Patents

Literature

463 results about "Organic media" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Organic Media Group is an SEO agency that revolves around an ecosystem where increased organic traffic and sales come by the way of 4 different core strategies. The three core strategies SEO, Social Media, and Content Marketing all work together in unison to generate traffic and branding.

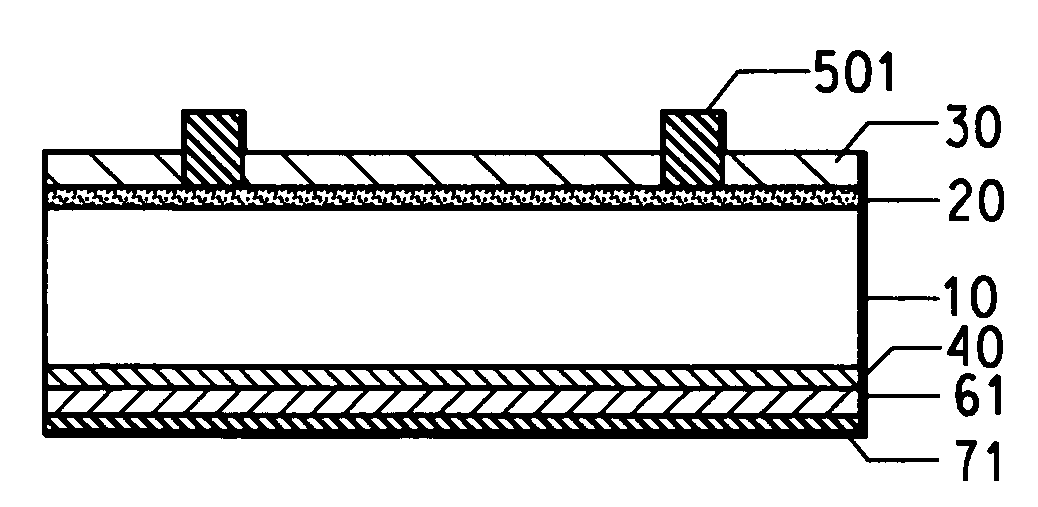

Electroconductive thick film composition(s), electrode(s), and semiconductor device(s) formed therefrom

The present invention is directed to an electroconductive thick film composition comprising: (a) electroconductive metal particles selected from (1) Al, Cu, Au, Ag, Pd and Pt; (2) alloy of Al, Cu, Au, Ag, Pd and Pt; and (3) mixtures thereof; (3) glass frit wherein said glass frit is Pb-free; dispersed in (d) an organic medium, and wherein the average diameter of said electroconductive metal particles is in the range of 0.5-10.0 μm. The present invention is further directed to an electrode formed from the composition as detailed above and a semiconductor device(s) (for example, a solar cell) comprising said electrode.

Owner:SOLAR PASTE LLC

Negative-acting no-process printing plates

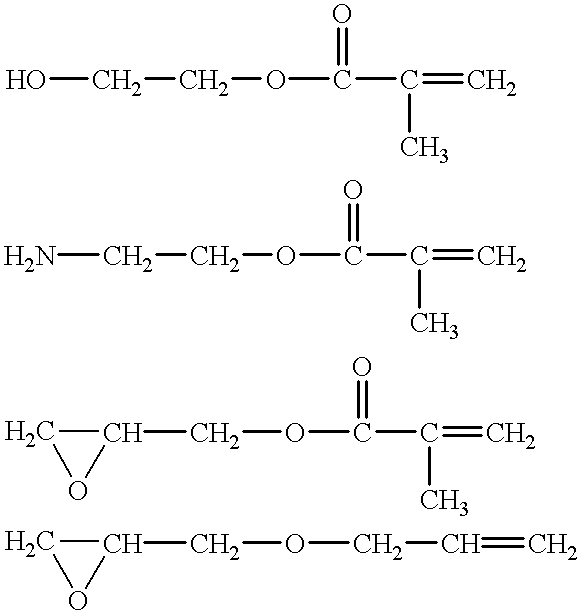

InactiveUS6027857APhotosensitive materialsPhotosensitive material processingFunctional monomerOligomer

A photosensitive composition is prepared containing a polymer of the formula B(X)(Y) wherein B represents an organic backbone, each X independently is an acidic group or salt thereof and each Y independently is a photocurable group and a photoinitiating compound or compounds. Preferably, free-radically polymerizable multi-functional monomer and / or oligomer is added to the photosensitive composition. The photosensitive composition can be coated on a suitable substrate for planographic printing plate applications. Imagewise irradiation causes the light struck regions to photocure, becoming insoluble in aqueous and organic mediums, while the non-light struck regions remain highly soluble / dispersable. Printing plates of this construction do not require processing prior to being run on a press.

Owner:3M CO

Negative-acting no-process printing plates

InactiveUS6171735B1Platen pressesSemiconductor/solid-state device manufacturingFunctional monomerOligomer

Owner:3M INNOVATIVE PROPERTIES CO

Thick-film pastes containing lead-tellurium-boron-oxides, and their use in the manufacture of semiconductor devices

The present invention provides a thick-film paste for printing the front side of a solar cell device having one or more insulating layers. The thick-film paste comprises an electrically conductive metal and a lead-tellurium-boron-oxide dispersed in an organic medium.

