Patents

Literature

107results about How to "High Efficiency Recycling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

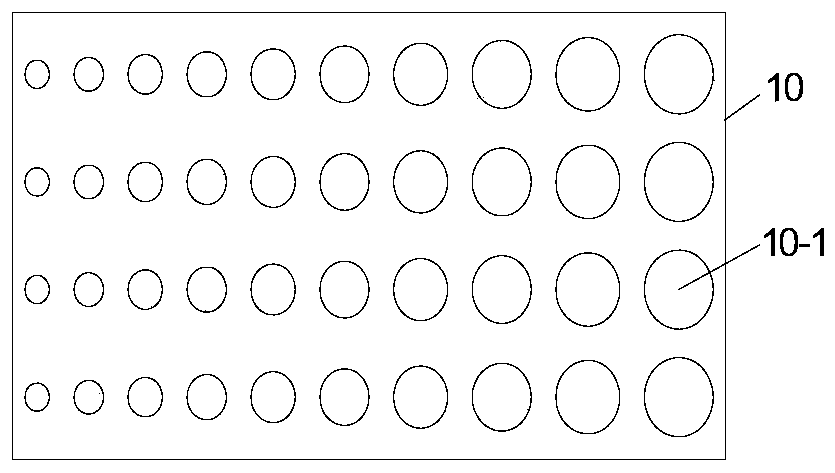

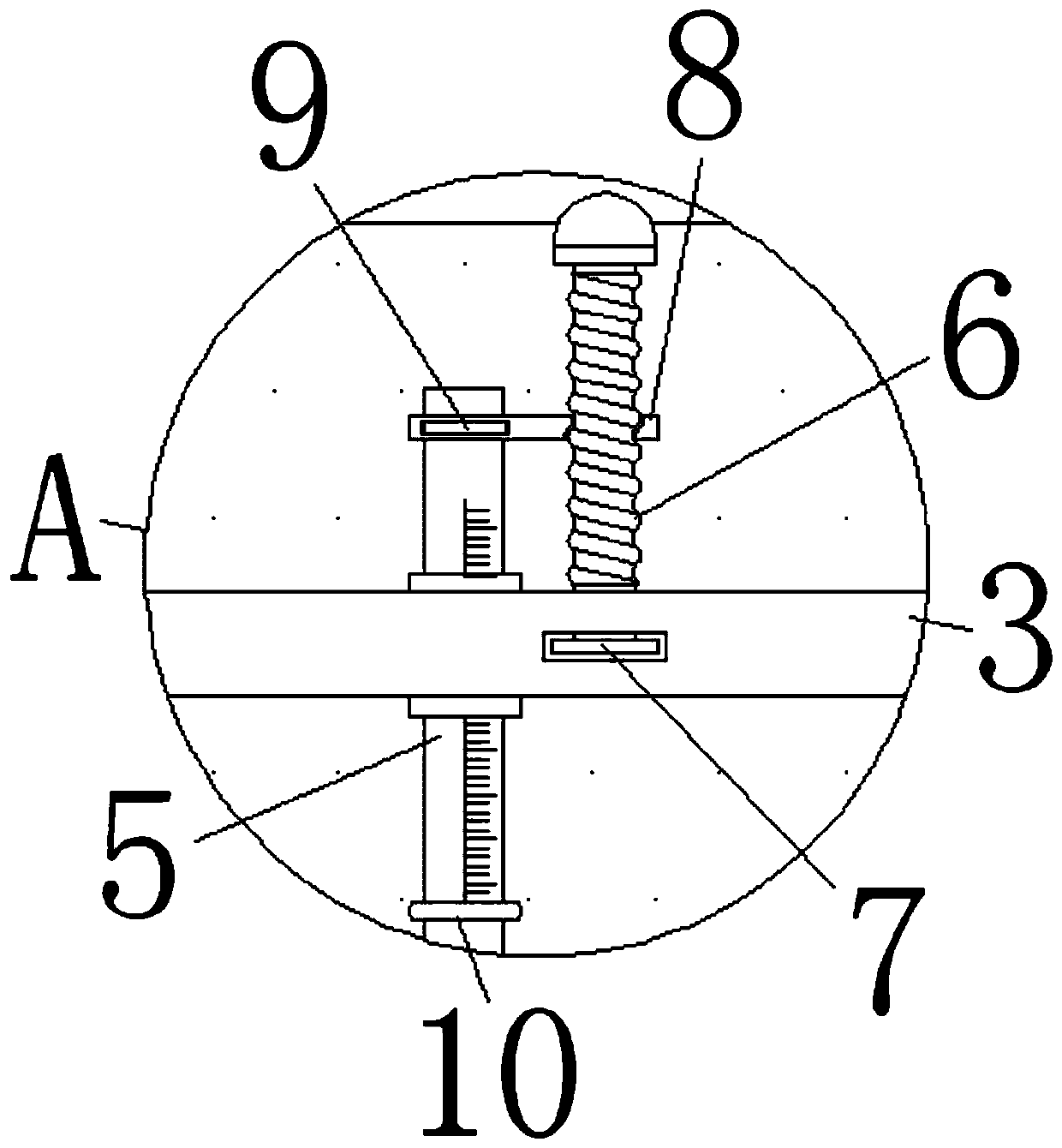

Desulfurization and denitrification method and treatment device for marine exhaust gas

