circuit, wherein the paper feeding channel is connected with a paper outlet channel of a printer, and the paper outlet channel is connected with the tail end of the paper feeding channel. The automatic stamping mechanism based on the copper stamp is mainly characterized by further including an automatic replenishing mechanism of stamp-pad ink in structure, the automatic replenishing mechanism of the stamp-pad ink and the stamping mechanism form a matching structure of stamp-retrieval first and oiling second through a compound driving mechanism arranged under the paper outlet channel. The automatic stamping mechanism based on the copper stamp is simple in structure, omits the complex process of manual dipping the stamp-pad ink before stamping, has clear stamp, prolongs the service life of the stamp, and is connected with a specialized paper outlet so that paper jam is not easy to happen and the failure rate is low.

Owner:HEBEI HUIJIN ELECTROMECHANICAL

Ink fountain roller, ink distributing unit and ink distributing system of carving photogravure press

ActiveCN101544098BMolushortNot easy to jamRotary intaglio printing pressPrinting press partsPhotogravurePrinting press

The invention provides an ink fountain roller, an ink distributing unit and an ink distributing system of a carving photogravure press. The ink duct roller is a cavity-die inking roller with quasi-grains at the surface, and the quasi-grains correspond to forme grains; the ink distributing unit comprises an ink fountain, the ink fountain roller, a hook type scraper and an elastic color model roller, wherein the ink fountain roller contacts with ink in the ink fountain, the scraper is arranged at one side of the ink fountain roller, the elastic color model roller is arranged at the other side of the ink fountain roller and is in rolling transmission with the ink fountain roller; and the ink distributing system also comprises a gravure roller and an impression roller. The ink fountain rollerof the ink distributing unit transmits ink grains which correspond to the gravure grains and have different thicknesses to the color model roller to form basso-relievo-shaped quasi-grain ink; the basso-relievo-shaped quasi-grain ink is transmitted into the gravure grains on the gravure roller; and the gravure roller and the impression roller mutually press to carry out printing. The invention hasshort ink path, easily ensures the accuracy of ink distribution and easily maintains the printing adaptability without ineffective circulation for the ink.

Owner:CHINA BANKNOTE PRINTING & MINTING

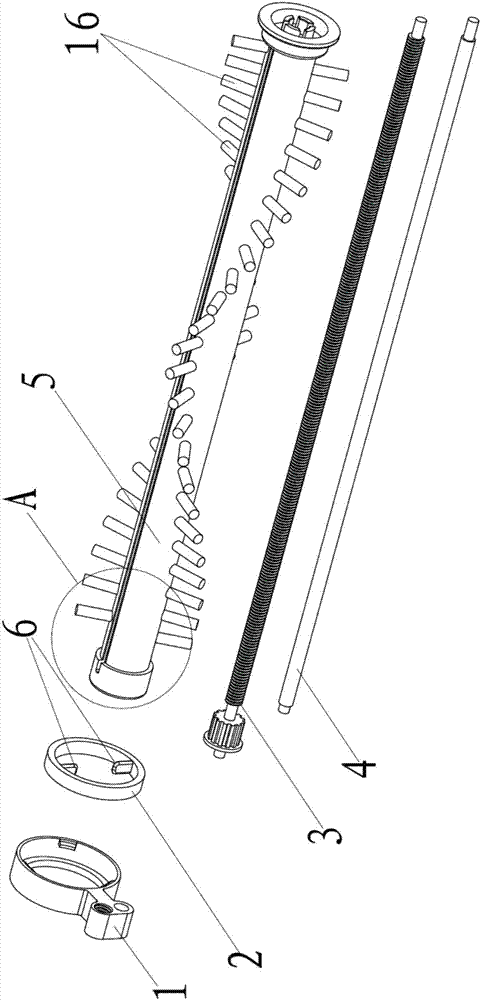

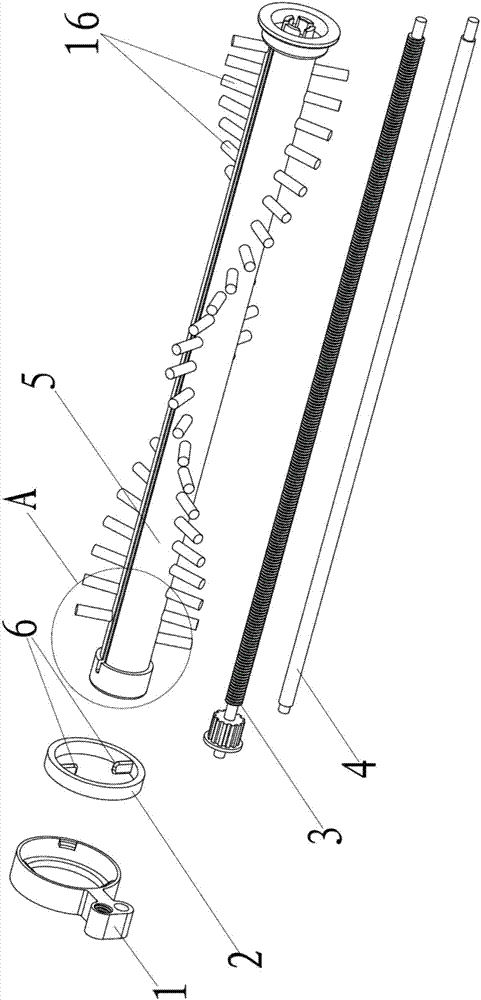

Cutter for cutting rolling brush entanglement on cleaning appliance and cleaning appliance thereof

ActiveCN106923758AEasy to cleanImprove cleaning efficiencyMachine detailsSuction nozzlesAxial displacementAnnular cutter

The invention discloses a cutter for cutting a rolling brush entanglement on a cleaning appliance. The cutter comprises a blade and a cutter rest, wherein the blade is used for cutting the entanglement on the peripheral wall of a rolling brush, connected with an annular cutter head and arranged on the inner ring of the annular cutter head; and the annular cutter head is nested into the cutter rest and has the degree of freedom of rotating along the own axis in the cutter rest, and a limiting structure for limiting axial movement of the annular cutter head is arranged between the cutter frame and the annular cutter head. At least one groove extending axially is formed in the peripheral wall of the rolling brush, the blade extends radially and is inserted into the groove. A fixing and guiding mechanism is provided with a sliding rod arranged in parallel beside the rolling brush and guided axially and a lead screw for outputting axial displacement, and the cutter rest is provided with holes matched with the sliding rod and the lead screw. The invention further provides a cleaning appliance. The cutter automatically cuts the entanglement without exposing the rolling brush, thereby improving the cutting environment and improving the cleaning effect and efficiency.

Owner:SUZHOU CHUNJU ELECTRIC CO LTD

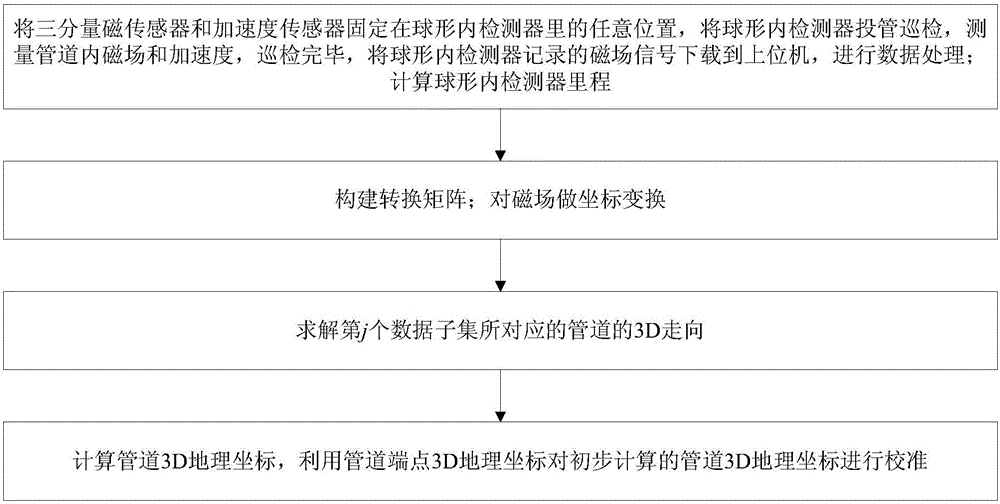

Measurement method for three-dimensional geographical coordinates of submarine pipeline

ActiveCN106197409AAvoid deformationNot easy to jamNavigation by speed/acceleration measurementsOcean bottomSubmarine pipeline

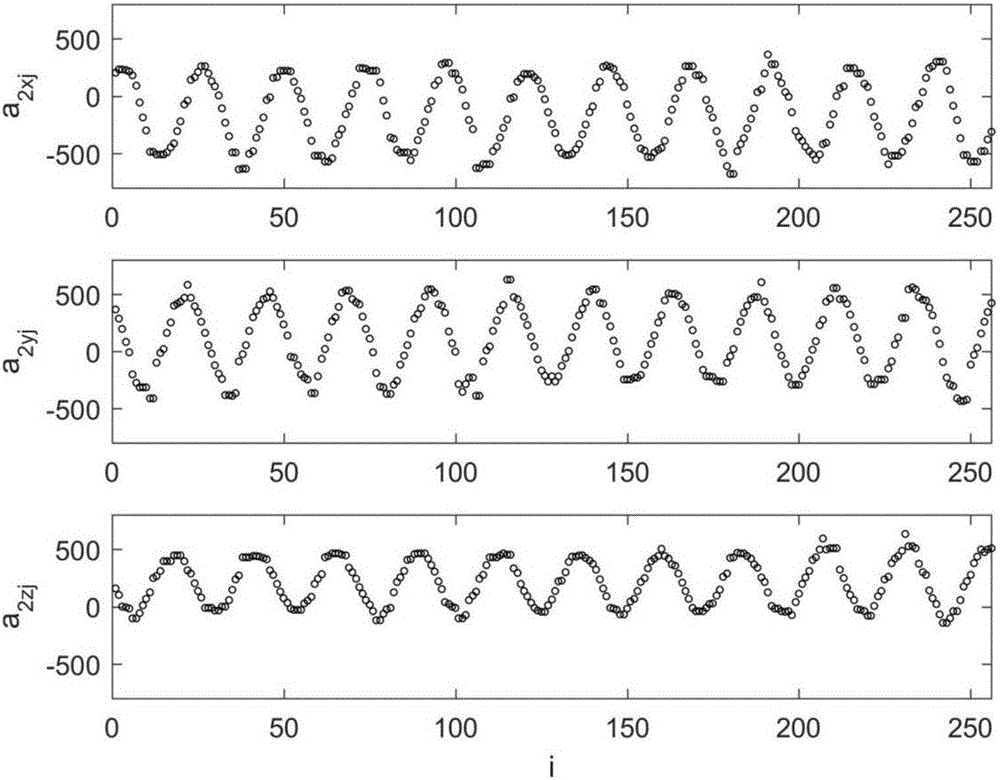

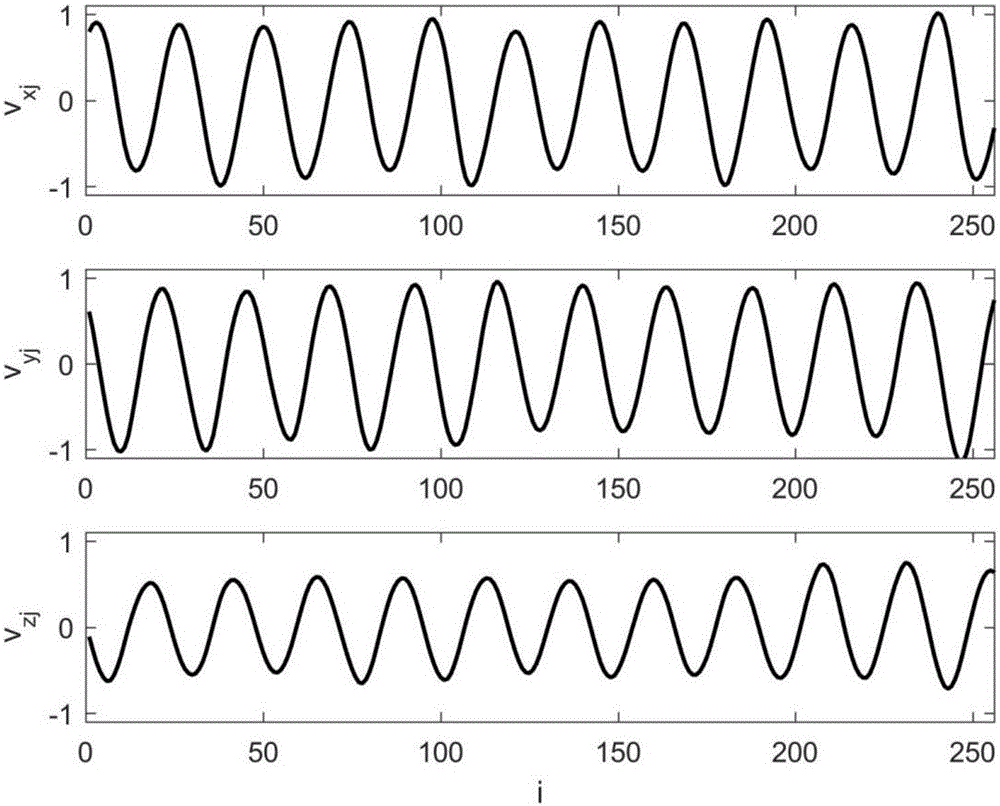

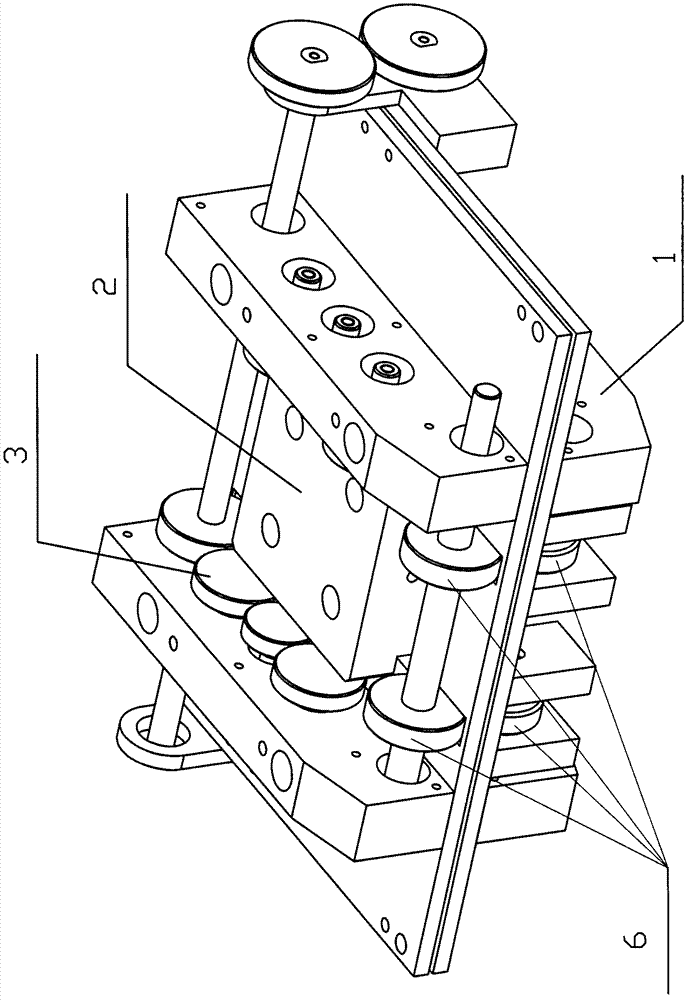

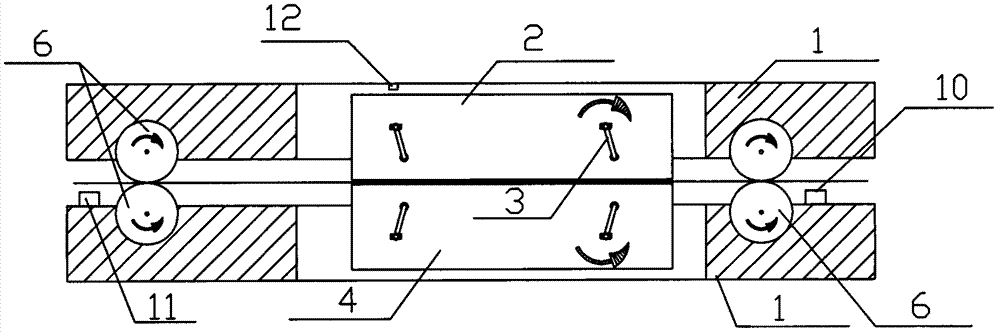

The invention discloses a measurement method for three-dimensional geographical coordinates of a submarine pipeline. The measurement method comprises the following steps: fixing a three-component magnetic sensor and an acceleration sensor at any positions of a spherical internal detector, arranging the spherical internal detector in the submarine pipeline for inspection, measuring the magnetic field and the acceleration in the pipeline, and after polling, downloading the magnetic field signal, recorded by the spherical internal detector, into an upper computer for data processing; calculating the mileage of the spherical internal detector; constructing a conversion matrix; performing coordinate transformation to the magnetic field; resolving the 3D direction of the pipeline corresponding to a jth data subset; calculating the 3D geographical coordinates of the pipeline, and calibrating the primarily calculated 3D geographical coordinates of the pipeline by utilizing the end 3D geographical coordinates of the pipeline. According to the measurement method, the full-pipeline, short-period, low-cost and convenient measurement on the three-dimensional geographical coordinates of the submarine pipeline through the spherical internal detector can be realized on the premise of having no assisted positioning method (such as GPS and ground marker).

Owner:天津精仪精测科技有限公司

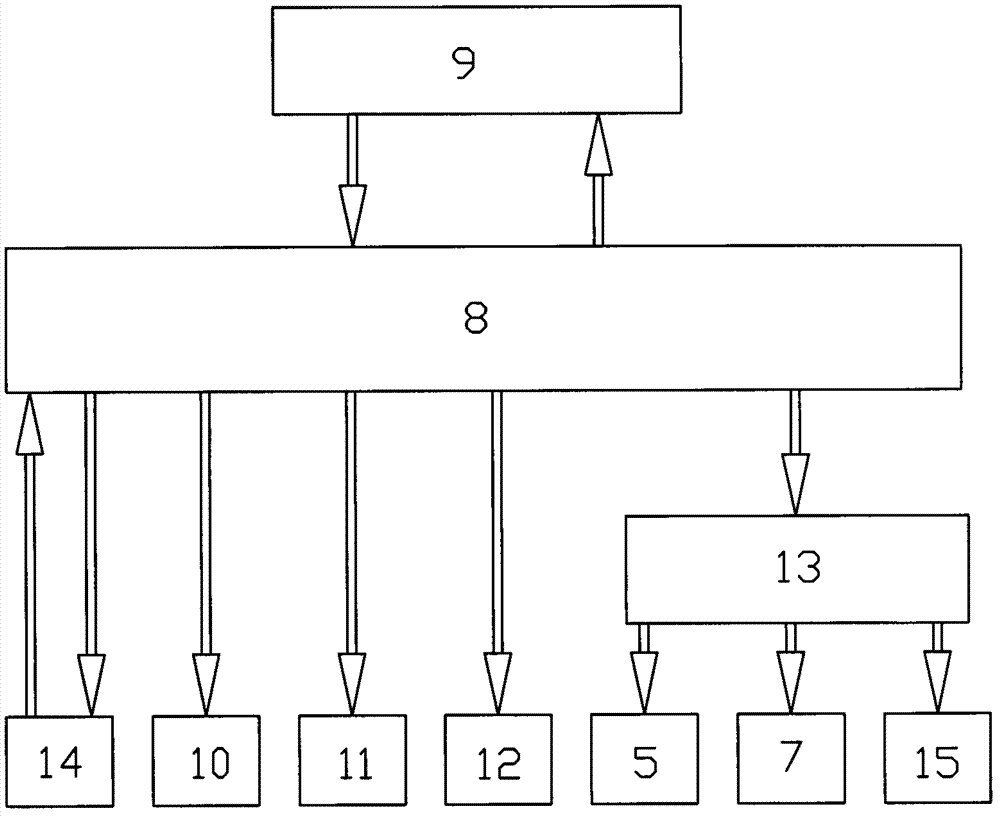

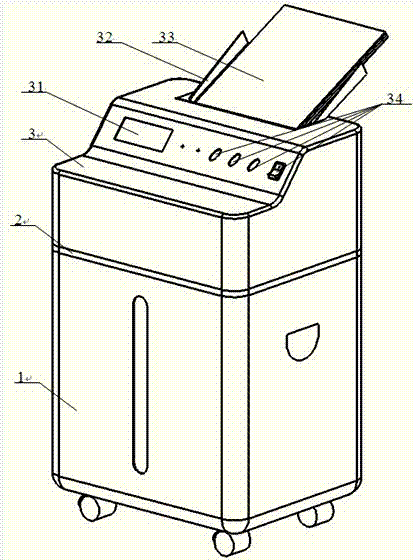

High-speed sealing machine, printing/sealing all-in-one machine and control method of printing/sealing all-in-one machine

InactiveCN103241019AHigh degree of automationNot easy to jamTypewritersStampingMotor speedElectric machinery

The invention relates to a high-speed sealing machine, a printing / sealing all-in-one machine and a control method of the printing / sealing all-in-one machine. Stability and safety of the existing high-speed sealing machine are needed to be improved. Therefore, the high-speed sealing machine is additionally provided with a central processor, a storage, a paper feeding sensor, a paper delivery sensor and a sealing reset sensor, wherein the paper feeding sensor and the paper delivery sensor which are both photoelectric induction sensors are arranged at positions of a paper inlet of a sealing mechanism and a paper outlet of the sealing mechanism; the paper feeding sensor, the paper delivery sensor and the sealing reset sensor are respectively connected with the signal input end of the central processor; the storage is connected with the central processor; a sealing motor and a paper delivery motor are respectively connected with the signal output end of the central processor through a motor speed regulation module; and an external communication port is arranged on the central processor. The control method of the printing / sealing all-in-one machine has the advantages of being high in automation and safety and not having paper clamping easily, and is applicable to various enterprises needing printing and sealing, especially the financial industry.