Owner:SOLAR PASTE LLC

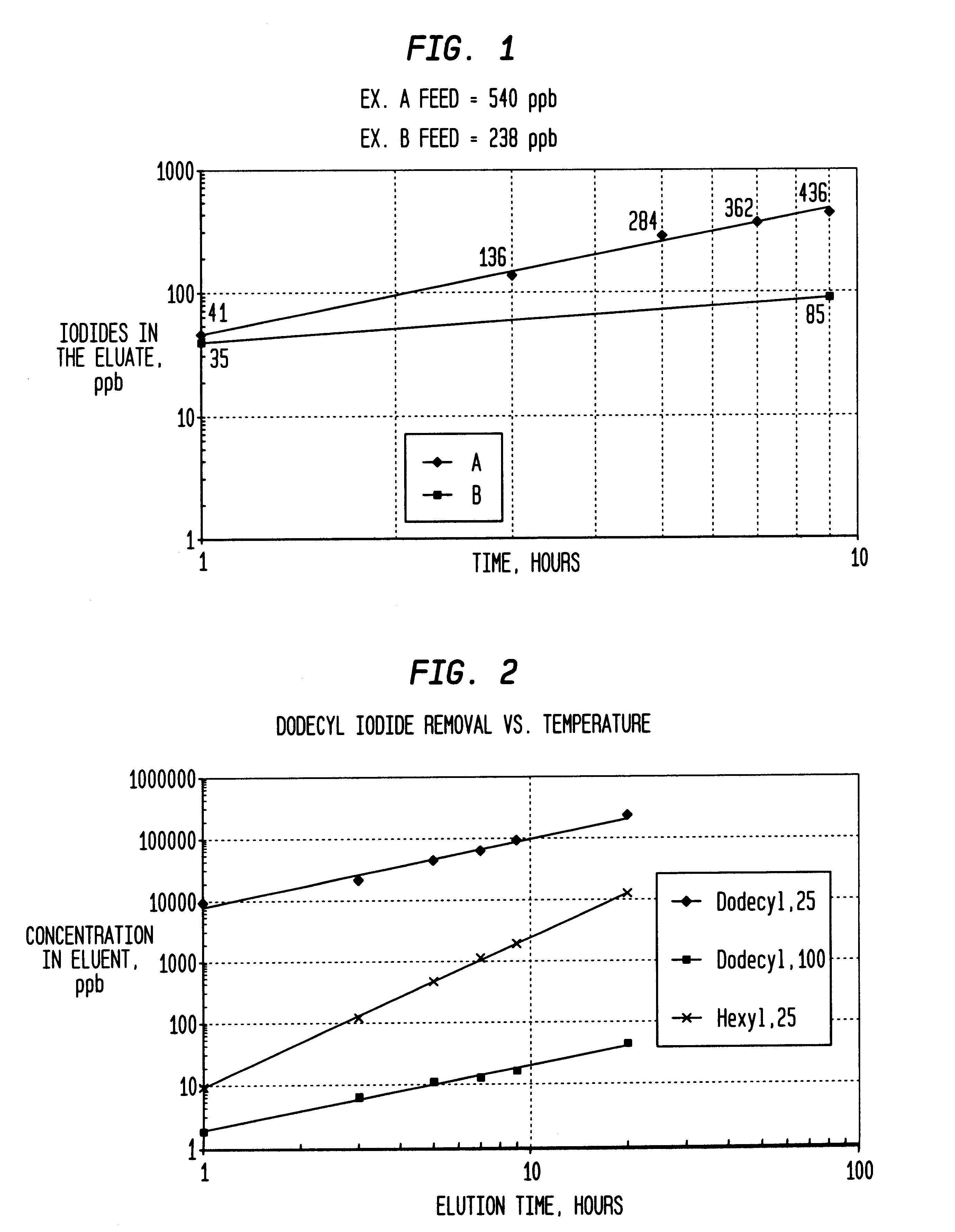

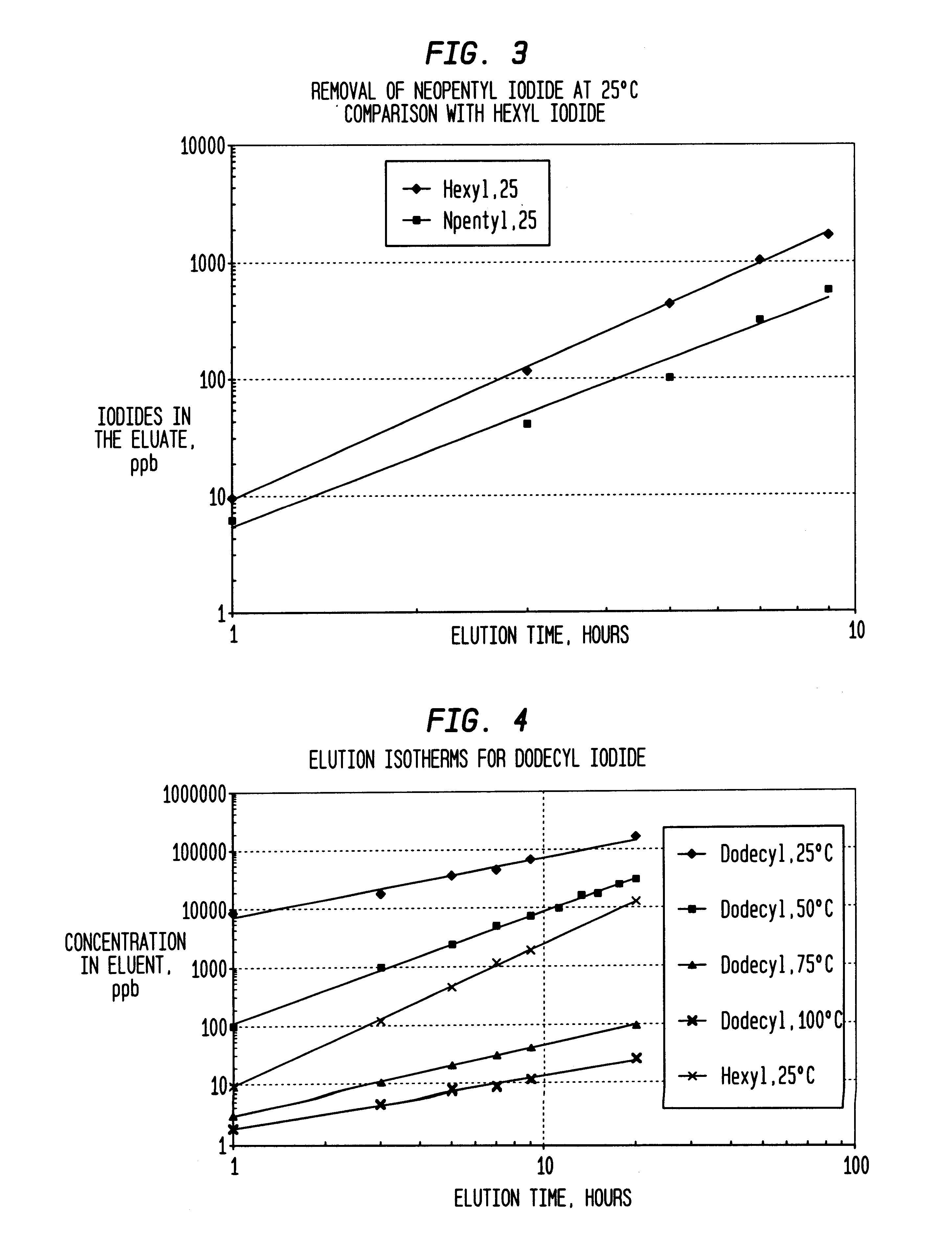

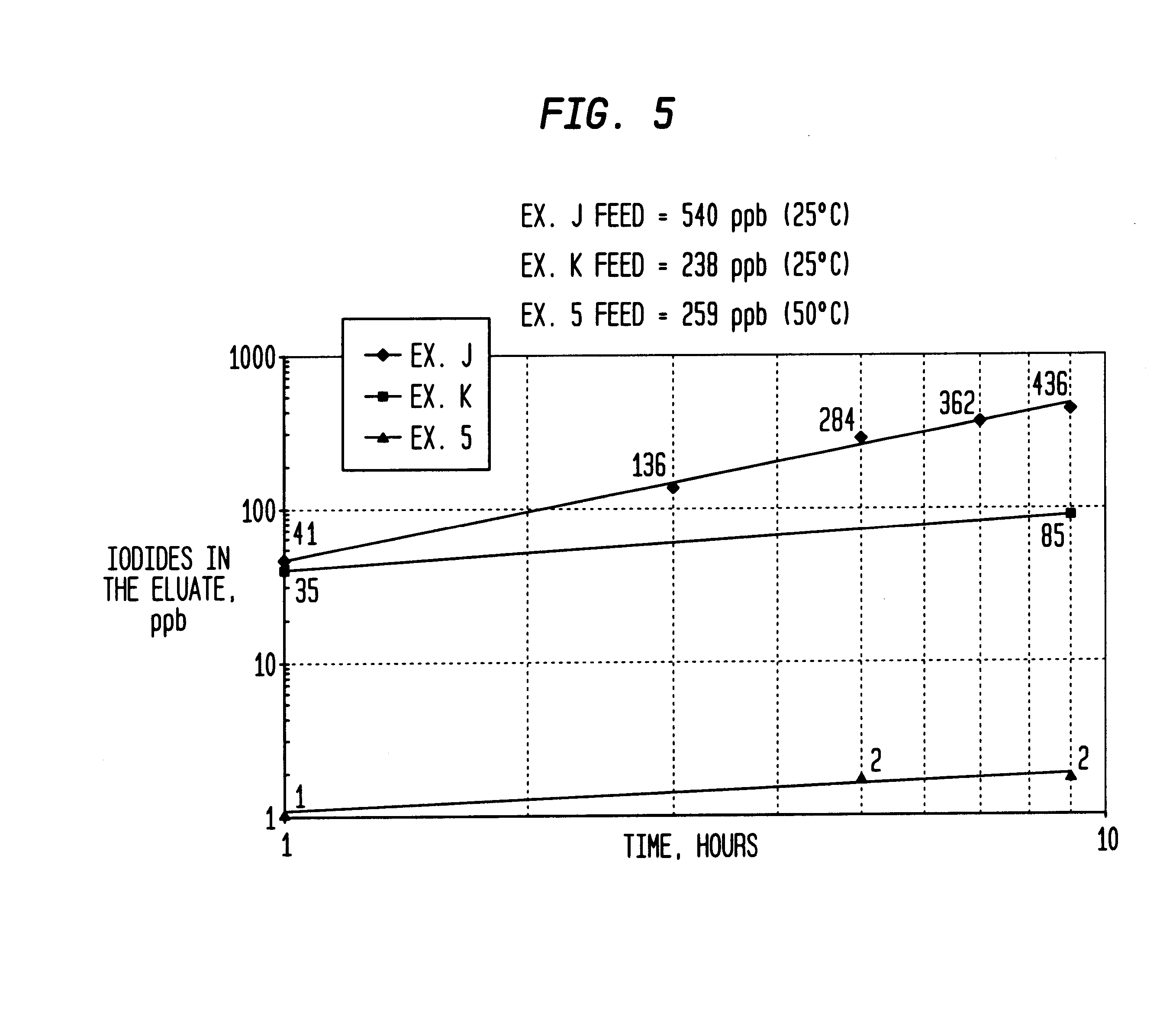

Method of removing organic iodides from organic media

InactiveUS6225498B1Efficient removalCation exchanger materialsOrganic compound preparationAcetic acidAcetic anhydride

Owner:CELANESE INT CORP

Electroconductive thick film composition(s), electrode(s), and semiconductor device(s) formed therefrom

