Patents

Literature

3384results about "Surface treatment compositions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

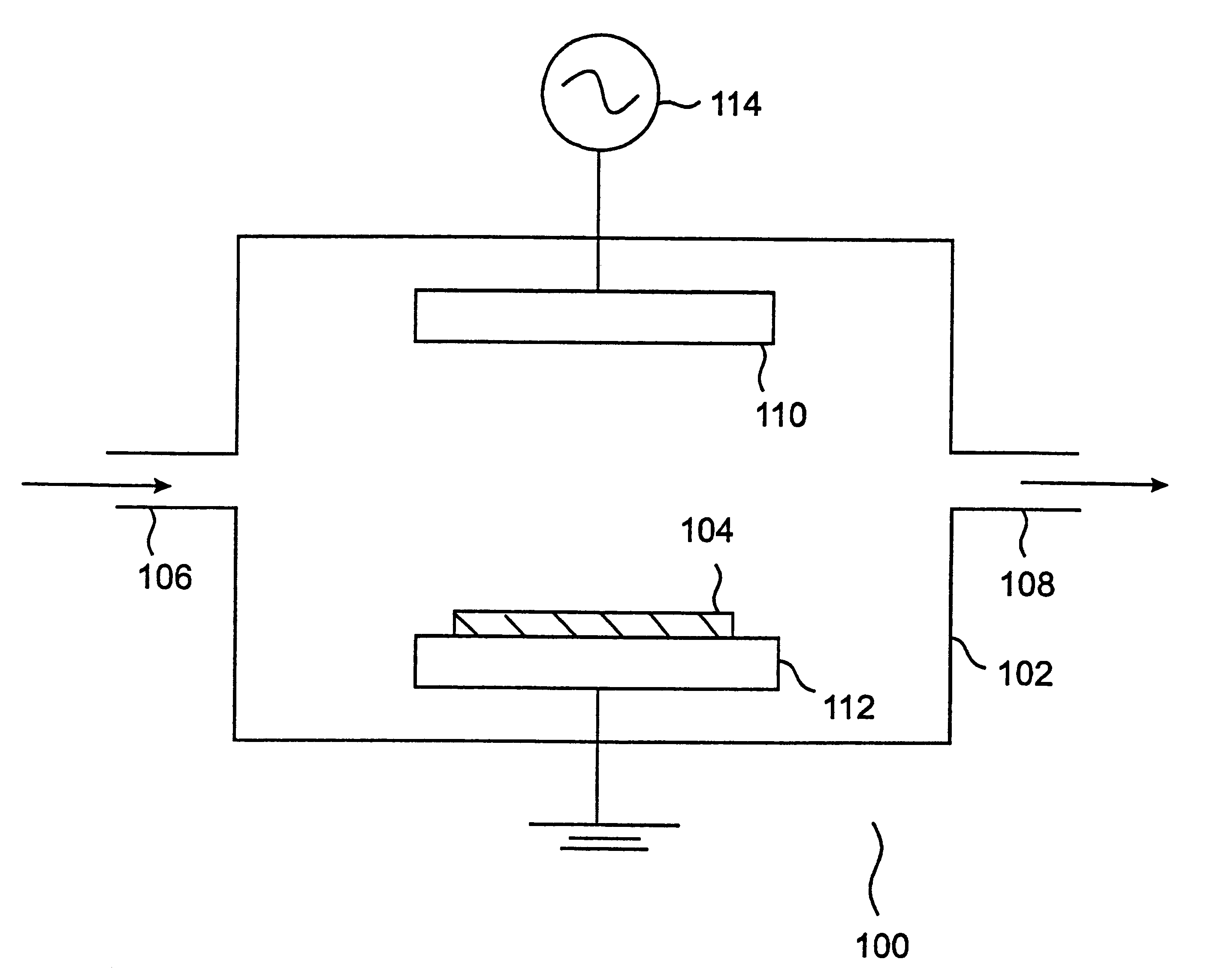

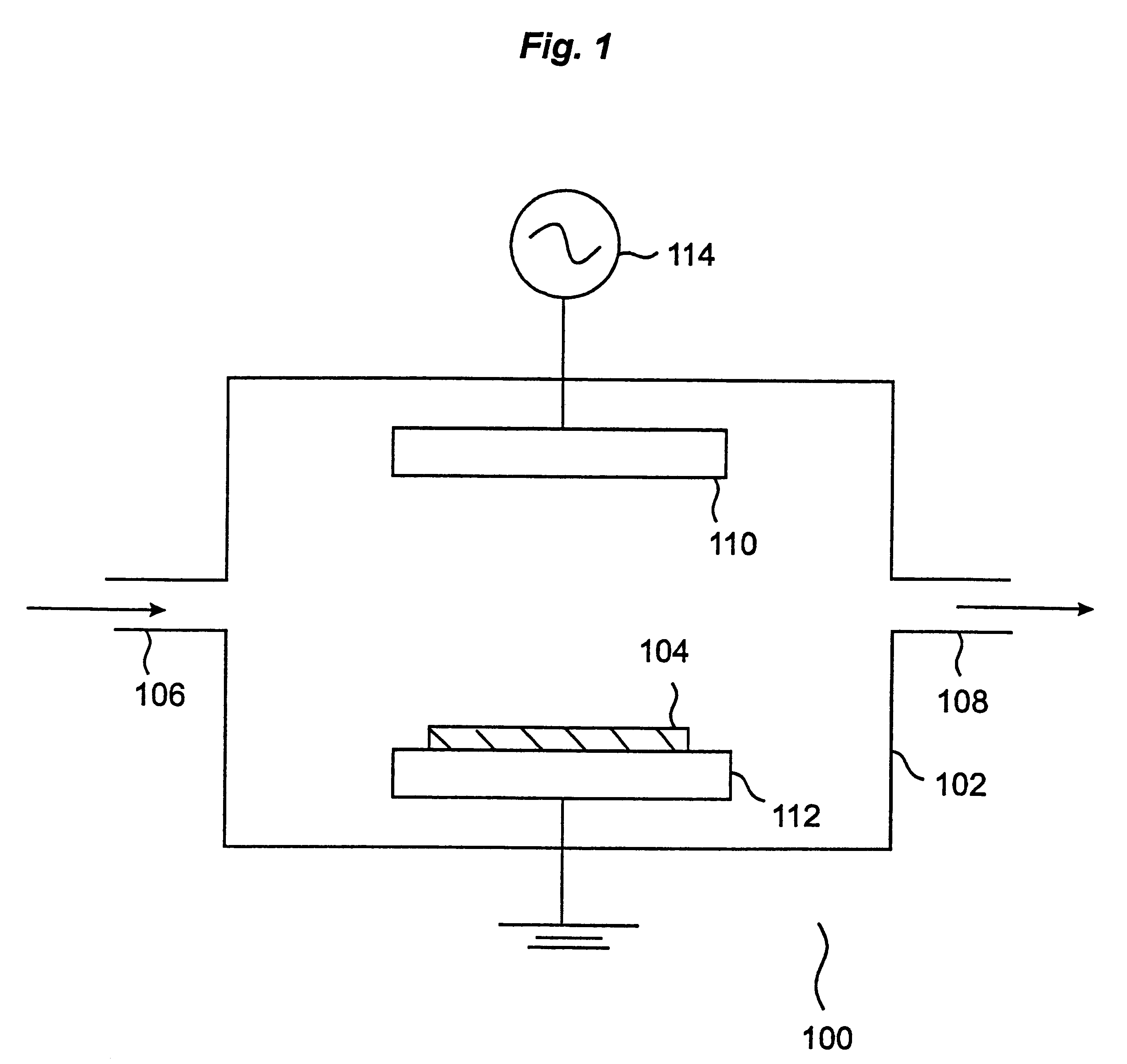

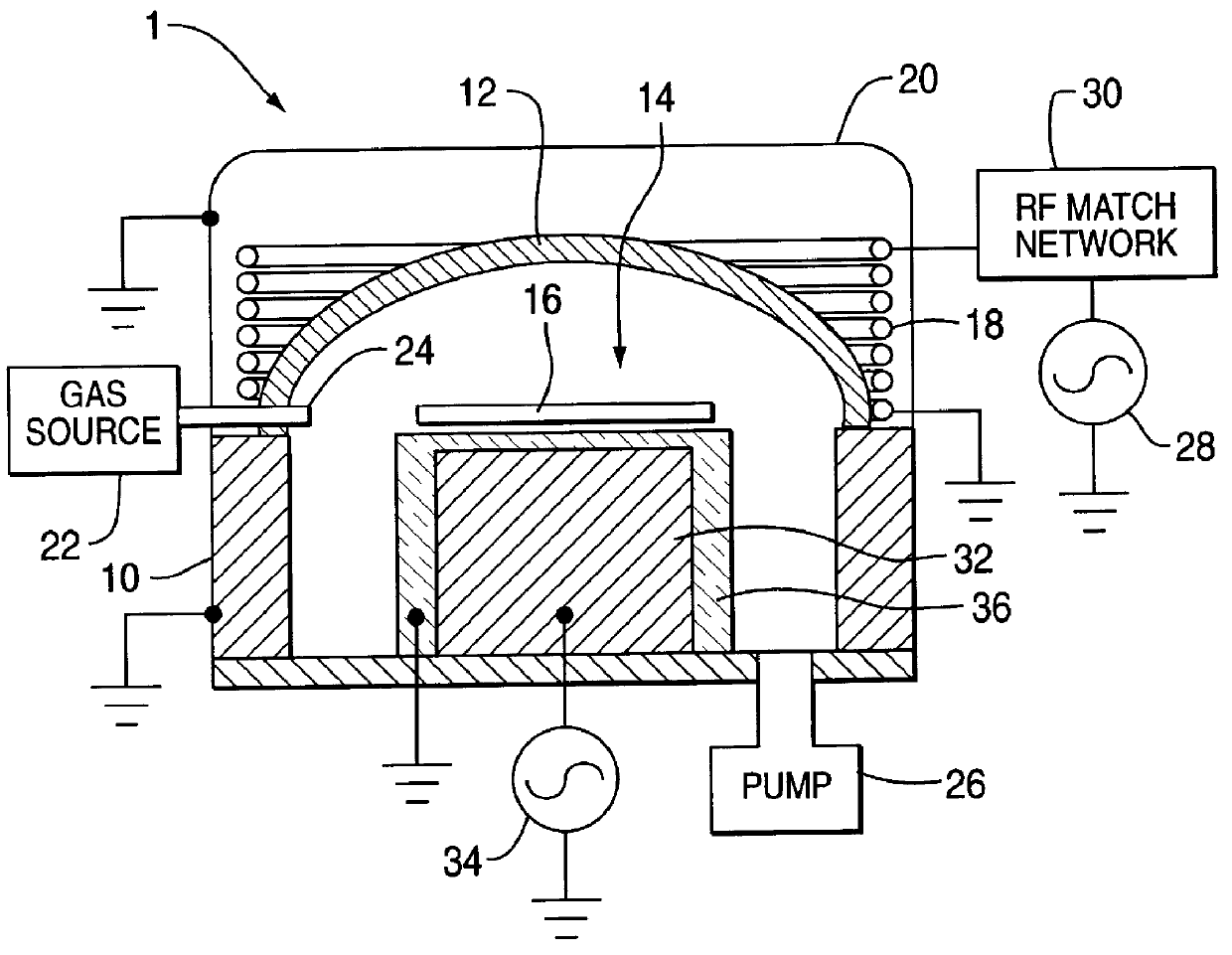

Plasma cleaning and etching methods using non-global-warming compounds

InactiveUS6242359B1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingTrifluoroacetic anhydrideChemical vapor deposition

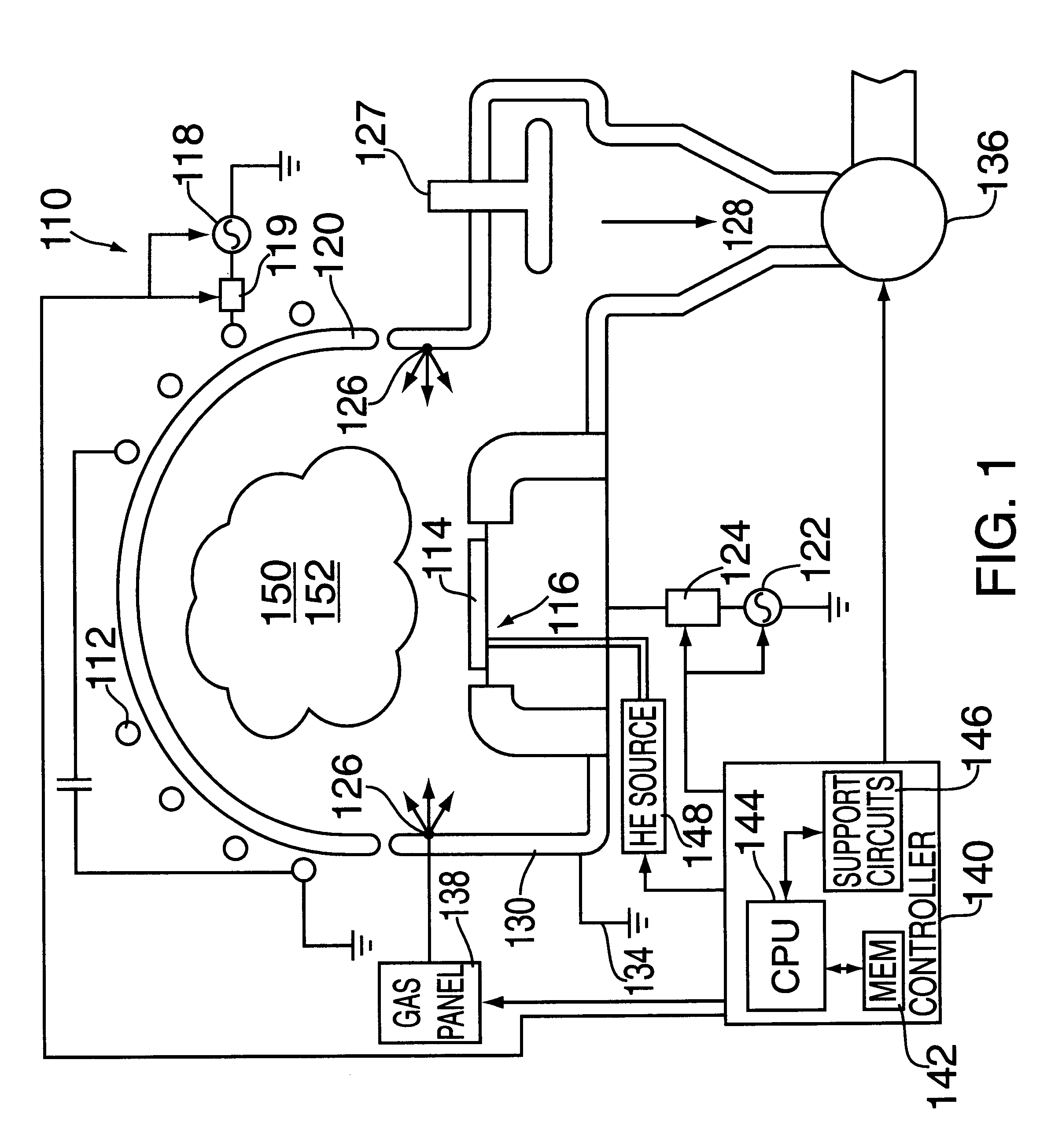

Provided is a novel method of cleaning a chemical vapor deposition processing chamber having deposits on an inner surface thereof is provided. The process involves forming a plasma from one or more gases comprising a fluorine-containing but otherwise halogen-free non-global-warming compound, and contacting active species generated in the plasma with the inner surface of the chamber, with the proviso that the non-global-warming compound is not trifluoroacetic anhydride. Also provided is a method of etching a layer on a silicon wafer. The method involves the steps of: (a) introducing a silicon wafer into a processing chamber, the silicon wafer comprising a layer to be etched; and (b) forming a plasma from one or more gases comprising a fluorine-containing but otherwise halogen-free non-global-warming compound. Active species generated in the plasma are contacted with the silicon wafer, thereby etching the layer, with the proviso that the non-global-warming compound is not trifluoroacetic anhydride. The chemistries in accordance with the invention provide environmentally benign alternatives to the conventionally used global-warming chemistries for chamber cleaning and semiconductor etching processes.

Owner:LAIR LIQUIDE SA POUR LETUDE & LEXPLOITATION DES PROCEDES GEORGES CLAUDE

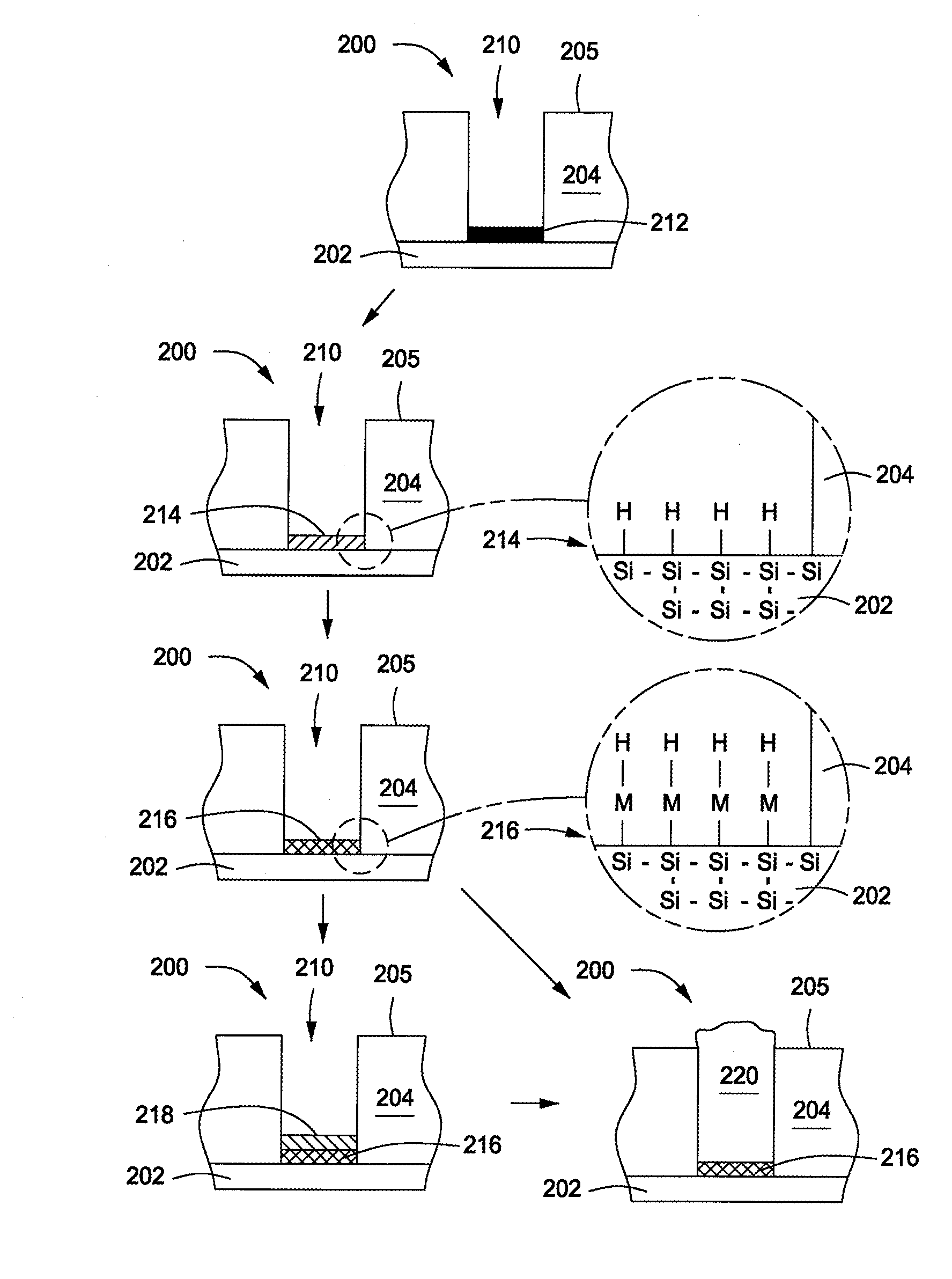

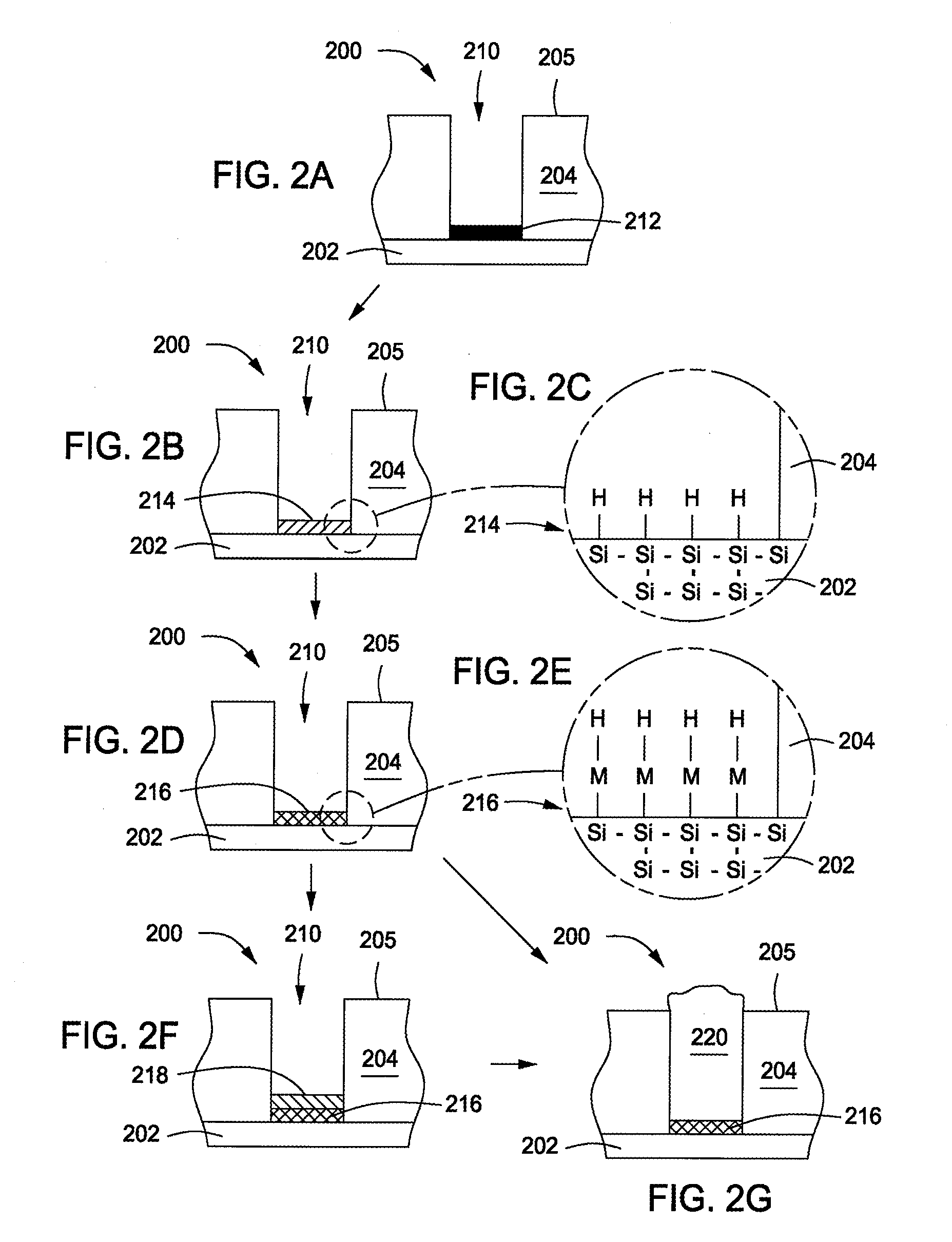

Method of selectively depositing a thin film material at a semiconductor interface

InactiveUS20070108404A1Detergent mixture composition preparationSemiconductor/solid-state device manufacturingDevice formMetal silicide

Embodiments of the invention provide processes to form a high quality contact level connection to devices formed on a substrate. In one embodiment, a method for depositing a material on a substrate is provided which includes exposing the substrate to a buffered oxide etch solution to form a silicon hydride layer during a pretreatment process, depositing a metal silicide layer on the substrate, and depositing a first metal layer (e.g., tungsten) on the metal silicide layer. The buffered oxide etch solution may contain hydrogen fluoride and an alkanolamine compound, such as ethanolamine diethanolamine, or triethanolamine. The metal silicide layer may contain cobalt, nickel, or tungsten and may be deposited by an electroless deposition process. In one example, the substrate is exposed to an electroless deposition solution containing a solvent and a complexed metal compound.

