Patents

Literature

55 results about "Ceo2 nanoparticles" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

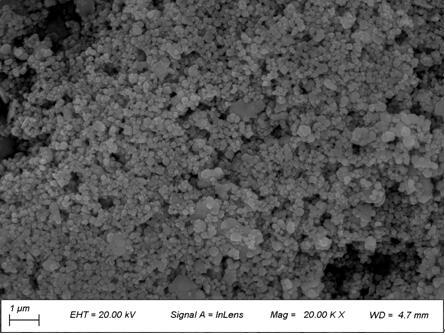

NANOTECH CeO2 CERIUM OXIDE NANOPARTICLES. NANOTECH CeO 2 is composed by cerium oxide nanoparticles. Thanks to its intrinsic characteristics, it has attracted much attention for its potential applications in electronic ceramic, ultra-precise polishing, catalysis and energy storage.

Raspberry-type metal oxide nanostructures coated with ceo2 nanoparticles for chemical mechanical planarization (CMP)

InactiveUS20120077419A1Efficient processCost-effective and convenient processMaterial nanotechnologySilicaCeo2 nanoparticlesWater soluble

Raspberry-type coated particles comprising a core selected from the group consisting of metal oxides of Si, Ti, Zr, Al, Zn and mixtures thereof with a core size of from 20 to 100 nm wherein the core is coated with CeCO2 particles having a particle size below 10 nm; process for preparing raspberry type coated particles comprising the steps of i) providing a mixture containing: a) core particles selected from the group of metal oxides of Si, Ti, Zr, Al, Zn and mixtures thereof, with a particle size of from 20 to 100 nm; b) a water soluble Ce-salt and c) water; ii) adding an organic or inorganic base to the mixture of step i) at temperatures of from 10 to 90° C. and iii) aging the mixture at temperatures of from 10 to 90° C.; and polishing agents containing the particles and their use for polishing surfaces.

Owner:BASF AG

Nickel-based catalyst for hydrogen production by ethanol steam reforming and preparation method thereof

InactiveCN101444737AHigh mechanical strengthHigh catalytic activityHydrogenMetal/metal-oxides/metal-hydroxide catalystsSteam reformingNanowire

The invention discloses a nickel-based catalyst for hydrogen production by ethanol steam reforming and a preparation method thereof. The catalyst is made by taking nanoporous silicon dioxide aerogel as a catalyst carrier, a metal elementary substance nickel nanowire as an active component, and nano-particles of MgO or CaO or ZrO2 or TiO2 or CeO2 or compound nano-particles thereof as an adjuvant. The preparation method comprises the following steps: preparing a sol from silanolate, an alcohol solvent, nickel nitrate or magnesium nitrate or calcium nitrate or zirconium nitrate or cerous nitrate or complex nitrate thereof and an acidic catalyst at certain proportions; forming a wet gel complex, and then performing supercritical fluid drying. The catalyst has strong catalytic activity and selectivity for the hydrogen production by the ethanol steam reforming, has higher hydrogen yield and stronger CO2 selectivity at a lower temperature, and limits the selectivity of byproducts CH4 and CO at a lower level. Meanwhile, the preparation method has simple process, low cost and certain mechanical strength.

Owner:HUNAN SHANGYIFENG NEW MATERIAL TECH CO LTD

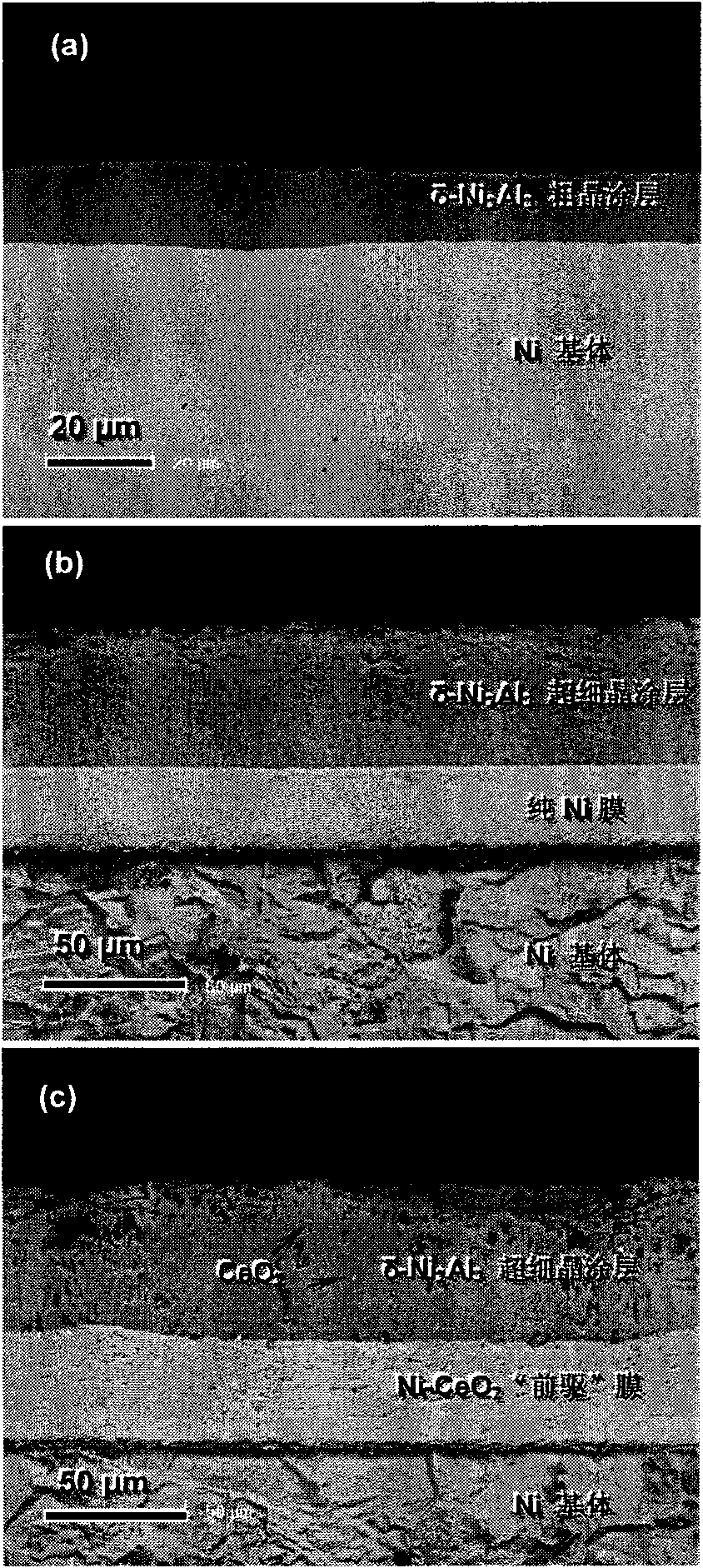

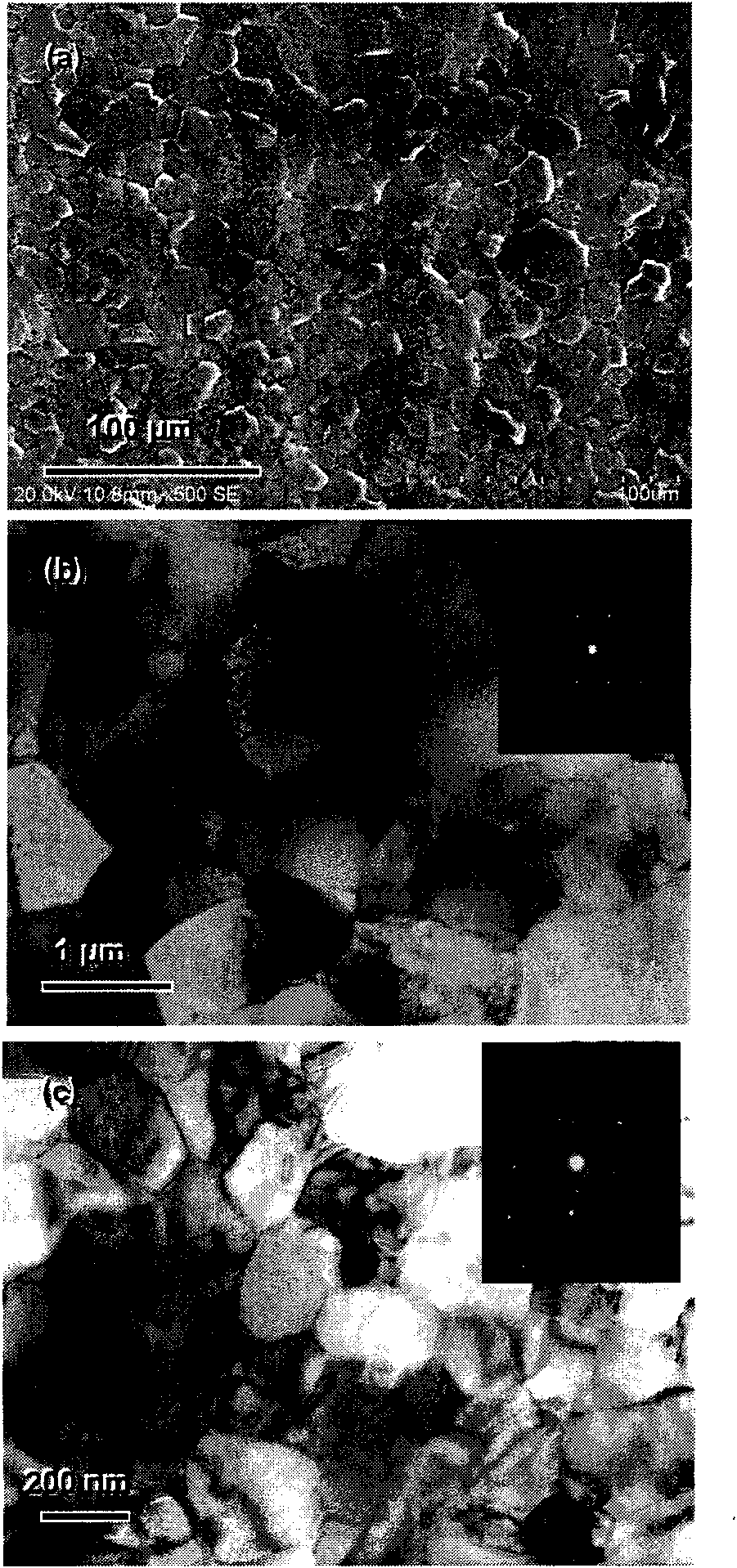

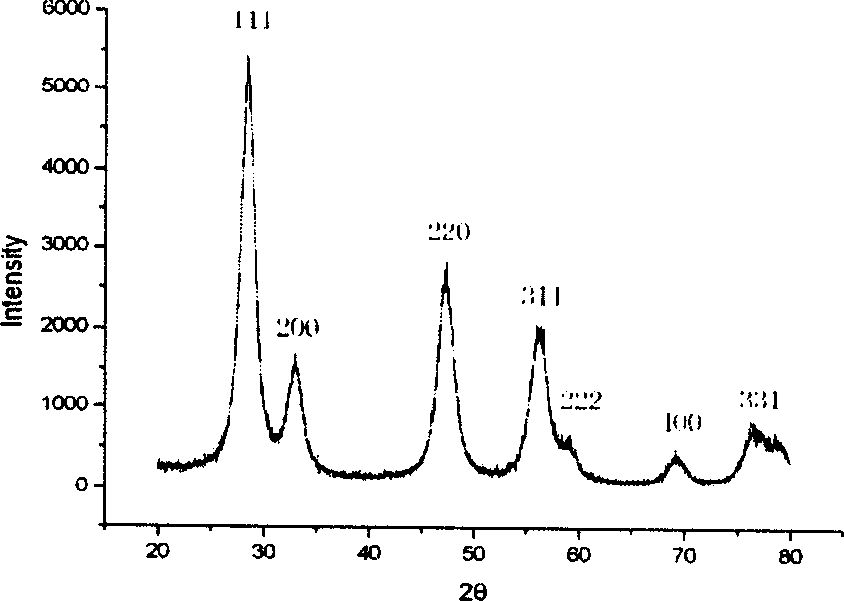

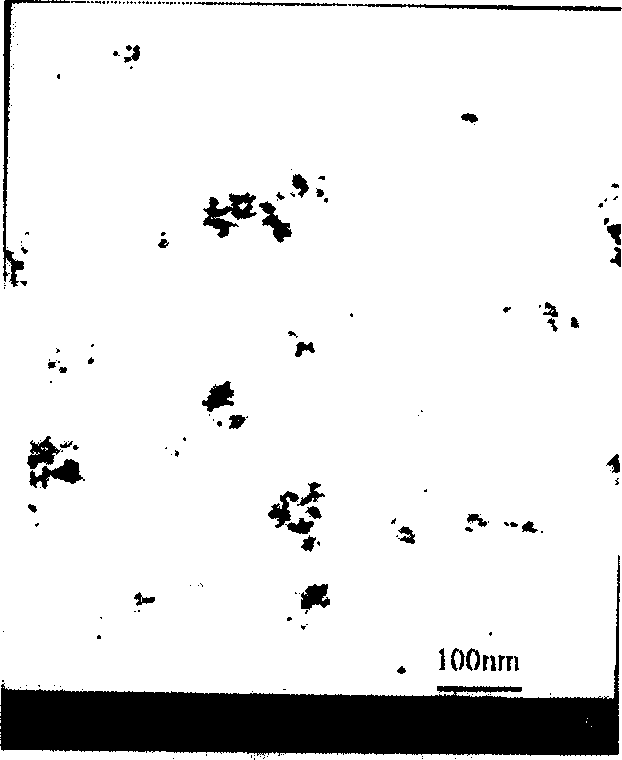

CeO2-diffused superfine crystalline delta-Ni2Al3 coating, and preparation method and application thereof

InactiveCN101988204AExpand the range of metal materialsSmall sizeElectrolytic coatingsSolid state diffusion coatingAlloy substrateCeo2 nanoparticles

The invention discloses a CeO2-diffused superfine crystalline delta-Ni2Al3 coating, and a preparation method and application thereof, which solve the problems of high temperature, weak Al2O3 layer bonding strength for the thermal growth of an alumetized coating, limitations to application, and the like of conventional alumetizing technology. The coating is prepared by the following two steps of: preparing an Ni-CeO2 nanometer compound precursor film with a nanocrystalline structure on a metal substrate, such as a low-carbon steel substrate, a low alloy steel substrate, an Ni-based alloy substrate or the like, by performing coelectrodeposition on Ni and CeO2 nanoparticles; and performing diffusion alumetizing on the precursor film at 500 to 700 DEG C to obtain the superfine crystalline CeO2 modified delta-Ni2Al3 coating. The coating consists of the following components in percentage by mass: 1 to 10 percent of diffused CeO2 nanoparticles and the balance of delta-Ni2Al3 phase. The CeO2-diffused superfine crystalline delta-Ni2Al3 coating of the invention can be applied to the metal substrate, such as the low-carbon steel substrate, the low alloy steel substrate, the Ni-based alloy substrate or the like, in an oxidizing atmosphere at the working condition temperature of less than 1,000 DEG C as a protective coating of a related part in a boiler, a heat exchanger, a gasifier or a garbage incinerator of a thermal power plant.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Method for preparing Nano cerium oxdie, and application in chemical mechanical polishing chip of gallium arsenide

InactiveCN1760132ASmall granularityEvenly distributedAqueous dispersionsRare earth metal compoundsCerium nitrateWafering

A process for preparing cerium oxide nanoparticles includes such steps as proportionally dissolving cerium nitrate and hexamethylenetetraamine (HMT) respectively in alcohol and distilled water, mixing, stirring, sealing, heating at 70-90 deg.C for 1-2 hr, cooling, ageing for 1-2 hr, filter, washing deposit, and drying at 60-80 deg.C for 6-10 hr. The obtained CeO2 nanoparticles can be used to prepare the polishing liquid for polishing the semiconductor wafer of gallium arsenide.

Owner:JIANGSU POLYTECHNIC UNIVERSITY

Process for preparing water-soluble ceria nanocrystalline

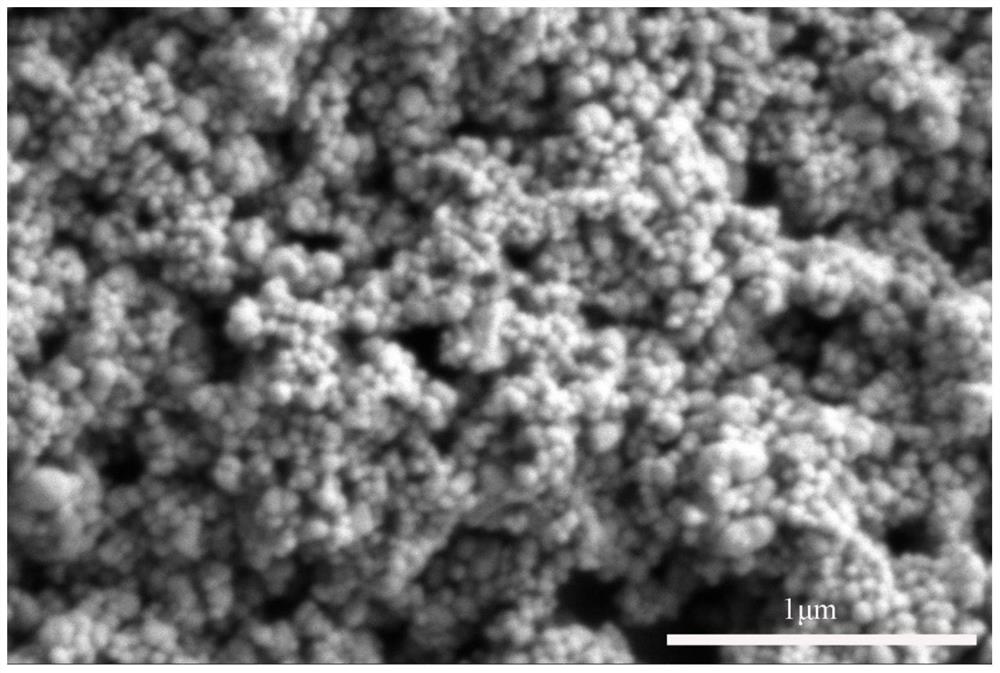

The invention provides a method for preparing a water-soluble ceria nano-crystal, belonging to the nano material technical field. The prior CeO2 nano particles include oil-soluble CeO2 nano particles without surface finishing. A back flow hydrolization method is adopted in the invention. The method of the invention comprises the following steps that: 1. the water-soluble nano particles dispersed in a solution are synthesized; and the back flow hydrolization method is adopted, wherein the cerium source is acetylacetone cerium, and the solvent and the surface finishing agent are 2-pyrrolidone; technical parameters are as follows: the temperature of the back flow hydrolization is between 225 and 240 DEG C, and the time of the back flow is between 60 and 120min; 2. the water-soluble nano particles are separated from the solution; the solution containing the water-soluble nano particles is cooled down to the room temperature and undergoes the steps of deposition by methanol, centrifugal separation, washing by acetone and drying; technical parameters are as follows: the use level of the methanol is between 200 and 300ml, the use level of the acetone is between 50 and 80ml, and the solution is dried by N2 flow for 4h or at a temperature of between 50 and 60 DEG C for 5 to 10h. The water-soluble ceria nano particles finally obtained are ball-shaped and the average particle diameter of which is approximately 5 to 10nm.

Owner:CHANGCHUN UNIV OF SCI & TECH

Ternary composite metal oxide solid alkali catalyst and preparation method and application thereof

InactiveCN109621939AUniform depositionInhibit growthOrganic chemistryMetal/metal-oxides/metal-hydroxide catalystsCeo2 nanoparticlesGlycerol

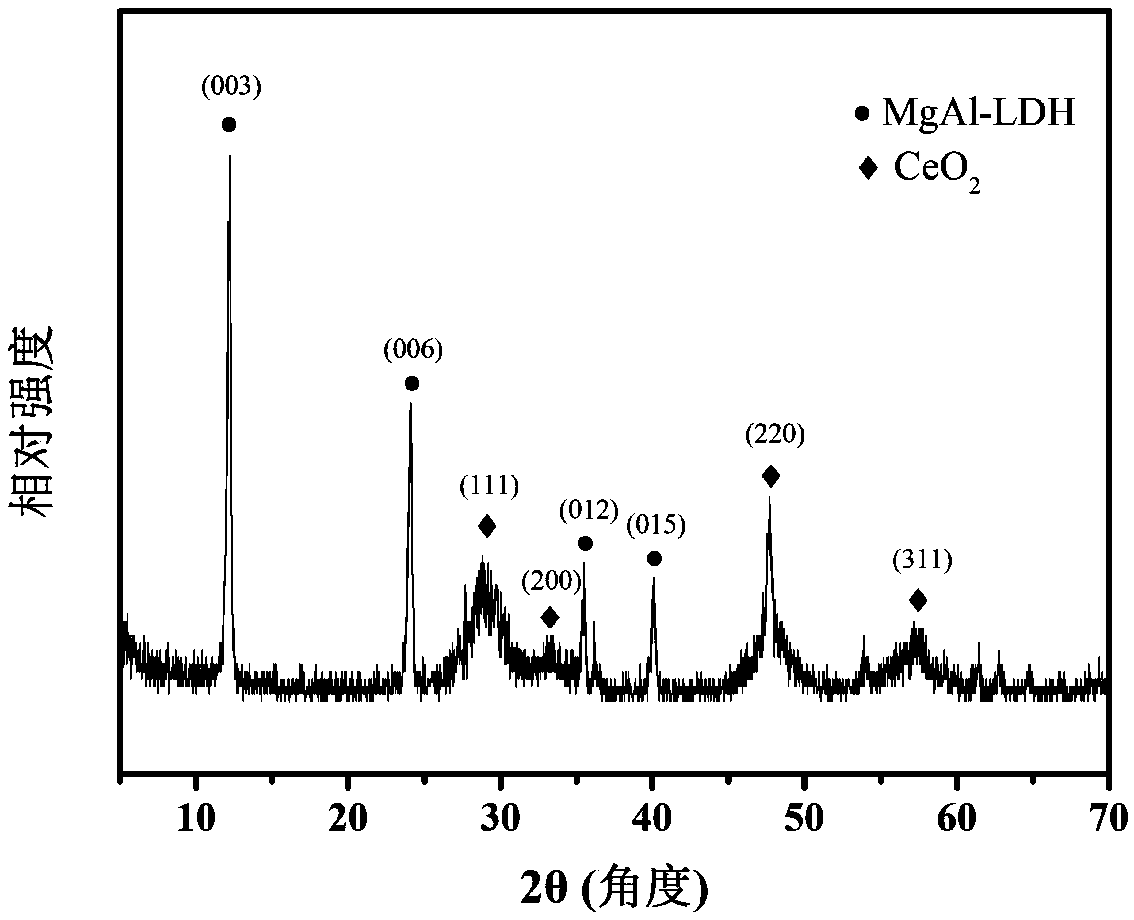

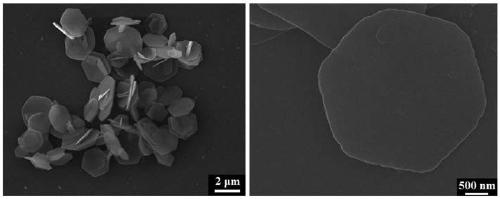

The invention provides a ternary composite metal oxide solid alkali catalyst and a preparation method and application thereof. According to the method, urea is taken as a precipitant, a hydrothermal method is adopted for preparing a magnalium hydrotalcite precursor, the magnalium hydrotalcite precursor is dispersed in a cerate solution, the mixture and a sodium borohydride solution are put in a colloid mill, stirred for a reaction and transferred into a hydrothermal reactor, and hydrothermal crystallization is conducted, so that CeO2 nanoparticles with rich defect sites and alkaline sites areuniformly deposited on the surface of an MgAl-LDH piece structure; a CeO2 / MgAl-LDH composite precursor is obtained, and after roasting treatment, the ternary composite metal oxide solid alkali catalyst CeO2 / MgO-Al2O3 is obtained. The CeO2 nanoparticles in the catalyst are uniformly dispersed on the surface of an MgO-Al2O3 composite oxide in a piece shape, the size of the particles is 20-30 nm, andthe mass percentage of CeO2 is 3-25%; the specific surface area of the catalyst is 80-130 m2 / g. The catalyst is used for the reaction for preparing glycerinum carbonic ester through the direct reaction of glycerinum and CO2, the conversion rate of the catalyst is 84.4-92.1%, and the selectivity of the catalyst is 92.3-93.6%.