Owner:北京宇信科技集团股份有限公司

Automatic page-separating paper crusher

The present invention relates to a full-automatic paging type cone breaker. Said paging type cone breaker mainly includes the following several portions: cutter shaft, cutter blade, paper carriage, cover board, main paper-guiding wheel drive dvice and control device. Said invention also provides the concrete operation method of said cone breaker.

Owner:SHANGHAI JUHSIN ELECTRONICS

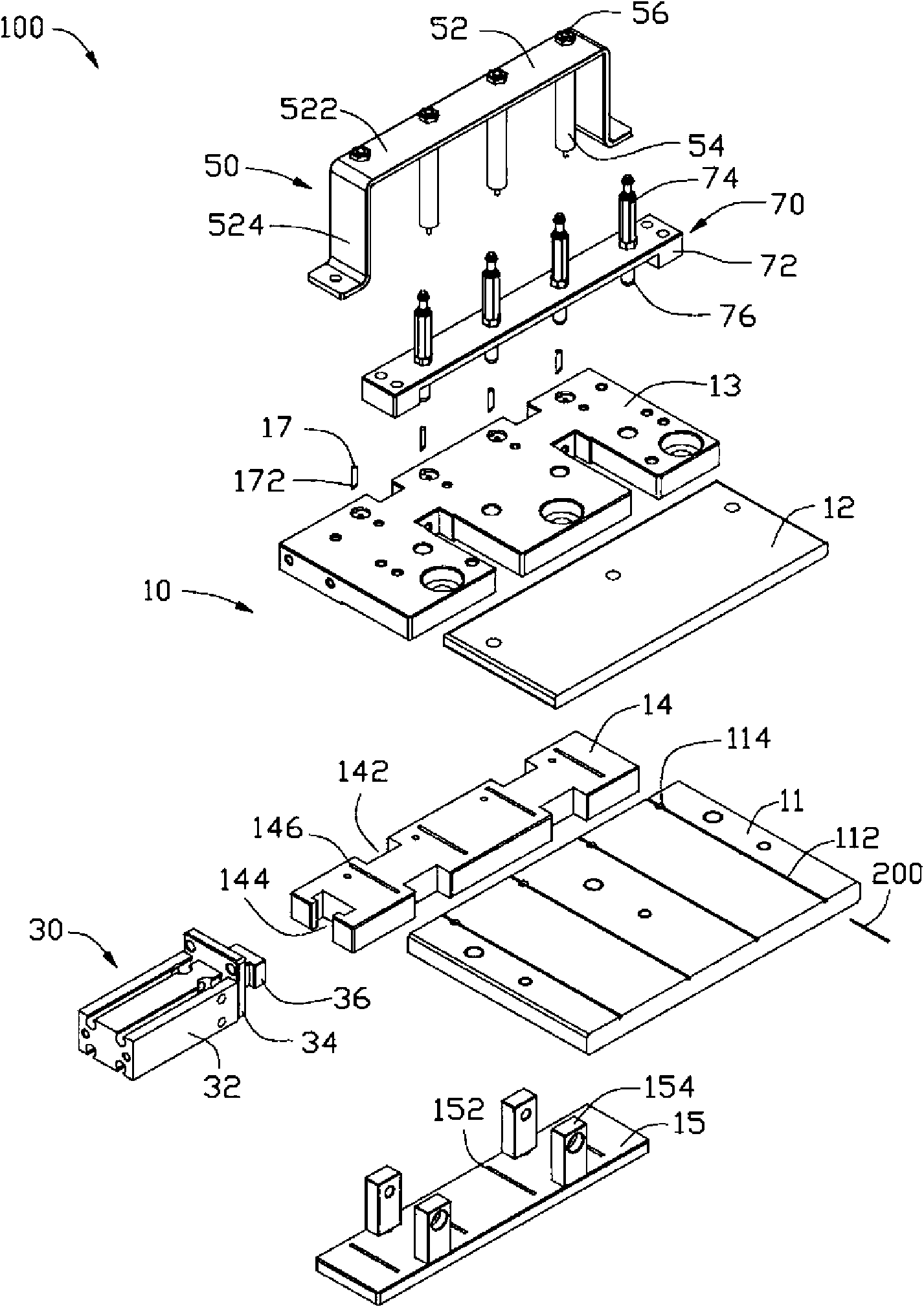

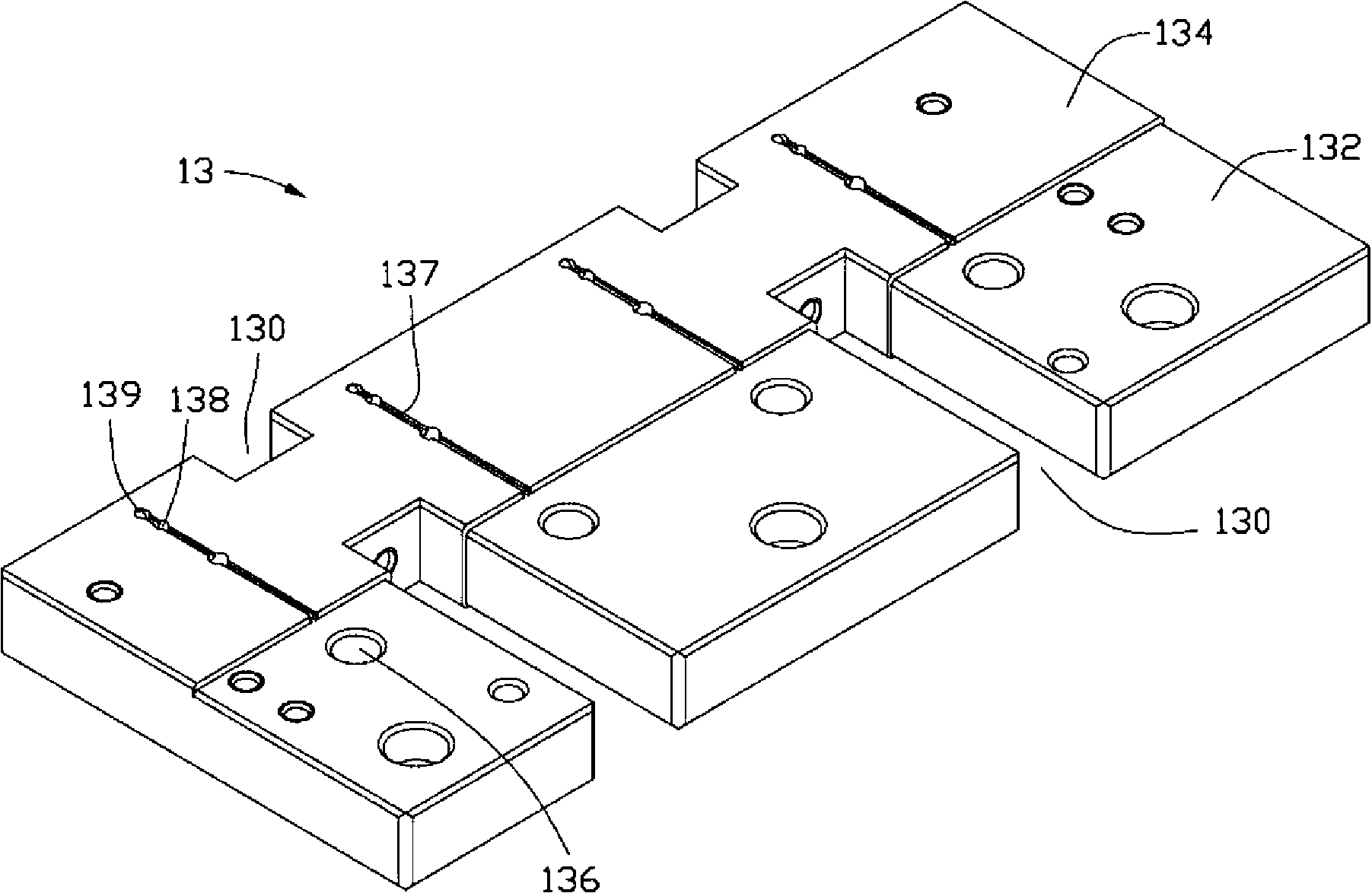

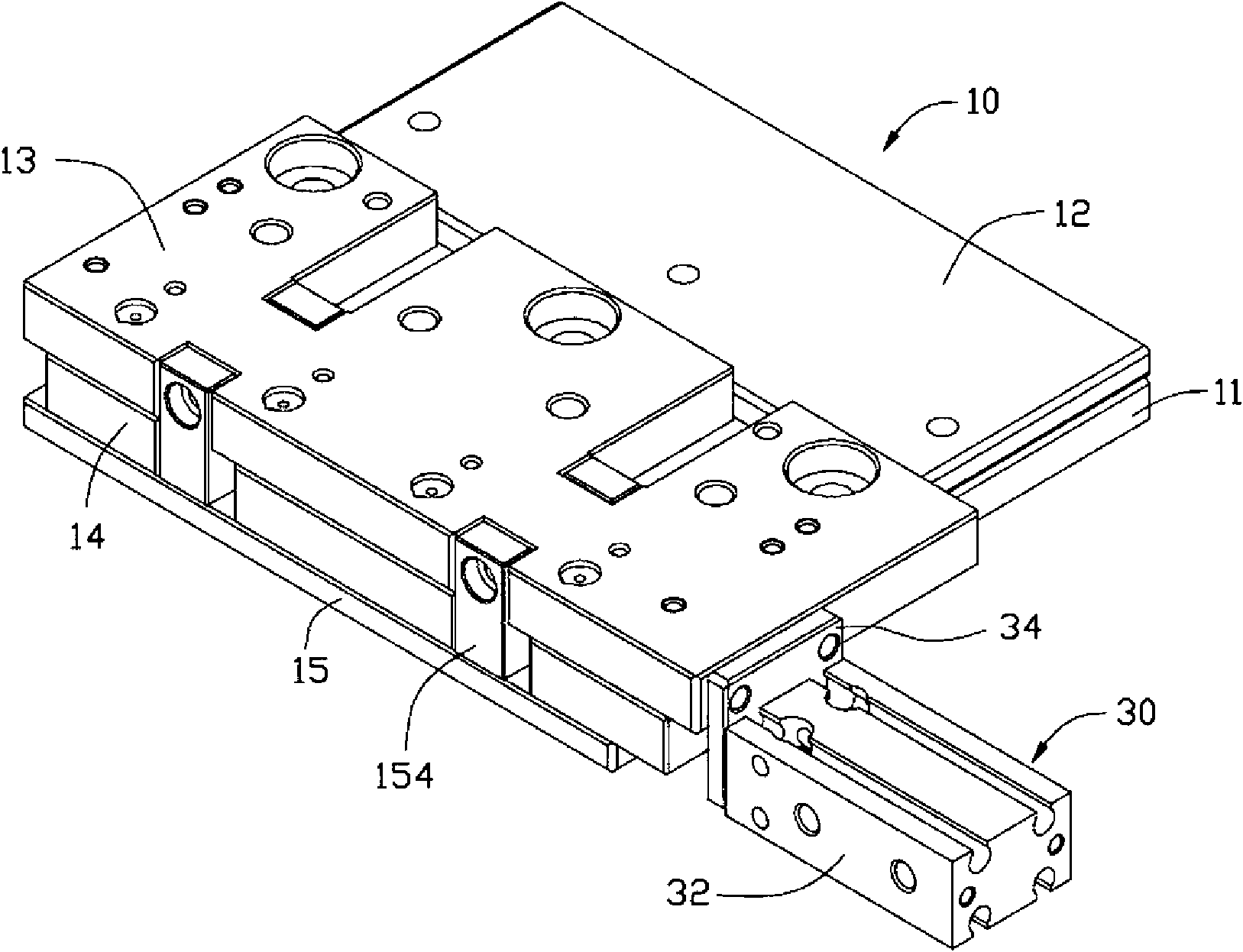

Material distribution device

The invention provides a material distribution device for conveying workpieces. The material distribution device for conveying workpieces comprises a material distribution mechanism, a sliding mechanism and a detection mechanism; the material distribution mechanism comprises a sliding plate and a plurality of grooves; the sliding plate is fixed on the sliding mechanism; a plurality of first material outlets are formed on the sliding plate; the detection mechanism is used for detecting positions of the workpieces in the grooves; and the sliding structure is used for driving the sliding plate to move so as to align or stagger the first material outlets and the grooves. The material distribution device has simple structure and high efficiency.

Owner:SHENZHEN FUTAIHONG PRECISION IND CO LTD

Rolling brush entanglement cutting device for cleaning appliance and cleaning appliance thereof

ActiveCN106923747AEasy to cleanImprove cleaning efficiencyMachine detailsSuction nozzlesAxial displacementAnnular cutter

The invention discloses a rolling brush entanglement cutting device for a cleaning appliance. The device comprises a blade and a fixing and guiding mechanism, wherein the blade is used for cutting the entanglement on the peripheral wall of a rolling brush; and the fixing and guiding mechanism is independently arranged outside the rolling brush and used for fixing the blade and guiding moving and cutting of the blade along the axis of the rolling brush. At least one groove extending axially is formed in the peripheral wall of the rolling brush, and the blade is inserted into the groove. The blade is connected with an annular cutter head, arranged on the inner ring of the annular cutter head, arranged in a manner of extending in the radial direction of the annular cutter head, and provided with cutting edges along two axial ends of the annular cutter head. The fixing and guiding mechanism is provided with a sliding rod arranged in parallel beside the rolling brush and guided axially and a lead screw for outputting axial displacement, and the cutter rest is provided with holes matched with the sliding rod and the lead screw. The invention further provides a cleaning appliance. The device automatically cuts the entanglement without exposing the rolling brush, thereby improving the cutting environment and improving the cleaning effect and efficiency.

Owner:SUZHOU CHUNJU ELECTRIC CO LTD

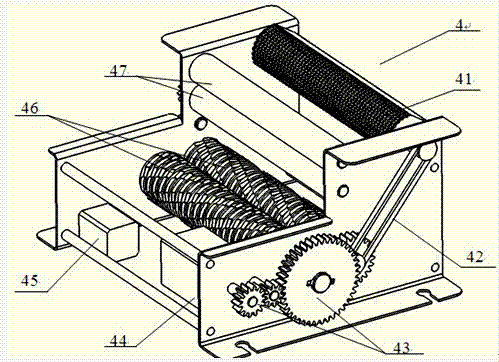

Intelligent paper shredder

ActiveCN102784699AImprove work efficiencyEasy to recycleGrain treatmentsAutomatic transmissionControl system

The invention discloses an intelligent paper shredder, which comprises a shredded paper receiving barrel, wherein a cover body is arranged on the upper end of the shredded paper receiving barrel; a paper shredder head is mounted in the cover body; a cover head is arranged on the upper end of the cover body and covers the paper shredder head; a circuit board, a control system, a display screen and control buttons are arranged in the cover head; the paper shredder head part further comprises a double-hob shredding mechanism, a transmission system, a paper feeding roller and a cam; and the shredded paper receiving barrel comprises a shredded paper receiving barrel body, a shredded paper recovery bag sleeved in the shredded paper receiving barrel and a shredded paper compressing mechanism. With the adoption of the intelligent paper shredder, automatic transmission of the paper can be realized, and the shredded paper is compressed into a bag instead of forming a pile of bubble-like shredded paper when processing the shredded paper, so that the recovery, classification and collection of the shredded paper are convenient.

