High temperature sintering resistive loading type noble metal catalyst for catalytic oxidation of carbon monoxide and preparation method thereof

A noble metal catalyst and catalytic oxidation technology, applied in the field of nanomaterials, can solve the problems of difficult preparation of supported noble metal catalysts, difficult high temperature sintering ability, etc., and achieve the effects of universality and practicability, good catalytic activity and simple method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The preparation method of the above-mentioned high-temperature-resistant sintered supported noble metal catalyst for catalytic oxidation of carbon monoxide comprises the following steps:

[0028] 1. Use deionized water to prepare the precursor of the active component noble metal (M) to 0.1mol L -1 508 μL of the solution was measured with a pipette and placed in a 100 mL beaker, and 40 mL of deionized water was added thereto, and stirred evenly. Use 0.1mol L - 1 NaOH solution to adjust the pH of the above solution to 9, and add 1g carrier TiO under stirring 2 , and with 0.1mol L -1 NaOH solution maintains the pH of the solution ≈ 9 and maintains it for 1h. Raise the temperature to 65°C, continue stirring for 1 h, stop stirring and centrifuge, wash the obtained product three times with deionized water, and dry it in an oven at 60°C for 24 h to obtain M / TiO 2 catalyst.

[0029] 2. Use a graduated cylinder to measure 40mL of absolute ethanol into a 100mL beaker, and add...