Owner:BEIJING UNIV OF CHEM TECH

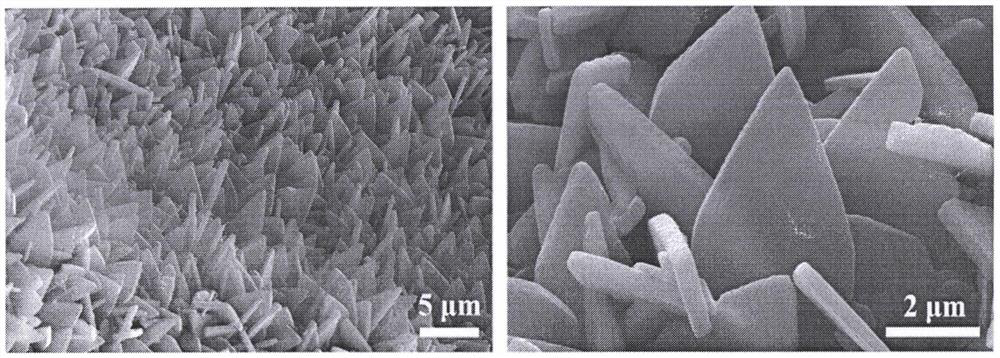

Preparation method of Co3S4 nanosheet array modified by CeO2 nanoparticles

ActiveCN112164592AKeep porousRetain multiple active sitesHybrid capacitor electrodesHybrid/EDL manufactureCapacitanceNickel substrate

The invention provides a preparation method of a Co3S4 nanosheet array modified by CeO2 nanoparticles. The method comprises the following steps: mixing a cobalt salt, an imidazole ligand and a solvent, adding foamed nickel, and growing a zeolite imidazolate framework CoZIFL nanosheet array on a foamed nickel substrate through a reaction; then, adding the CoZIFL nanosheet array into a sulfur sourcesolution, and generating a Co3S4 nanosheet array through hydrothermal vulcanization; and adding cerium salt, a precipitator and a solvent into the precursor, and obtaining a CeO2 nanoparticle modified Co3S4 nanosheet array through solvothermal reaction. The CeO2 nanoparticle modified Co3S4 nanosheet array prepared by adopting the method can be directly used as an electrode of a supercapacitor, and compared with a Co3S4 nanosheet array precursor, the specific capacitance of the CeO2 nanoparticle modified Co3S4 nanosheet array prepared by adopting the method is improved by 114.8% (under the condition of 0.5 A / g).

Owner:宁波市大学科技园发展有限公司

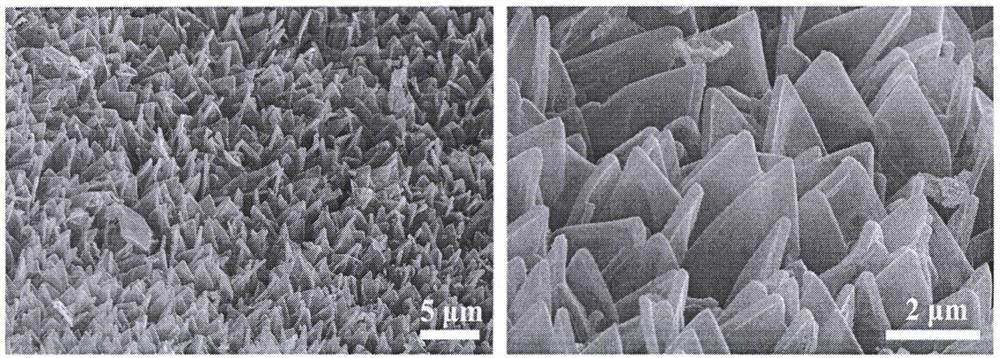

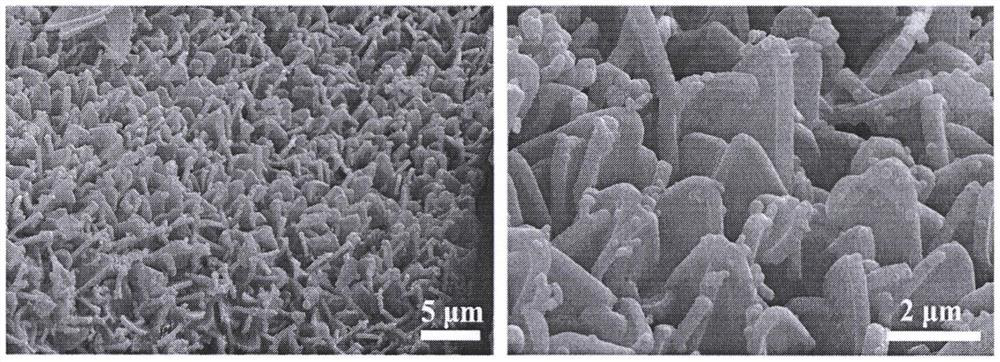

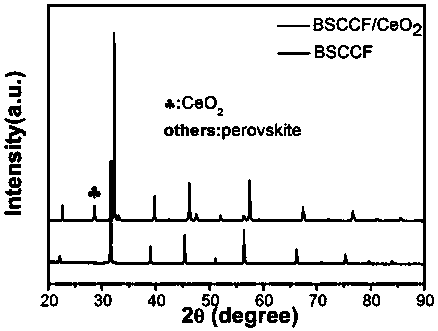

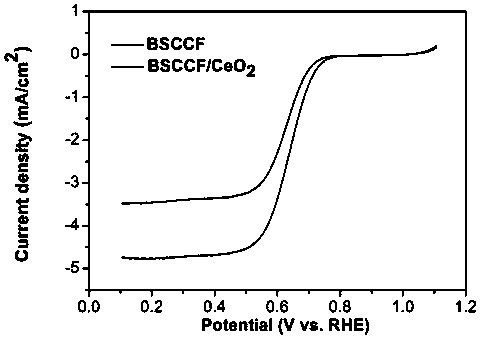

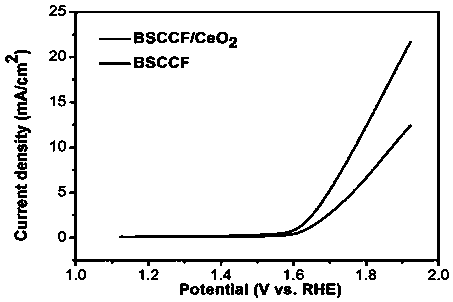

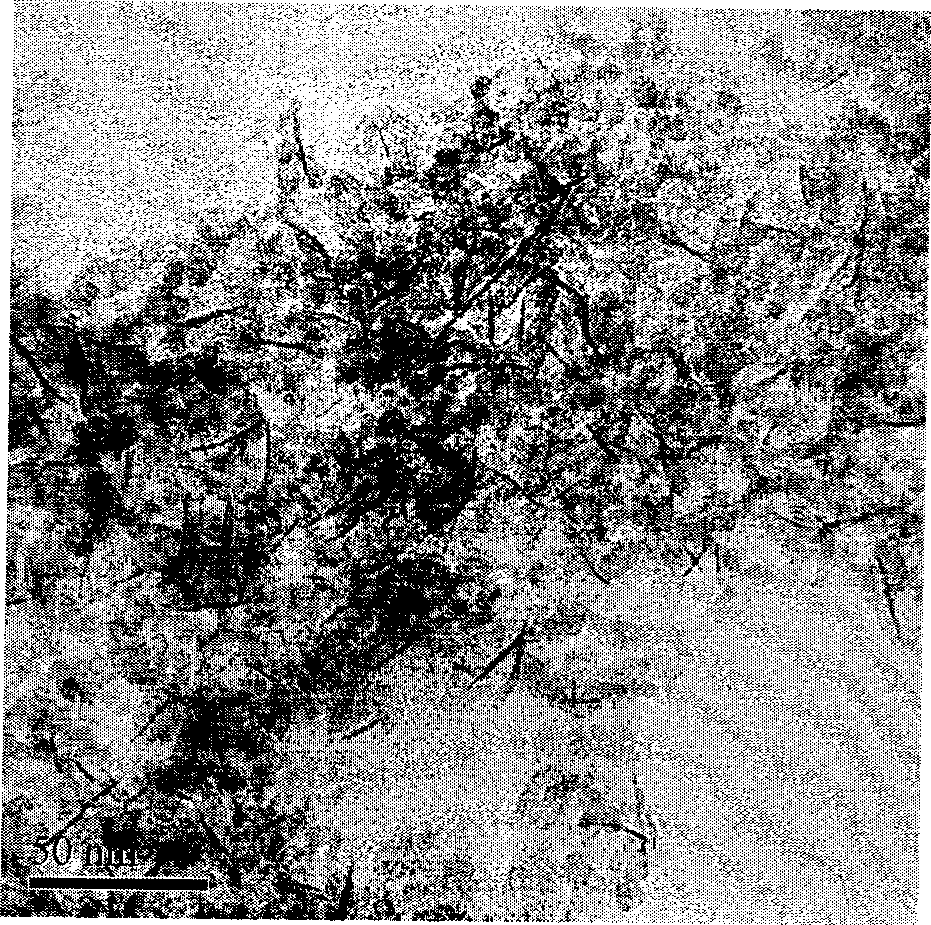

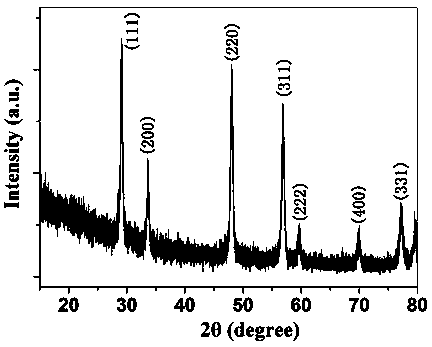

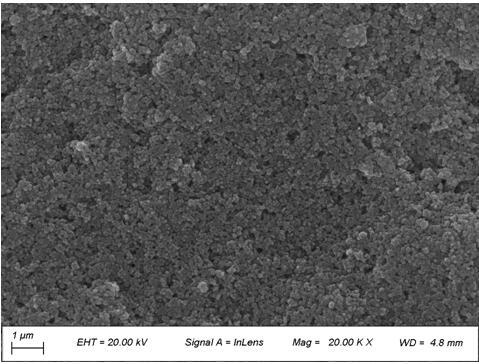

Double-functional perovskite/cerium oxide composite oxygen catalyst of bionic structure

ActiveCN110152677AImprove oxygen adsorption capacityImprove performanceHeterogenous catalyst chemical elementsCatalyst activation/preparationFiberConcentration polarization

The invention provides a double-functional perovskite / cerium oxide composite oxygen catalyst of a bionic structure and a preparation method, that is, CeO2 nanoparticles are grown on the surface of a perovskite nanofiber or nanotube in situ. According to physiological structure characteristics of fish gills, the perovskite nanofiber or nanotube is prepared by using an electrostatic spinning methodto simulate gill filaments in the fish gills. By using a desolvation or soaking method, nano cerium oxide granules are grown on the surface of the perovskite nanofiber or nanotube in situ to simulategill lamellae on the surfaces of the gill filaments. Due to the structure of the oxygen catalyst of the CeO2 nanoparticles grown on the surface of the perovskite nanofiber or nanotube in situ, the "concerted catalysis effect" of a catalyst body and a second phase can be sufficiently brought into play, the transmission velocity of oxygen ions and electrons can be increased, concentration polarization in the oxygen catalysis process can be degraded, and furthermore the activity of the oxygen catalyst can be improved.

Owner:NINGBO UNIV

Co-based nano-catalyst for hydrogen production by ethanol steam reforming and preparation method thereof

InactiveCN101444738AHigh porosityHigh catalytic activityHydrogenMetal/metal-oxides/metal-hydroxide catalystsSteam reformingNano catalyst

The invention discloses a Co-based nano-catalyst for hydrogen production by ethanol steam reforming and a preparation method thereof. The catalyst is made by taking nanoporous silicon dioxide aerogel as a catalyst carrier, a metal elementary substance cobalt nanowire as an active component, and CeO2 nano-particles and ZnO nano-particles as adjuvants. The preparation method comprises the following steps: preparing a sol from silanolate, an alcohol solvent, cobalt nitrate and zinc nitrate, cerous nitrate and an acidic catalyst at certain proportions; forming a wet gel complex, and then performing supercritical fluid drying. The catalyst has strong catalytic activity and selectivity for the hydrogen production by the ethanol steam reforming, has higher hydrogen yield and stronger CO2 selectivity at a lower temperature, limits the selectivity of byproducts CH4 and CO at a lower level, and has good deactivation resistance and stability. Meanwhile, the preparation method has simple process, low cost and certain mechanical strength.

Owner:HUNAN SHANGYIFENG NEW MATERIAL TECH CO LTD

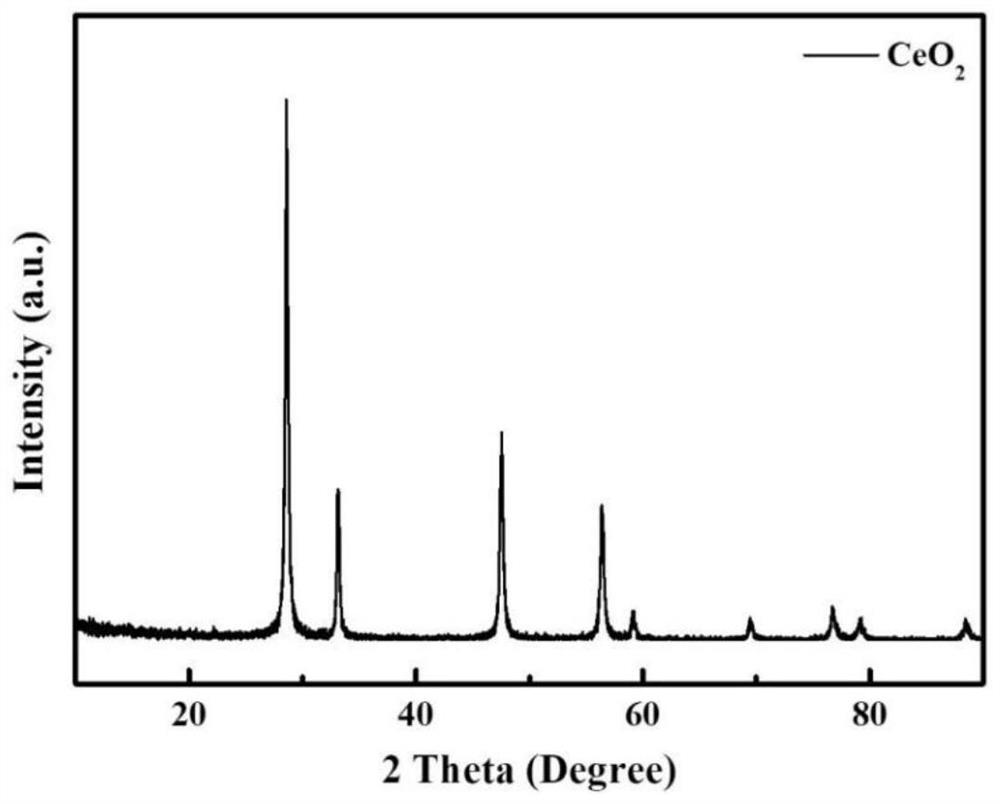

Method for synthesizing CeO2 nano spherical particles by a molten salt method

InactiveCN111099650ASmall dispersionGood chemical stabilityMaterial nanotechnologyCerium oxides/hydroxidesPhysical chemistryCeo2 nanoparticles

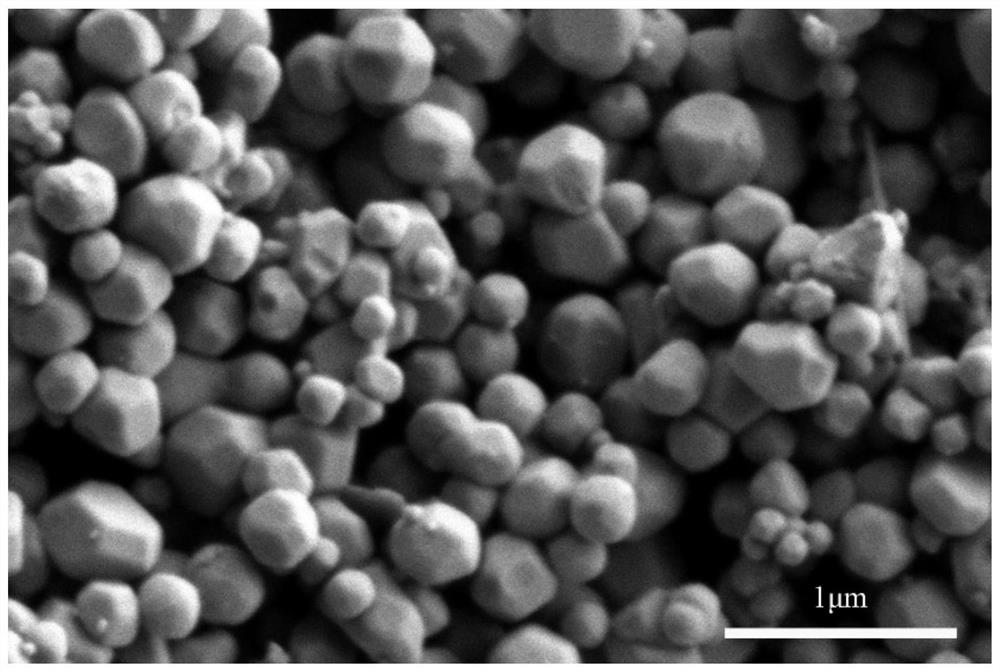

The invention discloses a method for synthesizing CeO2 nano spherical particles by a molten salt method. The preparation method comprises the following steps: firstly, uniformly mixing trivalent cerium salt, KCl and LiCl, roasting at high temperature, dipping and desalting with distilled water, carrying out suction filtration, washing and drying to obtain the product, and the synthesized CeO2 nano-particles are spherical, have the particle size of 100-800nm, and are uniform in size and good in dispersity; the method disclosed by the invention has the characteristics of low cost, simple process, environmental friendliness, short consumed time, low energy consumption and strong controllability; the prepared product has good chemical stability and uniform morphology, the application of the CeO2 nanoparticles in the fields of electricity and catalysis is widened, and the method has a wide market application prospect.