Owner:SOLAR PASTE LLC

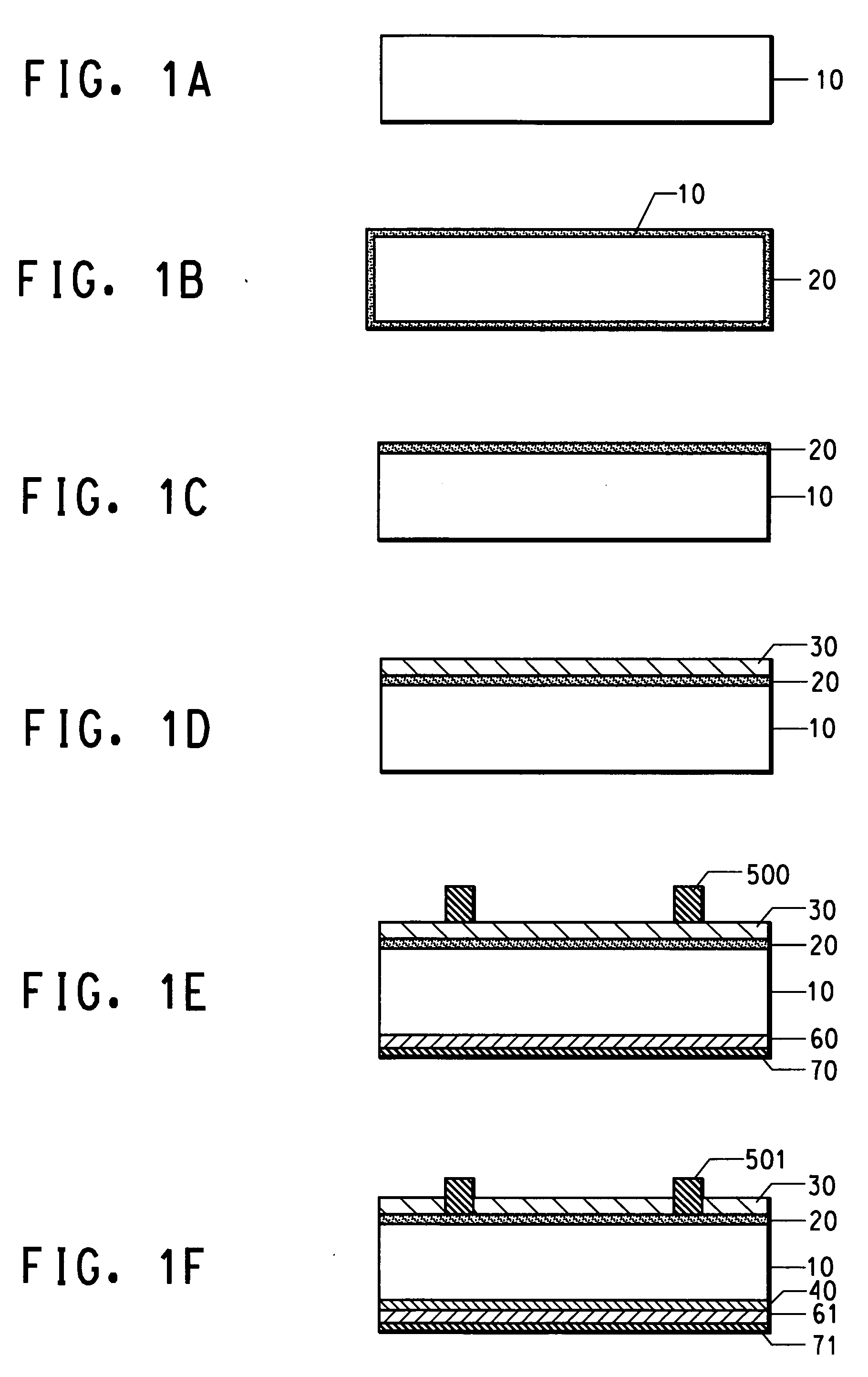

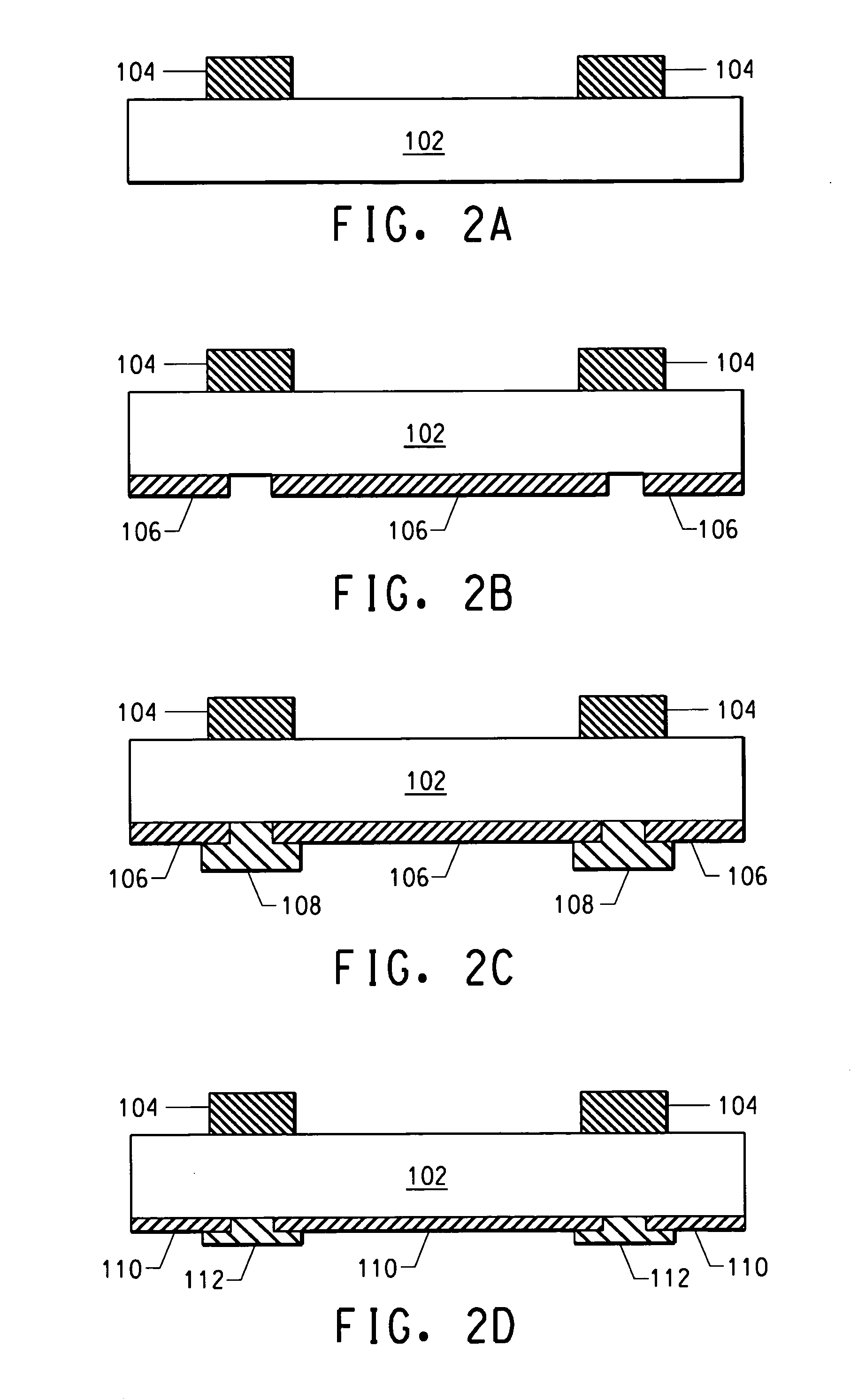

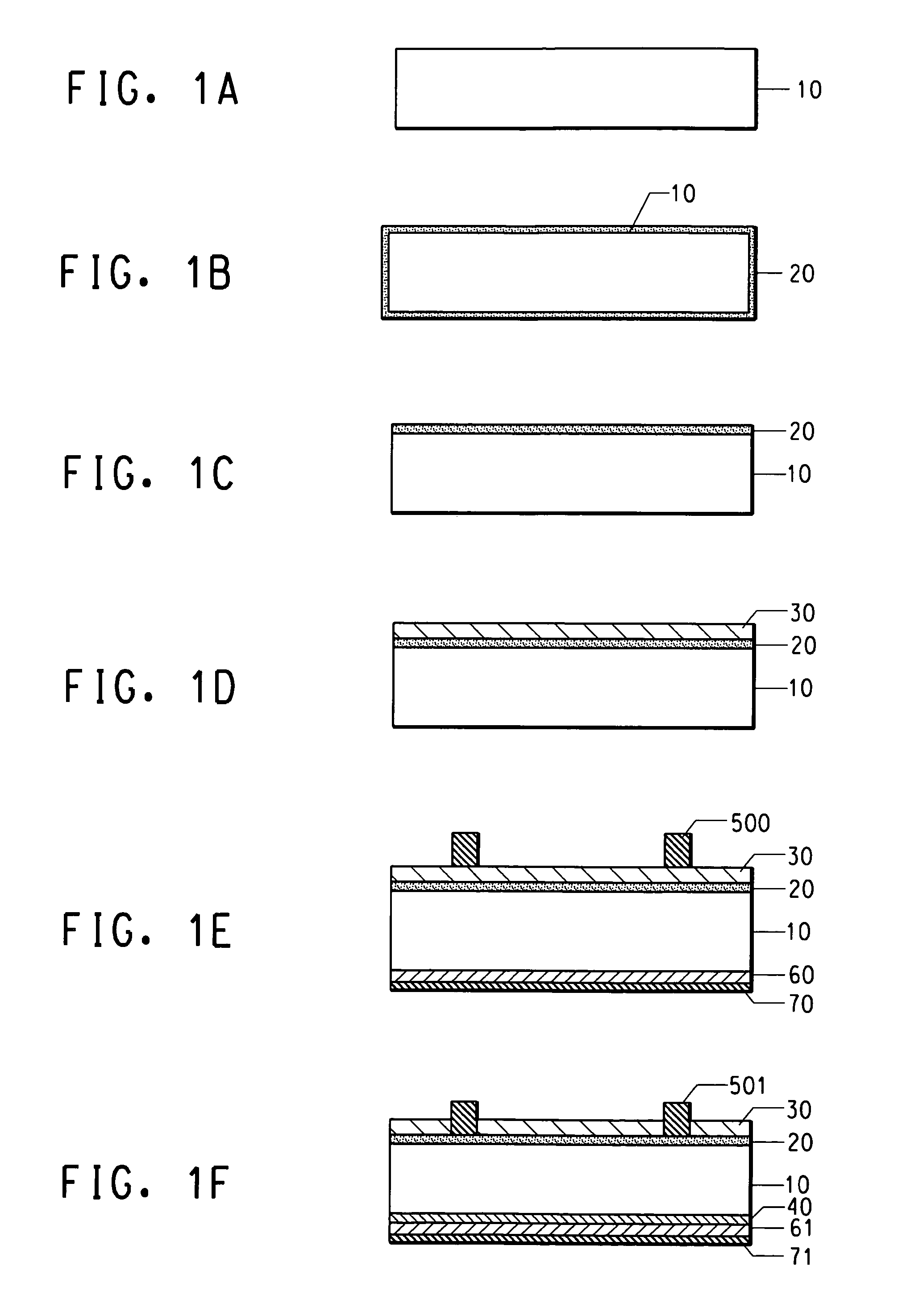

