Waste heat recycling system and method based on organic Rankine recycle and organic flash recycle

A technology of waste heat recovery system and Rankine cycle, which is applied in the direction of machines/engines, steam applications, mechanical equipment, etc., can solve the problems of effective energy loss, improve the recovery ability, increase the net electric power output, and reduce the effective energy loss Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings.

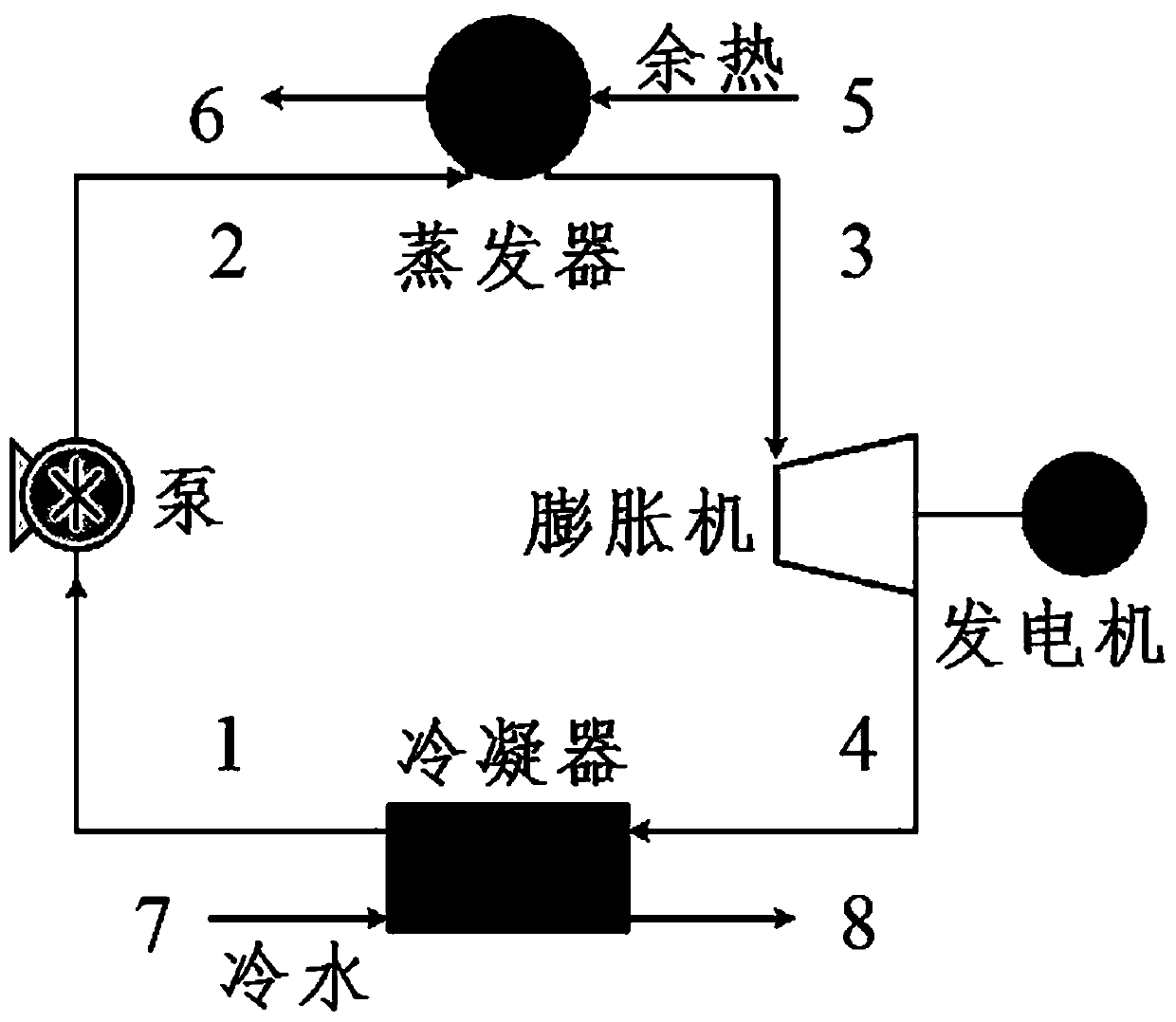

[0025] The traditional organic Rankine cycle-based waste heat recovery system consists of five main components, namely pump, evaporator, expander, condenser and generator. The system configuration is as follows: figure 1shown. In the traditional waste heat recovery system based on the organic Rankine cycle, the liquid organic working medium (state point 1) from the outlet of the condenser is pressurized by the pump and sent to the evaporator (state point 2); the liquid working medium in the evaporator Heated at constant pressure, from supercooled liquid state to saturated liquid state, gas-liquid two-phase state, and finally to saturated steam state (or superheated steam state), that is, state point 3; saturated steam (or superheated steam) is then sent to the expander De-expansion does work to output mechanical energy, the generator converts the mechanical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com