Owner:青岛鹰王谷电子商务有限公司

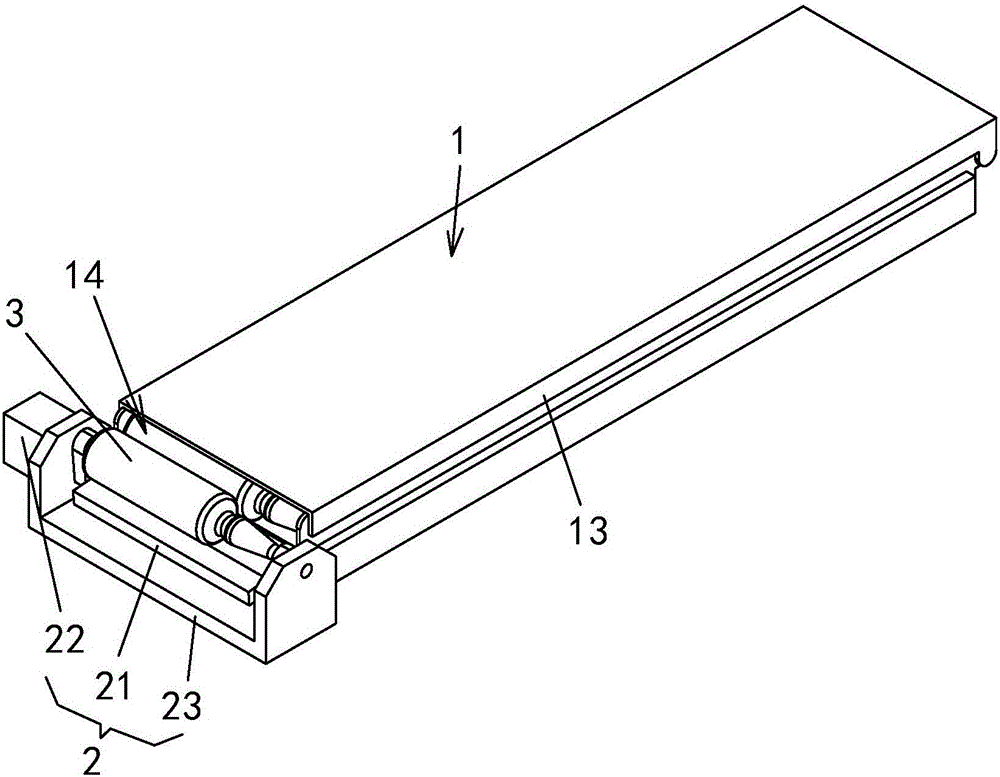

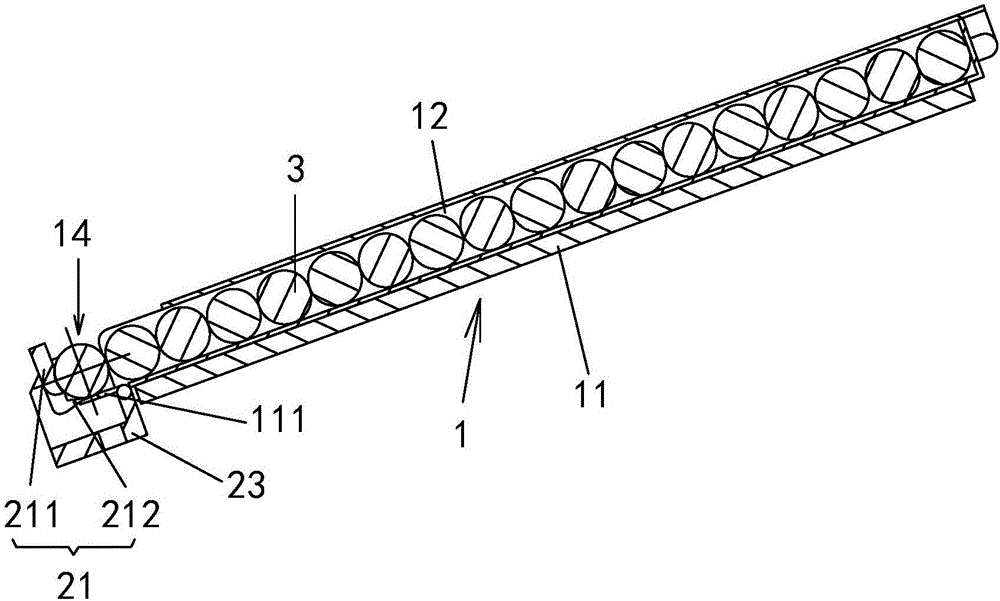

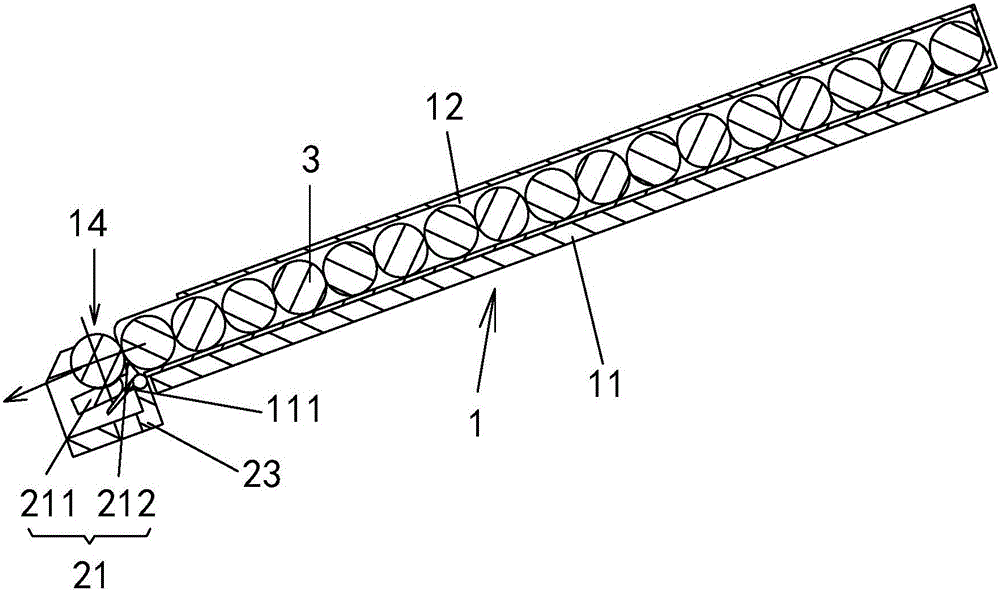

Baffle stop type medicine dispensing unit for bottled medicines

ActiveCN105966812AGuaranteed stable workNot easy to jamConveyorsCoin-freed apparatus detailsStopped workMedicine

A baffle stop type medicine dispensing unit for bottled medicines is characterized in that the bottled medicines (3) are flatly laid in a medicine storage body (1) in a single-row manner; the included angle between the length direction of the medicine storage body (1) and the horizontal plane is larger than 10 degrees, the medicine outlet end of the medicine storage body (1) is lower than the rear end of the medicine storage body (1), and an opening in the medicine outlet end serves as a medicine outlet (14); a medicine discharging mechanical device (2) comprises a medicine dispensing baffle (21) hinged to the medicine outlet (14), and when the medicine dispensing baffle (21) is in a covering closed stop work state, the medicine outlet (14) is sealed and covered; when the medicine dispensing baffle (21) is in an overturning opened work state, the medicine dispensing baffle (21) is overturned downwards and opened to be connected to the front side of a bottom wall (11), the first bottled medicine (3) at the medicine dispensing end is dispensed forwards at a straight plate part (211) of the medicine dispensing baffle (21), and a stop part (212) stops the second bottled medicine (3) at the medicine dispensing end.

Owner:SUZHOU XINHENG AUTOMATION TECH

Conducting wire box

InactiveCN101986475ANot easy to fall offNot easy to jamFlexible lead accommodationElectricityEngineering

Owner:CHANGZHOUASIAN ENDERGONIC ELECTRONICS TECH CO LTD

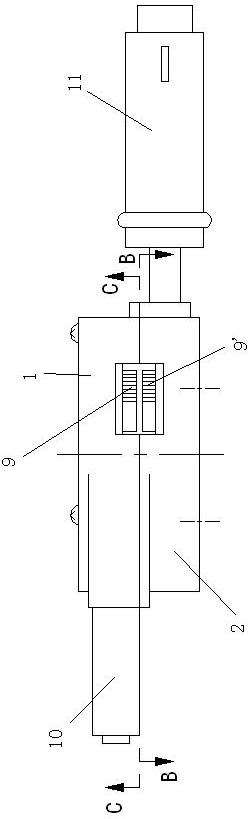

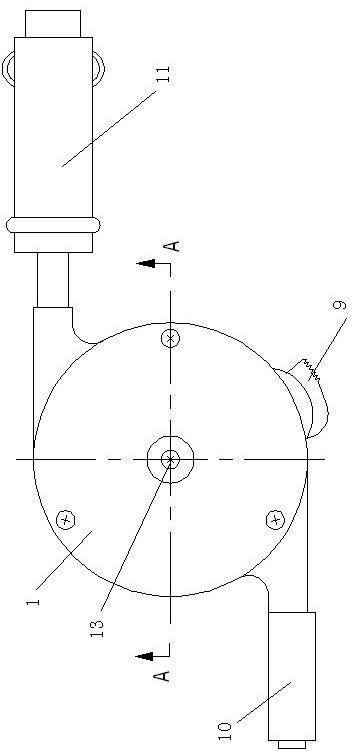

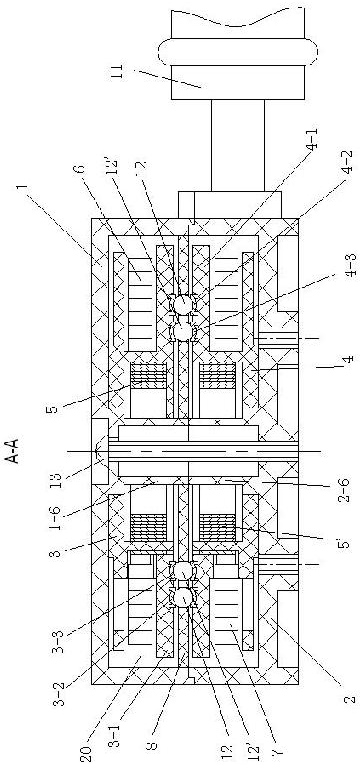

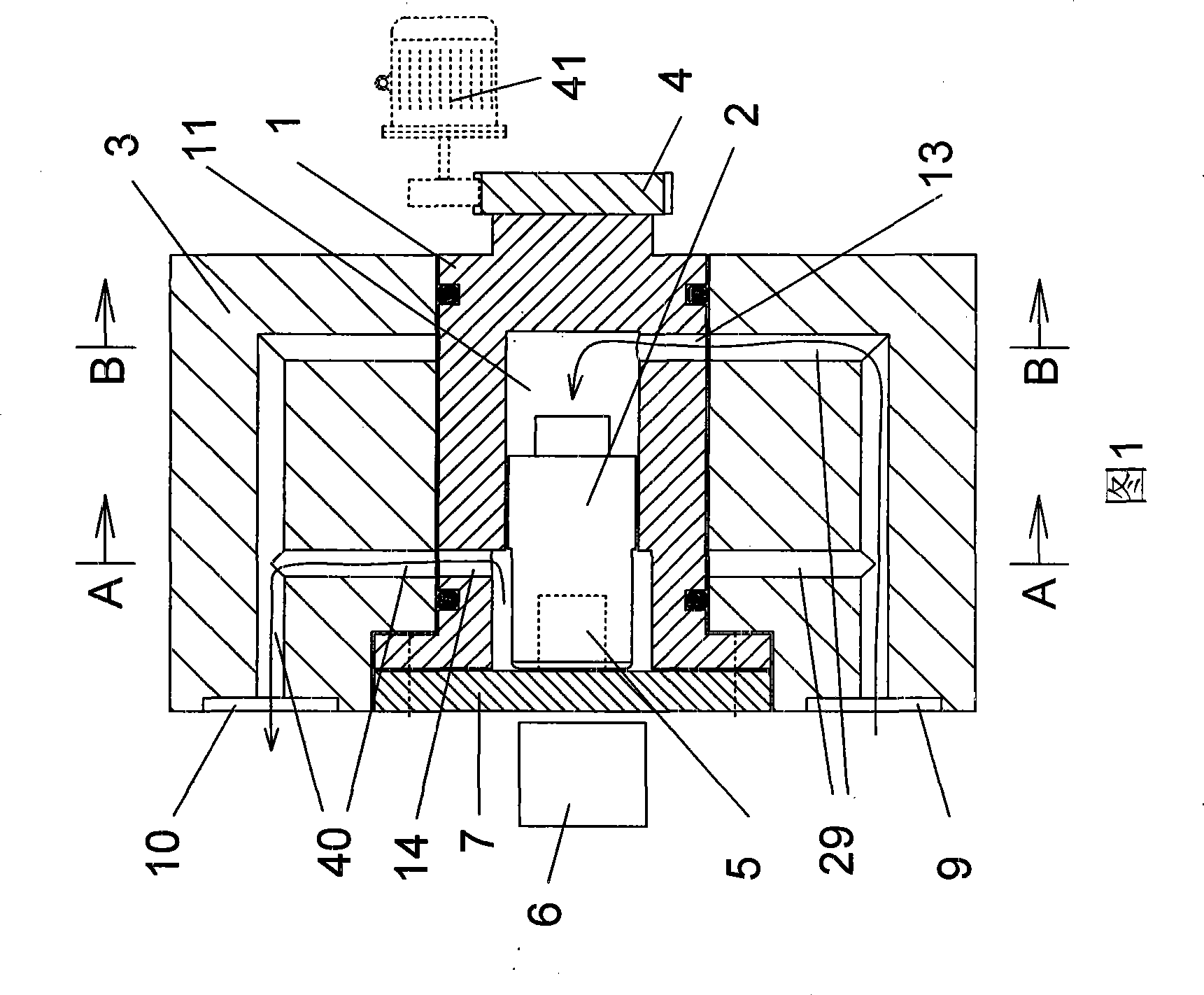

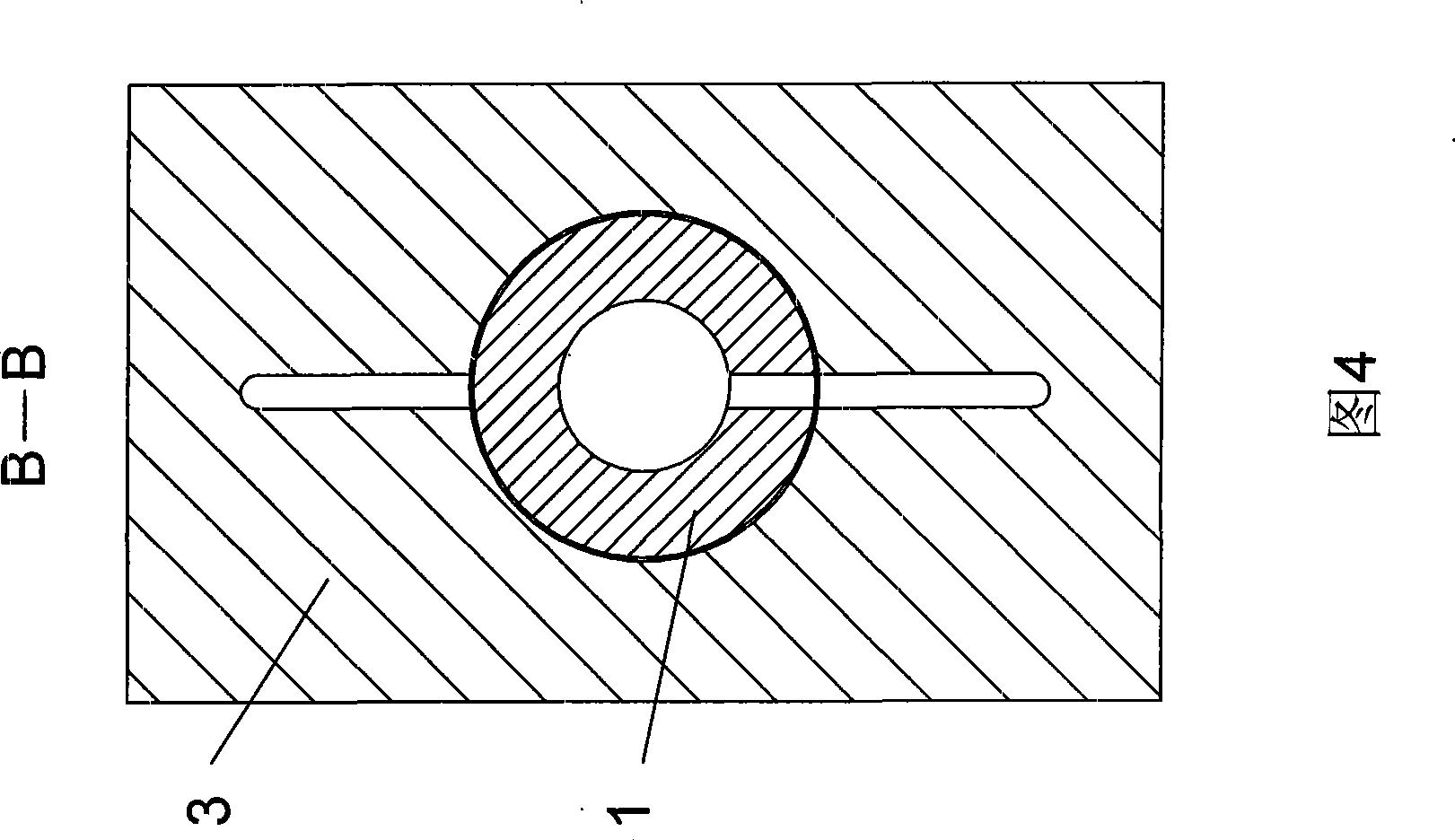

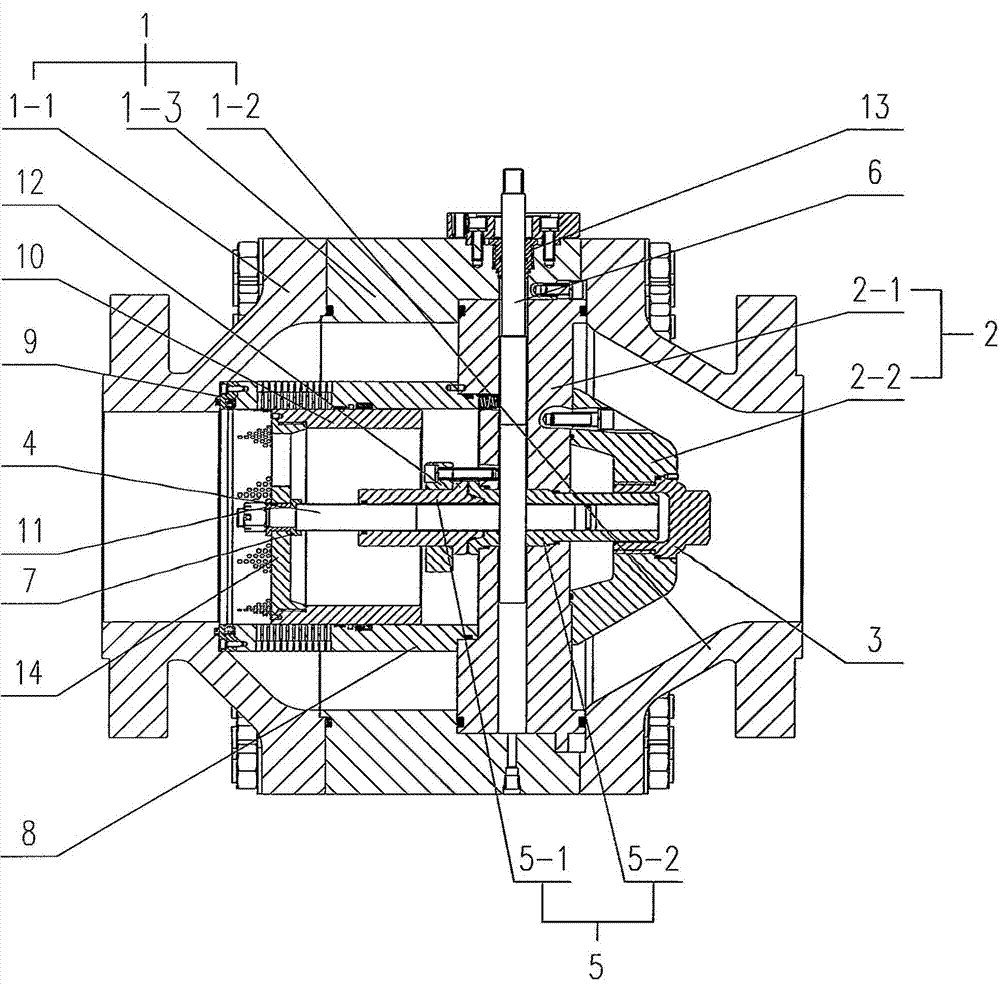

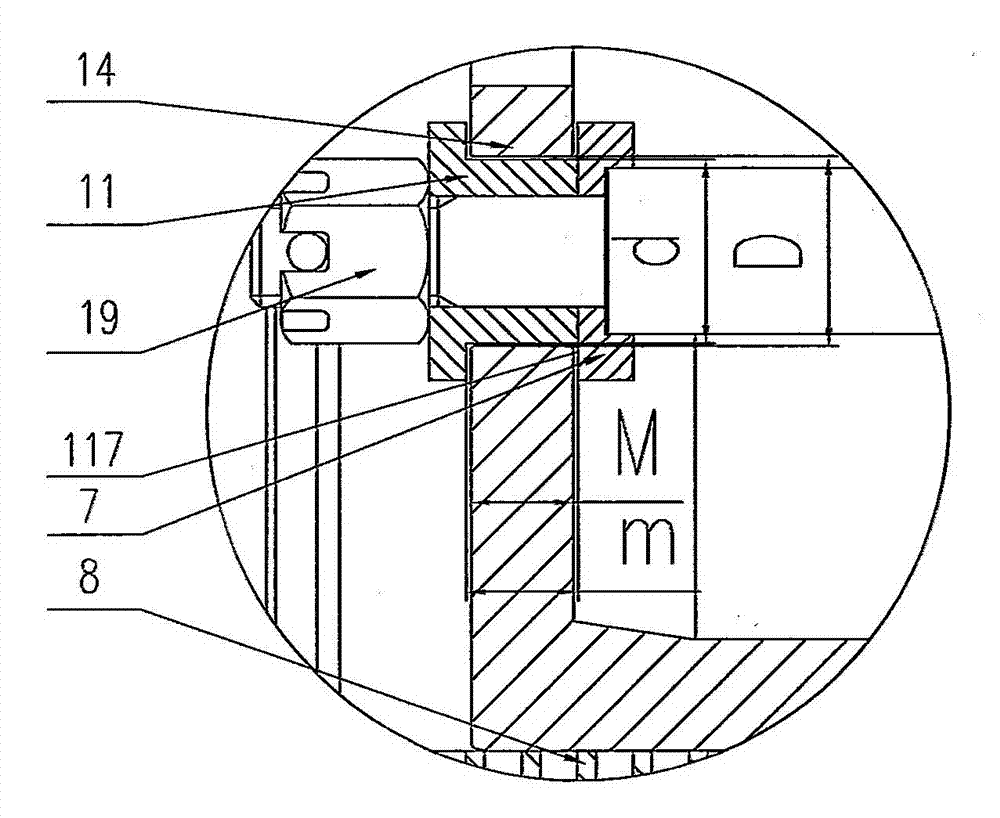

Fluid distributing valve, distributing valve combination unit and distributing system using the distributing valve

The invention discloses a fluid distributing valve, which comprises a valve body, wherein the inside of the valve body is provided with a rotatable valve core in driving connection with an external drive device, the inside of the valve core is provided with a cavity, the inside of the valve body is further provided with an oil inlet valve body passage and an oil outlet valve body passage the openings of which are positioned on the surface of the valve body, the valve core is provided with a valve core passage corresponding to the oil inlet valve body passage and the oil outlet valve body passage inside the valve body, and the inside of the cavity of the valve core is hermetically and slidably connected with a plunger which divides the cavity into a first cavity and a second cavity; and the second cavity selects to be communicate with the oil outlet valve body passage or the oil outlet valve body passage through the second valve core passage. The fluid distributing valve adopts the structure that the inside of the cavity of the rotatable valve core is provided with the plunger which divides the cavity into two parts, has the advantages of strong adaptability to impurities, long service life and difficult blockage brought by the rotatable valve core of the rotary circulating-distributing valve in the document number of 200420029881.1, and can accurately control the amount of the lubricant (the grease lubricant).