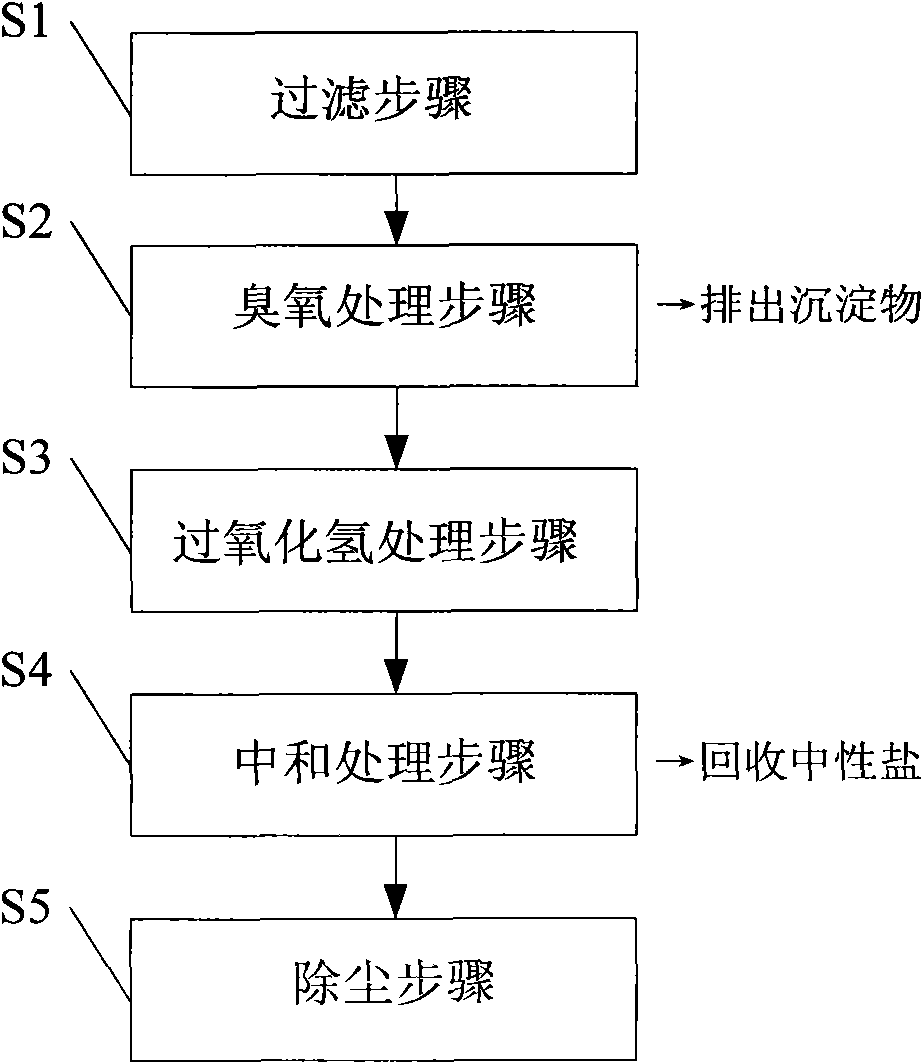

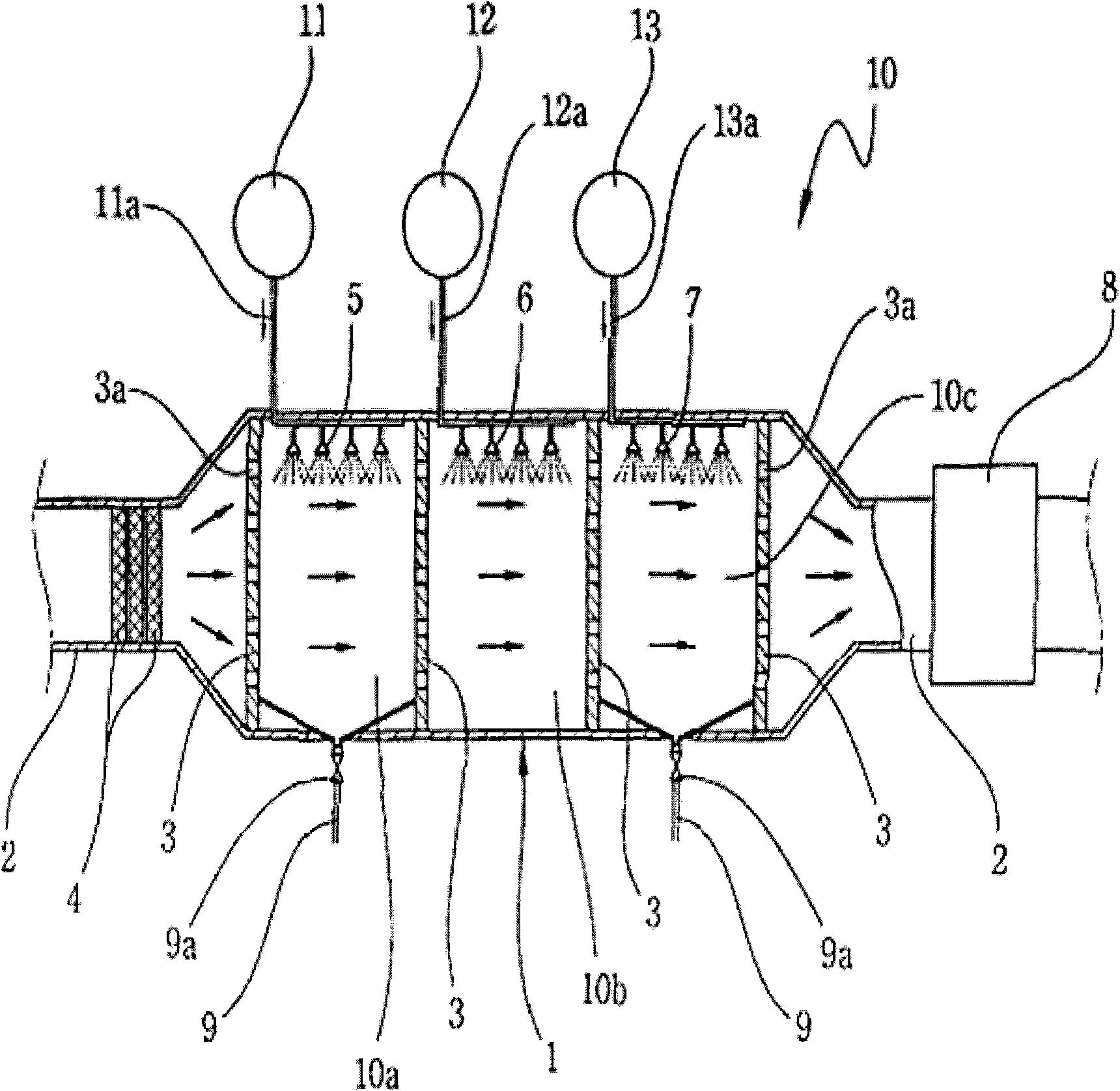

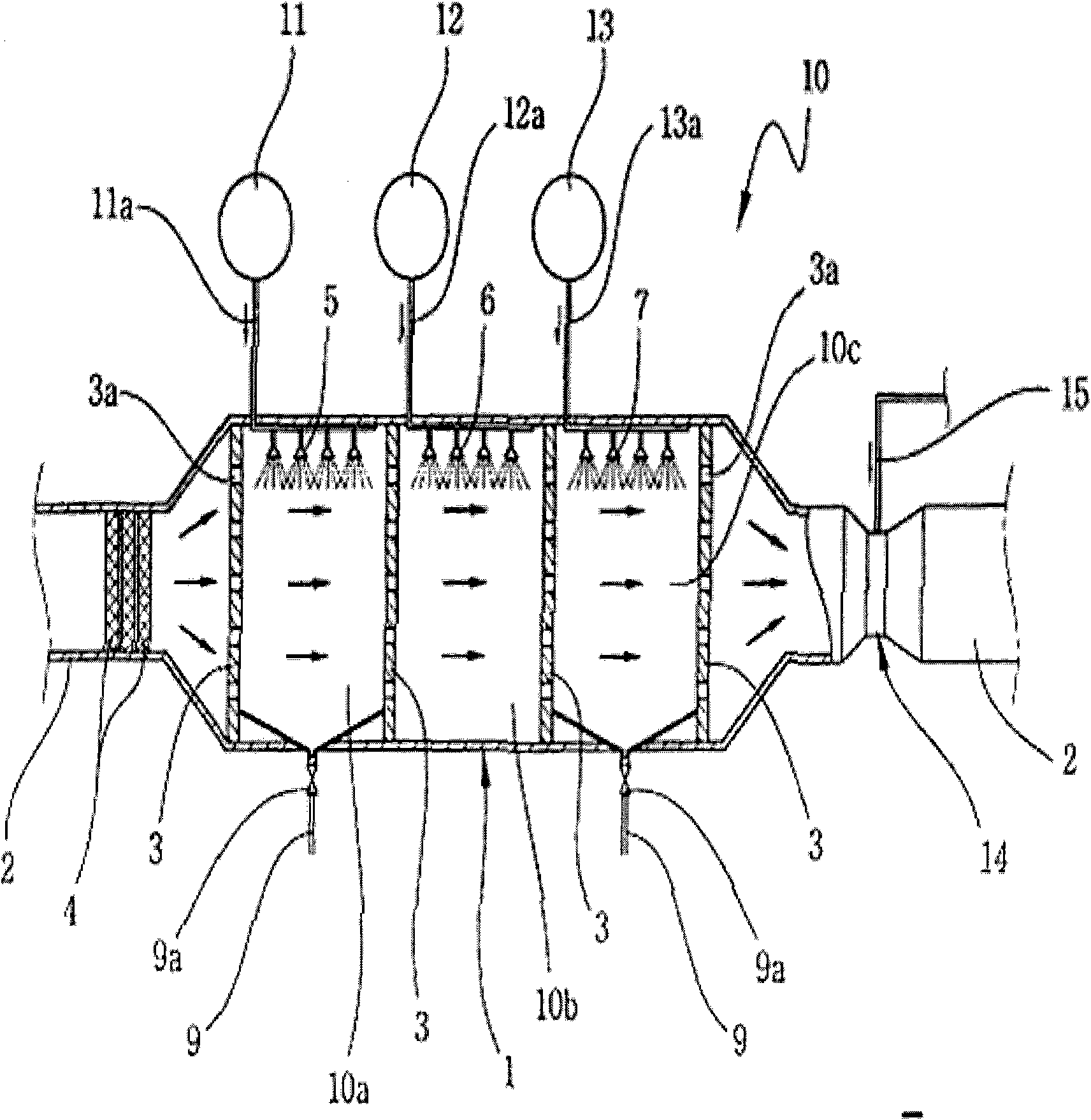

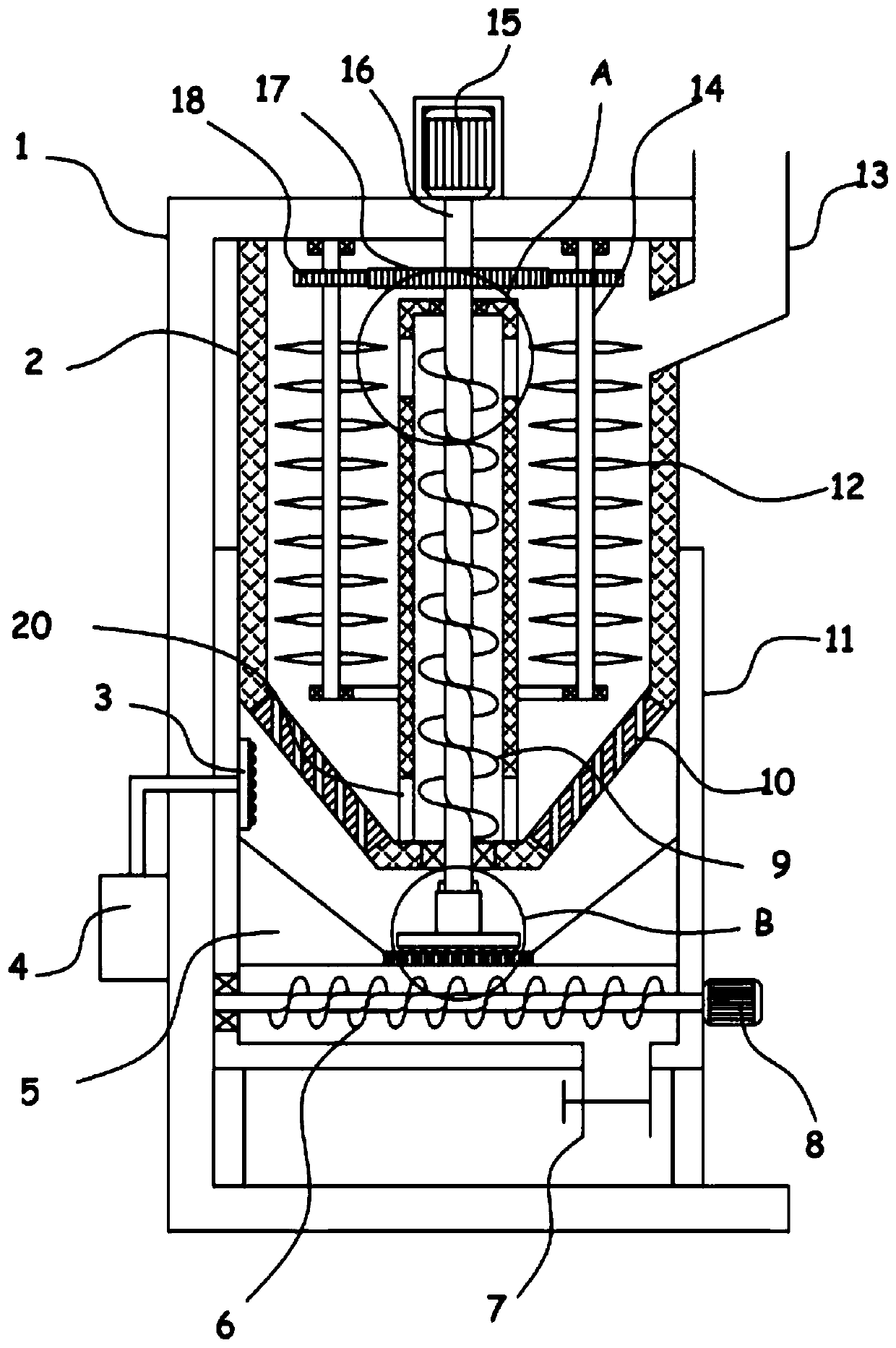

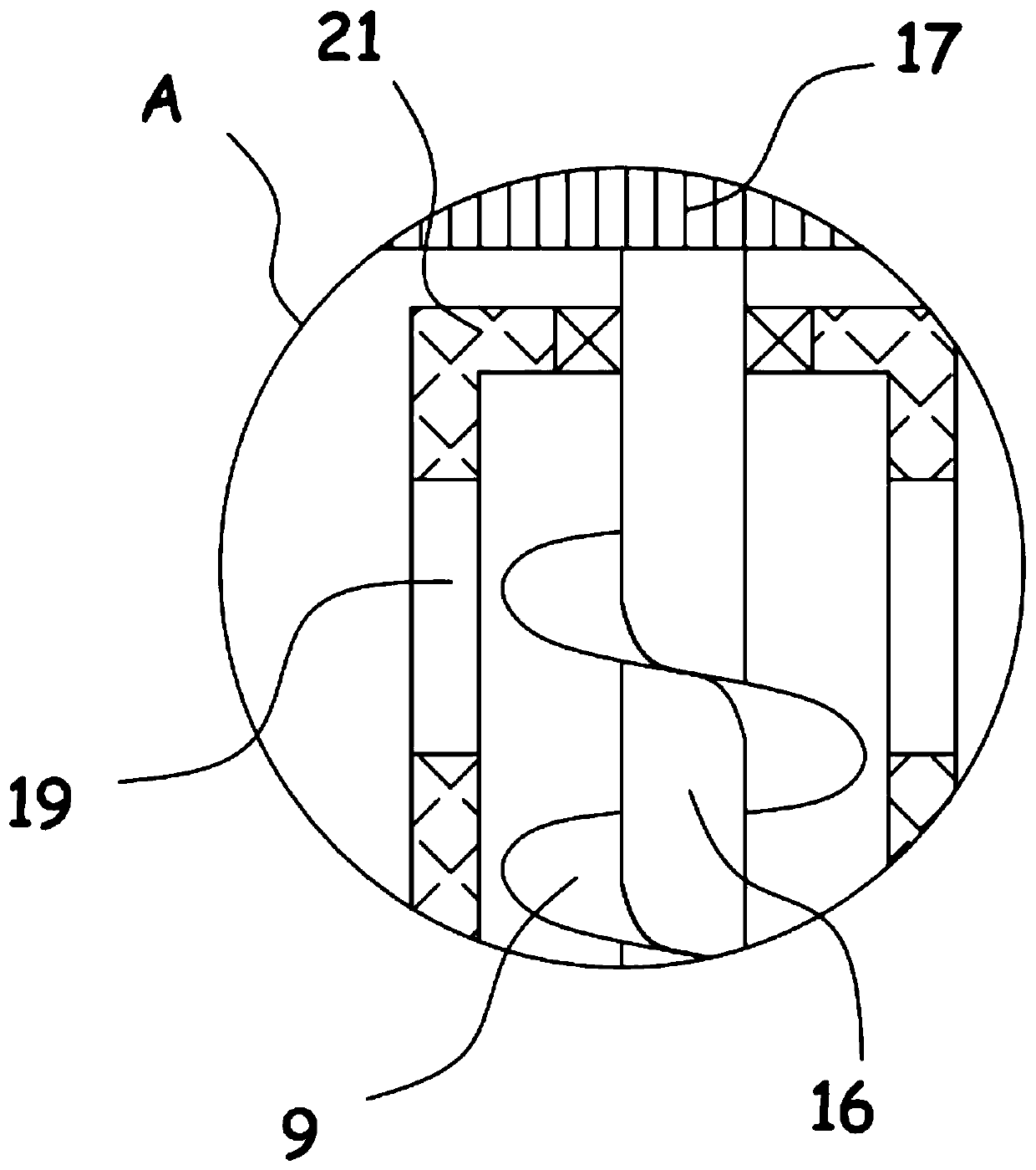

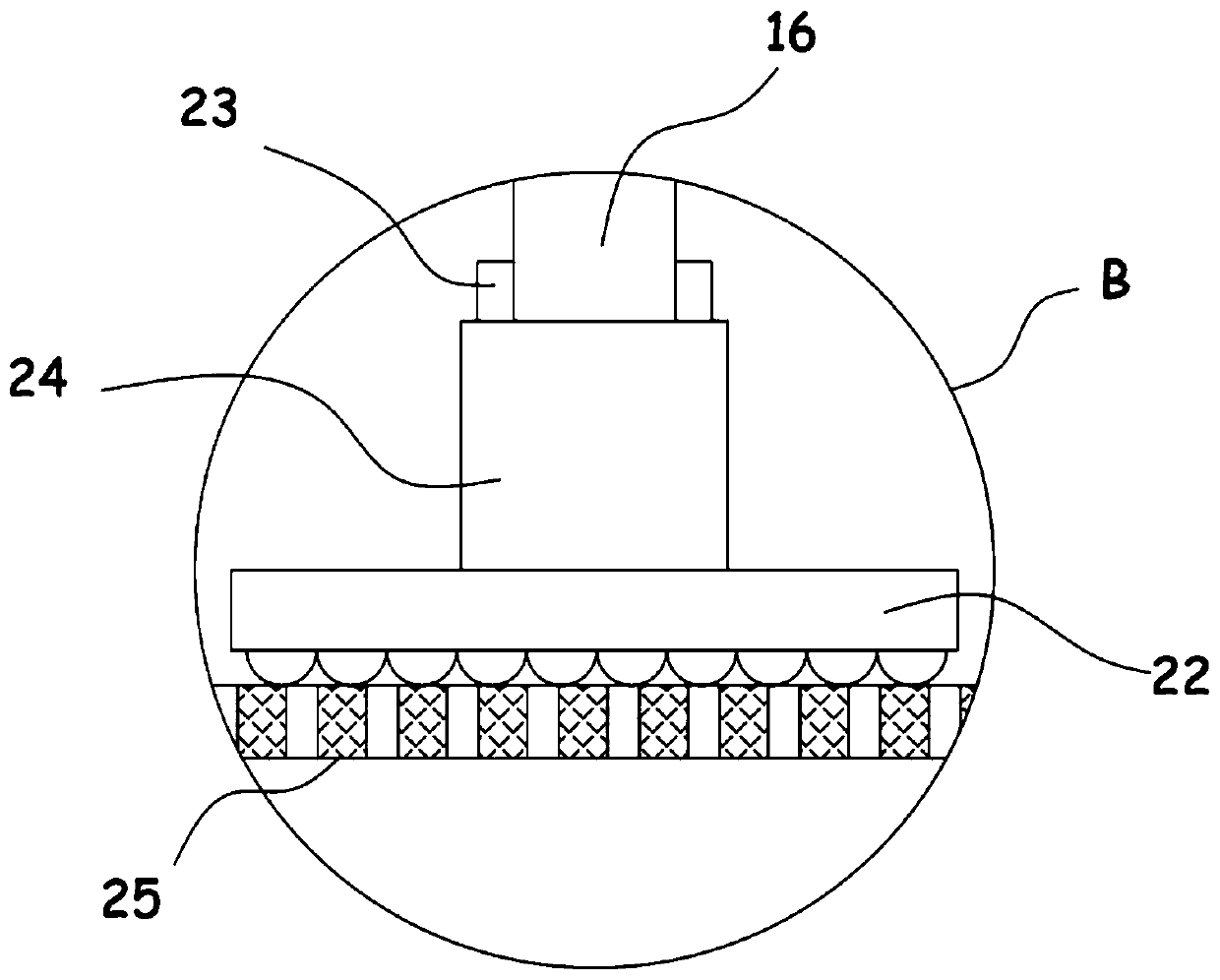

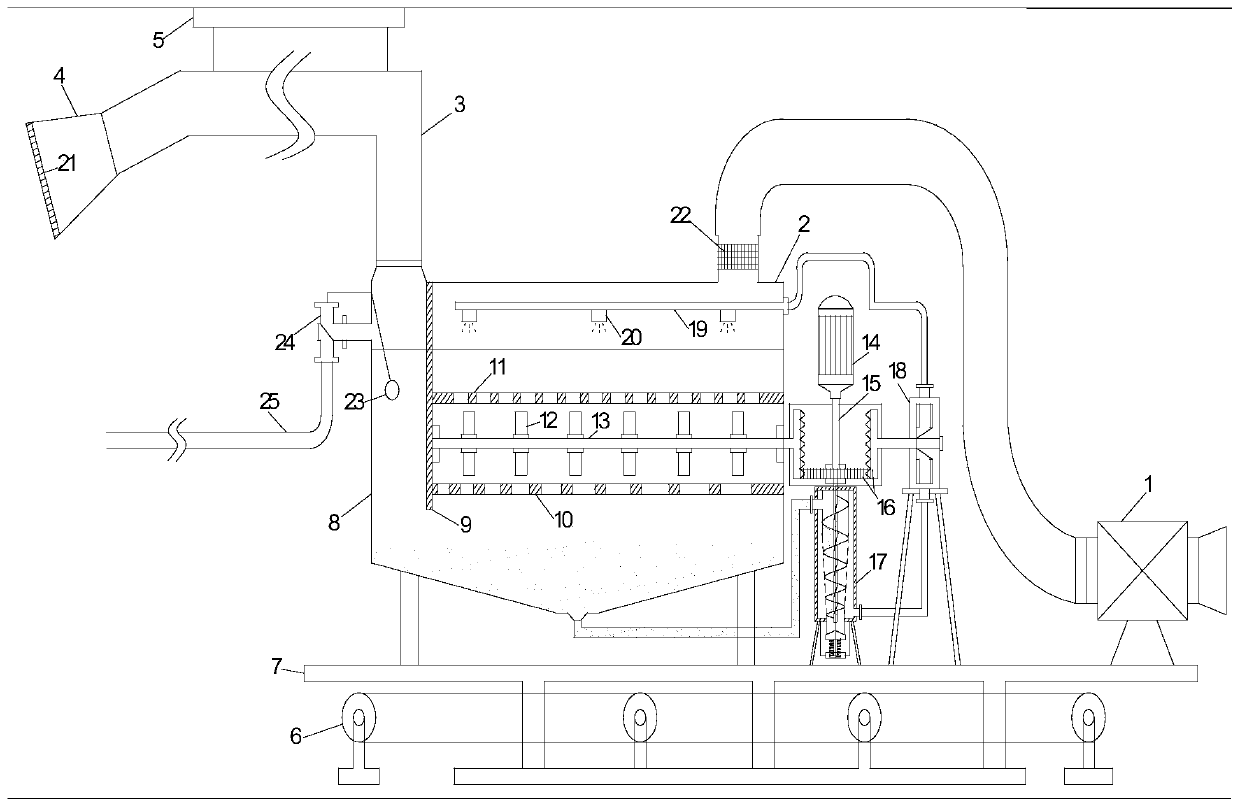

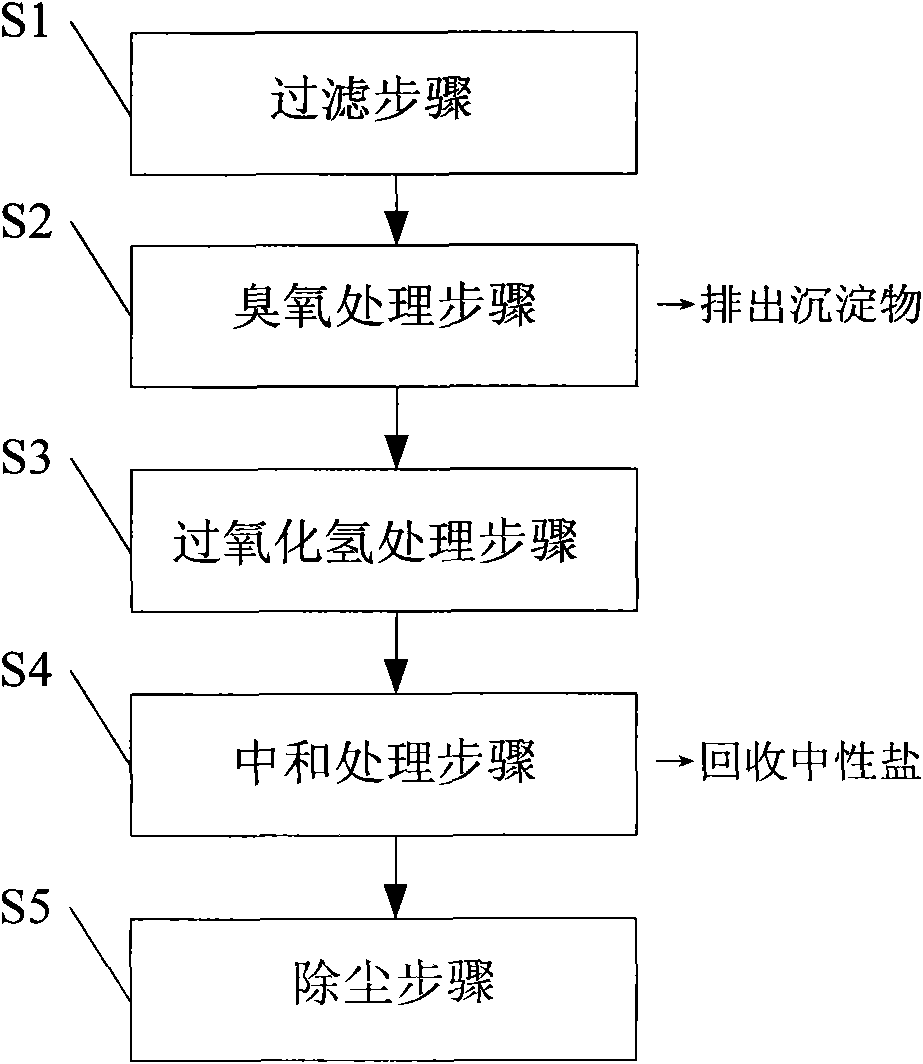

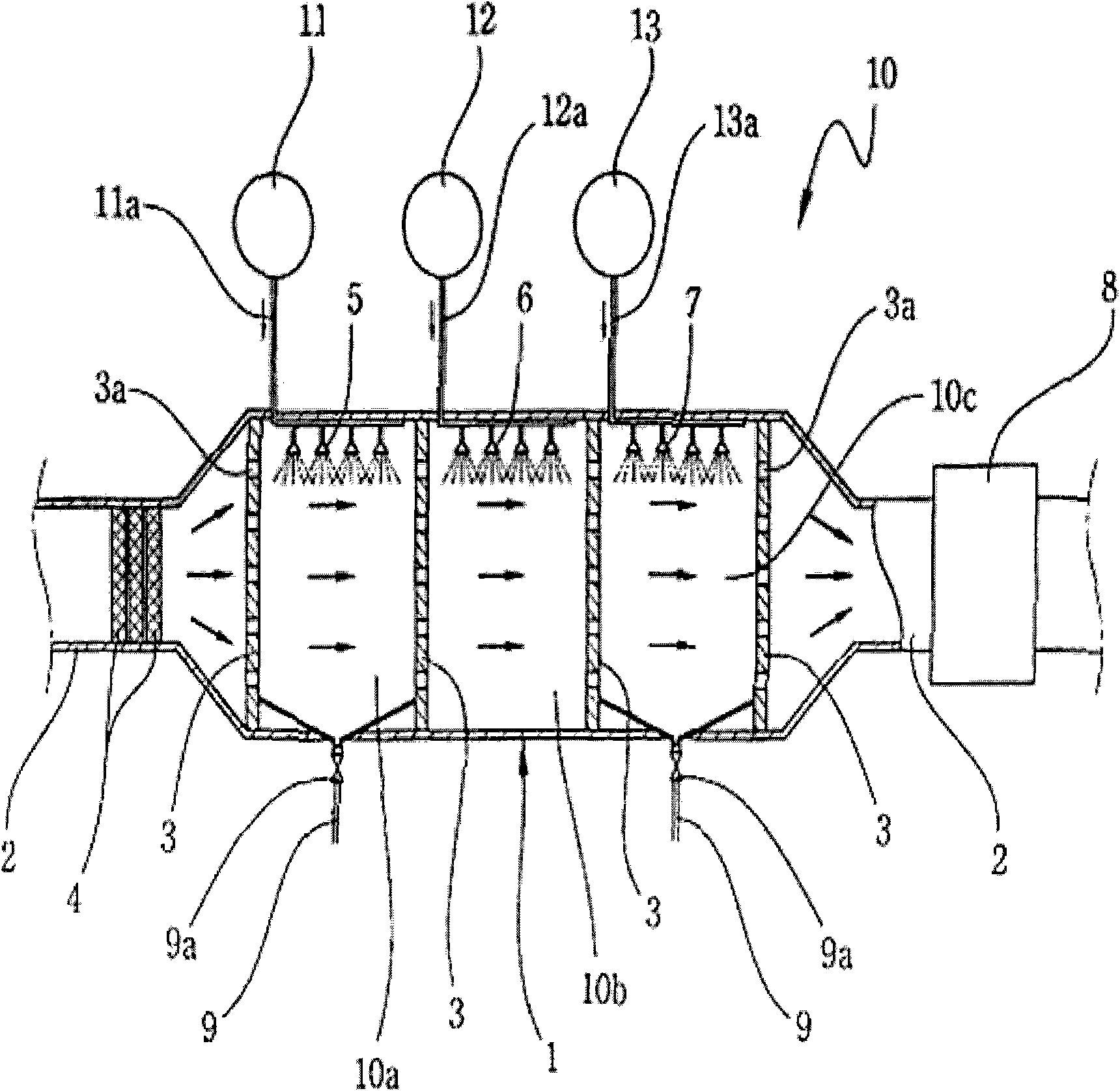

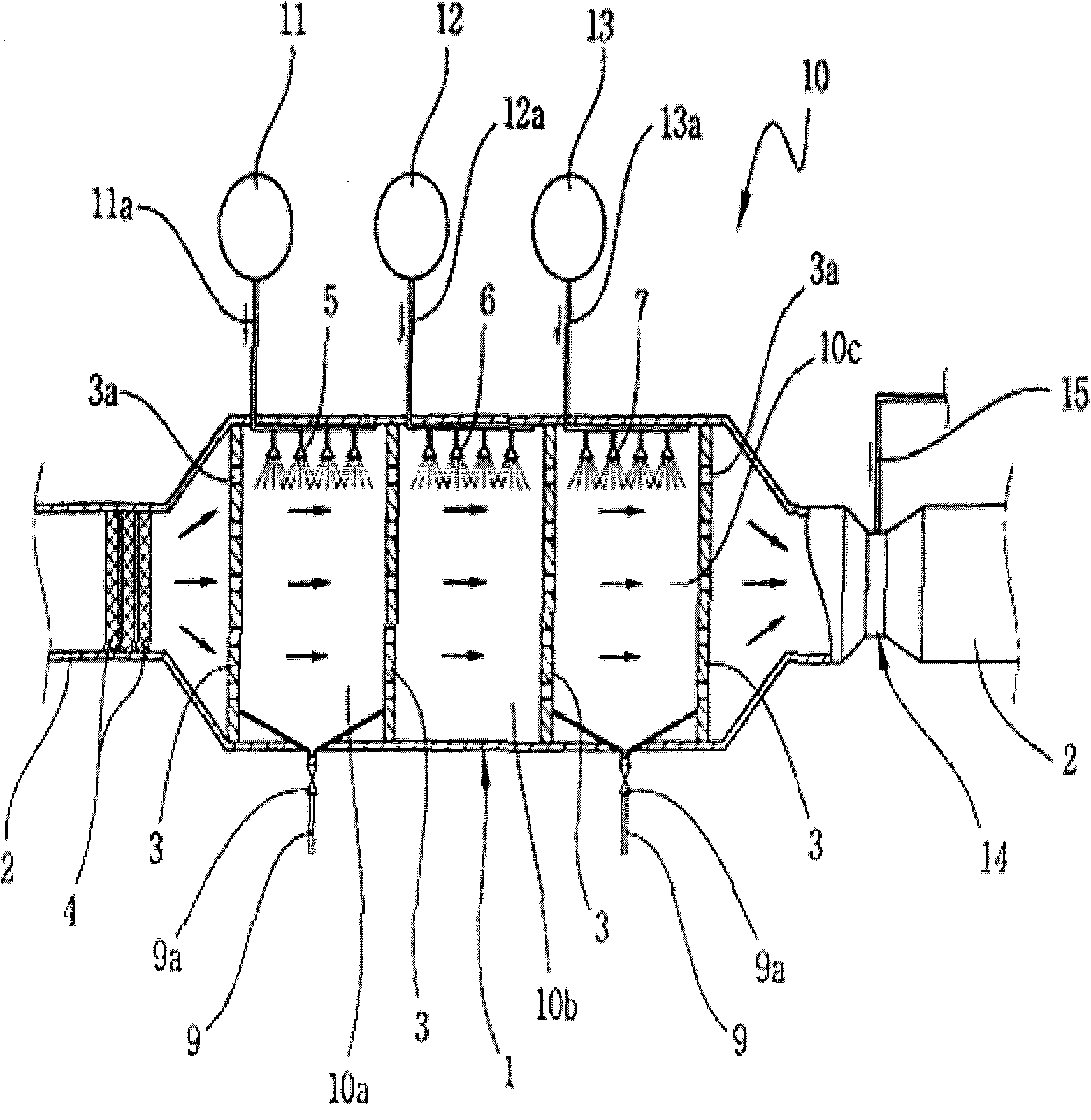

The invention discloses a desulfurization and denitrification method and a treatment device for marine exhaust gas. Exhaust gas produced by a marine diesel engine is treated with ozone, hydrogen peroxide and a neutralizing agent, and the neutralizing agent is sodium chloride with the characteristics of high desulfurization and denitrification capacities, low price and extraction from seawater at any time. Being different from high-irritation and toxic ammonia neutralizing agents, on-board permission of sodium chloride is not required, so that the problems of inconvenience in using and managing other similar neutralizing agents and adverse effects on the living environment of shipmen can be solved; and on the other hand, a neutral salt with a high added value is produced in a neutralizing treatment process, and is recovered through an exhaust pipe at the bottom of a reaction groove, so that the recovery rate and reutilization ratio of the neutral salt are increased greatly. Regions are partitioned inside the reaction space of a porous plate for distributing air current, so that ozone treatment, hydrogen peroxide treatment and neutralizing agent treatment are performed separately respectively. Exhaust gas treatment can be performed under a uniform distribution condition, so that treatment efficiency is increased.

Owner:南亮压力容器技术(上海)有限公司

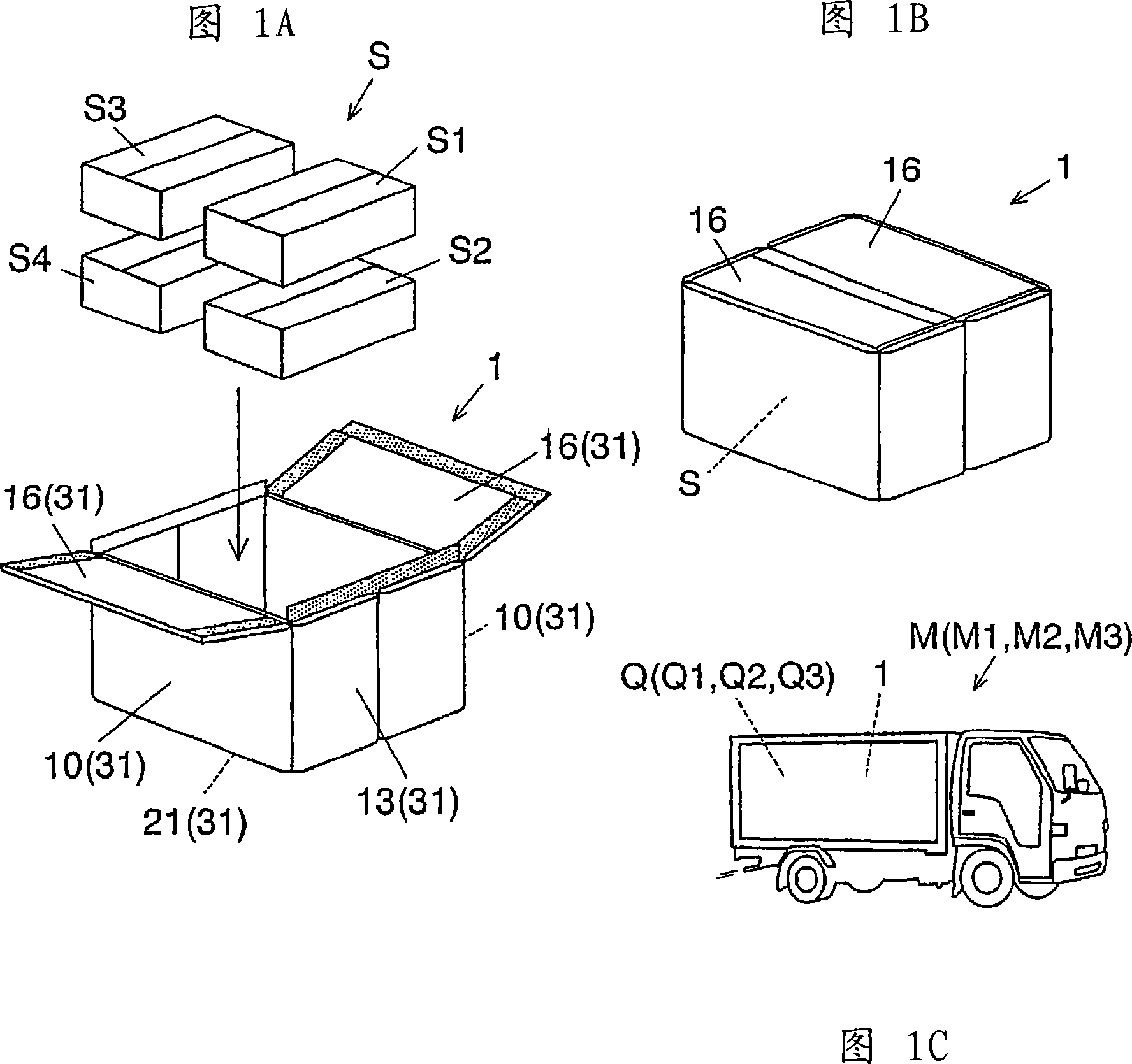

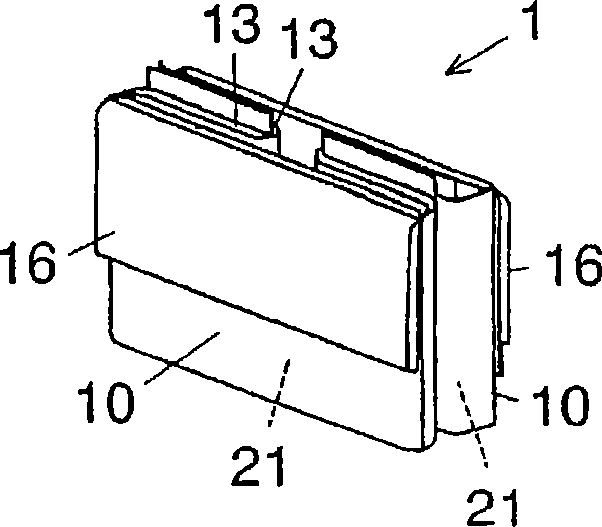

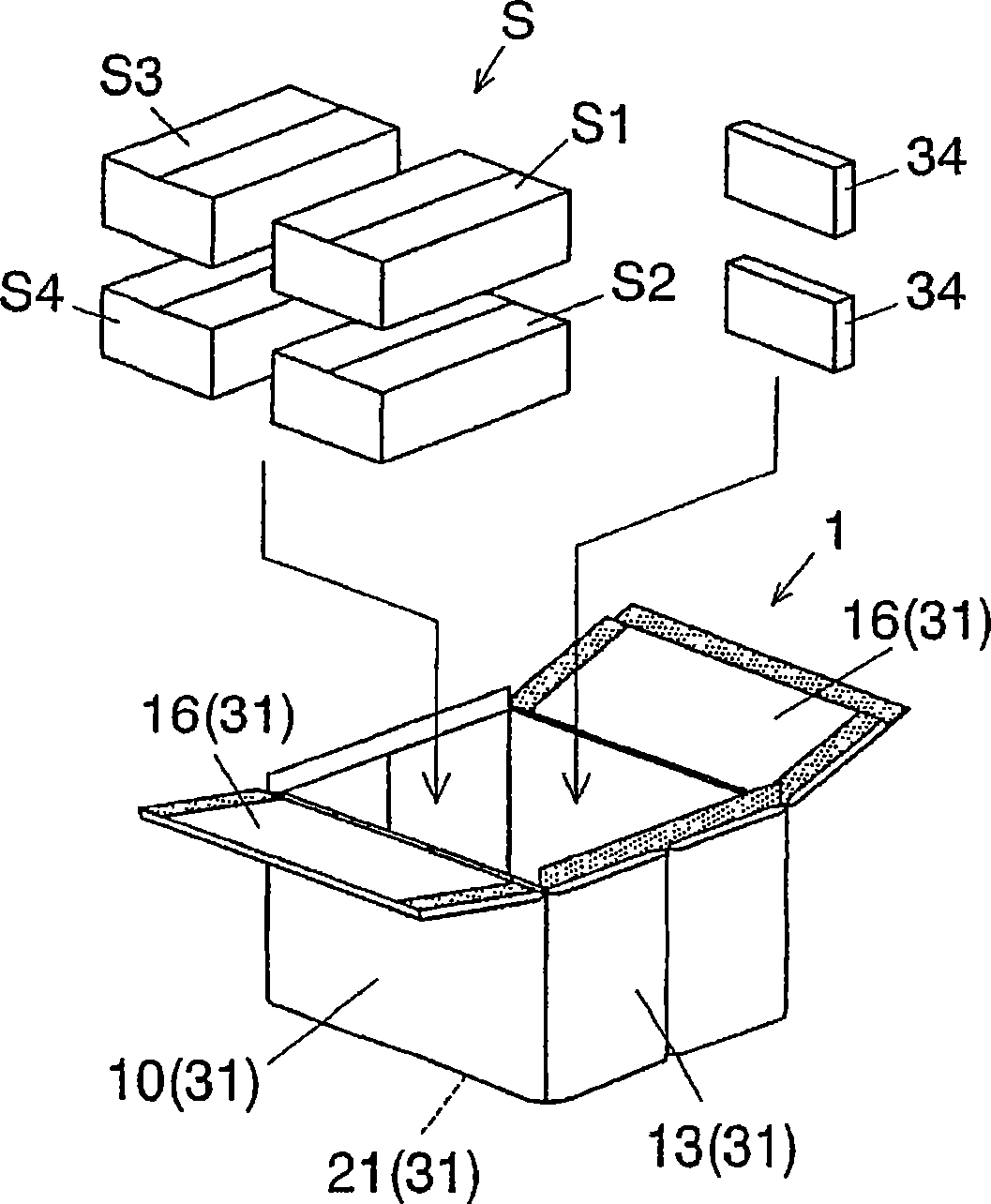

Foldable heat insulating container and distribution method

ActiveCN1914469AReduce delivery costsImprove distribution efficiencyDomestic cooling apparatusLighting and heating apparatusRefrigerator carThermal insulation