Owner:JIANGSU UNIV OF TECH

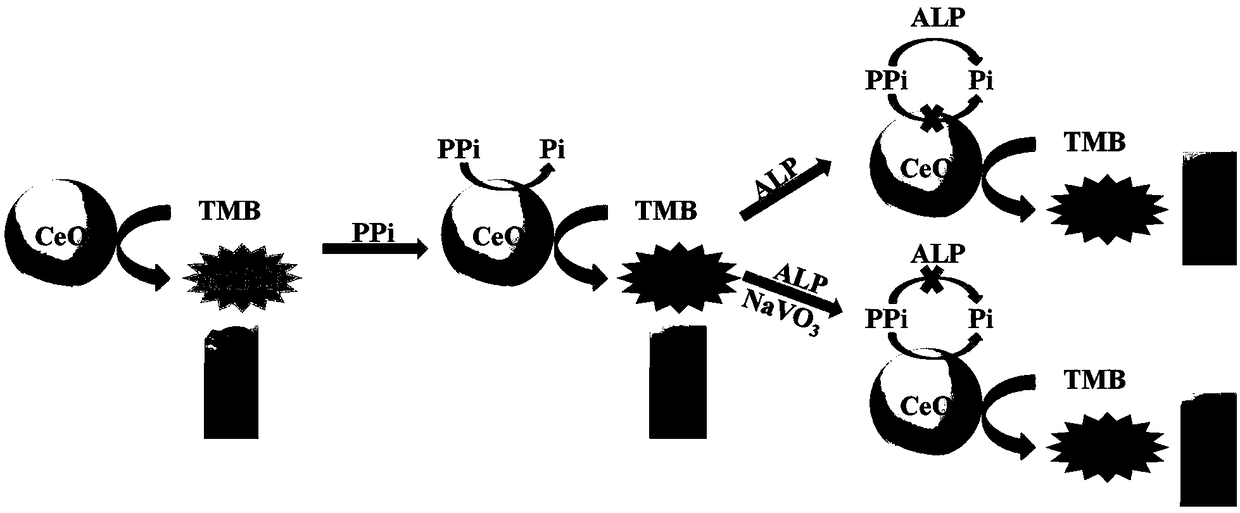

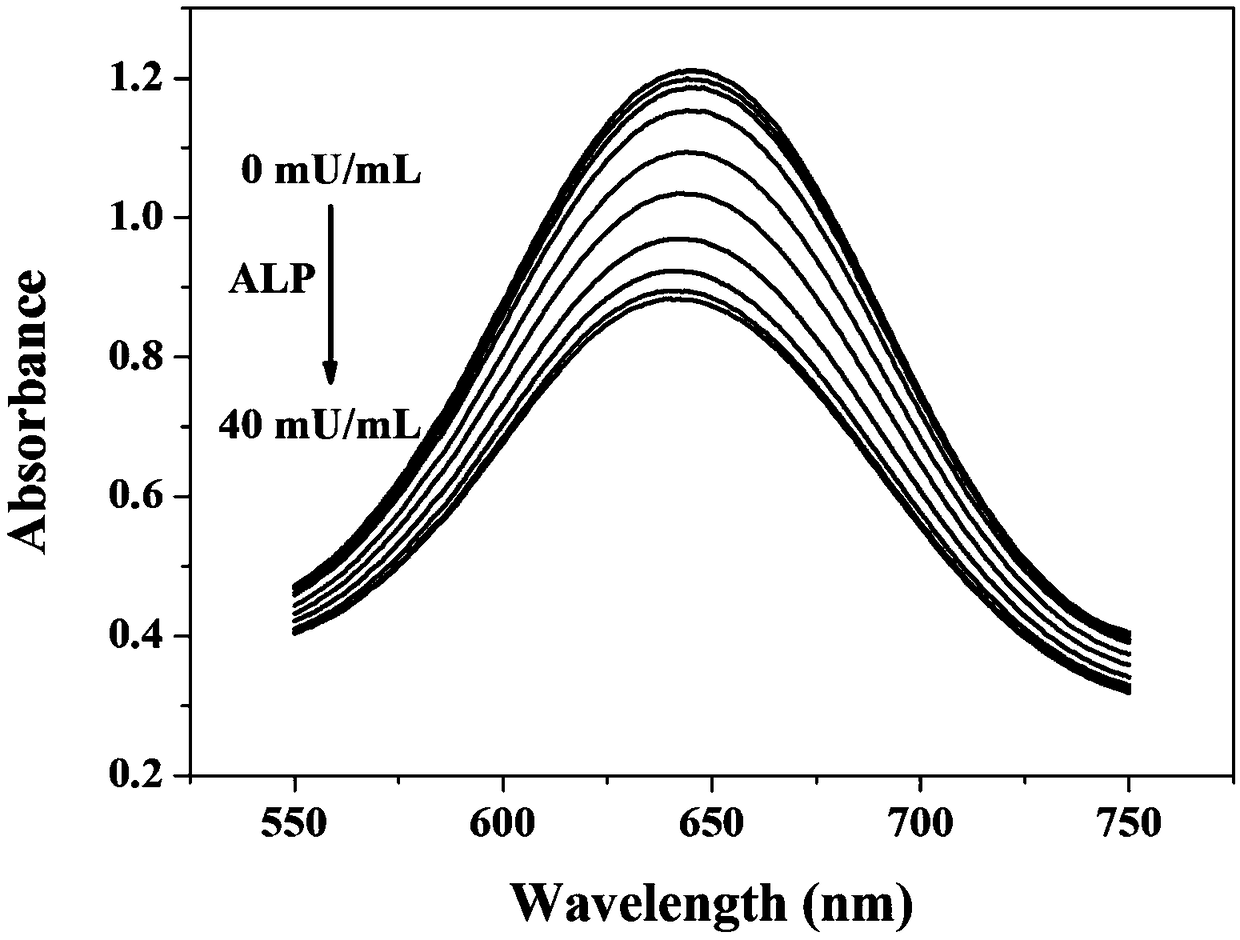

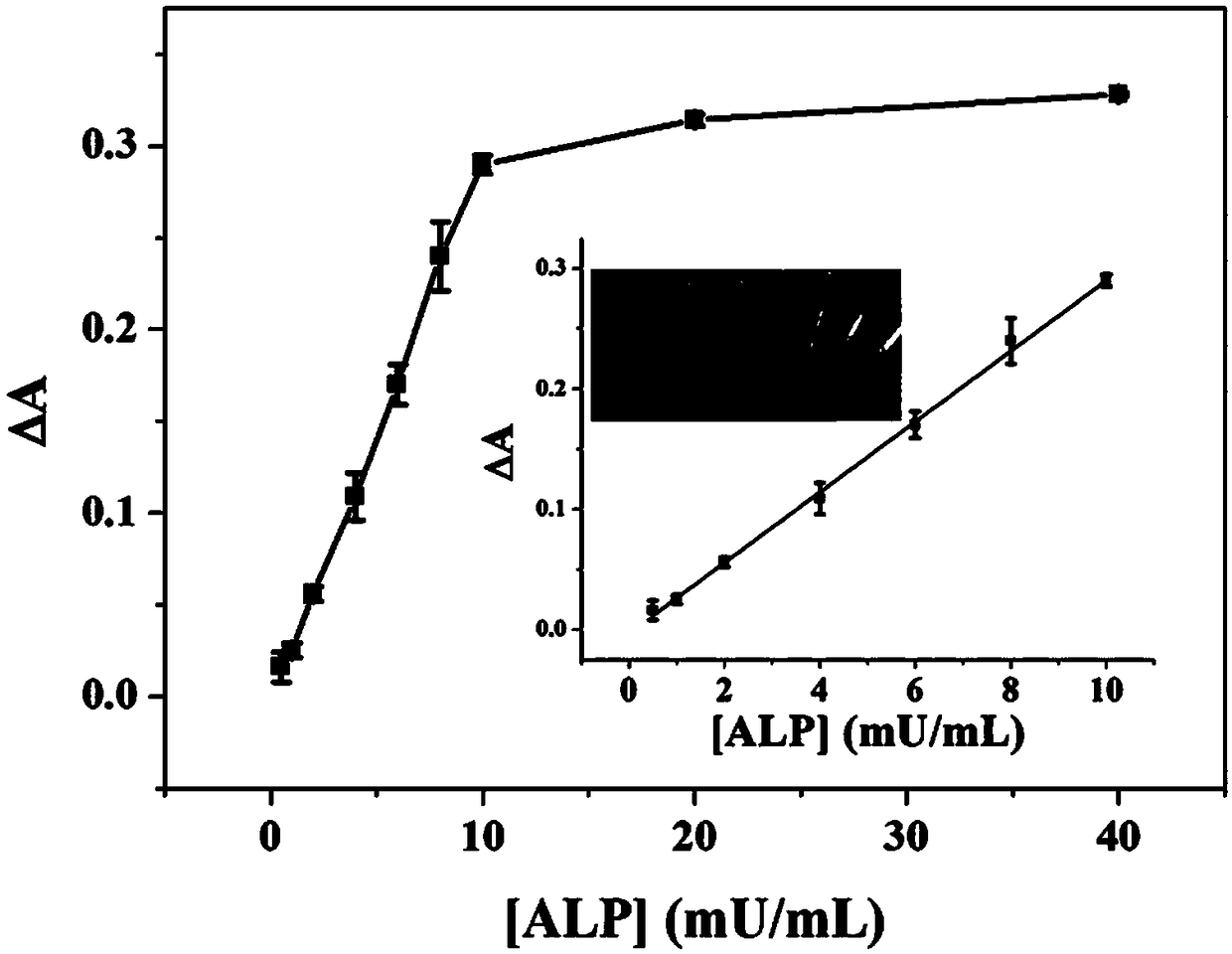

Method for detecting alkaline phosphatase activities and concentration of phosphatase inhibitors

ActiveCN108896506AGood dispersionShort detection timeColor/spectral properties measurementsCeo2 nanoparticlesPyrophosphate

The invention provides a method for detecting alkaline phosphatase activities. The method comprises the following steps: A1) uniformly mixing tri(hydroxymethyl) aminomethane and pyrophosphate, and then dividing into a plurality of reaction systems, respectively adding alkaline phosphatase with different concentrations into all the reaction systems, incubating at 37 DEG C, adding an acetate buffersolution, CeO2 nanoparticles and 3,3',5,5'-tetramethyl benzidine into each reaction system in turn, incubating at 22-47 DEG C, and then respectively measuring ultraviolet-visible absorption spectrum,thus obtaining a relation equation between alkaline phosphatase activities and Delta A; A2) measuring the ultraviolet-visible absorption spectrum for the to-be-detected alkaline phosphatase accordingto the operation in the step A1, thereby acquiring Delta A, substituting the Delta A into the relation equation of alkaline phosphatase activities and Delta A acquired in the step A1, and calculatingthe activities of the to-be-detected alkaline phosphatase. The method has the beneficial effects: 1) the CeO2 nanoparticles utilized by the invention are excellently dispersed in an aqueous solution and 2) the method provided by the invention is short in detecting time.

Owner:UNIV OF JINAN

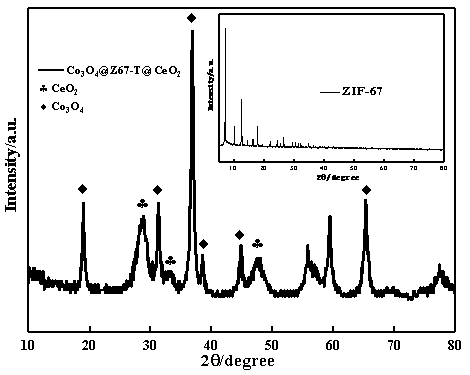

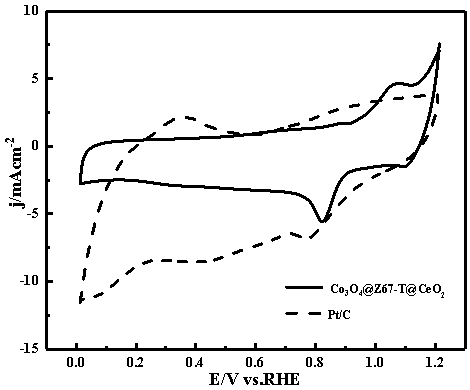

Preparation method of ZIF-67 carbide-loaded nano CeO2 oxygen reduction catalyst

The invention provides a preparation method of a ZIF-67 carbide-loaded nano CeO2 oxygen reduction catalyst; the catalyst is used as an oxygen reduction reaction (ORR) catalyst of a fuel cell cathode.A common platinum-based ORR catalyst has the defects of high cost, poor stability and the like, so that it is necessary to develop the non-noble metal catalyst with relatively high ORR catalytic activity, excellent anti-poisoning performance and high stability. In recent years, metal organic framework derived materials have become one of hotspots in the field of electrocatalysis, and in order to obtain higher ORR electrocatalytic activity, the conductivity can be enhanced, the active sites can be increased, or certain synergistic effects can be generated by modifying derivative materials, so that the better ORR catalytic performance can be obtained. According to the method, ZIF-67 carbide (Co3O4@Z67-T) prepared at different carbonization temperatures and CeO2 nanoparticles are compounded to obtain a Co3O4@Z67-T@CeO2 nano electrocatalyst with a core-shell structure, wherein the electrolyte shows excellent electrocatalytic performance; and the Co3O4@Z67-T@CeO2 catalyst has the potentialof the ORR catalyst being practically applied to the fuel cell cathode.

Owner:HEILONGJIANG UNIV

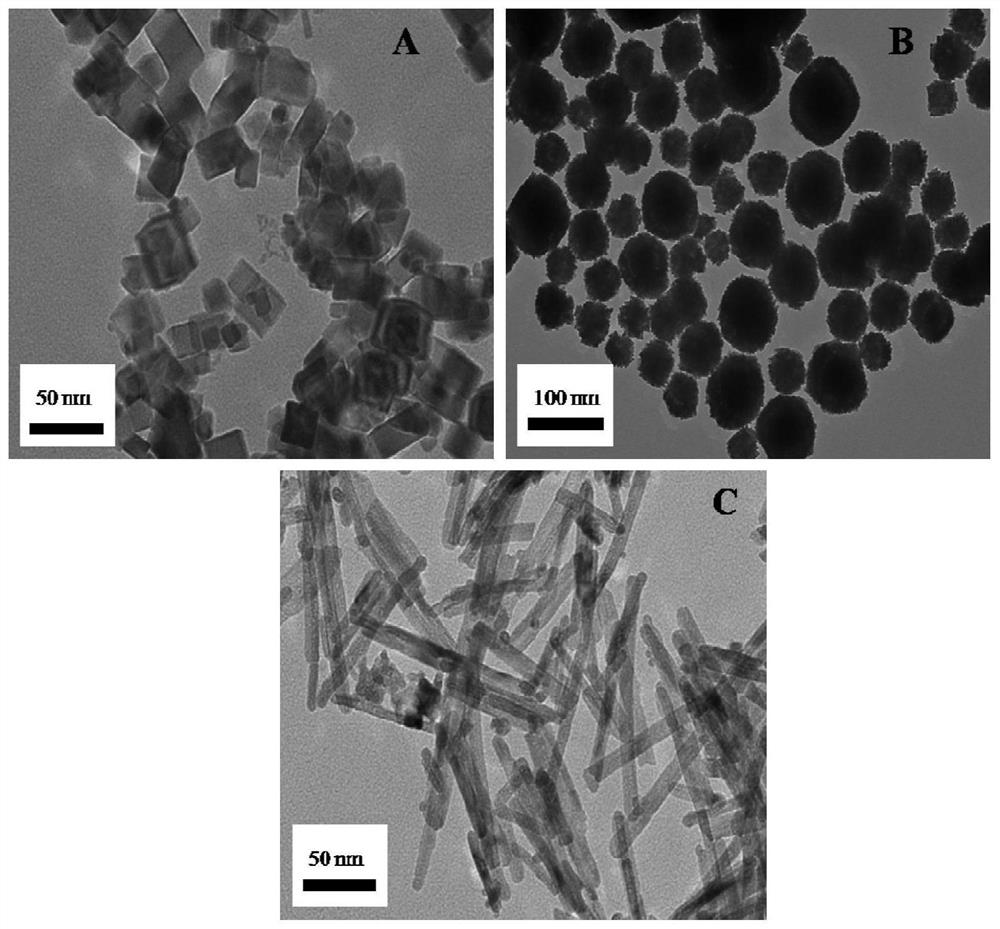

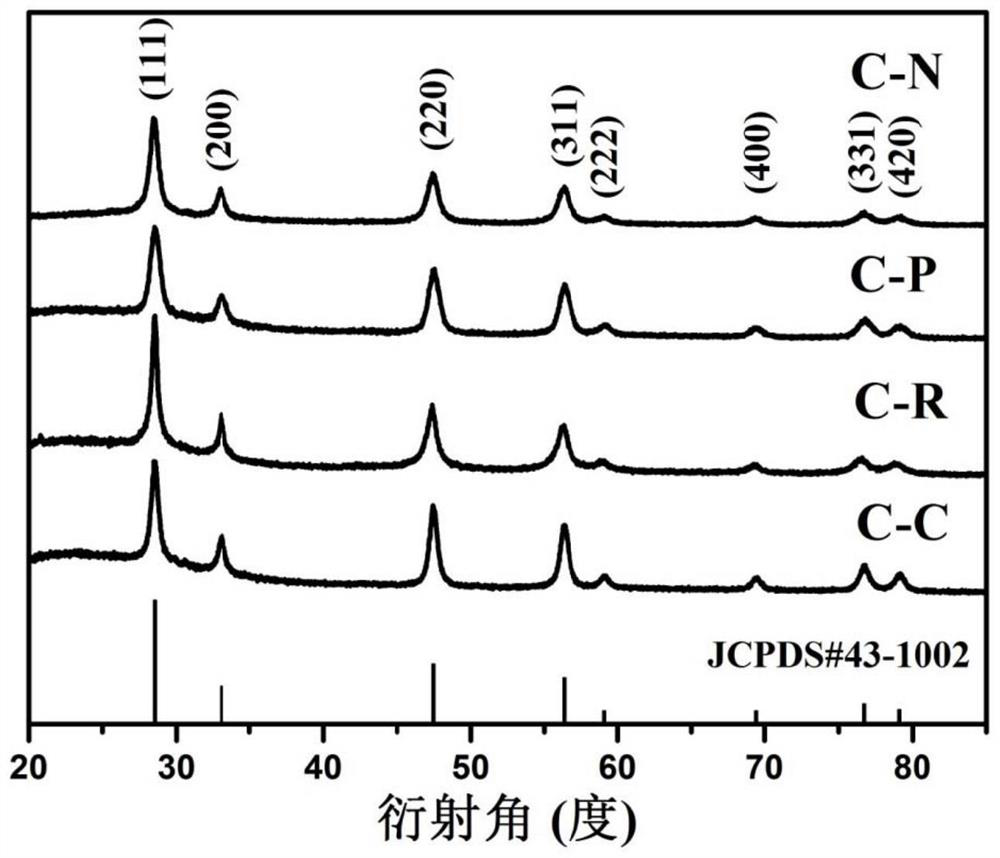

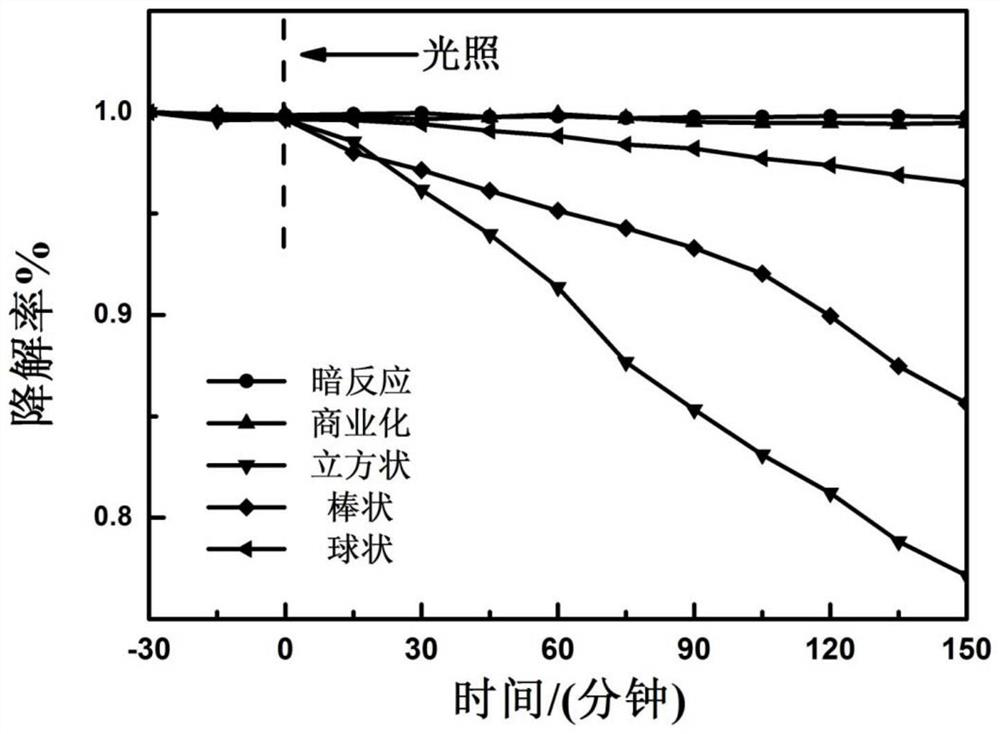

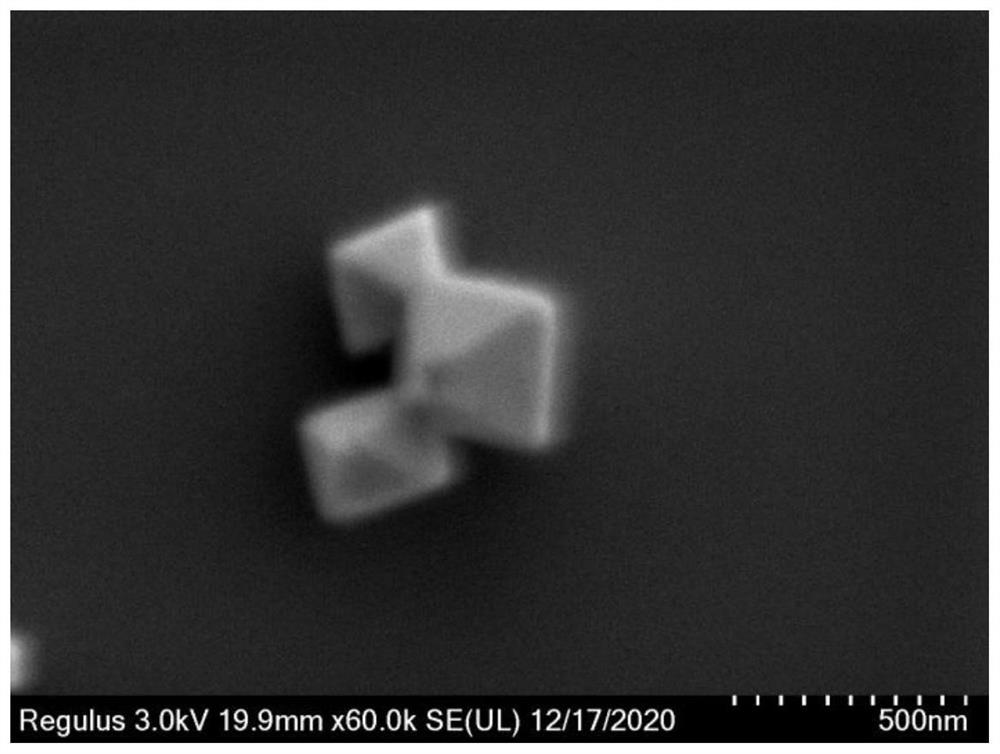

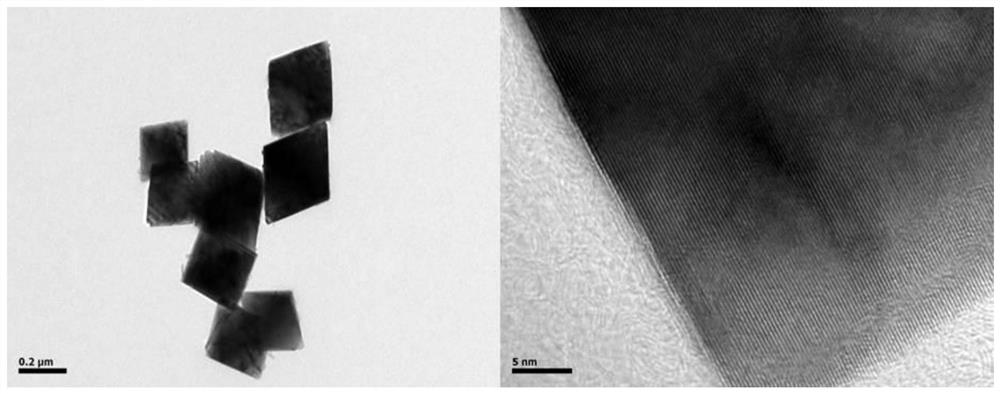

Preparation of cerium dioxide photocatalyst with exposed high-energy crystal face

InactiveCN112169785AImprove photocatalytic activityWater/sewage treatment by irradiationWater treatment compoundsPtru catalystCerium(IV) oxide

The invention relates to a preparation method of a cerium dioxide photocatalyst with an exposed high-energy crystal face. According to the invention, the CeO2 nano material with exposed different morphologies and crystal faces, such as nano spheres, nano cubes and nano rods, is prepared by controlling reaction conditions through a simple hydrothermal synthesis method. The preparation process of CeO2 comprises the following steps: respectively dissolving a proper amount of cerium salt and strong alkalis with different concentrations into distilled water to prepare solutions, adding a proper amount of surfactant into the system, stirring the mixture at normal temperature, transferring the mixed solution into a hydrothermal kettle for reaction, and controlling the reaction temperature to obtain products with different morphologies. The method is simple to operate, wherein the morphology and high-energy crystal face composition of the CeO2 nanoparticles can be well regulated and controlledby changing approximate preparation conditions. The method has important significance in application of related catalytic materials.