Owner:张淑敏

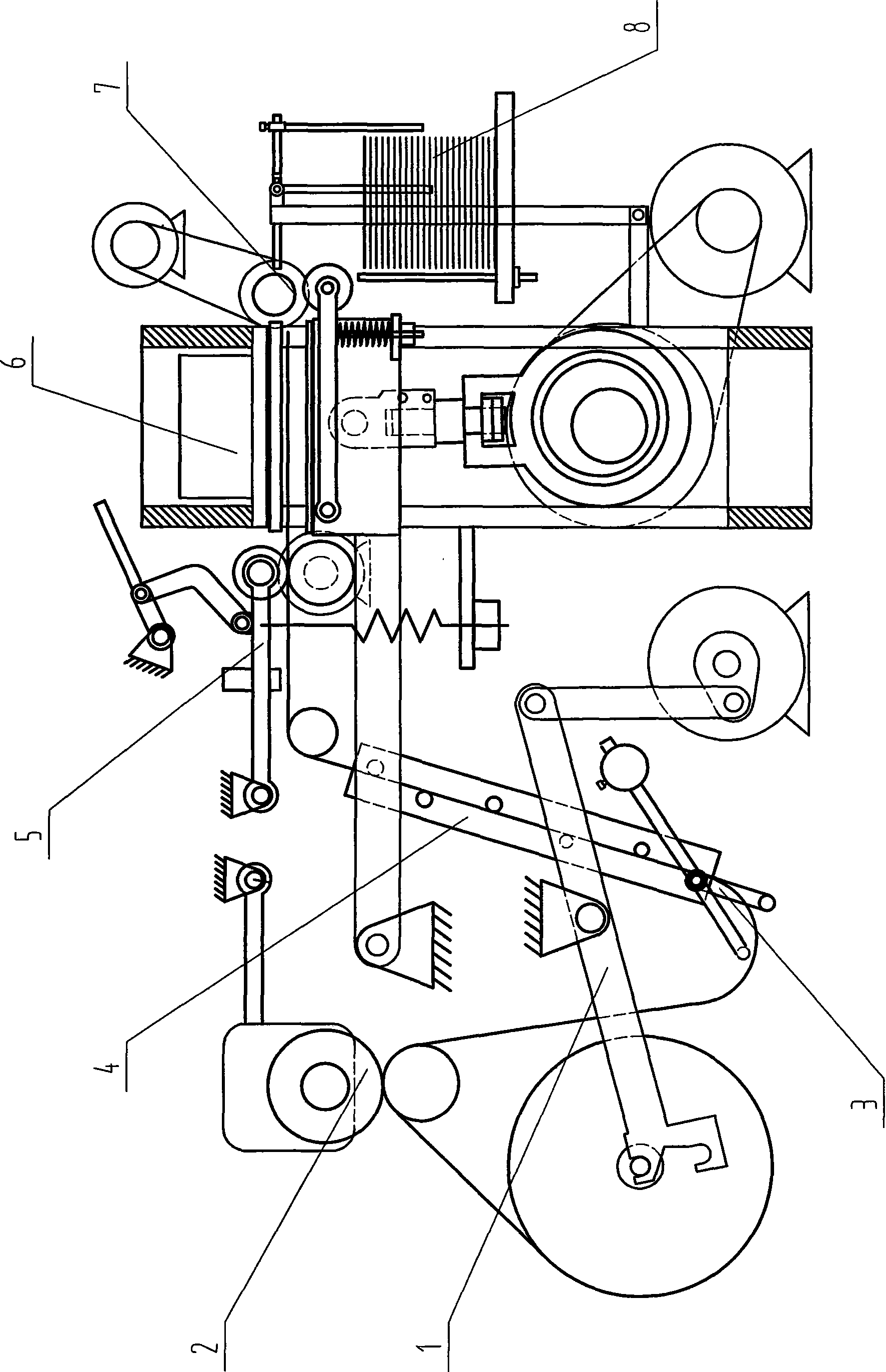

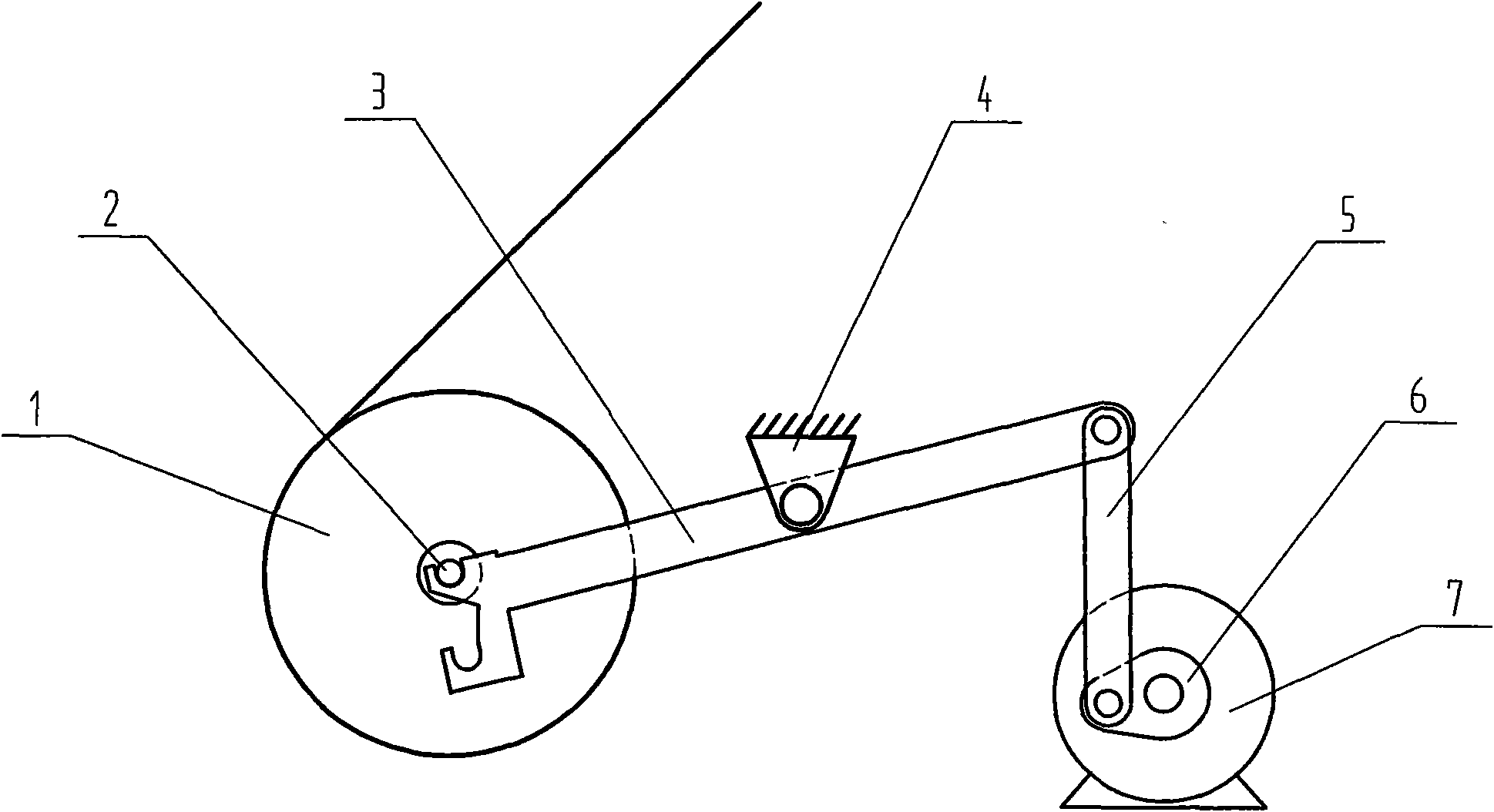

Reel flat pressing full-automatic die cutting machine

InactiveCN102039606ASingle die-cutting efficiency is lowShorten the timeMetal working apparatusEngineeringLight equipment

The invention relates to a reel flat pressing full-automatic die cutting machine which comprises a lifting mechanism, an unreeling mechanism, a guide mechanism, a contrary flexing mechanism, a feeding mechanism, a die cutting mechanism, a breaking mechanism and a collecting mechanism. The reel flat pressing full-automatic die cutting machine is designed aiming at the single-row (or less-row) die cutting. Starting from solving the problems of all links of unreeling, feeding, die cutting, breaking, collecting and the like, the invention greatly optimizes and simplifies the equipment structure, realizes light equipment and low cost as well as simple operation, and achieves the purpose of improving the whole production efficiency through improving the working frequency; and the reel flat pressing full-automatic die cutting machine manufactured according to the invention has the working frequency up to 300 per minutes and can be widely applied to the reel die cutting transaction processing of materials of paper, plastics, leather and the like.

Owner:陈建军

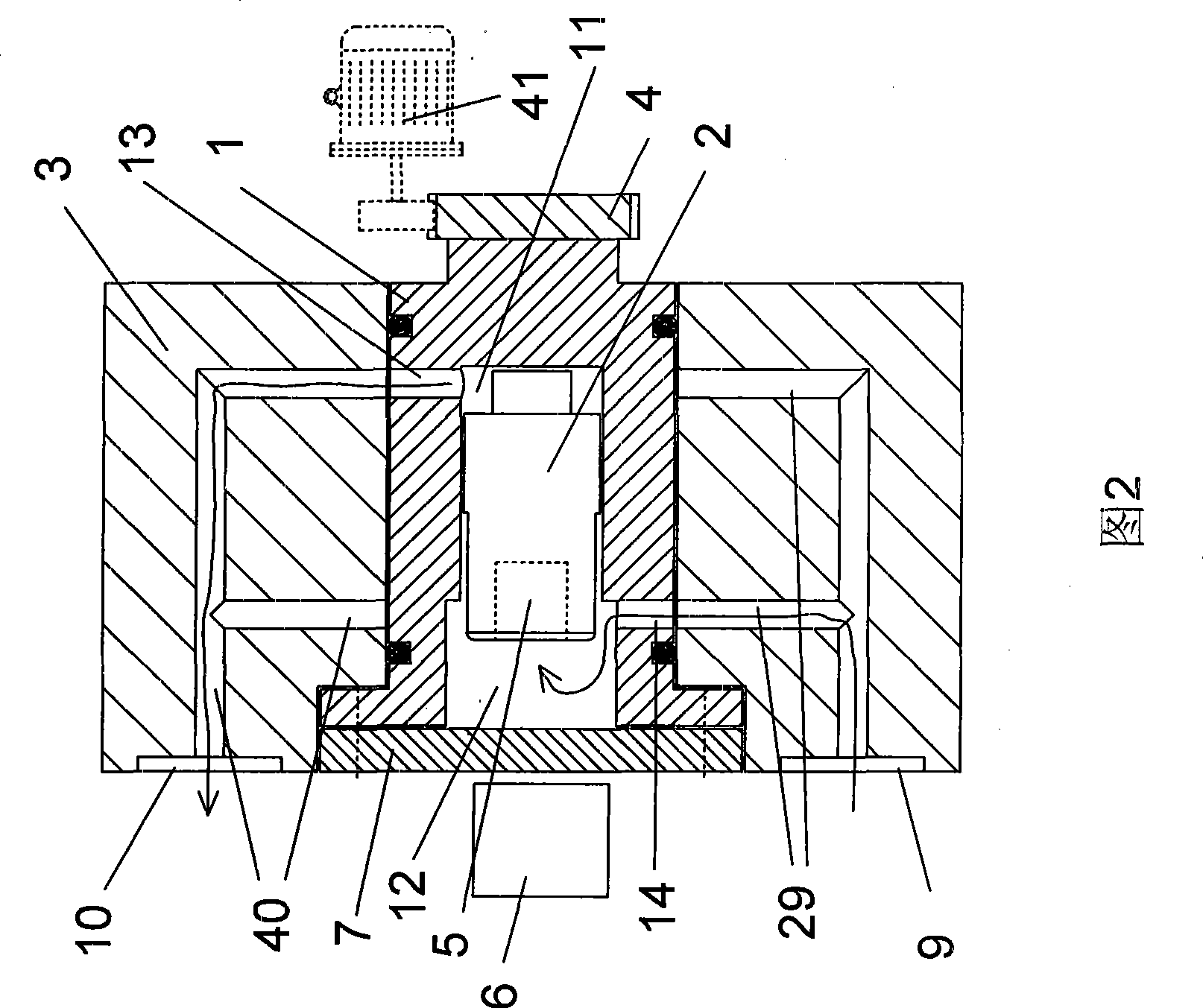

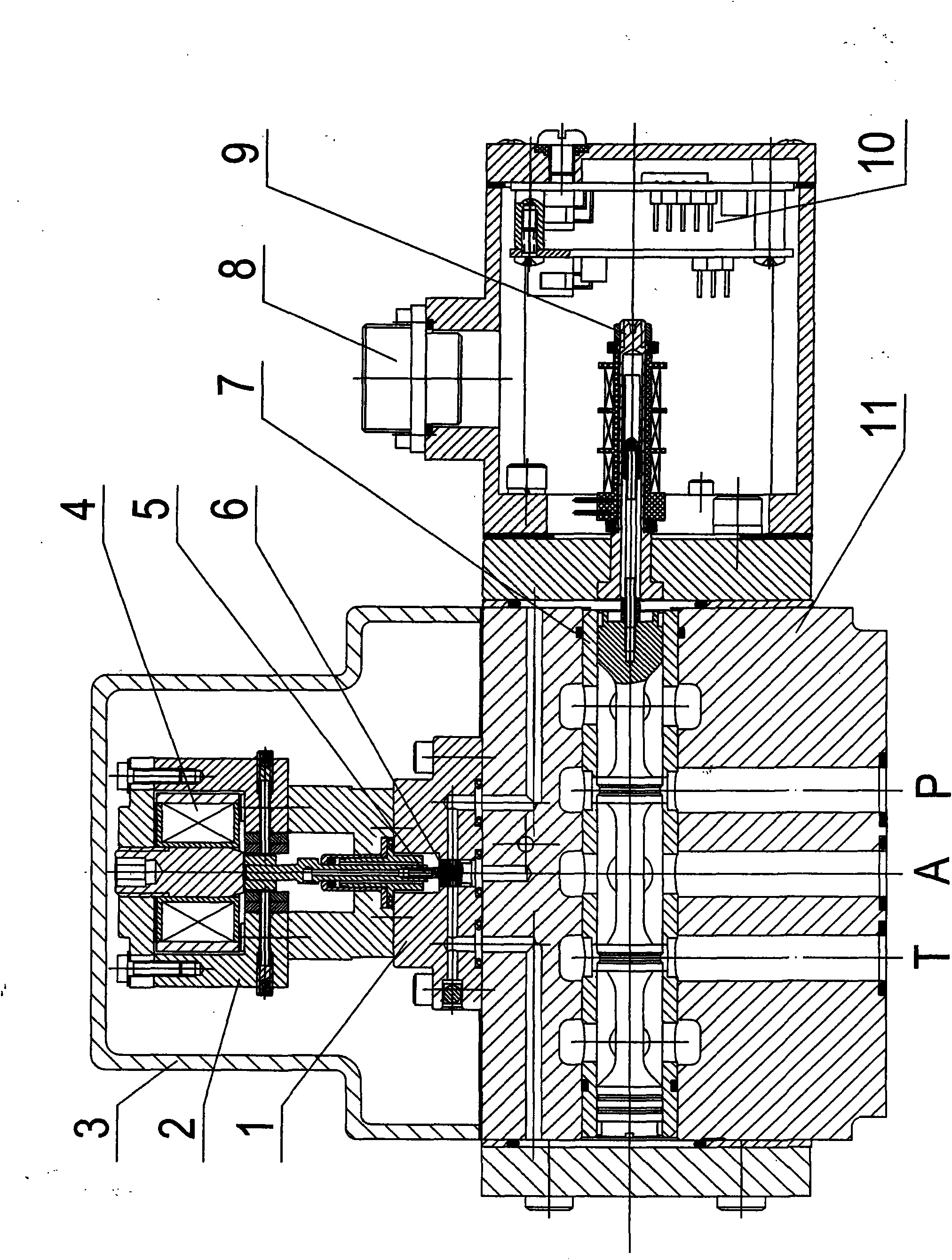

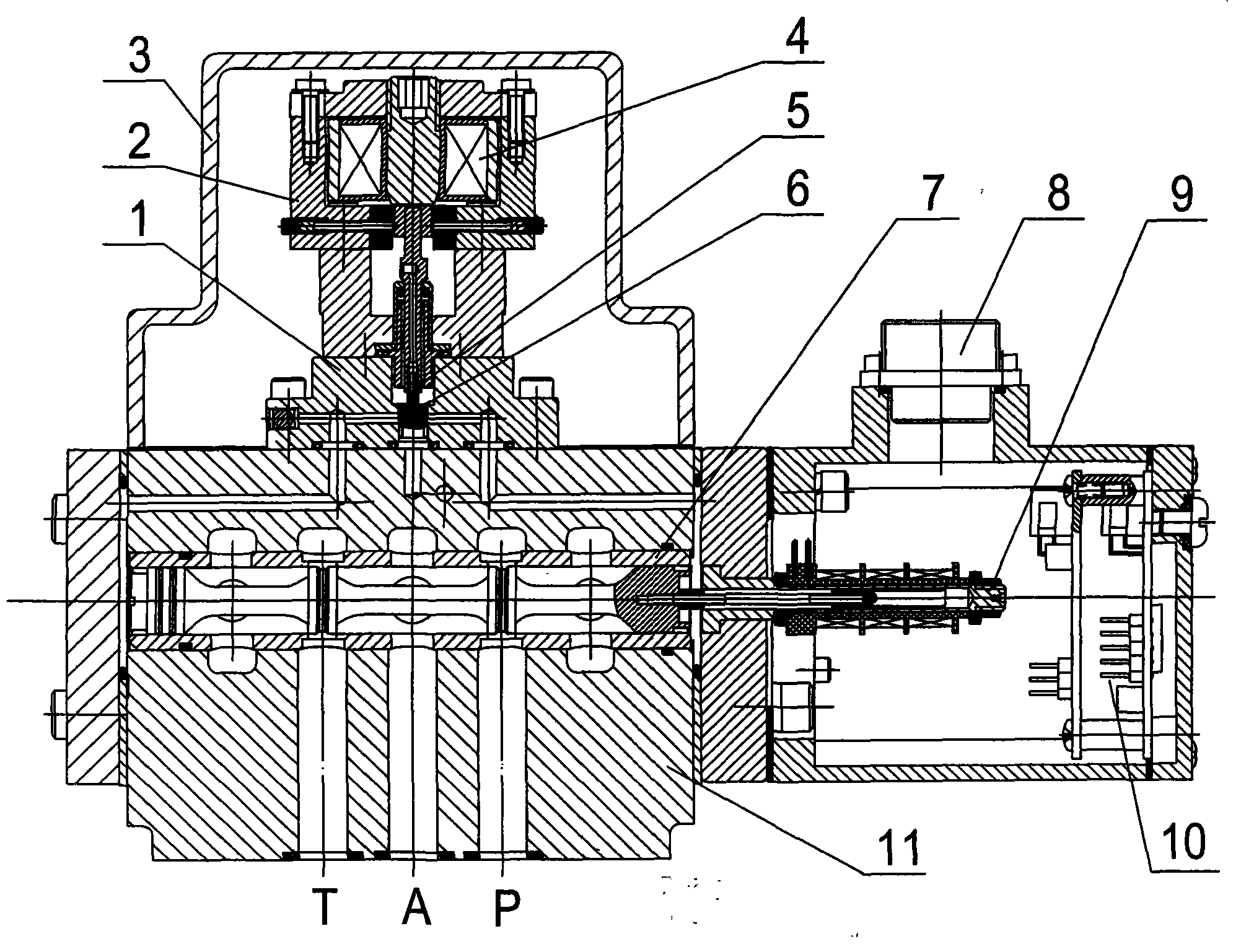

Special three-way electro hydraulic servo valve for down-pressing system of rolling mill

InactiveCN101776097ASimple structureReduce processing costsServomotor componentsMetal rolling stand detailsJet flowElectro hydraulic

The invention relates to a special three-way electro hydraulic servo valve for a down-pressing system of a rolling mill, which mainly consists of a main valve, a jet flow pipe pilot level and a detection feedback device, wherein the main valve uses a four-step three-way slide valve with a valve sleeve and is driven by the jet flow pipe type pilot level, the end part of a valve core is provided with a displacement sensor, the position of the valve core realizes the closed ring control through the signal feedback of a control circuit and the displacement sensor, the jet flow pipe pilot level mainly comprises a moment motor, a jet flow pipe and a receiver, the moment motor is arranged in an upper cover of the main valve, a dry type permanent-magnet structure is adopted, the jet flow pipe is arranged in a middle valve block, and two cavities of the receiver are communicated to both ends of a main valve core through an oil passage of the main valve body. The invention has the advantages of simple structure, low processing cost, strong practicability, excellent performance and the like, and can be used in down-pressing or up-pressing high-pressure servo systems with high resolution and high dynamic response required in the milling process.

