Automatic page-separating paper crusher

A paper shredder and automatic paper feeding technology, which is applied in the direction of grain processing, etc., can solve the problems of limited paper quantity, time-consuming and laborious, damage to the paper shredder, etc., and achieve the effect of not being easy to jam and easy to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

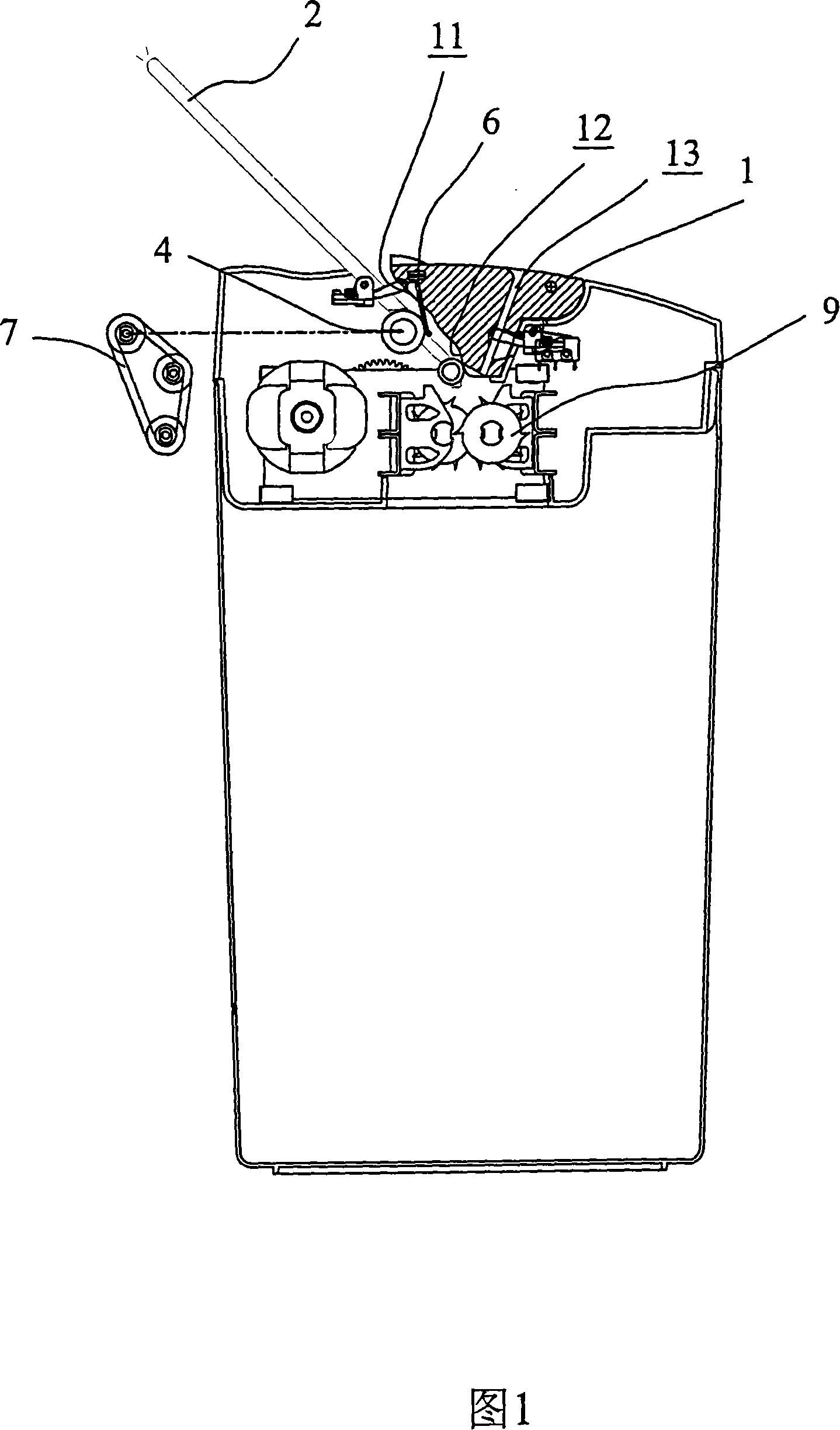

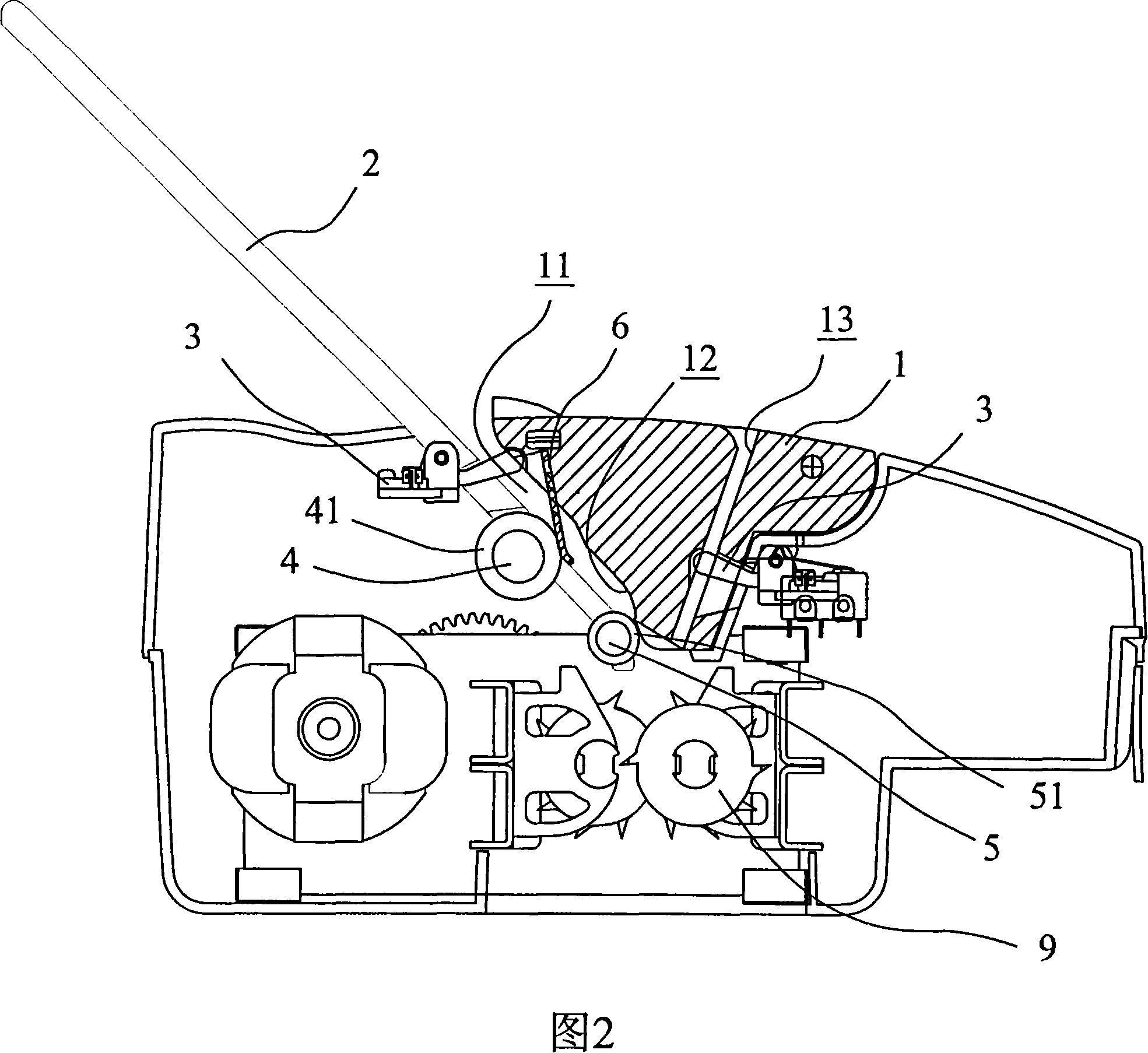

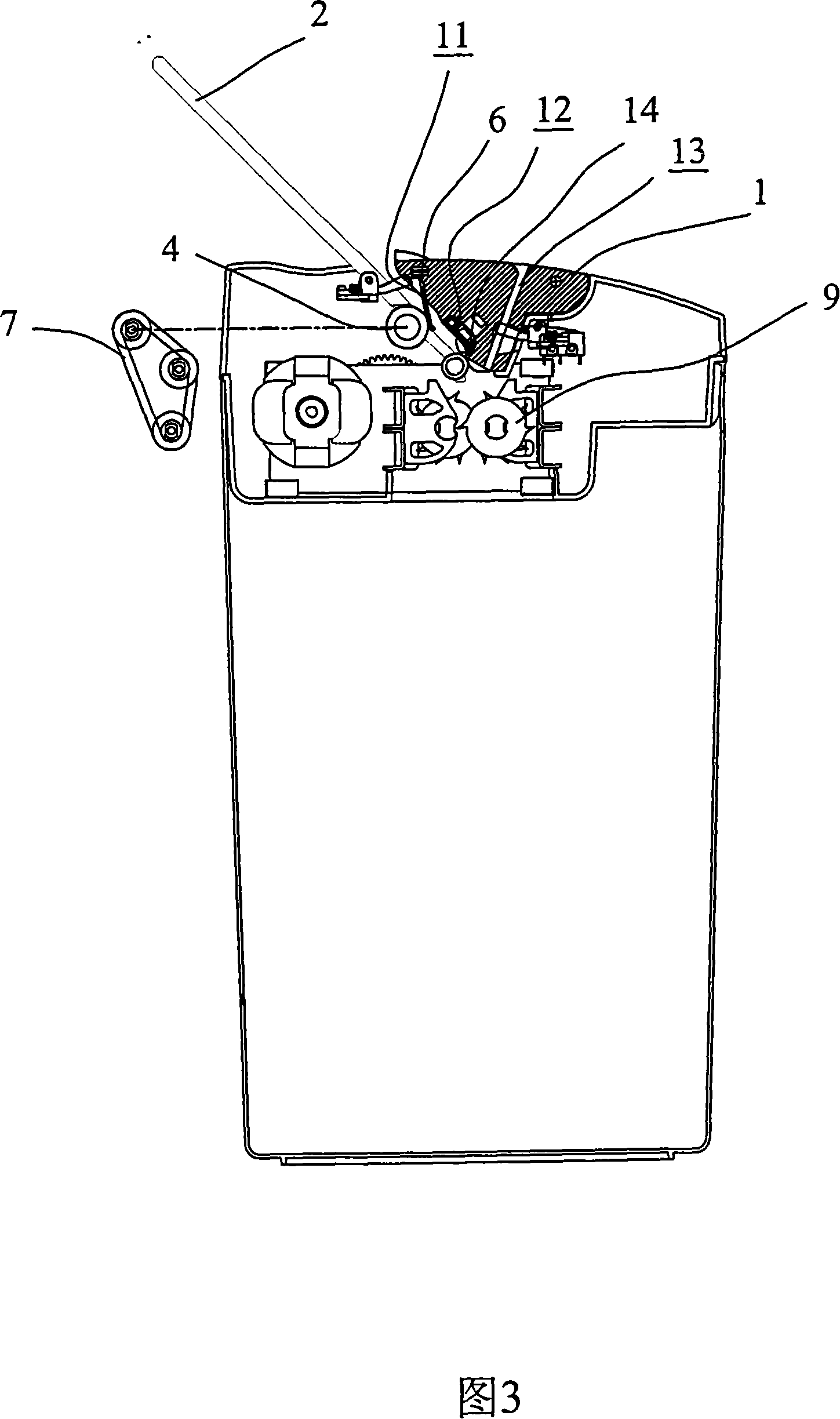

[0020] As shown in Figures 1 and 2, in the first embodiment of the present invention, an opening is formed on the top of the paper shredder at a position corresponding to the paper shredder shaft 9, and a cover plate 1 and a paper tray 2 are provided in the opening. The paper tray 2 obliquely extends under the cover plate 1, and an automatic paper feeding channel 11 is formed between the paper tray 2 and the cover plate 1. The cover plate 1 forms a narrowed section 12 near the bottom end of the paper tray 2 so that the automatic paper feeding passage 11 between the tray 2 and the cover plate is narrower. The narrowing section 12 is preferably arc-shaped.

[0021] The paper tray 2 is provided with a capstan wheel 4 in the middle of the automatic paper feeding channel 11. The capstan 4 can be driven by a driving device 7 linked with a motor that drives the shredder shaft, or it can be driven by a separate driving device. The automatic paper feeding channel 11 is provided with a micr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com