Owner:BEIJING UNIV OF CHEM TECH

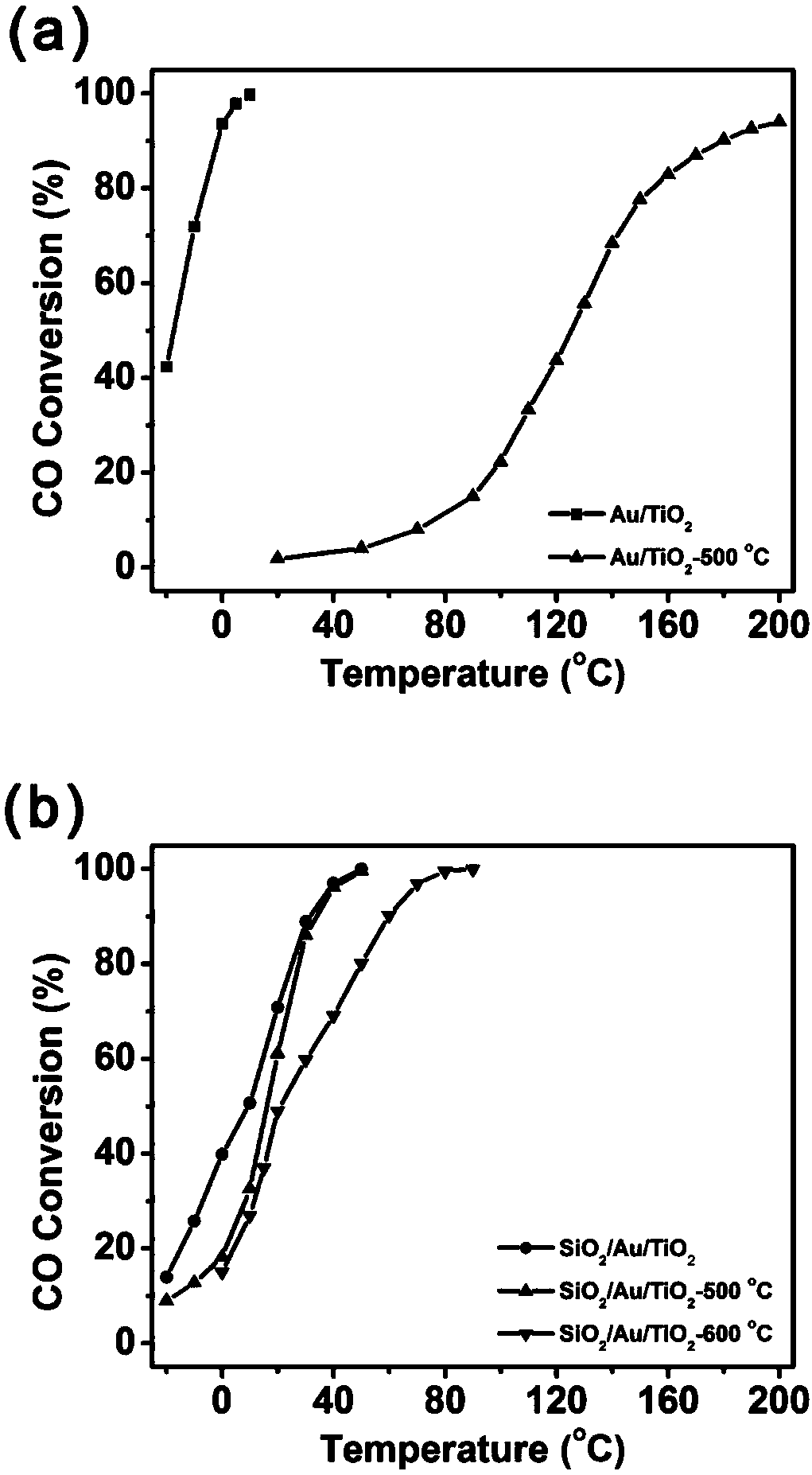

High temperature sintering resistive loading type noble metal catalyst for catalytic oxidation of carbon monoxide and preparation method thereof

InactiveCN108452798AReduce the impactSimple methodDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsActive componentCatalytic oxidation

The invention relates to a high temperature sintering resistive loading type noble metal catalyst for catalytic oxidation for carbon monoxide and a preparation method thereof. The catalyst comprises acarrier, active components and a cladding shell layer, wherein the carrier is TiO2 or CeO2 nanoparticles; the active components are noble metals Au, Pt or Pd nanoparticles; the active components areloaded on the surface of the carrier; the cladding shell layer which is SiO2 shell layer and clads the surfaces of the carrier nanoparticles and the noble nanoparticles of the active components. The method is simple; the condition is mild; the period is short; massive synthesizing can be carried out; and the environment is influenced a little.

Owner:EAST CHINA UNIV OF SCI & TECH

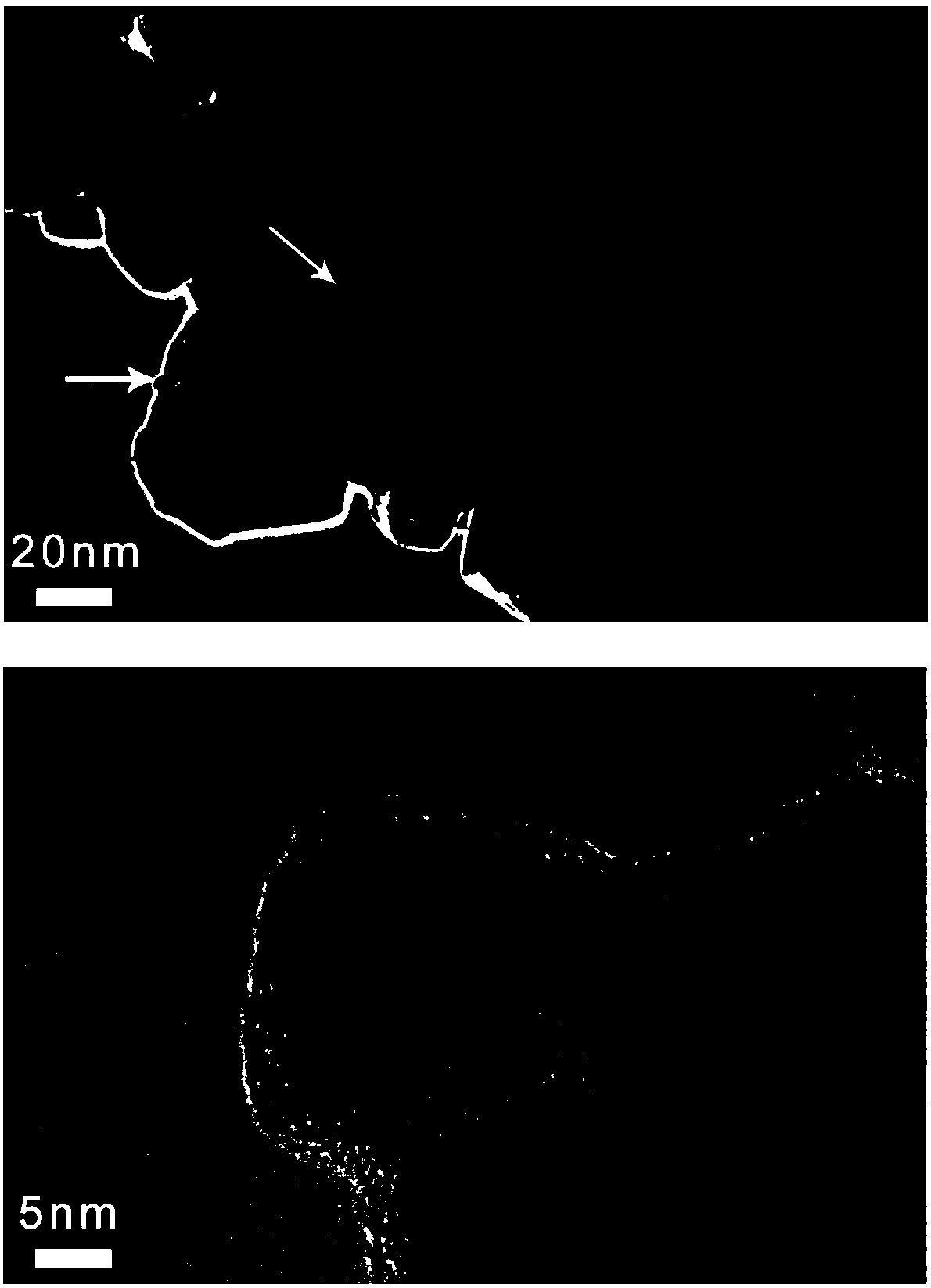

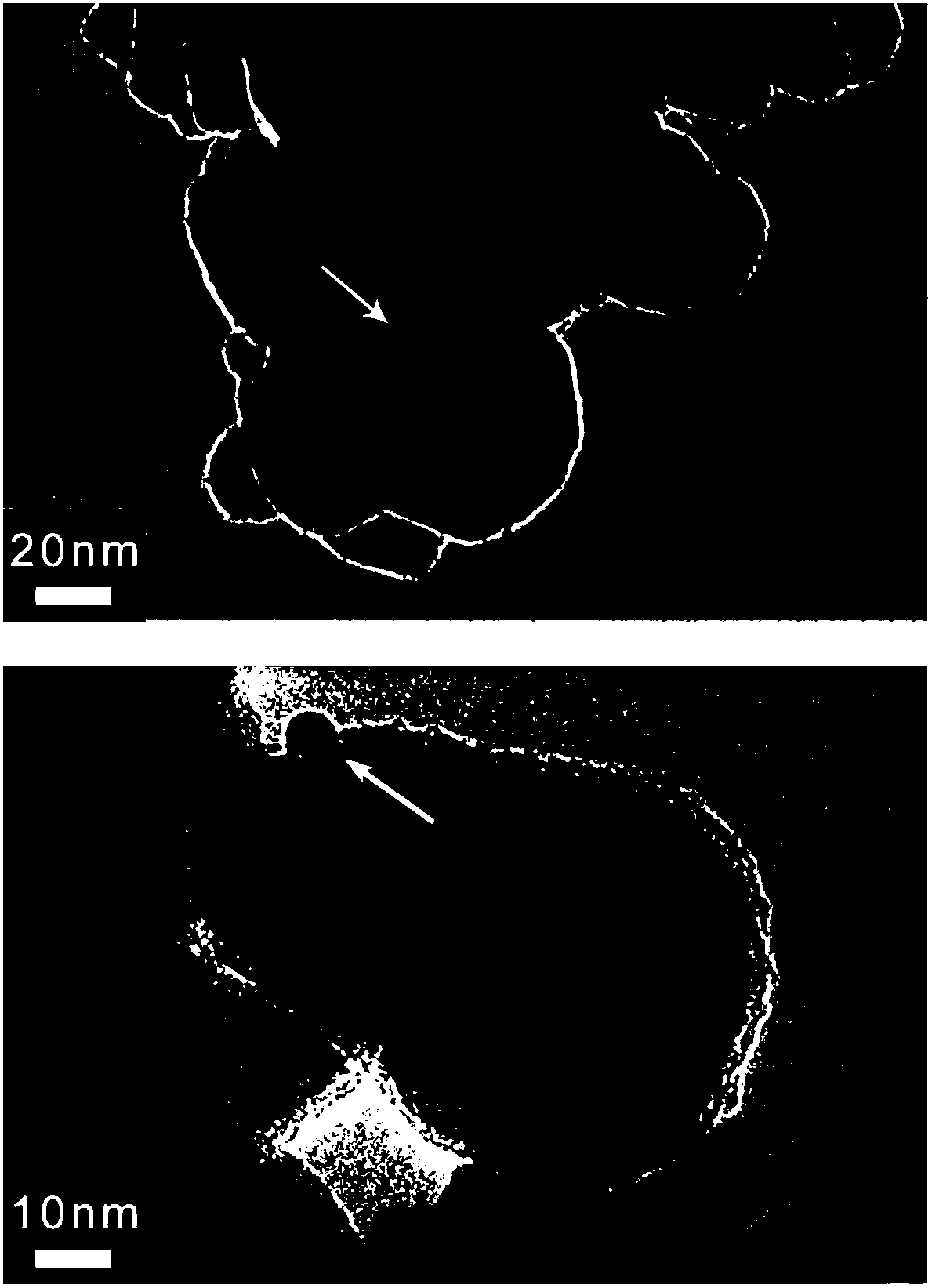

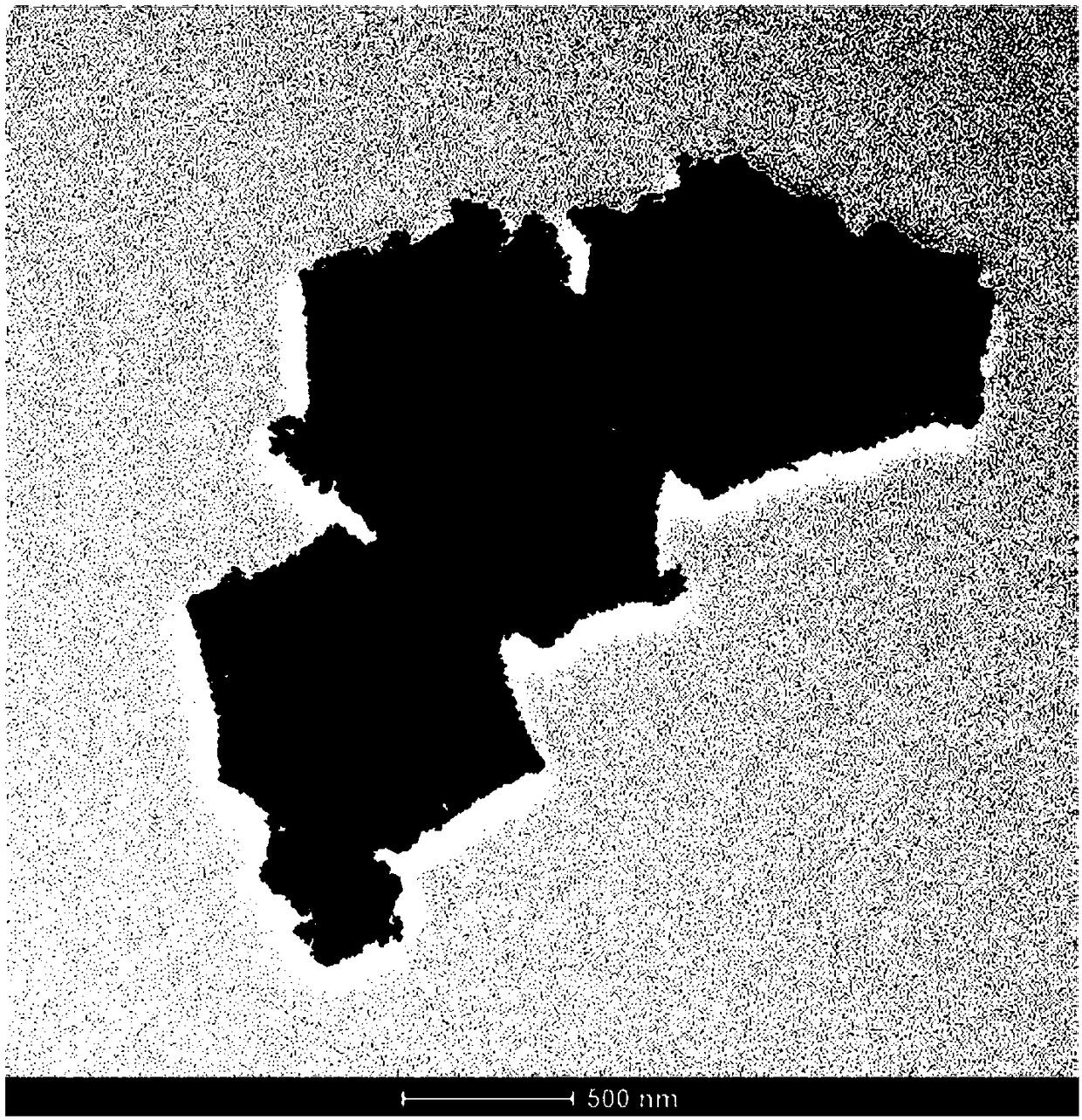

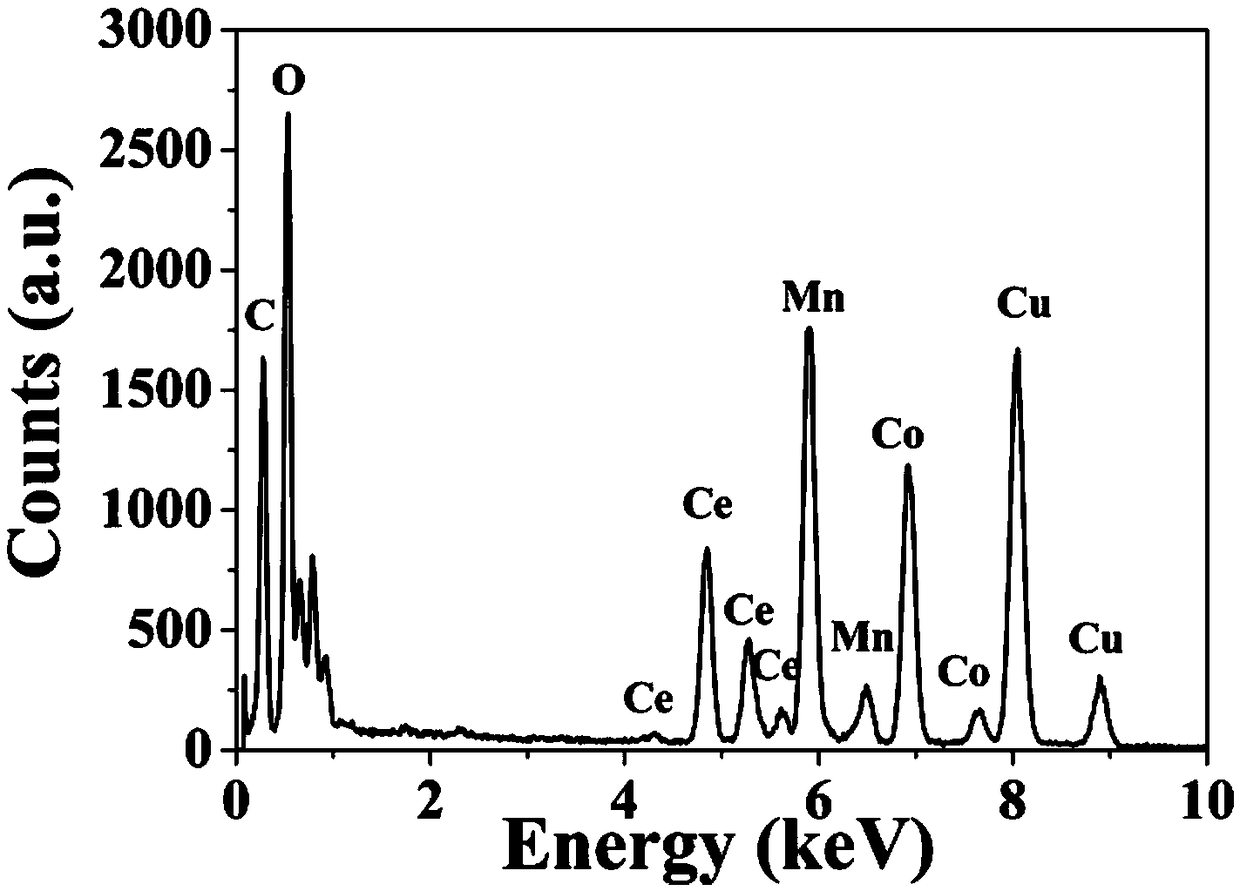

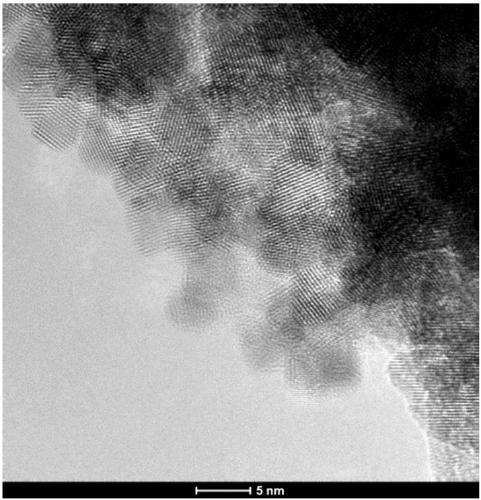

Polyhedral hollow core-shell structure MxM'3-xO4@CeO2 composite material and preparation method thereof

ActiveCN109289856AEvenly dispersedEasy to prepareCarbon compoundsHeterogenous catalyst chemical elementsCatalytic oxidationCerium

The invention discloses a polyhedral hollow core-shell structure MxM'3-xO4@CeO2 composite material and a preparation method thereof. The method comprises the following steps: firstly, selecting a suitable metal salt and an organic ligand to synthesize an MM'-MOFs polyhedral structural material having different transition metal element composition ratios and spatial distributions in a solvent system; secondly, conducting heating treatment on MM'-MOFs at a specific heating rate and reaction temperature, synthesizing an MxM'3-xO4 polyhedral hollow structure material with porous distribution basedon an unbalanced heat shrinkage mechanism; and finally, selecting a suitable cerium salt, deposition agent and mixed solvent system, uniformly coating the surface of the MxM'3-xO4 polyhedral hollow structure with CeO2 nanoparticles with adjustable shell thickness, and synthesizing an MxM'3-xO4@CeO2 core-shell polyhedral structure. The method of the invention has the advantages of a simple process, mild condition, and high yield; and the composite material has a controllable structure, so that the composition, proportion and spatial distribution of M:M' can be regulated according to actual needs, and the thickness of the CeO2 shell layer can be easily regulated; the obtained composite material has a rich pore structure, a high specific surface area and high catalytic oxidation activity.