Owner:WISDRI ENG & RES INC LTD

Cone breaker device

The paper breaker device includes a first shaft, a second shaft arranged parallelly with the first shaft, a paper-breaking channel formed between parallelly-arranged said first shaft and second shaft, several cutting knifes which are respectively fixed and cover-mounted on the first shaft and second shaft in the mode of that every both two knifes have a gap space. It is characterized by that several gap paper-guiding sheets are respectively placed in said gap spaces and movably cover-mounted on the first shaft and second shaft, all the gap paper-guiding sheets are made up by adopting integral-forming process, and all the gap-paper-guiding sheets are formed into a continuous surface at paper-breaking channel.

Owner:PRIMAX ELECTRONICS LTD

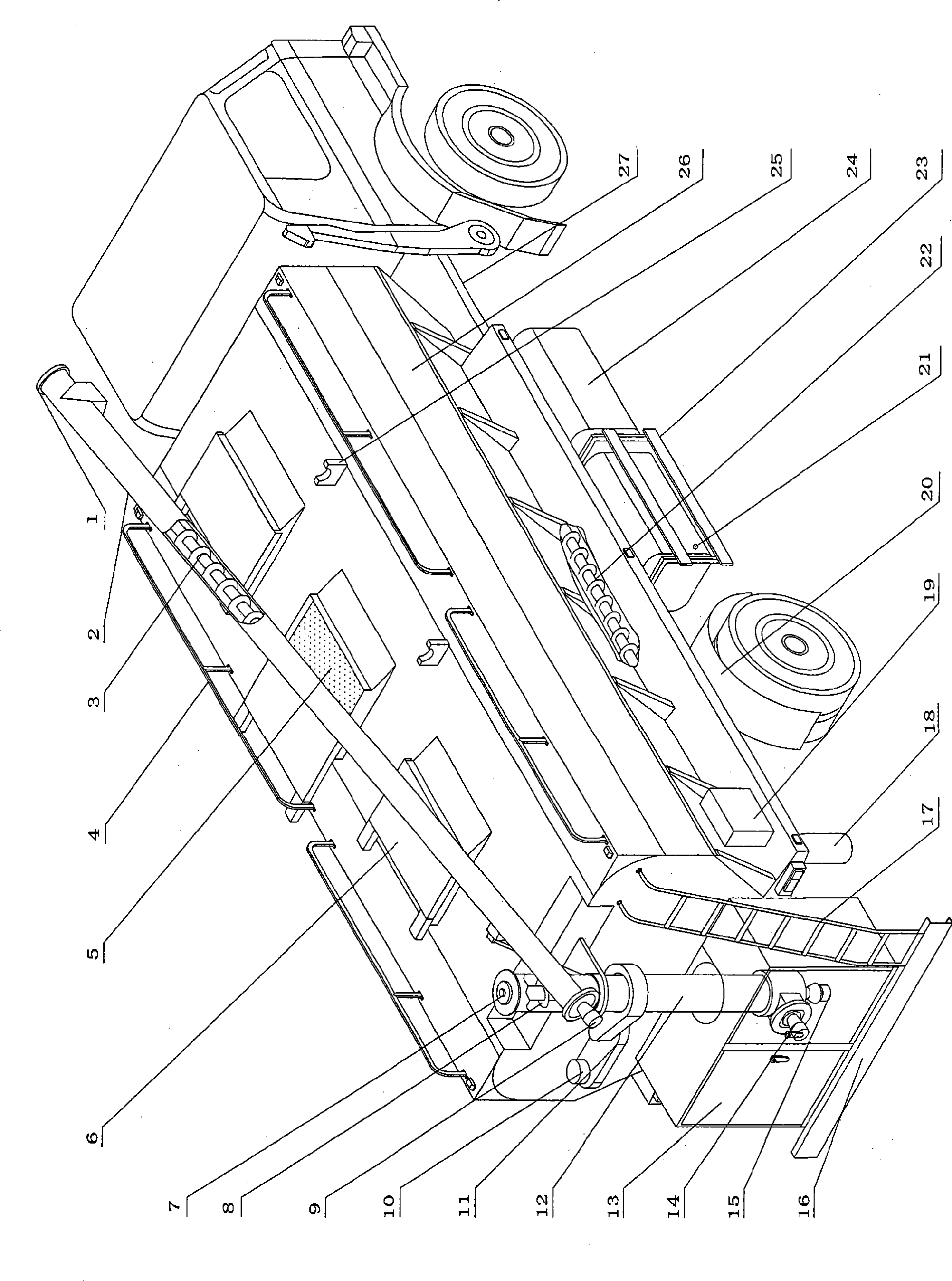

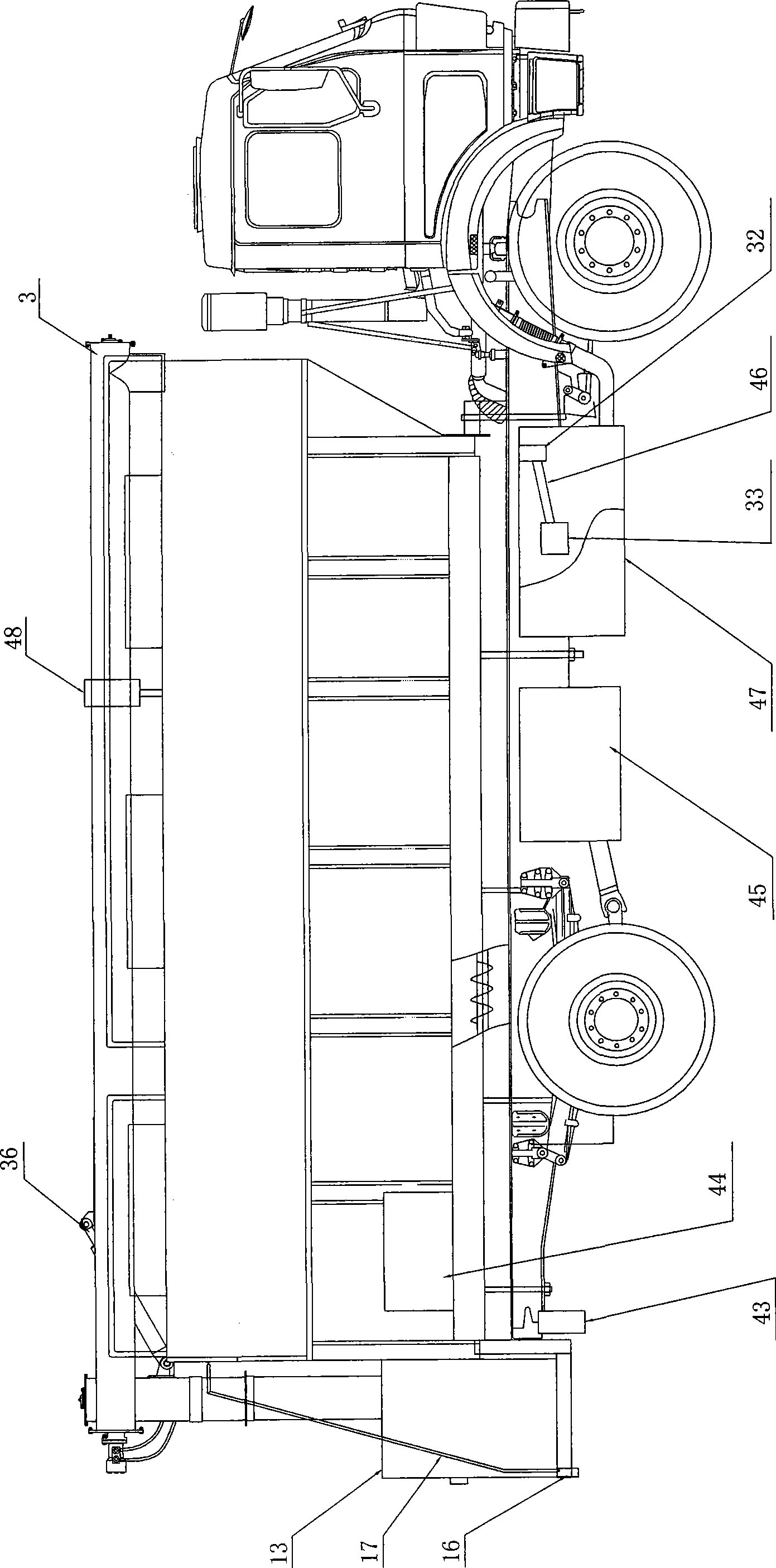

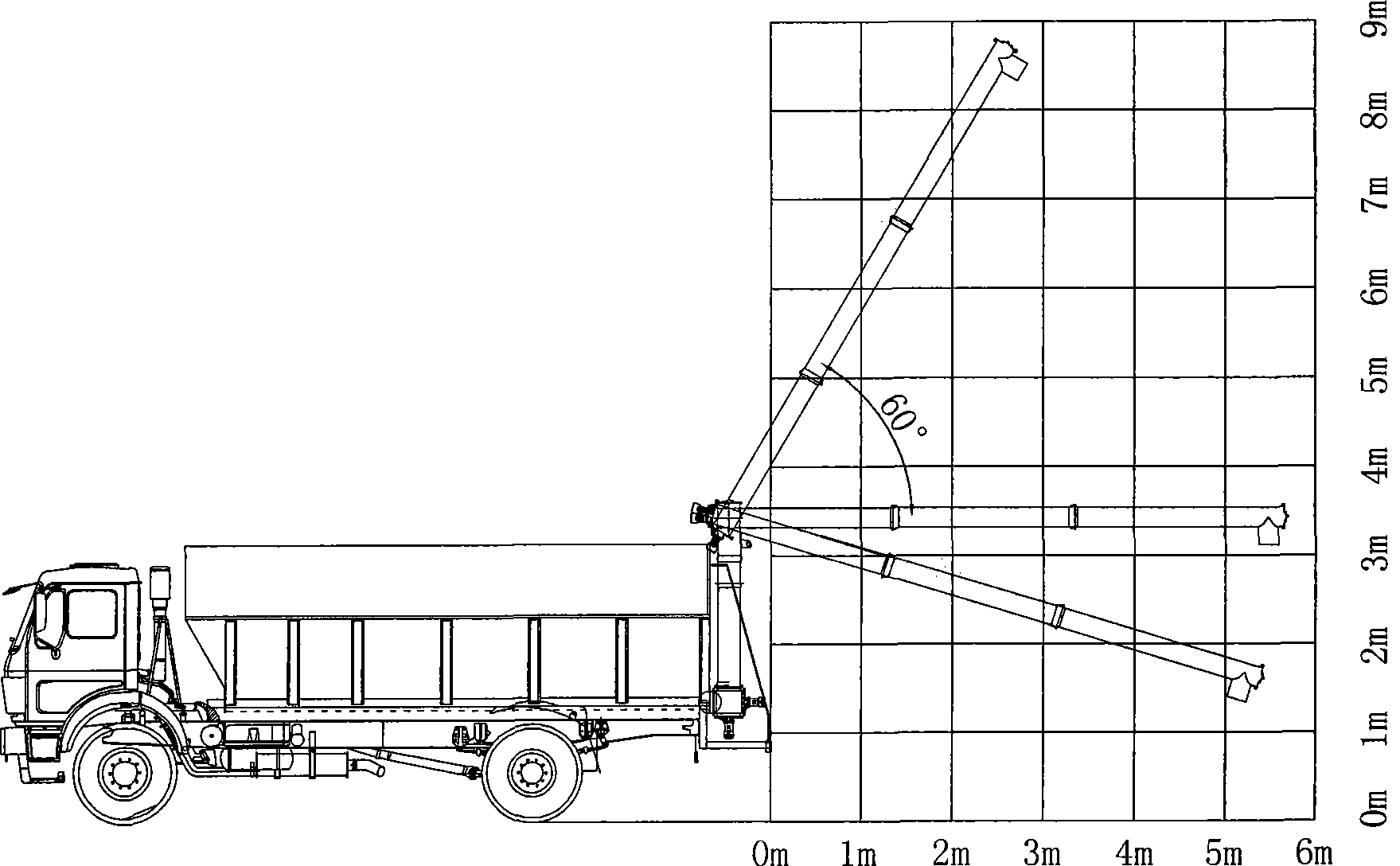

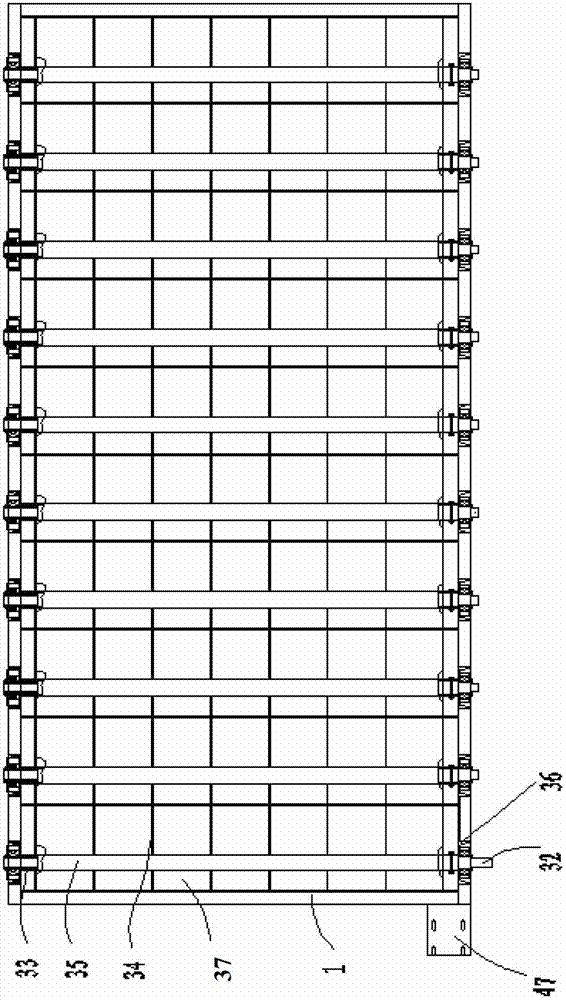

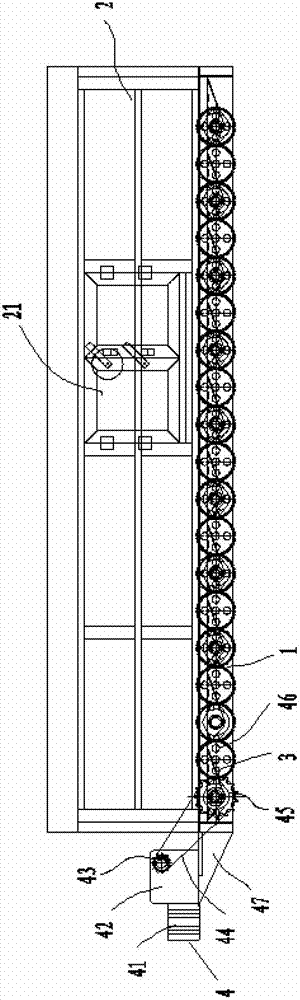

Hydraulic bulk feed truck

ActiveCN101474975AFully configuredEasy to operateItem transportation vehiclesVehicle with tipping movementHydraulic motorEngineering

The invention relates to a hydraulic type bulk feed transportation vehicle. A power takeoff device is driven by the output power of an automobile gearbox; a high-pressure oil pump is transmitted to drive a hydraulic system; the high-pressure oil pump is connected with a distributing valve through a pipeline; three output ends of the valve are connected with a corner hydraulic motor, a lifting oil cylinder and a horizontal discharging hydraulic motor, vertical discharging hydraulic motor and movable discharging hydraulic motor in serial connection respectively; a discharging device consists of a horizontal discharging system, a vertical discharging system and a movable discharging system which are spiral conveyors driven by the hydraulic motor; the horizontal discharging system is arranged inside a tank body; the vertical discharging system is positioned outside the tank body; a feed port and a discharge port of the vertical discharging system are communicated with a discharge port of the horizontal discharging system and a feed port of the movable discharging system respectively; the lifting oil cylinder and a cylinder body of the movable discharging system are connected to realize up-and-down lifting; and the discharging device is also provided with a corner system for producing horizontal deflexion of the movable discharging cylinder body. The hydraulic type bulk feed transportation vehicle has the advantages of reducing packaging cost, saving feed, avoiding causing pollution in the loading and unloading and transportation links.

Owner:成都国远机电科技有限公司

Plate turnover device for eccentric fermentation tower and fermentation tower

ActiveCN102731178ARealize continuous fermentationReduce energy consumptionBio-organic fraction processingOrganic fertiliser preparationContinuous fermentationAgricultural engineering

The invention is applicable to the field of fermentation technology, and discloses a plate turnover device of an eccentric fermentation tower. The device includes a housing and a baffle, and also includes a drive assembly and at least one aeration assembly arranged between two broadsides of the housing; the aeration assembly includes a plate turnover shaft and a turning aeration plate rotating around the plate turnover shaft; the turning aeration plate is arranged above the plate turnover shaft; the turning aeration plate is located at a central axis at a radial direction of the plate turnover shaft, deviated from the shaft axis of the plate turnover shaft and in eccentric arrangement. The invention also discloses a fermentation tower, comprising at least one layer of fermentation chamber, and the plate turnover device of the eccentric fermentation tower is arranged in the fermentation tower. As adaption of the eccentric design by the invention, materials can make full use of their gravity to reduce energy consumption and material, so as to realize continuous fermentation; besides, the device consumes a small amount of energy, and is not easily jammed or damaged.