Provided is a frozen commodity distribution method reduced in labor and cost while holding the quality of frozen commodities and a cold insulation container unfoldable and foldable in a short time while providing high cold insulation performance. In the distribution method, the frozen commodities requiring cold insulation are stored in the cold insulation container formed of a vacuum thermal insulation material, and the cold insulation container is distributed by a refrigerator car, cold insulation car, or a room temperature car other than a chill car. In the foldable cold insulation container, each of peripheral wall parts, cover parts, and bottom face parts is formed by including the vacuum thermal insulation material in a sheet material, and the peripheral wall parts of the cover parts adjacent to the continuously arranged peripheral wall parts are foldable since the vacuum thermal insulation material is divided along pleat lines. When the container is used, the cover parts and the bottom face parts are rotated in closed attitudes to form into a box. When the container is not used, the bottom face parts are bent to the inside or outside of the peripheral wall parts, the cover parts are bent in the reverse direction of the bottom face parts, and the peripheral wall parts are allowed to approach each other while bending the peripheral wall parts inward along the pleat lines, stacked on each other, and folded.

Owner:PANASONIC CORP

Industrial cultivation method for preparing agaricus bisporus by using fungi residues of edible fungi

InactiveCN104472217AGuaranteed breathability and oxygen contentIncrease carbon to nitrogen ratioCalcareous fertilisersExcrement fertilisersRice strawUrea

The invention provides an industrial cultivation method for preparing agaricus bisporus by using fungi residues of edible fungi. The industrial cultivation method comprises the following steps of establishing a heap by using the following materials in part by weight: 100 parts of wheat straws or rice straws serving as a main material, 20-40 parts of chicken manure, 5-10 parts of plaster, 0.5-1 part of urea and 3-5 parts of cake powder according to the conventional method and turning the heap once; adding 10 parts of the chicken manure in 20-40 parts of fungi residues which are discharged from a bag, smashed and dried, adding water in the mixture and blending the mixture evenly; fermenting various mixed raw materials for 3-5 days and pouring the mixture in a primary fermentation tank; fermenting the main material and auxiliary materials again for 3-5 days; pouring the main material and the auxiliary materials in a secondary fermentation tunnel; forming an air inlet hole in the bottom of a fermentation material pile; properly blowing up and supplying oxygen by using a centrifugal fan; fermenting the main material and the auxiliary materials for 7-10 days; racking and sowing 0.5-1 liter of agaricus bisporus fungi in every square meter of land after the main material and the auxiliary materials are ripe; covering the agaricus bisporus fungi by using soil and producing the fungi; and harvesting the fungi in good time. By the industrial cultivation method, raw materials for producing the agaricus bisporus can be found out easily, and residues generated after industrialized production of pleurotus eryngii and asparagus are circularly and efficiently utilized.

Owner:刘召东

Method of fully separating copper, manganese, zinc, cobalt and calcium chloride solution

InactiveCN102888513ALow costHigh Efficiency RecyclingProcess efficiency improvementPhysical chemistryManganese

The invention discloses a method of fully separating copper, manganese, zinc, cobalt and calcium chloride solution. The method comprises the following steps: by taking P2O4 impurity removal liquid produced in a cobalt production process as a raw material, removing calcium, enriching copper, zinc and cobalt, extracting manganese, extracting copper and extracting cobalt in sequence. According to the invention, through fully separating copper, manganese, zinc, cobalt and calcium chloride solution, valuable metals are recycled at low cost and high efficiency, the resource value is maximized, and the method has the advantages of simple process, convenience for operation, greenness and environmental friendliness.

Owner:GANSU NORMAL UNIV FOR NATTIES

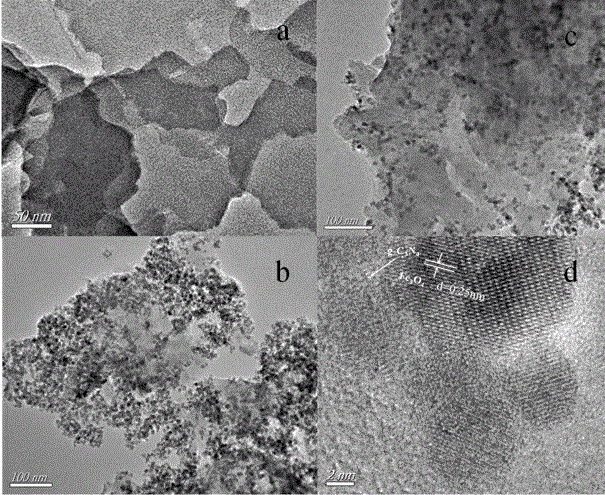

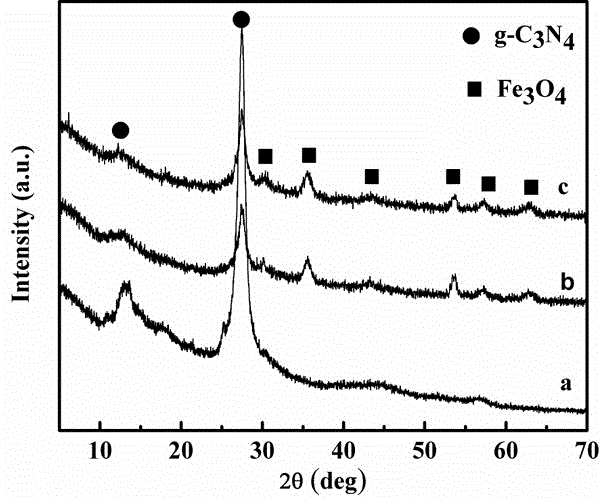

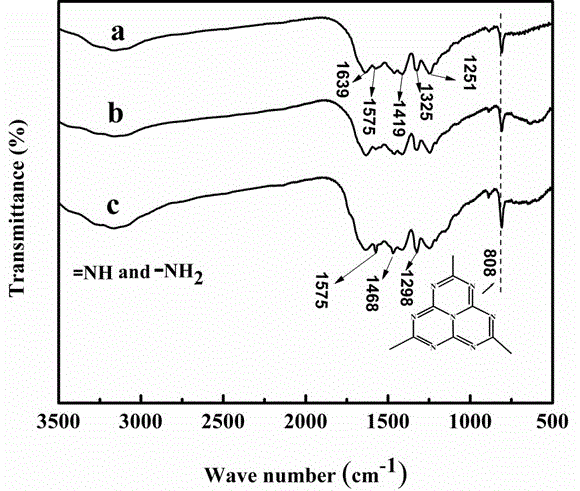

Surface molecular imprinting composite photocatalytic material as well as preparation method and application thereof

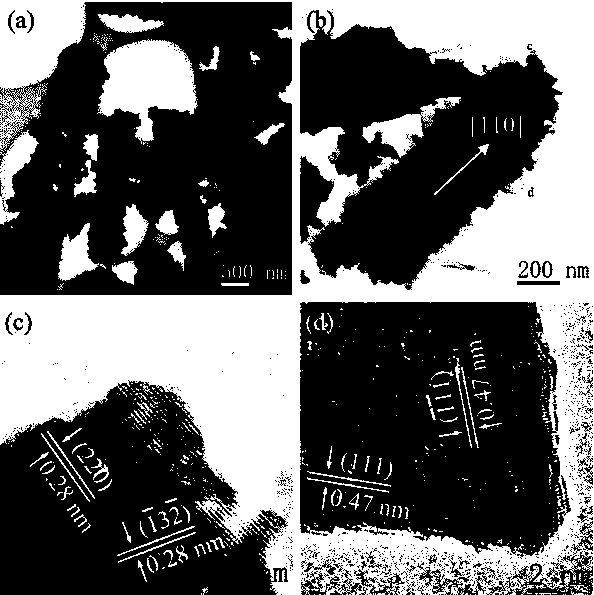

InactiveCN105032493AGood electrical conductivityImprove photocatalytic effectOrganic-compounds/hydrides/coordination-complexes catalystsChemistryPollutant

The invention provides a preparation method of a surface molecular imprinting composite photocatalytic material and belongs to the technical field of environmental material preparation. The preparation method comprises the following steps: preparing g-C3N4 by use of high-temperature calcining, preparing Fe3O4 / g-C3N4-loaded photocatalyst by use of a hydrothermal sedimentation technology, and performing polypyrrole modification on the Fe3O4 / g-C3N4-loaded photocatalyst; and performing surface modification on the Fe3O4 / g-C3N4-loaded photocatalyst by use of a surface molecular imprinting technology, thereby preparing a surface molecular imprinting PPy / Fe3O4 / g-C3N4 composite photocatalytic material with relatively high catalytic activity. By virtue of the synergetic effect of PPy and g-C3N4, the photocatalytic effect is improved; furthermore, due to the excellent conduction performance of Fe3O4, the photocatalytic speed, the Fe3O4 magnetism and the surface molecular imprinting composite photocatalyst recycling are greatly improved, By virtue of introduction of the surface molecular imprinting technology, the purpose of selectively degrading target pollutants can be well realized, and the defect that a common photocatalyst can not selectively degrade the target pollutants can be overcome.

Owner:JIANGSU UNIV

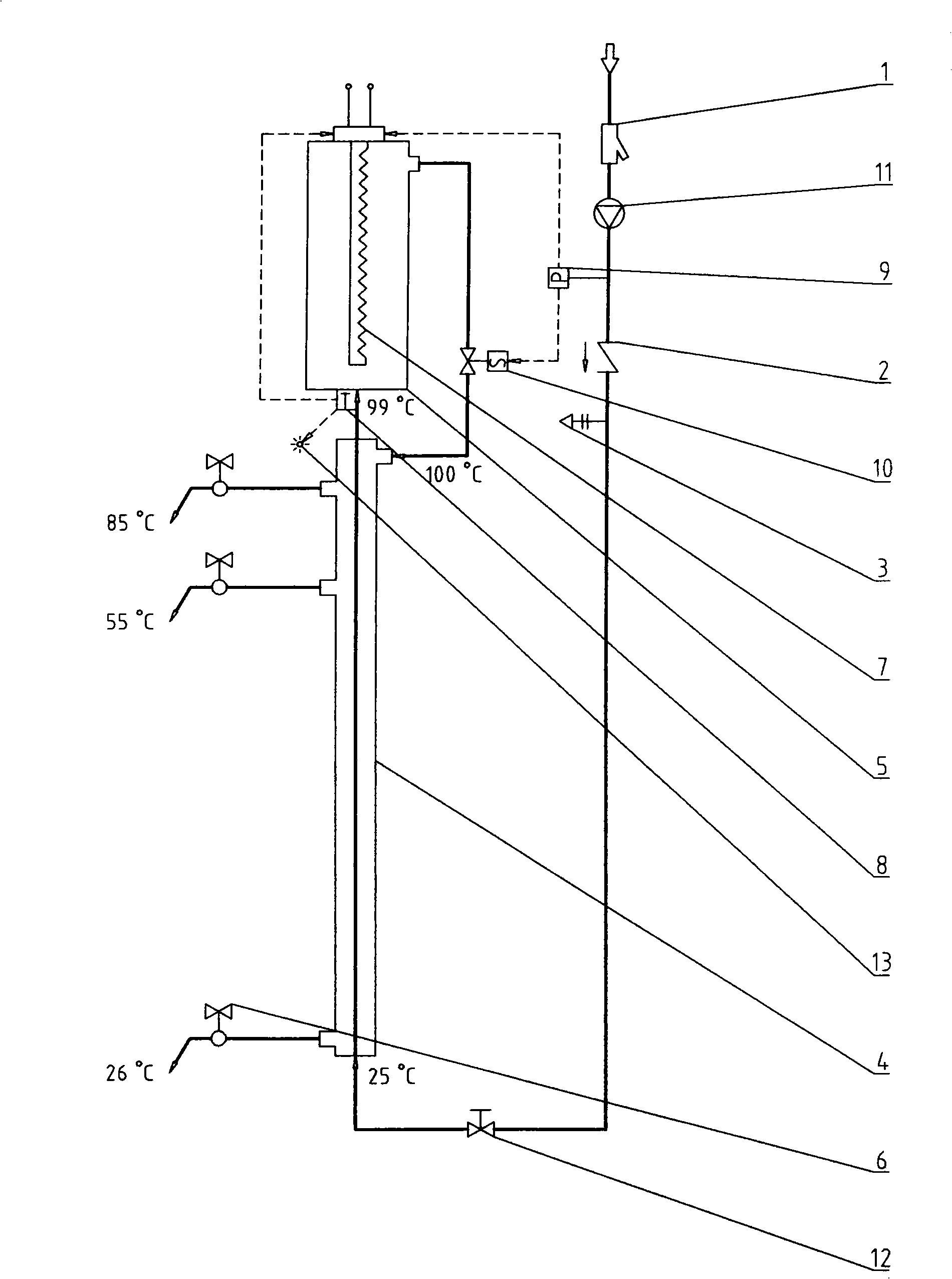

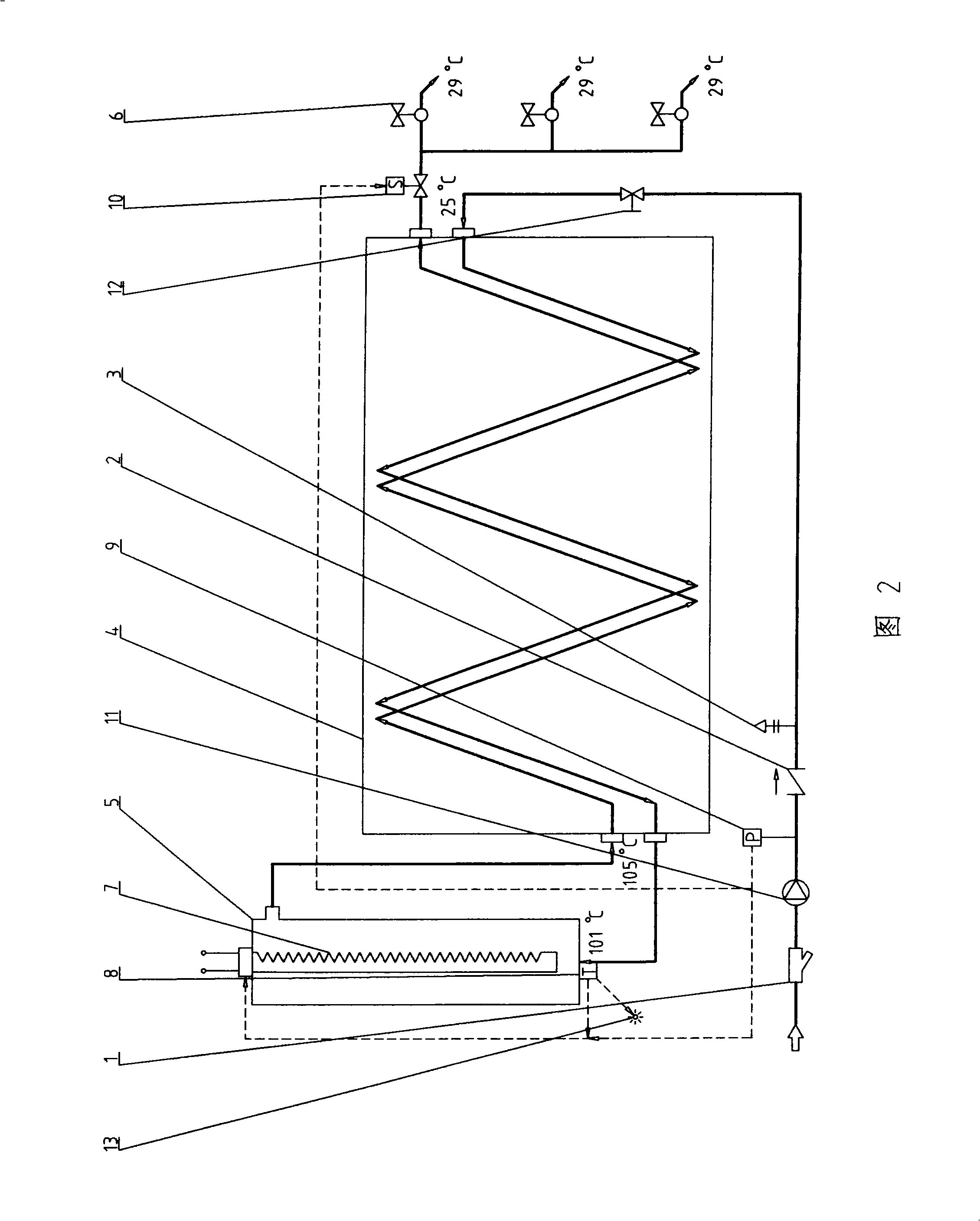

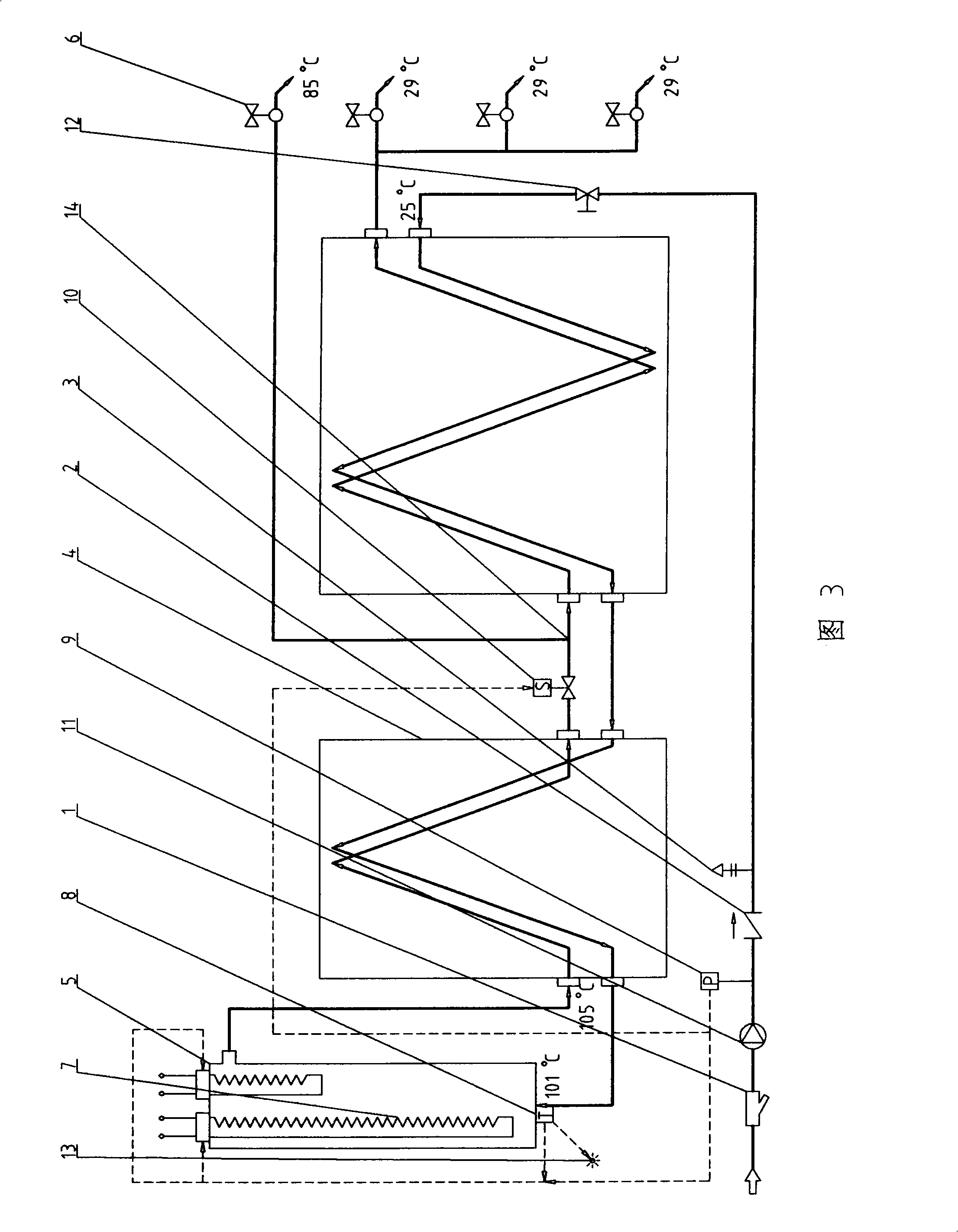

Green direct drinking machine capable of recovering whole sensible heat

InactiveCN101322619AShort manufacturing timeEasy to useBeverage vesselsWarming devicesElectricityTemperature difference

The invention relates to an environment-friendly direct drinking water machine which can recycle all sensible heat; during the process that upper water is heated to 100-200 DEG C for sterilizing to become drinking water, a closed-circuit caloric content cycle, which is formed by 1-40 DEG C small temperature difference heat exchange technology, is adopted for producing the drinking water, the temperature of which is higher than that of the upper water by 1-40 DEG C, and 50-99% of sensible heat is recycled in total; therefore, only by compensating 1-50% of sensible heat loss and heat loss in the systemic circulation through heating, 20-1000 liters of drinking water can be produced by one kwh of electricity, the coefficient of performance of the drinking water machine can reach 80, which is 100 times of the traditional electric kettle for boiling water (100 DEG C); therefore, the drinking water machine is the most energy-saving product in the world in the 21st century.