Owner:CHINA UNIV OF MINING & TECH

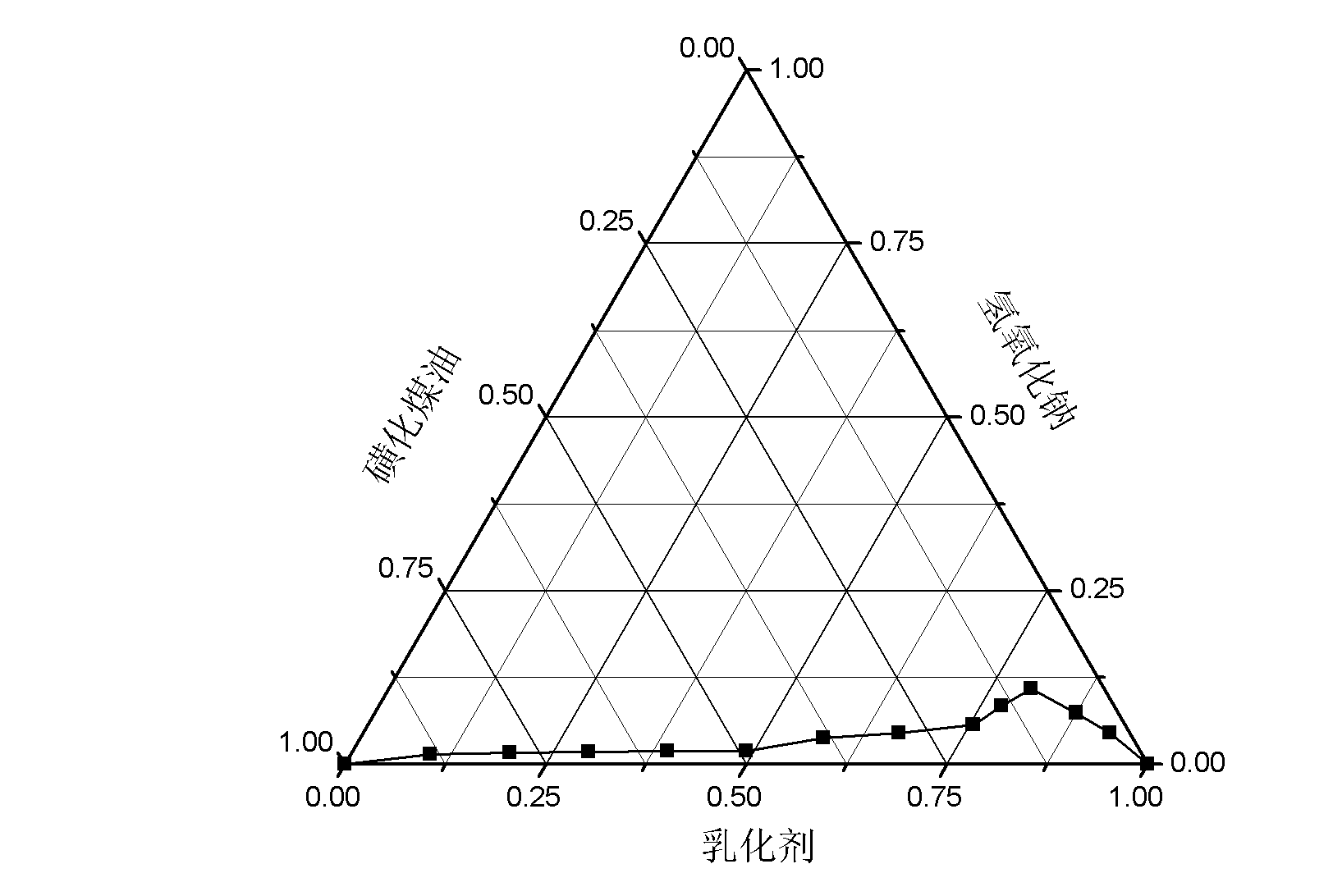

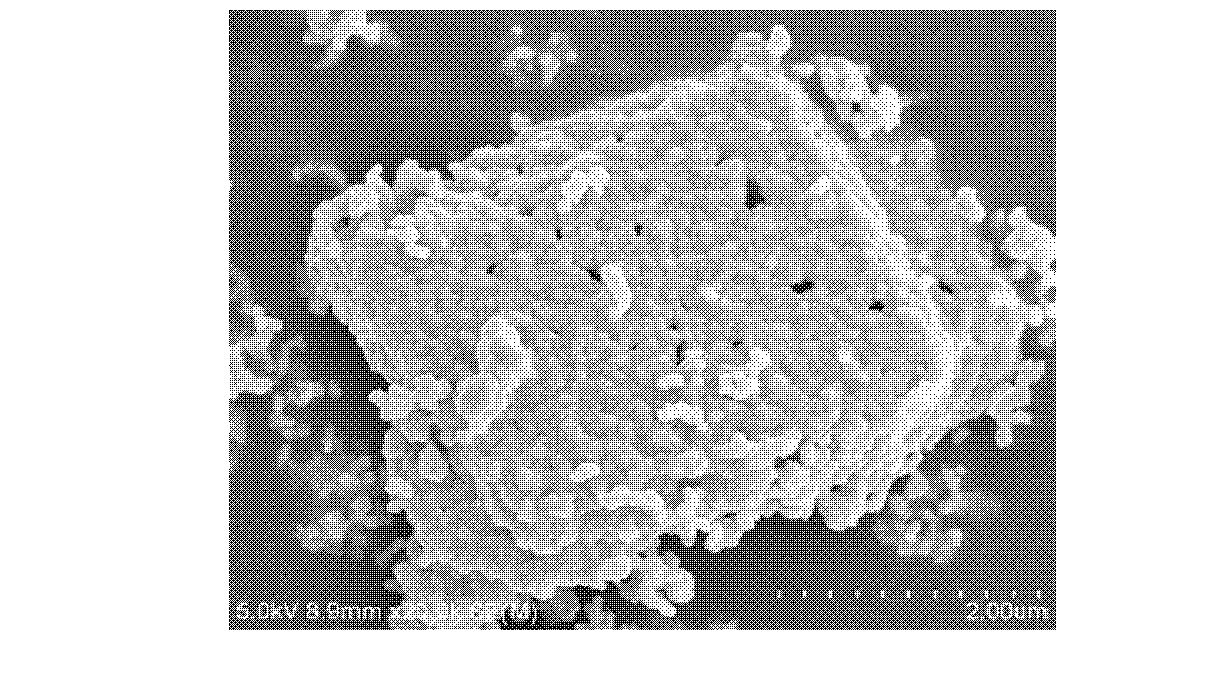

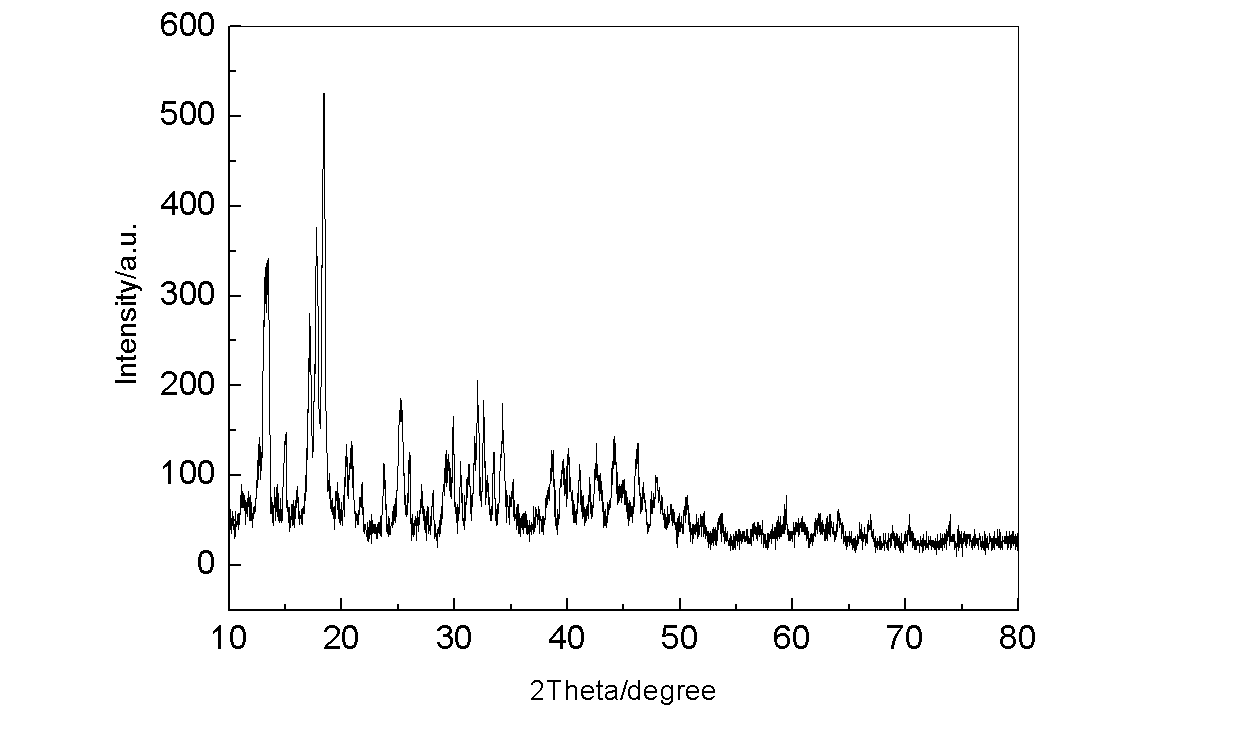

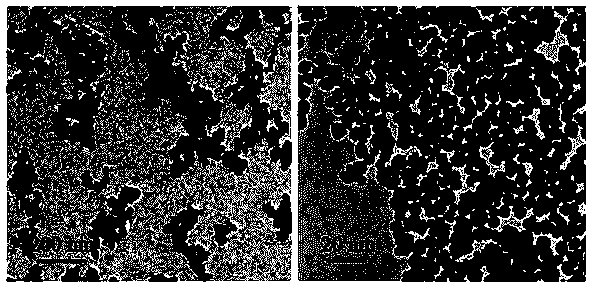

Method for preparing CeO2 nanoparticles from W/O type microemulsion

ActiveCN102515241AUniform particle size distributionNanotechnologyRare earth metal compoundsKeroseneCerium

The invention which relates to a method for preparing CeO2 nanoparticles from a W / O type microemulsion belongs to the nanomaterial preparation field. The method comprises the following steps: 1, determining a microemulsion region which comprises a surfactant 2-ethylhexyl phosphonic acid mono-2-ethylhexyl ester (hereinafter referred to as P507), an oil phase sulfonated kerosene, an organic solvent n-heptane and a water phase sodium hydroxide solution, wherein an emulsifier comprises the surfactant P507 and the organic solvent n-heptane, and the range of the mass ratio of the emulsifier to the sulfonated kerosene to NaOH in the sodium hydroxide solution is 9.85-93.08:2.39-88.67:1.48-10.85; 2, adding a Ce salt solution to the microemulsion region under stirring to obtain a loaded organic phase; 3, adding a precipitant oxalic acid solution to the loaded organic phase to obtain a predecessor; and 4, roasting the predecessor at 250-750DEG C for 1.5-6.5h to obtain the spherical CeO2 nanoparticles with the powder morphology of 10-20nm. The CeO2 nanoparticles prepared in the invention have the advantages of no obvious particle agglomeration and uniform particle size distribution.

Owner:BEIJING UNIV OF TECH

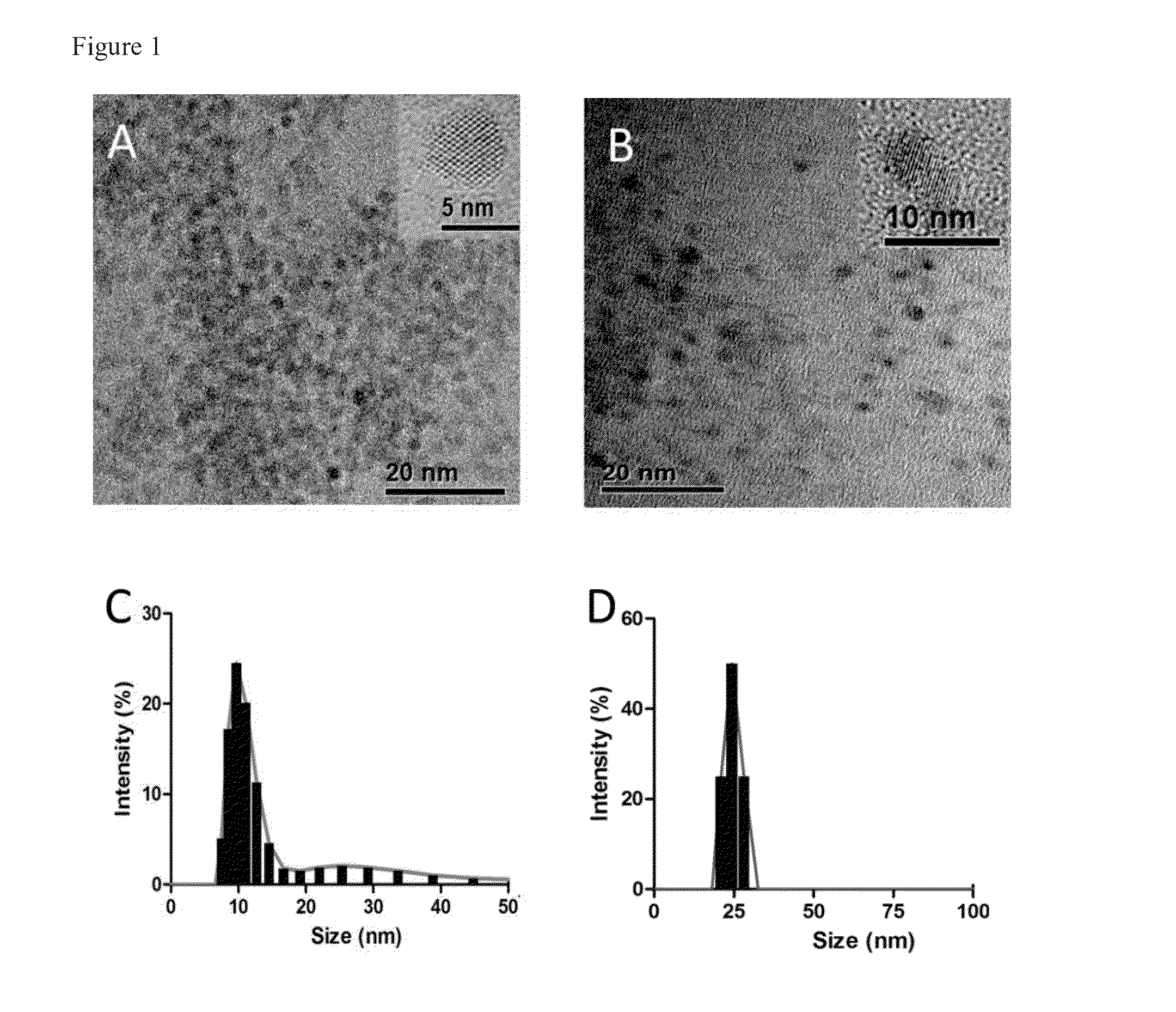

Novel rare earth nano bimodal developer, preparation method thereof and application thereof

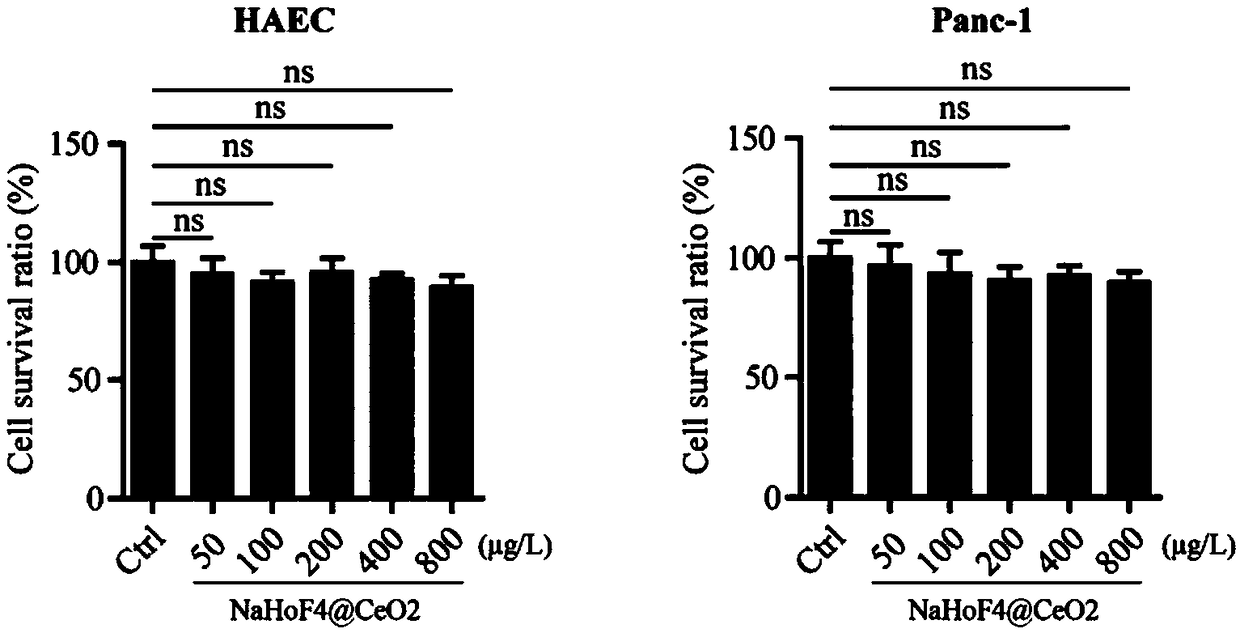

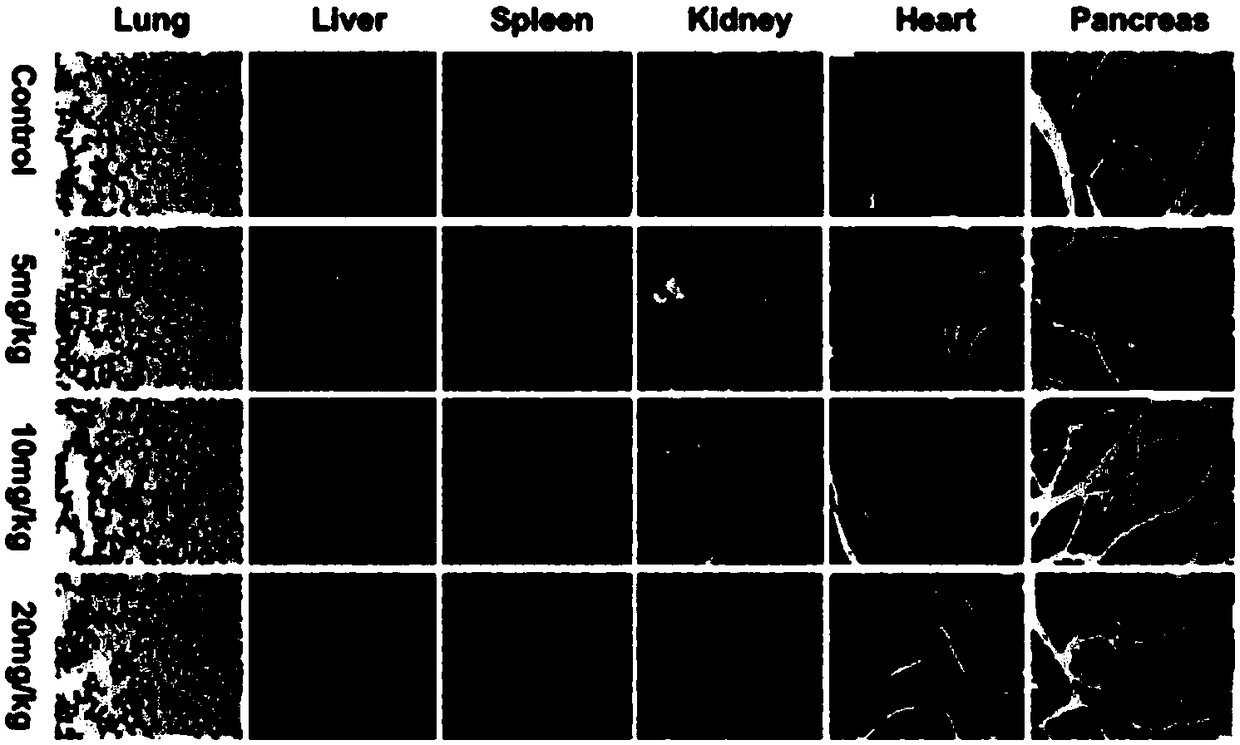

ActiveCN109172828ALarge atomic numberEasy accessInorganic active ingredientsGeneral/multifunctional contrast agentsImaging agentPancreatic cancer cell

The invention discloses a novel rare earth nanometer bimodal developer, and a preparation method thereof and an application thereof. The novel rare earth nanometer bimodal developer is NaHoF4@CeO2 nanoparticles, and the preparation of the developer comprises the following steps: 1) preparation of NaHoF4 nanoparticles, 2) preparation of CeO2 nanoparticles, 3) adding nanometer CeO2 into NaHoF4 to obtain NaHoF4@CeO2 nanometer particles, the imaging agent is used in CT and MRI bimodal imaging. Physical and chemical characterization and toxicity test showed that the nanoparticles had good biological safety. In vitro experiment showed that the nanoparticles had good CT and MRI bimodal imaging effect, and had radiotherapy sensitization effect on pancreatic cancer cells.

