Preparation method of carbon quantum dot modified n-n type MFe12O19/CeO2 magnetic separation photocatalyst

A technology of mfe12o19 and carbon quantum dots, which is applied in the direction of metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of poor photocatalytic degradation ability and achieve cheap raw materials , Excellent effect, various effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

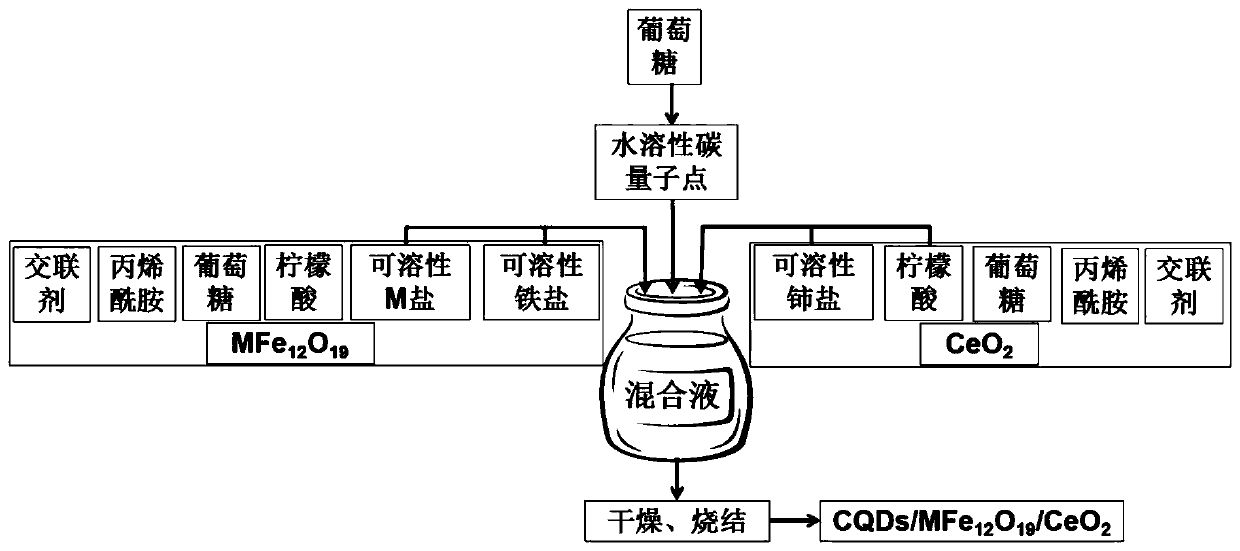

[0024]A carbon quantum dot modified n-n type MFe 12 o 19 / CeO 2 The preparation method of magnetic separation photocatalyst comprises the following steps:

[0025] Step 1: Weigh 50g of glucose and dissolve it in 80mL of aqueous solution. After it is completely dissolved, transfer it to a reaction kettle lined with polytetrafluoroethylene, and place the reaction kettle in a drying oven at a constant temperature of 180°C for 5 hours , to obtain water-soluble carbon quantum dots.

[0026] Step 2: Press SrFe 12 o 19 The mol ratio of Sr and Fe in the middle is that the ratio of Sr:Fe=1:12 takes by weighing soluble 0.2442g strontium nitrate, soluble 5.5938g ferric nitrate, takes by weighing and cation molar ratio is the chelating agent citric acid 4.7282g of 1.5:1; Weigh 20g of gel-collapsing agent glucose; weigh 9.5958g of acrylamide with a molar ratio of 9:1 to the cation; weigh 1.9192g of a cross-linking agent methylenebisacrylamide with a mass ratio of 5:1 to acrylamide Sl...

Embodiment 2

[0030] A carbon quantum dot modified n-n type MFe 12 o 19 / CeO 2 The preparation method of magnetic separation photocatalyst comprises the following steps:

[0031] Step 1: Weigh 50g of glucose and dissolve it in 80mL of aqueous solution. After it is completely dissolved, transfer it to a reaction kettle lined with polytetrafluoroethylene, and place the reaction kettle in a drying oven at a constant temperature of 180°C for 5 hours , to obtain water-soluble carbon quantum dots.

[0032] Step 2: Press SrFe 12 o 19 The mol ratio of Sr and Fe in the middle is that the ratio of Sr:Fe=1:12 takes by weighing soluble 0.2442g strontium nitrate, soluble 5.5938g ferric nitrate, takes by weighing and cation molar ratio is the chelating agent citric acid 4.7282g of 1.5:1; Weigh 20g of gel-collapsing agent glucose; weigh 9.5958g of acrylamide with a molar ratio of 9:1 to the cation; weigh 1.9192g of a cross-linking agent methylenebisacrylamide with a mass ratio of 5:1 to acrylamide S...

Embodiment 3

[0038] A carbon quantum dot modified n-n type MFe 12 o 19 / CeO 2 The preparation method of magnetic separation photocatalyst comprises the following steps:

[0039] Step 1: Weigh 50g of glucose and dissolve it in 80mL of aqueous solution. After it is completely dissolved, transfer it to a reaction kettle lined with polytetrafluoroethylene, and place the reaction kettle in a drying oven at a constant temperature of 180°C for 5 hours , to obtain water-soluble carbon quantum dots.

[0040] Step 2: Press SrFe 12 o 19 The mol ratio of Sr and Fe in the middle is that the ratio of Sr:Fe=1:12 takes by weighing soluble 0.2442g strontium nitrate, soluble 5.5938g ferric nitrate, takes by weighing and cation molar ratio is the chelating agent citric acid 4.7282g of 1.5:1; Weigh 20g of gel-collapsing agent glucose; weigh 9.5958g of acrylamide with a molar ratio of 9:1 to the cation; weigh 1.9192g of a cross-linking agent methylenebisacrylamide with a mass ratio of 5:1 to acrylamide S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com