Owner:APPLIED MATERIALS INC

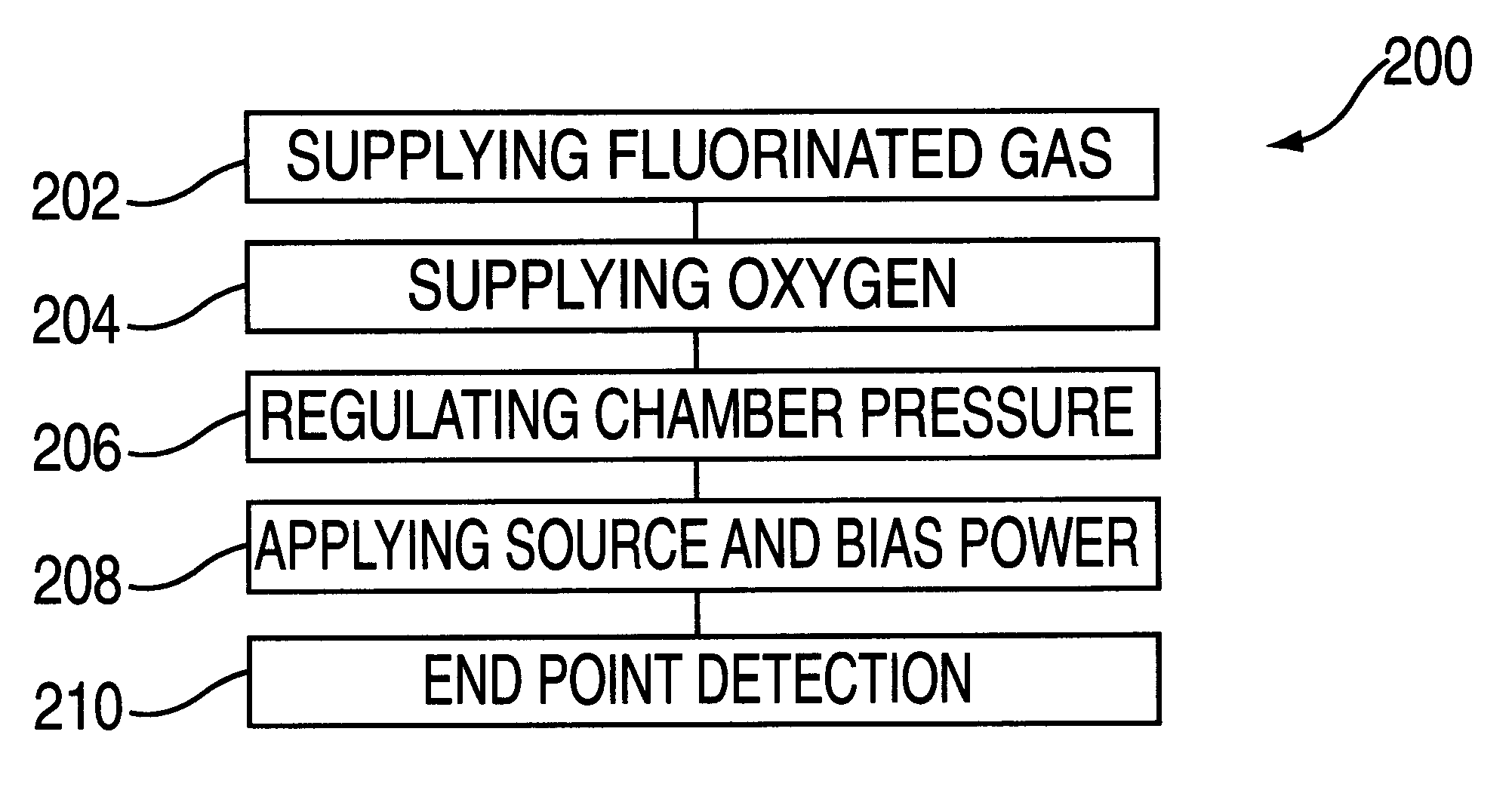

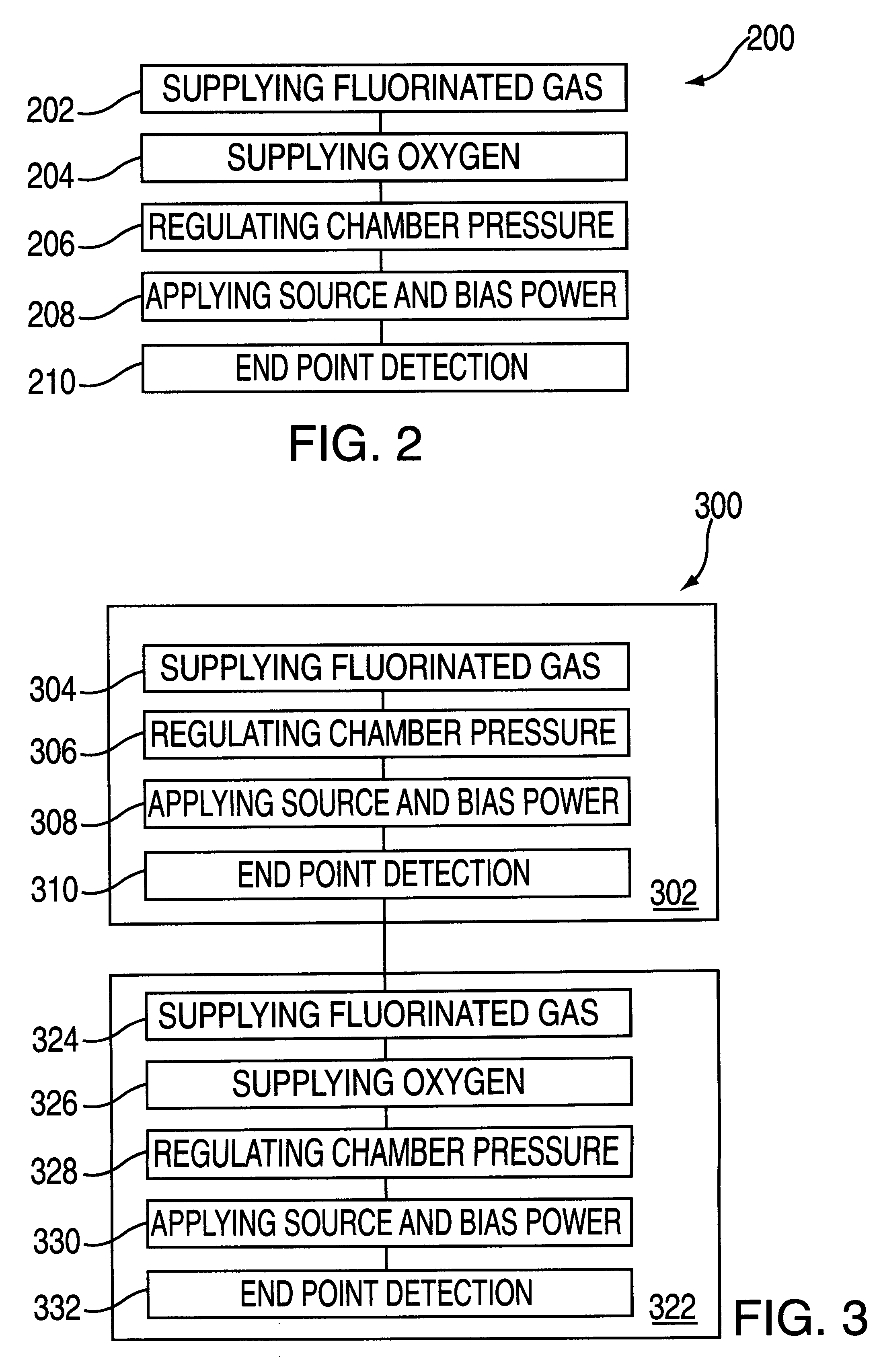

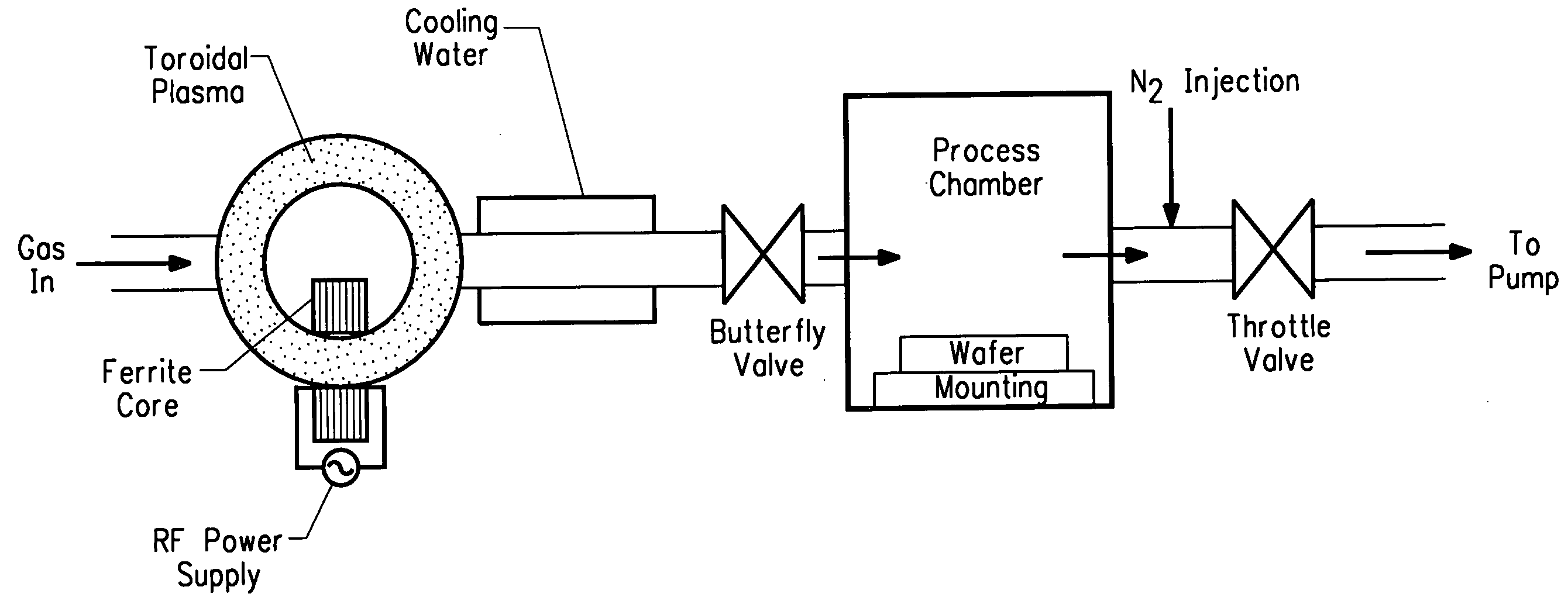

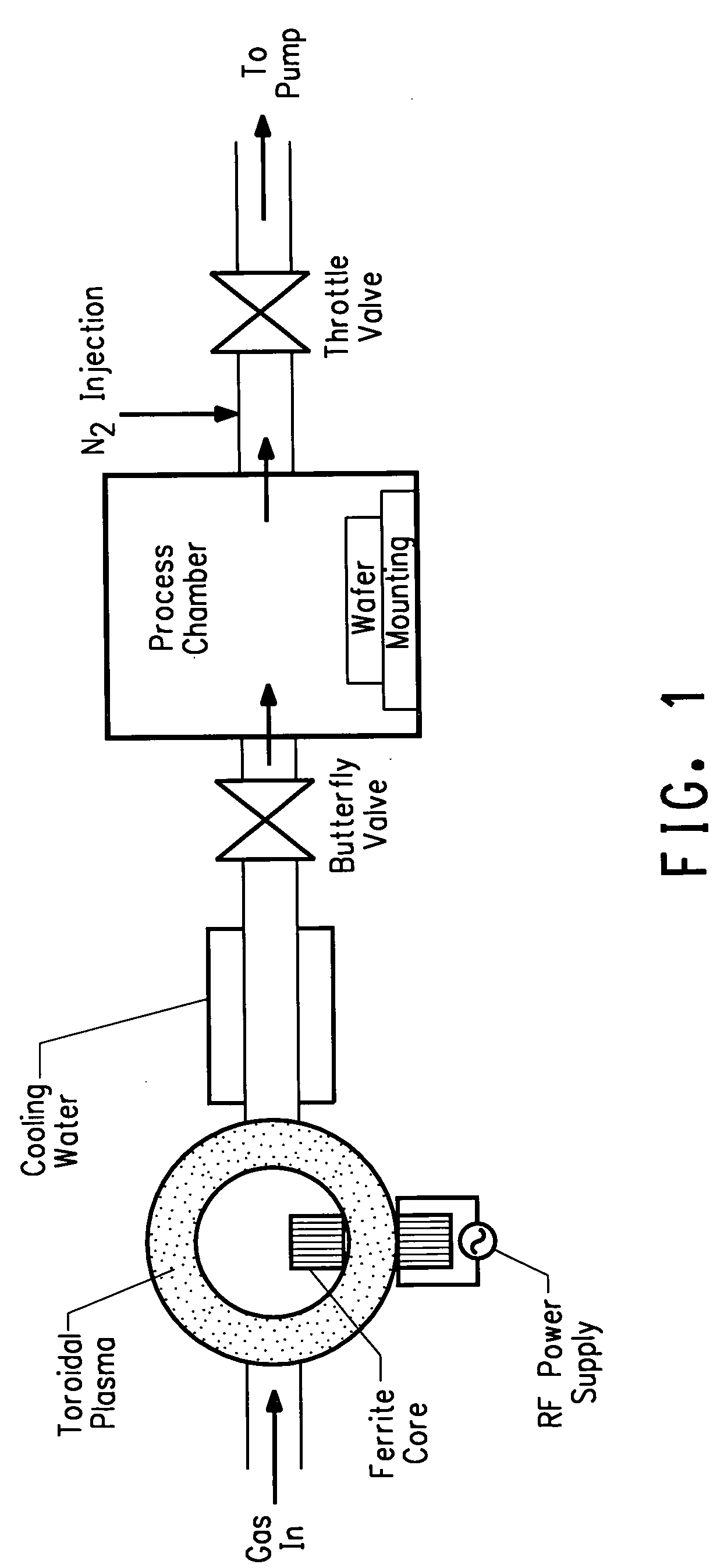

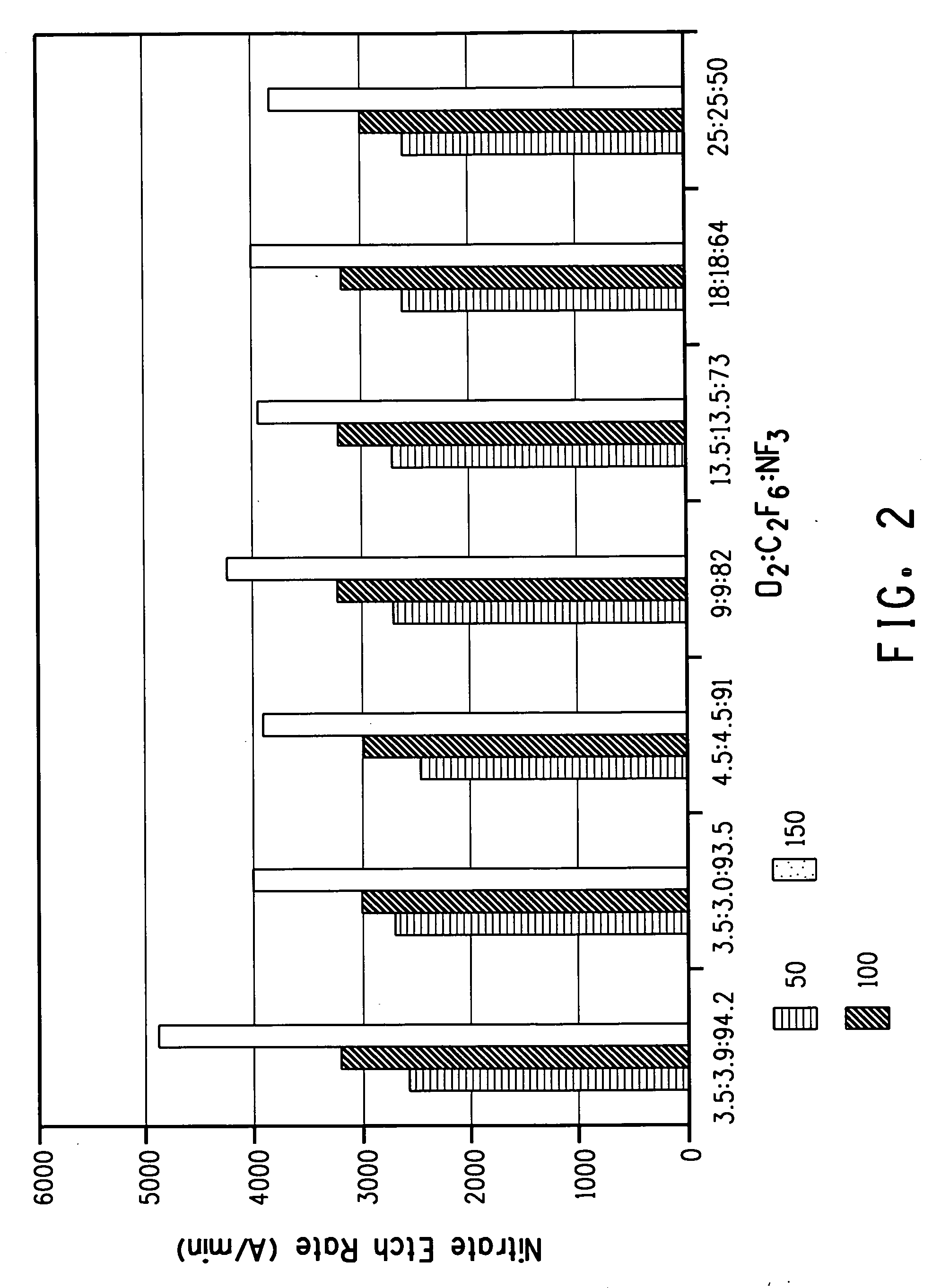

Plasma processing of tungsten using a gas mixture comprising a fluorinated gas and oxygen

InactiveUS6277763B1Good choiceElectric discharge tubesVacuum gauge using ionisation effectsFluorinated gasesProduct gas

Owner:APPLIED MATERIALS INC

Method of using NF3 for removing surface deposits from the interior of chemical vapor deposition chambers

InactiveUS20070107750A1Efficient methodElectrostatic cleaningChemical vapor deposition coatingRemote plasmaOxygen

The present invention relates to a remote plasma cleaning method for removing surface deposits from a surface, such as the interior of a depositions chamber that is used in fabricating electronic devices. The process involves activating a gas stream comprising an oxygen source, NF3, and a fluorocarbon and contacting the activated gas mixture with surface deposits to remove the surface deposits.

Owner:MASSACHUSETTS INST OF TECH

Etching solution for silicon oxide and method of manufacturing a semiconductor device using the same

InactiveUS20070090325A1Efficient removalAvoid damageDecorative surface effectsSolid-state devicesHydrogen fluorideDevice material

An etching solution for silicon oxide may be used in a process for enlarging an opening formed through a silicon oxide layer. The etching solution includes about 0.2 to about 5.0 percent by weight of a hydrogen fluoride solution, about 0.05 to about 20.0 percent by weight of an ammonium fluoride solution, about 40.0 to about 70.0 percent by weight of an alkyl hydroxide solution and remaining water. The etching solution may etch the silicon oxide layer without damage to a metal silicide layer exposed by the opening.

Owner:CONVERSANT INTPROP MANAGEMENT INC

Precursors and processes for low temperature selective epitaxial growth

InactiveUS20090087967A1Practical and cost-effective SEGReduce processingDecorative surface effectsSemiconductor/solid-state device manufacturingBromineGas phase

This invention generally relates to low temperature epitaxy. More specifically, this invention relates to processes for achieving low temperature selective epitaxial growth by chemical vapor deposition of source precursors containing Si or Ge in the presence of bromine or iodine, compositions containing precursors and brominated or iodinated compounds suitable for achieving selective epitaxial growth using the processes, epitaxial layers made using the processes, devices and other types of structures made using the processes, and processes for cleaning epitaxy reactor chambers using a bromine etchant source.