Owner:汪建华

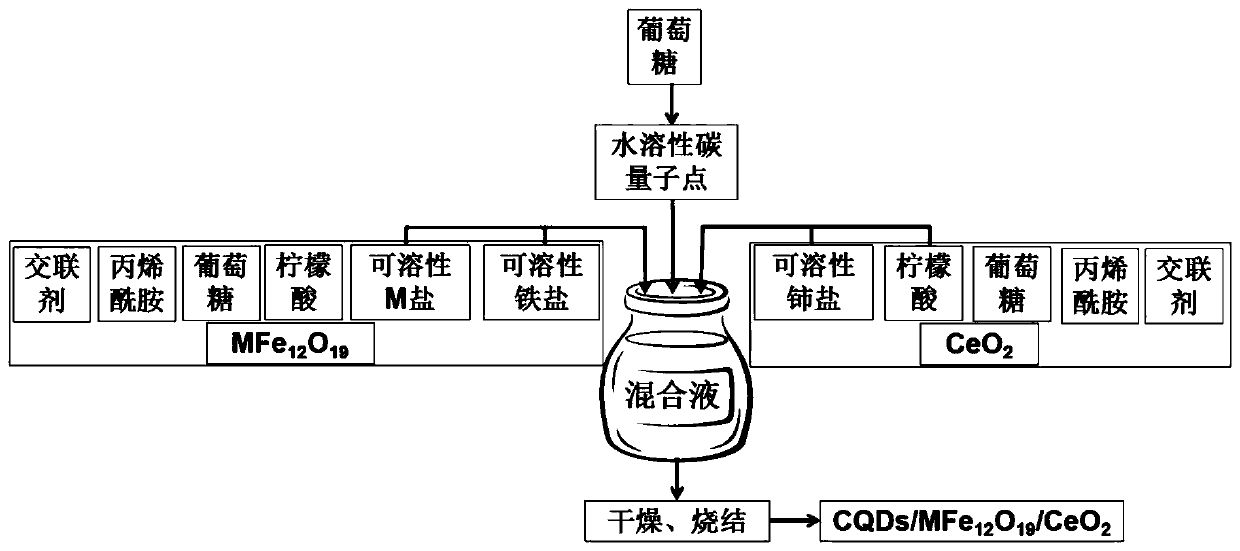

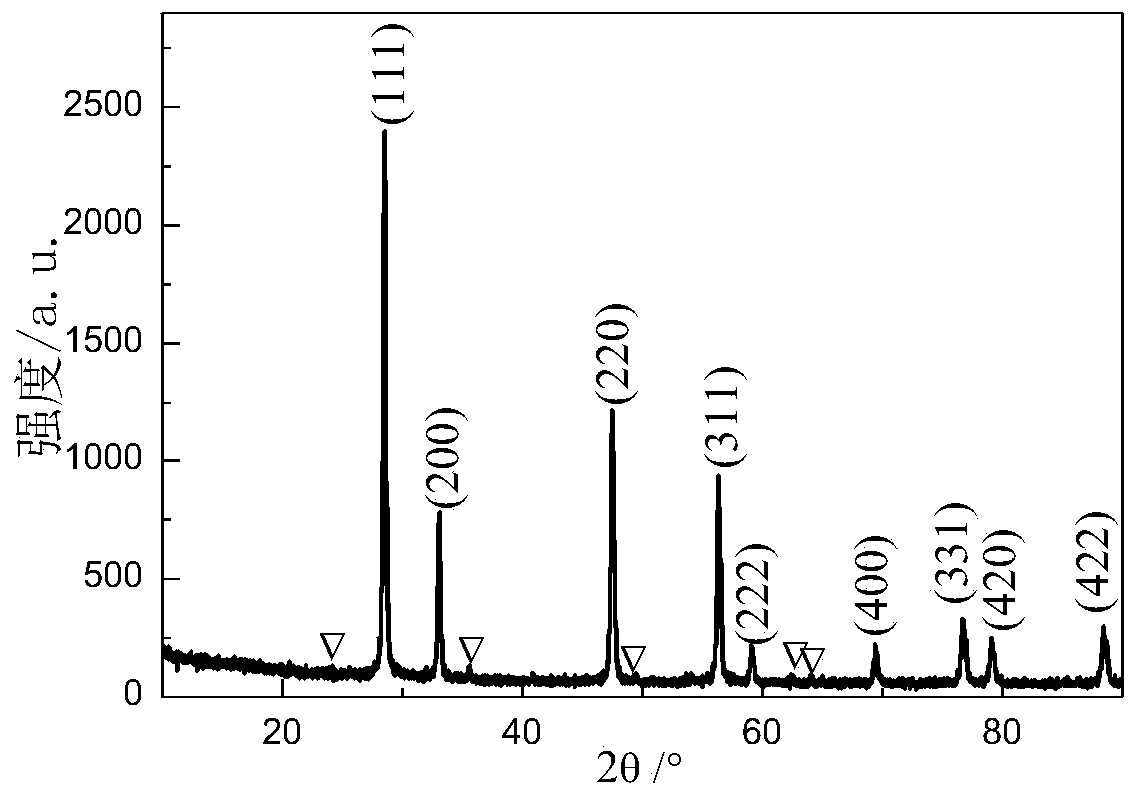

Preparation method of carbon quantum dot modified n-n type MFe12O19/CeO2 magnetic separation photocatalyst

ActiveCN111151258AImprove photocatalytic effectVarious ways of aggregationWater/sewage treatment by irradiationWater treatment compoundsAlcoholCeo2 nanoparticles

The invention discloses a preparation method of a carbon quantum dot modified n-n type MFe12O19 / CeO2 magnetic separation photocatalyst, wherein the preparation method comprises the steps: by using glucose as a raw material, synthesizing carbon quantum dots in a reaction kettle; using M metal salt, ferric salt or cerium salt as a raw material, adding a chelating agent, an anti-gel collapse agent, acrylamide and a cross-linking agent step by step, and polymerizing acrylamide and the cross-linking agent under the action of a field, to form gel; carrying out drying, sintering and other processes on the gel to synthesize MFe12O19 or CeO2 nanoparticles; ultrasonically stirring a proper amount of carbon quantum dots, MFe12O19 and CeO2 nanoparticles in an alcohol solution, pouring out supernatantliquid, drying, transferring into a box-type furnace, sintering, and adjusting the ratio of the carbon quantum dots, MFe12O19 and CeO2 nanoparticles, to obtain the n-n type MFe12O19 / CeO2 magnetic separation photocatalyst modified by the carbon quantum dots and having controllable photocatalytic activity. The photocatalyst is low in cost and easy to synthesize, and overcomes the defects that a traditional photocatalyst is low in charge separation efficiency and difficult to recycle.

Owner:CHONGQING THREE GORGES UNIV

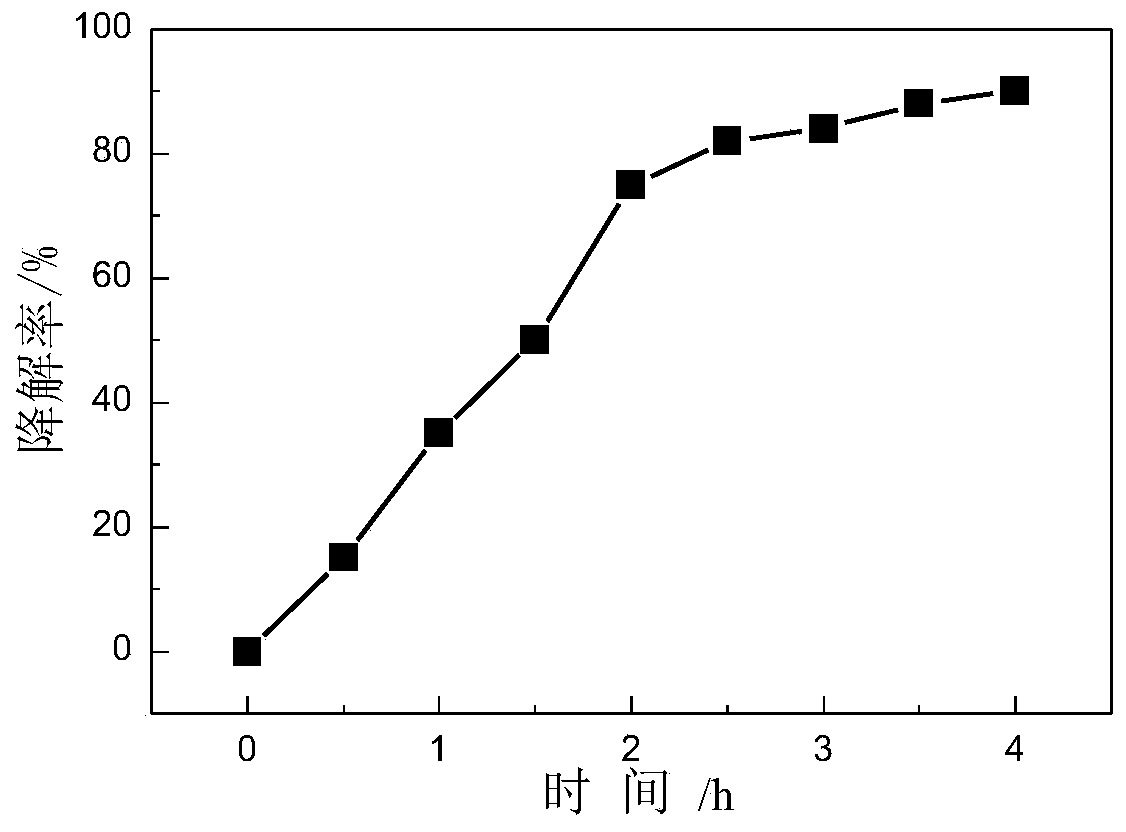

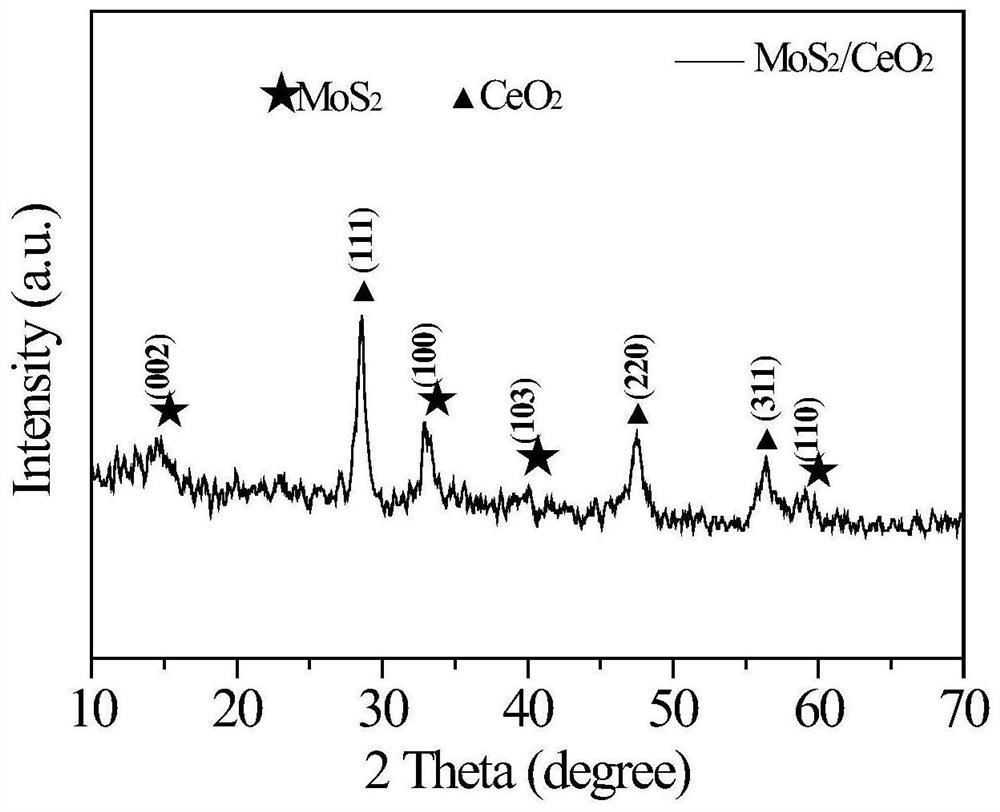

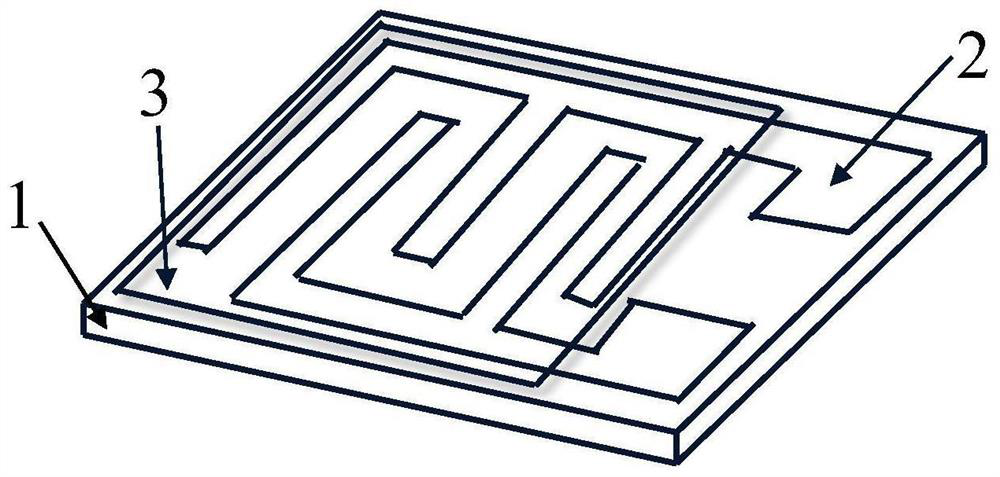

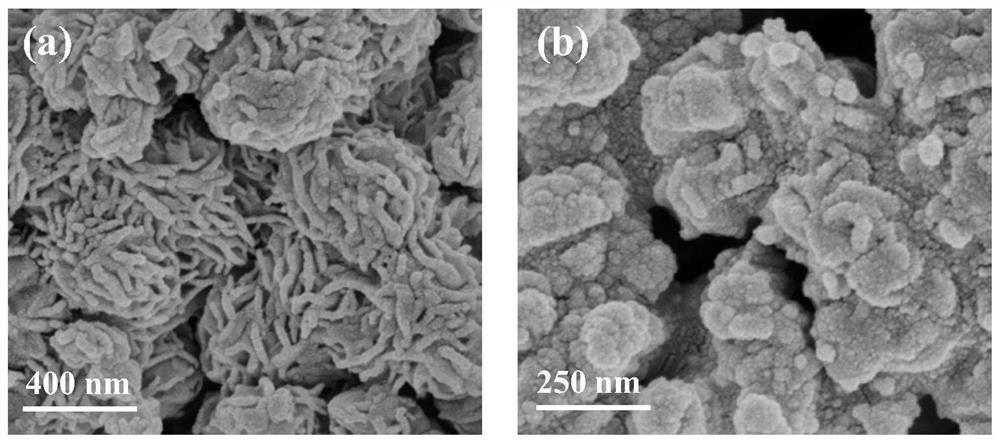

MoS2/CeO2 composite gas-sensitive material as well as preparation method and application thereof

The invention relates to the technical field of semiconductor oxide gas-sensitive materials, in particular to a MoS2 / CeO2 composite gas-sensitive material as well as a preparation method and application thereof. According to the preparation method disclosed by the invention, the MoS2 nanoflower which is modified with CeO2 nanoparticles, has a large specific surface area and consists of a plurality of wormlike micelles is prepared by adopting a secondary hydrothermal method; a MoS2 / CeO2 gas-sensitive coating is prepared on an interdigital electrode after carrying out heat treatment on a MoS2 / CeO2 composite material through a tubular furnace, and finally heat treatment on is performed the MoS2 / CeO2 gas-sensitive coating through an aging table to obtain the ethanol gas-sensitive element based on MoS2 / CeO2. The maximum sensitivity of the gas sensitive element to 30 ppm ethanol gas at room temperature is 5.2, the response time and the recovery time are 7 s and 5 s respectively, the reversibility and the selectivity are good, the response / recovery speed is high, the simple and low-cost preparation method of secondary hydrothermal is adopted, CeO2 nanoparticles are successfully and tightly attached to MoS2 nanoflowers, and the preparation cost of the functional MoS2 / CeO2 nano material is greatly reduced.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Industrial preparation method of non-oxidative cerium oxide nanoparticles

InactiveCN101948127AAvoid it happening againHigh crystallinityRare earth metal compoundsSol-gelCeo2 nanoparticles

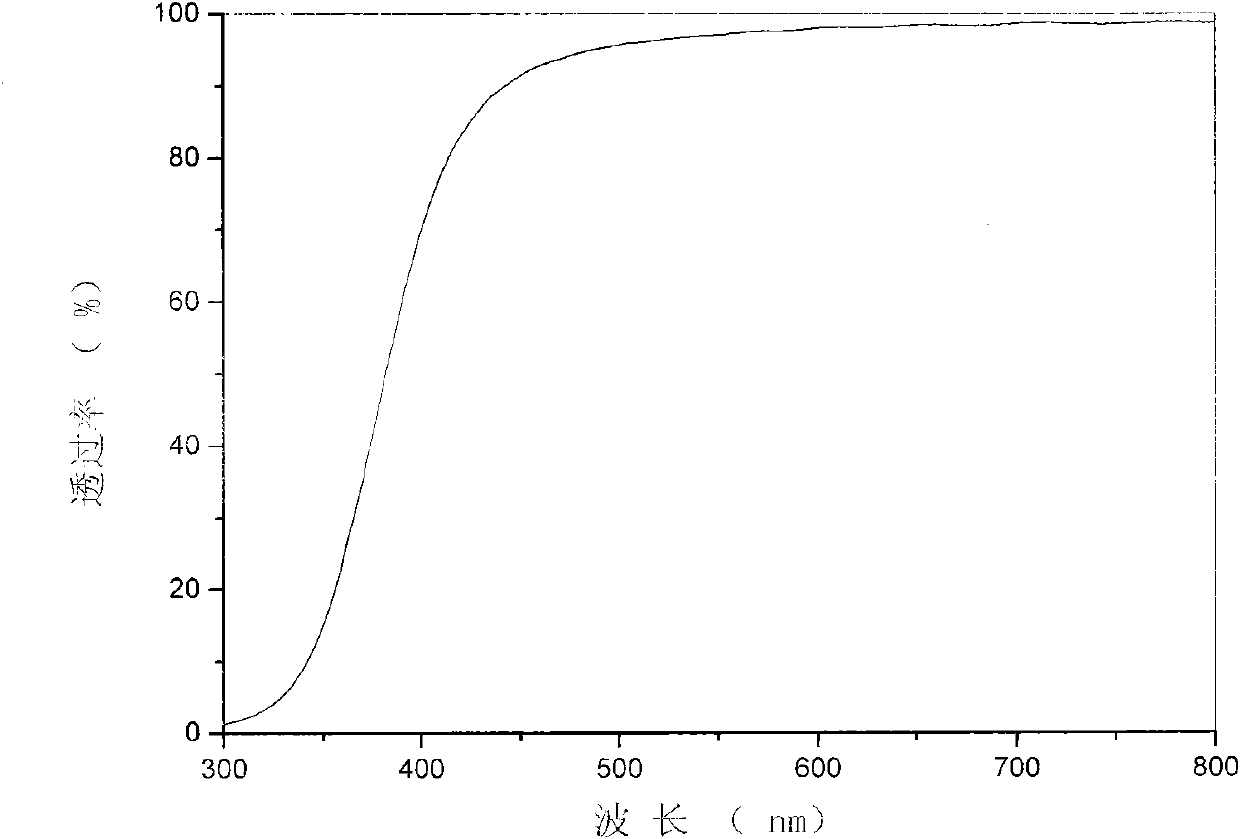

The invention discloses an industrial method for preparing monodisperse CeO2 nanoparticles by using a novel low-temperature sol-gel route and eliminating the oxidability of the CeO2 nanoparticles by surface modification. Characterization results show that the prepared product is monodisperse CeO2 nanoparticles and that the CeO2 nanoparticles subjected to surface modification have no oxidability for organic materials, high absorbability and various ultraviolet absorption applications and particularly can be used as an ultraviolet absorption additive for sunscreen cream and cosmetics. The method adopts cheap raw materials, a simple process and mild reaction conditions, reduces waste discharge and is suitable for large-scale industrial production.