Owner:侴乔力

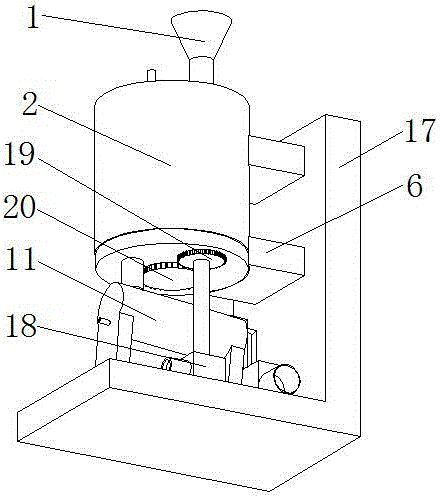

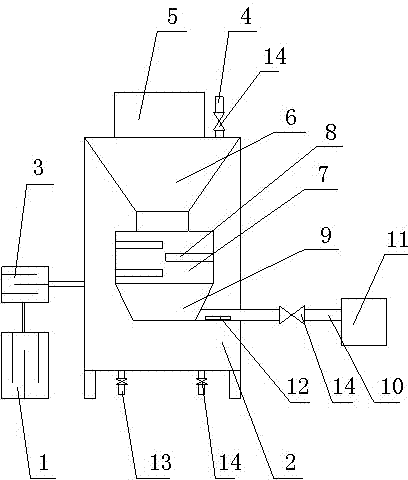

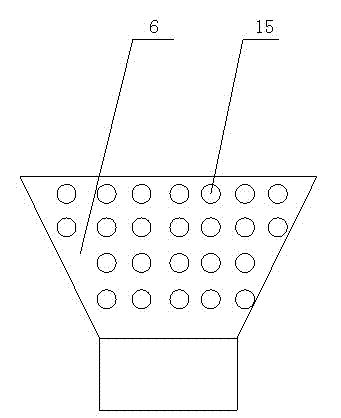

Organic waste crushing device used during agricultural sideline product processing

InactiveCN110180646AImprove the degree of crushing and refinementImprove the crushing and refining effectCocoaGrain treatmentsDrive shaftAgricultural engineering

The invention discloses an organic waste crushing device used during agricultural sideline product processing, and relates to the technical field of agricultural sideline product processing. The device comprises a supporting frame, wherein a crushing cone cylinder is fixed on the supporting frame, a feeding hopper is arranged on the crushing cone cylinder, a sleeve box communicating with the crushing cone cylinder is arranged at the bottom of the crushing cone cylinder in a sleeve mode, the lower end of a driving shaft is in transmission connection with a grinding disc through a connecting assembly, and a grinding groove matched with the grinding disc is fixed in the sleeve box. According to the organic waste crushing device, a crushing mechanism is used for carrying out rotary crushing onorganic waste of agricultural sideline products entering the crushing cone cylinder, the waste is driven to repeatedly and circularly ascend and descend in the crushing cone cylinder by an arranged lifting mechanism so that the waste can be repeatedly rotated and crushed by crushing blades, the crushing and refining degree of the waste is greatly improved, the crushed waste can be further groundand refined by the arranged grinding disc, so that the crushing and refining effect of the waste is greatly improved, and the recycling effect of the waste is higher.

Owner:何玉红

Production technology for producing sintered wall bricks or building blocks with glaze on surfaces from construction waste

ActiveCN106587928AImprove insulation effectLow bulk densityCeramic materials productionClaywaresIndustrial wasteScrap

The invention discloses a production technology for producing sintered wall bricks or building blocks with glaze on surfaces from construction waste and belongs to the technical field of recycling of construction waste for brick production. Green bricks are produced from bricks, concrete blocks, viscous spoil and other construction waste as well as garden waste, trees, plant straw, rice chaff, sawdust or waste in paper mills, sugar refineries and coffee plants and other mixtures of plant materials, and molded green bricks (green building blocks) or dried and preheated green bricks (green building blocks) or sintered bricks (building bricks) are glazed and fired. With the adoption of the method, the construction waste, the garden waste and industrial waste are utilized effectively, the recycling efficiency of waste is improved, glaze application is easier due to addition of plant materials, glaze can permeate micropores in surfaces of the bricks (building blocks), glaze layers and the bricks are bonded more closely and firmly, and the probability of falling of glaze in the later period is far lower than that of existing exterior wall tiles.

Owner:中科智通固体废物处置科技有限公司

Full-wet circulating water filtration dust removal system for tunnel roadway driving face and working method

ActiveCN110410135AIncrease contact timeImprove dust removal efficiencyMining devicesDust removalFiltrationWater resources

The invention discloses a full-wet circulating water filtration dust removal system for a tunnel roadway driving face and a working method, and belongs to the technical field of roadway driving face dust removal. The dust removal system comprises a water inlet system, a spray dust fall system, a power distribution system, a circulation system and a solid-liquid separation system; the spray dust fall system comprises a box body. The interior of the box body is partitioned into an air inlet zone and an air outlet zone through a baffle. Dust generated on the roadway driving face enters the air inlet zone, the air outlet zone is provided with an upper partition and a lower partition, a stirring zone is arranged between the upper partition and the lower partition, and a stirring unit is arranged in the stirring zone. The bottom of the box body communicates with the solid-liquid separation system. The circulation system is used for collecting water treated by the solid-liquid separation system and circularly spraying the water into the box body. The power distribution system supplies power to the stirring unit and the solid-liquid separation system. The dust removal effect is improved, meanwhile, waste of water resources caused by spray dust fall and pollution to the working environment are avoided, and recycling of water resources is achieved.

Owner:SHANDONG UNIV OF SCI & TECH

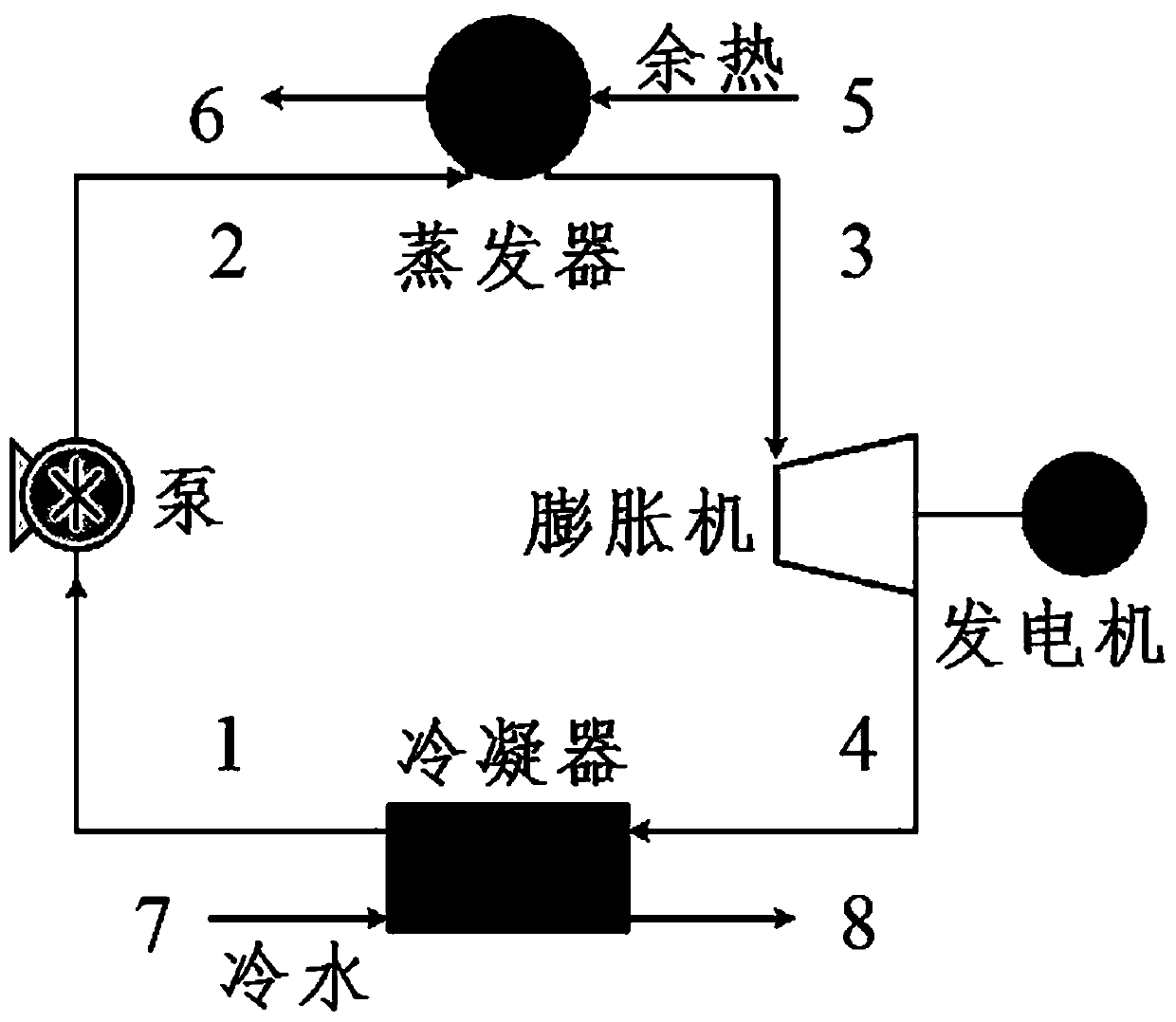

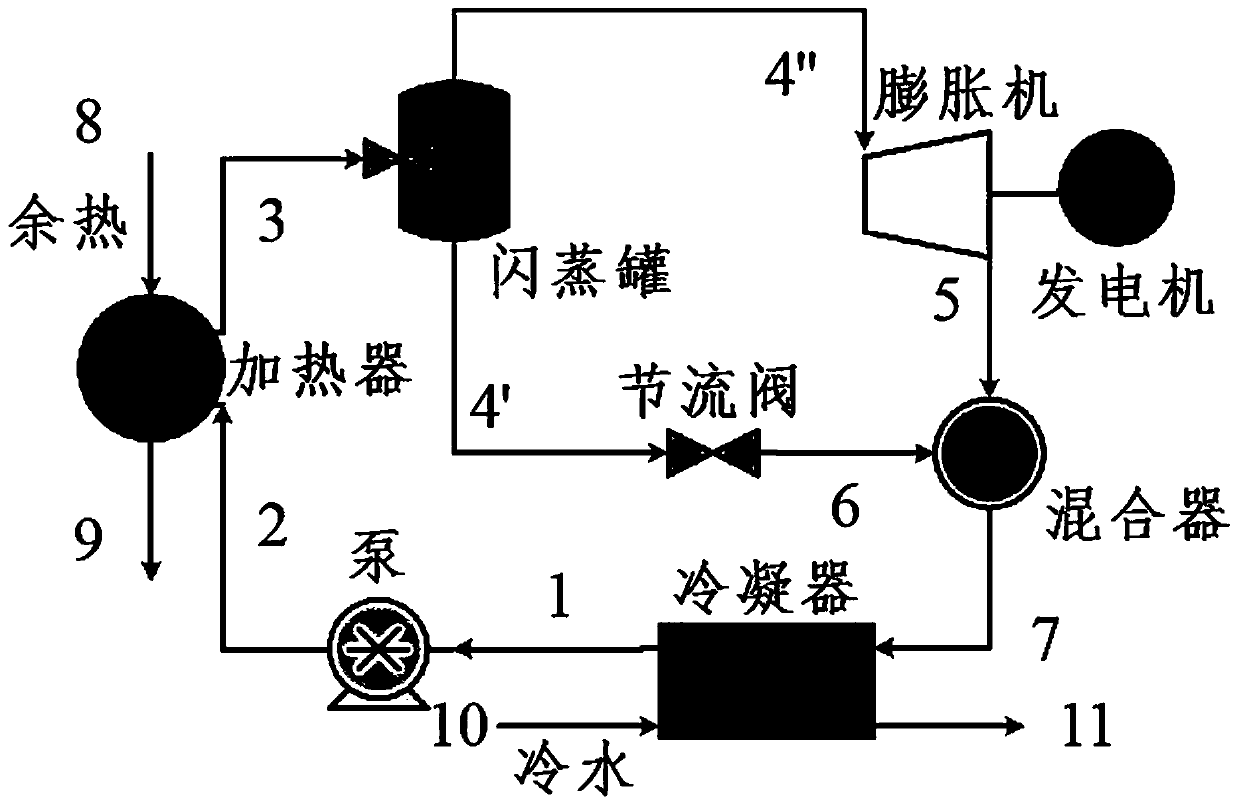

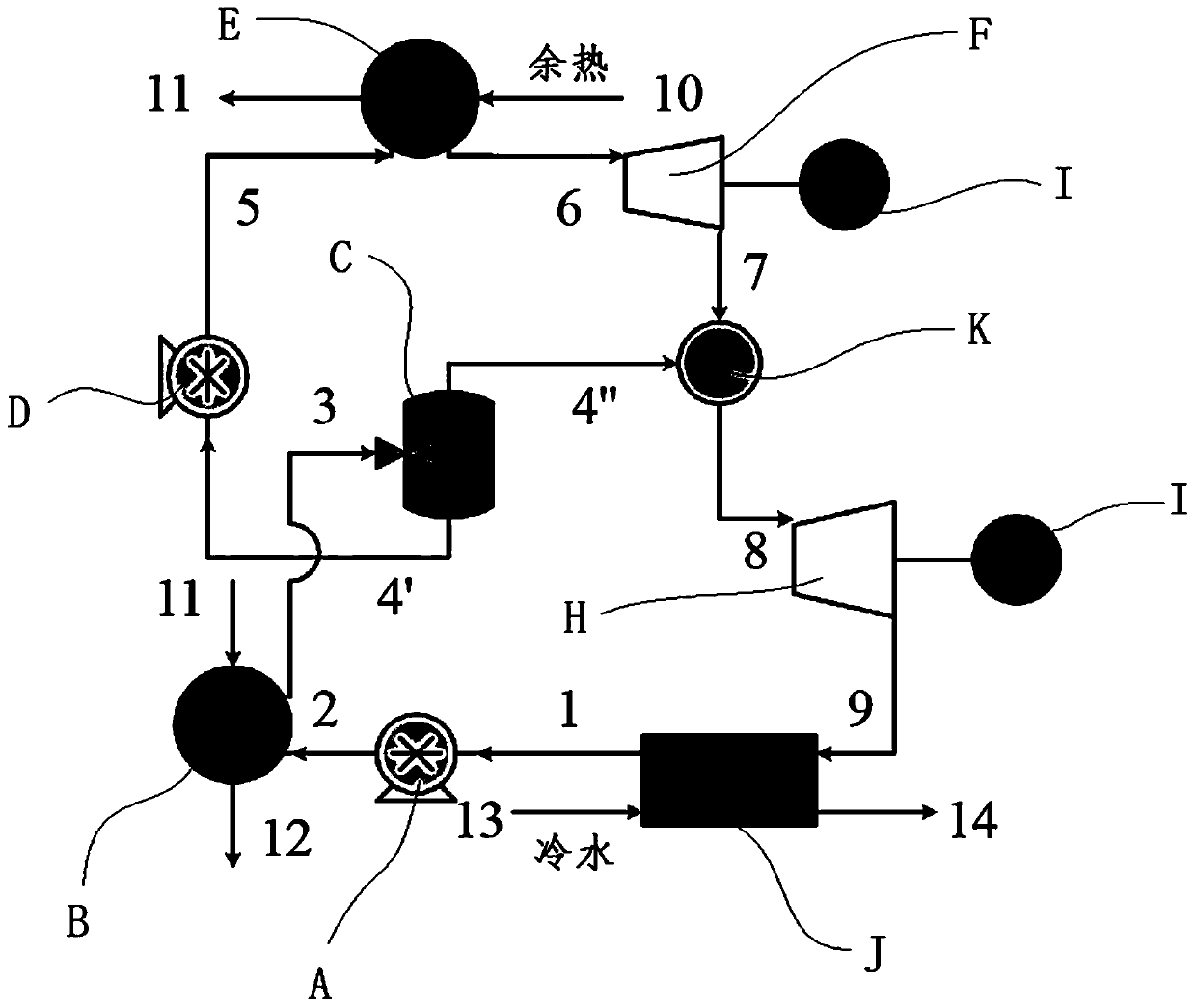

Waste heat recycling system and method based on organic Rankine recycle and organic flash recycle

ActiveCN111022137AElimination of irreversible energy lossImprove the ability to recycleSteam useOrganic Rankine cycleProcess engineering

The invention relates to a waste heat recycling system and method based on organic Rankine recycle and organic flash recycle. Liquid organic media output by a condenser are pressurized through a low-pressure pump, then introduced into a heater and subjected to constant pressure heating in the heater to become saturate liquid media, and the saturate liquid media are fed into a flash tank and subjected to the throttling action in the flash tank to become a gas-liquid two-phase mixture through flash vaporization, the liquid media are pressurized through a high-pressure pump and then fed into an evaporator to carry out heat exchange with waste heat, and saturate steam is fed into a mixer; and superheated steam or saturate steam at an outlet of the evaporator enters a high-pressure expanding machine to do work, exhaust steam of the high-pressure expanding machine is fed into the mixer to be mixed with the saturate steam from the flash tank, the mixed steam is fed into a low-pressure expanding machine to do work, and exhaust steam of the low-pressure expanding machine is fed into a condenser and cooled into liquid working media by cooling media in the condenser. By means of the waste heat recycling system and method based on the organic Rankine recycle and the organic flash recycle, effective energy loss in the organic flash recycle and the organic Rankine recycle is reduced, and thepure electric power output and the waste heat energy recycling capability of the system are improved.

Owner:XI AN JIAOTONG UNIV

Water-soluble polymer solution degrading agent, and preparation method and application thereof

InactiveCN105967306AReduce apparent viscosityHigh Efficiency RecyclingWaste water treatment from quariesWater treatment parameter controlPolymer scienceApparent viscosity

Owner:PETROCHINA CO LTD

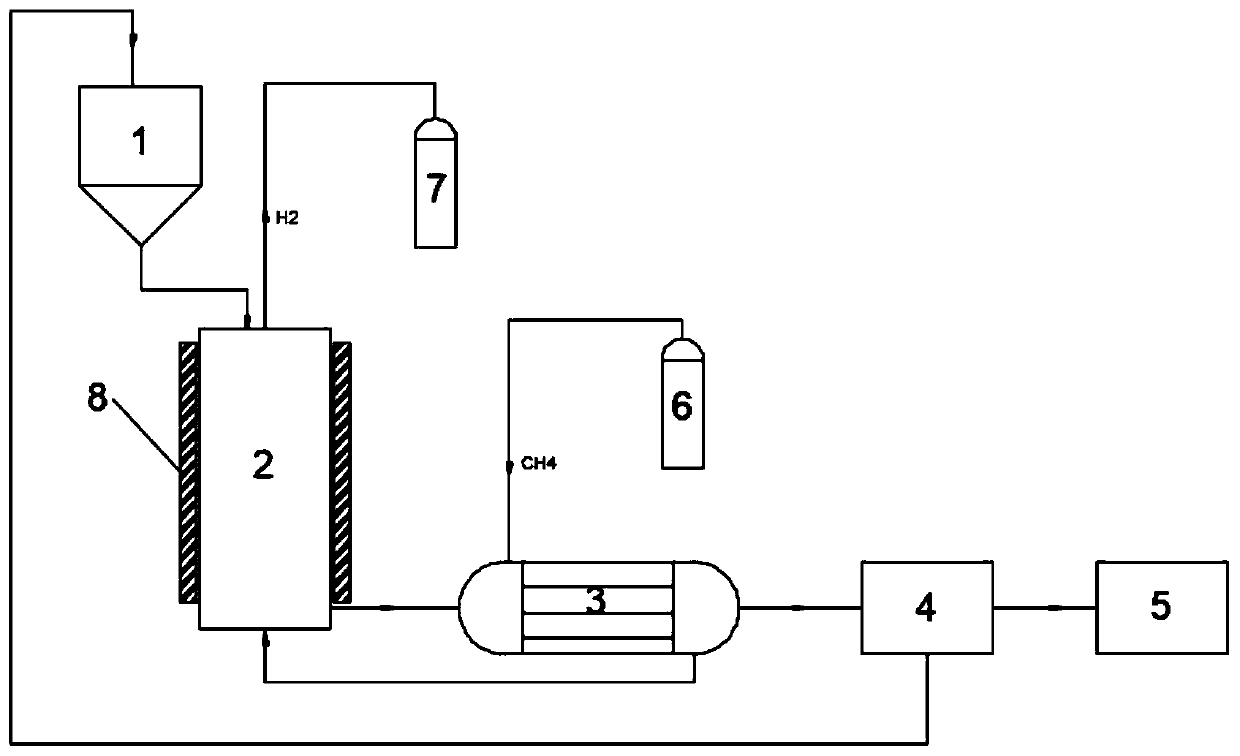

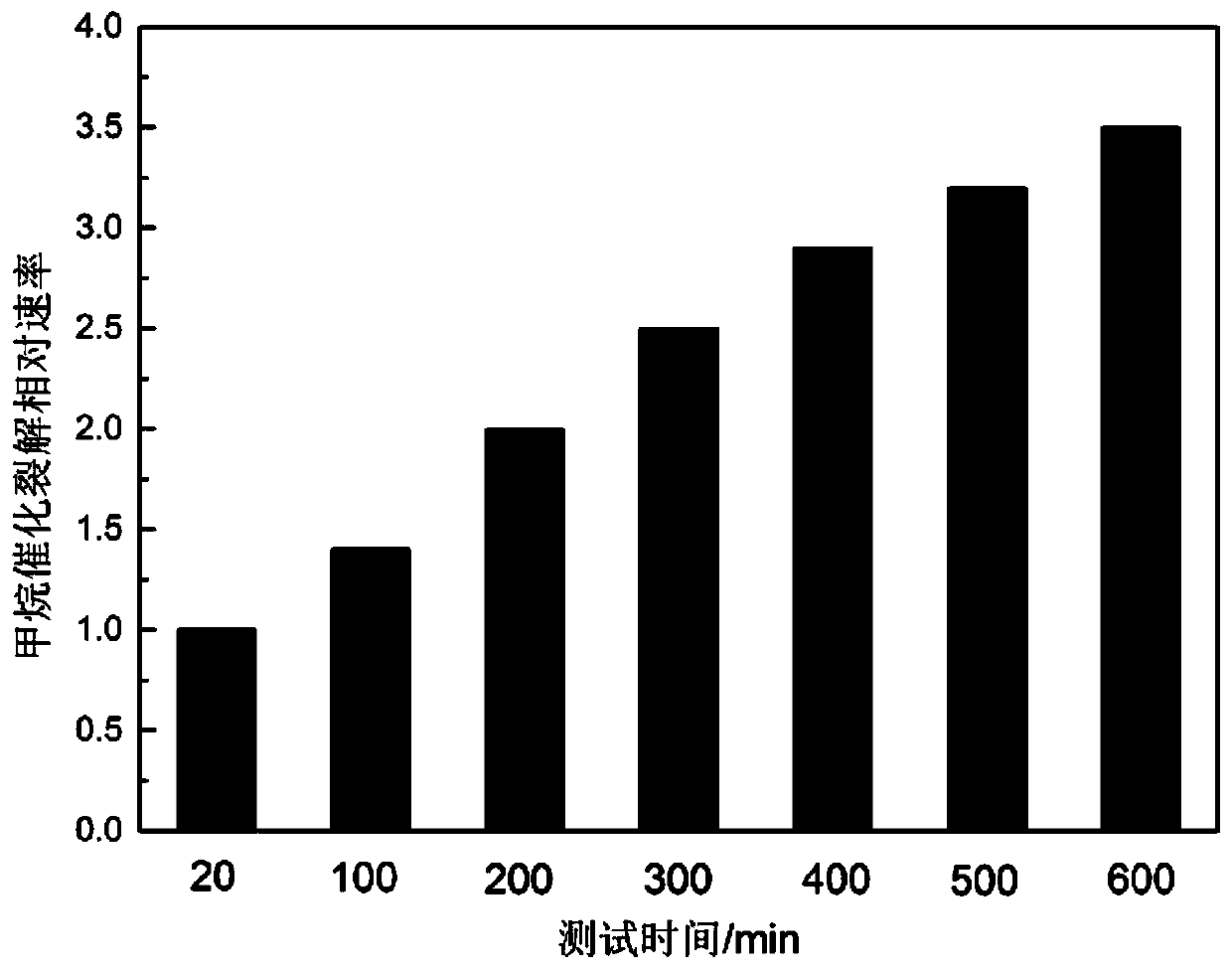

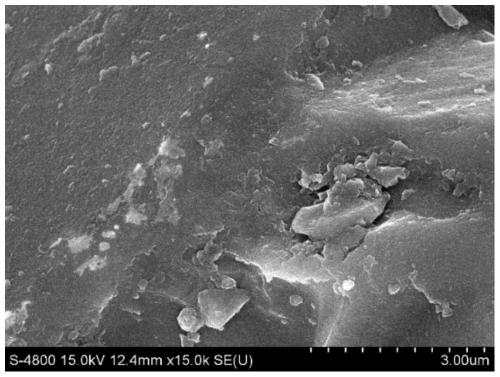

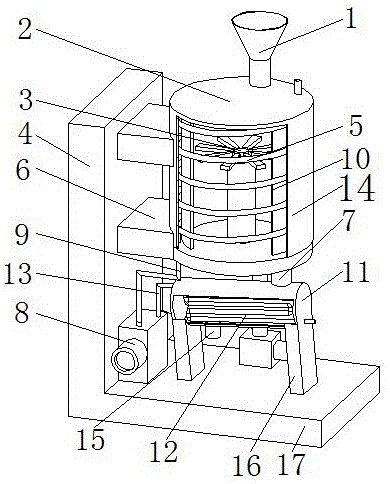

Carbon nanotube and hydrogen production system and method with autocatalysis function