Owner:TODD MICHAEL A

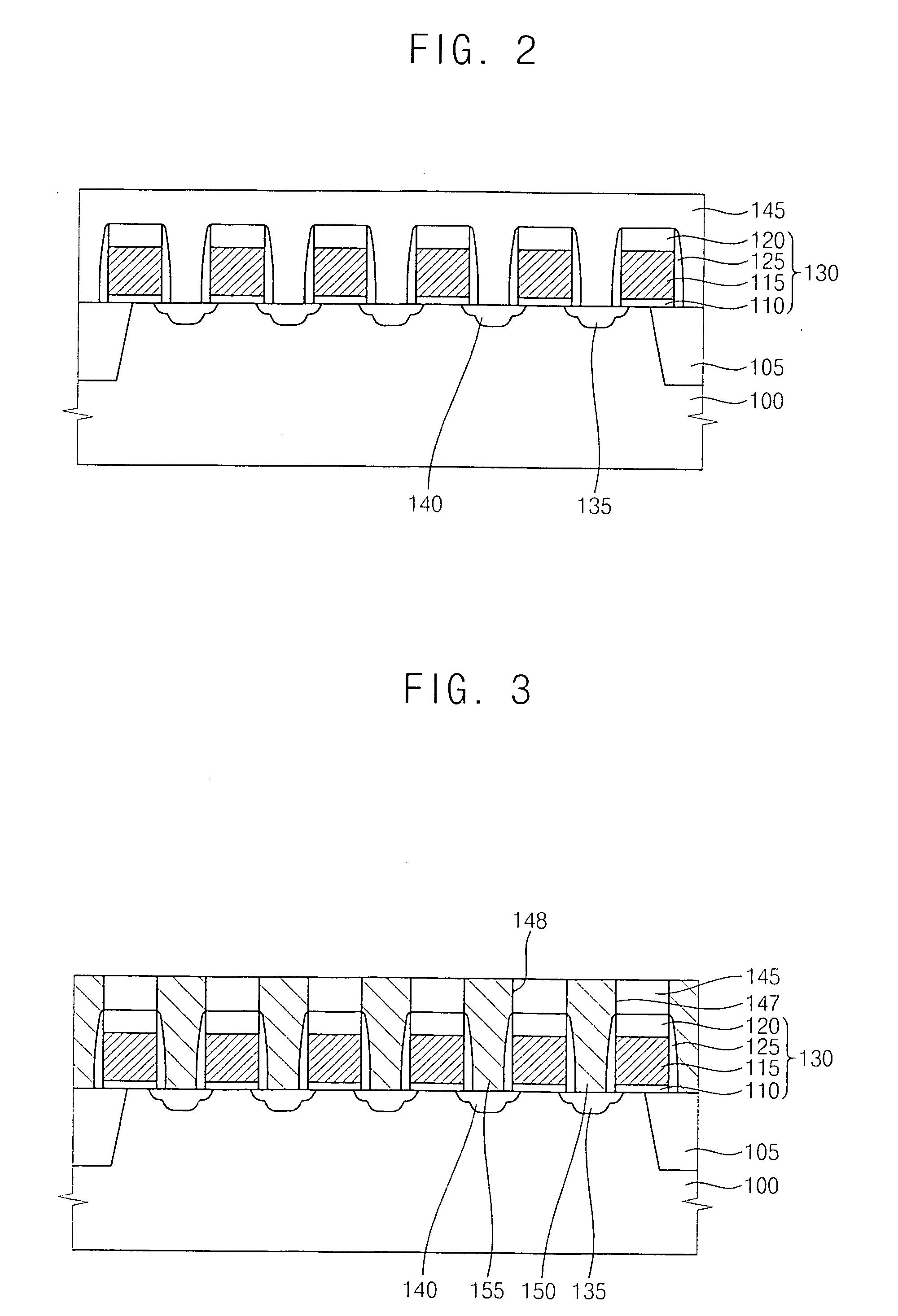

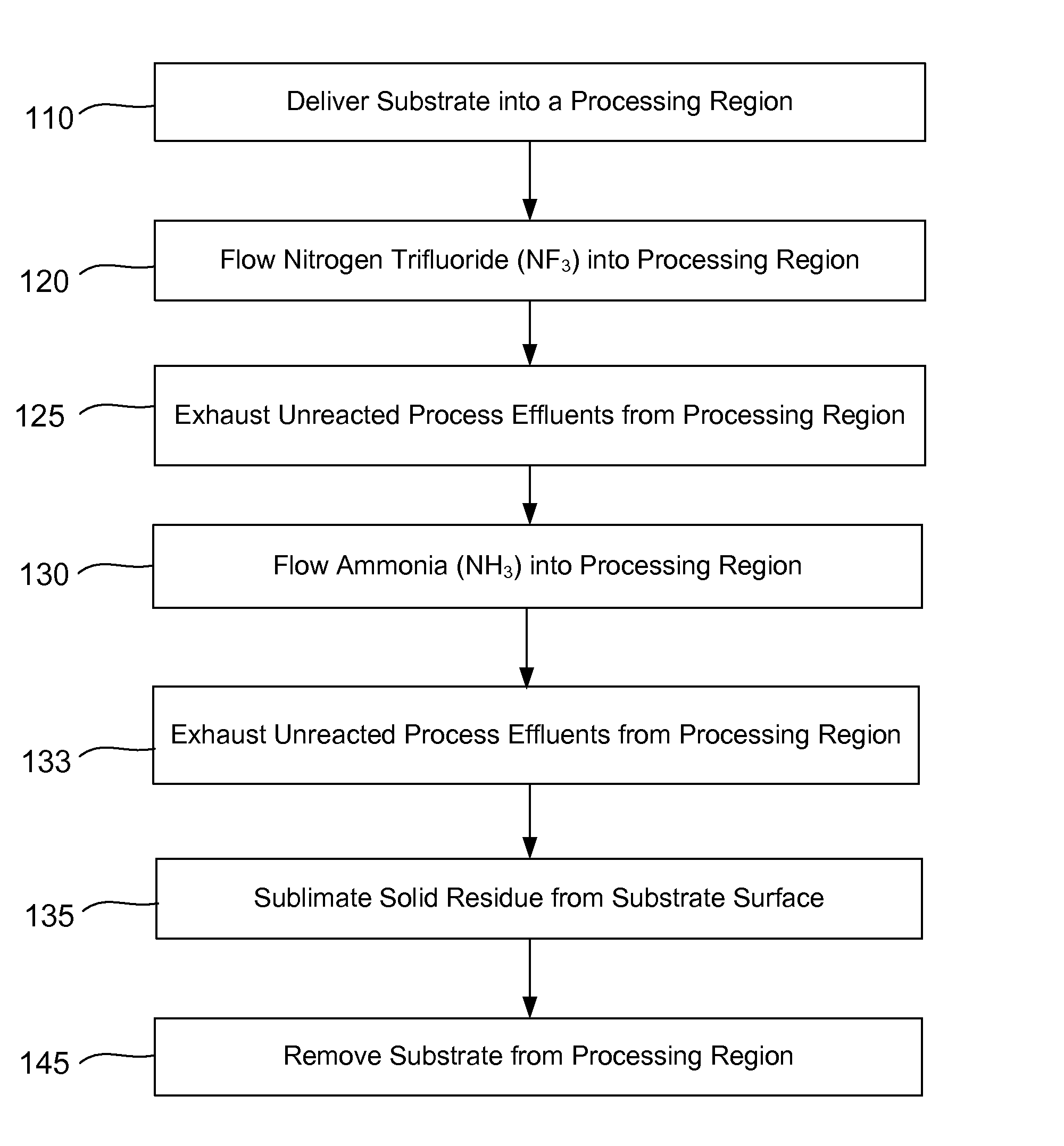

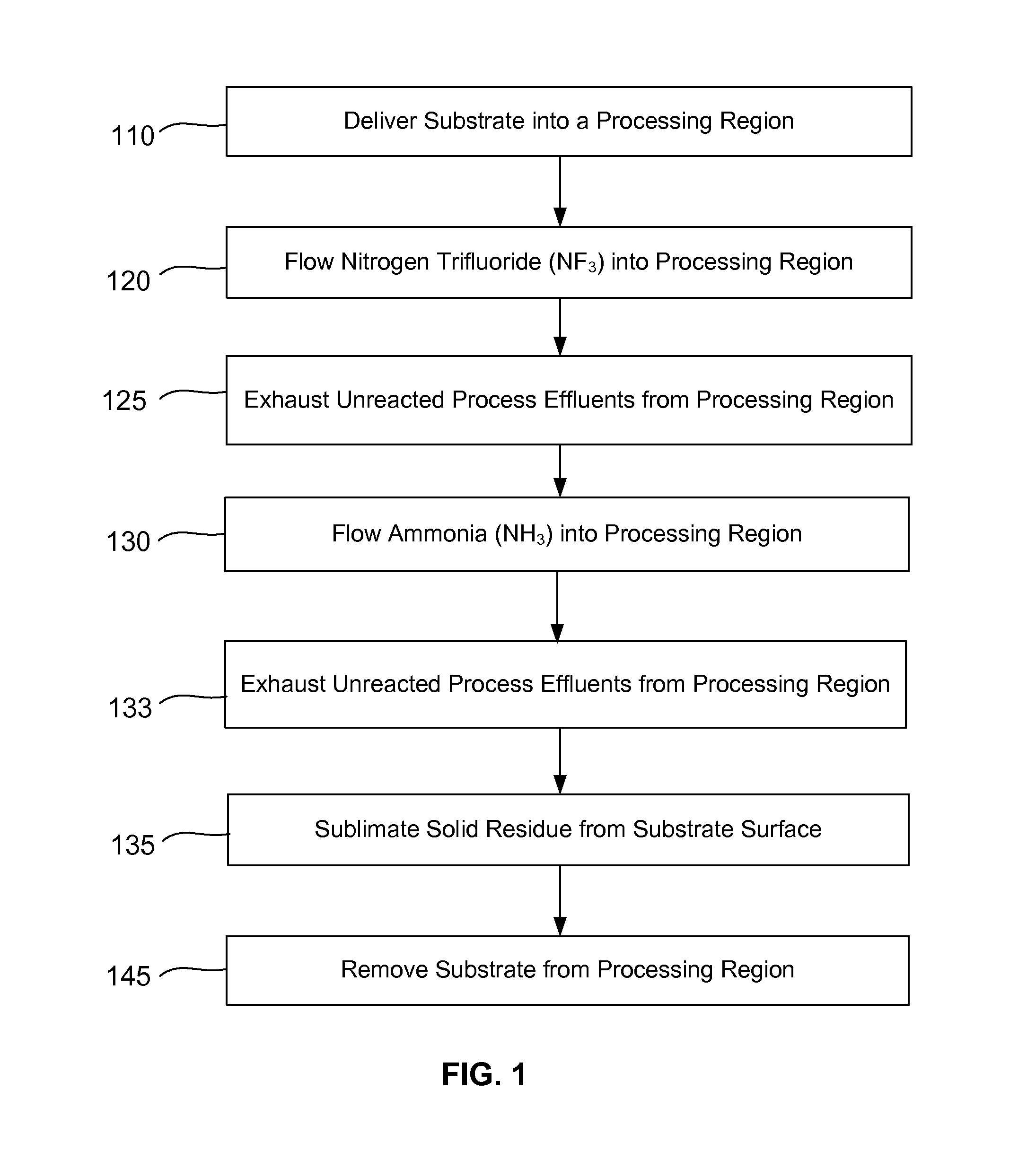

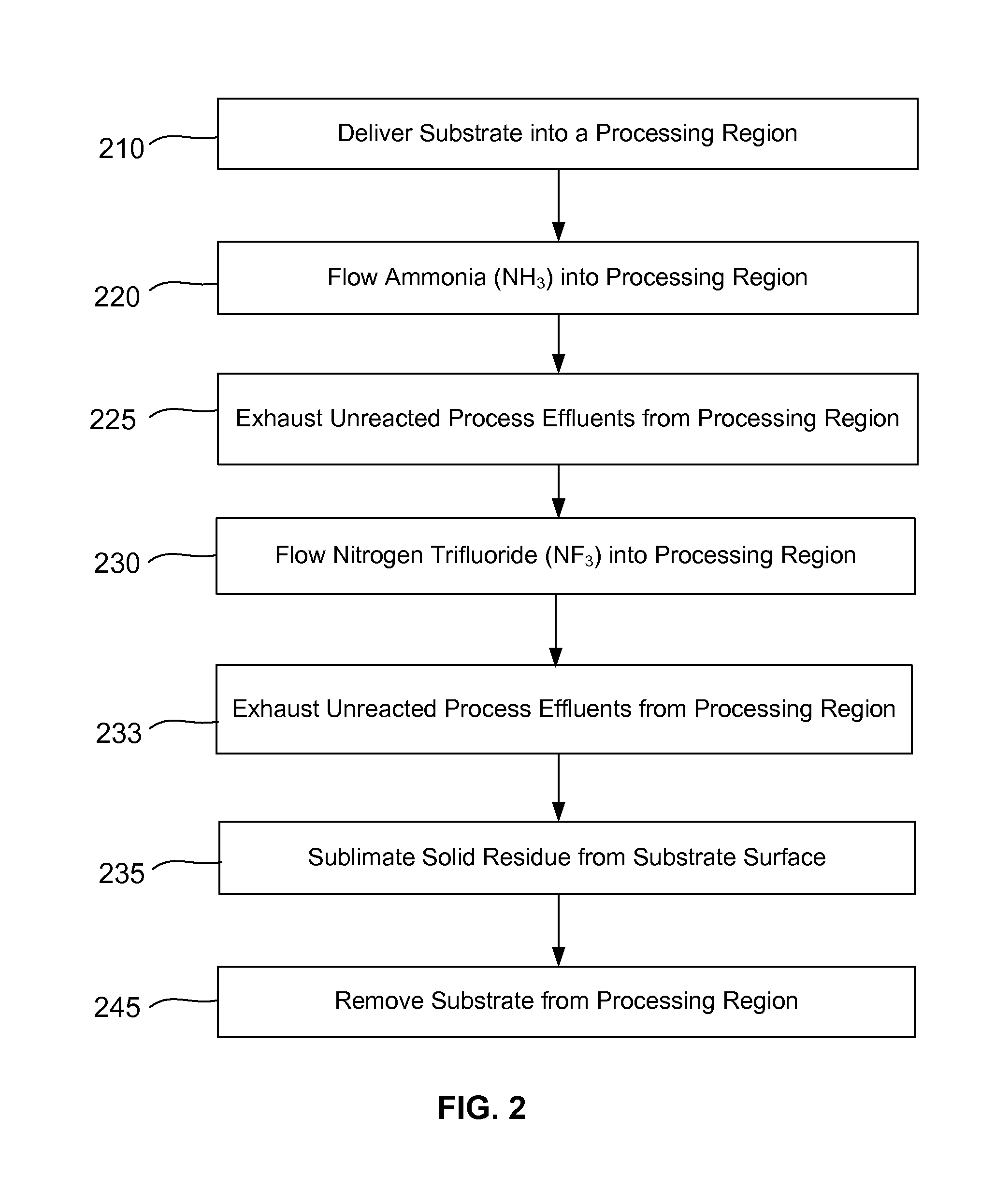

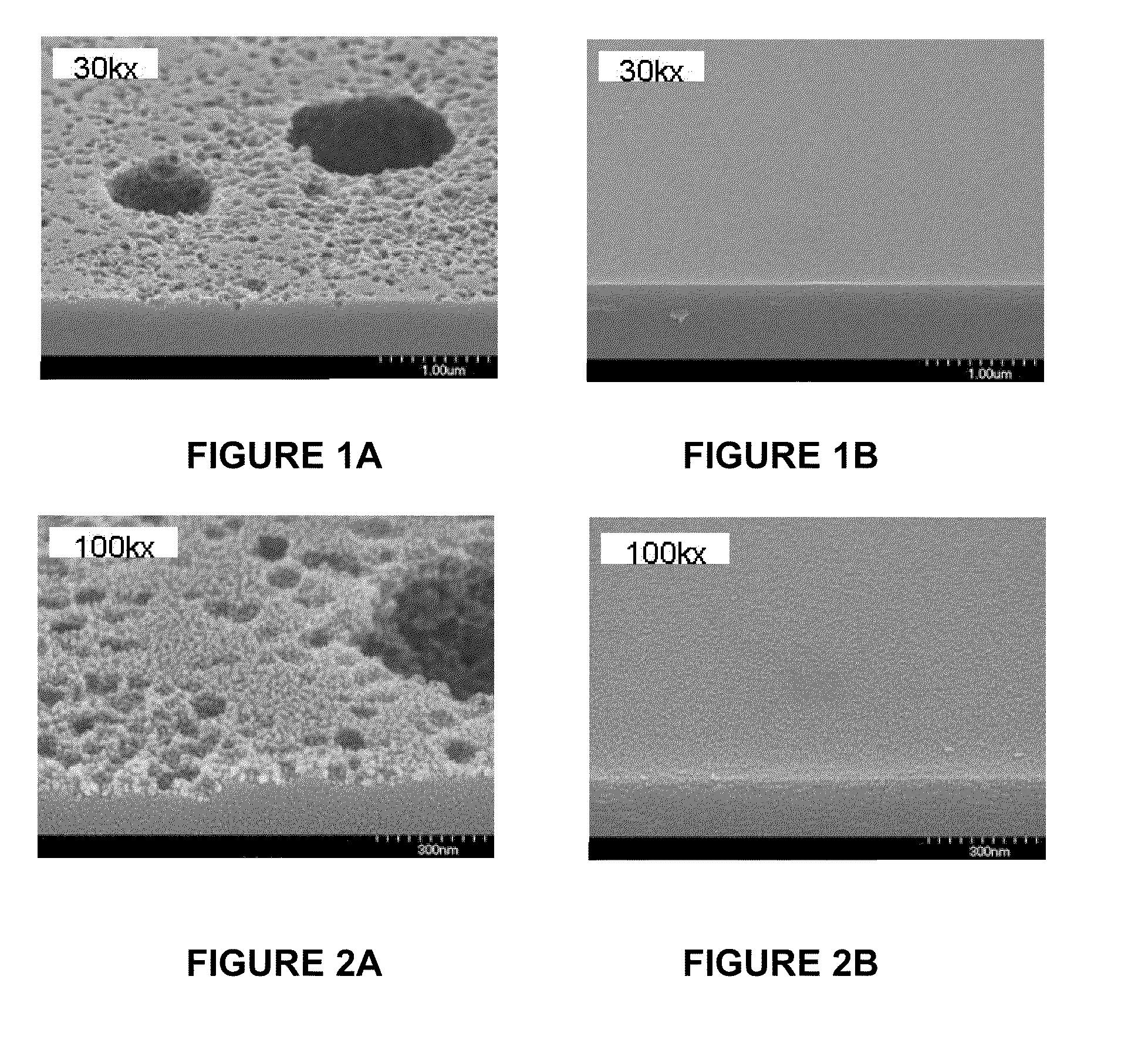

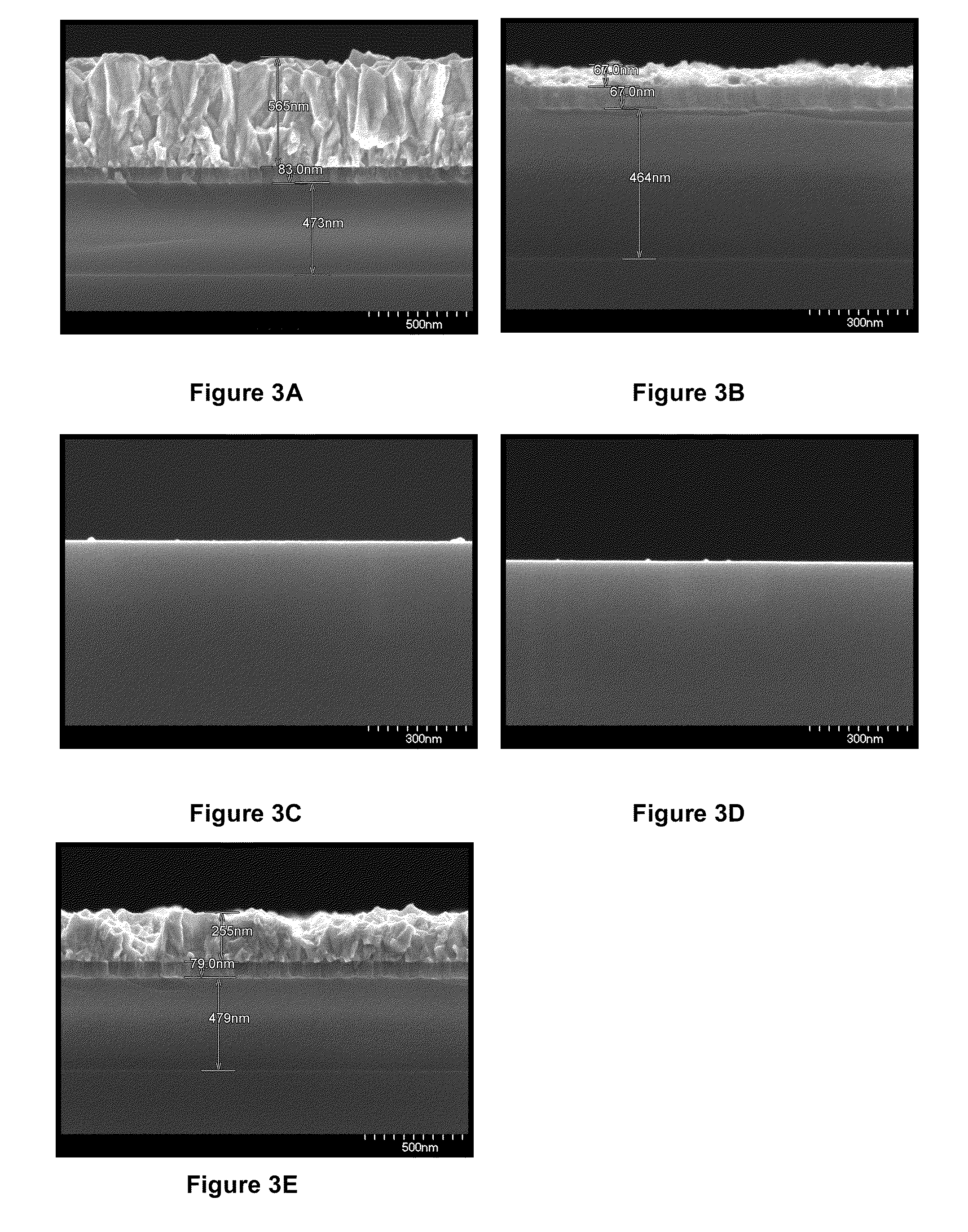

Conformal oxide dry etch

InactiveUS8801952B1Reduce the temperatureElectric discharge tubesDecorative surface effectsHydrogenSilicon oxide

A method of etching silicon oxide from a trench is described which allows more homogeneous etch rates up and down the sides of the trench. One disclosed method includes a sequential introduction of (1) a hydrogen-containing precursor and then (2) a fluorine-containing precursor into a substrate processing region. The temperature of the substrate is low during each of the two steps in order to allow the reaction to proceed and form solid residue by-product. A second disclosed method reverses the order of steps (1) and (2) but still forms solid residue by-product. The solid residue by-product is removed by raising the temperature in a subsequent sublimation step regardless of the order of the two steps.