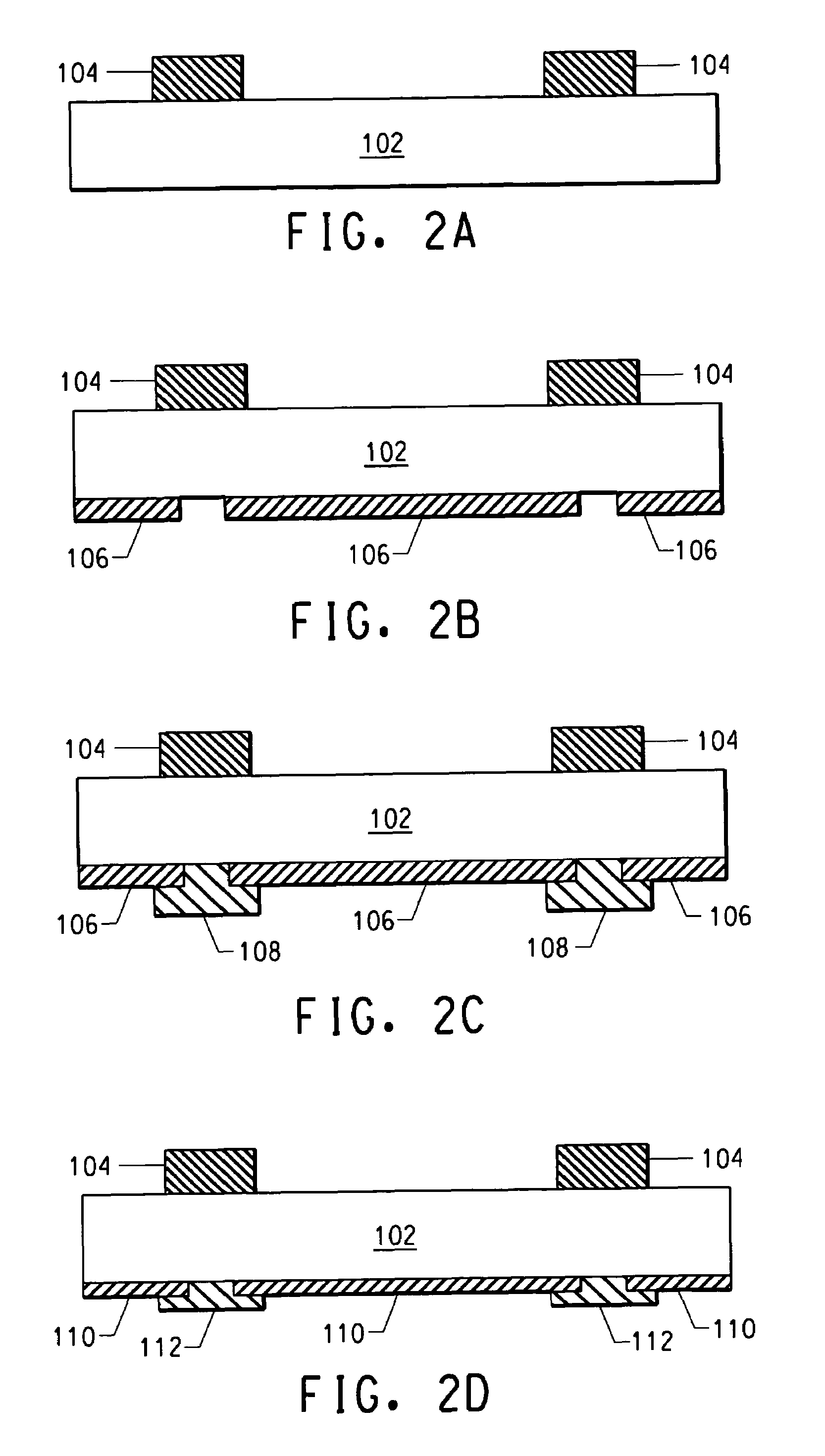

Method of manufacture of semiconductor device and conductive compositions used therein