Owner:深圳市如茵生态环境建设有限公司

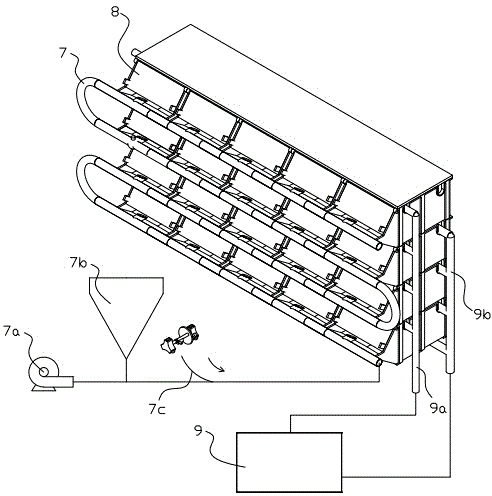

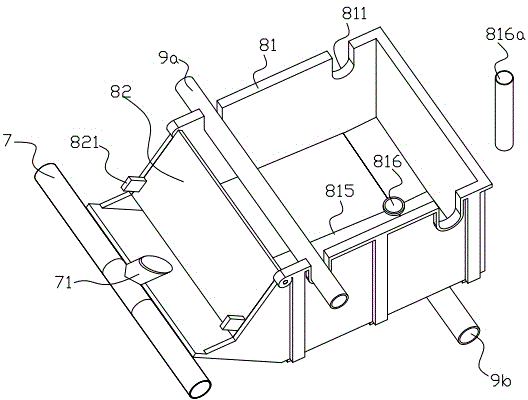

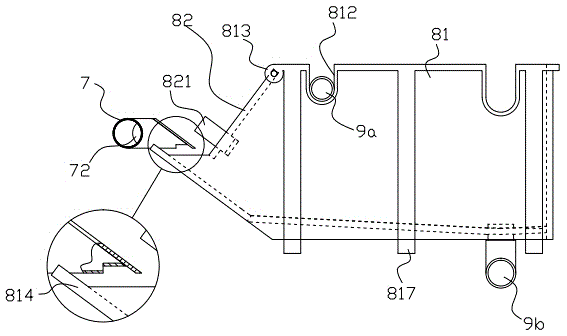

Rapid feeding industrial aquaculture device

ActiveCN104381185AHigh degree of intelligenceReduce configuration costsPisciculture and aquariaAgricultural scienceWater circulation

The invention discloses a rapid feeding industrial aquaculture device which comprises an intensive aquaculture box component and a feeding device, wherein the intensive aquaculture box component is connected with a water circulation treatment device through a water inlet pipe and a water outlet pipe, and the feeding device can pneumatically convey feed to an intensive aquaculture box. The intensive aquaculture box component comprises box bodies which can be stacked, the feeding device comprises a feed main pipe arranged near the intensive aquaculture box, a fan and a quantitative feeding hopper are arranged at an initial end of the feed main pipe, arc-shaped branches are arranged on the feed main pipe, the feed main pipe is provided with feeding branch pipes along the intensive aquaculture box component, rotating vanes of the corresponding feeding branch pipes are opened or closed as required by the aid of a slidable and intelligent feeding control device in the feed main pipe, and pellet feed can be intelligently and pneumatically fed by the aid of high pressure. The rapid feeding industrial aquaculture device has the advantages that the configuration cost of the device is saved, the pellet feed is rapidly and accurately fed, and the device is not easy to jam, high in intelligent degree, convenient to maintain and manage and suitable for large-scale feeding.

Owner:ZHEJIANG OCEAN UNIV

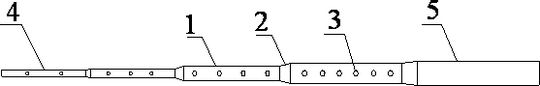

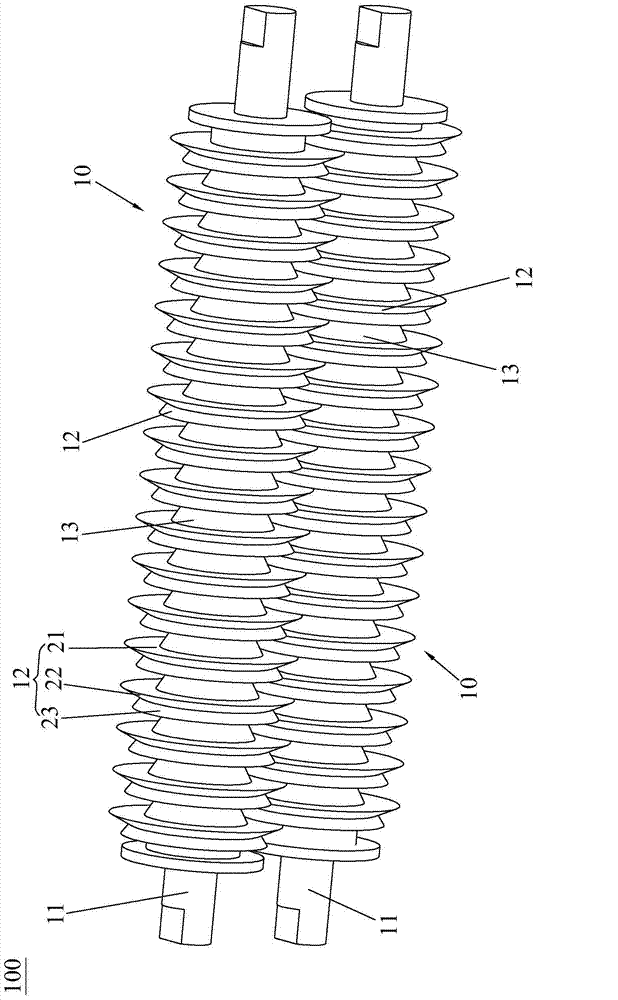

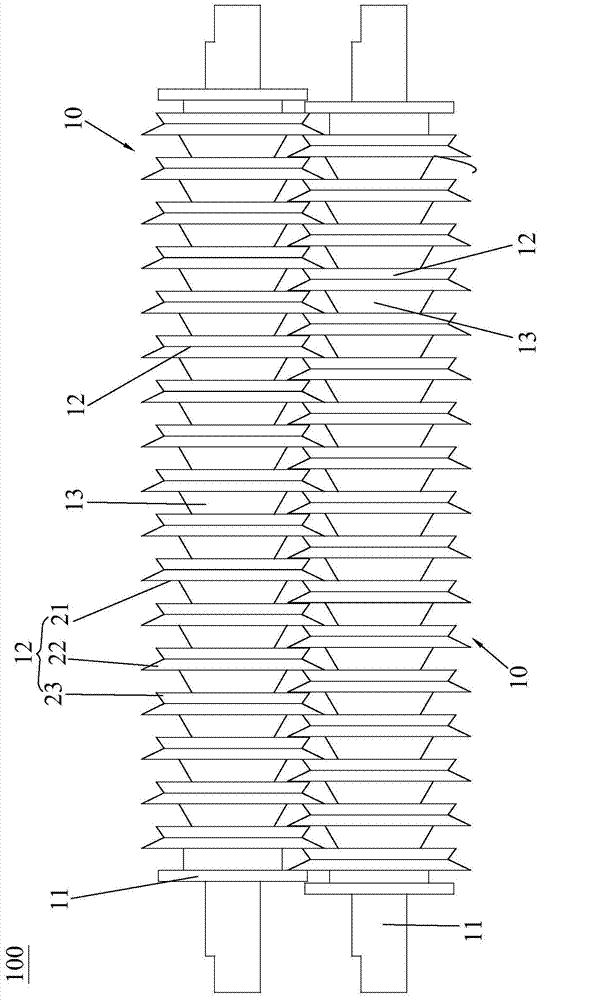

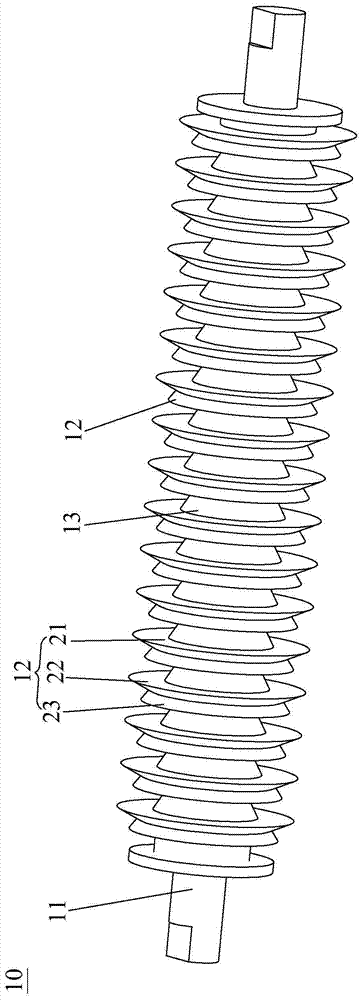

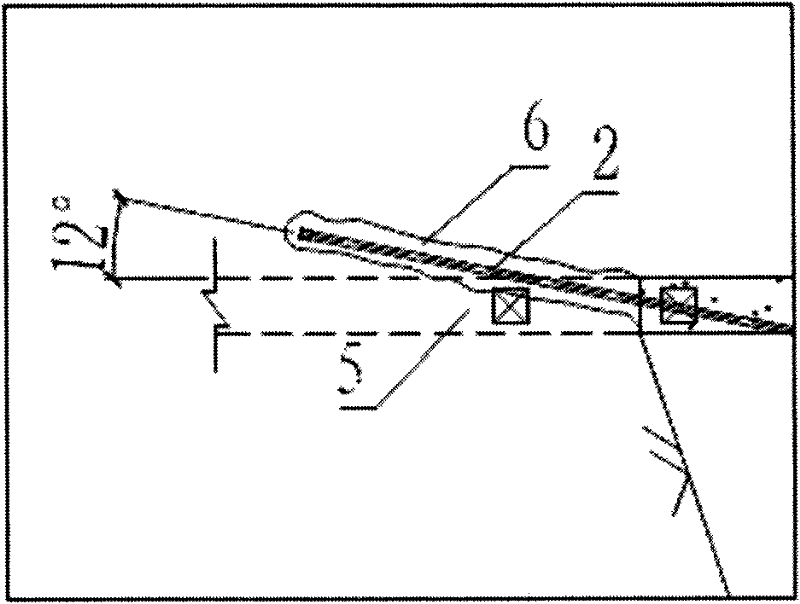

Pipe body structure of step type hole protecting pipe for gas extraction hole in soft coal bed

ActiveCN102619476AEasy to passConform to the gushing lawDrilling rodsGas removalPore diameterReducer

A pipe body structure of a step type hole protecting pipe for a gas extraction hole in a soft coal bed, and belongs to the hole protecting pipe. The hole protecting pipe comprises multiple groups of pipes, which are connected from the front end to the tail end in sequence; the diameters of the pipes in different groups are different, the diameters of the pipes in each group of pipes from the front end to the tail end of the hole protecting pipe are reduced in sequence, and every two adjacent pipes in different groups are connected through a reducer pipe; the whole profile of the hole supporting pipe is of a step type structure with a gradually changed diameter; the diameters of the pipes in the same group are the same, and the lengths of the pipes are the same; sieve pores are not formed in the pipe walls of one group of pipes at the most front end but are formed in the pipe walls of the rest groups of pipes, and the pore diameters of the sieve pores in the pipes in the same group are the same; the number of the sieve pores in each group is reduced from the front end to the tail end in sequence; the diameters of the sieve pores in each group are reduced from the front end to the tail end in sequence, the minimal diameter is 4 mm, and the maximal diameter is 10 mm; and the sieve pores are externally wound with gauzes. The pipe body structure has the advantages as follows: the structure is simple, the hole protecting pipe is not easily blocked and is more easily fed in a deflected drilled hole due to large flexibility, the hole protecting length is long, and the gas extraction efficiency is high at the same time. Therefore, the pipe body structure is suitable for the gas extraction hole in the soft easily-collapsed coal bed.

Owner:CHINA UNIV OF MINING & TECH

Paper shredding blade, cutting-type paper shredding tools and a cutting-type paper shredding mechanism

The invention discloses a cutting-type paper shredding mechanism. The cutting-type paper shredding mechanism comprises two cutting-type paper shredding tools which are arranged oppositely, wherein each cutting-type paper shredding tool comprises a cutter shaft and a plurality of paper shredding blades which are installed at certain intervals or integrally formed on the cutter shaft; two sides of the tail end of a cutter body of each paper shredding blade are respectively provided with long cutting edges and short cutting edges with different lengths, and a long cutting edge of one cutting-type paper shredding tool and a short cutting edge of the other cutting-type paper shredding tool are mutually matched to shred paper, so that according to the invention, when paper is shredded, two cutting edges with different lengths are matched to cut paper, and meanwhile paper is cut open, and force is saved in paper shredding; on the other hand, when the two paper shredding cutter blades provided by the invention are matched to shred paper, because two cutting edges corresponding to opposite surfaces of two adjacent cutter blades are a long cutting edge and a short cutting edge with different lengths, when paper is shredded, paper shredded particles obliquely fall off between two adjacent cutter blades, and paper is difficult to clamp.