ActiveCN109928361AHigh purityReduce initial investmentHydrogenCarbon nanotubesGas cylinderCatalytic function

The invention discloses a carbon nanotube and hydrogen production system and method with autocatalysis function. The production system includes a quartz sand feeding device, a moving bed reactor, a heat exchanger, an ultrasonic separation device, a carbon nanotube purification device, a methane gas cylinder and a hydrogen storage tank. The moving bed reactor is adopted, cheap and easily availablemethane gas is taken as the carbon source, natural quartz sand is used as an unconventional catalyst for catalytic cracking to produce carbon nanotubes and high purity hydrogen at the same time, alsothe carbon nanotubes loaded on the surface of natural quartz sand are separated and purified, quartz sand does not inactivate in the reaction process as an unconventional catalyst, and shows increasingly high catalytic efficiency with the proceeding of the reaction, and catalyzes methane cracking to rapidly produce carbon nanotubes with large length-diameter ratio, controllable length and high geometric dimension consistency at low cost. The reaction by-product is high purity hydrogen, which can be used as a high value-added raw material of downstream industry, thus further improving the economical efficiency of the whole system.

Owner:CHINA UNIV OF MINING & TECH

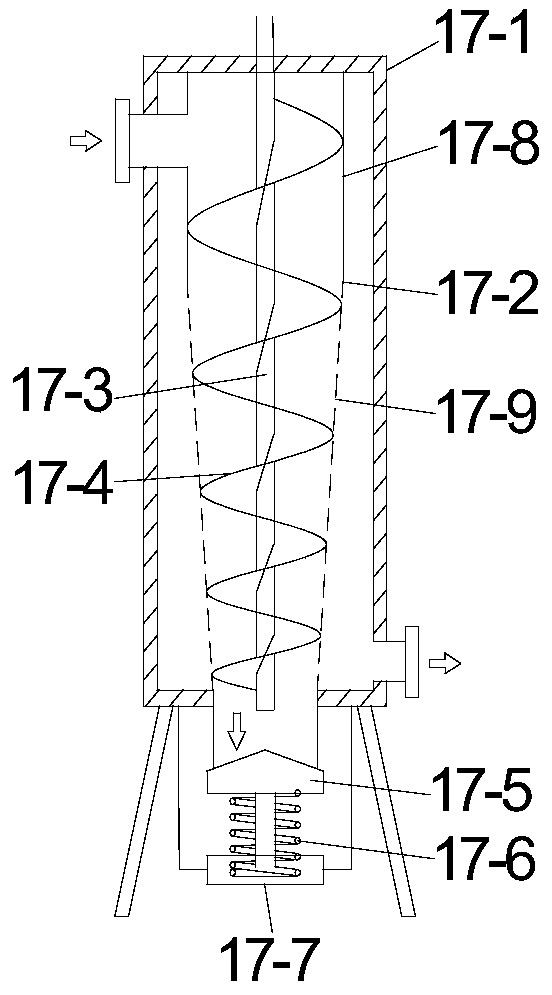

Deslagging waste heat utilization device of industrial boiler

ActiveCN105953200AIncrease surface areaImprove recycling efficiencySteam generation using hot heat carriersMolten slagWaste heat

The invention discloses a deslagging waste heat utilization device of an industrial boiler. The deslagging waste heat utilization device comprises a crushing box body, wherein the crushing box body comprises an inner box and an outer box; the top of the inner box communicates with a feeding hopper; a rotating shaft is arranged in the inner box; one end of the rotating shaft is provided with a crushing blade, and the other end of the rotating shaft is connected with a second gear; an electromotor is connected with a first gear intermeshed with the second gear; a first water cooling channel is arranged between the outer box and the inner box; a water inlet of the first water cooling channel communicates with a first water outlet of a water pump; a discharging hole of the crushing box body communicates with a feeding hole of a waste heat boiler body on which a second water cooling channel is arranged; a water inlet of the second water cooling channel communicates with a second water outlet of the water pump; and a discharging hole is formed in the bottom of the waste heat boiler body. The device is combined with a molten slag crushing device, a waste heat recycling device and other devices, so that the deslagging capacity of the industrial boiler is improved, and the recycling efficiency of molten slag waste heat is increased.

Owner:额济纳旗圆通矿业有限责任公司

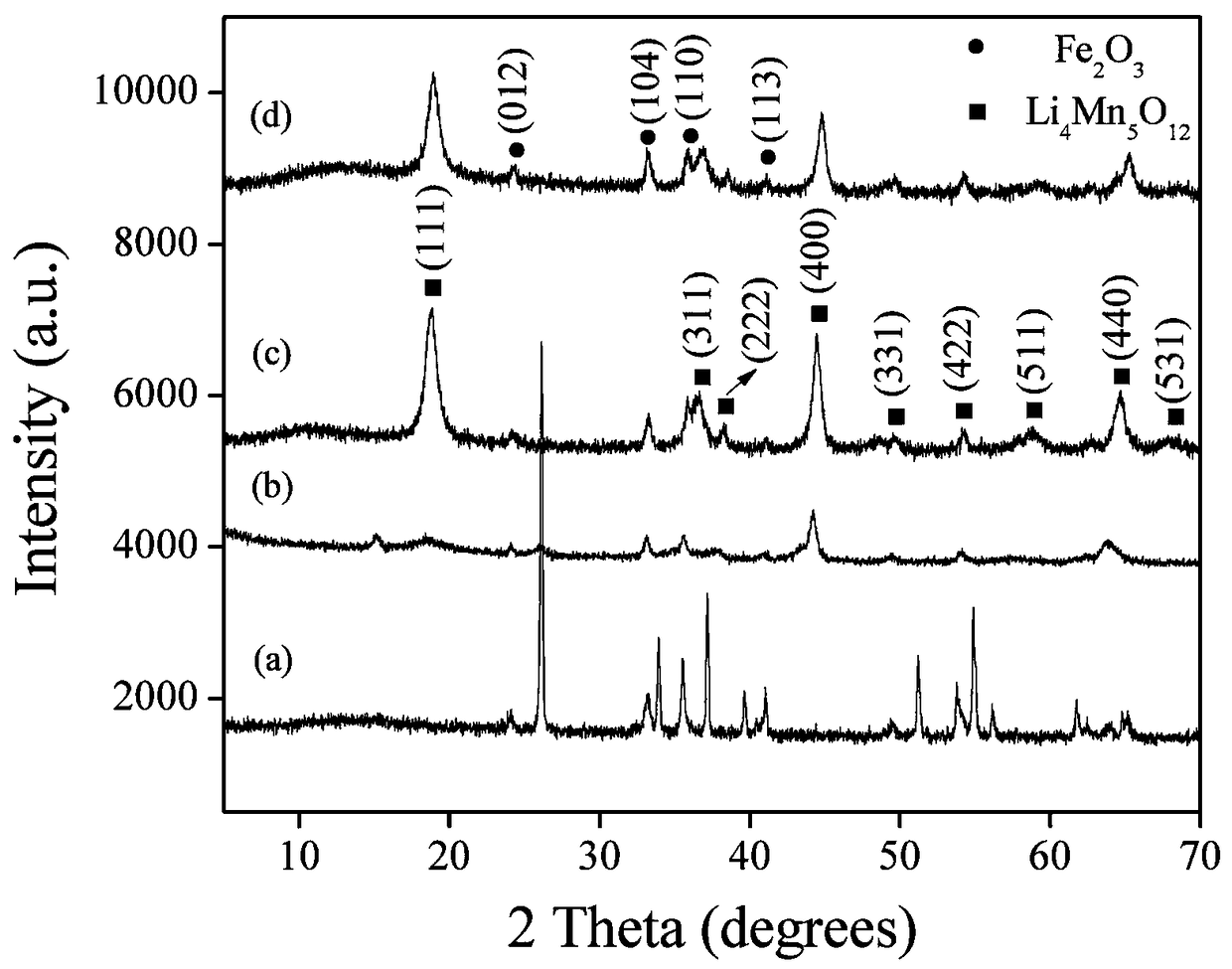

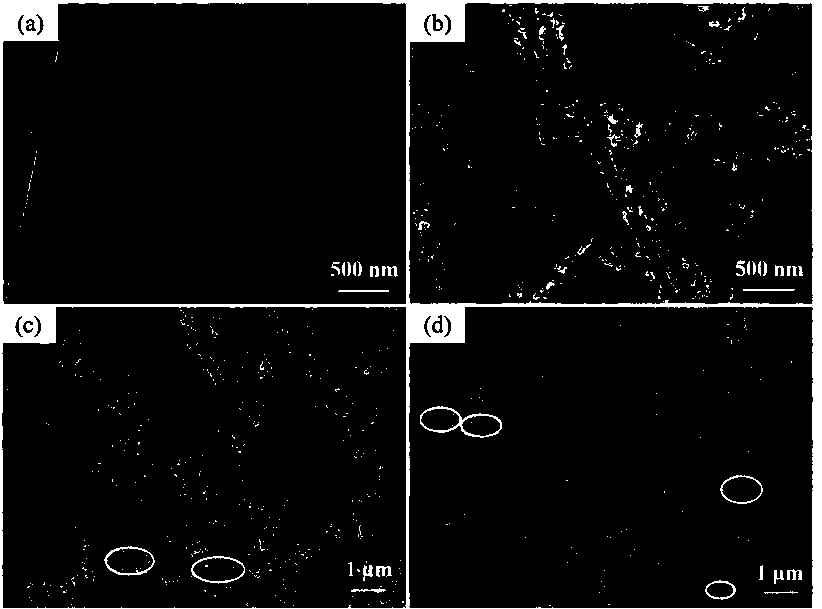

Preparation method of nanotube-shaped manganite lithium ion sieve absorbent

InactiveCN109078601ALarge adsorption capacityFast adsorption rateOther chemical processesAlkali metal oxides/hydroxidesLithiumSorbent

The invention relates to the field of preparation of inorganic materials (manganese oxide series), in particular to a preparation method of a nanotube-shaped manganite lithium ion sieve absorbent. Thepreparation method comprises the following four steps: preparing gamma-MnOOH; synthesizing LiMnO2; preparing a lithium ion sieve precursor Li4Mn5O12; and preparing a lithium ion sieve absorbent H4Mn5O12. The preparation method is simple, and the production cost for an existing method used at present can be reduced. The prepared lithium ion sieve adsorber H4Mn5O12 has a nanotube-shaped morphology,regular thorn-shaped substances grow on the surface of the lithium ion sieve adsorber H4Mn5O12, the specific surface area is large and is 90.979-92.997 m<2> / g, the lithium ion sieve adsorber with thespecial morphology has large adsorption capacity to lithium ions and high adsorption rate, wherein the adsorption capacity is 14.0-37.0 mg / g, the nanotube-shaped manganite lithium ion sieve absorbentis environmentally friendly, and has high-efficiency recycling property, and industrialized production is easy to realize. The preparation method of the nanotube-shaped manganite lithium ion sieve absorbent can be used for extracting lithium ions in an alkali metal competition system such as a salt lake.

Owner:QINGHAI NORMAL UNIV

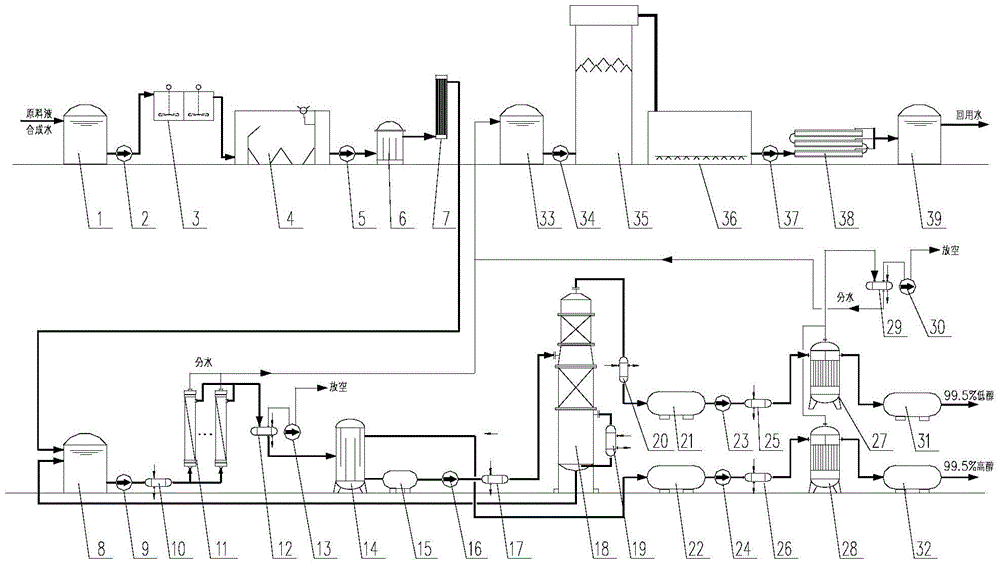

Alcohol-water separation recycling device of fischer-tropsch synthesis water

ActiveCN103601329AImprove economyEfficient separationChemical industryMultistage water/sewage treatmentVacuum pumpEnergy source

The invention discloses an alcohol-water separation recycling device of fischer-tropsch synthesis water, and belongs to the technical fields of environmental protection and recycling. The alcohol-water separation recycling device comprises a pretreatment system, a separation system, a concentration system, a dehydration system and a recycle water system, wherein the pretreatment system comprises a raw material tank, a first feeding pump, neutralization reaction equipment, a coagulation air floatation device, a second feeding pump, a precision filter, a membrane filter and a first middle material liquid tank, which are sequentially connected; the separation system comprises a third feeding pump; a feeding hole of the third feeding pump is connected with the first middle material liquid tank; a discharge hole is connected with the feeding hole of alcohol-penetrating membrane equipment after being connected with a first heat exchanger; a penetrating fluid discharge hole of the alcohol-penetrating membrane equipment is connected with a second heat exchanger; and the second heat exchanger is respectively connected with a first vacuum pump, a liquid-liquid separator and the like. By adopting the alcohol-water separation recycling device, available resources which are discharged as wastewater in the past are effectively recovered by using low energy consumption; a disadvantage is converted into an advantage; resources and energy sources are saved; and the target of recycling to create profit is also achieved.

Owner:上一环保科技(杭州)有限公司

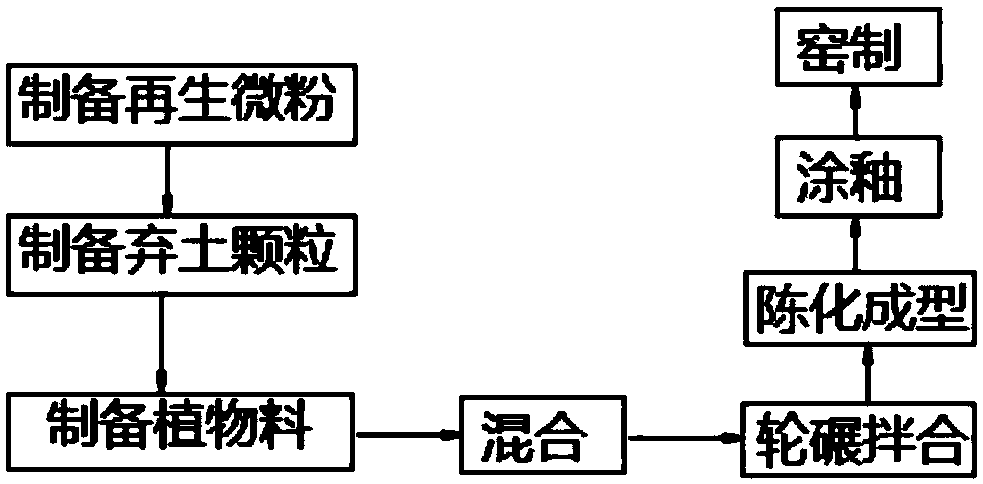

Recycled aggregate art brick manufacturing process

InactiveCN107892555AHigh Efficiency RecyclingEasy to hang glazeStacking articlesDe-stacking articlesSurface patternBrick

The invention discloses a recycled aggregate art brick manufacturing process, which comprises: preparing regenerated micro-powder, preparing waste soil particles, preparing a plant material, mixing, carrying out wheel grinding stirring, carrying out aging molding, coating a glaze, preparing in a kiln, discharging out of the kiln, stacking, repairing, packaging, and warehousing. According to the present invention, the recycled aggregate art brick has characteristics of excellent wear resistance, light weight and high-temperature resistance; by effectively using the building waste, the garden and park waste and the industrial waste, the recycling effect of waste is improved; by adding the plant material, the glaze coating is easily performed; the recycled aggregate art brick has advantages of excellent insect prevention, excellent corrosion resistance, excellent moisture resistance, no maintenance, long service life and wide color selection range, can be customized according to customerrequirements, has the rich surface pattern decoration effect, is superior to the stone material, can be comparable to the wood, is the art brick product with advantages of high performance price ratio, stable performance and cultural and emotional inheritance, and is environmentally friendly; and with the recycled aggregate art brick manufacturing process, the resource utilization can be maximized, and the living environment can be beautified.