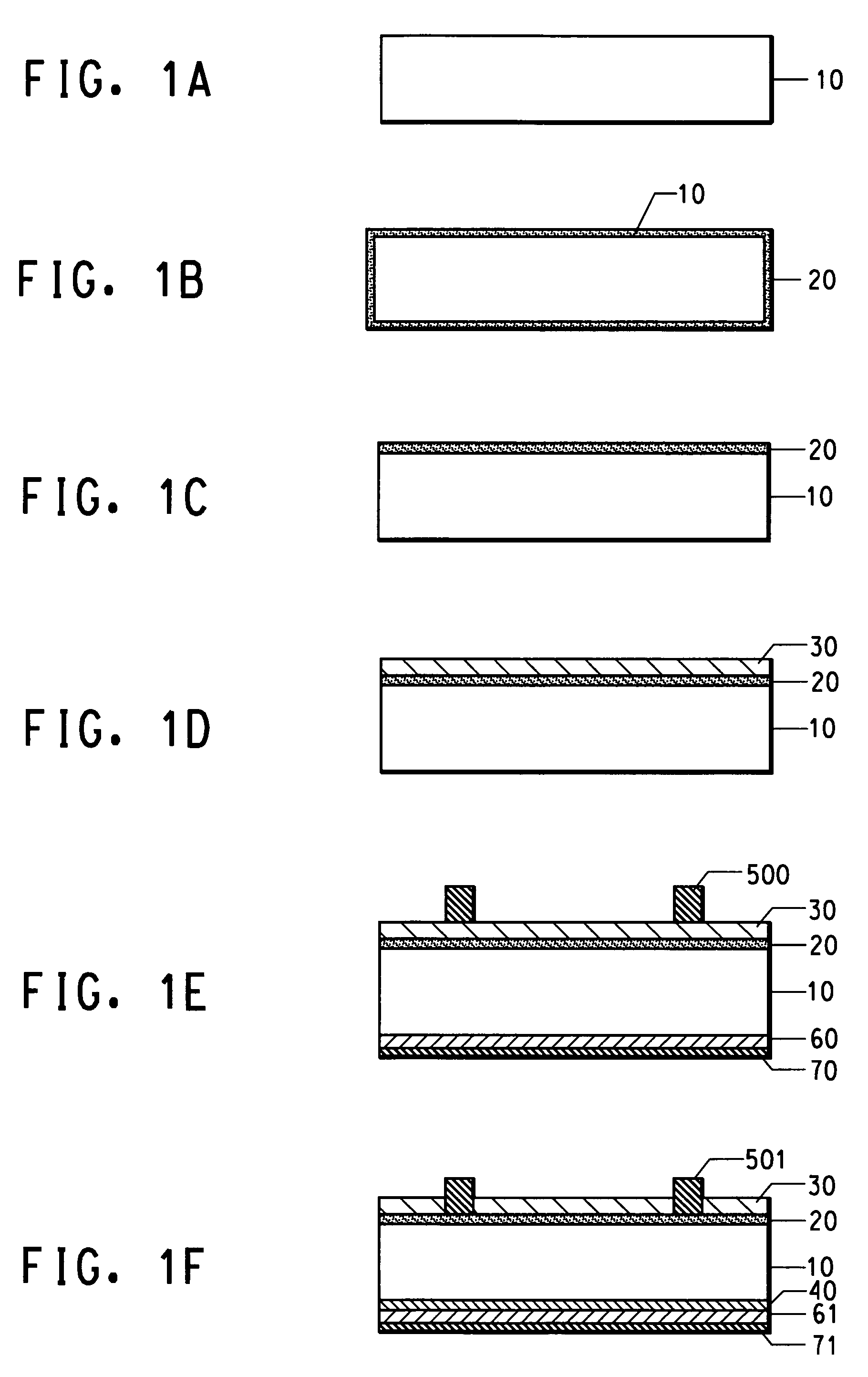

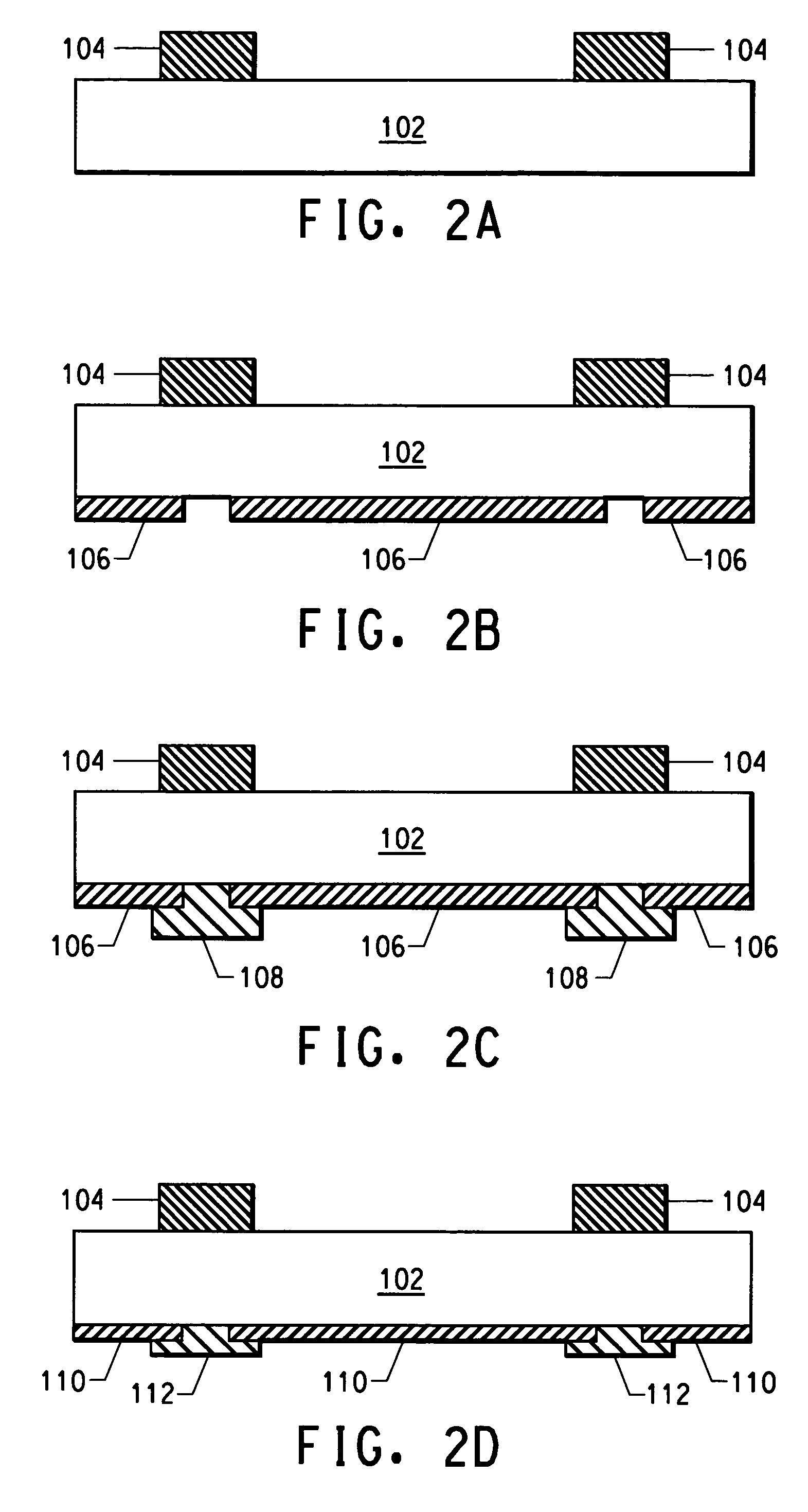

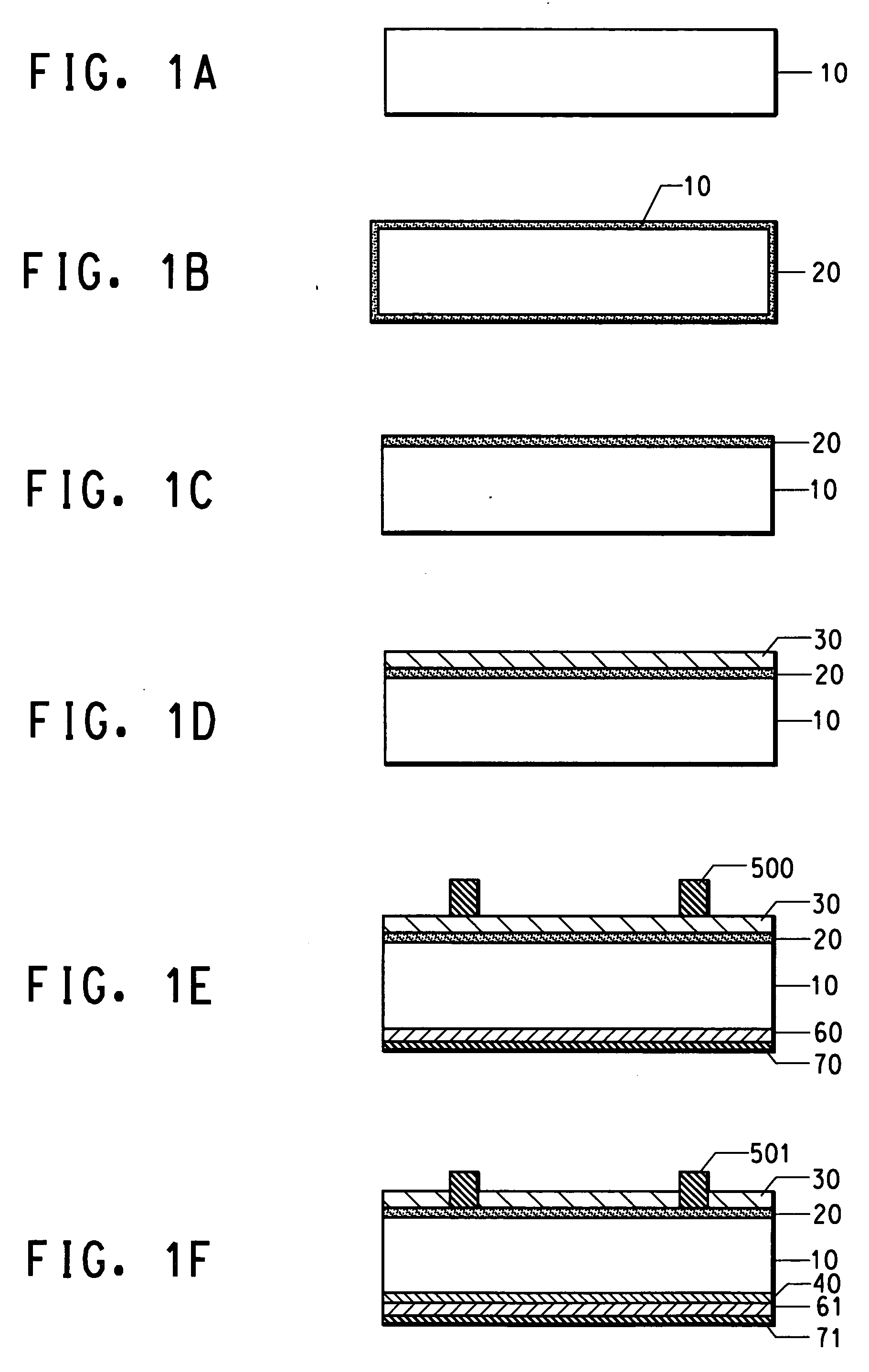

InactiveUS20060231804A1Semiconductor/solid-state device detailsConductive materialDevice materialFrit

The present invention is directed to a thick film conductive composition comprising: (a) electrically conductive silver powder; (b) Zn-containing additive wherein the particle size of said zinc-containing additive is in the range of 7 nanometers to less than 100 nanometers; (c) glass frit wherein said glass frit has a softening point in the range of 300 to 600° C.; dispersed in (d) organic medium. The present invention is further directed to a semiconductor device and a method of manufacturing a semiconductor device from a structural element composed of a semiconductor having a p-n junction and an insulating film formed on a main surface of the semiconductor comprising the steps of (a) applying onto said insulating film the thick film composition as describe above; and (b) firing said semiconductor, insulating film and thick film composition to form an electrode.