Owner:APPLIED MATERIALS INC

Methods for stripping material for wafer reclamation

InactiveUS20100112728A1Improve concentrationSemiconductor/solid-state device manufacturingSurface treatment compositionsHydrofluoric acid

Removal compositions and processes for removing at least one material layer from a rejected microelectronic device structure having same thereon. The removal composition includes hydrofluoric acid. The composition achieves substantial removal of the material(s) to be removed while not damaging the layers to be retained, for reclaiming, reworking, recycling and / or reuse of said structure.

Owner:ADVANCED TECH MATERIALS INC

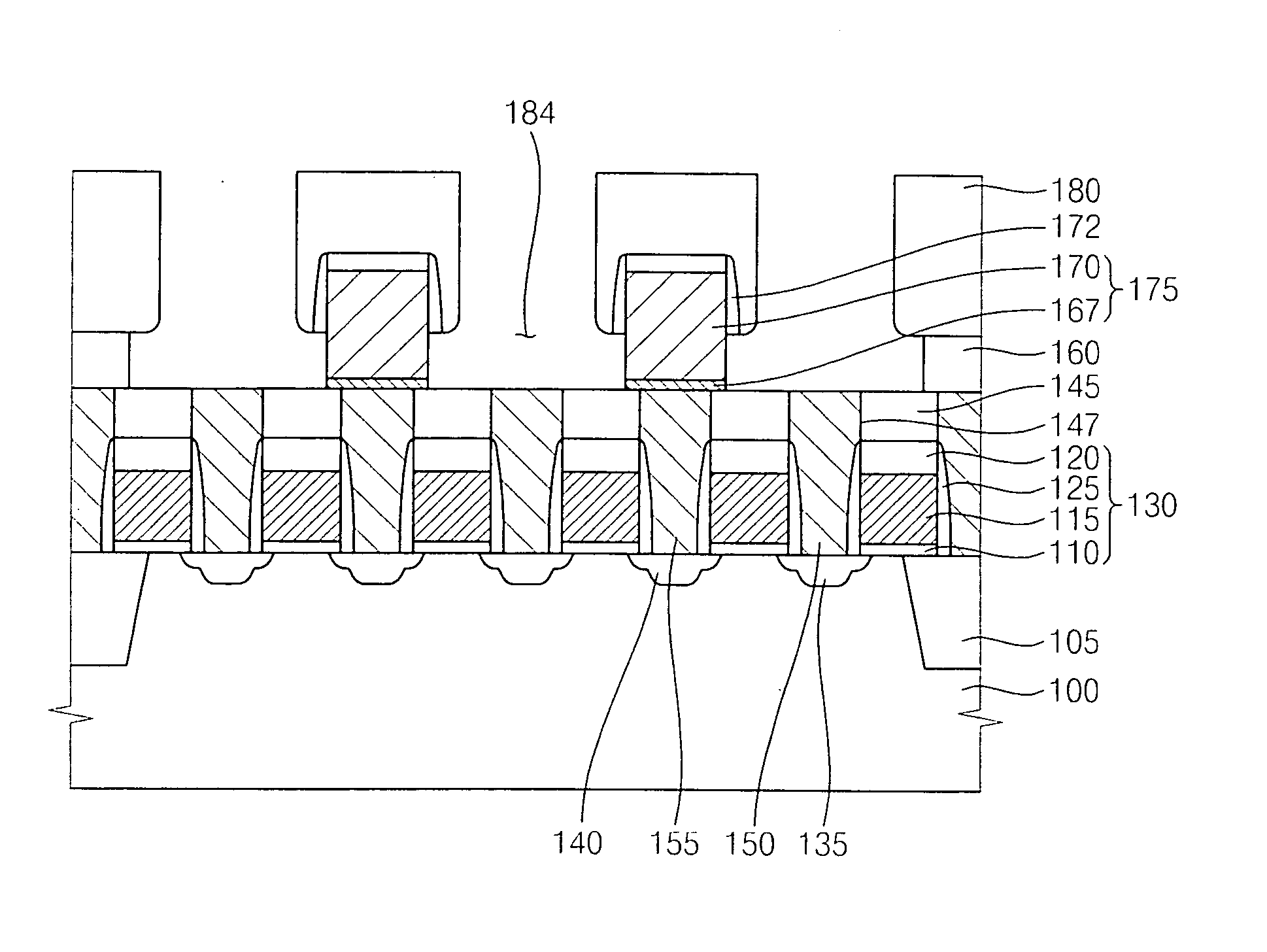

Method of topology-selective film formation of silicon oxide

ActiveUS20200251328A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingDielectric membraneSilicon oxide

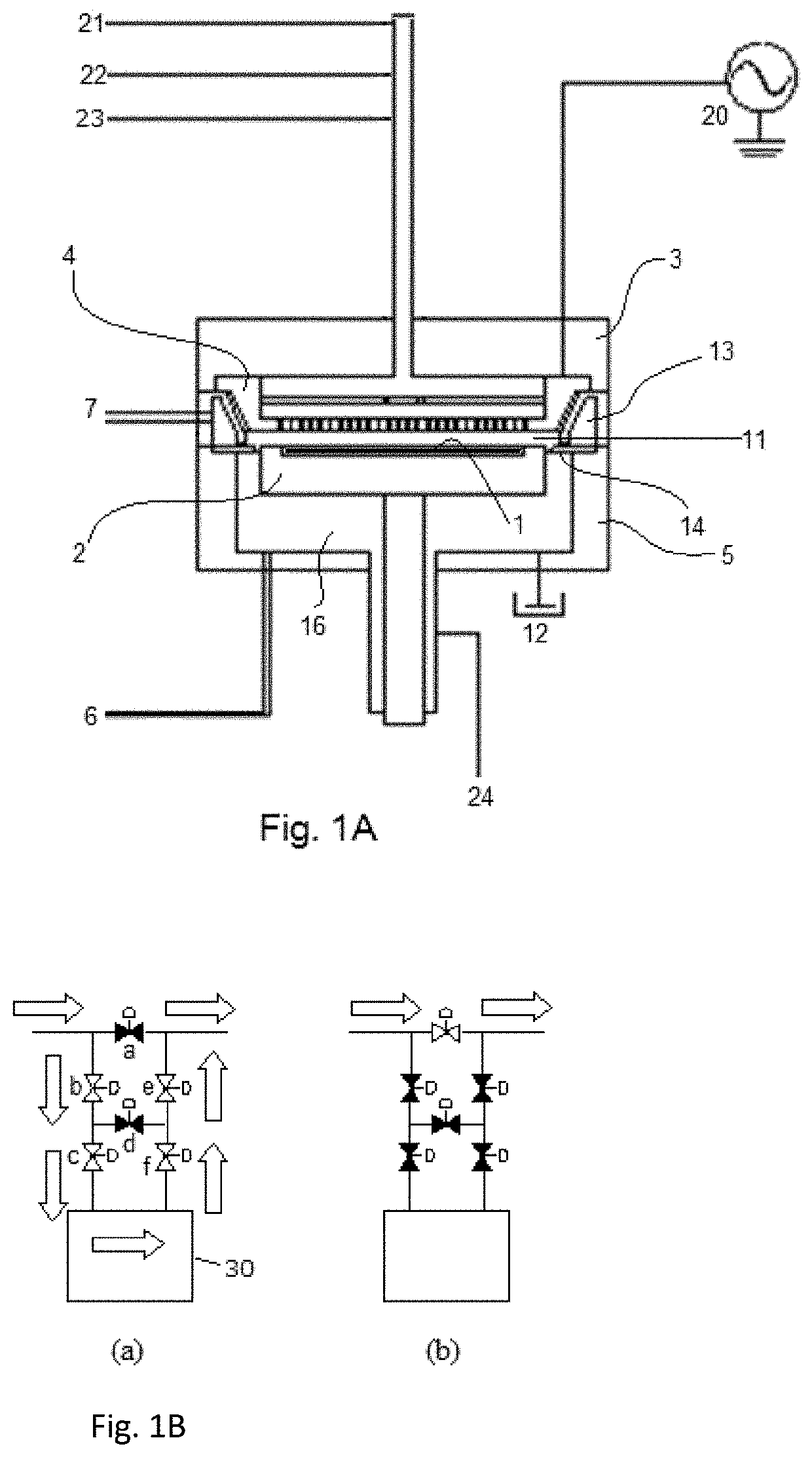

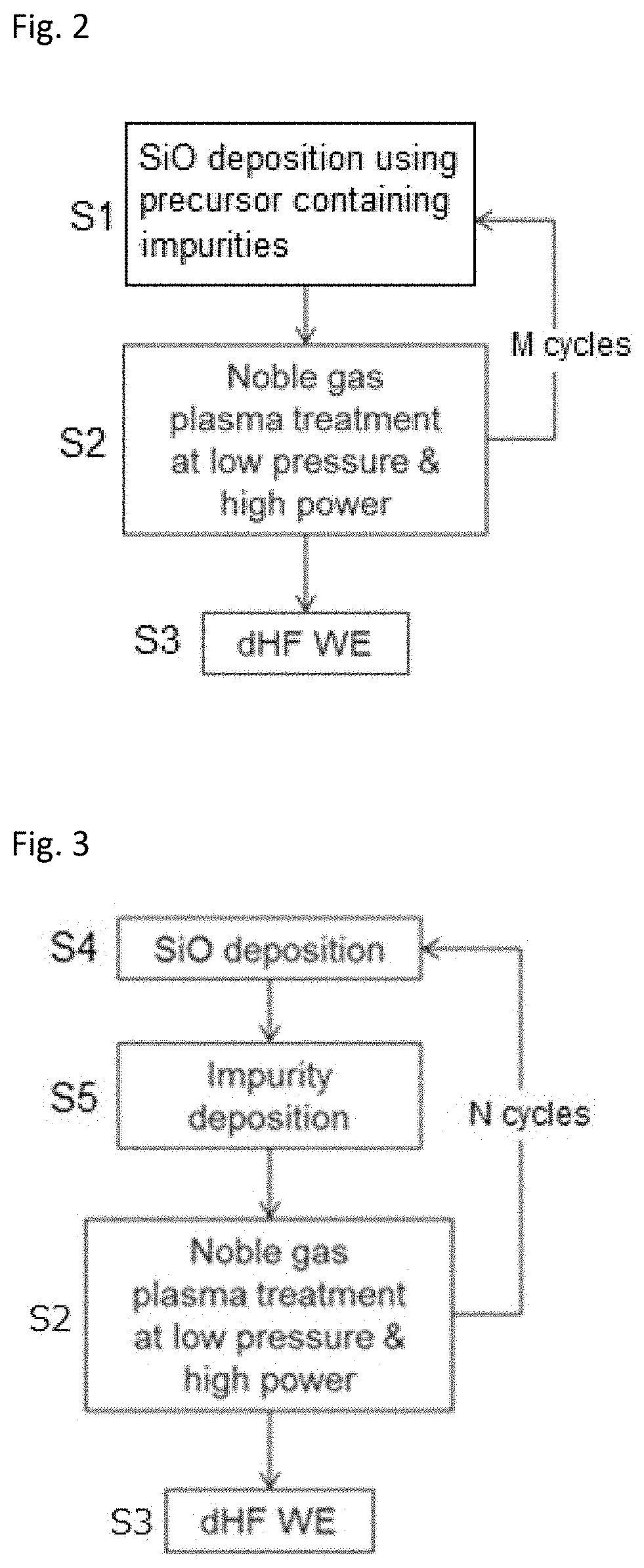

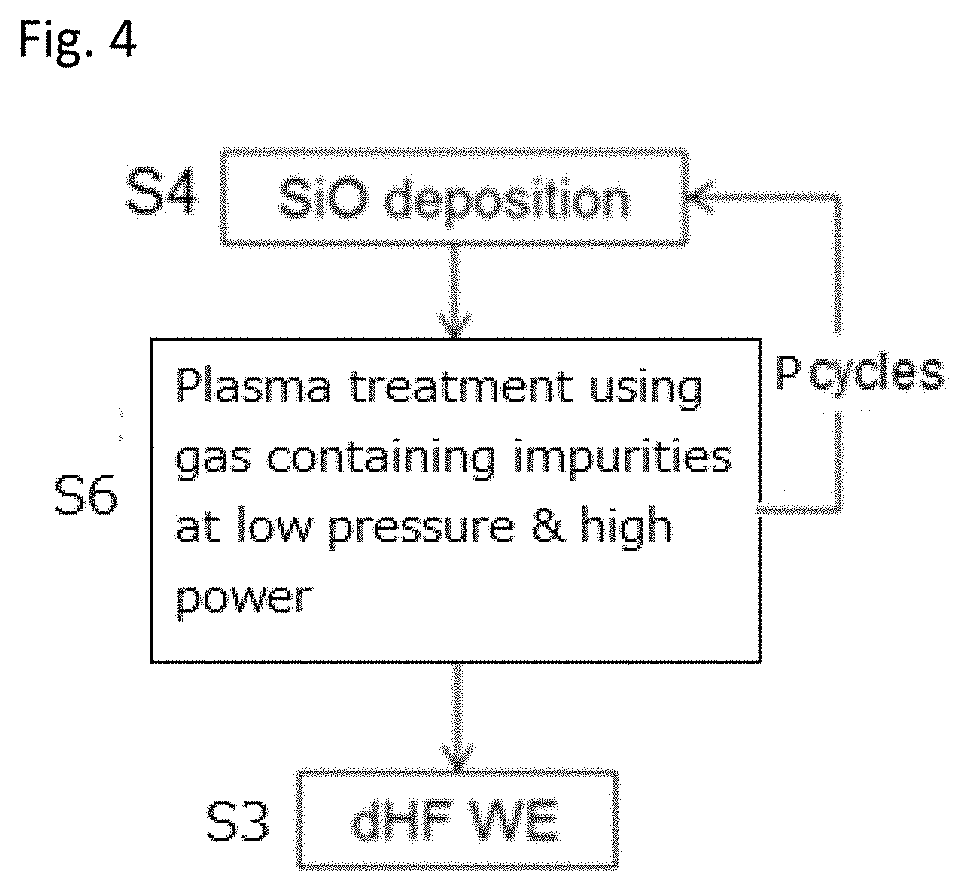

A method for forming a dielectric film containing a Si—O bond a trench formed in an upper surface of a substrate, includes: designing a topology of a final dielectric film containing a Si—O bond formed in the trench by preselecting a target portion to be selectively removed relative to a non-target portion of an initial dielectric film resulting in the final dielectric film; conformally depositing the initial dielectric film on the upper surface and in the trench; and relatively increasing an amount of impurities contained in the target portion of the initial dielectric film relative to an amount of impurities contained in the non-target portion of the initial dielectric film to obtain a treated dielectric film, thereby giving the target portion and the non-target portion different chemical resistance properties when subjected to etching.