Owner:SHENZHEN HUAWEI ENVIRONMENTAL PROTECTION BUILDINGMATERIAL

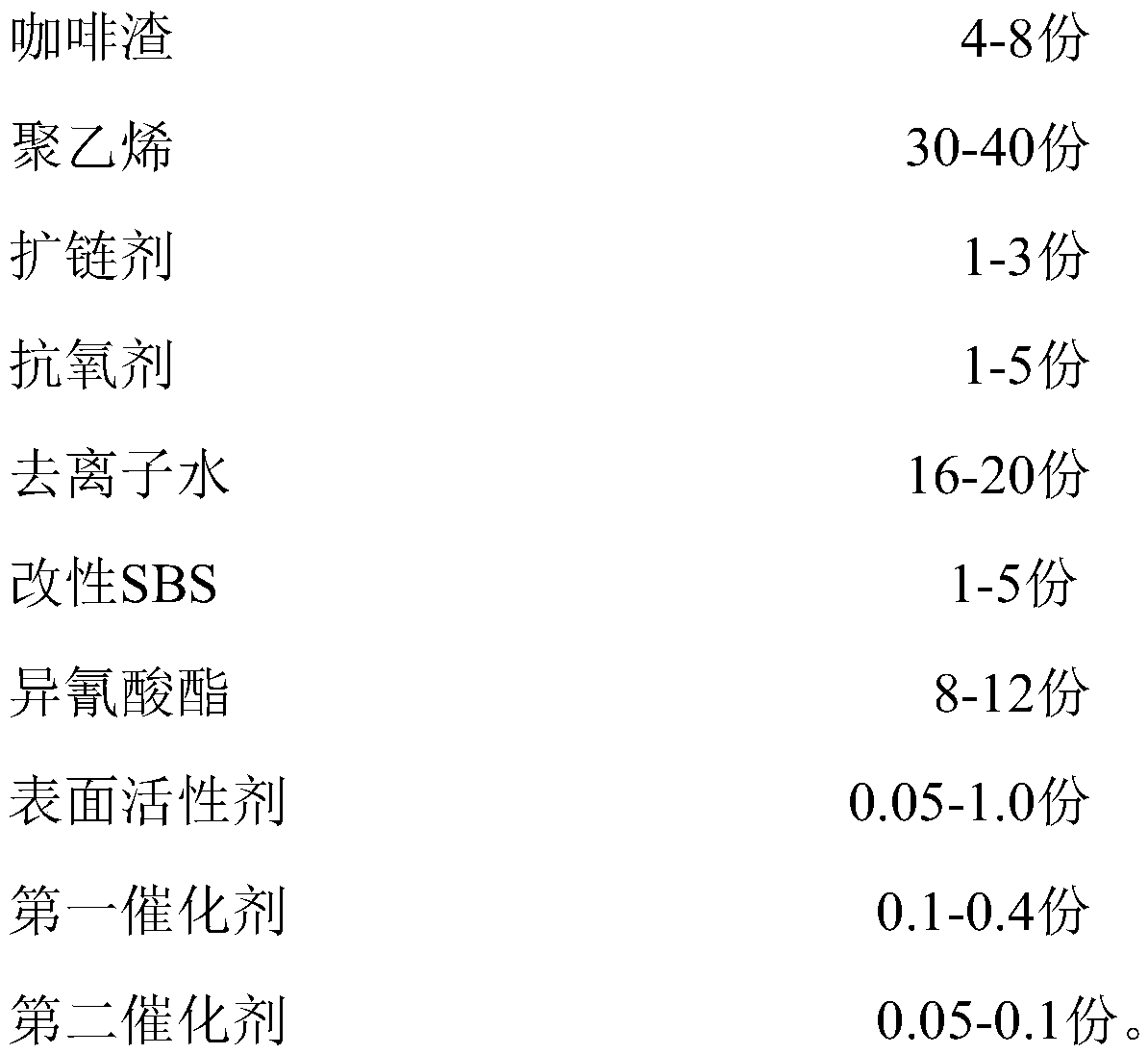

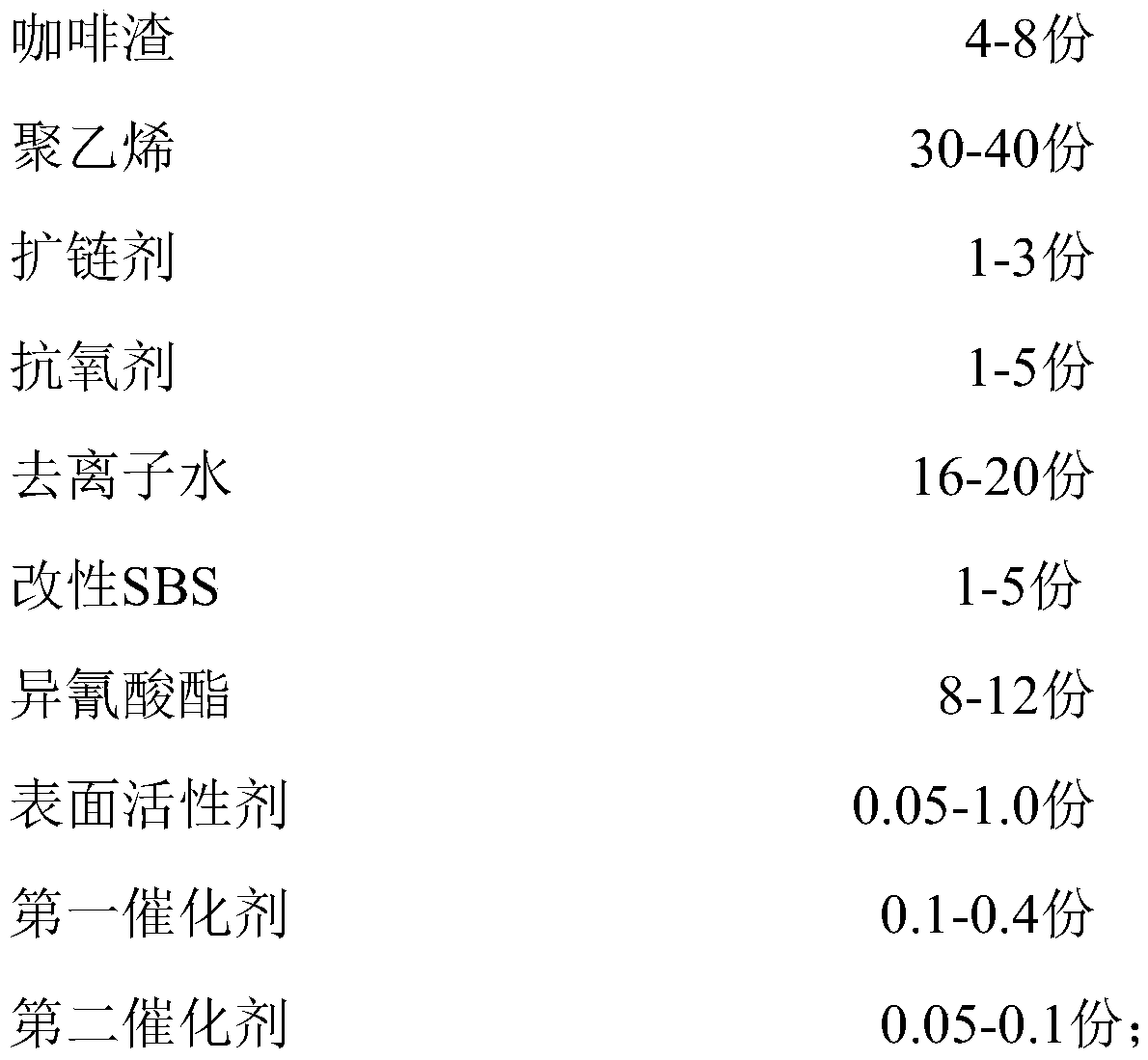

Coffee grounds shoe material and preparation method thereof

PendingCN111484662AGood deodorizing effectHigh peel strengthTextile/flexible product manufactureFootwearPtru catalystActive agent

The invention relates to the technical field of shoe materials. The invention relates to coffee grounds, in particular to coffee grounds shoes and a preparation method thereof. The formula comprises the following raw materials in parts by weight; 4-8 parts of coffee grounds, 30-40 parts of polyethylene, 1-3 parts of a chain extender, 1-5 parts of an antioxidant, 16-20 parts of deionized water, 1-5parts of modified SBS, 8-12 parts of isocyanate, 0.05-1.0 part of a surfactant, 0.1-0.4 part of a first catalyst and 0.05-0.1 part of a second catalyst. The shoe material disclosed by the invention is prepared by taking coffee grounds as raw materials, so that the recycling property of wastes is improved, and the prepared shoe material has excellent peel strength, thermal aging resistance, waterresistance and deodorization effect, can be naturally decomposed after being used, and does not pollute the environment; the preparation method is simple, efficient, convenient to operate and control,high in product quality, low in cost and beneficial to industrial production.

Owner:广东粤盛新材料科技有限公司

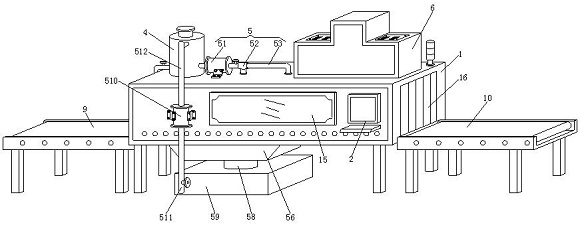

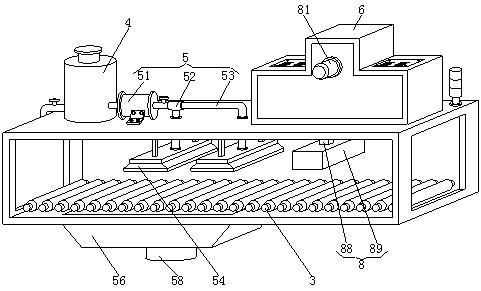

Improved film cleaning machine

InactiveCN103240810ASimple structureEasy to usePlastic recyclingFlat articlesSocial benefitsEnvironmental resistance

The invention discloses an improved film cleaning machine which is characterized by comprising a motor and a cleaning device. The motor is arranged on the bottom of the outside of the cleaning device. The motor is connected with the cleaning device through a speed adjusting device. An inlet pipe is arranged at one side of the top of the cleaning device. A feed inlet is disposed in the middle of the top of the cleaning device. The upper portion of the cleaning device is provided with a first cyclone separator which is connected with a crushing device. A crushing tool is mounted inside the crushing device. The crushing device is connected with a filter which is connected with a discharging pipeline. A tail end of the discharging pipeline is connected with a material storage device. A suction conveyer is arranged inside the discharging pipeline. The bottom of the cleaning device is provided with a plurality of sewage outlet pipes. The improved film cleaning machine provided by the invention has a simple structure, is convenient and fast to use, can be used to thoroughly clean films, greatly raise recycling and reusing abilities of films and save resources, is environmentally friendly to utilize, and has great economic benefits and social benefits.

Owner:环球新材料(南通)股份有限公司

Flue gas waste heat utilization system for annealing furnace

InactiveCN105509493AReduce the temperatureLower exhaust gas temperatureCharge treatment typeIncreasing energy efficiencyMetallurgyFlue gas

The invention discloses a flue gas waste heat utilization system for an annealing furnace. The flue gas waste heat utilization system for the annealing furnace comprises the annealing furnace, a heat exchanger connected with the annealing furnace, a flue and a discharge chimney, wherein an intake part with a dust removal function is arranged on the heat exchanger; a cooling furnace is arranged between the chimney and the heat exchanger; a water jet pump is connected above the cooling furnace; the water jet pump is connected with a water tank; a cooling water cooling device is connected below the cooling furnace; a filter device is arranged between the cooling furnace and the cooling water cooling device; a water suction pump is further connected to the cooling water cooling device; and the water suction pump is used for inputting water cooled in the cooling water cooling device into the water tank. Compared with the prior art, the flue gas waste heat utilization system for the annealing furnace, which is disclosed by the invention, is capable of effectively lowering a flue gas exhaust temperature of the annealing furnace, improving a recycling effect for flue gas heat energy, and removing dust and other impurities in a flue gas, thus preventing environmental pollution.

Owner:NINGBO HEXIE ENERGY CONSERVATION

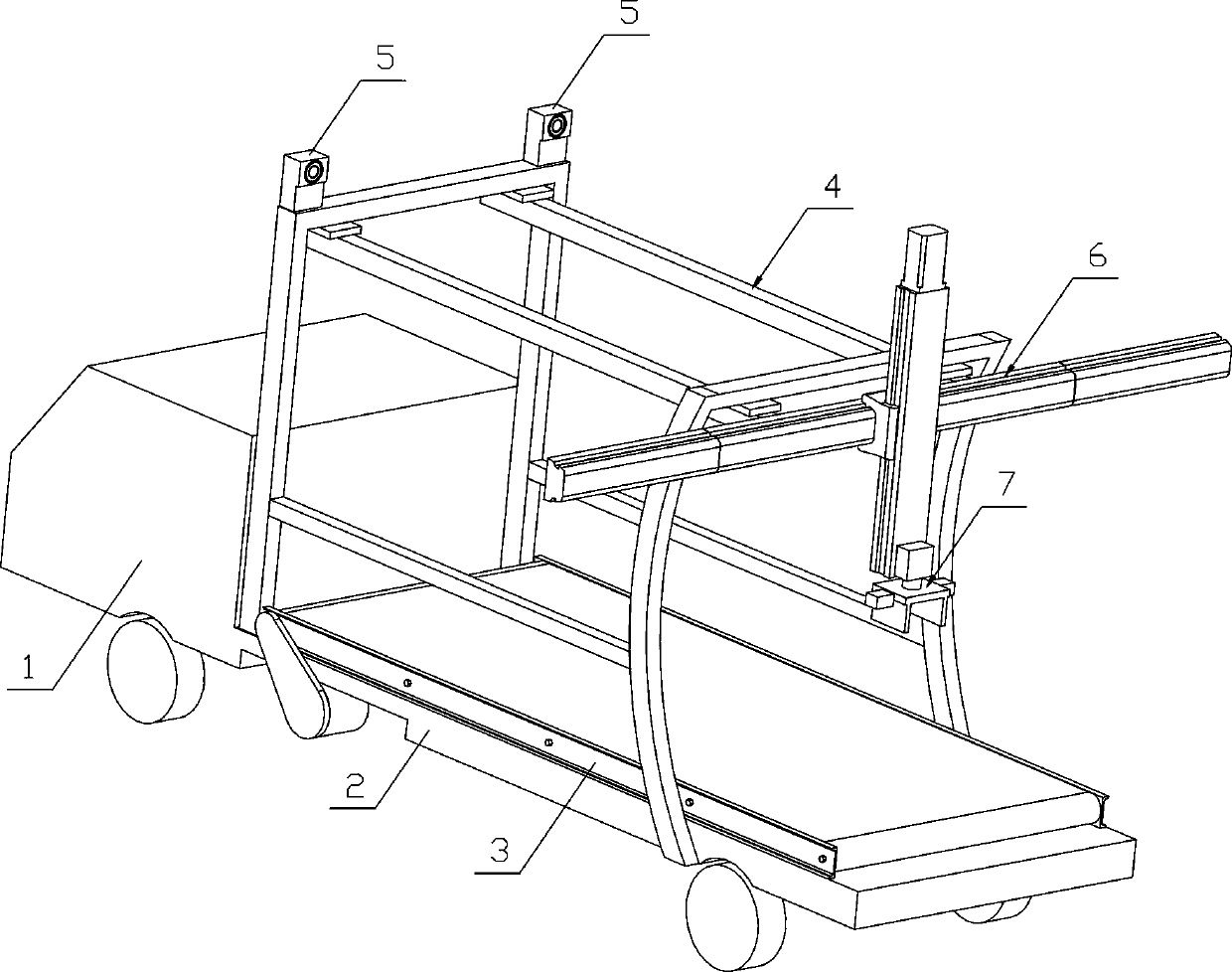

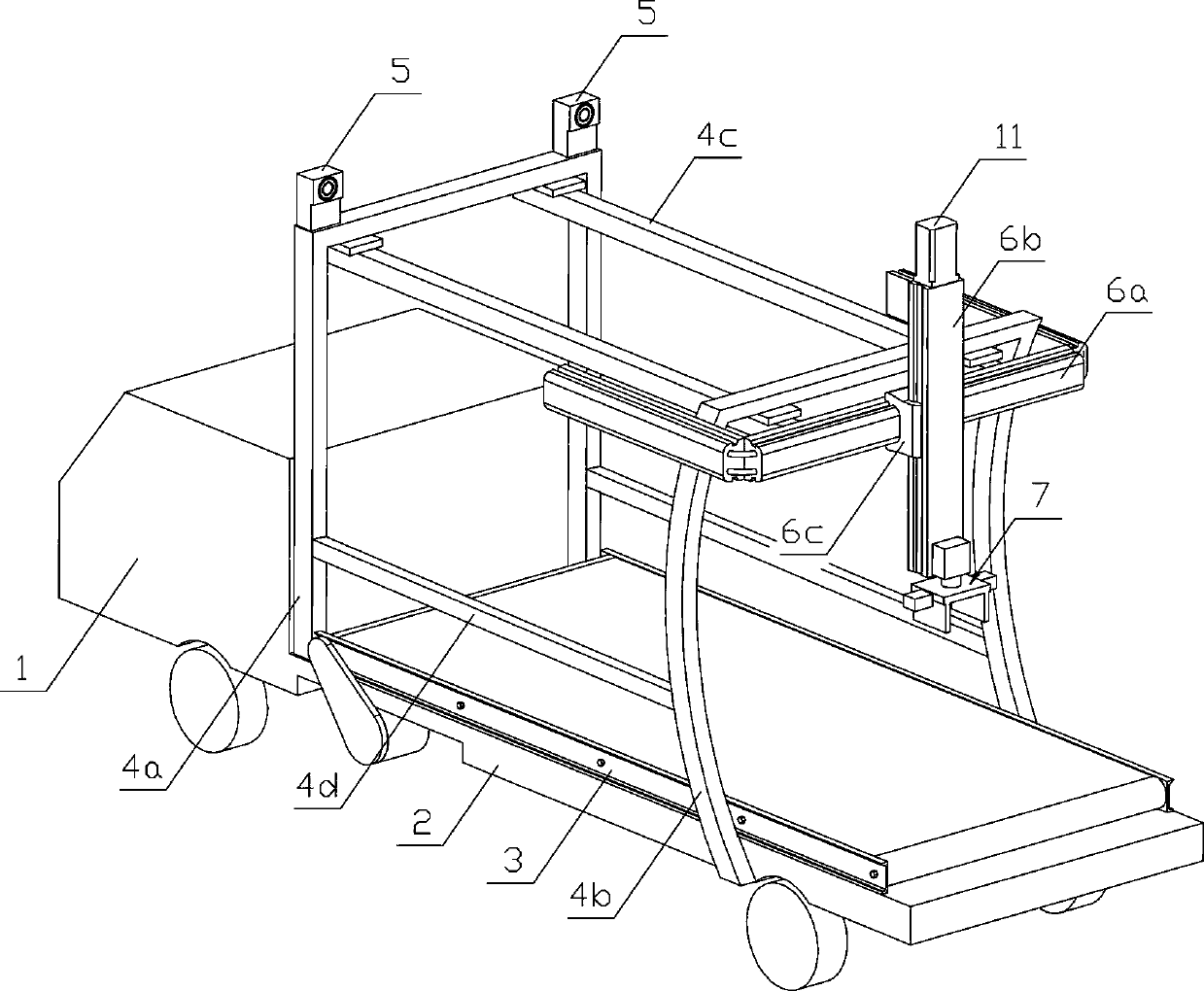

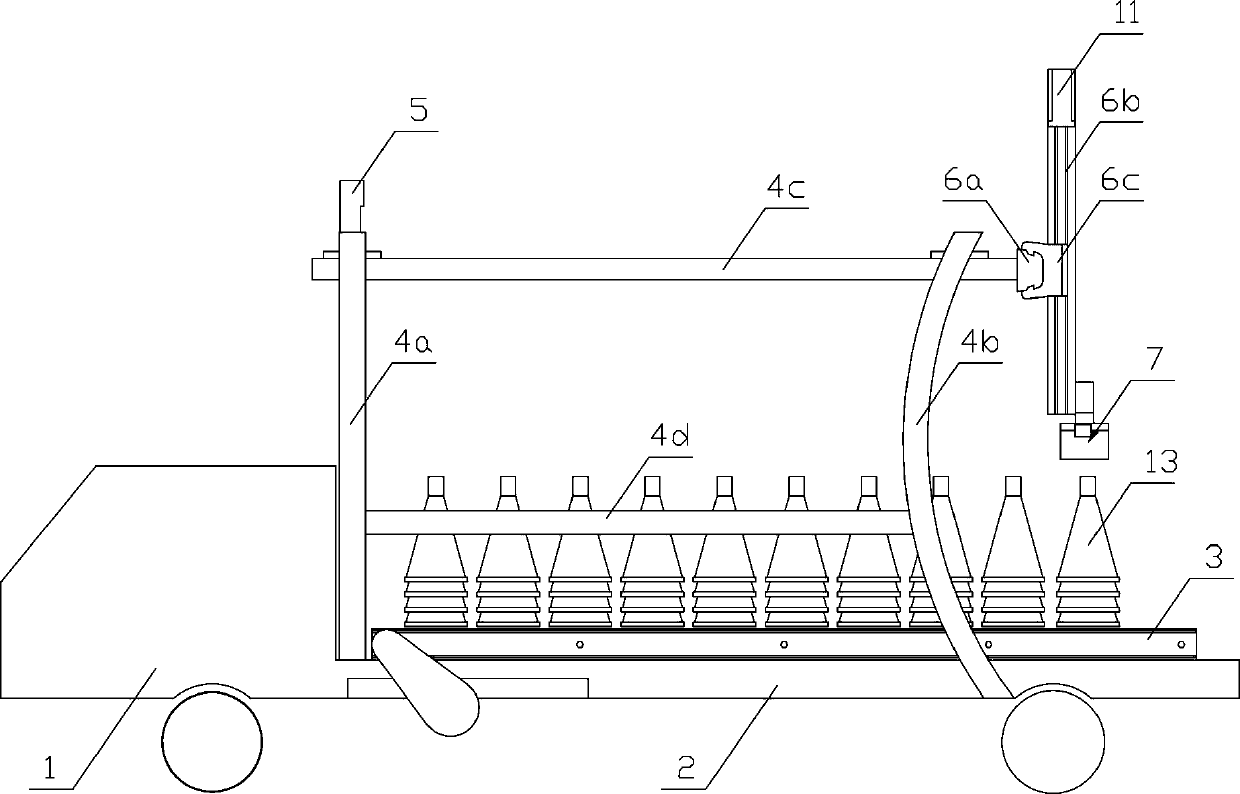

Intelligent and automatic roadblock retraction vehicle

InactiveCN109577236AEfficient castHigh Efficiency RecyclingTraffic signalsRoad signsControl systemInput control

The invention discloses an intelligent and automatic roadblock retraction vehicle. The vehicle includes a vehicle head, a trailer rack and a control system; the trailer rack is provided with a belt conveyor and a fixing support; the fixing support is provided with visual identification systems and a manipulator; the manipulator is provided with a mechanical claw; the control system a PLC and a touch screen controller; the touch screen controller can realize the information interaction with the PLC, so that operators can conveniently input control instructions; and the PLC can control the running state of the belt conveyor in real time and perform real-time control on the working state of the manipulator and the mechanical claw according to the roadblock information identified by the visualidentification systems. The vehicle is simple in structure and convenient in operation; highly efficient releasing and retraction of roadblocks can be realized without equipping many workers, so thatthe vehicle is high in intelligent degree; and danger of manually releasing the roadblocks can be effectively avoided, and therefore, the vehicle has wide utilization prospects.

Owner:湖北瑞尔特重工科技有限公司

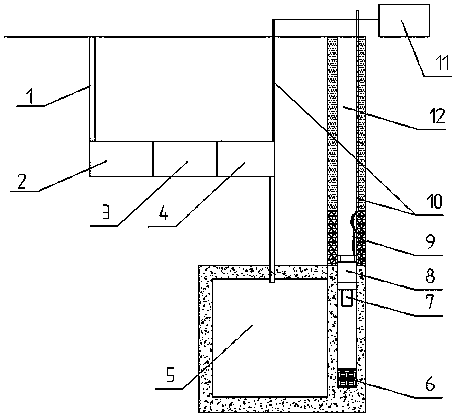

Deep foundation pit rainwater recycling device based on BIM and using method thereof

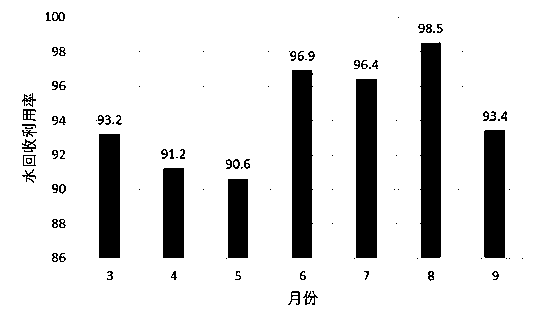

InactiveCN107587517AImprove the utilization rate of precipitationImprove recycling ratesForecastingFoundation engineeringVideo monitoringWater use

The invention discloses a deep foundation pit rainwater recycling device based on a BIM and a using method thereof. A deep foundation pit rainwater recycling method based on the BIM and the internet is adopted, a BIM5D is utilized to construct a visualized water supply and drainage system and a water recycling system, the simulated function of the BIM5D is utilized to simulate the construct progress, with the assistance of water volume calculation software, the water volume in all construct stages is measured, so that the stored water volume is reasonable, and the cost for building a water pool is lowered; meanwhile, a video monitoring system is utilized to monitor an actual water use condition of a construction site at any time, and feed the actual water use condition back to a BIM+ internet system to conduct summary, analysis and prediction. According to the using method of the deep foundation pit rainwater recycling device, the recycling rate of deep foundation pit rainwater can beincreased comprehensively, it is guaranteed that all use water in the construction site is reuse water, the waste of the water resource is reduced, the recycling effect of the water resource is improved, the construction cost is lowered, and good economic and social benefit is obtained.