Owner:EI DU PONT DE NEMOURS & CO

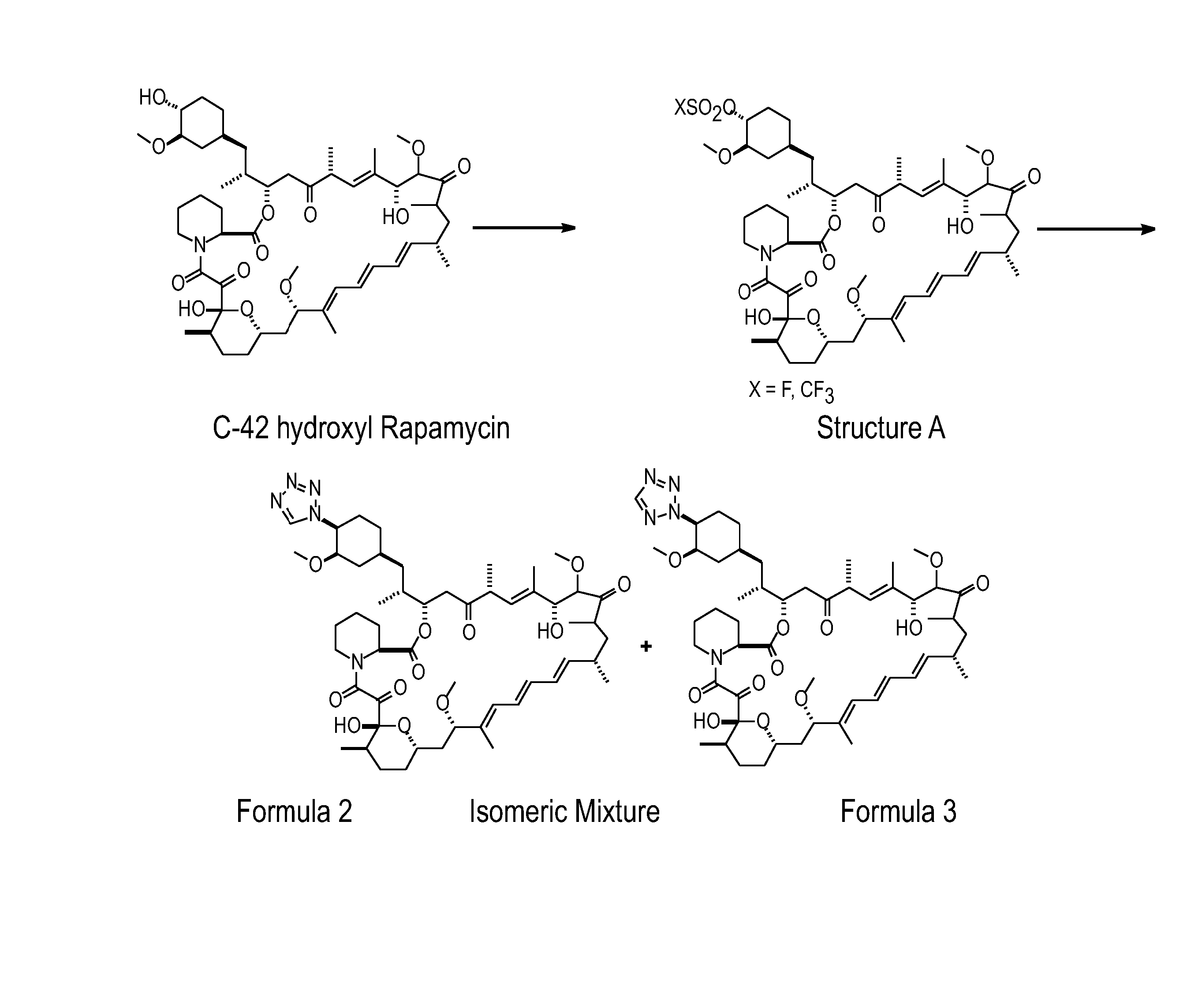

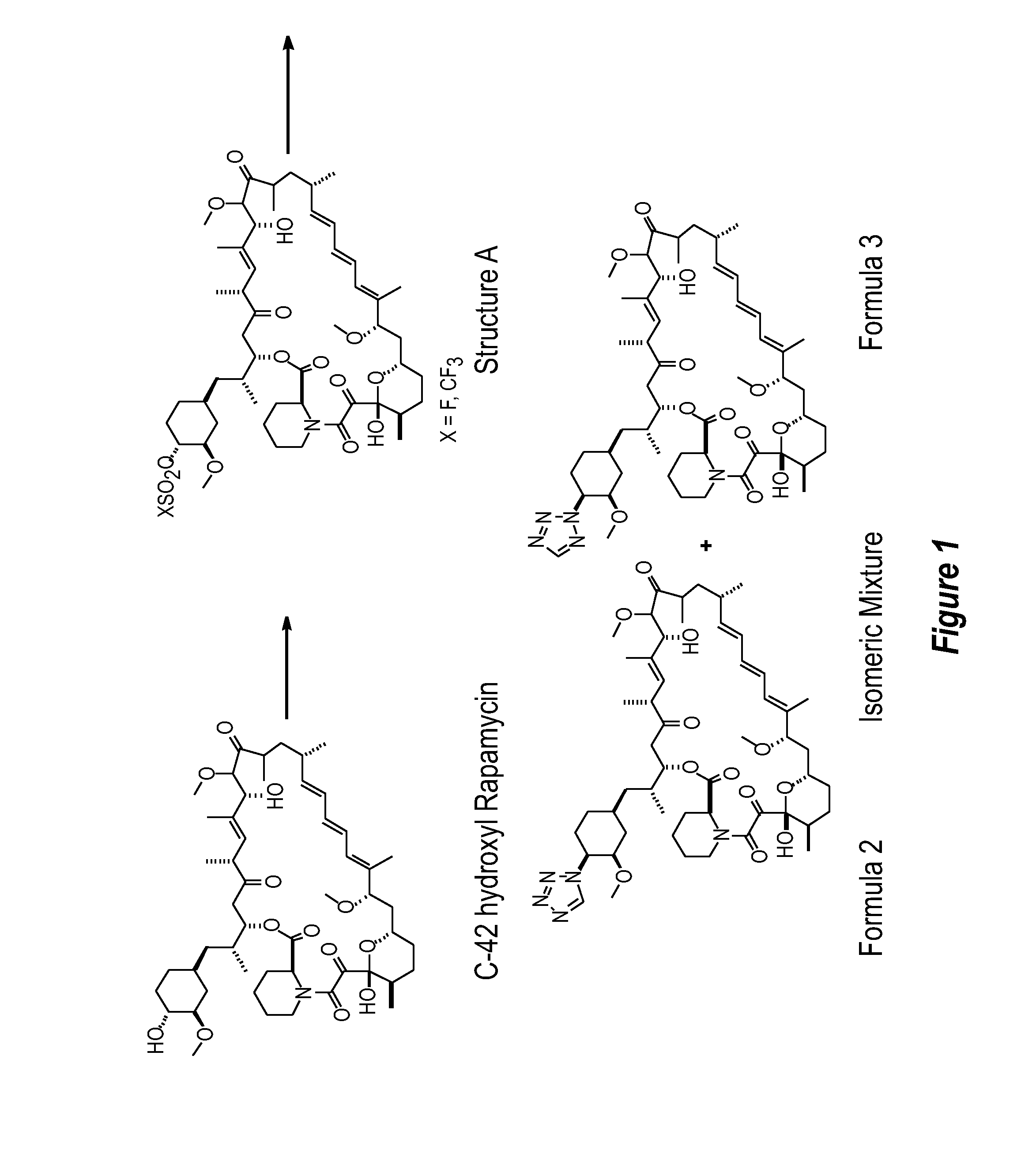

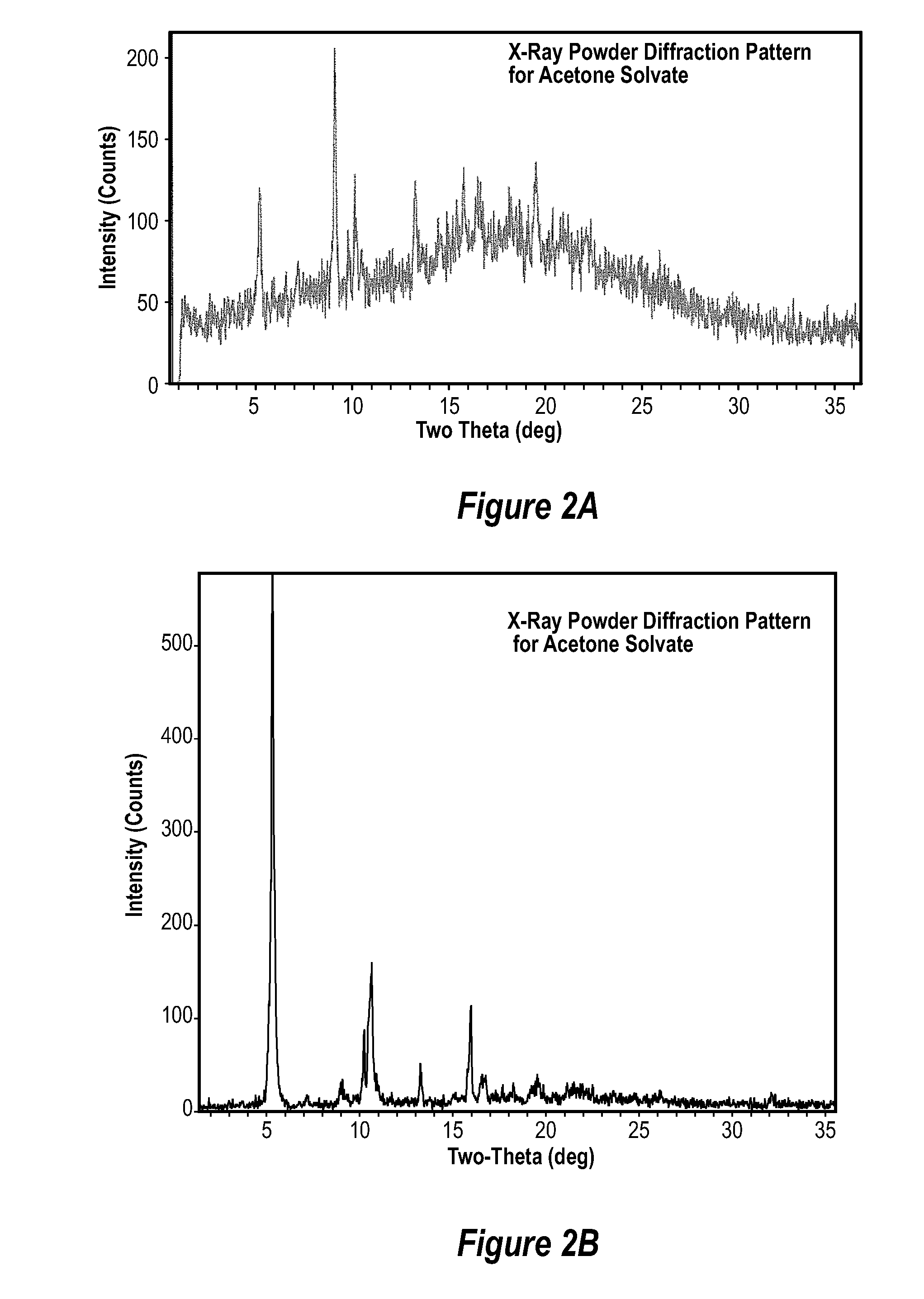

Methods of manufacturing crystalline forms of rapamycin analogs

A process for preparing a crystalline rapamycin analog includes: combining the rapamycin analog with an organic medium to form a mixture; incubating the mixture until the rapamycin analog crystallizes; and recovering the crystalline rapamycin analog. The organic medium can be a solvent, and the process can include causing the rapamycin analog to dissolve into the solvent, and incubating the solvent until the rapamycin analog crystallizes. The following can also be performed: forming a slurry of crystalline rapamycin analog; stirring the rapamycin analog mixture until the rapamycin analog crystallizes; saturating the rapamycin analog solution; forming a supersaturated rapamycin analog solution; combining an antisolvent with the rapamycin analog and the solvent to form a biphasic mixture, and incubating the biphasic mixture to cause a liquid-liquid phase split.

Owner:ABBOTT LAB INC

Solar cell

InactiveUS20090120490A1Improve conversion efficiencyReduce warpageNon-conductive material with dispersed conductive materialPhotovoltaic energy generationStearic acidSolar cell

A solar cell, comprising: a substrate, including p-n doping structure formed within said substrate; material attached to the back of said substrate, where said material includes glass mixture, aluminum material, organic medium and additive. Wherein said glass needs to be formed by combining two or more glasses: the main composition for post-mixed glass should include Al2O3, Bi2O5, B2O3, SiO2, PbO, Tl2O3 and other metal and non-metal oxides. For the material composition, aluminum powder content is 60˜80 mass %, with approximately 90 to 99.99% purity. Additives include C10˜C24 stearic acid, with the content of less than 5 mass %. The C10˜C24 stearic acid may include oleic acid. Organic medium content is roughly 20˜35 mass %. Wherein said organic medium includes 60˜90 mass % ether class organic solvent, 10˜20 mass % cellulosic resin and 1˜5 mass % of leveling agent, rheological agent or thixotropic agent.

Owner:GIGASTORAGE CORP

Thick-film pastes containing lead- and tellurium-oxides, and their use in the manufacture of semiconductor devices

ActiveUS20110308595A1Transportation and packagingSemiconductor/solid-state device detailsTe elementOrganic media

Owner:SOLAR PASTE LLC

Thick-film pastes containing lead-tellurium-lithium- oxides, and their use in the manufacture of semiconductor devices

The present invention provides a thick-film paste for printing the front side of a solar cell device having one or more insulating layers. The thick-film paste comprises an electrically conductive metal, and a lead-tellurium-lithium-oxide dispersed in an organic medium.