Owner:YANTAI UNIV

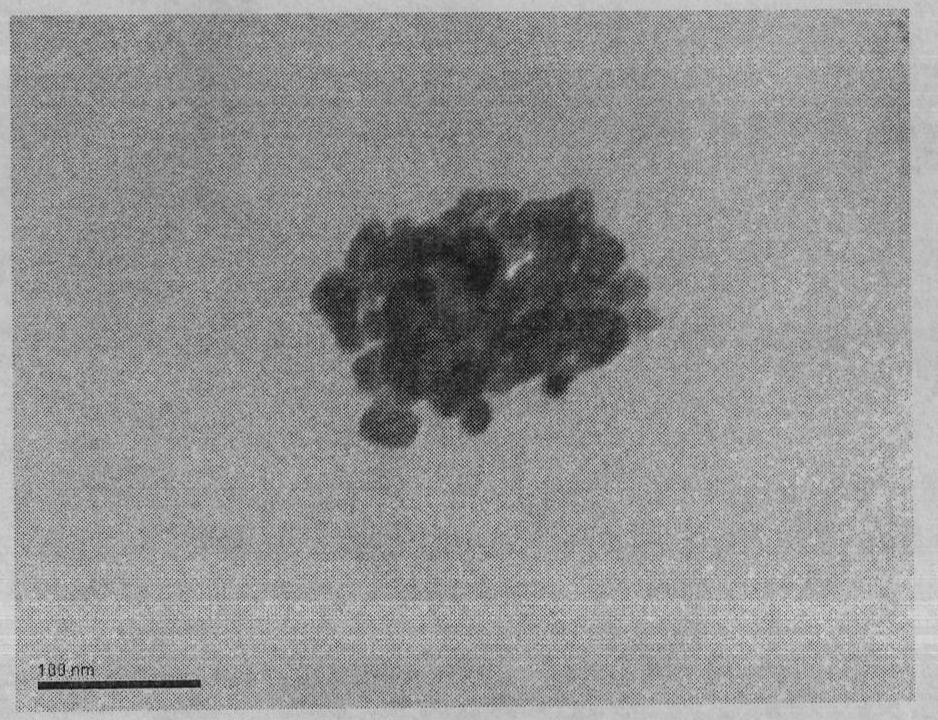

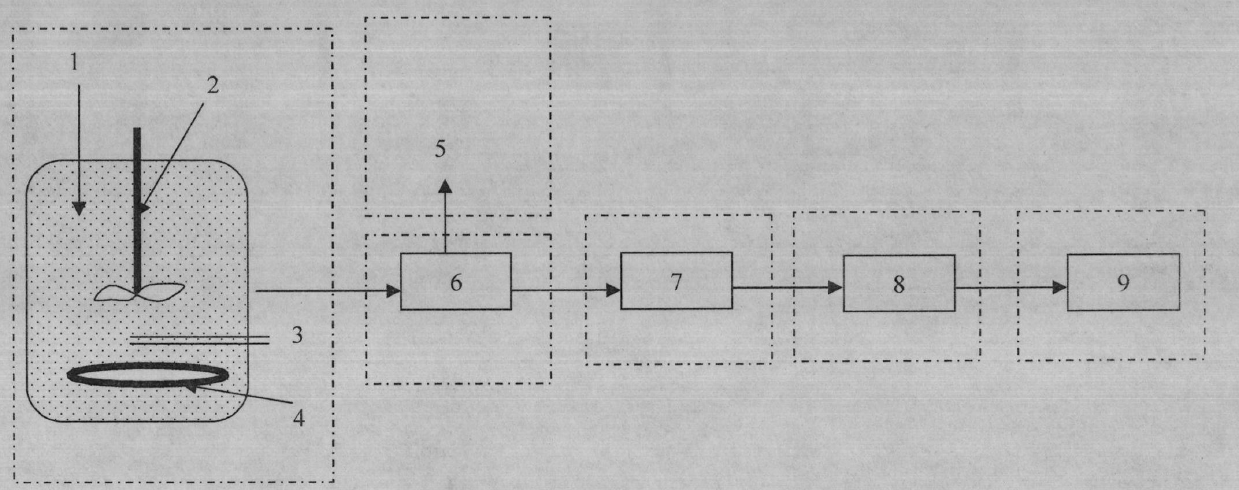

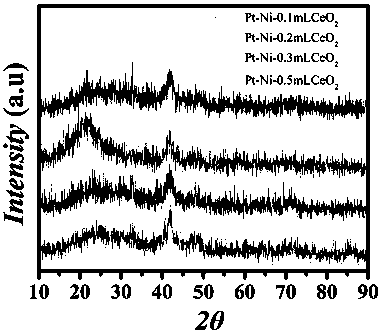

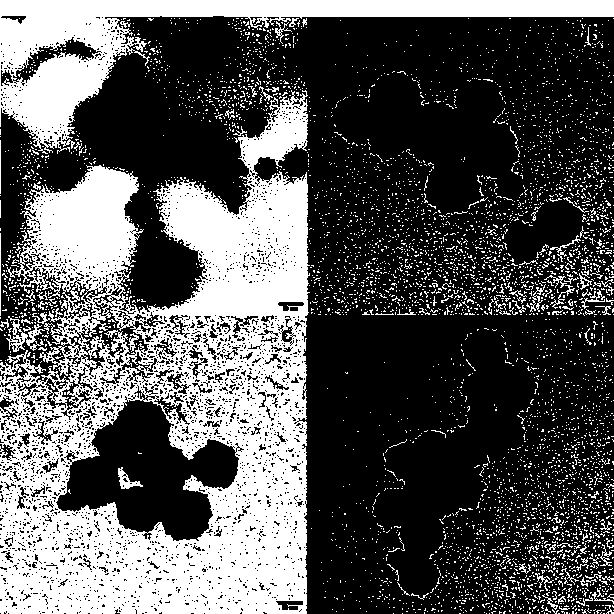

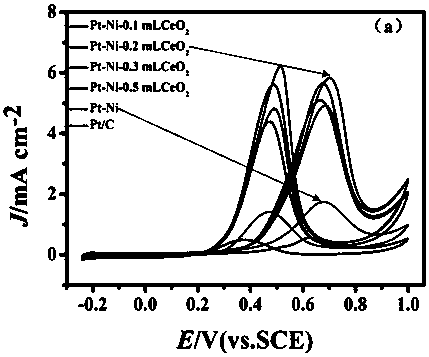

Pt-Ni binary alloy supported CeO2 nanoparticles and preparation method thereof

ActiveCN110993967AImprove anti-poisoning performanceImproved resistance to CO poisoningCell electrodesPtru catalystCerium(IV) oxide

The invention relates to Pt-Ni binary metal alloy supported cerium dioxide nanoparticles and a preparation method thereof. The Pt-Ni binary metal alloy loaded cerium dioxide is synthesized in one stepby utilizing a solvothermal method. Specifically, oleylamine oleic acid is adopted as a dispersing agent to inhibit growth of crystals, and added formaldehyde can induce CeO2 in gaps in the surface of Pt-Ni alloy, so that whether rare earth metal oxide has the effects of improving CO poisoning resistance of the catalyst and improving electro-catalysis of the catalyst or not is explored. The synthesized CeO2 with very small diameter is added to the surface of the catalyst by utilizing gaps in Pt-Ni alloy groups, and the CO poisoning resistance of the metal catalyst is improved by utilizing thestrong oxidation effect of the CeO2 on CO, so that the electro-catalytic stability of the metal catalyst is remarkably improved.

Owner:UNIV OF JINAN

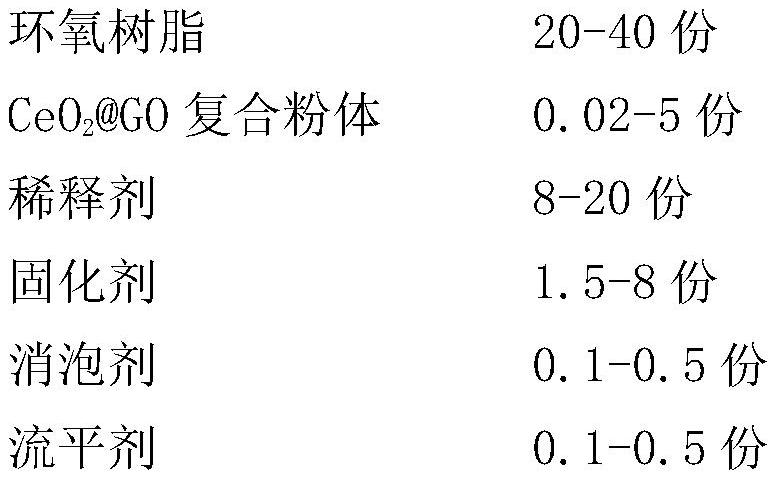

Anti-corrosion photovoltaic cable coating and preparation method thereof

InactiveCN111876005AStrong redox capacityExcellent oxygen storage and release performanceAnti-corrosive paintsEpoxy resin coatingsWeather resistanceCeo2 nanoparticles

The invention provides an anti-corrosion photovoltaic cable coating. The anti-corrosion photovoltaic cable coating is prepared from the following components in parts by weight: 20-40 parts of epoxy resin, 0.02-5 part of CeO2@GO composite powder, 8-20 parts of a diluent, 1.5-8 parts of a curing agent, 0.1-0.5 part of a defoamer and 0.1-0.5 part of a leveling agent. The CeO2@GO composite powder is prepared by modifying graphene oxide GO by utilizing CeO2 nanoparticles through a surface grafting method, so that the CeO2 nanoparticles can be stably loaded on the surface of the GO and are insertedbetween GO laminates to play a role in blocking GO agglomeration, and the dispersity and compatibility of the GO in an epoxy resin matrix are improved; meanwhile, due to the existence of GO, a good support body is provided for the CeO2 nano particles, the CeO2 nano particles are promoted to be uniformly dispersed in an epoxy resin matrix, so that the GO and the CeO2 can better exert respective anti-corrosion effects and enhancing effects; therefore, the anti-corrosion performance of the coating is further improved, and the service life of the coating is prolonged. Furthermore, the comprehensive performances of waterproofness, corrosion resistance, weather resistance, chemical stability, adhesion and the like of the photovoltaic cable can be effectively ensured.

Owner:江苏大地电缆有限公司

Modified perovskite negative electrode material for directly electrolyzing pure CO2 at high temperature

InactiveCN109837557AImprove performanceImprove catalytic performanceElectrodesElectrolysisCeo2 nanoparticles

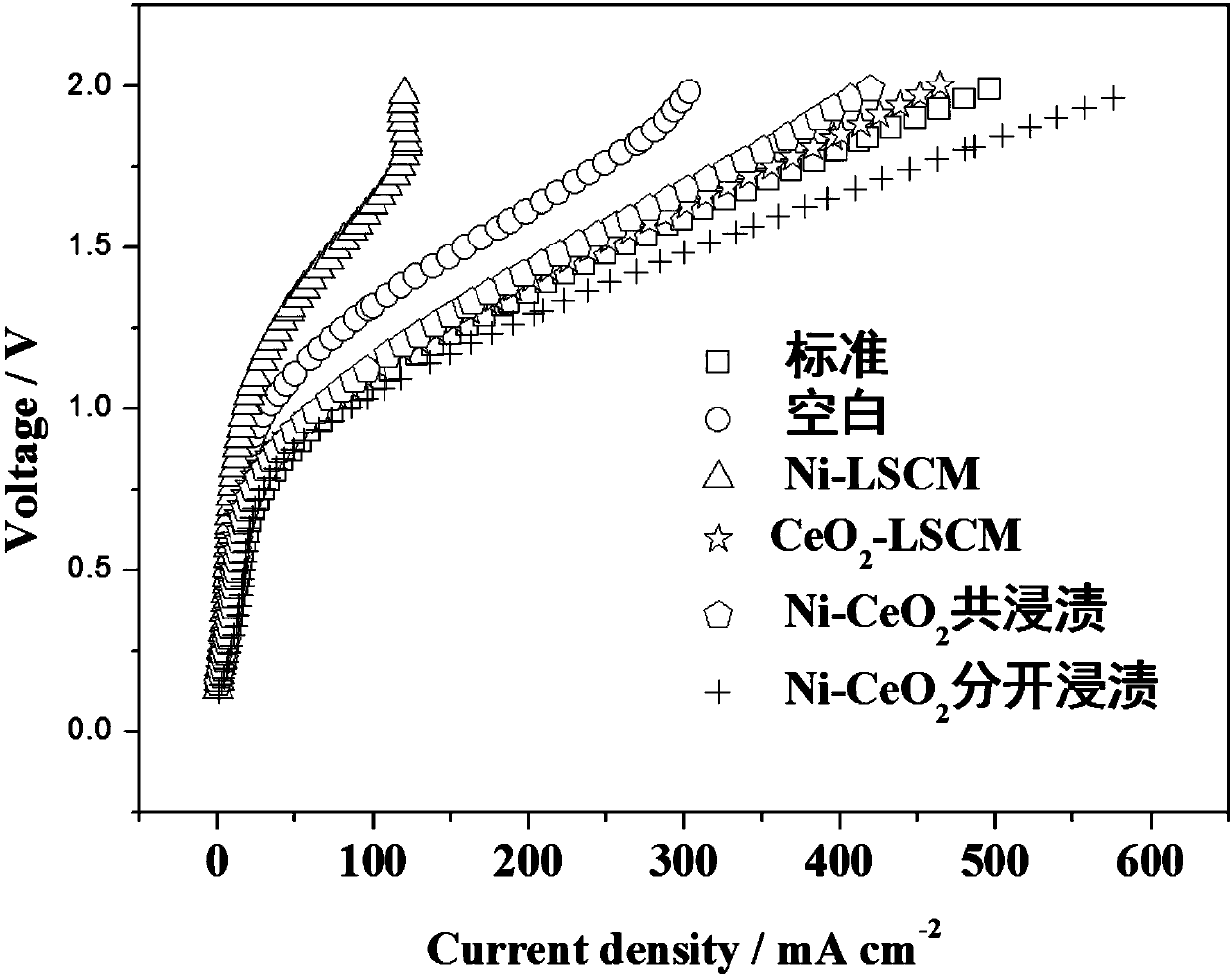

The invention relates to a modified perovskite negative electrode material for directly electrolyzing pure CO2 at a high temperature. The negative electrode material is a Ni-CeO2 modified perovskite material. A preparation method of the negative electrode material comprises the following steps: impregnating a perovskite electrode framework in a Ni(NO3)2 solution, impregnating the impregnated framework in a Ce(NO3)3 solution, and calcining and reducing the obtained material to obtain the modified perovskite negative electrode material for directly electrolyzing pure CO2, having better electrochemical performances than the simple perovskite negative electrode material. Ni-CeO2 nanoparticles are prepared on the framework of perovskite oxide by the conventional impregnation process, Ni has a better catalysis effect on CO2 electrolysis than the perovskite material, but is prone to deposit carbon and be oxidized in a pure CO2 environment, the impregnation with CeO2 achieves oxidation resistance and carbon deposition resistance, and the CeO2 also has a certain catalysis property.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

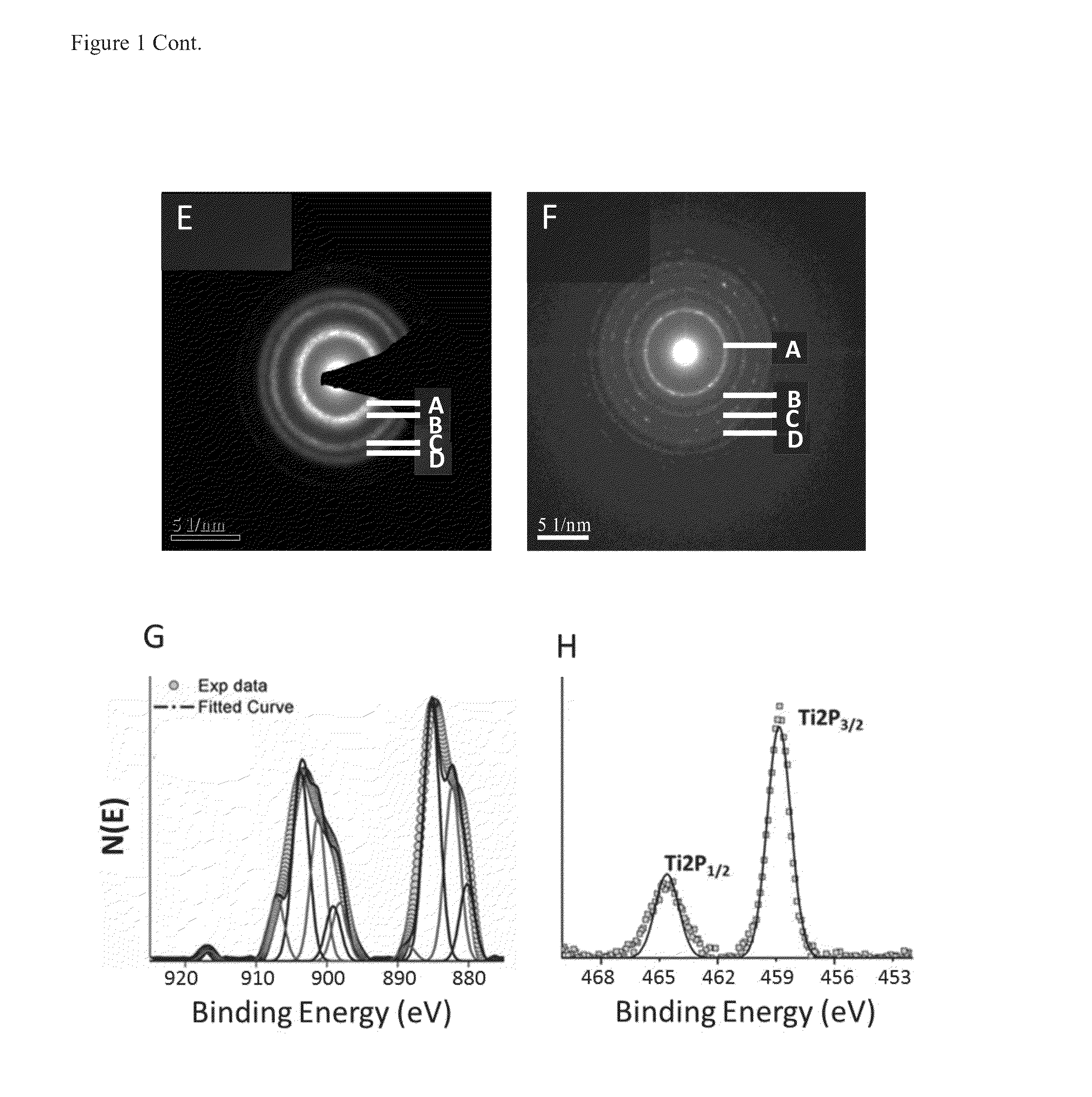

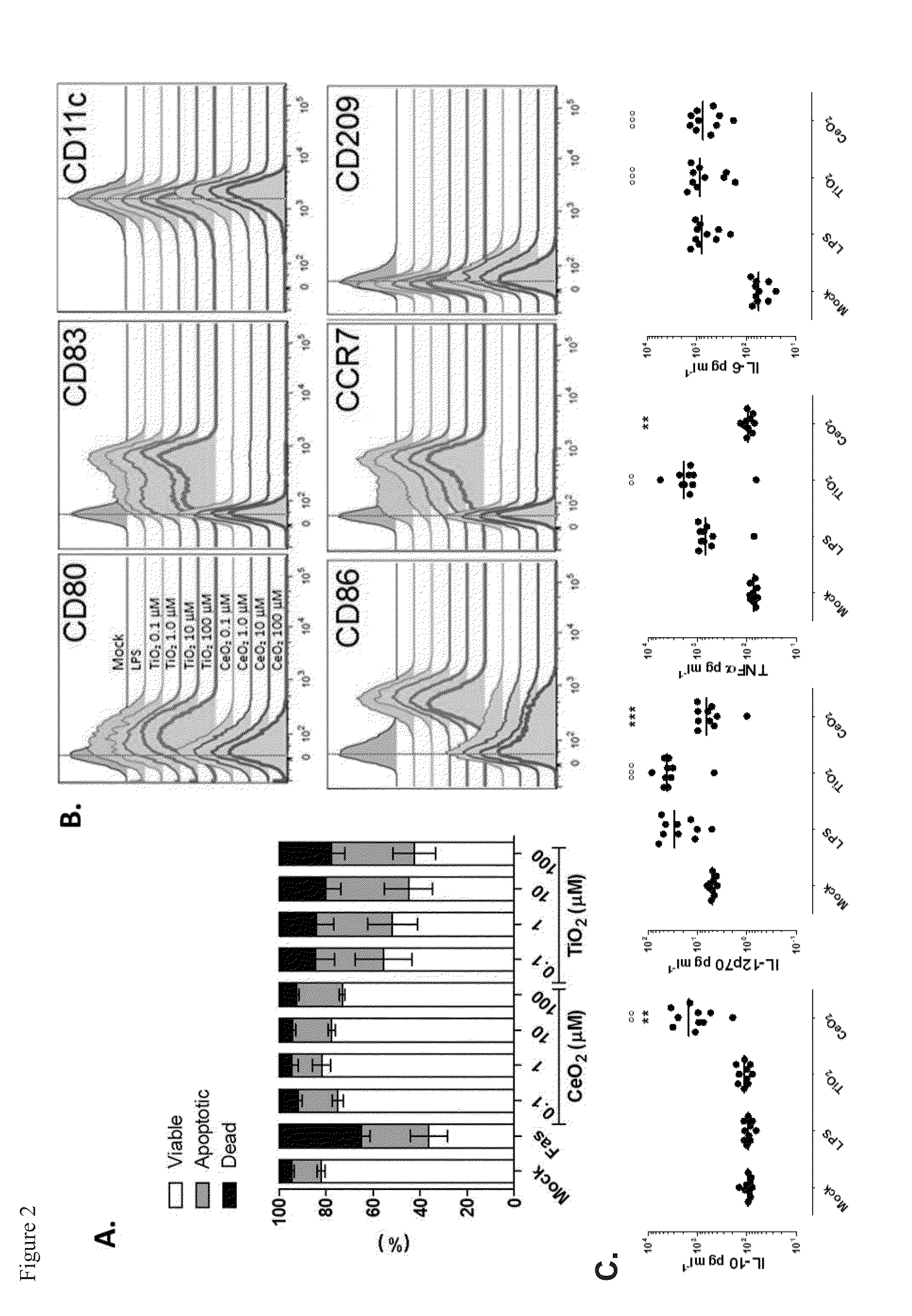

Methods of using ceo2 and tio2 nanoparticles in modulation of the immune system

InactiveUS20150190503A1Good curative effectModulating the immune systemHeavy metal active ingredientsPowder deliveryDc maturationCeo2 nanoparticles

Redox-active NPs are disclosed that can potentiate innate immunity and stimulate distinct adaptive responses, producing distinct T cell subset polarization outcomes. Nanomaterials that can alter the cellular redox environment through ROS modulation can impact human immunology. TiO2 nanoparticles potentiate DC maturation, inducing the secretion of IL-12, p70, and IL-1B, while treatment with CeO2 nanoparticles induces IL-10, a hallmark of suppression. When delivered to T cells, the materials direct distinct TH polarization, where TiO2 stimulates largely a TH1 dominated response, whereas CeO2 stimulates a TH2 bias and TReg differentiation.