Owner:CHINA MCC17 GRP

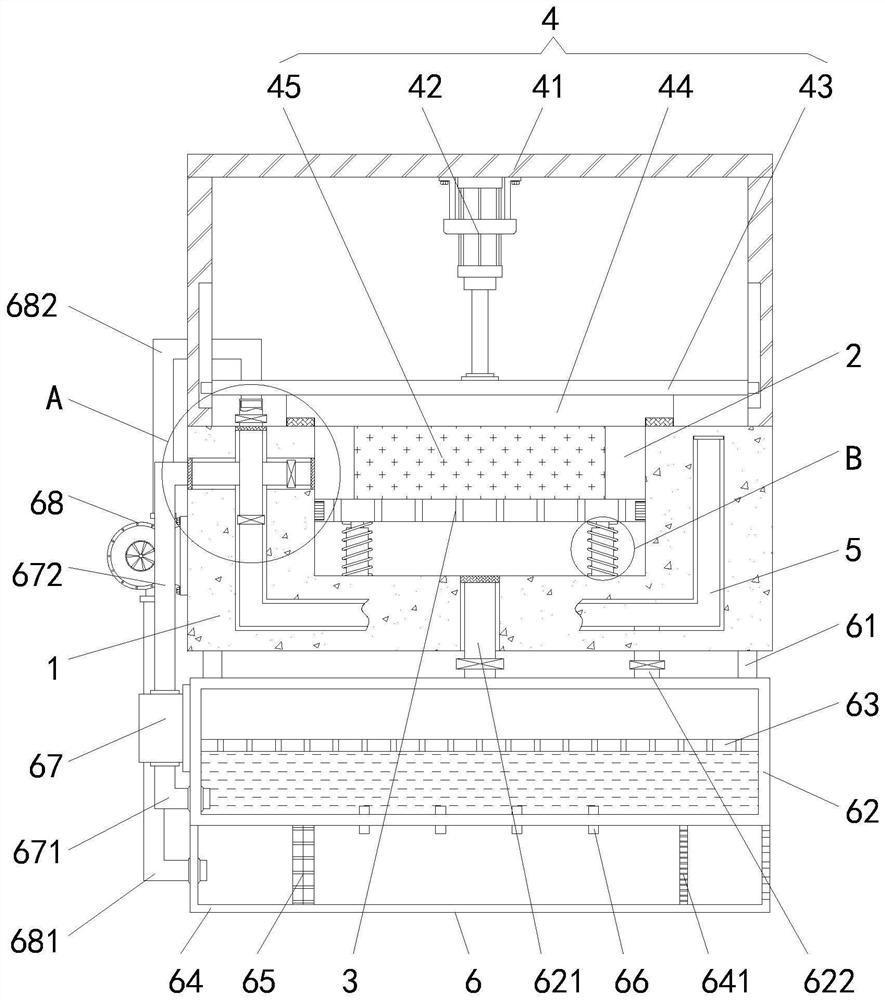

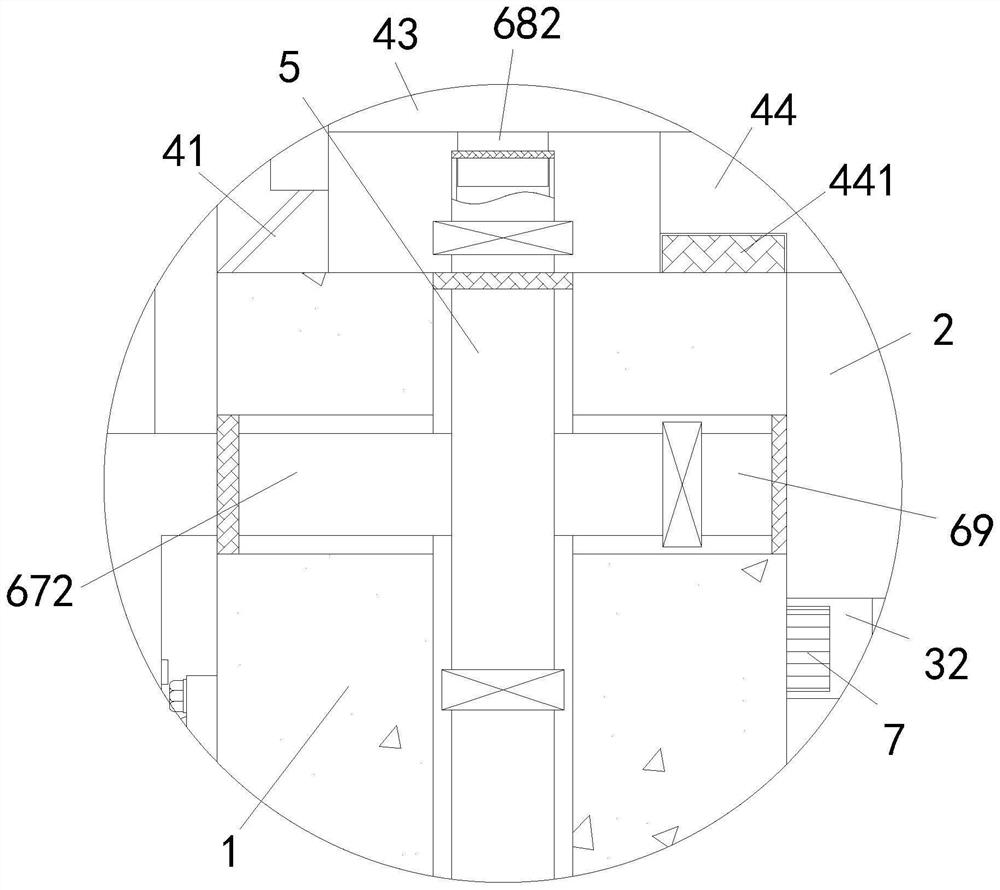

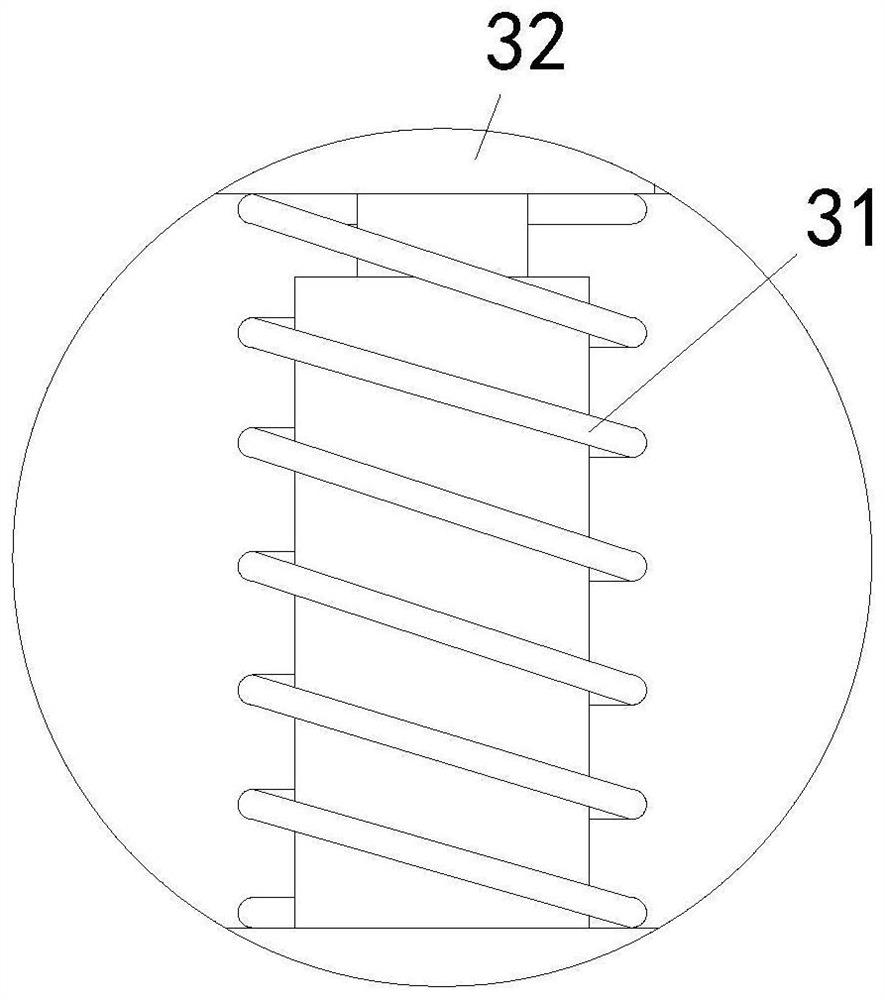

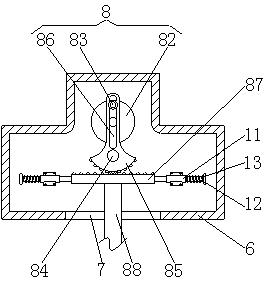

Injection mold with water blowing device

PendingCN114536682AImprove the effectImprove the life of the moldDrying gas arrangementsCleaning using toolsEngineeringEnvironmental geology

The injection mold with the water blowing device comprises a lower mold base, the top of the lower mold base is provided with a lower mold base body, a jacking assembly is arranged in an injection molding groove, the top of the lower mold base body is provided with a mold pressing assembly, a cooling pipe is arranged in the lower mold base body, and a regulation and control assembly is arranged on the lower mold base body. And a cleaning plate is arranged on the jacking assembly. According to the injection mold with the water blowing device, a hydraulic cylinder is started to drive an upper mold base to move up and down, so that a lifting plate is pressed to move up and down to drive a cleaning plate to move up and down to be attached to the interior of an injection molding groove for brushing and cleaning, and a fan is started to suck gas into a treatment box through ventilation holes; gas can be preheated when making contact with the heat collection plate layer, hot gas enters the exhaust pipe, enters the cooling pipe through the gas conveying pipe and enters the injection molding groove through the connecting pipe, and therefore the purpose of rapidly drying the cooling pipe and the injection molding groove is achieved, the water resource utilization effect is improved, and the service life of the mold is prolonged.

Owner:东莞市邦德精密模具有限公司

Desulfurization and denitrification method and treatment device for marine exhaust gas

Owner:南亮压力容器技术(上海)有限公司

High-concentration breeding wastewater treatment process

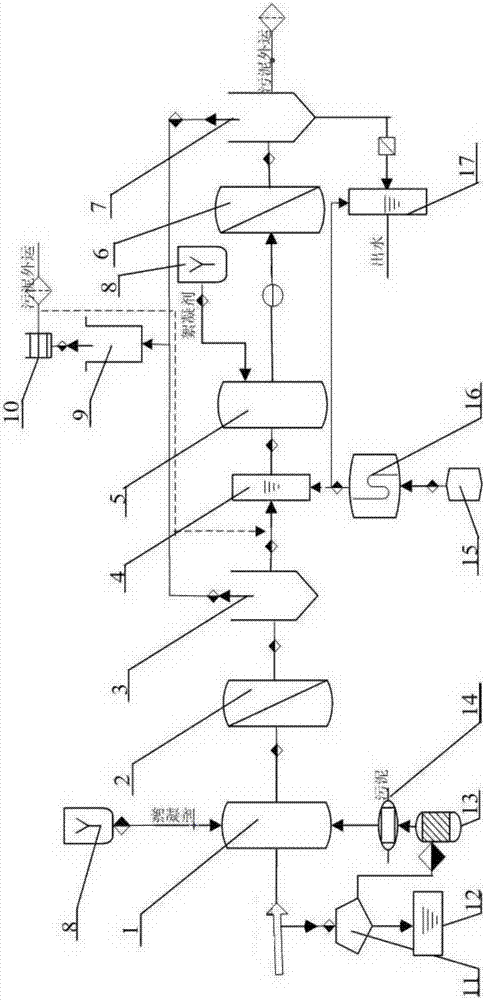

InactiveCN107188340AStable removal rateHigh Efficiency RecyclingSpecific water treatment objectivesWaste water treatment from animal husbandryHigh concentrationFlocculation

The invention discloses a high-concentration breeding wastewater treatment process. After breeding wastewater is rapidly stirred, stirred at low speed, subjected to suspending clarification and adjusted, a flocculant is added for treatment, the PH is adjusted after flocculation is carried out, and suspending clarification is carried out again. Supernatant can be directly drained after reaching the standard, and submerged flocculating constituents can be directly subjected to plate-frame pressure filtration. Organic pollutants in the breeding wastewater can be treated through a lime reaction pond or a VOC reaction pond, the treated breeding wastewater can be drained after reaching the standard, and the content of COD, ammonia nitrogen, high-salinity compounds, VOC and other pollutants in the breeding wastewater can be reduced.

Owner:重庆阳正环保科技股份有限公司

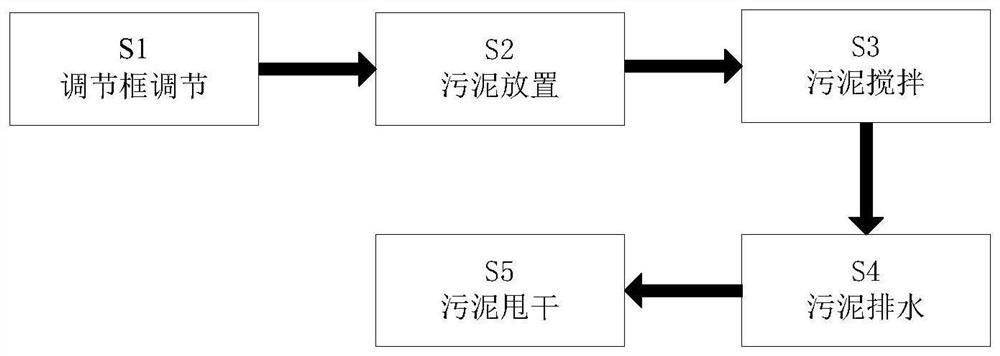

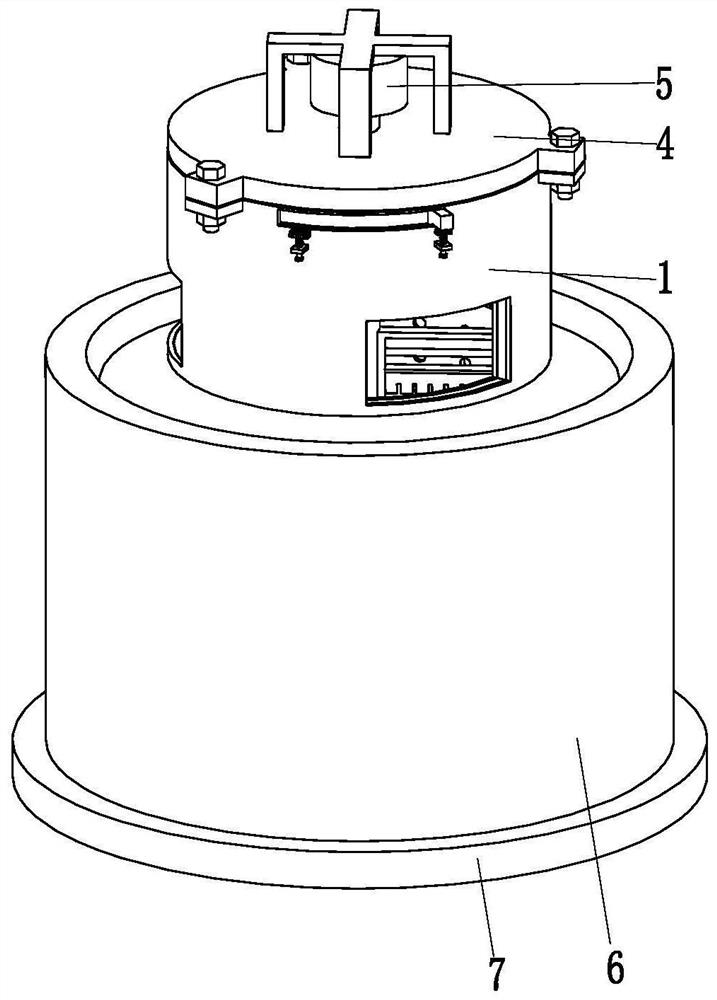

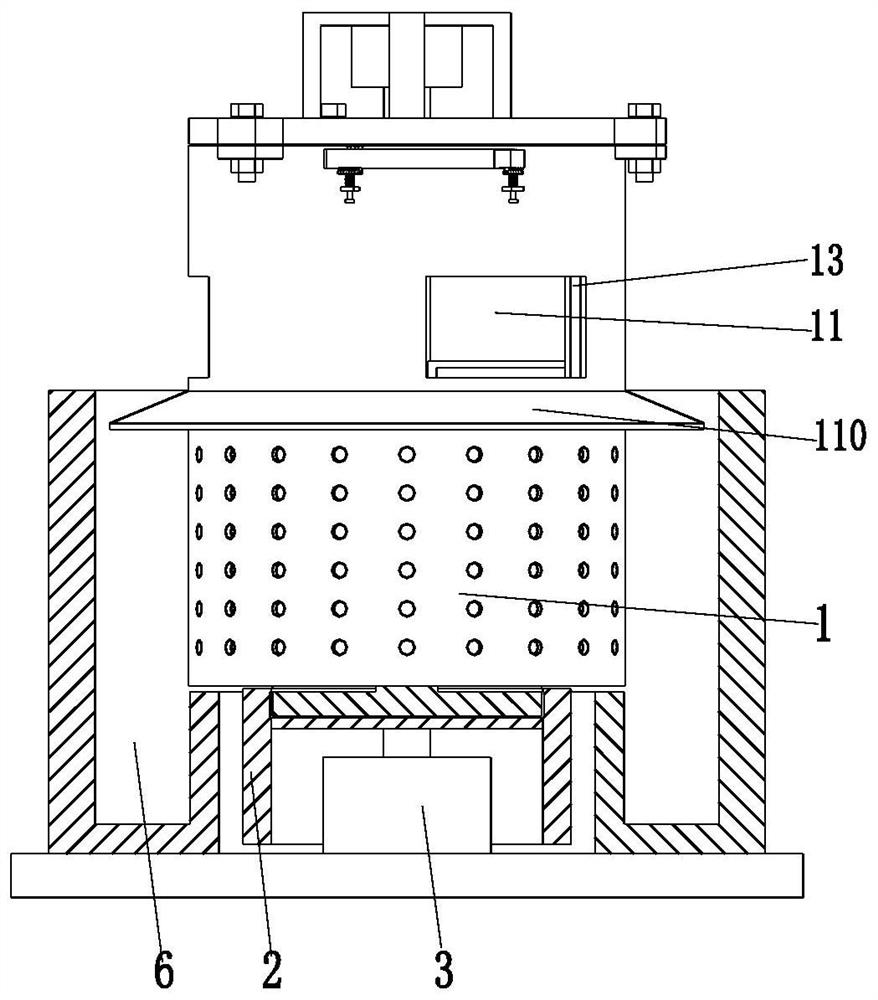

Sludge recycling comprehensive treatment method

InactiveCN111635099AHigh Efficiency RecyclingEasy to handleSludge treatment by de-watering/drying/thickeningSludgeElectric machine

The invention relates to a sludge recycling comprehensive treatment method. The sludge recycling comprehensive treatment method adopts a sludge recycling treatment device, and the sludge recycling treatment device comprises a treatment barrel, a rotary table, a rotary motor, a stirring support plate, a stirring mechanism, a sewage frame and a bottom plate; the stirring mechanism comprises a stirring motor, a stirring rotating shaft, stirring blades, a stirring column and an adsorption plate; the sludge recycling comprehensive treatment method adopting the sludge recycling treatment device comprises the following steps: S1, adjusting the adjusting frame; S2, sludge placement; S3, stirring the sludge; S4, sludge drainage; S5, sludge spin-drying. The method can solve the problems of low sludge impurity removal treatment efficiency, poor effect, low water removal speed after sludge stirring, low water removal degree and the like caused by incomplete sludge stirring and incapability of removing scrap iron in sludge in the sludge stirring process when impurities are removed from sludge in the prior art.

