Surface molecular imprinting composite photocatalytic material as well as preparation method and application thereof

A technology of surface molecular imprinting and composite photocatalysis, applied in chemical instruments and methods, organic compound/hydride/coordination complex catalysts, physical/chemical process catalysts, etc., can solve the problem of long degradation time and inability to selectively degrade a single To achieve high purity, enhance recycling performance, and improve utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Step 1. Preparation of g-C 3 N 4 Photocatalyst: Put 5g of purchased melamine into a crucible, place it in a muffle furnace, and calcine it in an air atmosphere, raise the temperature to 500°C at a heating rate of 4°C / min, and keep it at a constant temperature for 2 hours. Continue to heat up to 520°C, keep at constant temperature for 2 hours, and cool down to room temperature naturally to obtain g-C 3 N 4 Photocatalyst; save for future use.

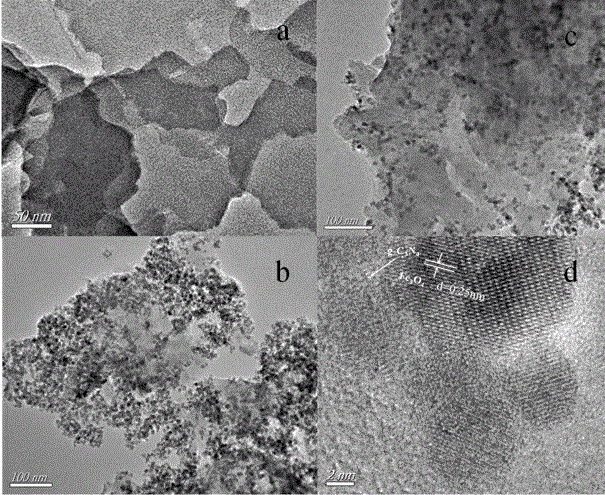

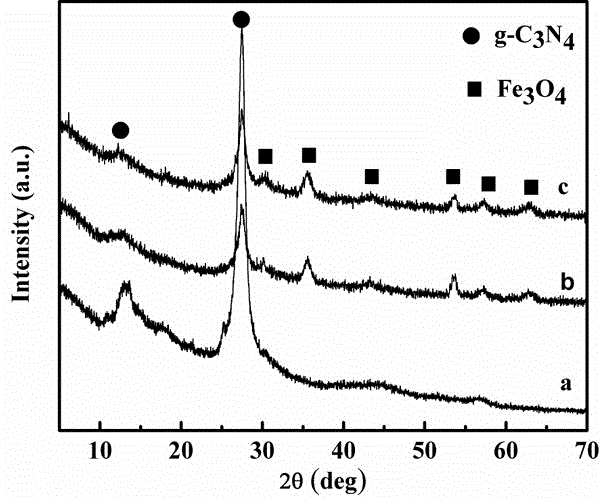

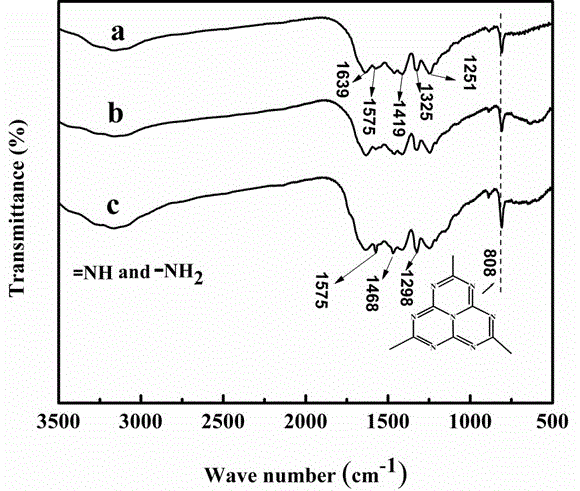

[0033] Step 2, preparation of Fe by hydrothermal deposition technology 3 o 4 / g -C 3 N 4 Composite material: weigh 2.2gg-C 3 N 4 Disperse in 600ml of ethanol / water solution with a volume ratio of 1:2 and sonicate for 5 hours to make g-C 3 N 4 suspension; the 2mmolFeCl 3 ·6H 2 O and 1 mmol FeCl 2 4H 2 O each dissolved in 20ml of distilled water and added to the above g-C 3 N 4 suspension to obtain a mixed solution. The above mixture was stirred at 80°C for 30 min, and then 10 ml of ammonia water was quickly injected...

Embodiment 2

[0037] Step 1. Preparation of g-C 3 N 4 Photocatalyst: Put 5 g of purchased melamine into a crucible, place it in a muffle furnace, and calcine it in an air atmosphere. Raise the temperature to 500°C at a heating rate of 2.3°C / min, and keep it at a constant temperature for 2 hours. The heating rate continued to rise to 520°C, and kept at a constant temperature for 2 hours, and then cooled to room temperature naturally to obtain g-C 3 N 4 Photocatalyst; save for future use.

[0038] Step 2, preparation of Fe by hydrothermal deposition technology 3 o 4 / g -C 3 N 4 Composite material: weigh 2.2gg-C 3 N 4 Disperse in 600ml of ethanol / water solution with a volume ratio of 1:2 and sonicate for 5 hours to make g-C 3 N 4 suspension; the 2mmolFeCl 3 ·6H 2 O and 1 mmol FeCl 2 4H 2 O each dissolved in 20ml of distilled water and added to the above g-C 3 N 4 suspension to obtain a mixed solution. The above mixture was stirred at 80°C for 30 min, and then 10 ml of ammonia ...

Embodiment 3

[0042] Step 1. Preparation of g-C 3 N 4 Photocatalyst: Put 5 g of purchased melamine into a crucible, place it in a muffle furnace, and calcine it in an air atmosphere, raise the temperature to 500 °C at a heating rate of 4 °C / min, and keep it at a constant temperature for 2 hours. The heating rate continued to rise to 520°C, and kept at a constant temperature for 2 hours, and then cooled to room temperature naturally to obtain g-C 3 N 4 Photocatalyst; save for future use.

[0043] Step 2, preparation of Fe by hydrothermal deposition technology 3 o 4 / g -C 3 N 4 Composite material: weigh 2.2gg-C 3 N 4 Disperse in 600ml of ethanol / water solution with a volume ratio of 1:2 and sonicate for 5 hours to make g-C 3 N 4 suspension; the 2mmolFeCl 3 ·6H 2 O and 1 mmol FeCl 2 4H 2 O each dissolved in 20ml of distilled water and added to the above g-C 3 N 4 suspension to obtain a mixed solution. The above mixture was stirred at 80°C for 30 min, and then 10 ml of ammonia ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com