Owner:SANOFI PASTEUR VAX DESIGN +1

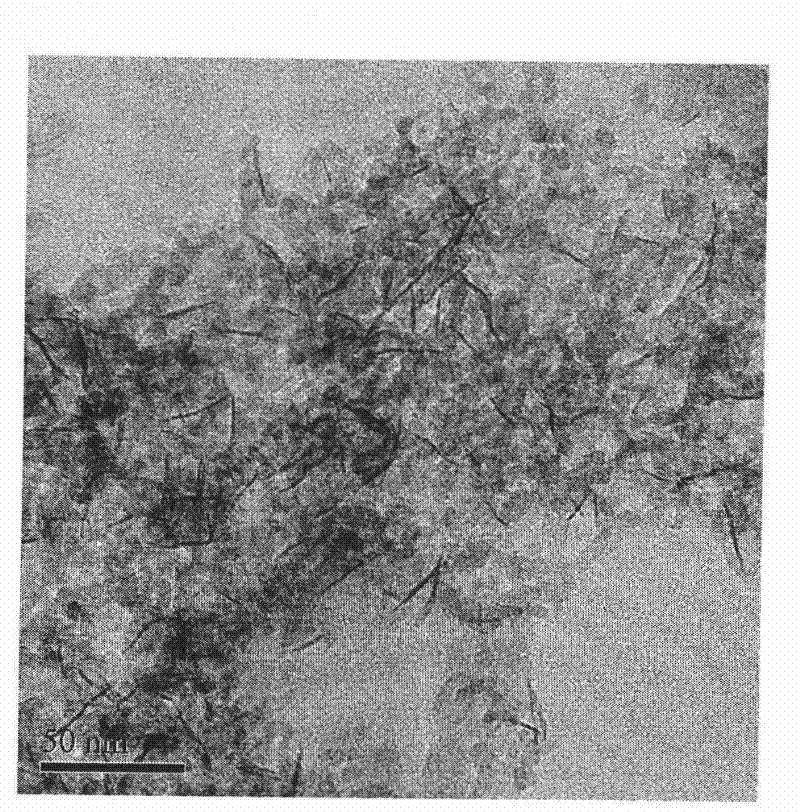

SnS2-Ce2S3-CeO2 ternary heterojunction and its preparation method and use

ActiveCN107224984APromote absorptionPromote conversionPhysical/chemical process catalystsHydrogen productionHeterojunctionEnvironmental resistance

The invention relates to a SnS2-Ce2S3-CeO2 ternary heterojunction and its preparation method and use and belongs to the field of inorganic semiconductor nanomaterials. The SnS2-Ce2S3-CeO2 ternary heterojunction comprises a SnS2 layer, a Ce2S3 layer and a CeO2 layer, has an excellent structure and stable chemical properties, greatly enhances the light absorption, can be used for photocatalytic hydrogen evolution, has good performances, greatly improves a hydrogen evolution rate and has the highest hydrogen evolution rate of 0.24 mmol*g<-1>*h<-1>. According to the method, SnS2 nanosheets are formed on a carbon cloth, then the SnS2 nanosheets are immersed into the solution containing a cerium source and urotropine, and Ce2S3 nanobelts and CeO2 nanoparticles grow in the solution by a hydrothermal method to form the SnS2-Ce2S3-CeO2 ternary heterojunction. The preparation method has the advantages of simple processes, operation convenience, fast speed, environmental friendliness and broad application prospects.

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

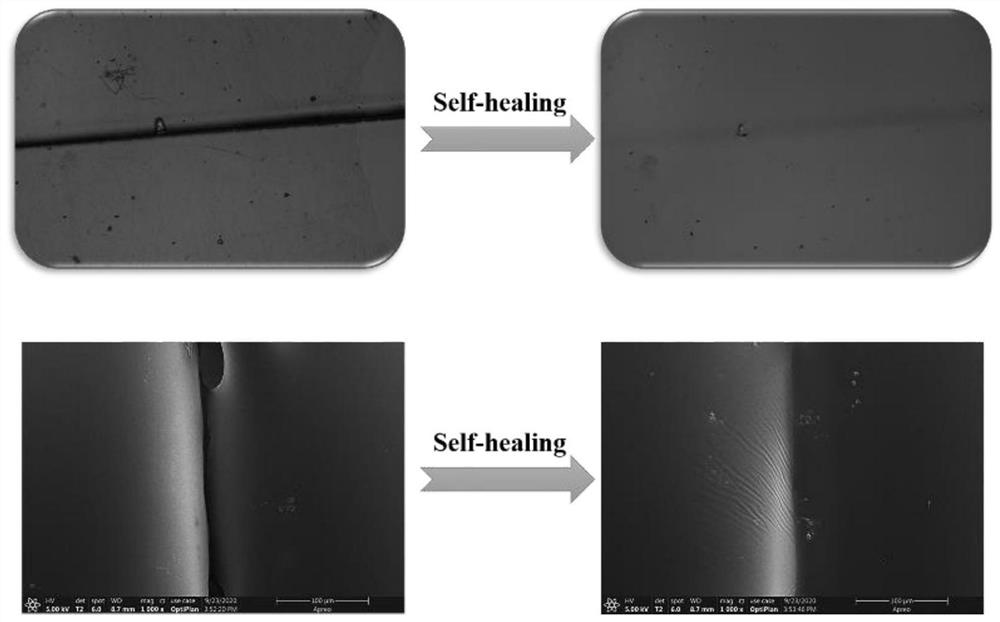

Near-infrared quick-response precise self-repairing anticorrosive coating and preparation method thereof

ActiveCN113249025APromote formationAchieve self-healingAnti-corrosive paintsPolyurea/polyurethane coatingsFuranCeo2 nanoparticles

The invention provides a near-infrared rapid-response precise-self-repairing anticorrosive coating and a preparation method thereof. The near-infrared rapid-response precise-self-repairing anticorrosive coating comprises furan-modified nanoparticles and a maleimide-terminated polyurethane coating matrix, the furan-modified nanoparticles are CeO2 nanoparticles wrapped by dopamine, and furan groups are grafted on the surfaces of the CeO2 nanoparticles. The preparation method comprises the following steps: dispersing CeO2 nanoparticles in a Tris-HCl buffer solution, adding dopamine hydrochloride, carrying out high-speed stirring, carrying out centrifugal separation to obtain nanoparticles, and uniformly dispersing the nanoparticles with ethanol; and placing the uniformly dispersed dopamine-coated nanoparticle ethanol dispersion liquid at 60 DEG C, adjusting the pH value to about 9 by using triethylamine, dropwise adding furfuryl mercaptan, continuously stirring and reacting for 24 hours, centrifugally separating out nanoparticles, uniformly dispersing by using butanone, finally adding the nanoparticles into maleimide-terminated polyurethane, uniformly stirring and mixing, and drying to obtain the anticorrosive coating with the near-infrared quick response and precise self-repairing functions.

Owner:SICHUAN UNIV

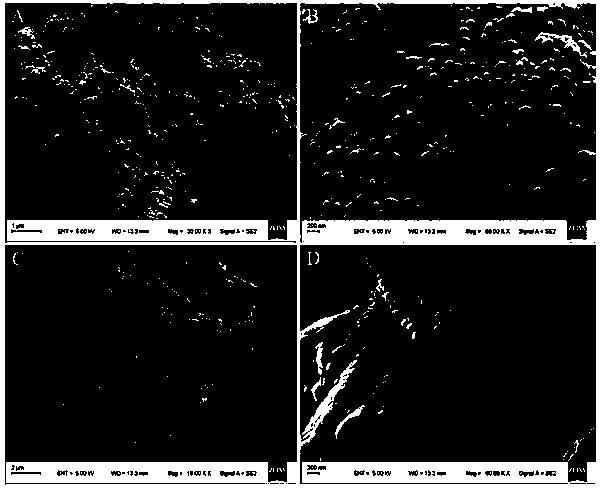

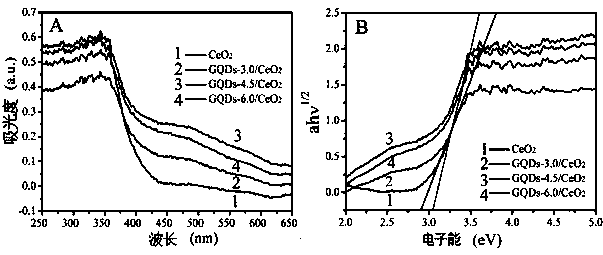

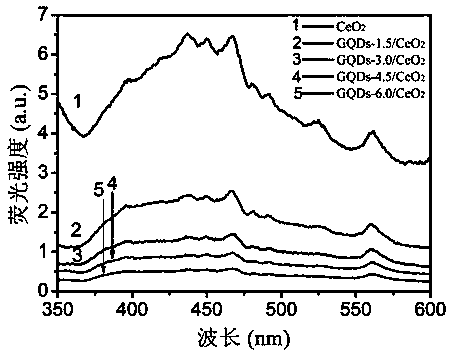

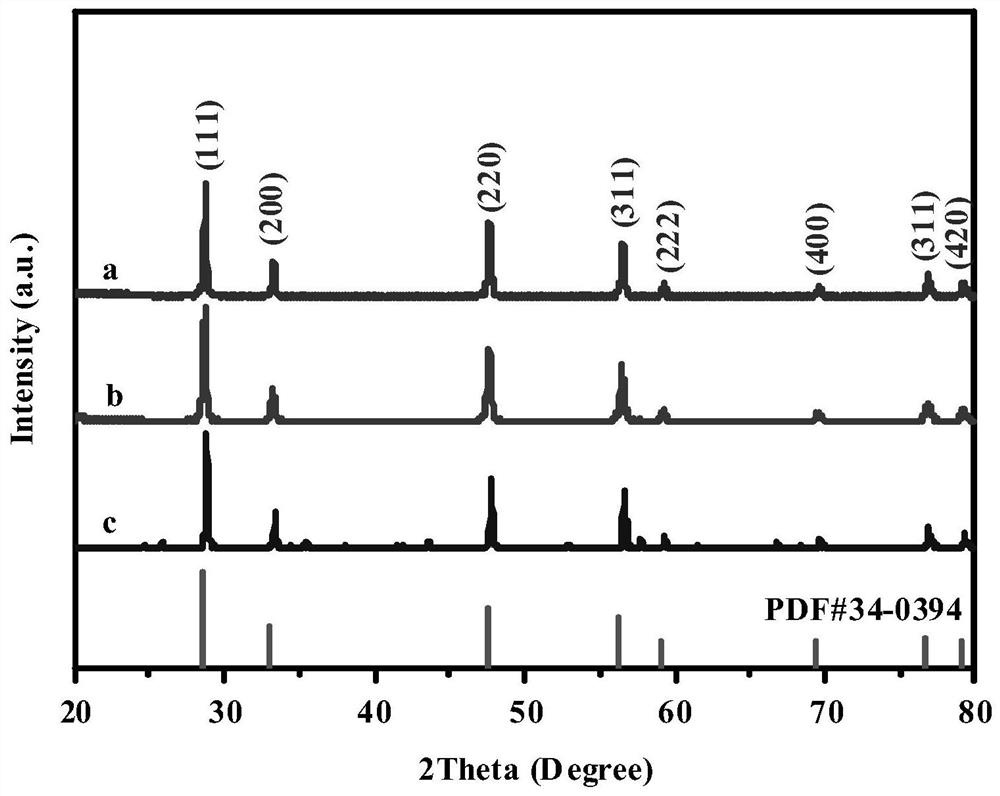

Preparation method of rodlike structure graphene quantum dot/cerium oxide composite photocatalyst

ActiveCN110639498ARich reservesPlay a structural roleWater/sewage treatment by irradiationWater treatment compoundsFreeze-dryingCeo2 nanoparticles

The invention provides a rodlike structure graphene quantum dot / cerium oxide composite photocatalyst. The rodlike structure graphene quantum dot / cerium oxide composite photocatalyst is prepared by thesteps: adding CeO2 nanoparticles into a graphene quantum dot aqueous solution, and after ultrasonically dispersing uniformly, transferring into a reaction kettle to perform hydrothermal reaction; andafter the reaction ends, cooling, centrifugally separating products, washing with ultrapure water and performing freeze drying. The rodlike composite material is obtained by taking CeO2 as a photocatalyst and GQDs as a photosensitive agent under the hydrothermal condition, wherein the surface of the CeO2 is wrapped with the GQDs. On one hand, in the hydrothermal treatment process, the GQDs outside the material achieve the structure guide effect, so that the composite material has optimized sequential rodlike special appearance; and on the other hand, the small-size GQDs are on the surface ofthe CeO2, so the electron-cavity transfer life under the irradiation of the composite material visible light is prolonged, the photocatalytic capacity of the composite photocatalyst is improved and application prospect in the fields of photocatalytic waste water treatment and the like is achieved.

Owner:NORTHWEST NORMAL UNIVERSITY

CeO2 nano-particles for chemical mechanical polishing and preparation method of CeO2 nano-particles

PendingCN113044873ASave raw materialsSimple processMaterial nanotechnologyCerium oxides/hydroxidesAlcoholCrucible

The invention discloses CeO2 nanoparticles for chemical mechanical polishing and a preparation method thereof, and the preparation method comprises the following steps: step 1, grinding and mixing Ce(NO3)3.6H2O and a molten salt system according to a molar ratio of 1:(10-40) to obtain a mixture; step 2, pouring the mixture in the step 1 into absolute ethyl alcohol, uniformly conducting stirring, pouring the system into a crucible, and conducting drying in a drying oven to obtain mixed salt; step 3, placing the mixed salt in the step 2 and the crucible in a muffle furnace, conducting heating to the baking temperature of a molten salt system from the room temperature at the heating rate of 5 DEG C / min, keeping the temperature for 2-4 hours, naturally conducting cooling, taking out a reaction product, and conducting washing to obtain a white precipitate; and step 4, pouring the white precipitate obtained in the step 3 into a centrifugal tube and conducting centrifugal washing in a centrifugal machine, and then conducting drying and grinding to obtain CeO2 nano powder. The preparation method has the characteristics of cheap selected raw materials, simple preparation process and short production period; and the CeO2 nano-powder prepared by the method has the advantages of uniform size distribution and good dispersity.

Owner:SHAANXI UNIV OF SCI & TECH

Preparation method and application of cerium dioxide with different defect degrees

PendingCN113680342ARaw materials are easy to getEasy to operateProductsReagentsHydration reactionPtru catalyst

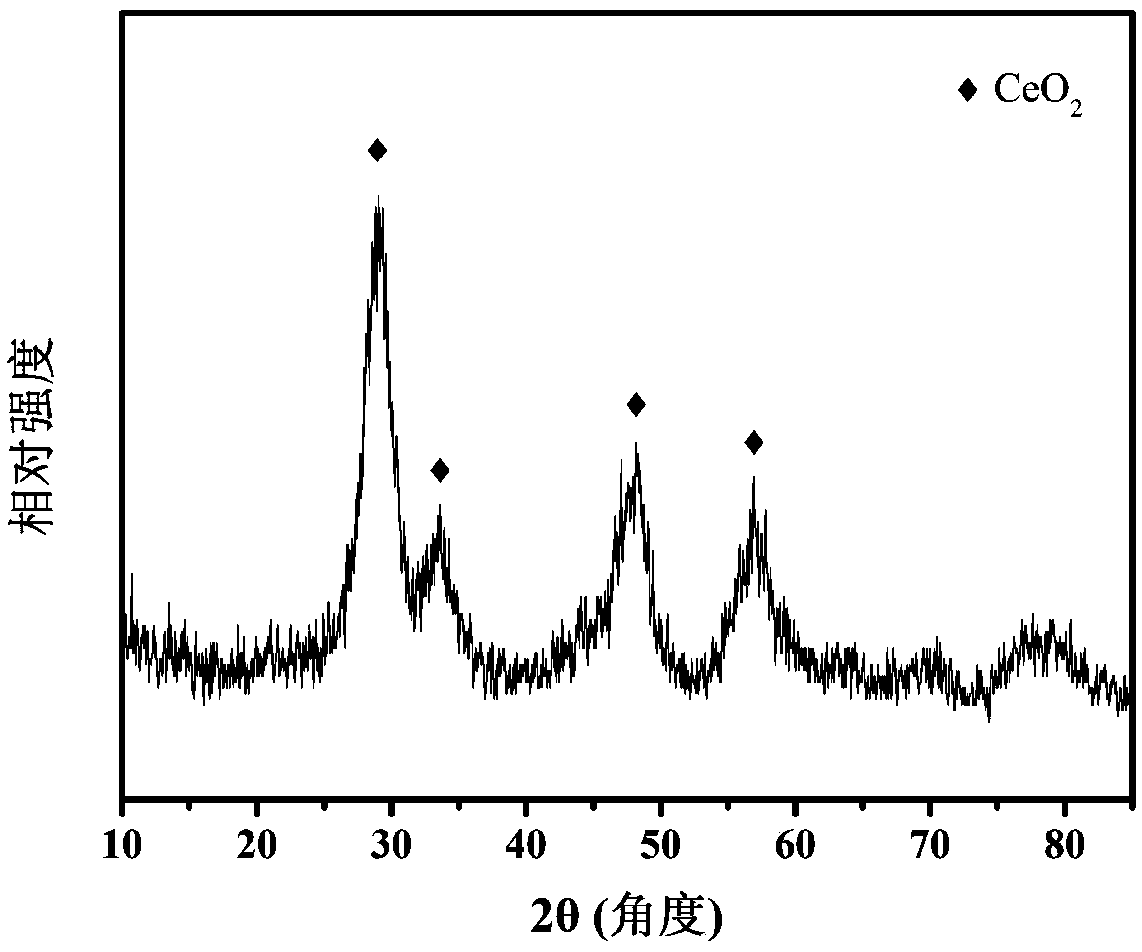

The invention discloses a preparation method of a catalyst for dimethyl carbonate synthesis, which comprises the following steps: taking a cerium source cerium nitrate hexahydrate, combining the cerium source cerium nitrate hexahydrate with a pH regulator trisodium phosphate, and carrying out hydrothermal synthesis to obtain octahedral CeO2; using a plasma enhanced chemical vapor deposition (PECVD) discharge device for generating plasma flow, directly applying the plasma flow on the surface of the dried CeO2 powder, and obtaining uniformly dispersed CeO2 nanoparticles with different defect degrees after discharge is completed under different parameters; and mixing the treated CeO2 catalyst with methanol, and carrying out photo-thermal catalysis on synthesis of DMC under the conditions of specific pressure, temperature and illumination. The method has the advantages of easily available raw materials, simple operation, easily controllable reaction conditions, low cost, no hazardous waste gas in the reaction process, and environmental protection.

Owner:安徽工业技术创新研究院六安院

Co-based nano-catalyst for hydrogen production by ethanol steam reforming and preparation method thereof

InactiveCN101444738BHigh porosityHigh catalytic activityHydrogenMetal/metal-oxides/metal-hydroxide catalystsSteam reformingNano catalyst

The invention discloses a Co-based nano-catalyst for hydrogen production by ethanol steam reforming and a preparation method thereof. The catalyst is made by taking nanoporous silicon dioxide aerogel as a catalyst carrier, a metal elementary substance cobalt nanowire as an active component, and CeO2 nano-particles and ZnO nano-particles as adjuvants. The preparation method comprises the following steps: preparing a sol from silanolate, an alcohol solvent, cobalt nitrate and zinc nitrate, cerous nitrate and an acidic catalyst at certain proportions; forming a wet gel complex, and then performing supercritical fluid drying. The catalyst has strong catalytic activity and selectivity for the hydrogen production by the ethanol steam reforming, has higher hydrogen yield and stronger CO2 selectivity at a lower temperature, limits the selectivity of byproducts CH4 and CO at a lower level, and has good deactivation resistance and stability. Meanwhile, the preparation method has simple process, low cost and certain mechanical strength.

Owner:HUNAN SHANGYIFENG NEW MATERIAL TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com