Label stripping mechanism, emptying module and label stripping method for automatically tightening strips

A component and label stripping technology, which is applied in the field of label stripping, label stripping mechanism, and automatic label stripping equipment for unwinding components and their self-tightening tapes, which can solve the problems of hindering normal tape rotation, single structure and easy material jam , to achieve the effect of improving the efficiency and quality of stripping, improving efficiency and quality, and reducing maintenance work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The preferred embodiments of the present invention will be described in detail below; it should be understood that the preferred embodiments are only for illustrating the present invention, not for limiting the protection scope of the present invention.

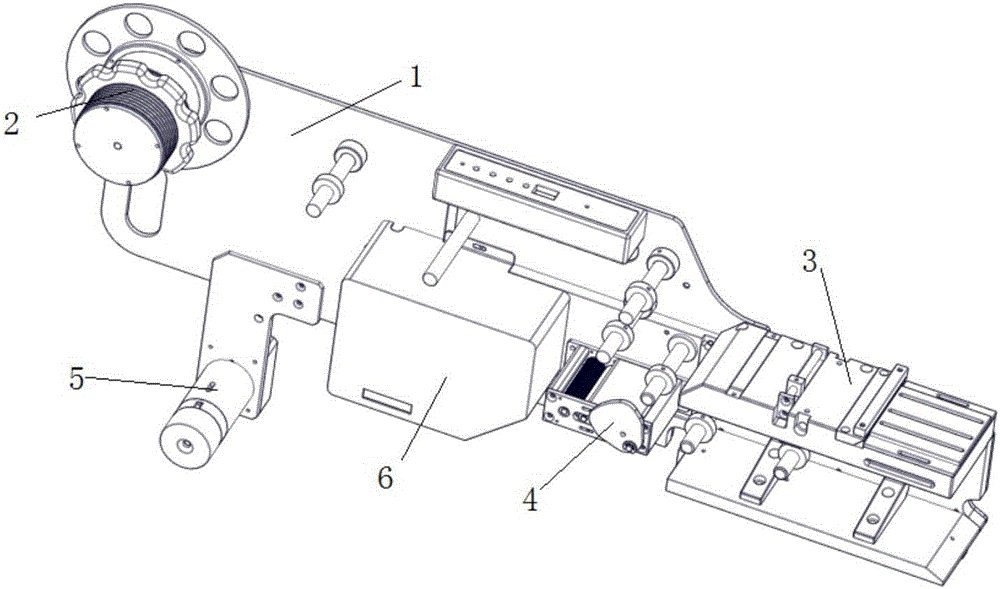

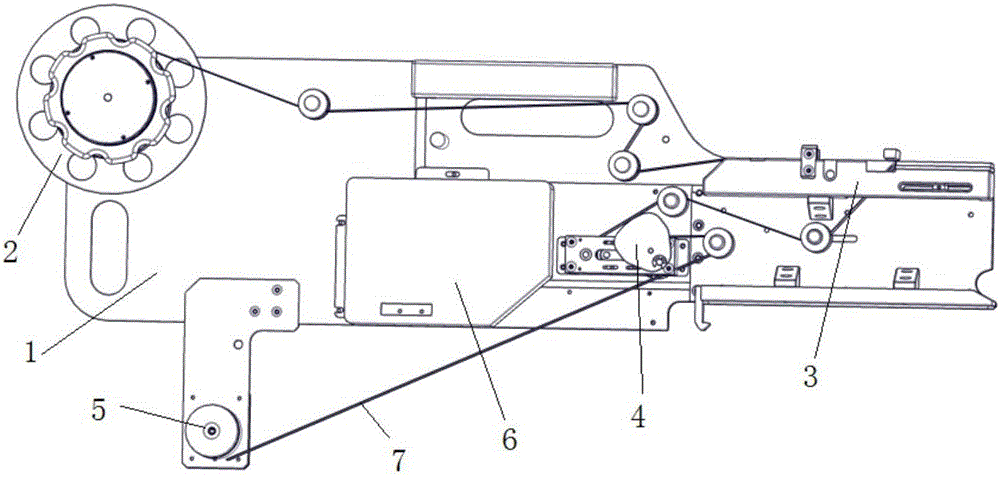

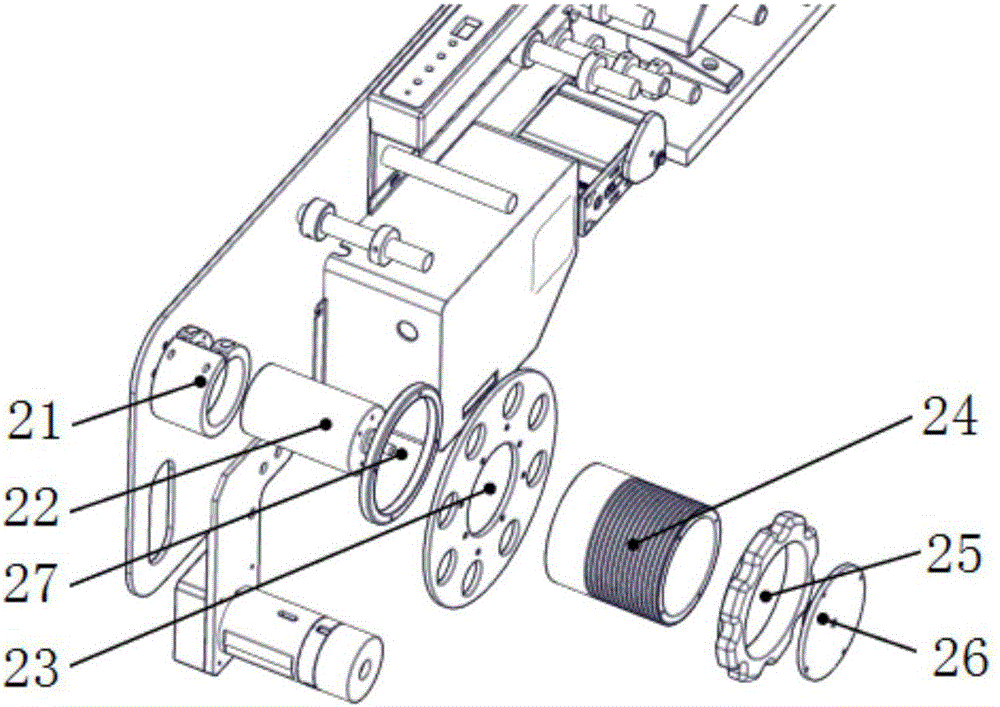

[0053] Such as Figure 1-3 As shown, a stripping mechanism of this embodiment includes a frame 1 and a discharge assembly 2, a stripping board assembly 3, a collection assembly 4, and a waste recycling assembly 5 all installed on the frame 1. The discharge assembly 2 and the label stripping component 3 are respectively located at the two ends of the frame 1. A waste recycling component 5 is arranged near the lower left of the unwinding component 2, and a receiving component 4 is arranged on the lower right near the unwinding component 3. The assembly 2 is mainly composed of a fixed seat 21, a motor 22, an inner baffle 23, a roller 24, a locking ring 25 and a turntable 26. The motor 22 is installed in the fixed seat 21, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com