Owner:ASM IP HLDG BV

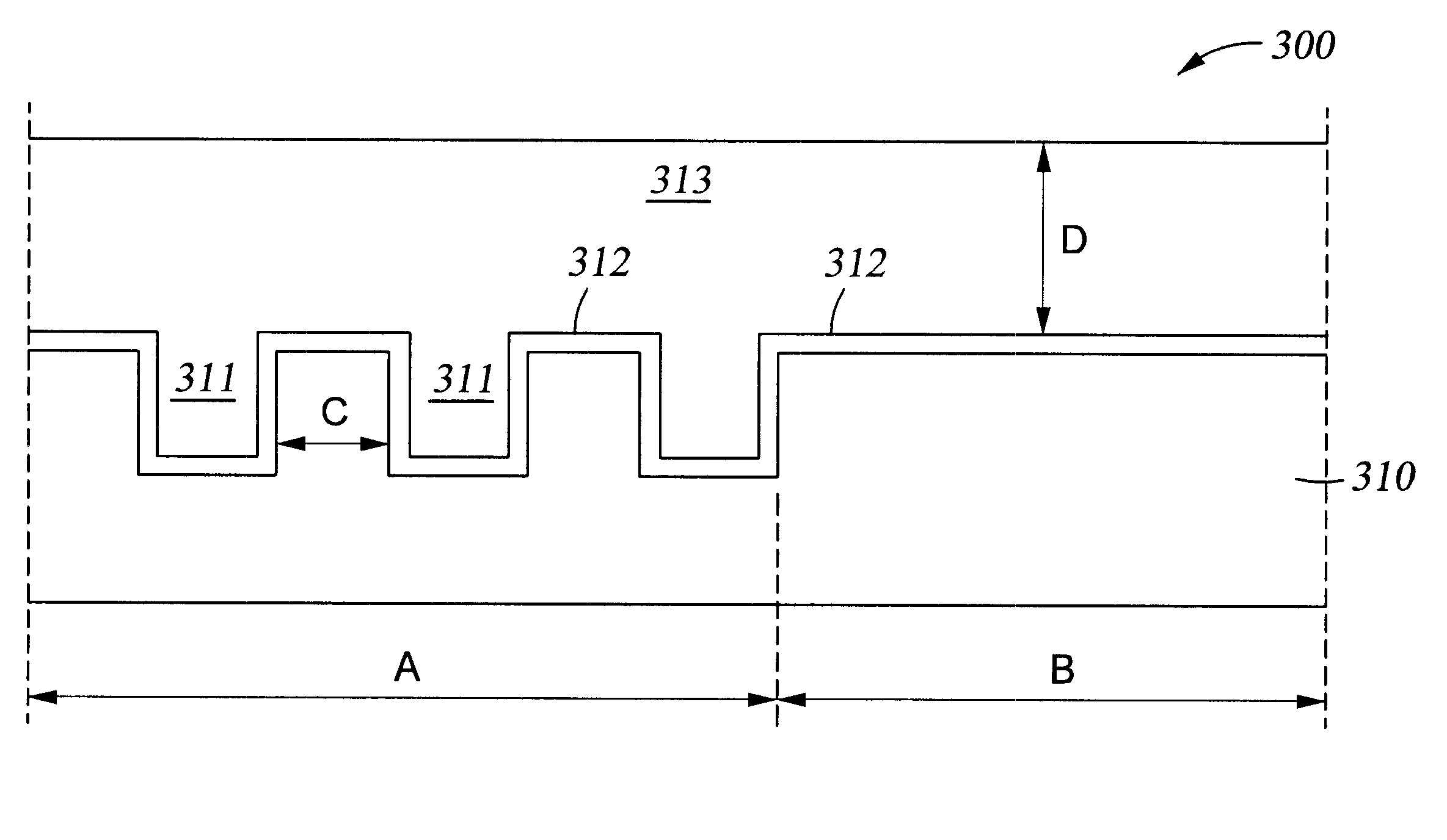

Implants with textured surface and methods for producing the same

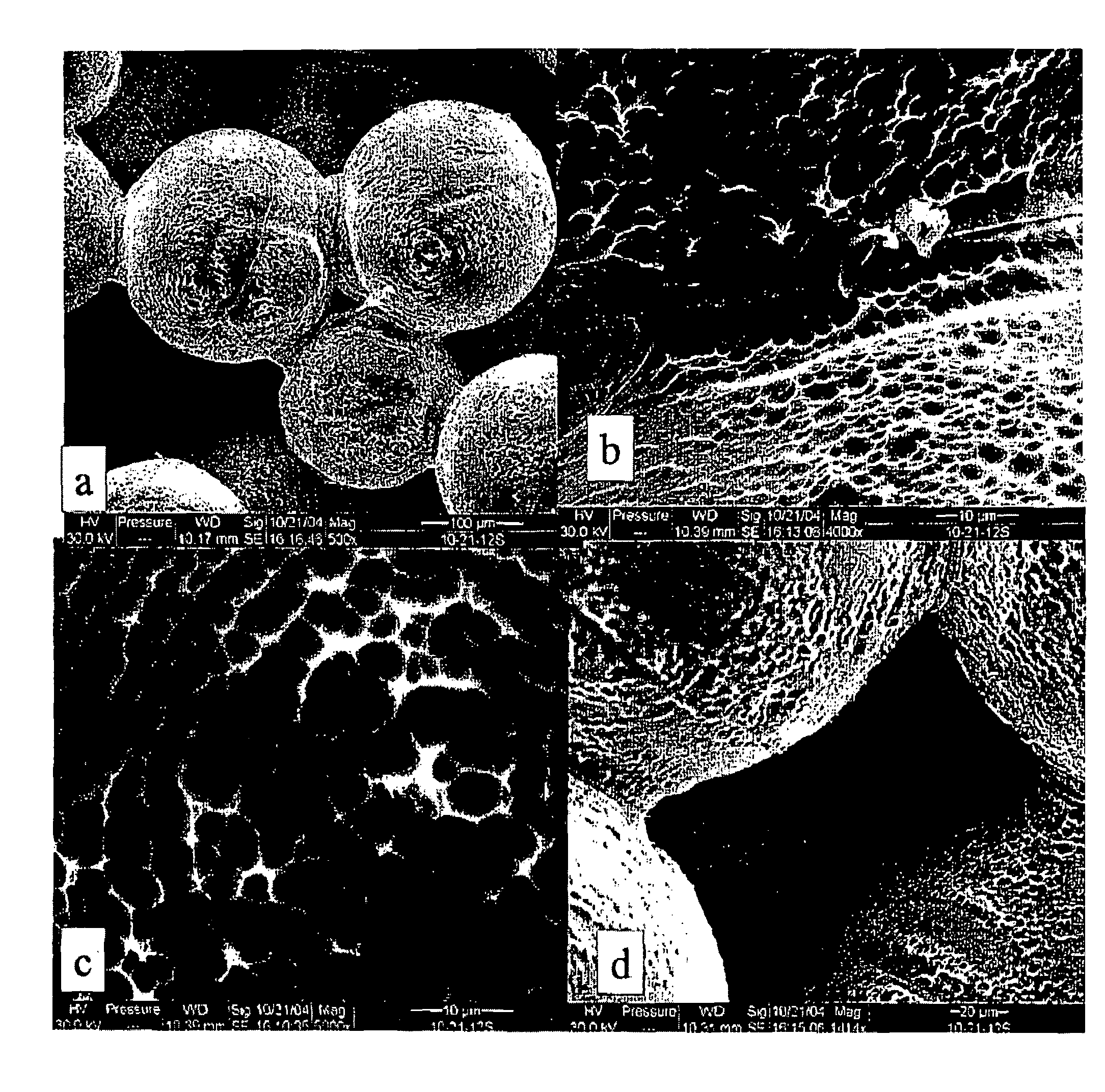

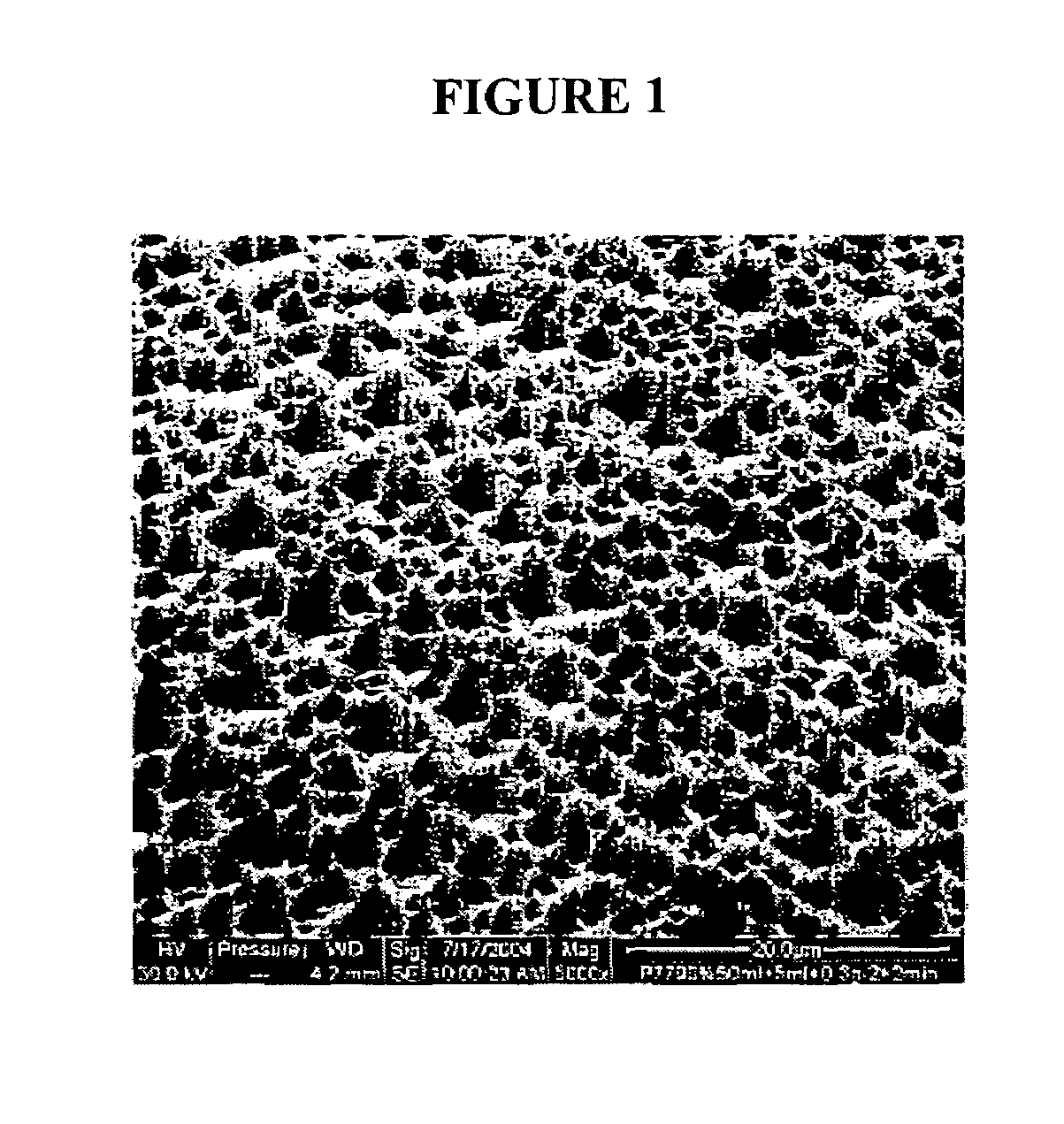

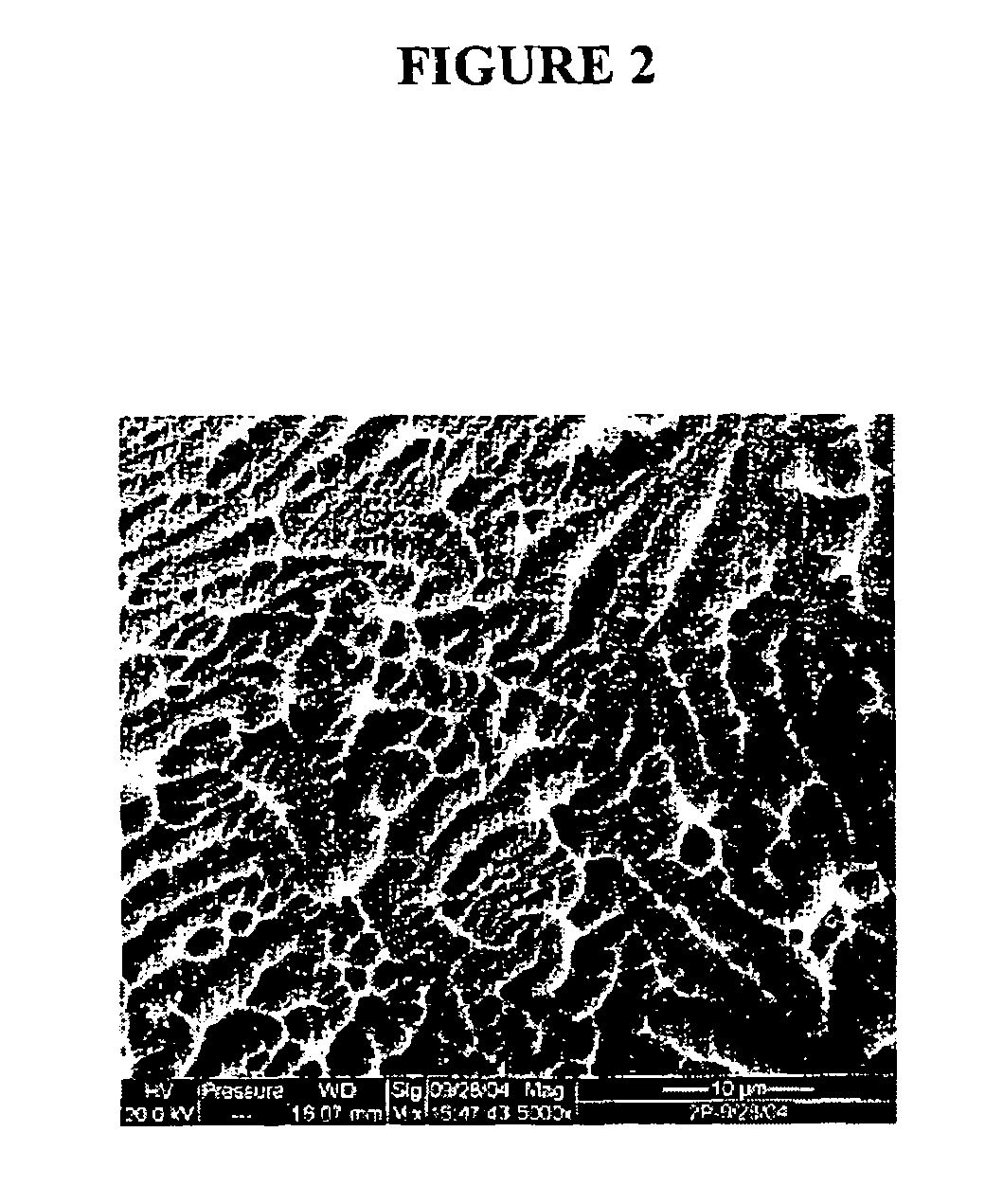

ActiveUS7368065B2High retention rateConvenient coatingImpression capsDecorative surface effectsMicrometerChloride

Compositions and methods are provided for preparing a metal substrate having a uniform textured surface with a plurality of indentations with a diameter in the nanometer and micrometer range. The textured surface is produced by exposing the substrate to an etching fluid comprising a hydrohalic acid and a mixture of a hydrohalic acid and an oxyacid, a chloride containing compound, and an oxidant. The etching solution can be used at ambient temperature. This textured surface enhances adherence of coatings or cells onto the textured surface, improves the retention of proteins on the surface, and encourages bone in-growth.

Owner:DEPUY PROD INC

Stabilized alkaline compositions for cleaning microelectronic substrates

InactiveUS6599370B2Eliminate contaminationLong lastingInorganic/elemental detergent compounding agentsLighting and heating apparatusWater solubleSURFACTANT BLEND

The invention provides aqueous alkaline compositions useful in the microelectronics industry for stripping or cleaning semiconductor wafer substrates by removing photoresist residues and other unwanted contaminants. The compositions typically contain (a) one or more metal ion-free bases at sufficient amounts to produce a pH of about 10-13 and one or more bath stabilizing agents having at least one pKa in the range of 10-13 to maintain this pH during use; (b) optionally, about 0.01% to about 5% by weight (expressed as % SiO2) of a water-soluble metal ion-free silicate; (c) optionally, about 0.01% to about 10% by weight of one or more chelating agents; (d) optionally, about 0.01% to about 80% by weight of one or more water-soluble organic co-solvents; and (e) optionally, about 0.01% to about 1% by weight of a water-soluble surfactant.

Owner:AVANTOR PERFORMANCE MATERIALS LLC

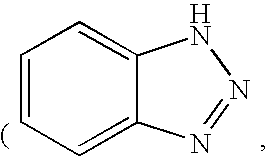

Alkaline, post plasma etch/ash residue removers and photoresist stripping compositions containing metal-halide corrosion inhibitors

InactiveUS20070060490A1Avoiding consequenceAvoid expensesDetergent mixture composition preparationElectrostatic cleaningAlkaline earth metalMetal halides

The invention provides alkaline compositions useful in the microelectronics industry for stripping or cleaning semiconductor wafer substrates by removing photoresist residues and other unwanted contaminants. The compositions contain (a) one or more bases and (b) one or more metal corrosion inhibiting metal halides of the formula: WzMXy where M is a metal selected from the group Si, Ge, Sn, Pt, P, B, Au, Ir, Os, Cr, Ti, Zr, Rh, Ru, and Sb; X is a halide selected from F, Cl, Br and I; W is selected from H, to an alkali or alkaline earth metal, and a metal ion-free hydroxide base moiety; y is a numeral of from 4 to 6 depending on the metal halide; and z is a numeral of 1, 2 or 3.

Owner:AVANTOR PERFORMANCE MATERIALS INC

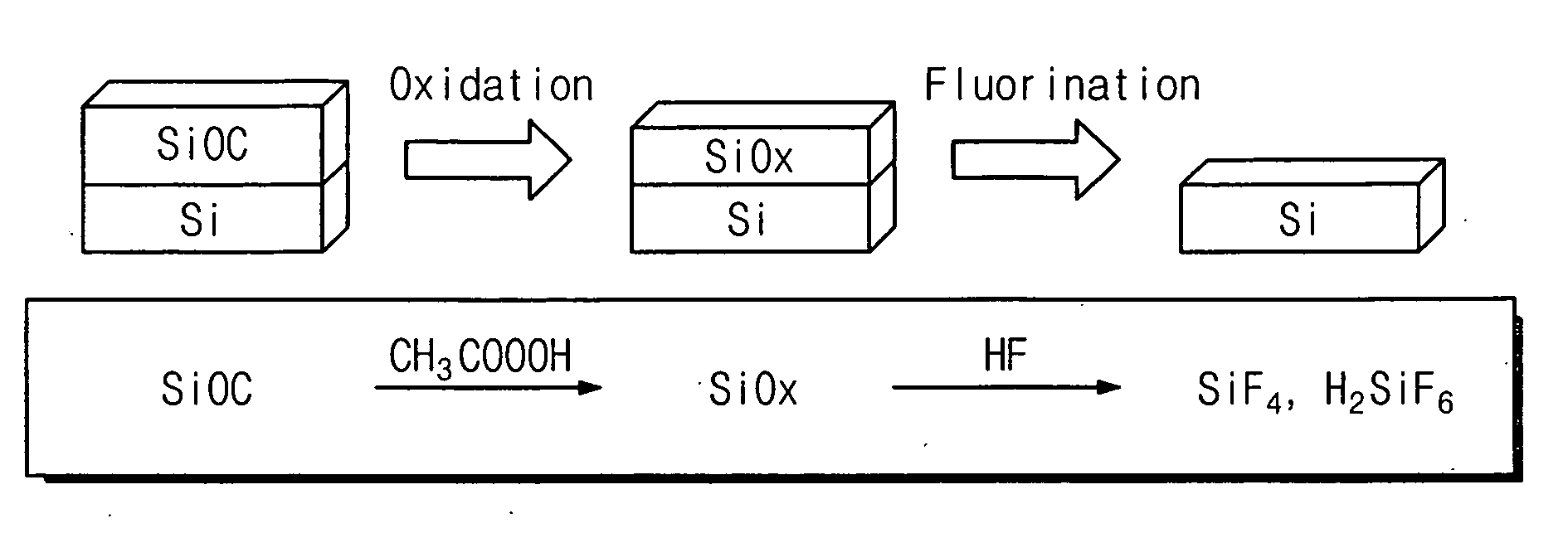

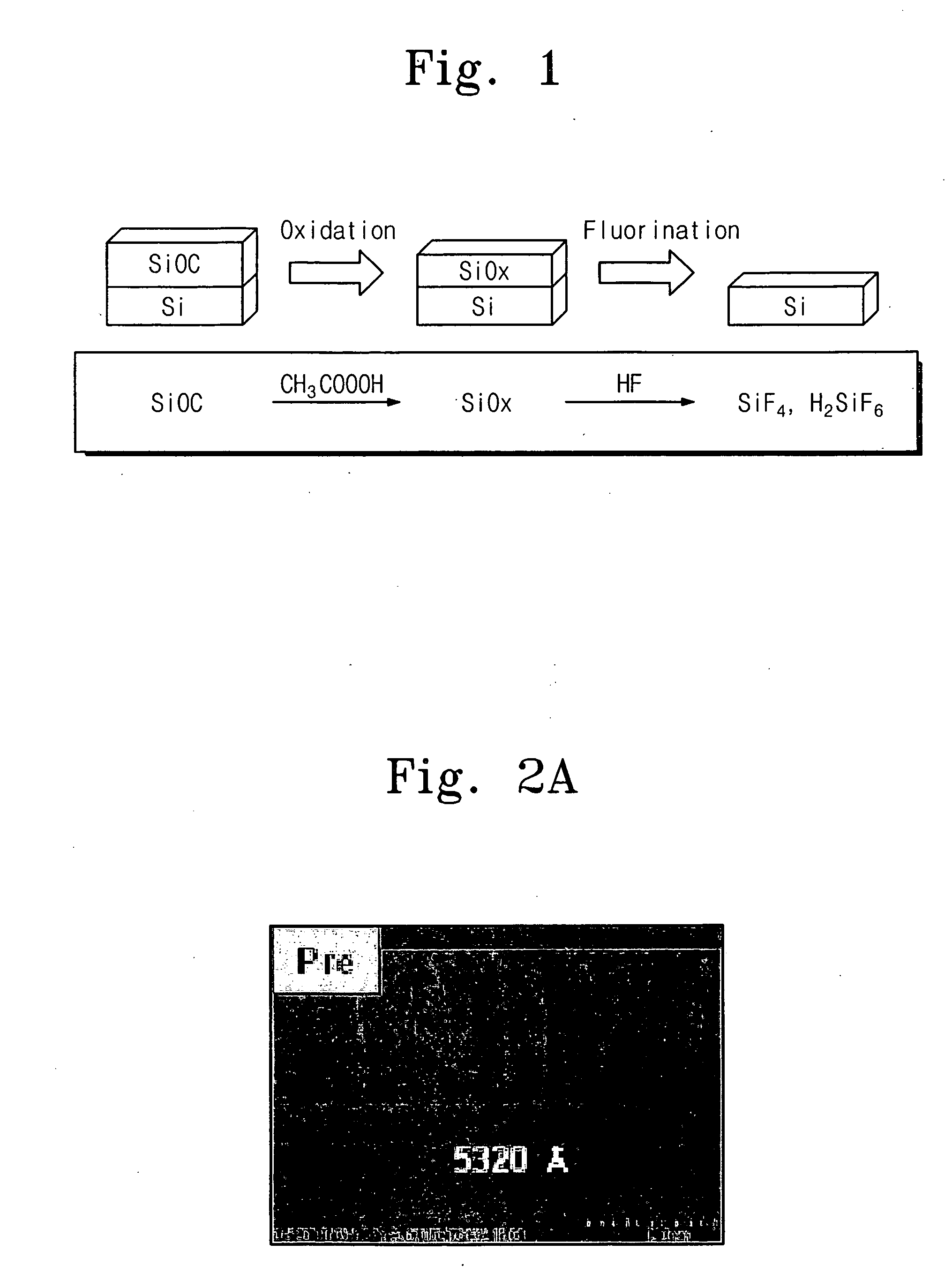

Etching solution and method for removing low-k dielectric layer

InactiveUS20060097220A1Easy to prepareReagents is relatively inexpensiveDecorative surface effectsDetergent mixture composition preparationSingle stageOxidizing agent

Etching solutions are disclosed for etching low-k dielectric layers on substrates, said solutions including effective proportions of an oxidant for oxidizing a low-k dielectric layer and effective proportions of an oxide etchant for removing oxides. It is possible to easily remove a low-k dielectric layer using such etching solutions by a single-stage treatment process.