Owner:SOLAR PASTE LLC

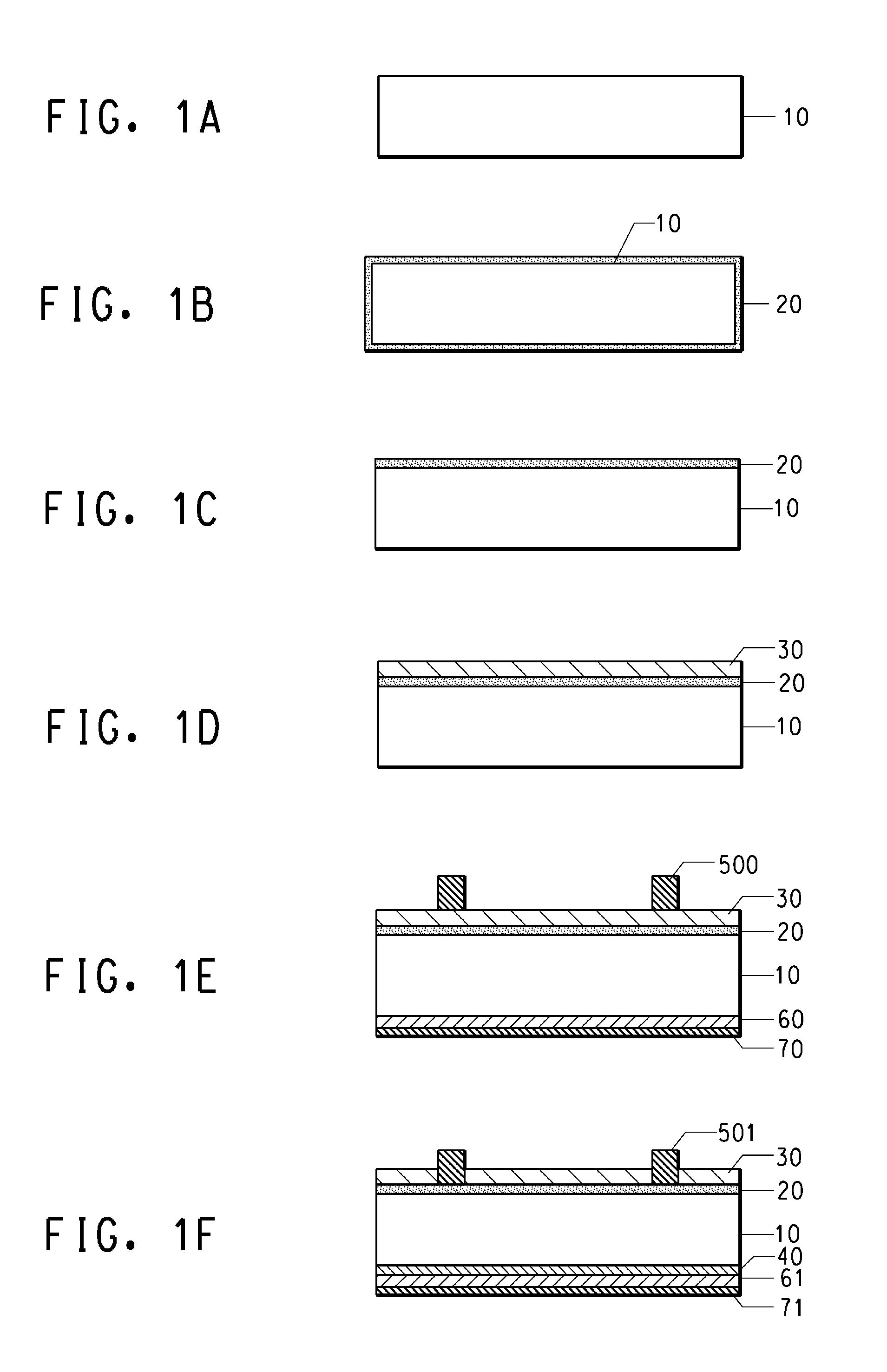

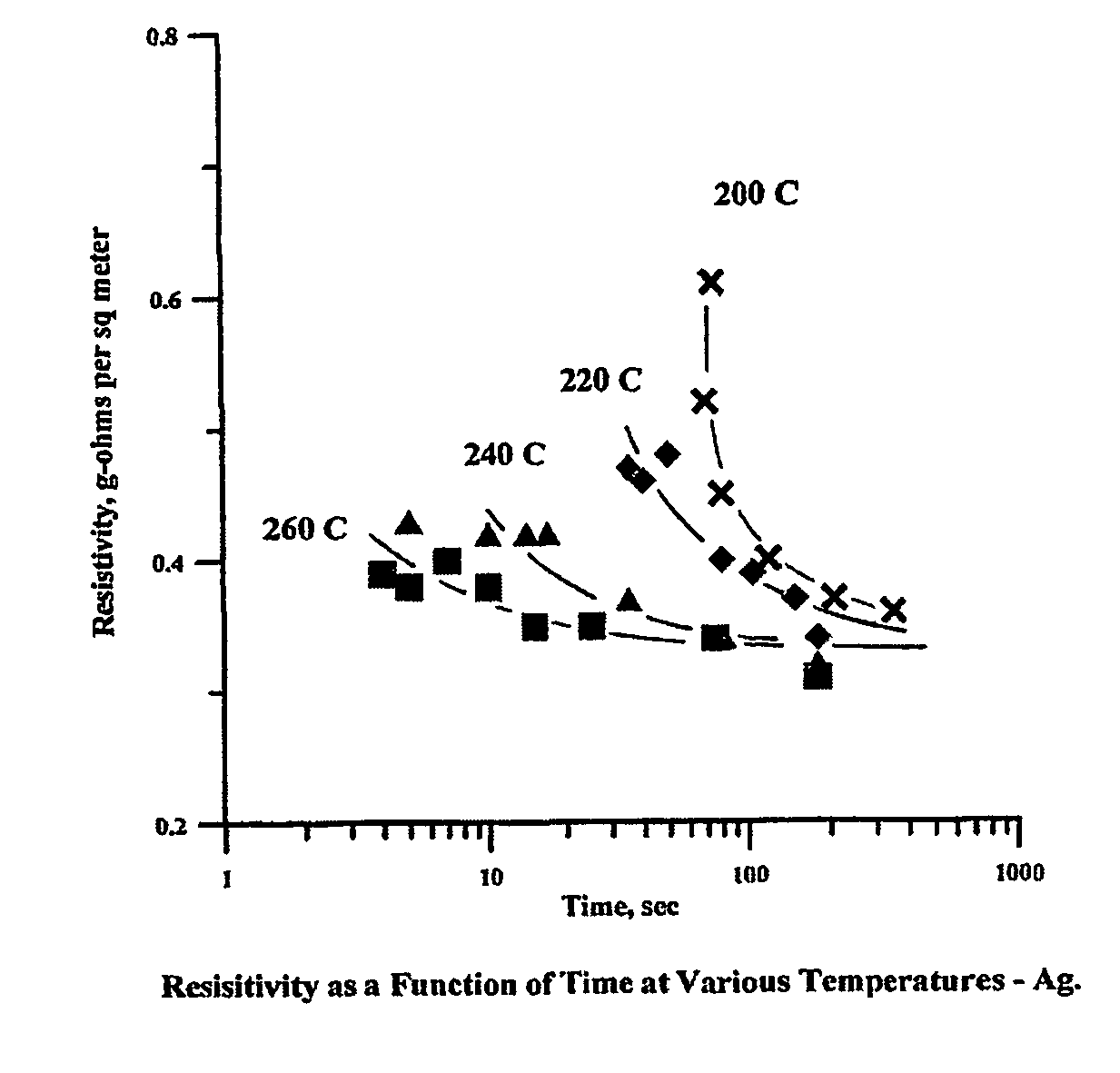

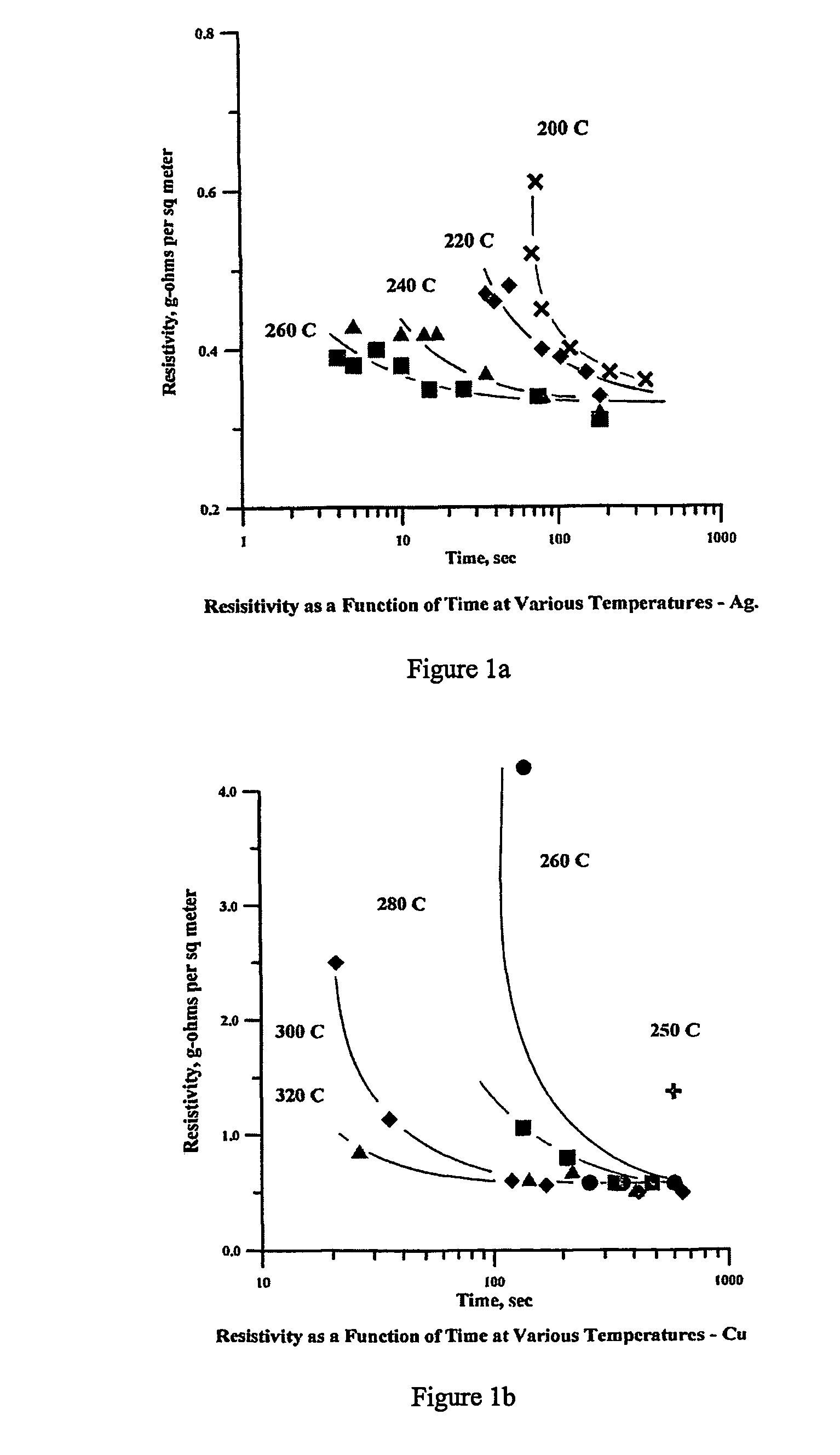

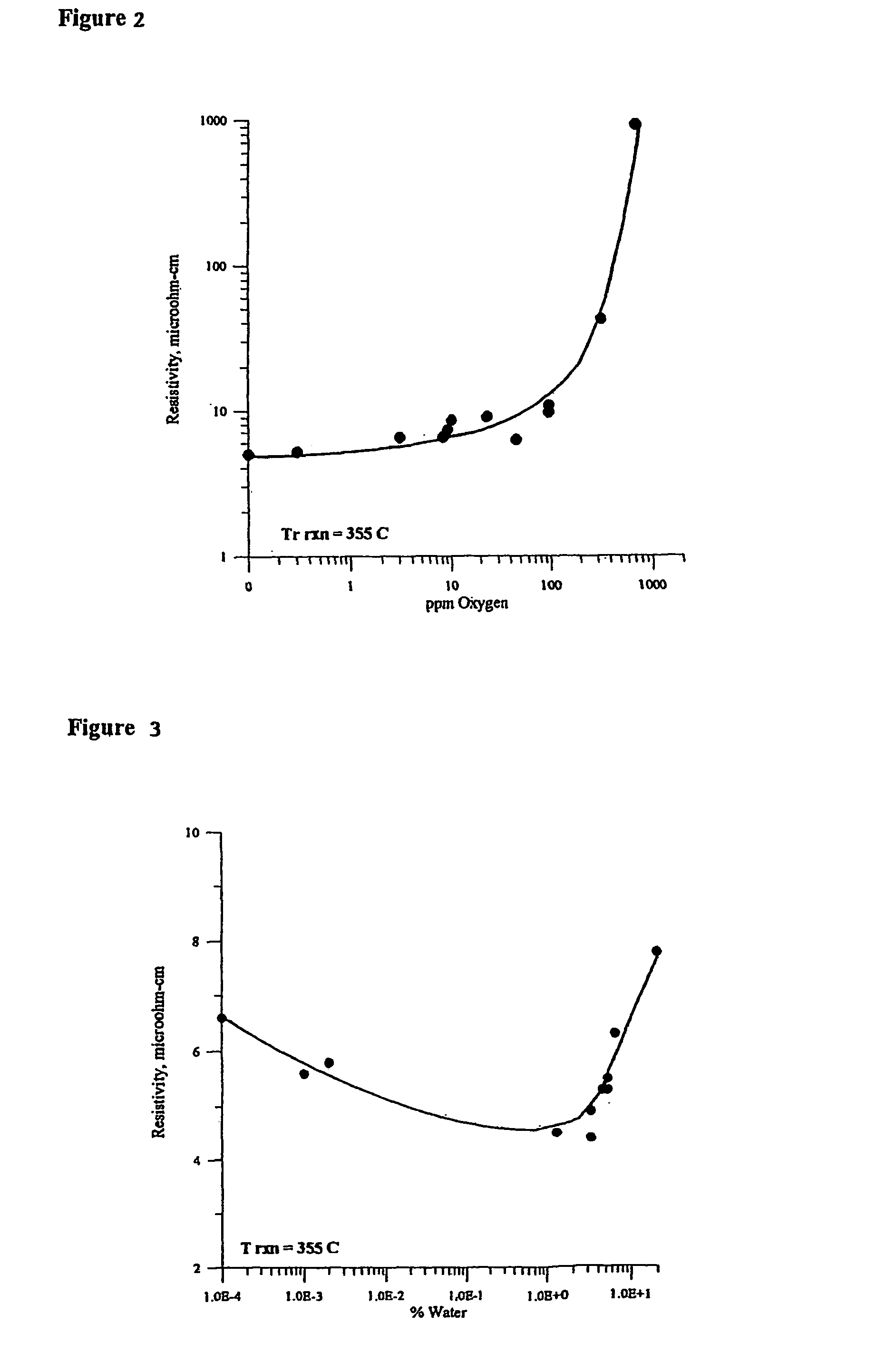

Low temperature method and composition for producing electrical conductors

InactiveUS7115218B2Increase speedLow costLayered productsSemiconductor/solid-state device detailsElectrical conductorOrganic media

A composition of matter having a metal powder or powders of specified characteristics in a Reactive Organic Medium (ROM). These compositions can be applied by any convenient printing process to produce patterns of electrical conductors on temperature-sensitive electronic substrates. The pattern can be thermally cured in seconds to form pure metal conductors at a temperature low enough to avoid damaging the substrate.

Owner:PARELEC

Thick-film conductive paste

InactiveUS20060001009A1Conductive materialNon-conductive material with dispersed conductive materialConductive pasteCompound (substance)