Embodiment 1

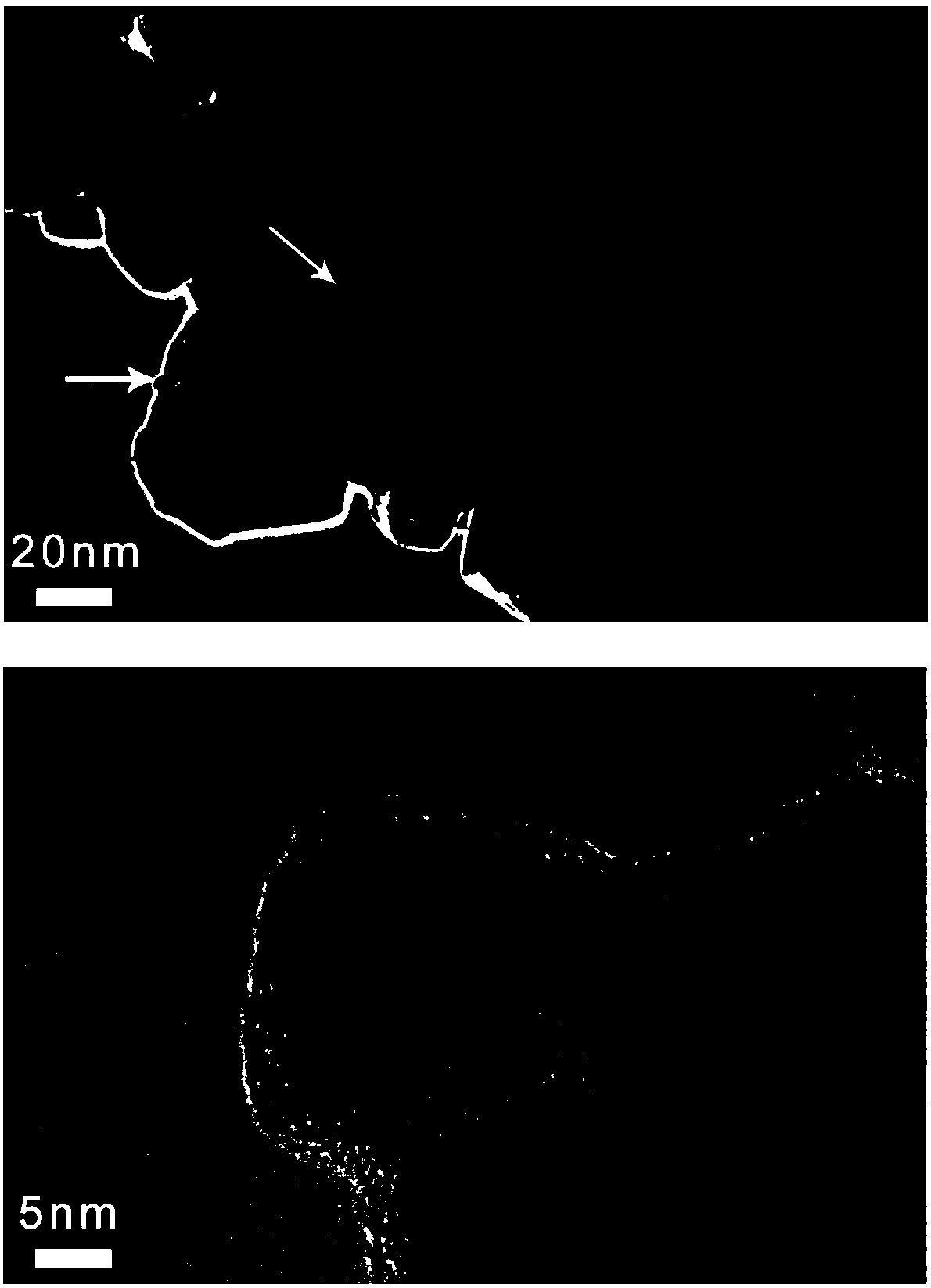

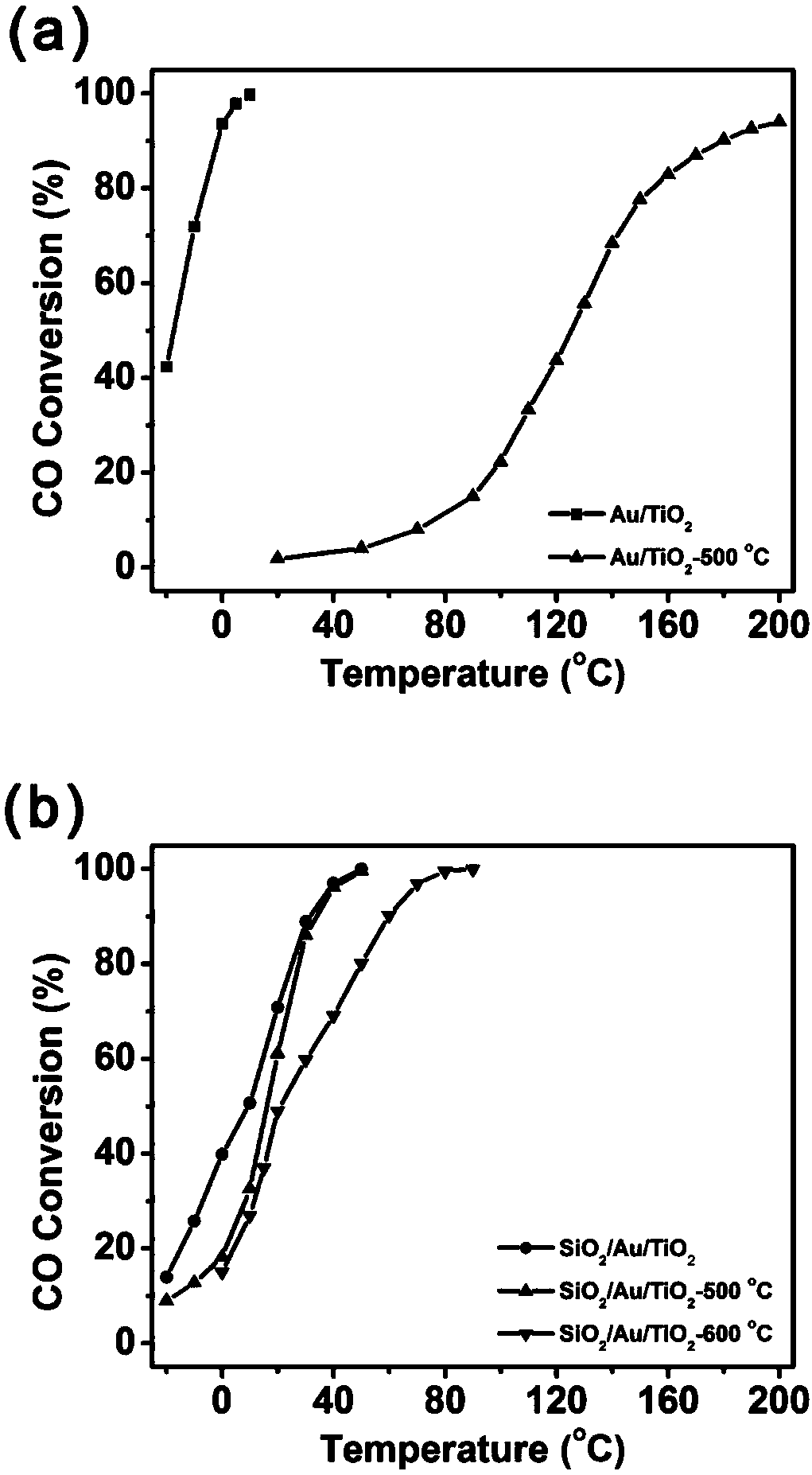

[0033] Example 1: SiO 2 / Au / TiO 2 catalyst

[0034] The active component Au precursor HAuCl was deionized water 4 ·3H 2 O prepared as 0.1mol L -1 508 μL of the solution was measured with a pipette and placed in a 100 mL beaker, and 40 mL of deionized water was added thereto, and stirred evenly. Use 0.1mol L -1 NaOH solution to adjust the pH of the above solution to 9, and add 1g carrier TiO under stirring 2 , and with 0.1mol L -1 NaOH solution maintains the pH of the solution ≈ 9 and maintains it for 1h. Raise the temperature to 65°C, continue stirring for 1 h, stop stirring and centrifuge, wash the obtained product three times with deionized water, and dry it in an oven at 60°C for 24 h to obtain Au / TiO 2 catalyst. Use a measuring cylinder to measure 40mL of absolute ethanol into a 100mL beaker, add 1mmol of n-dodecanethiol, 0.2g of Au / TiO 2 catalyst, heated to 60°C and kept stirring for 30min, centrifuged, washed with ethanol for 3 times, and dried in an oven at 60...