Owner:吴远光

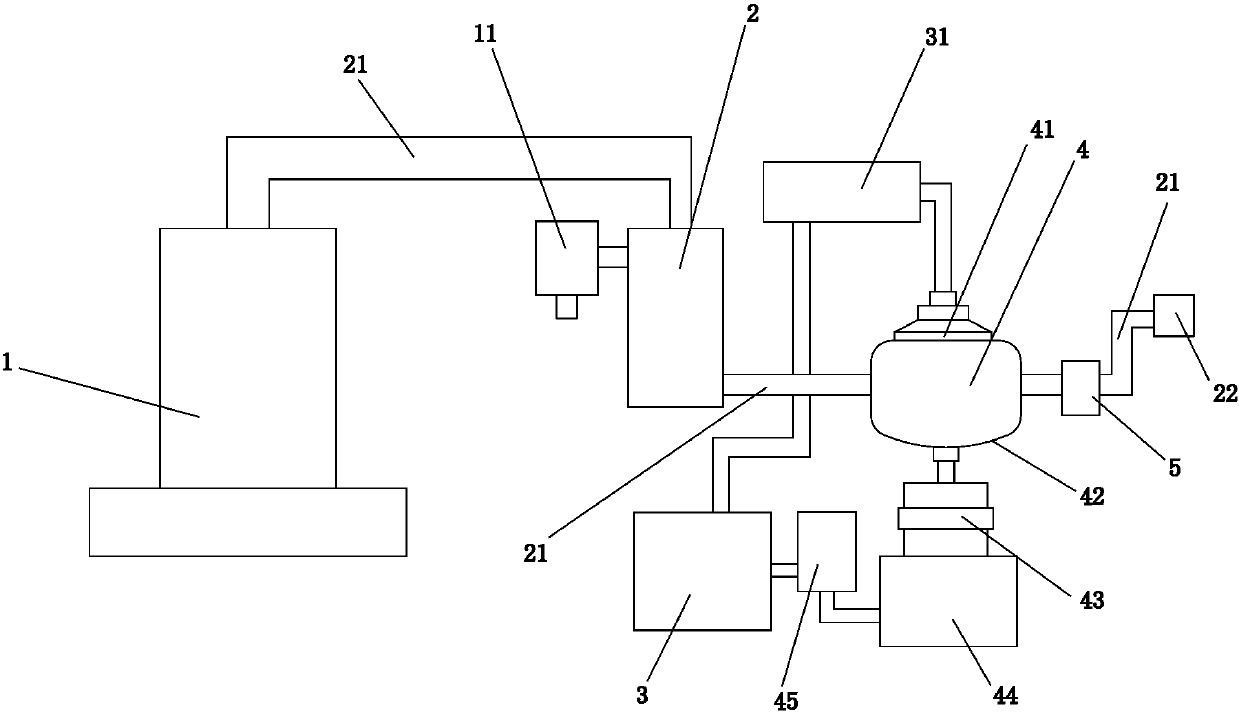

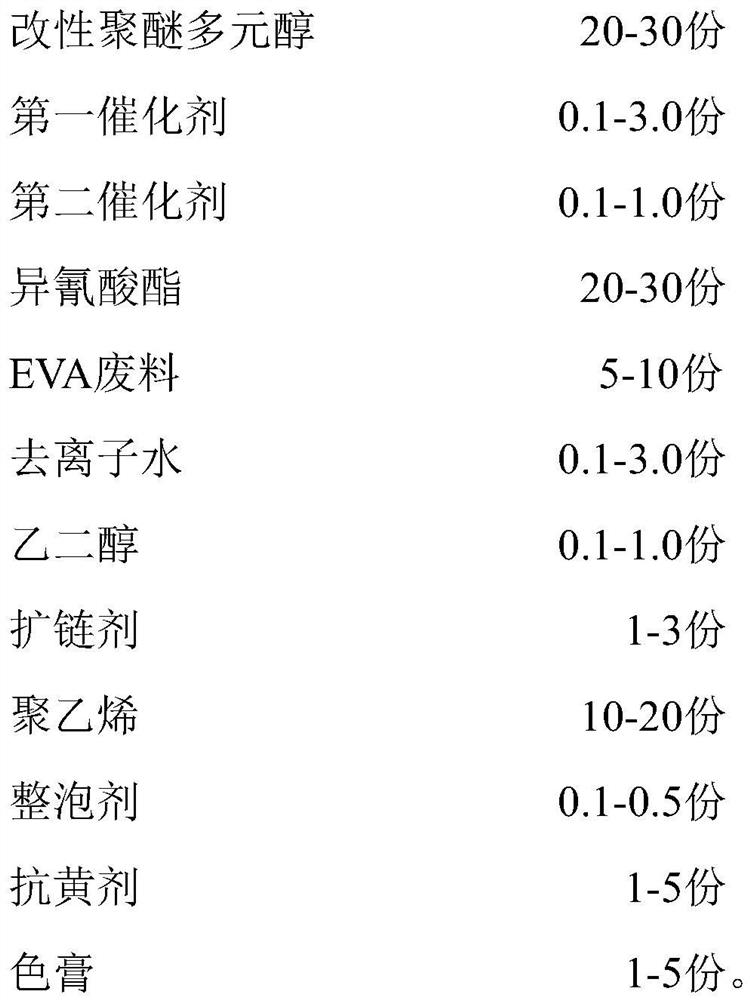

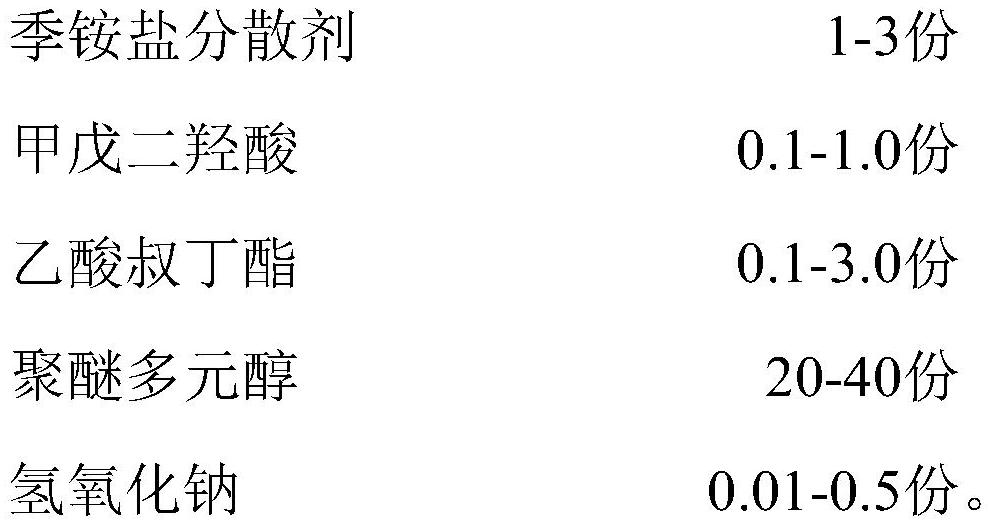

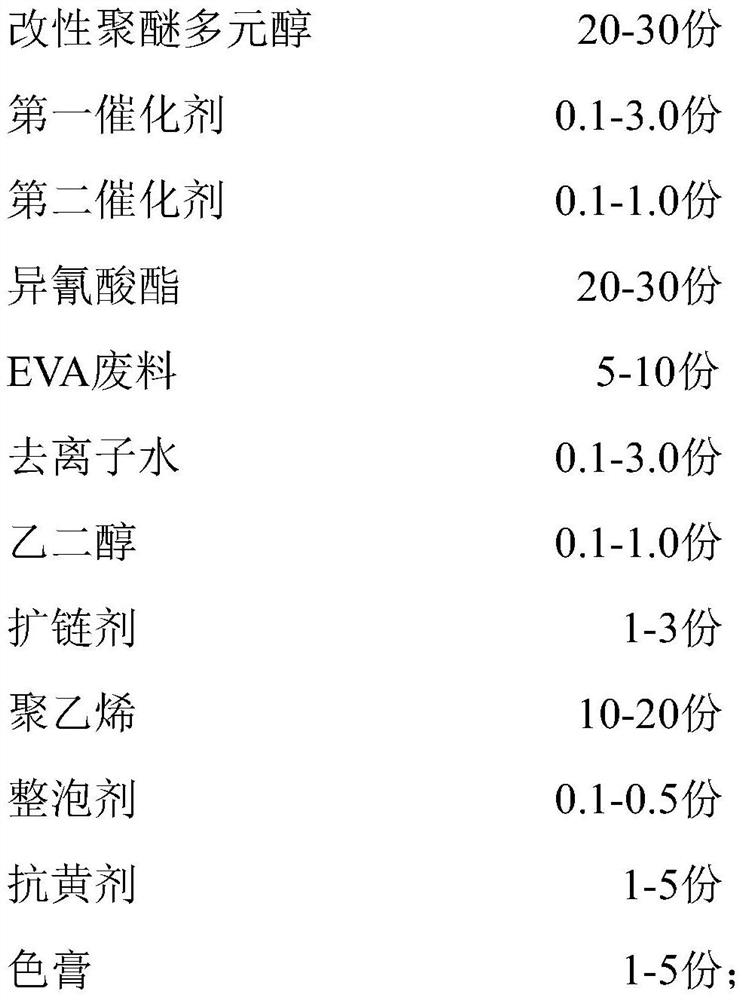

EVA-modified polyurethane composite shoe material and preparation method thereof

The invention relates to the technical field of shoe materials, particularly to an EVA-modified polyurethane composite shoe material and a preparation method thereof. The EVA-modified polyurethane composite shoe material comprises the following raw materials in parts by weight: 20-30 parts of modified polyether polyol, 0.1-3.0 parts of a first catalyst, 0.1-1.0 part of a second catalyst, 20-30 parts of isocyanate, 5-10 parts of EVA waste, 0.1-3.0 parts of deionized water, 0.1-1.0 part of ethylene glycol, 1-3 parts of a chain extender, 10-20 parts of polyethylene, 0.1-0.5 part of a foam adjusting agent, 1-5 parts of an anti-yellowing agent and 1-5 parts of color paste. The EVA-modified polyurethane composite shoe material provided by the invention has excellent tensile strength, elongationat break, tearing strength and peel strength, and can well meet requirements on the mechanical properties of the material when being used as a sole material; and the adopted preparation method is simple and efficient in process, convenient to operate and control, high in product quality, low in cost and convenient for industrial production.

Owner:广东粤盛新材料科技有限公司

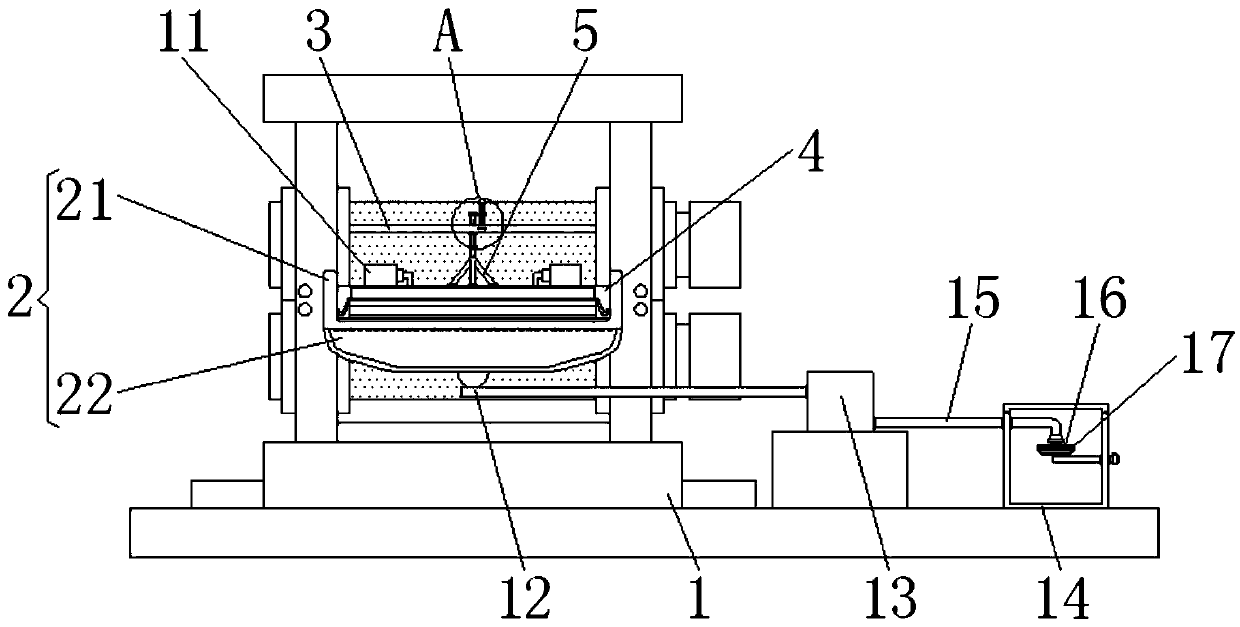

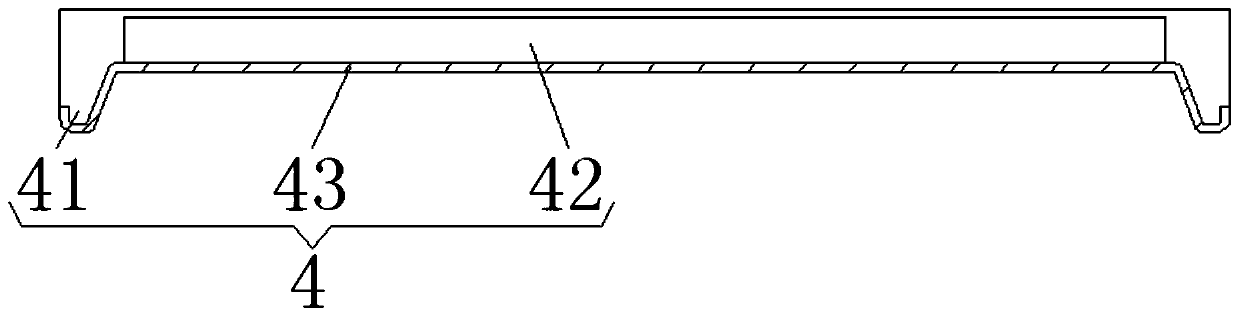

Emulsion control and recovery device for cold-rolling mill

ActiveCN110479779AEasy to blow offHigh Efficiency RecyclingCleaning using gasesWork cleaning devicesEmulsionEngineering

The invention relates to the technical field of intelligent manufacturing, and discloses an emulsion control and recovery device for a cold-rolling mill. The emulsion control and recovery device comprises a machine body, wherein a horizontal plate is fixedly mounted at the top of the front surface of the machine body; a connecting rod is movably connected to the inner part of the horizontal platein a sleeving manner; a limiting block is fixedly connected to the bottom of the connecting rod; a limiting plate is movably connected to the right side of the horizontal plate in a sleeving manner; athreaded rod is fixedly connected to the top of the limiting plate; and the top end of the threaded rod penetrates through the horizontal plate and extends to a position above the horizontal plate. According to the emulsion control and recovery device for the cold-rolling mill disclosed by the invention, through the cooperation of a blowing device and blowing fans, emulsion on the upper surface of iron sheets are convenient to blow away; emulsion which is blown away in the bottom and the upper part of the iron sheets is adsorbed through an overflow resisting baffle and an accommodating ware in an overflow resisting and absorbing device; and besides, the collected emulsion is purified through a fixing disk and a filtering device, so that the situation that emulsion remains on the outer surfaces of the iron sheets, and emulsifying spots are formed is avoided, the emulsion is recovered simultaneously, and the effect of recovering and utilizing of emulsion is improved.

Owner:山东乾钢金属科技有限公司

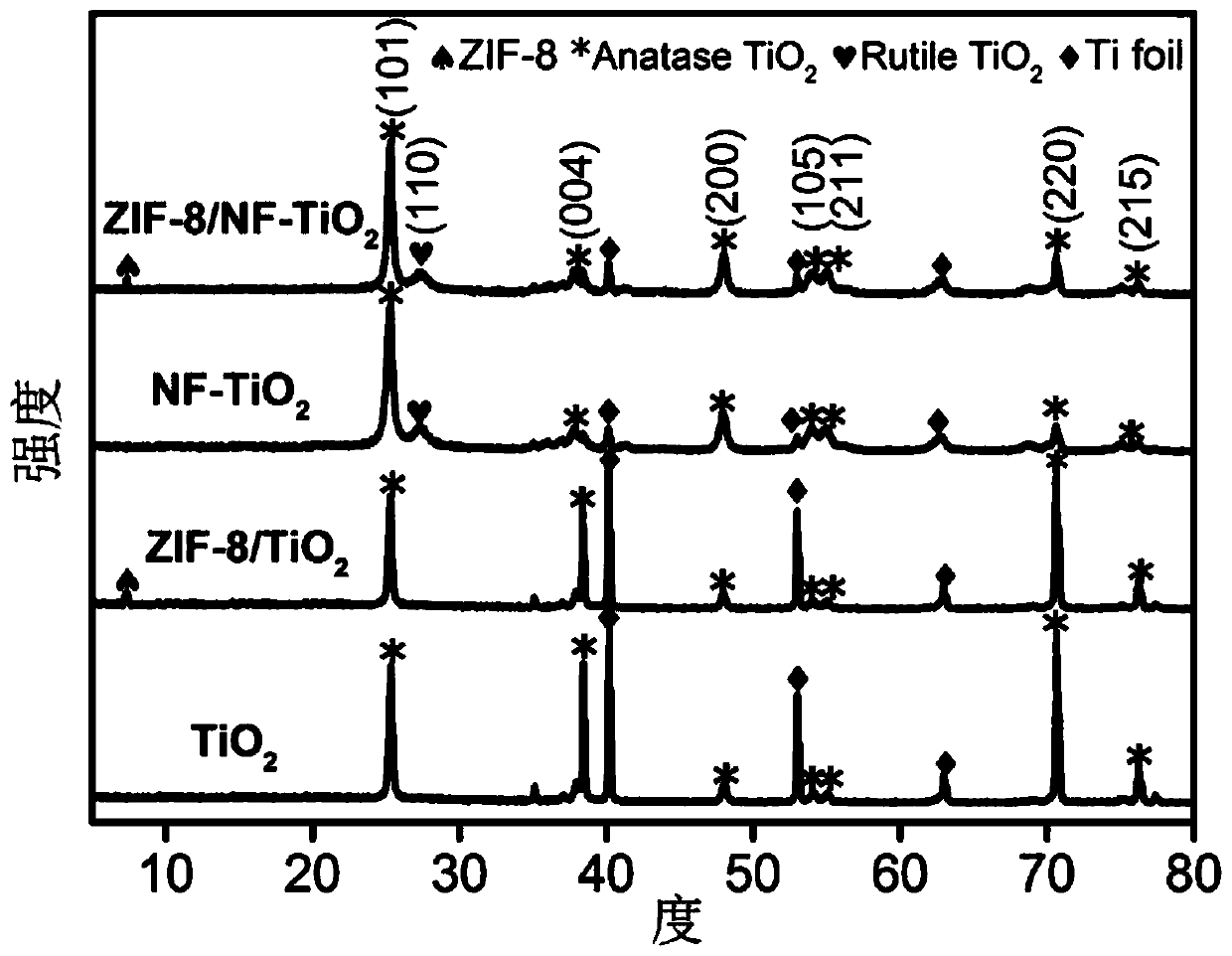

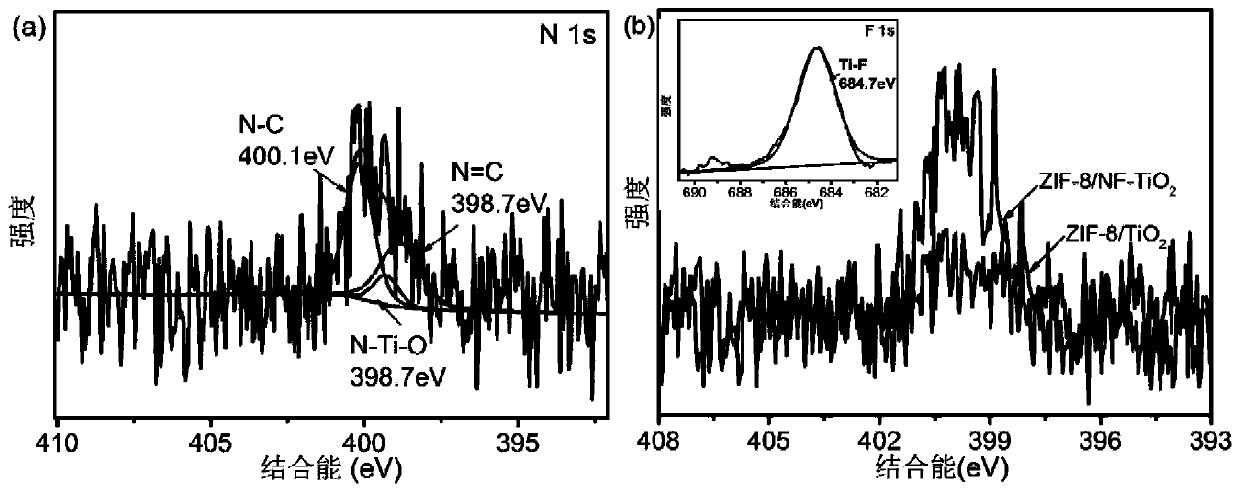

Method for treating antibiotic wastewater by utilizing visible light response semiconductor-MOFs hybrid photoelectrocatalytic material electrode

ActiveCN110862120ACatalytic degradationReduce dosageWater/sewage treatment by irradiationWater treatment compoundsTitanium oxideAntibiotic drug

The invention discloses a method for treating antibiotic wastewater by utilizing a visible light response semiconductor-MOFs hybrid photoelectrocatalytic material electrode. According to the method, avisible light response semiconductor-MOFs hybrid photoelectrocatalytic material electrode is used as an anode to treat antibiotics in wastewater through photoelectrocatalytic reaction; according to the visible light response semiconductor-MOFs hybrid photoelectrocatalytic material electrode, a nitrogen-fluorine co-doped titanium dioxide electrode plate is used as an electrode substrate, and is loaded with ZIF-8. The method provided by the invention not only has the advantages of quick recycling, good removal effect, high circulation efficiency, high practicability and the like, but also has the advantages of less raw material consumption, no secondary pollution, simple and easily available used reagents and the like, is a treatment method which can be widely used and can effectively remove antibiotics in water, and has quite high use value and application prospect.

Owner:HUNAN UNIV

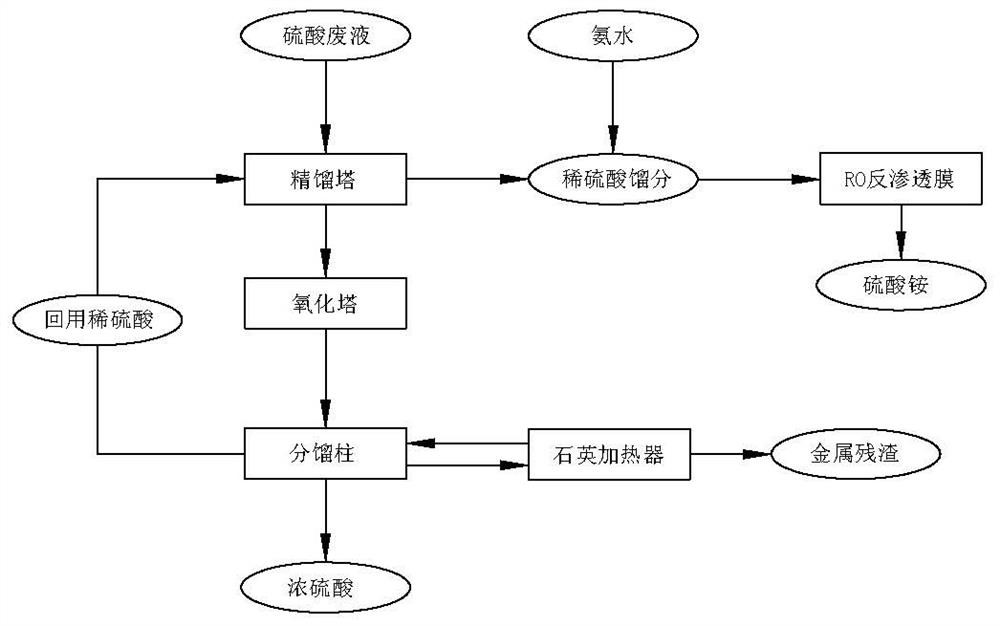

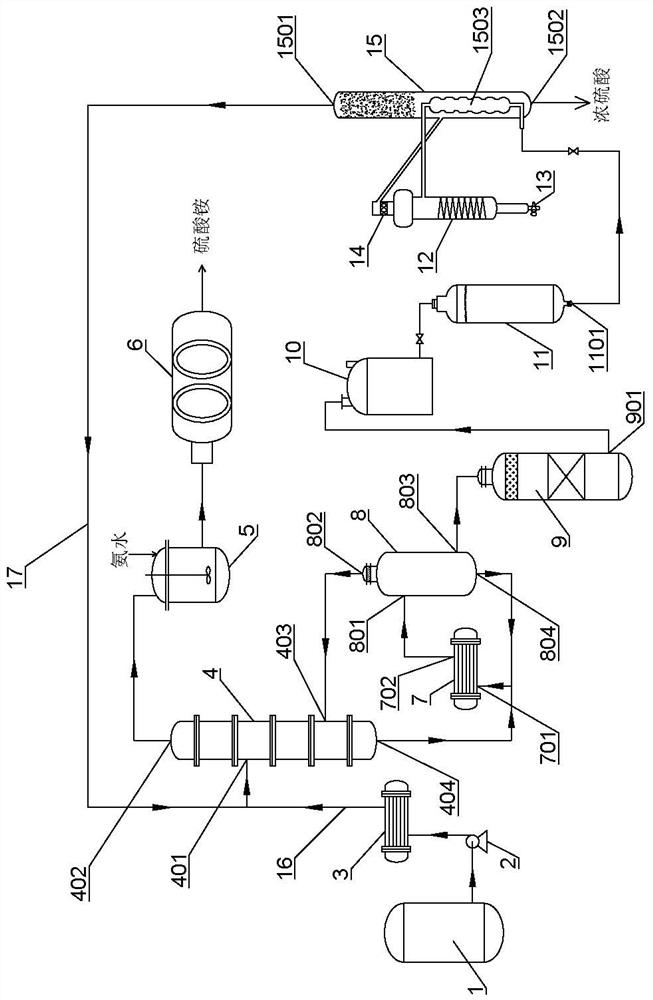

Sulfuric acid recovery method and system

PendingCN111994881ADouble removalAchieve purificationSulfur-trioxide/sulfuric-acidAmmonium salt fertilisersHigh concentrationDistillation

The invention provides a sulfuric acid recovery method. The method can be conveniently used for recovery treatment of semiconductor industrial sulfuric acid waste liquid and is low in production cost,low in energy consumption and good in recovery utilization effect, and therefore, the invention further provides a sulfuric acid recovery system. High-concentration semiconductor industrial sulfuricacid waste liquid containing sulfuric acid with the mass fraction of 50-60% is treated by utilizing a distillation principle and adopting a rectification and fractionation two-stage process; during rectification, hydrogen peroxide impurities in the sulfuric acid waste liquid can oxidize organic matter impurities to degrade the organic matters, and when the hydrogen peroxide cannot be completely oxidized and degraded, oxidative degradation of the hydrogen peroxide is performed through an oxidation tower to realize double removal of the organic matters and the hydrogen peroxide impurities; during fractionation, due to the fact that the boiling point of metal salt impurities is high, the metal salt impurities are left at the bottom of a heater after being fractionated, the metal salt impurities are removed through deslagging, the mass fraction of recycled concentrated sulfuric acid reaches 92.5%, and the recycled concentrated sulfuric acid is industrial-grade sulfuric acid which can be directly sold.

Owner:江苏电科环保有限公司

Environment-friendly antirust oil coating device for connecting rod machining

InactiveCN112427210AImprove rust resistanceHigh Efficiency RecyclingPretreated surfacesCoatingsGear wheelElectric machine

The environment-friendly antirust oil coating device for connecting rod machining comprises a box body, a control panel is embedded in the right side of the front face of the box body, conveying rollers are sequentially and rotationally connected to the bottom of an inner cavity of the box body from left to right, an oil storage tank is in bolted connection to the left side of the top of the box body, and an oil filling pipe communicates with the center of the top of the oil storage tank. Through cooperation of an oil injection pump, a three-way connector, a manifold and a main pipe, oil injection heads can conduct sufficient and uniform oil injection operation on the surface of the connecting rod, and a smearing missing area on the surface of the connecting rod is avoided. Through cooperation of a collection frame, a filter screen, a flow guide pipe, an oil storage box, a booster pump, an oil suction pipe and a conveying pipe, antirust oil dripping from the surface of the connecting rod can be collected and utilized, the integral recycling and utilizing effect of the antirust oil is enhanced, and the cost of the antirust oil is saved. Through cooperation of a motor, a rotating disc, a convex column, a rotating shaft, a sector gear, a sliding groove, a rack plate, a connection rod, a fan frame and an electric fan, reciprocating air blowing can be conducted on the surface of theoiled connecting rod.

Owner:东莞市劲华五金机械有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com