Owner:SAMSUNG ELECTRONICS CO LTD

Oxide etching method

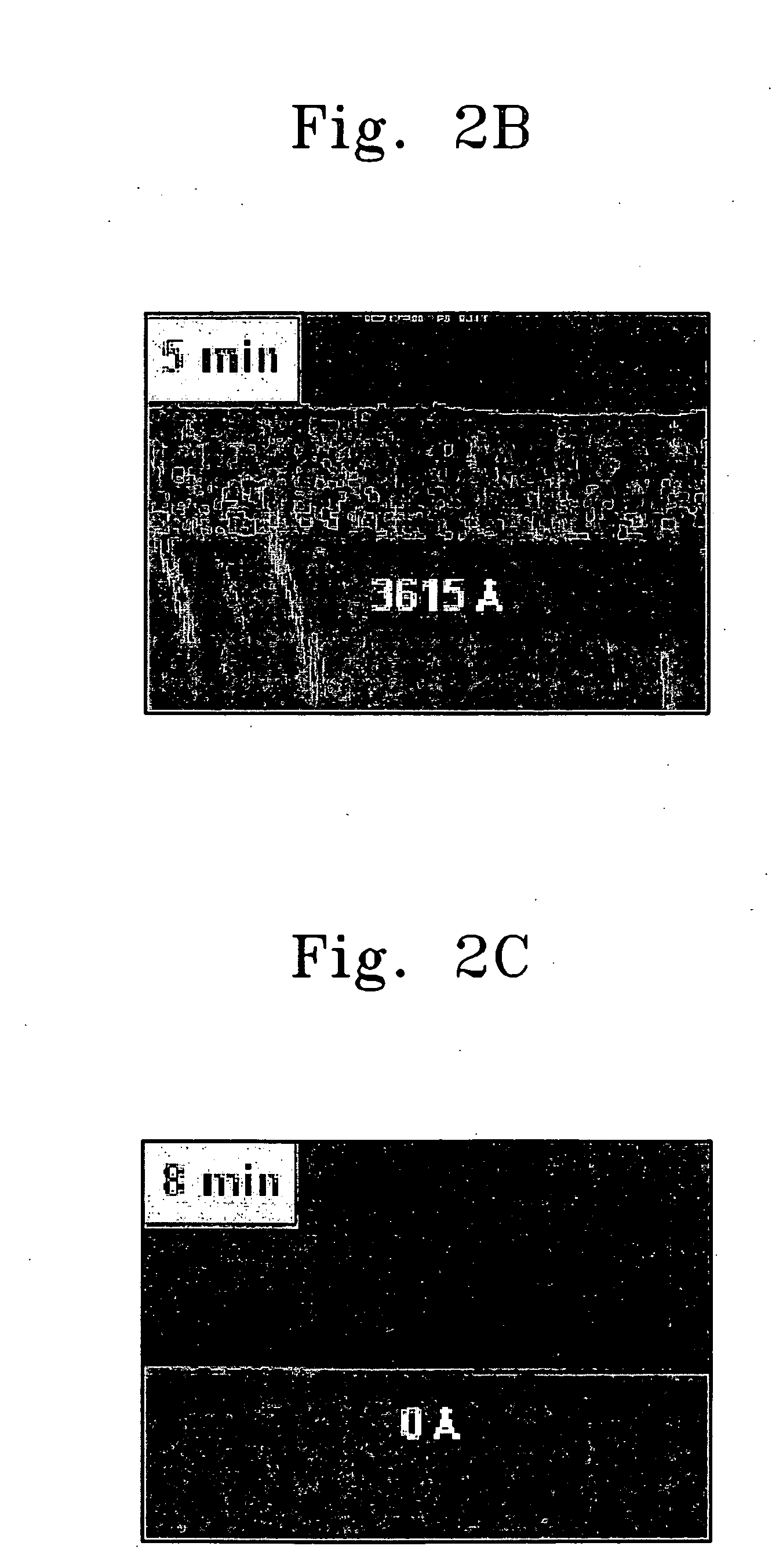

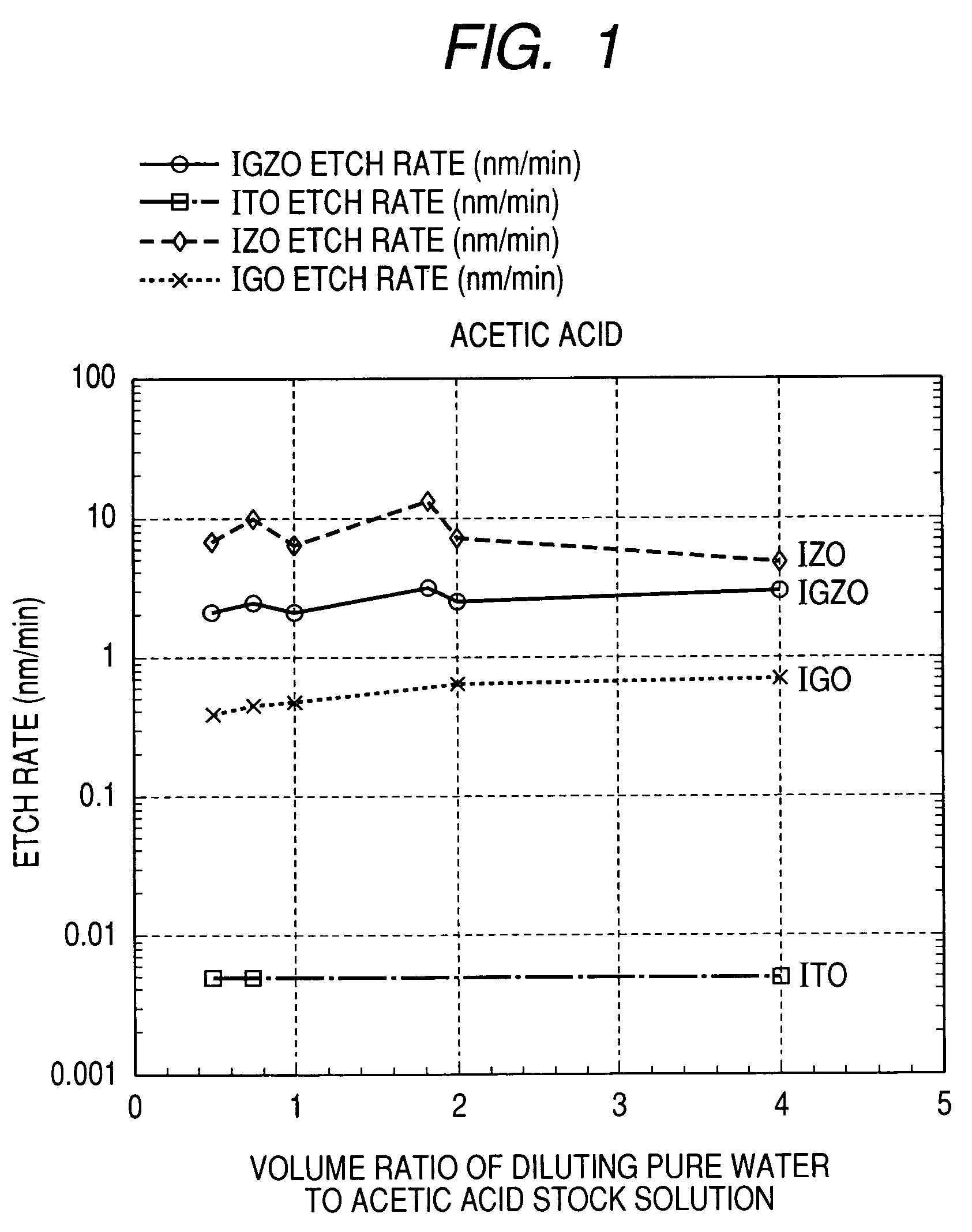

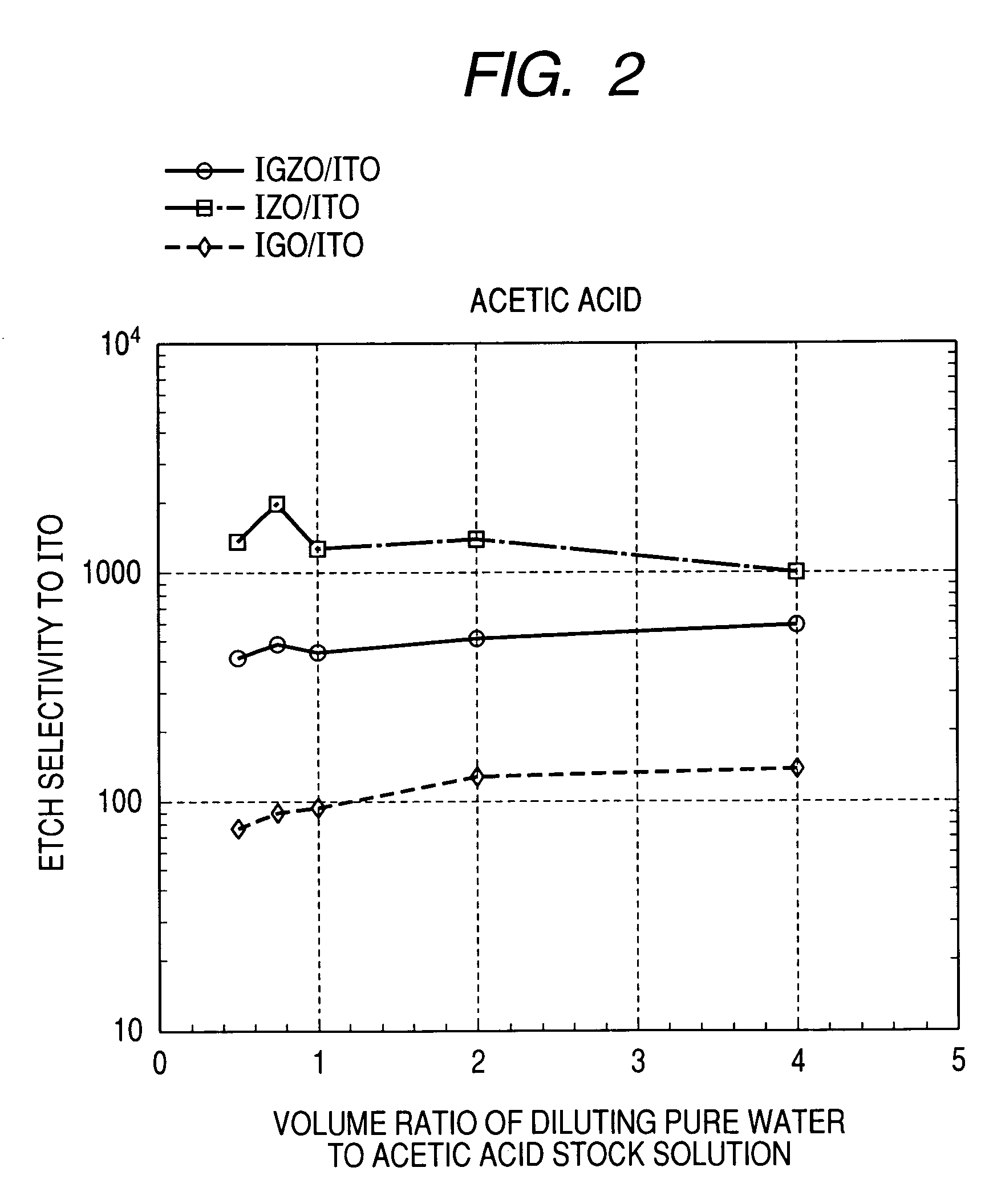

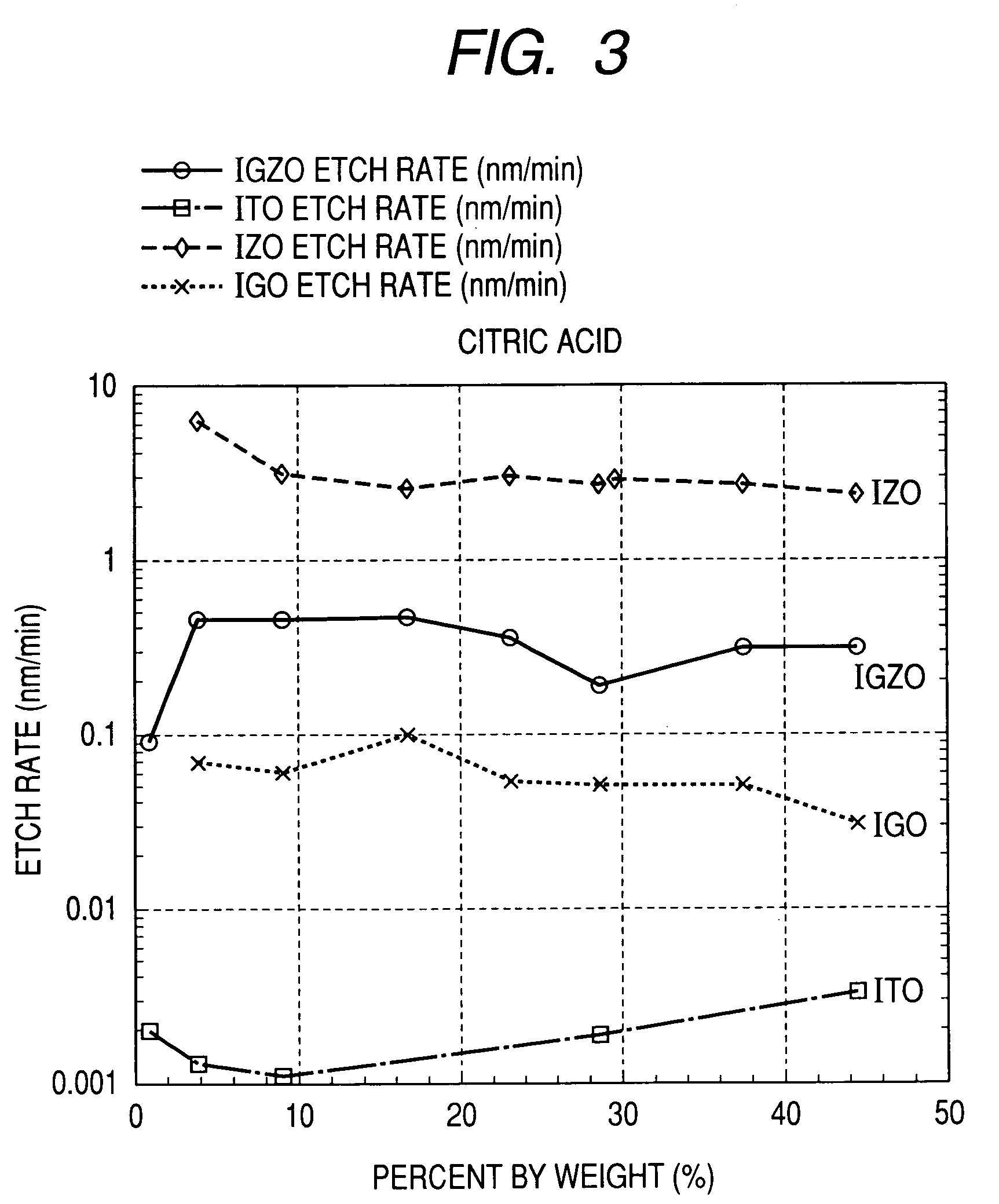

InactiveUS8168544B2Precise and easy etchingPrecise and highly selective wet etchingDecorative surface effectsFinal product manufactureAcetic acidEtching

There is provided an etching method of an amorphous oxide layer containing In and at least one of Ga and Zn, which includes etching the amorphous oxide layer using an etchant containing any one of acetic acid, citric acid, hydrochloric acid, and perchloric acid.

Owner:CANON KK

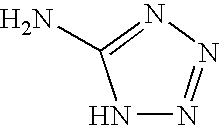

Passivative chemical mechanical polishing composition for copper film planarization

ActiveUS20040108302A1Decorative surface effectsSemiconductor/solid-state device manufacturingCompound (substance)Copper

A CMP composition containing 5-aminotetrazole, e.g., in combination with oxidizing agent, chelating agent, abrasive and solvent. Such CMP composition advantageously is devoid of BTA, and is useful for polishing surfaces of copper elements on semiconductor substrates, without the occurrence of dishing or other adverse planarization deficiencies in the polished copper, even in the presence of substantial levels of copper ions, e.g., Cu<2+>, in the bulk CMP composition at the copper / CMP composition interface during CMP processing.

Owner:ENTEGRIS INC

Method of Etching a High Aspect Ratio Contact

ActiveUS20090176375A1Decorative surface effectsSemiconductor/solid-state device manufacturingGas compositionContact method

Methods and an etch gas composition for etching a contact opening in a dielectric layer are provided. Embodiments of the method use a plasma generated from an etch gas composed of C4F8 and / or C4F6, an oxygen source, and a carrier gas in combination with tetrafluoroethane (C2F4) or a halofluorocarbon analogue of C2F4.

Owner:MICRON TECH INC

Compositions and methods for rapidly removing overfilled substrates

InactiveUS20050178742A1Decorative surface effectsNon-surface-active detergent compositionsAcetic acidOxidizing agent

This invention relates to compositions and methods for removing overfilled substrates, preferably at a relatively high removal rates. Advantageously, a composition according to the invention can contain an oxidizer, preferably a per-type oxidizer such as a peroxide, periodic acid, and peracetic acid, and may also optionally contain an abrasive.

Owner:DUPONT AIR PRODS NANOMATERIALS +1

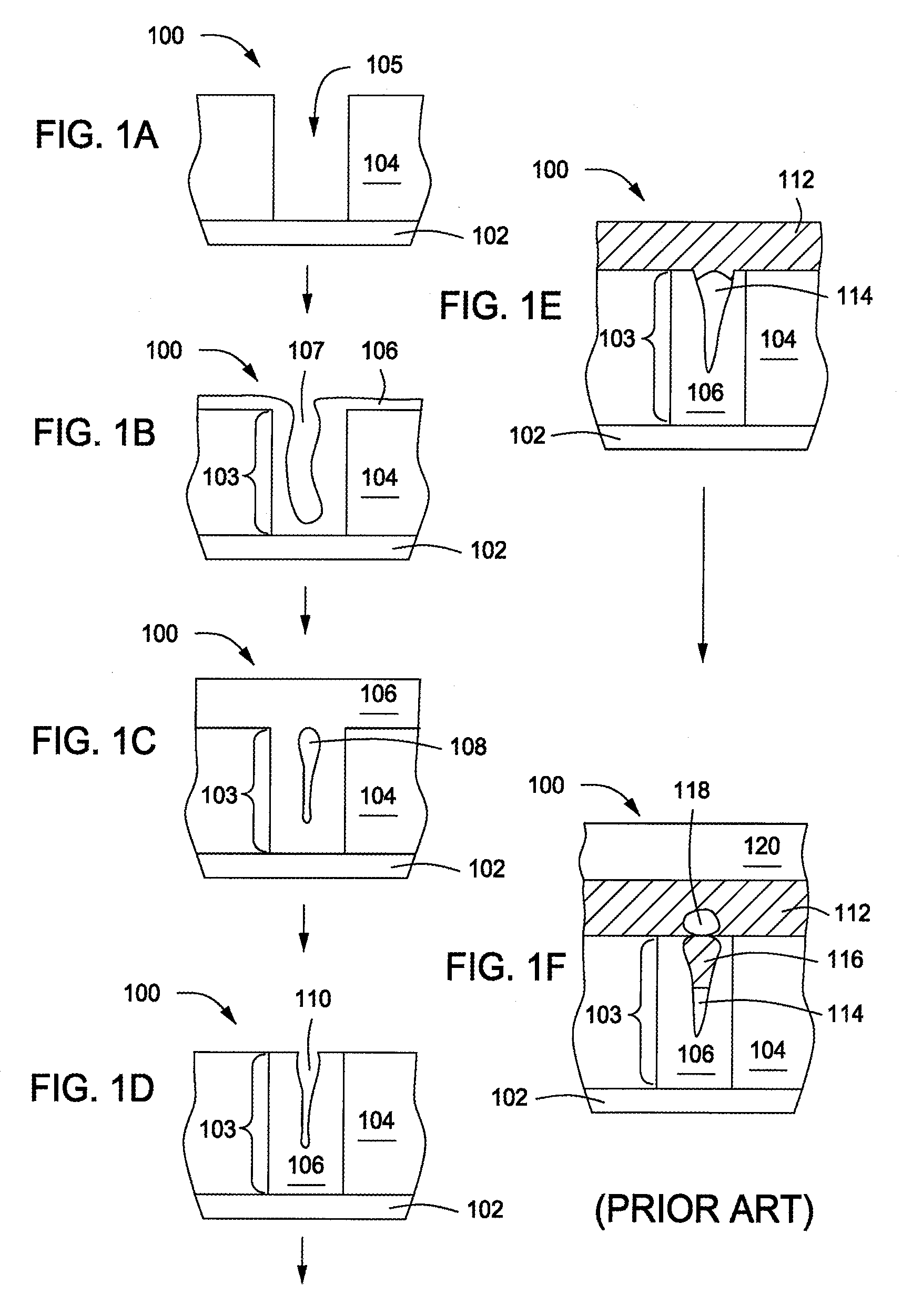

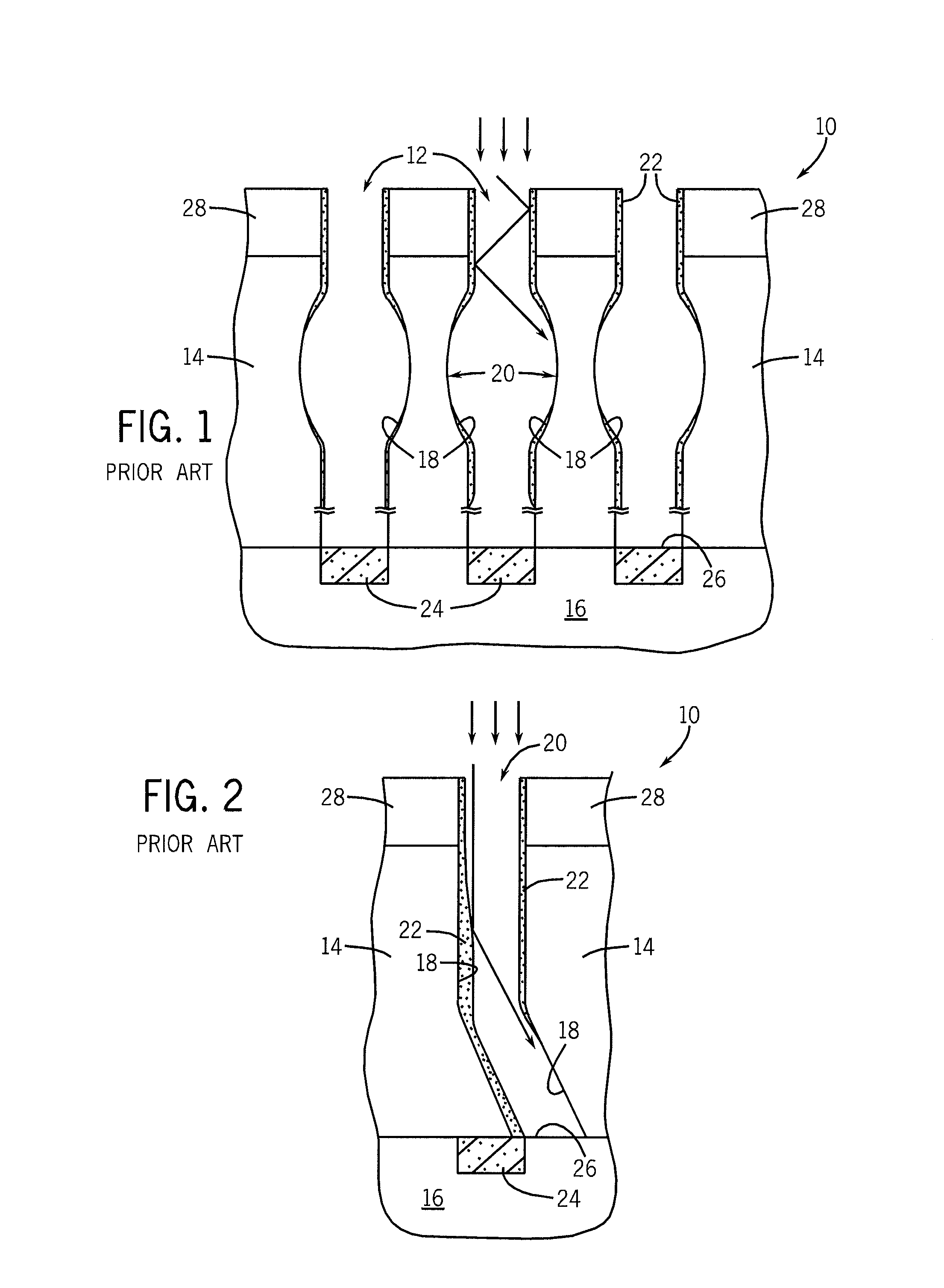

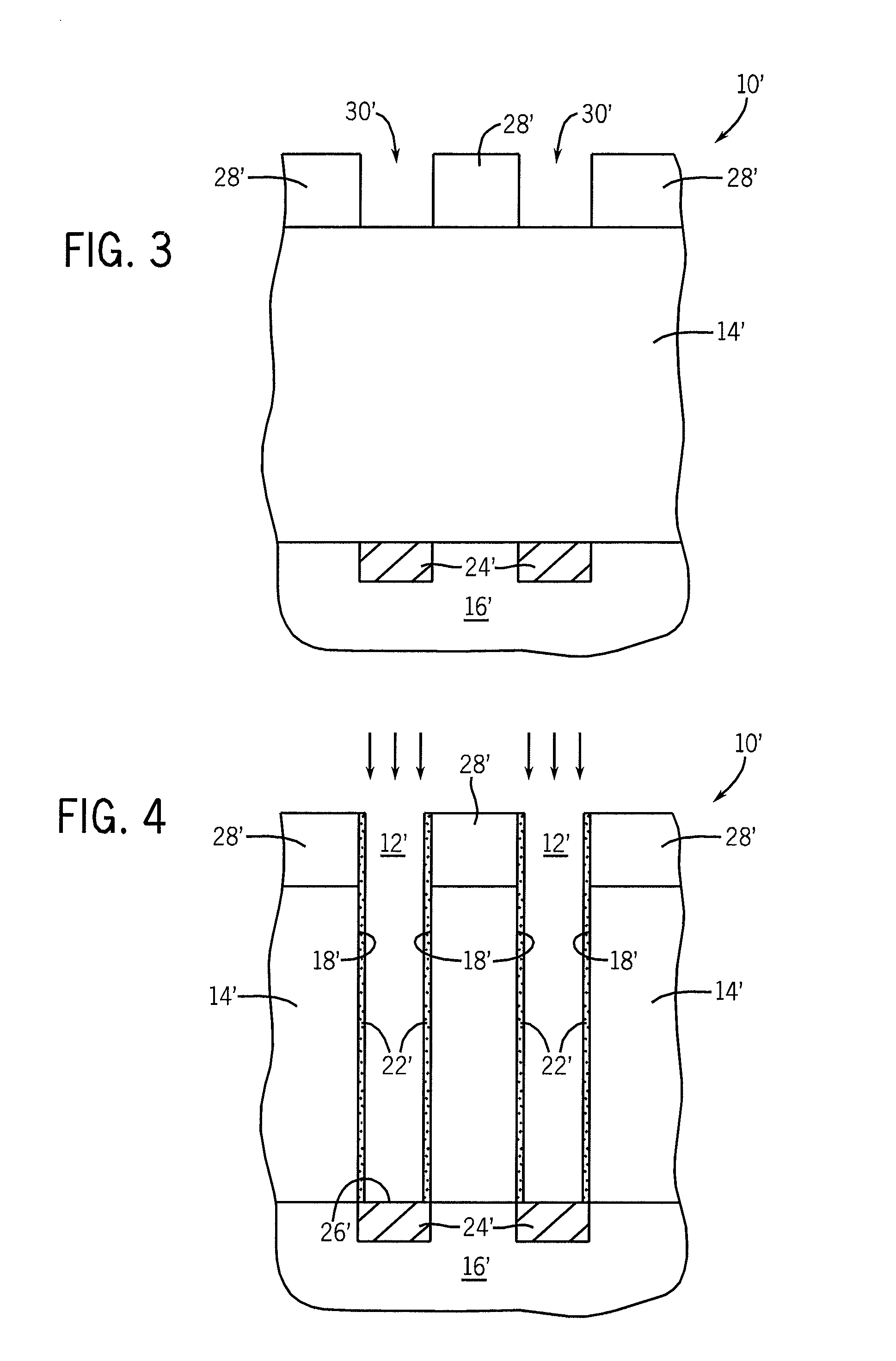

Etch process for forming high aspect ratio trenched in silicon

A multistep etch process for forming high aspect ratio trenches in silicon having a silicon oxide and / or silicon nitride hardmask. In a first step, an etch composition of HBr and oxygen is used, depositing a passivation layer on the sidewalls and producing slightly tapered openings. In the second step, an etch composition of a fluorine-containing gas such as SF6, HBr and oxygen is used, producing more vertical openings at a high etch rate. The taper of the openings during the second step can be controlled by adjusting the relative amount of HBr or SF6 employed. This process is a clean process that does not require cleaning of the etch chamber between etch steps.

