Method for preparing CeO2 nanoparticles from W/O type microemulsion

A microemulsion and nanotechnology, applied in nanotechnology, chemical instruments and methods, rare earth metal compounds, etc., can solve problems such as uneven dispersion, limited particle application and development, product agglomeration, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

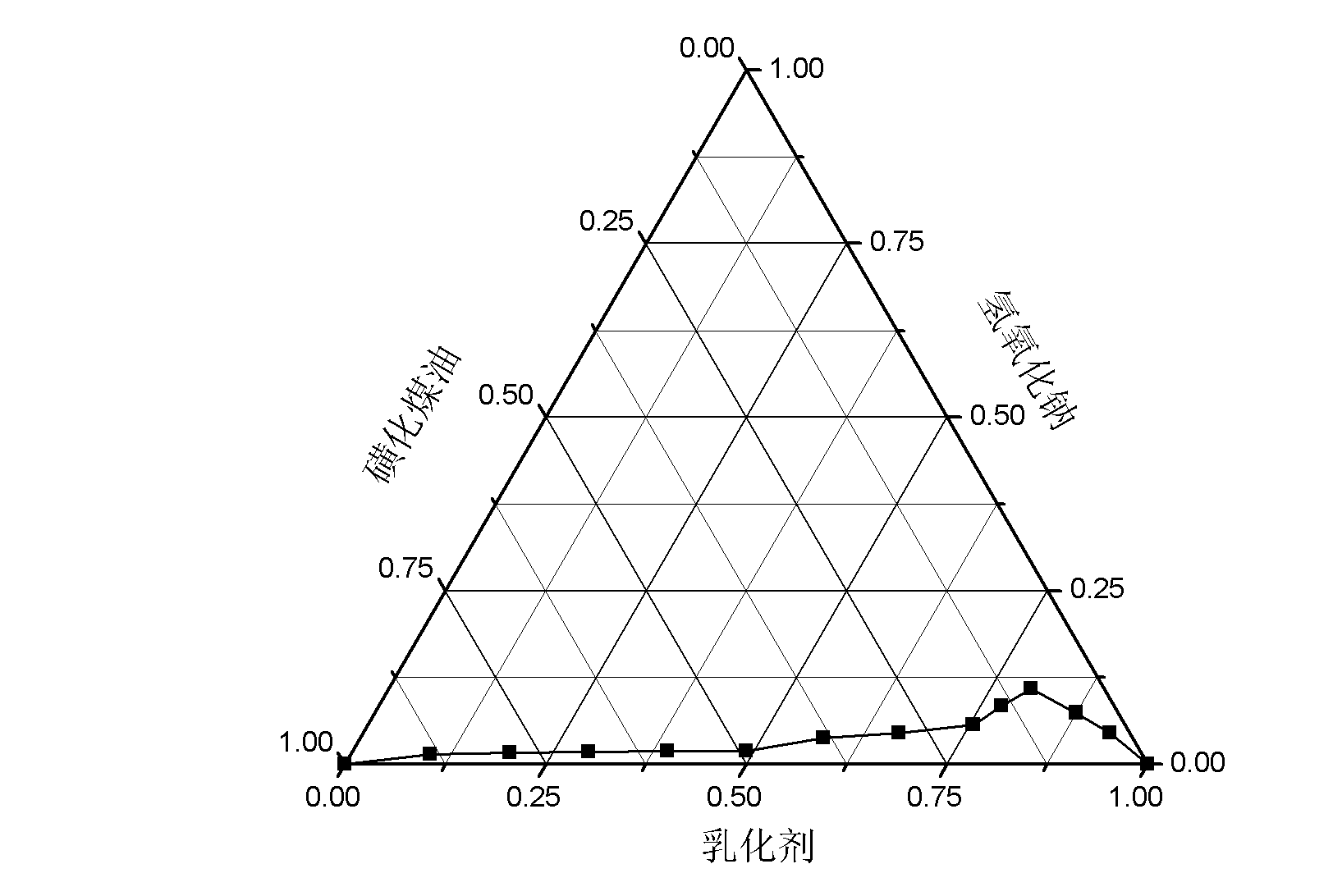

[0037] 1. Surfactant P507 and organic solvent n-heptane are mixed into an emulsifier, wherein the mass ratio of P507 and n-heptane is 95:5, 90:10, 88:12, 85:15, 80:20,70: 30, 60:40, 50:50, 40:60, 30:70, 20:80, 10:90, and then use the same concentration of NaOH solution to saponify emulsifiers with different mass ratios until a clear and uniform solution is obtained by visual observation until.

[0038] 2. obtain according to specific embodiment: the solubilizing effect of microemulsion zone is the most obvious when n-heptane mass ratio is 10%, so P507 and C in the emulsifier 7 h 16 The mass ratio was determined to be 90:10.

[0039] The embodiment of emulsifier preparation process sees the following table:

[0040]

[0041] 3. Add emulsifier (P507: C 7 h 16 The mass ratio of emulsifier to sulfonated kerosene is 90:10) mixed with sulfonated kerosene, and the mass ratios of emulsifier and sulfonated kerosene are respectively set to 9.75:0.25, 9.5:0.5, 9:1, 8.5:1.5, 8:2, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com