Owner:DONGGUAN ELITE ELECTRIC HARDWARE PRODUCT CO LTD

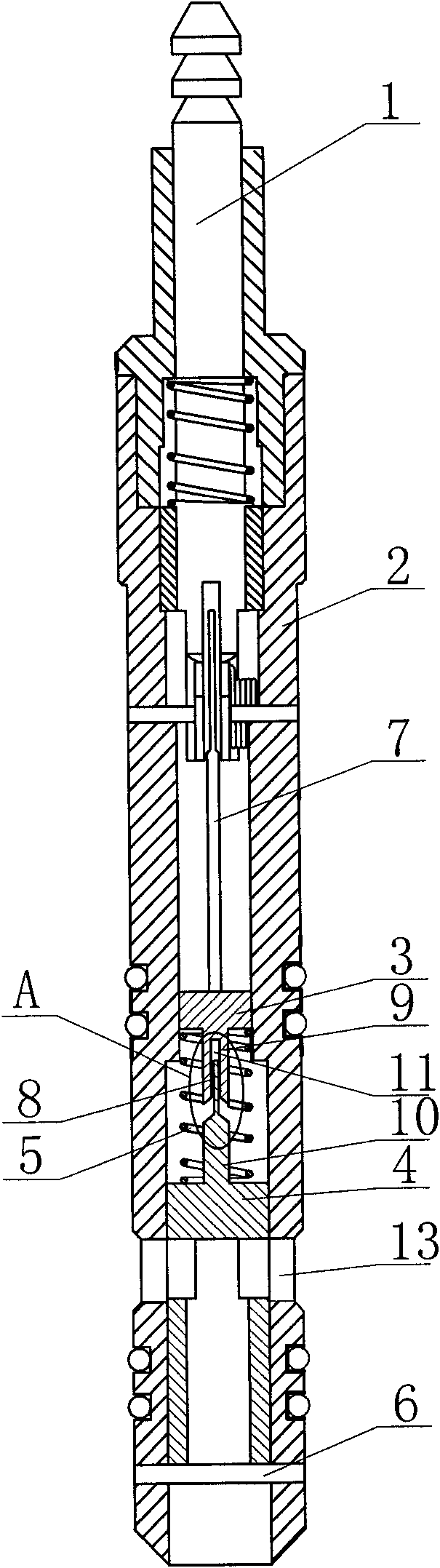

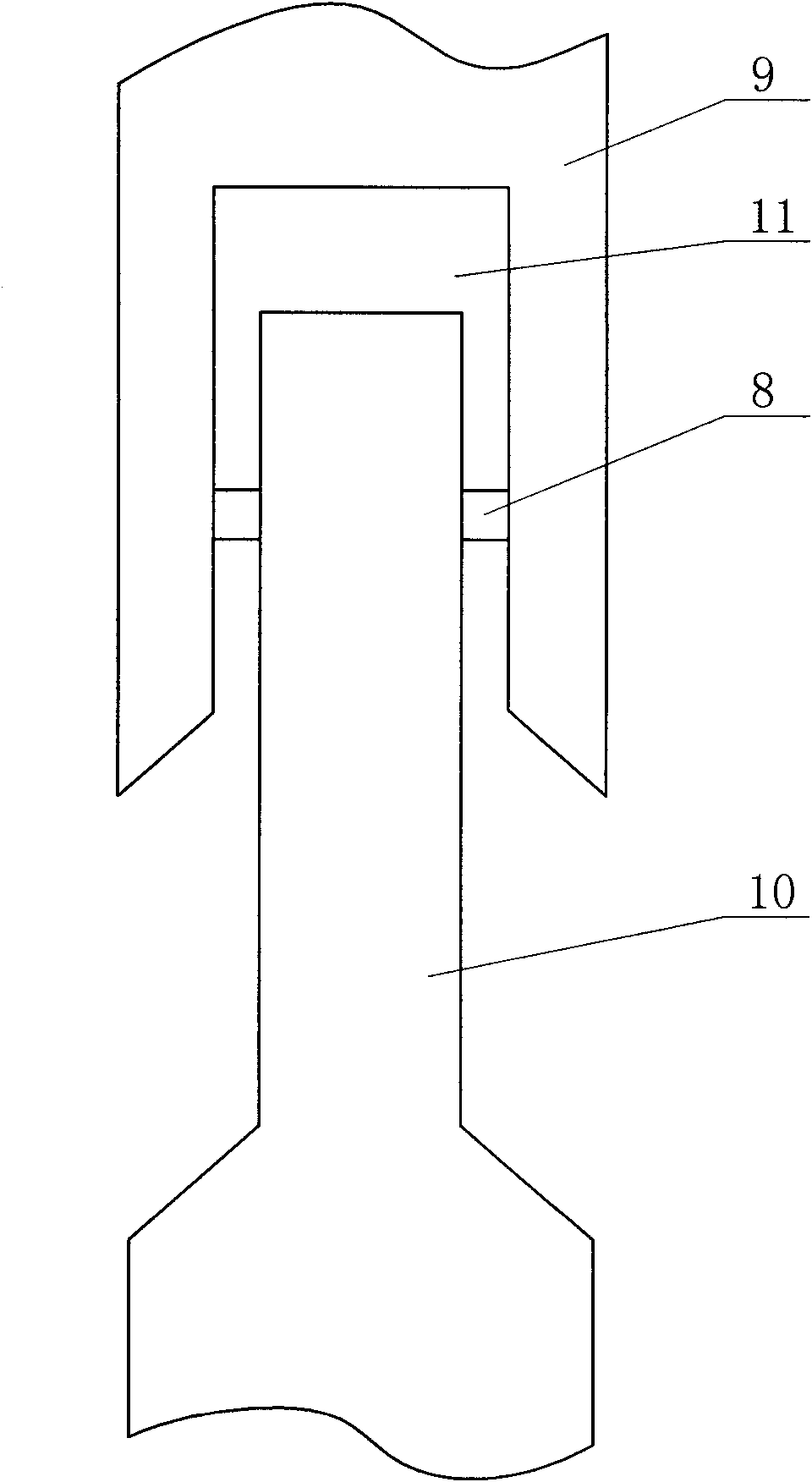

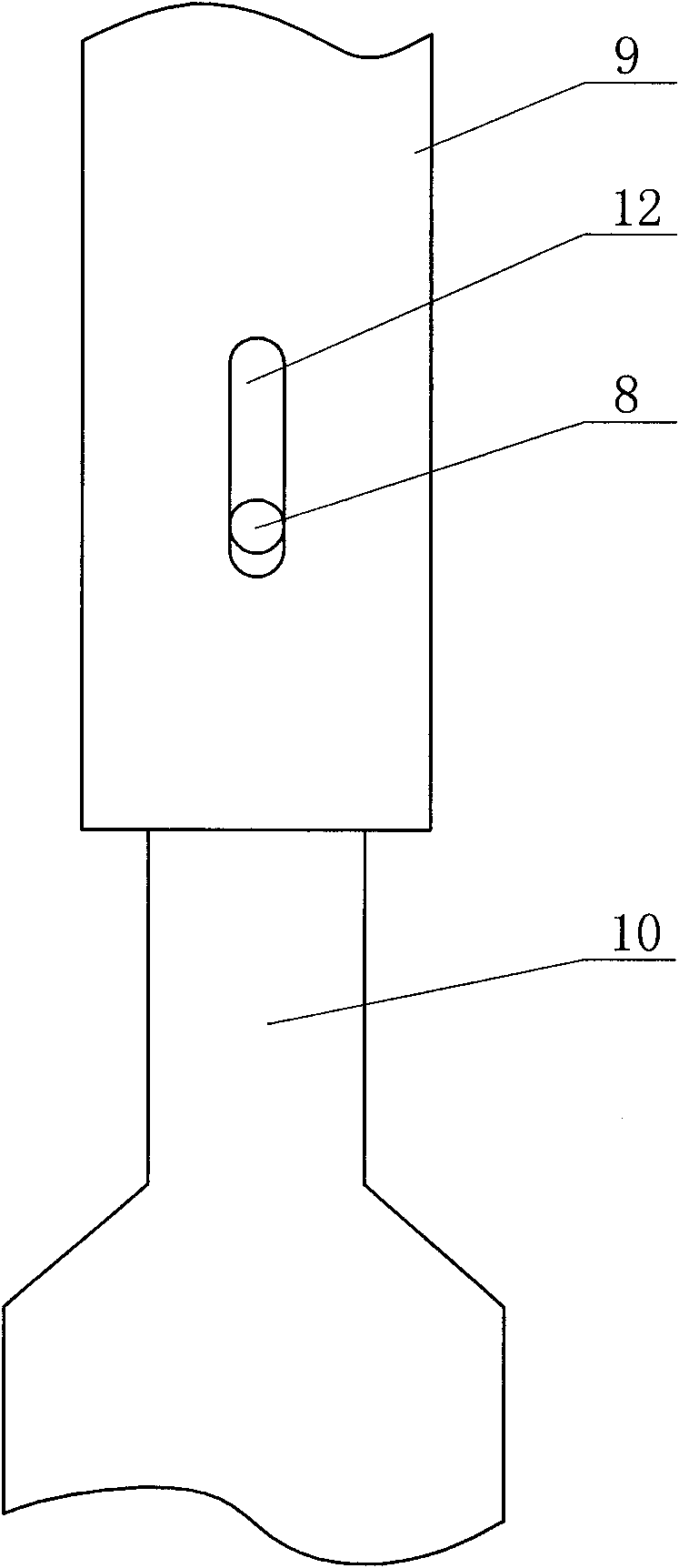

Adjustable constant-flow multifunctional blanking plug

The invention discloses an adjustable constant-flow multifunctional blanking plug and mainly solves a problem that the traditional blanking plug a short constant-flow time. The blanking plug is characterized in that: the lower end of a fishing rod (1) is connected with a driving shaft (7) for rotating in an up and down sliding manner; the lower end of driving shaft (7) is provided with a rotationadjusting nut (3) which is connected with the inside of a main body (2) through threads; the lower end of the rotation adjusting nut (3) is provided with a rotary telescopic rod (9); the upper end ofa plunger (4) is provided with a telescopic rod (10) which is fit and connected with the rotary telescopic rod (9) in an up and down sliding manner; a balance spring (5) is arranged between the rotation adjusting nut (3) and the plunger (4); the main body (2) on the lower end of the plunger (4) is fixed with a limiting pin (6) for limiting; and the diameter of an axial internal hole of the plunger (4) is 11 millimeters. The adjustable constant-flow multifunctional blanking plug has the characteristic of long automatic adjustment and long constant-flow time.

Owner:董力维

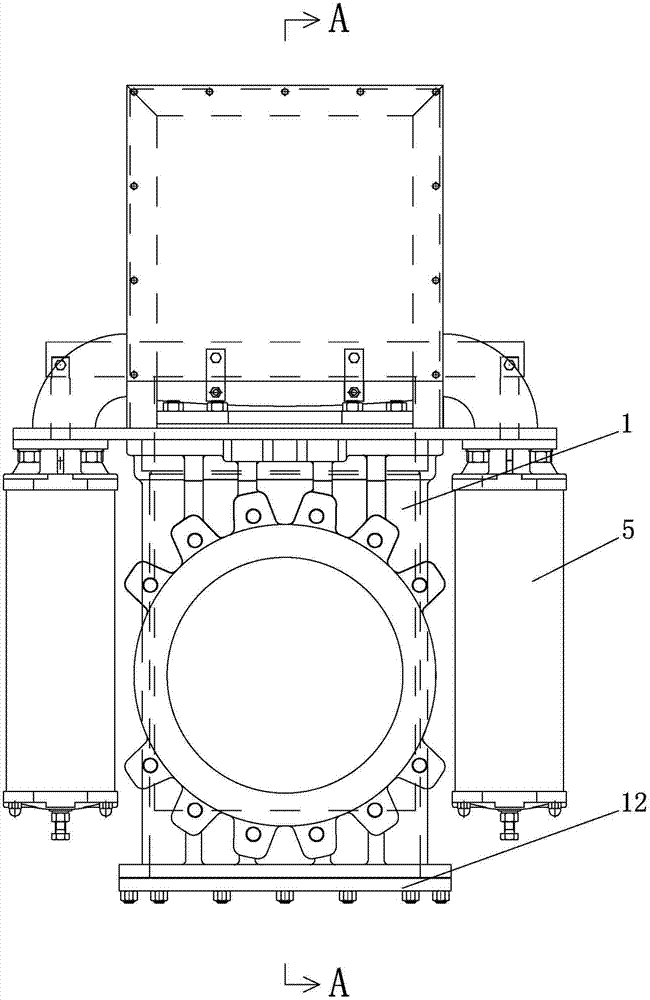

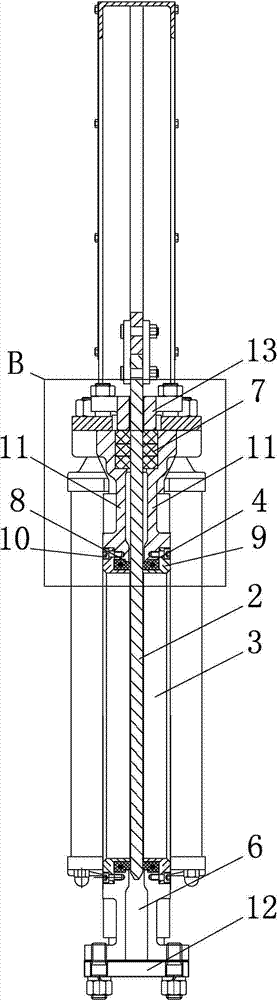

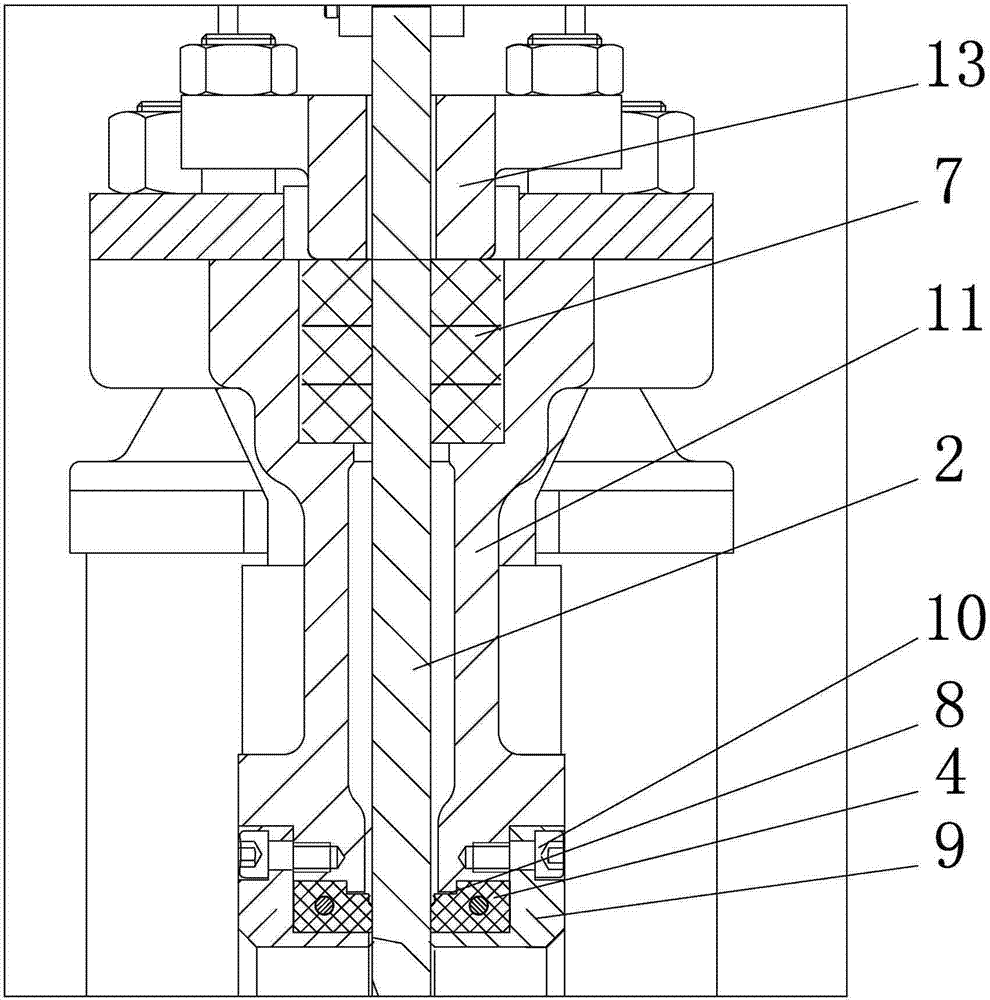

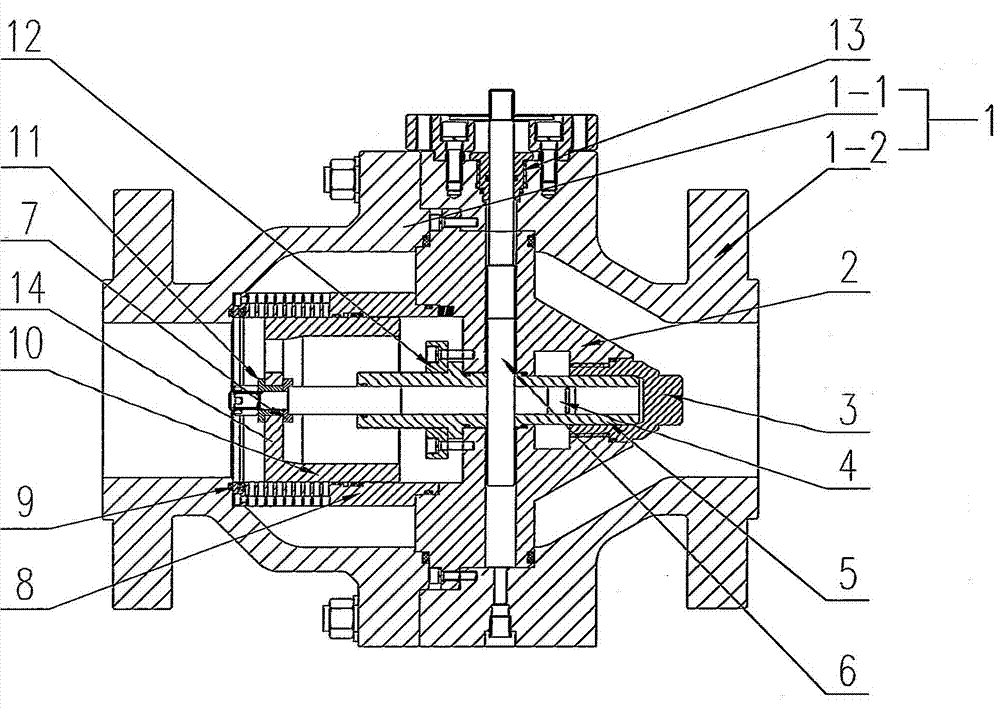

Highly-sealed gate valve of vacuum spray-coating machine

ActiveCN103527802AImprove sealingNot easy to jamOperating means/releasing devices for valvesSlide valveMaintainabilitySpray coating

The invention discloses a highly-sealed gate valve of a vacuum spray-coating machine, which comprises a valve seat (1) and a gate plate (2), wherein the valve seat comprises two parallel valve seat plates (11) and a fixing plate (12) for fixedly connecting two ends of the two valve seat plates through bolts; valve holes (3) are formed in the middle parts of the two valve seat plates; the gate plate is arranged between the two valve seat plates in a sliding manner; sealing rings (4) in sealing fit with the gate plate (2) are arranged at the peripheries of the valve holes of the two valve seat plates; the valve seat (1) is provided with a pressure cylinder (5) for driving the gate plate (2). The valve seat is composed of the two valve seat plates and the fixing plate for fixedly connecting the two valve seat plates through the bolts, so that the highly-sealed gate valve of the vacuum spray-coating machine is disassembled conveniently and has good maintainability; the valve seat is of a two-piece type structural design, so that the inner cavity has no clearance, and a medium is not easy to be clamped and blocked; in addition, the sealing rings in matching fit with the gate plate are arranged at the peripheries of the valve holes of the two valve seat plates, better sealing effects of double-sided soft sealing are achieved, and leakage rate is reduced greatly.

Owner:ZHANJIANG HENGRUN MASCH CO LTD

Regulating valve of axial flow sleeve

ActiveCN103090019AImprove securityImprove organizational structureLift valveValve housingsValve seatEngineering

The invention discloses a regulating valve of an axial flow sleeve. The regulating valve of the axial flow sleeve comprises a split type valve body, a valve element, a guide sleeve, a valve cage, a valve seat, a valve cylinder, a transmission valve rod and a driving valve rod, wherein the driving valve rod can enable the transmission valve rod to axially move inside the guide sleeve. An automatic valve cylinder aligning mechanism is arranged between the other end of the transmission valve rod and the valve cylinder, the automatic valve cylinder aligning mechanism comprises a center regulating sleeve and a center regulating ring, the center regulating sleeve and the center regulating ring are both supported on the transmission valve rod, and a moving groove with two sides closed is formed between the center regulating sleeve and the center regulating ring. A valve cylinder cover is fixedly connected on the valve cylinder, the valve cylinder is clamped inside the moving groove through the valve cover, and the valve cylinder can move on the axial direction and the radical direction of the transmission valve rod inside the moving groove through the valve cylinder cover. The valve cylinder and the valve cage of the regulating valve of the axial flow sleeve can regulate center automatically, the matching precision of the valve cylinder and the valve cage is improved, a jamming phenomenon is not prone to occurring, a service life is long, and reliability is high.

Owner:TERRENCE ENERGY

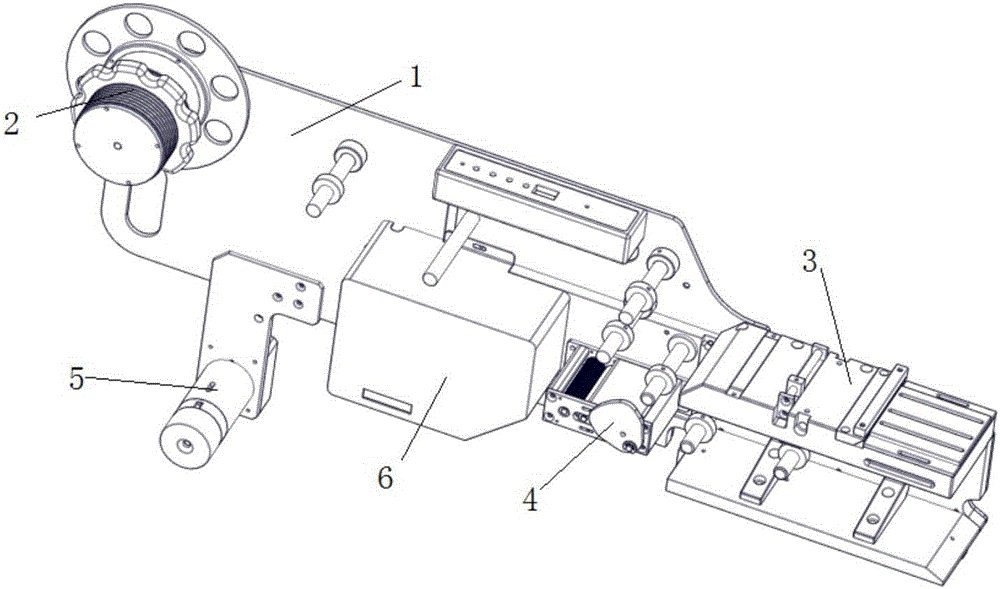

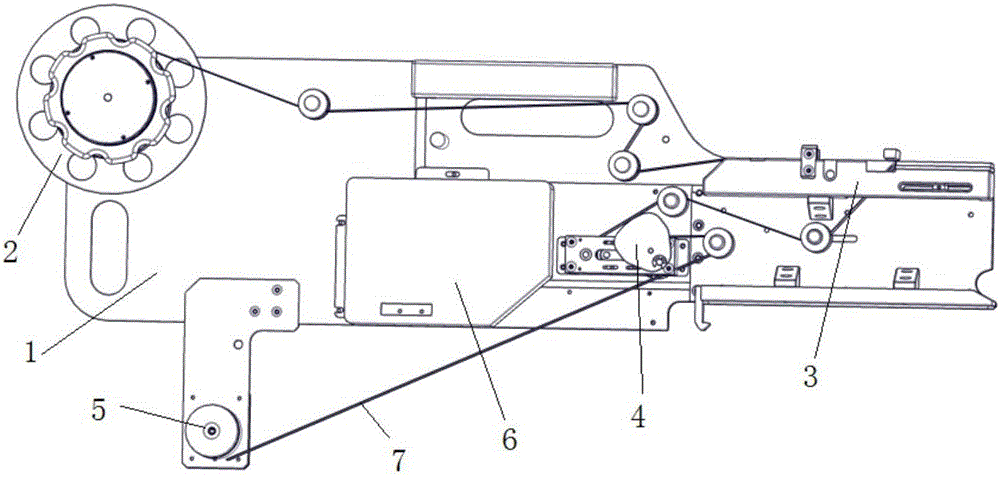

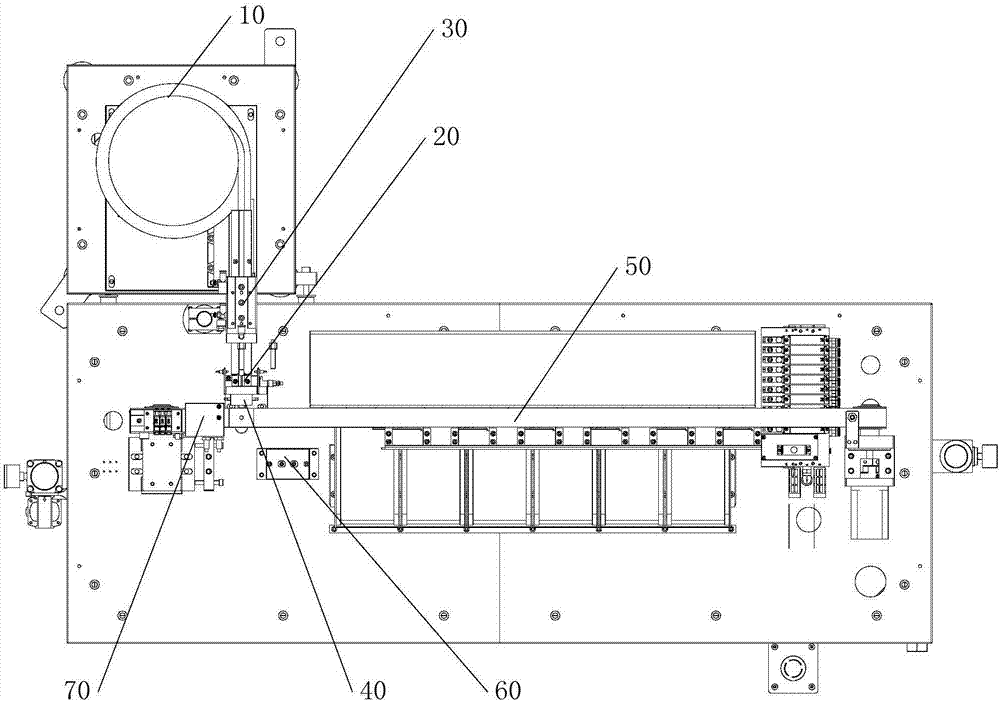

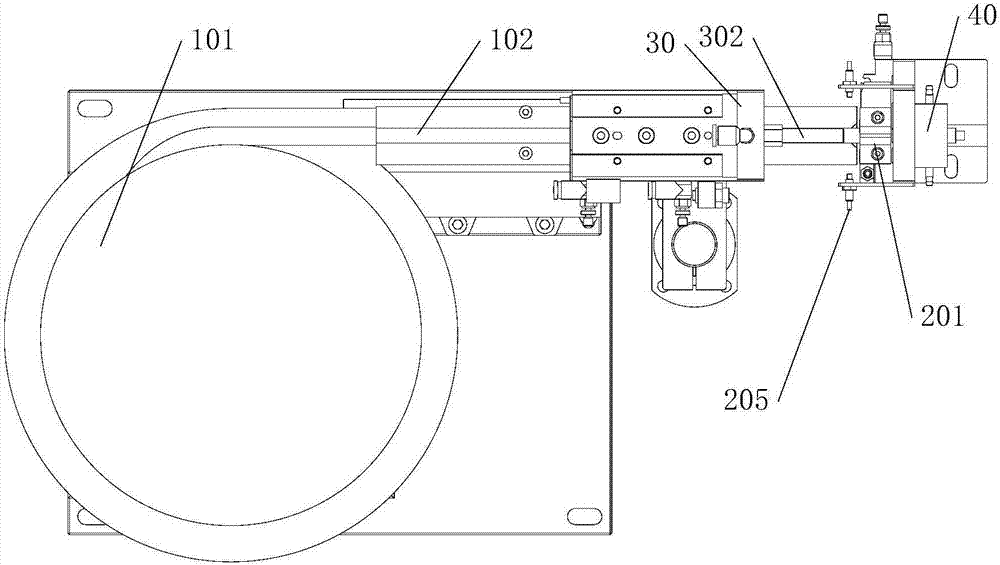

Label stripping mechanism, emptying module and label stripping method for automatically tightening strips

ActiveCN106184952ASimple structureEasy to operateLabelling machinesWebs handlingEngineeringIntelligent control

The invention provides a label stripping mechanism, an emptying module and a label stripping method for automatically tightening strips, and belongs to the technical field of machining equipment. The emptying module consists of a fixed base, a motor, an inner baffle plate, a roller, a locking ring and a turntable; and the label stripping mechanism includes a frame, and the emptying module, a label stripping plate module, a collecting module and a waste recovery module mounted on the frame. The label stripping mechanism has the advantages of intelligent control and capability of stripping labels without manual operation, can automatically tighten the strips, and greatly improves the label stripping efficiency and quality.