Owner:APPLIED MATERIALS INC

Liquid cleaner for the removal of post-etch residues

InactiveUS20100163788A1Cationic surface-active compoundsDetergent mixture composition preparationMetal interconnectTitanium nitride

Cleaning compositions and processes for cleaning post-plasma etch residue from a microelectronic device having said residue thereon. The composition achieves highly efficacious cleaning of the residue material, including titanium-containing, copper-containing, tungsten-containing, and / or cobalt-containing post-etch residue from the microelectronic device while simultaneously not damaging the interlevel dielectric, metal interconnect material, and / or capping layers also present thereon. In addition, the composition may be useful for the removal of titanium nitride layers from a microelectronic device having same thereon.

Owner:ENTEGRIS INC

Polishing composition and method utilizing abrasive particles treated with an aminosilane

ActiveUS20090081927A1Other chemical processesSemiconductor/solid-state device manufacturingMaterials science

Owner:CMC MATERIALS INC

Etch patterning of nanostructure transparent conductors

Owner:CHAMP GREAT INTL

Non-chrome plating on plastic

InactiveUS20050199587A1Insulating substrate metal adhesion improvementDecorative surface effectsPERMANGANATE IONBiological activation

The invention comprises a process of preparing a non-conductive substrate for subsequent metalization. The process replaces the traditional chromic acid etching step with an etching solution comprising a permanganate and a mineral acid. The process also includes a novel activation solution comprising a palladium salt and an amine complexor. The new process of the invention is more environmentally friendly than the traditional chromic acid etching solutions but achieves a comparable result on most non-conductive substrates.

Owner:MACDERMID INC

Additives to CMP slurry to polish dielectric films

A method and composition for planarizing a substrate. The composition includes one or more chelating agents, one or more oxidizers, one or more corrosion inhibitors, a polar solvent, and deionized water. The composition may further comprise one or more surfactants, one or more agents to adjust the pH and / or abrasive particles. The method comprises planarizing a substrate using a composition including a polar solvent.

Owner:APPLIED MATERIALS INC

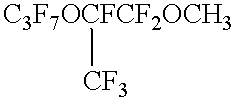

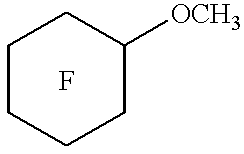

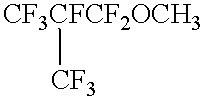

Fluorinated solvent compositions containing hydrogen fluoride

InactiveUS6310018B1Not easily recoveredEasy to separateDecorative surface effectsDetergent mixture composition preparationHydrogen fluorideEtching

Owner:3M INNOVATIVE PROPERTIES CO

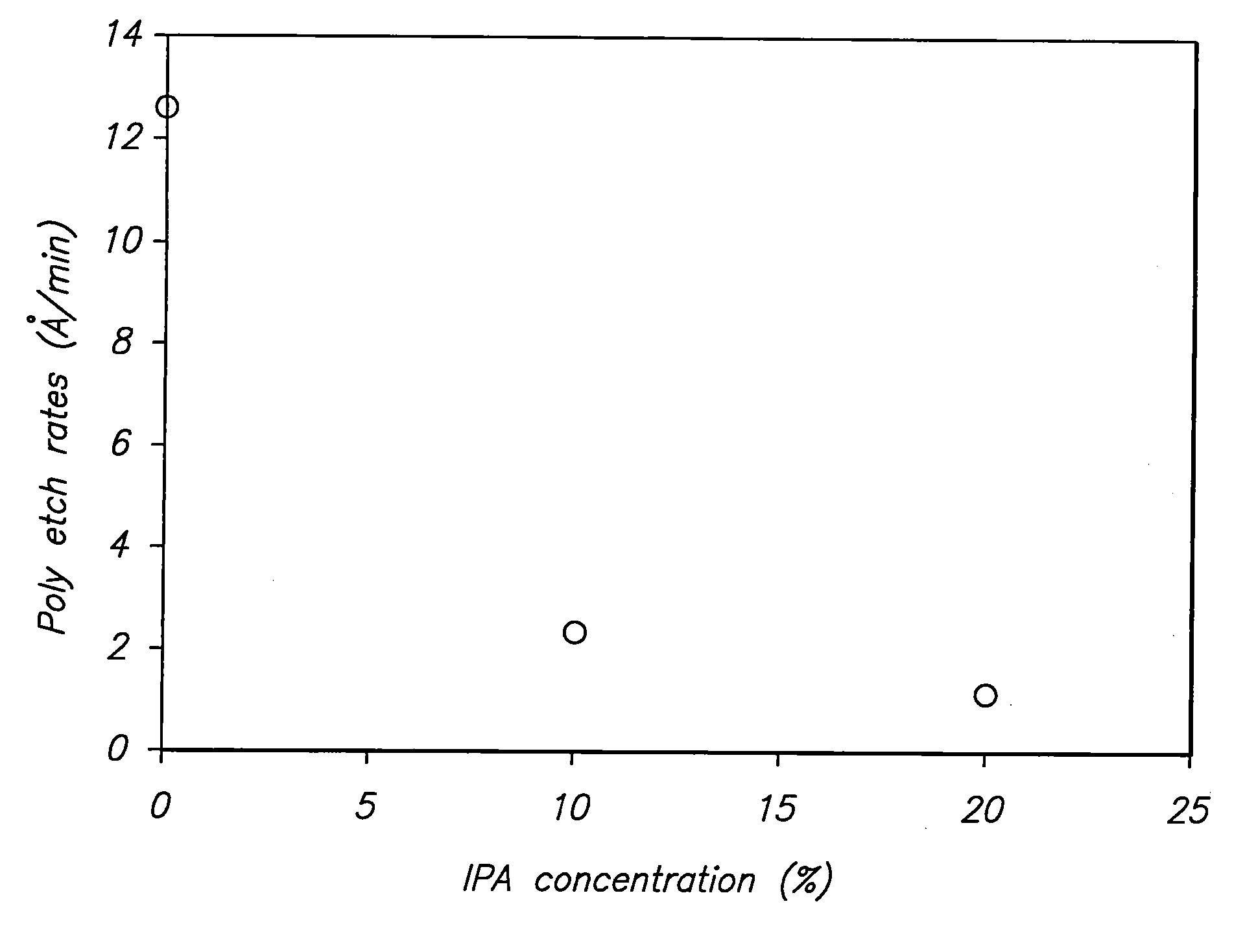

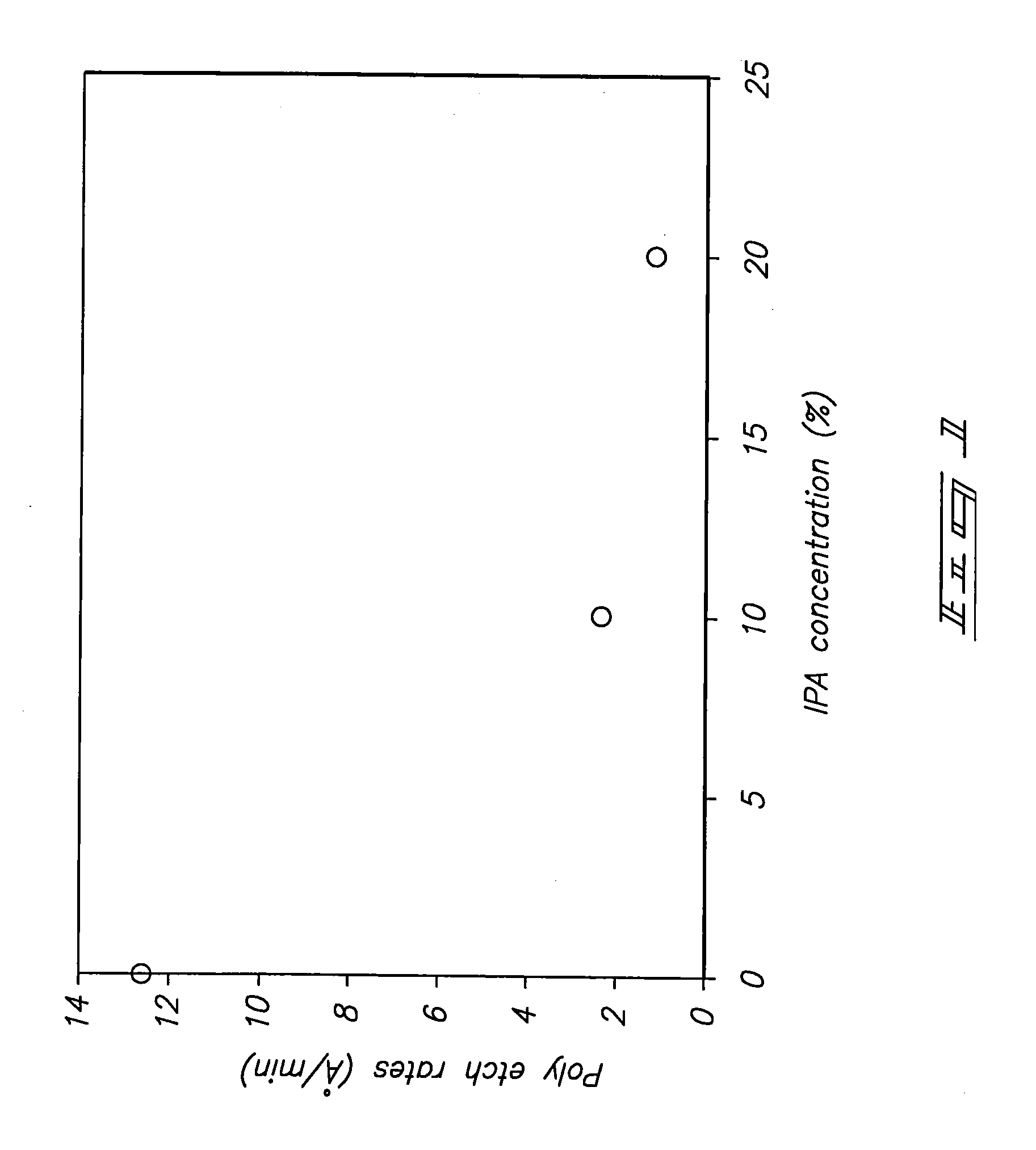

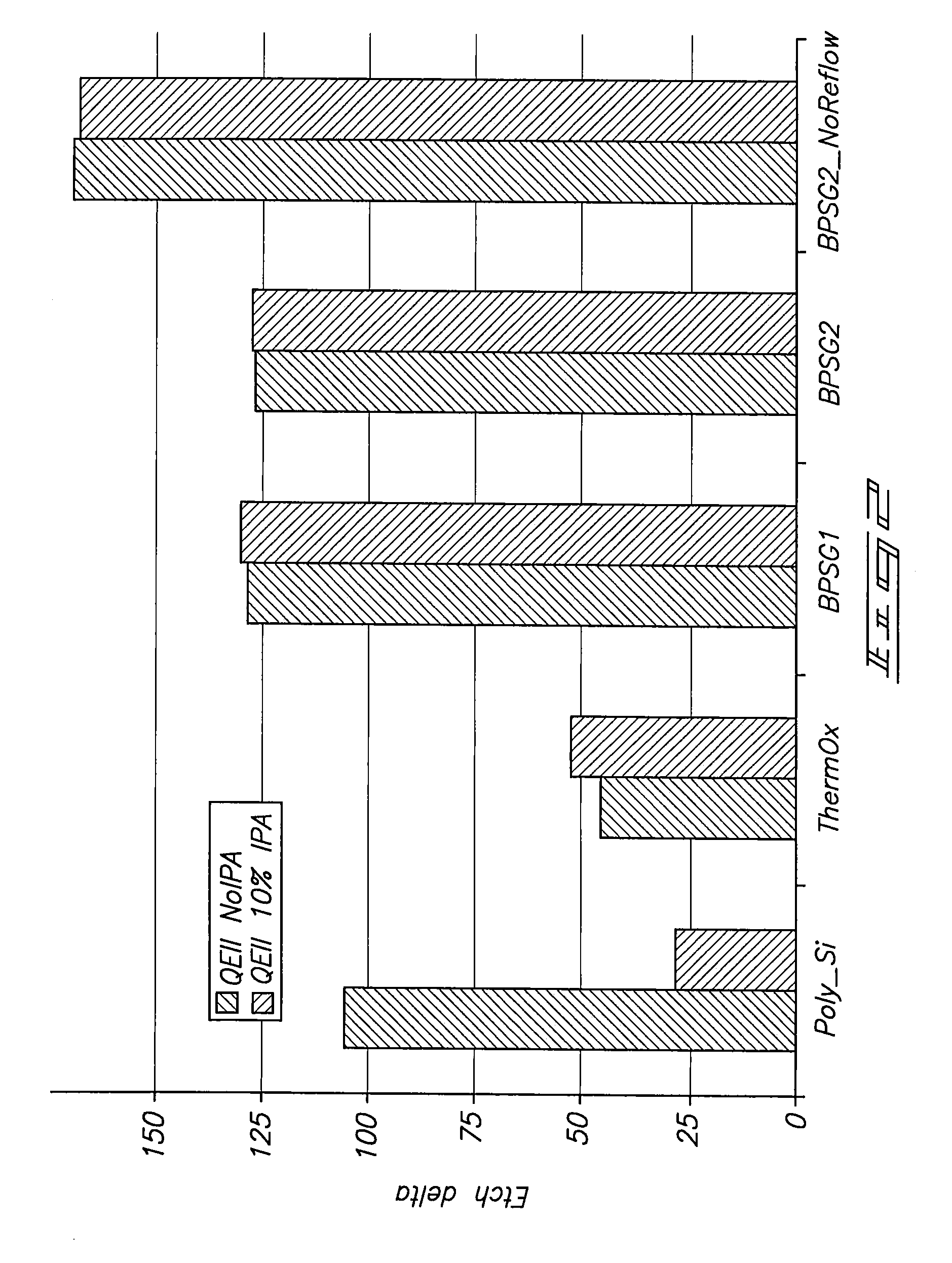

Etch Compositions and Methods of Processing a Substrate

InactiveUS20070145009A1Decorative surface effectsSemiconductor/solid-state device manufacturingChemistryIsotropic etching

The invention includes an etchant composition containing isopropyl alcohol and one or more of HF, NH4F and tetramethyl ammonium fluoride (TMAF). The invention encompasses a method of processing a substrate. A substrate is provided which has a first material containing at least one of polysilicon, monocrystalline silicon and amorphous silicon, and a second material. The substrate is exposed to an etch composition which comprises isopropyl alcohol and at least one of HF, NH4F and TMAF. The invention includes a method of processing a semiconductor construction including providing a construction which has a capacitor electrode material and an oxide material along at least a portion of the capacitor electrode material. At least some of the oxide material is removed by isotropic etching utilizing an etchant composition comprising isopropyl alcohol.