Embodiment 2

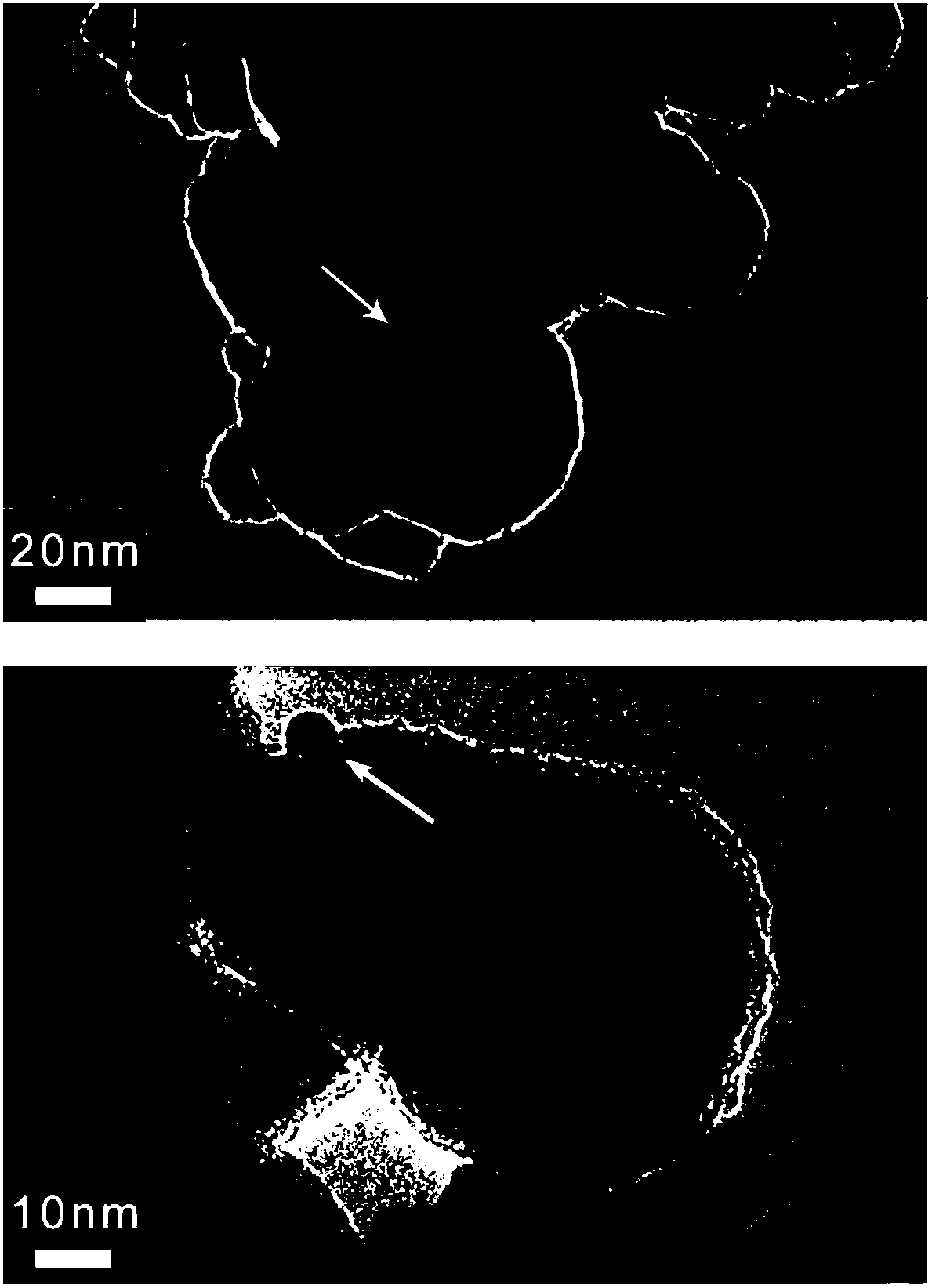

[0038] Example 2: SiO 2 / Pt / TiO 2 catalyst

[0039] The active component Au precursor H was deionized with deionized water 2 PtCI 6 ·6H 2 O prepared as 0.1mol L -1 508 μL of the solution was measured with a pipette and placed in a 100 mL beaker, and 40 mL of deionized water was added thereto, and stirred evenly. Use 0.1mol L -1 NaOH solution to adjust the pH of the above solution to 9, and add 1g carrier TiO under stirring 2 , and with 0.1mol L -1 NaOH solution maintains the pH of the solution ≈ 9 and maintains it for 1h. Raise the temperature to 65°C, continue stirring for 1 h, stop stirring and centrifuge, wash the obtained product three times with deionized water, and dry it in an oven at 60°C for 24 h to obtain Pt / TiO 2 catalyst. Use a graduated cylinder to measure 40mL of absolute ethanol into a 100mL beaker, and add 1mmol of oleyl ammonium, 0.2g of Pt / TiO 2 Catalyst, heated to 60°C and kept stirring for 30min, centrifuged, the obtained product was washed 3 tim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com