Owner:吴凯旋

Work piece measuring device and measuring method

The invention provides a work piece measuring device which includes a vibration feeding mechanism, a measuring mechanism, a group discharging mechanism, and a feeding material pushing mechanism. The measuring mechanism has a measuring part of which the inlet is coupled to the discharge hole of the vibration feeding mechanism. The group discharging mechanism includes a conveyor belt coupled to the outlet of the measuring part of the measuring mechanism, different material boxes arranged in turn in the conveying stroke of the conveyor belt and corresponding to different measurement results of the measuring part, and a discharging material pushing mechanism used for pushing work pieces on the conveyor belt to the corresponding material boxes. The feeding material pushing mechanism is used for pushing work pieces output from the discharge hole of the vibration feeding mechanism to the measuring part of the measuring mechanism and to the conveyor belt of the group discharging mechanism. A measuring method is provided accordingly. Through the device and the method, work pieces can be fed automatically, and can be sorted and discharged to the different material boxes corresponding to different detection results after detection.

Owner:BEIJING BRANCH JIKE DEV SCI & TECH

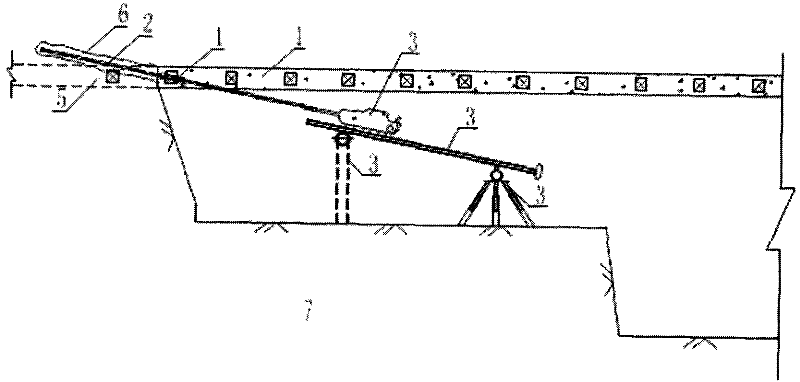

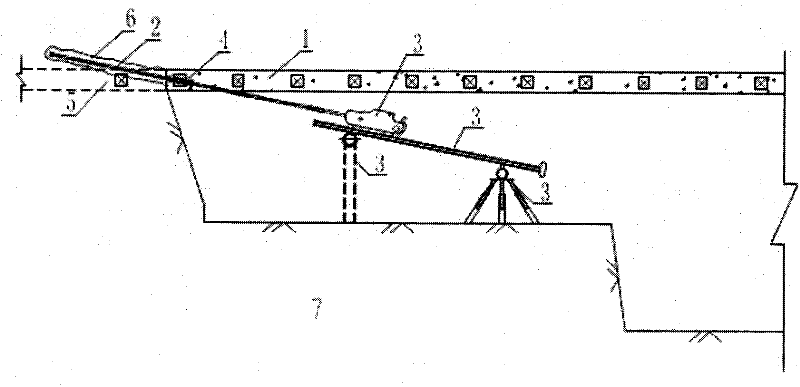

Advanced hole-forming method of sand gravel boulder layer

The invention provides an advanced hole-forming method of a sand gravel boulder layer, comprising the following steps of: during construction, welding a preserved orifice pipe on a former hinged grille according to the design; after spraying concrete on the former hinged grille, splicing a guide tail type heavy pneumatic drill on steps of a tunnel and then mounting a self-advancing hollow groutedbolt on a drilling machine after the splicing is finished; starting the drilling machine and adjusting the height and the angle of the guide tail type heavy pneumatic drill according to the preservedposition; and after all preparations are finished, starting drilling, separating the self-advancing hollow grouted bolt from the guide tail type heavy pneumatic drill after the drilling depth reachesthe requirement and forming a hole. The advanced hole forming method provided by the invention has the characteristic of great impact and drill rod rotating torque and can be used for respectively adjusting the impact energy, the drill rod rotating speed and the torque; the drilling speed is high, thus one hole can be formed within about 2 minutes after the mounting is in place; and the advanced hole forming method ensures that the equipment used in the method has light weight, high mounting in-place and displacing speed, reasonable overall dimension and small occupied space and is not easy to cause the phenomenon of clamping the drill rod in the sand gravel layer and is low in cost and especially suitable for narrow operation places in the pit.

Owner:RANKEN RAILWAY CONSTR GROUP

Rolling brush assembly and cleaning device

The invention discloses a rolling brush assembly and a cleaning device. The rolling brush assembly comprises a cam shaft, a rolling brush shaft cover surface and at least two cutters. The cutter restsof the cutters are assembled in grooves corresponding to the rolling brush shaft cover surface; the cam shaft is of a shaft body structure with a guide structure, and a shaft of the cam shaft is fixedly embedded in the rolling brush shaft cover surface; the axial lengths of the guide structures on the two sides of a shaft body of the cam shaft are different. Each cutter is driven to rotate by anexternal force; the stressed body of one cutter is always pushed and extruded by the end surface with relatively large axial length of the guide structure; the stressed body drives the second blade ofthe same cutter to move relative to the first blade of the same cutter; the elastic element of the same cutter is in a force accumulation state, and when the cutter pushed away by the guide structurein an abutting mode rotates to the position where the cutter is not pushed away by the guide structure, the elastic element automatically resets the second blade of the same cutter, so that the second blade does left-right reciprocating movement relative to the first blade.

Owner:DONGGUAN XINSU TECH CO LTD

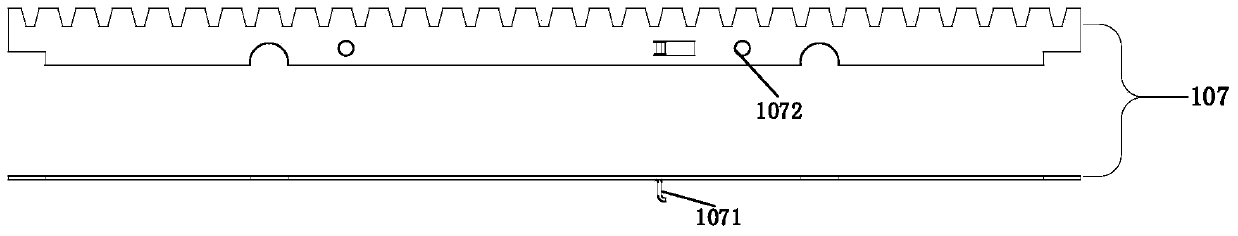

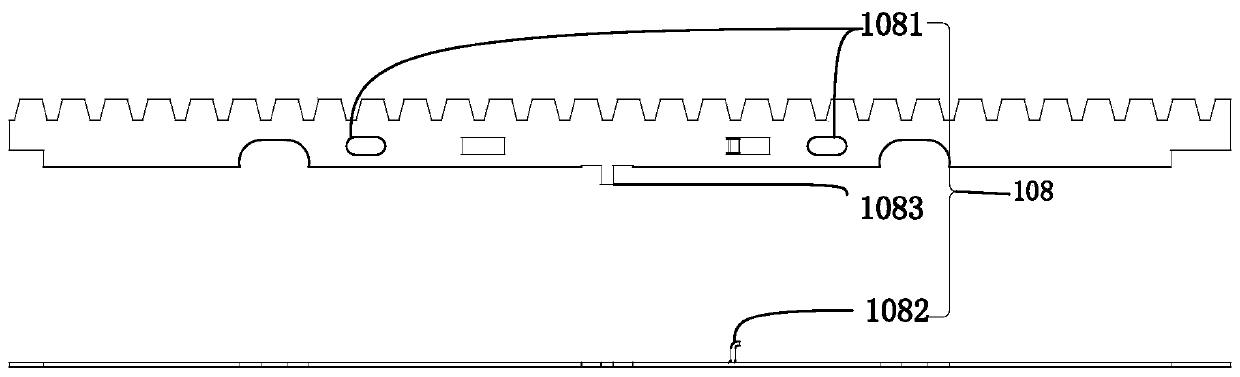

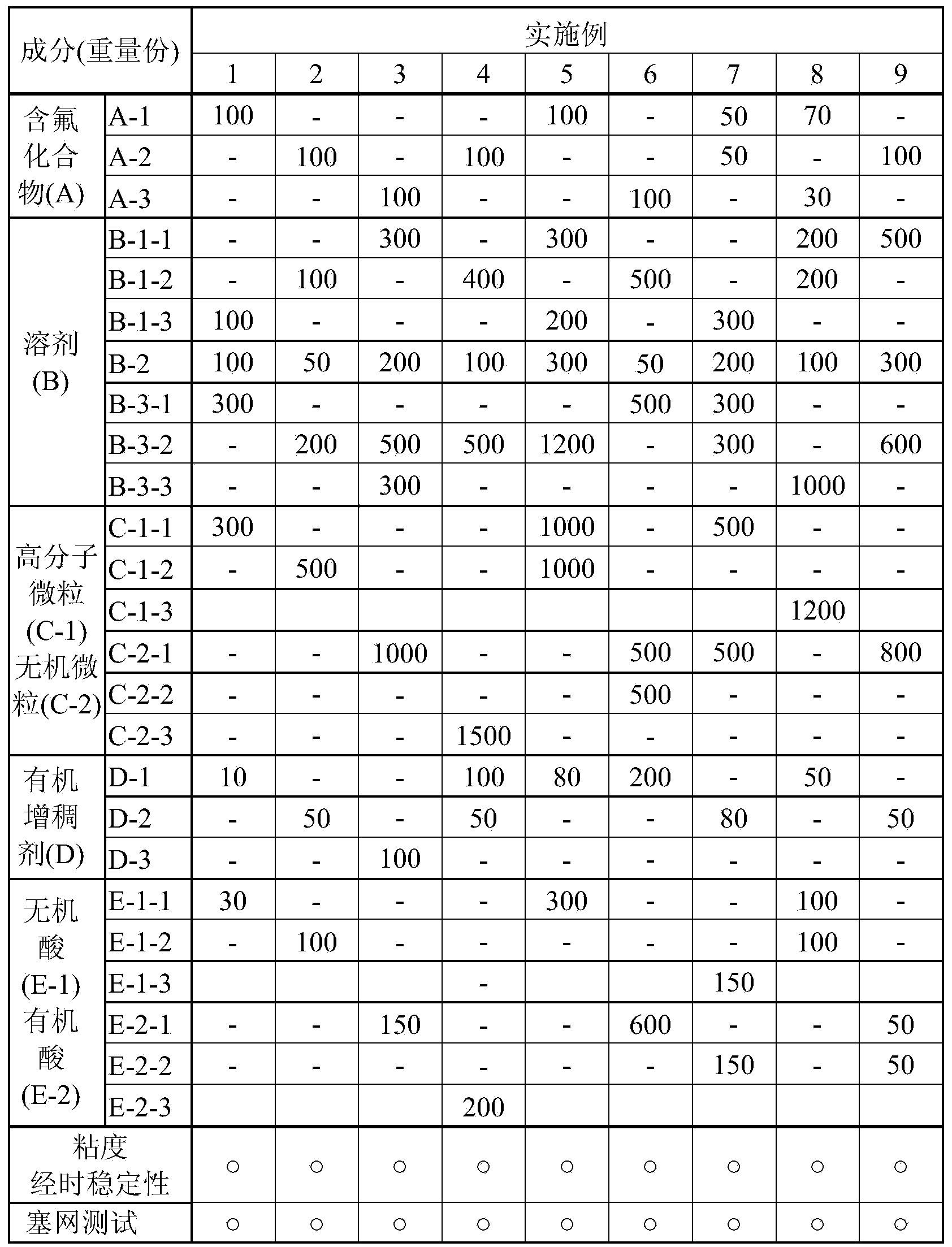

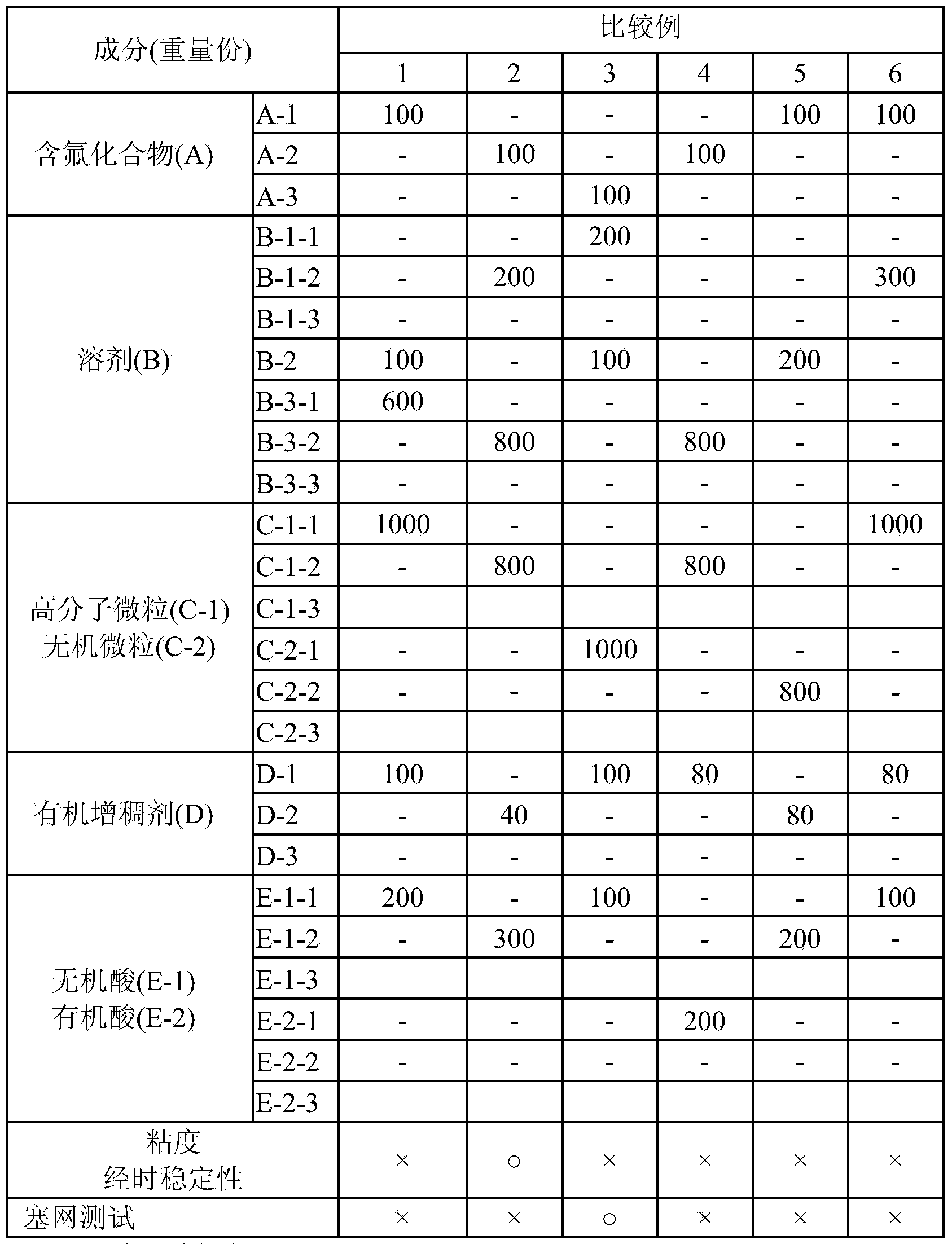

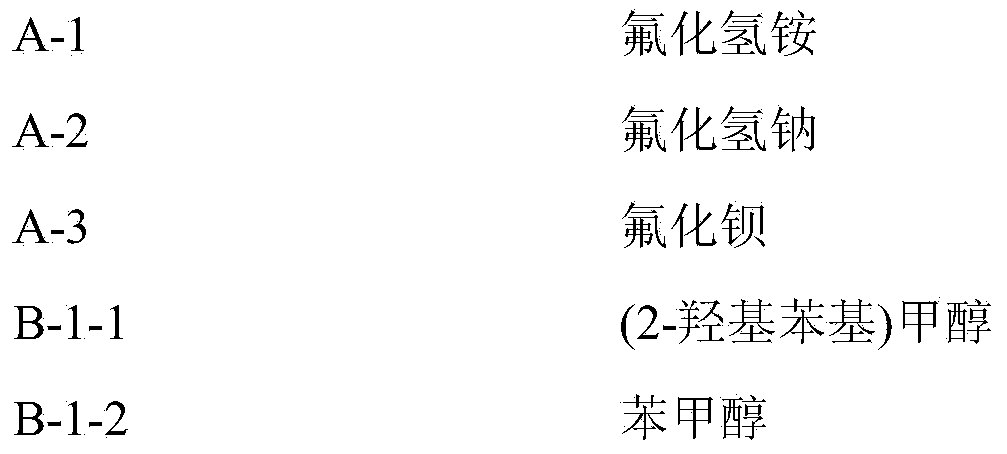

Etching paste component and application thereof

InactiveCN104119921AGood viscosity stability over timeNot easy to jamSemiconductor/solid-state device manufacturingSurface treatment compositionsSolventTouch panel

The invention relates to an etching paste component and an application thereof; the etching paste component comprises the following elements: a fluorinated compound (A); a solvent (B) comprising am linalool solvent (B-1), water (B-20 and other solvent (B-3); a micro particle (C) selected from a group formed by or combined by a polymer particle (C-1) and inorganic compound particle (C-2); an organic thickener (D); and acid (E) selected from a group formed by or combined by organic acid (E-1) and inorganic acid (E-2). The invention also provides an etching method: arranging the etching paste compound on a monox layer or a silicon nitride layer of a substrate of a touch panel through silk-screen printing; carrying out etching step and cleaning step; the etching paste compound is excellent in durable stability, and suitable for silk-screen printing operation.

Owner:CHI MEI CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com