Owner:MICRON TECH INC

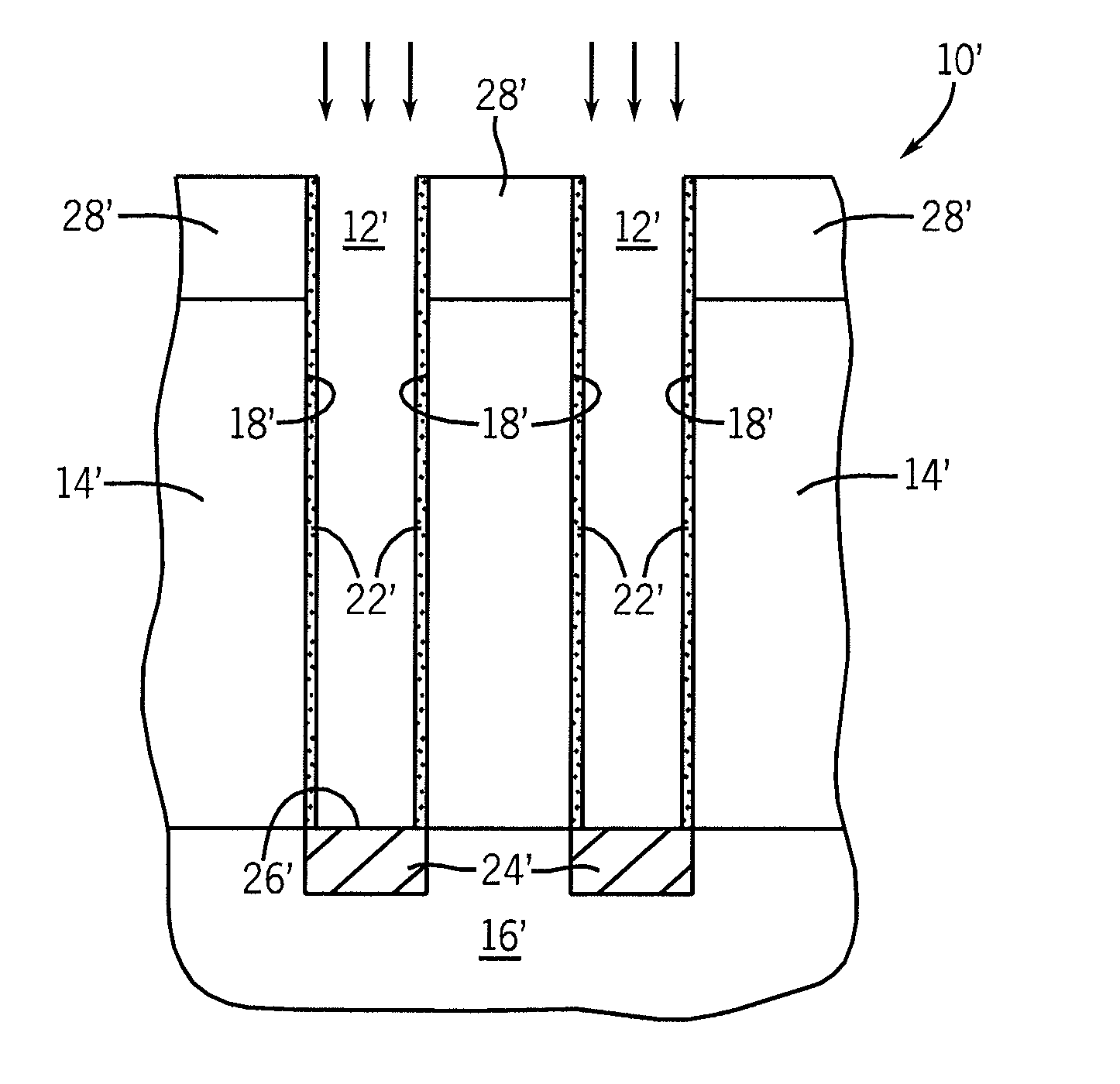

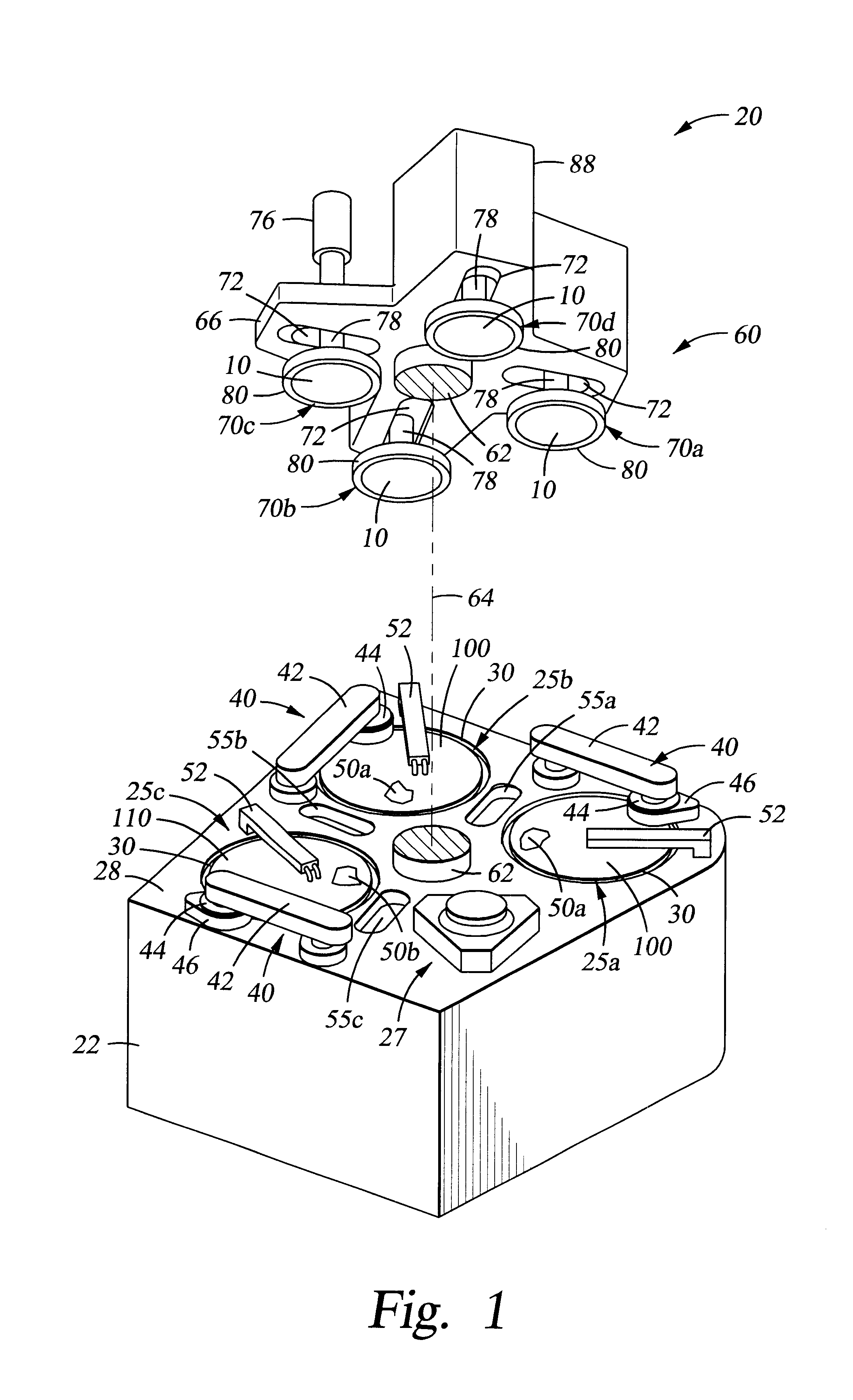

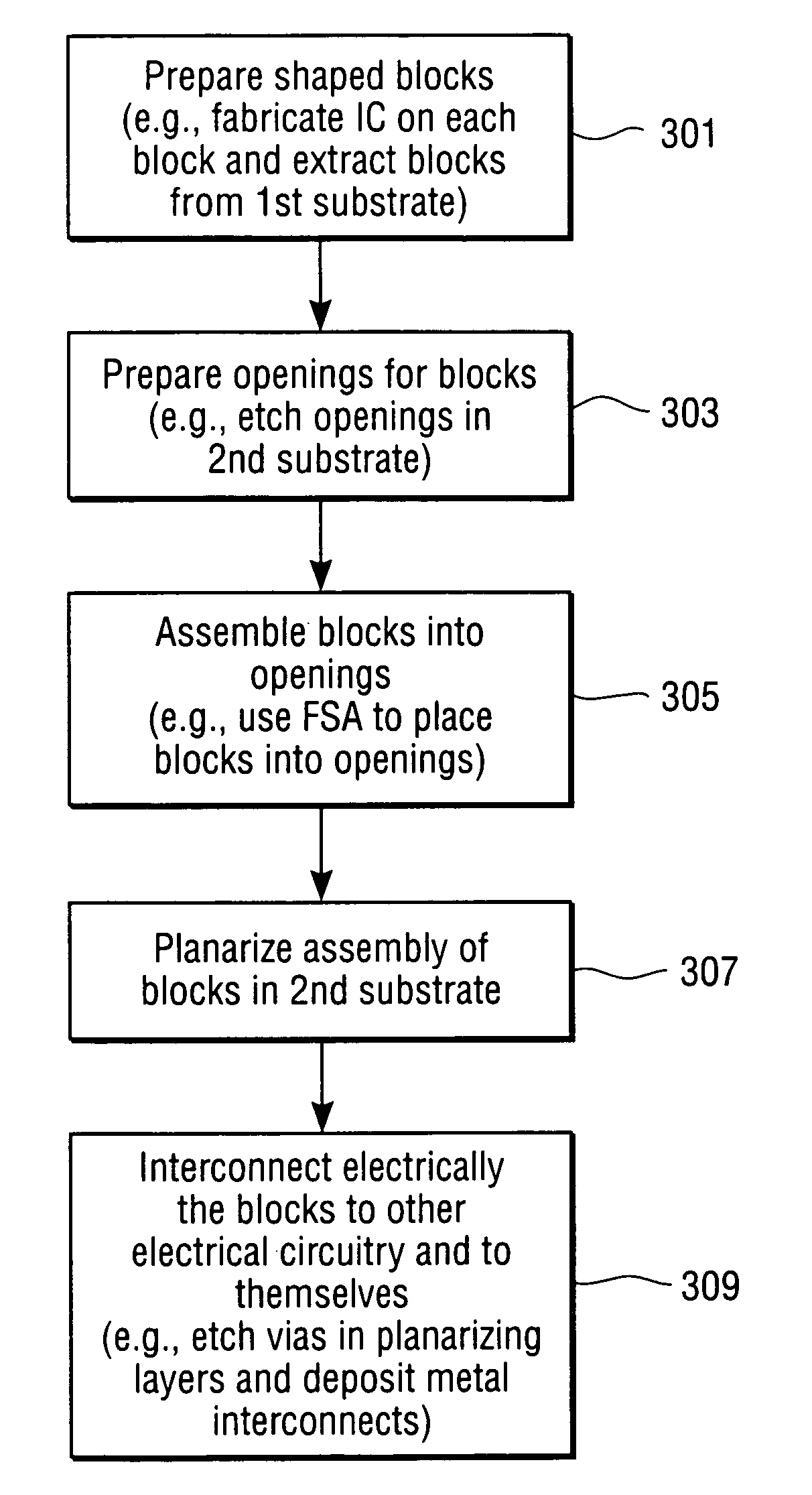

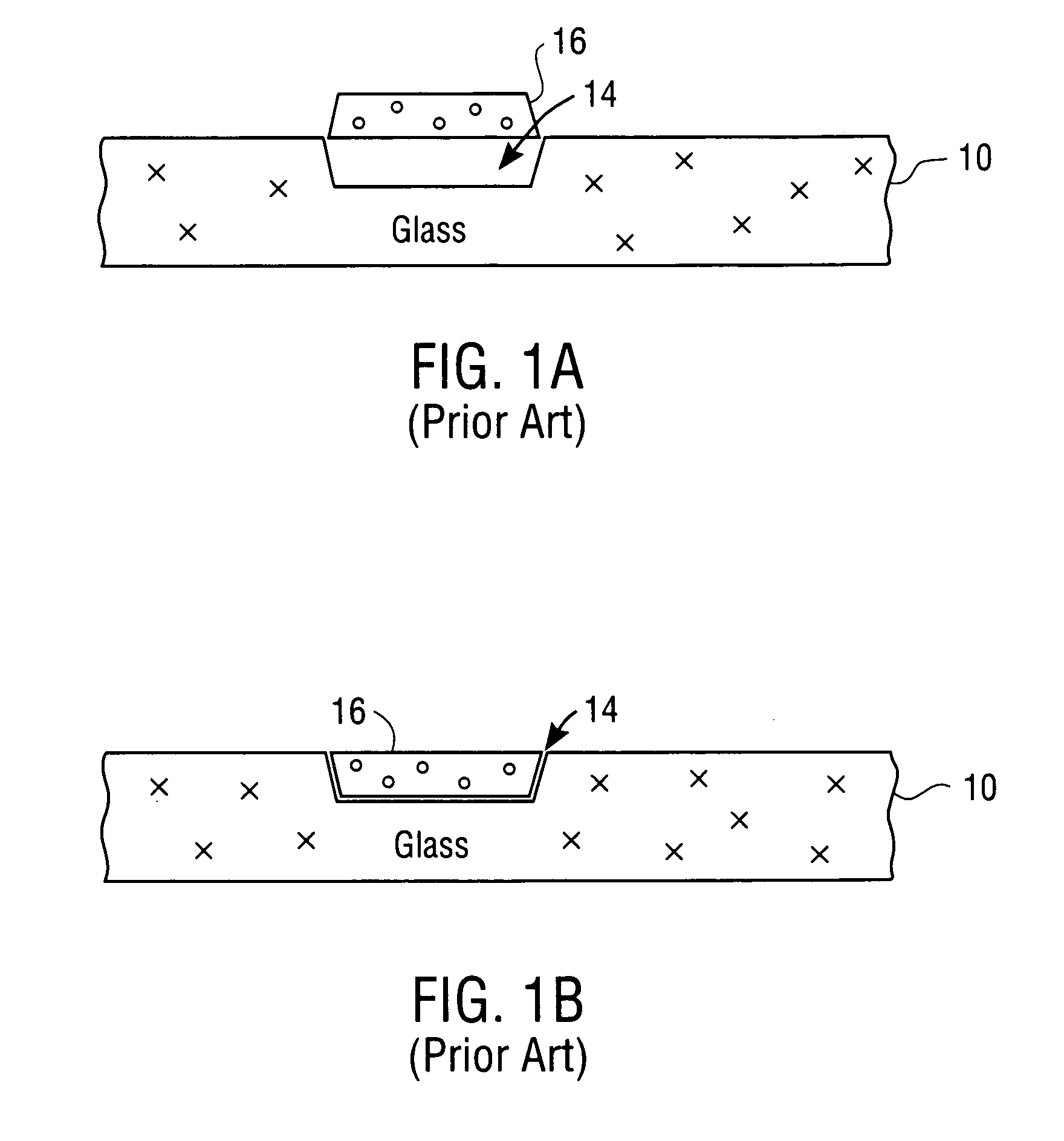

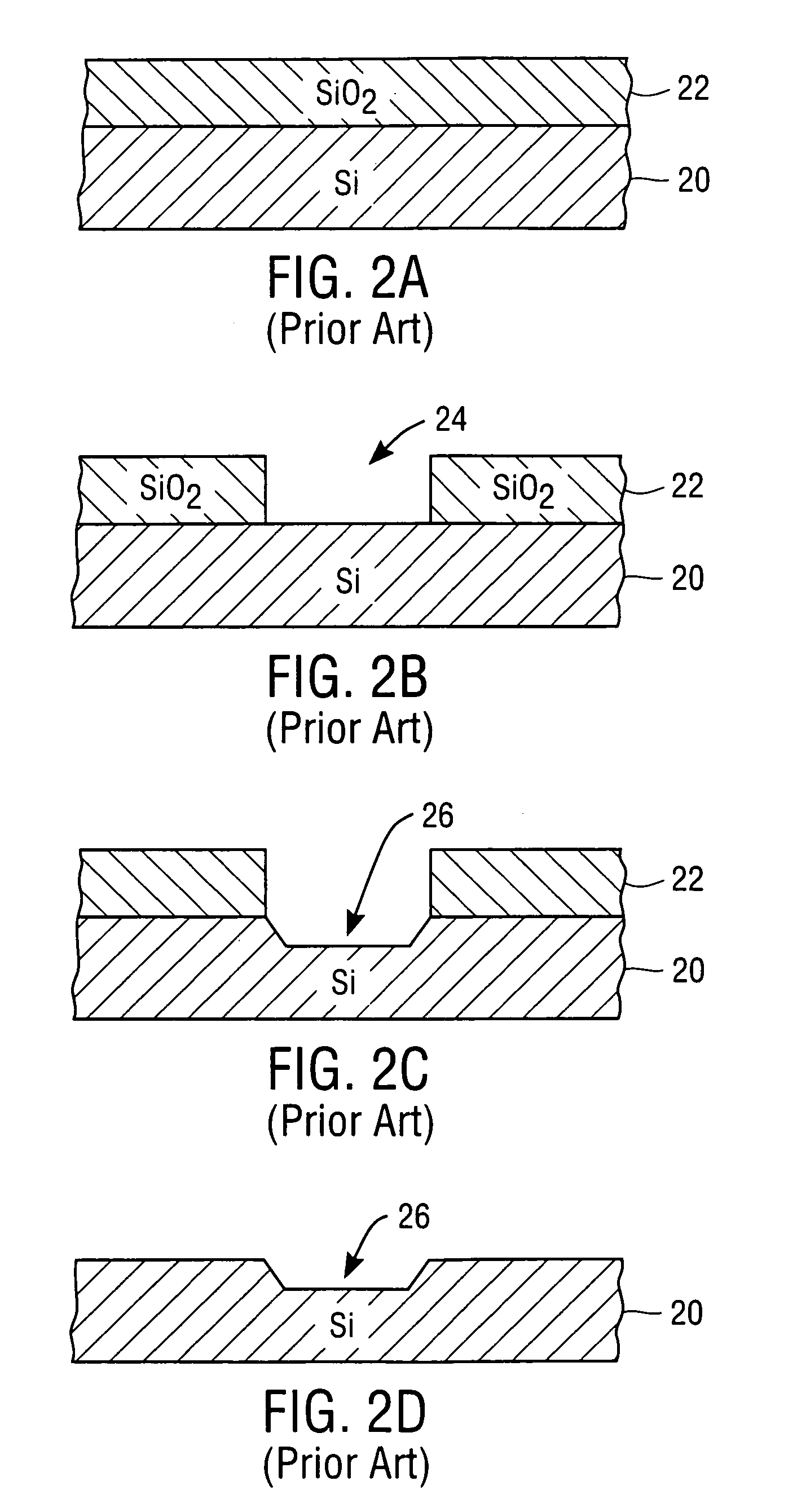

Methods and apparatuses for assembling elements onto a substrate

Methods and apparatuses for assembling elements onto a substrate. The surfaces of the elements and / or the substrate are treated and the elements are dispensed over the substrate in a slurry. In one example of the invention, the substrate is exposed to a surface treatment fluid to create a surface on the substrate which has a selected one of a hydrophilic or a hydrophobic nature, and a slurry is dispensed over the substrate. The slurry includes a fluid and a plurality of elements (each of which includes a functional component). Each of the plurality of elements is designed to be received by a receptor region on the substrate. The dispensing of the slurry with the fluid occurs after the substrate is exposed to the surface treatment fluid, and the fluid is the selected one of a hydrophilic or a hydrophobic nature. In another example of the invention, a plurality of elements is exposed to a surface treatment fluid to create surfaces on the elements having a selected one of a hydrophilic or a hydrophobic nature. A slurry is dispensed over a substrate, wherein the slurry contains a fluid and the plurality of elements which are designed to be received by a plurality of receptor regions. The fluid is the selected one of a hydrophilic or hydrophobic nature. In another example of an aspect of the invention, a surfactant is used with a slurry having elements which are deposited onto receptor regions in a fluidic self assembly process. Other examples of methods are also described.

Owner:RUIZHANG TECH LTD CO

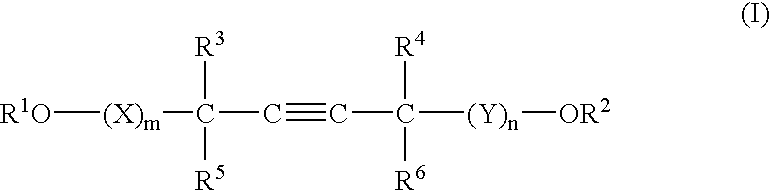

Barrier polishing liquid and chemical mechanical polishing method

InactiveUS20070181534A1Sufficient rateSufficient polishing ratePigmenting treatmentOther chemical processesOrganic acidColloidal silica

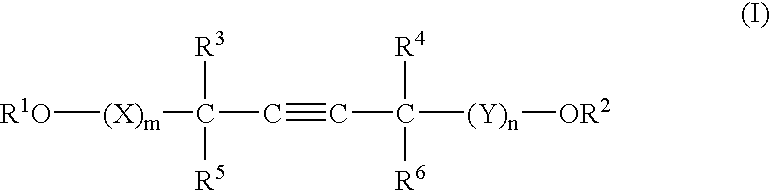

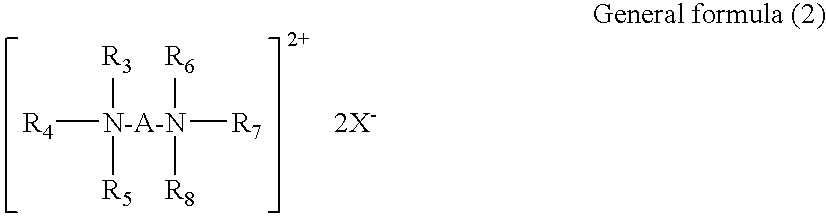

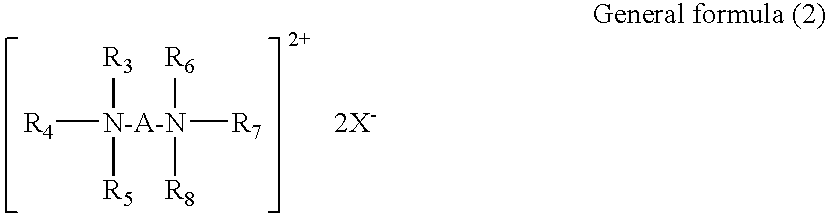

A barrier polishing liquid is provided that includes (a) a nonionic surfactant represented by Formula (I) below, (b) at least one type of organic acid selected from the group consisting of an aromatic sulfonic acid, an aromatic carboxylic acid, and a derivative thereof, (c) colloidal silica, and (d) benzotriazole or a derivative thereof.(In Formula (I), R1 to R6 independently denote a hydrogen atom or an alkyl group having 1 to 10 carbons, X and Y independently denote an ethyleneoxy group or a propyleneoxy group, and m and n independently denote an integer of 0 to 20.) There is also provided a chemical mechanical polishing method that includes supplying the barrier polishing liquid to a polishing pad on a polishing platen at a flow rate per unit area of a semiconductor substrate per unit time of 0.035 to 0.25 mL / (min·cm2), and polishing by making the polishing pad and a surface to be polished move relative to each other while they are in a contacted state.

Owner:FUJIFILM CORP

Particulate or particle-bound chelating agents

The invention generally relates to compositions and methods for chemically mechanically polishing a substrate, including a polishing accelerator, which is normally one or more oxidizers, an abrasive material, and chelating particles and / or metal-absorbent clay material. In addition, the invention can also involve methods of forming chelator particles and methods of separating metal-containing ions from polishing and / or etching solutions after polishing and / or etching.

Owner:VERSUM MATERIALS US LLC

Raspberry-type metal oxide nanostructures coated with ceo2 nanoparticles for chemical mechanical planarization (CMP)

InactiveUS20120077419A1Efficient processCost-effective and convenient processMaterial nanotechnologySilicaCeo2 nanoparticlesWater soluble

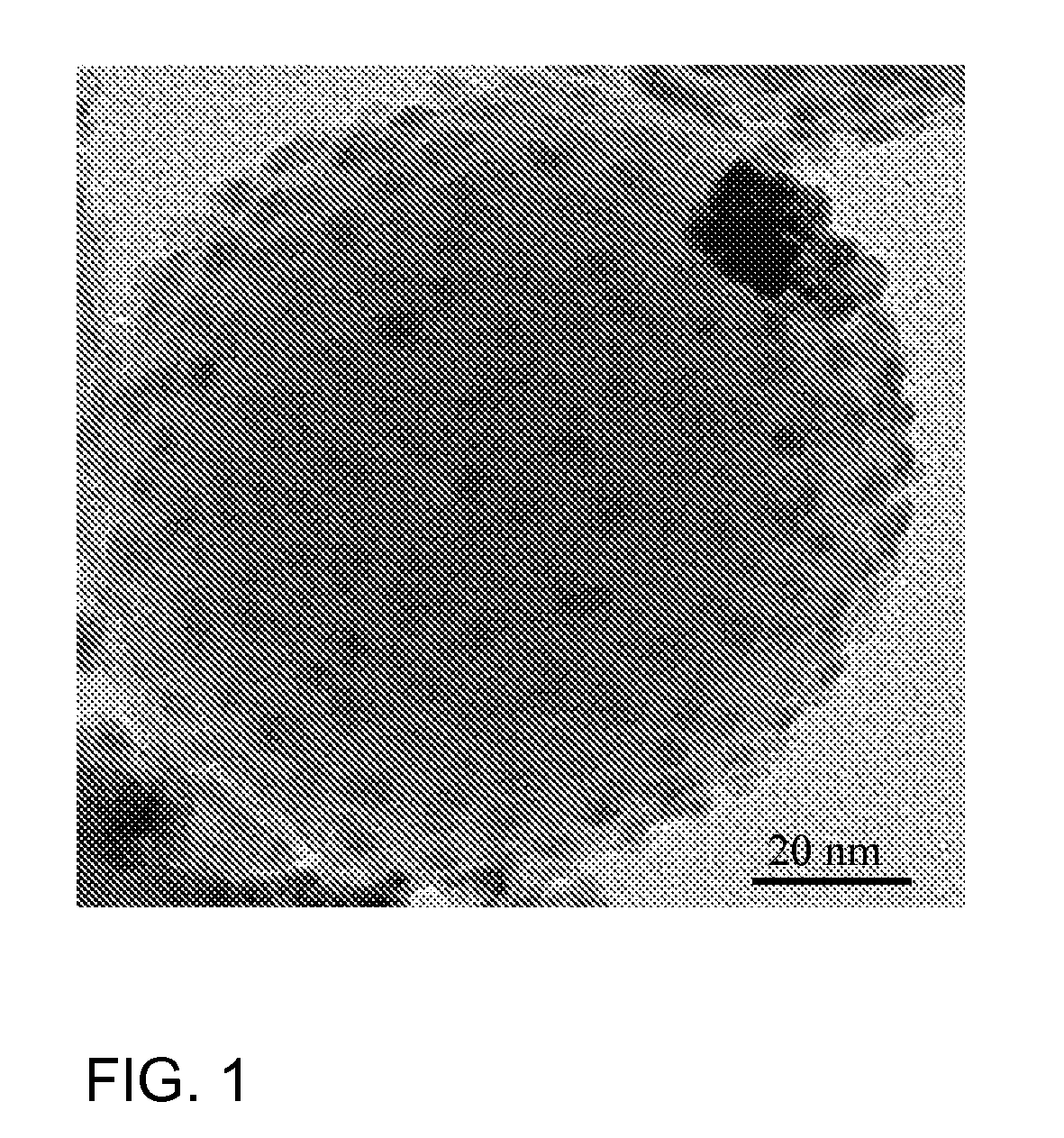

Raspberry-type coated particles comprising a core selected from the group consisting of metal oxides of Si, Ti, Zr, Al, Zn and mixtures thereof with a core size of from 20 to 100 nm wherein the core is coated with CeCO2 particles having a particle size below 10 nm; process for preparing raspberry type coated particles comprising the steps of i) providing a mixture containing: a) core particles selected from the group of metal oxides of Si, Ti, Zr, Al, Zn and mixtures thereof, with a particle size of from 20 to 100 nm; b) a water soluble Ce-salt and c) water; ii) adding an organic or inorganic base to the mixture of step i) at temperatures of from 10 to 90° C. and iii) aging the mixture at temperatures of from 10 to 90° C.; and polishing agents containing the particles and their use for polishing surfaces.

Owner:BASF AG

Polishing slurry

ActiveUS20090311864A1Avoid corrosionLow costMaterial nanotechnologyOther chemical processesMetallurgySlurry

A polishing slurry used in chemical mechanical polishing of a barrier layer and an interlayer dielectric film in a semiconductor integrated circuit includes an abrasive, an oxidizer, an anticorrosive, an acid, a surfactant and an inclusion compound. The polishing slurry has a pH of less than 5. The resulting polishing slurry contains a solid abrasive used in barrier CMP for polishing a barrier layer made of a metallic barrier material, has excellent storage stability, achieves a good polishing rate in various films to be polished such as the barrier layer, and is capable of independently controlling the polishing rate with respect to the various films to be polished while further suppressing agglomeration of the abrasive particles.

Owner:FUJIFILM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com