A thick-film composition comprising: (a) conductive metal; (b) one or more inorganic binders; (c) antimony, antimony oxide, antimony-containing compound capable of forming an antimony oxide upon firing, or mixtures thereof; dispersed in (d) organic medium. The windshield defogger element and a method of forming a windshield defogger element comprising: (a) providing the thick film composition as above; (b) providing a glass substrate; (c) printing the composition of (a) onto said glass substrate; and (d) firing said composition and substrate. A vehicle having as the conductive element in the windshield defroster system a windshield defogger element comprising an antimony oxide containing layer as a protective layer. A windshield defogger element comprising an antimony oxide containing layer as a protective layer.

Owner:EI DU PONT DE NEMOURS & CO

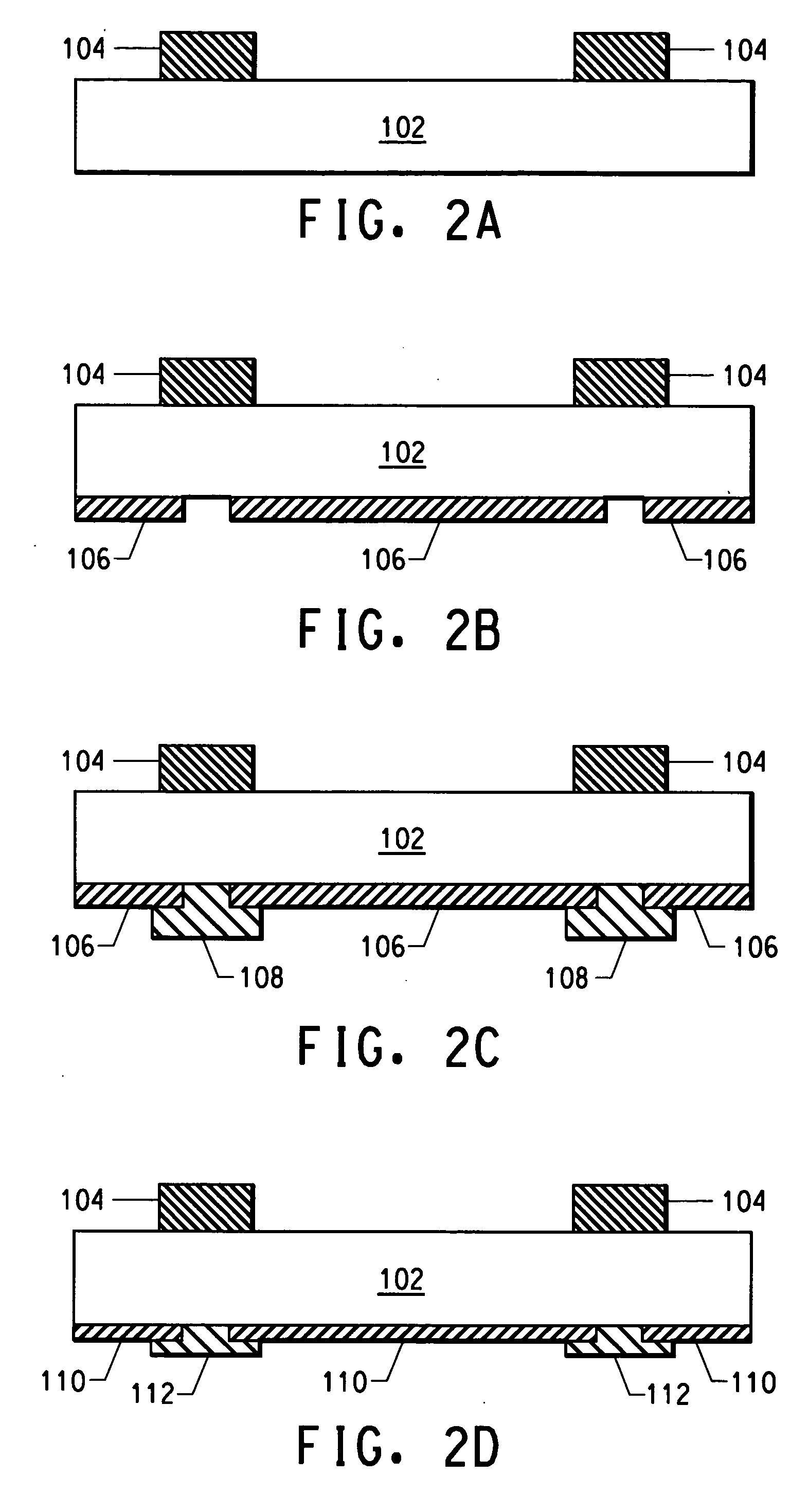

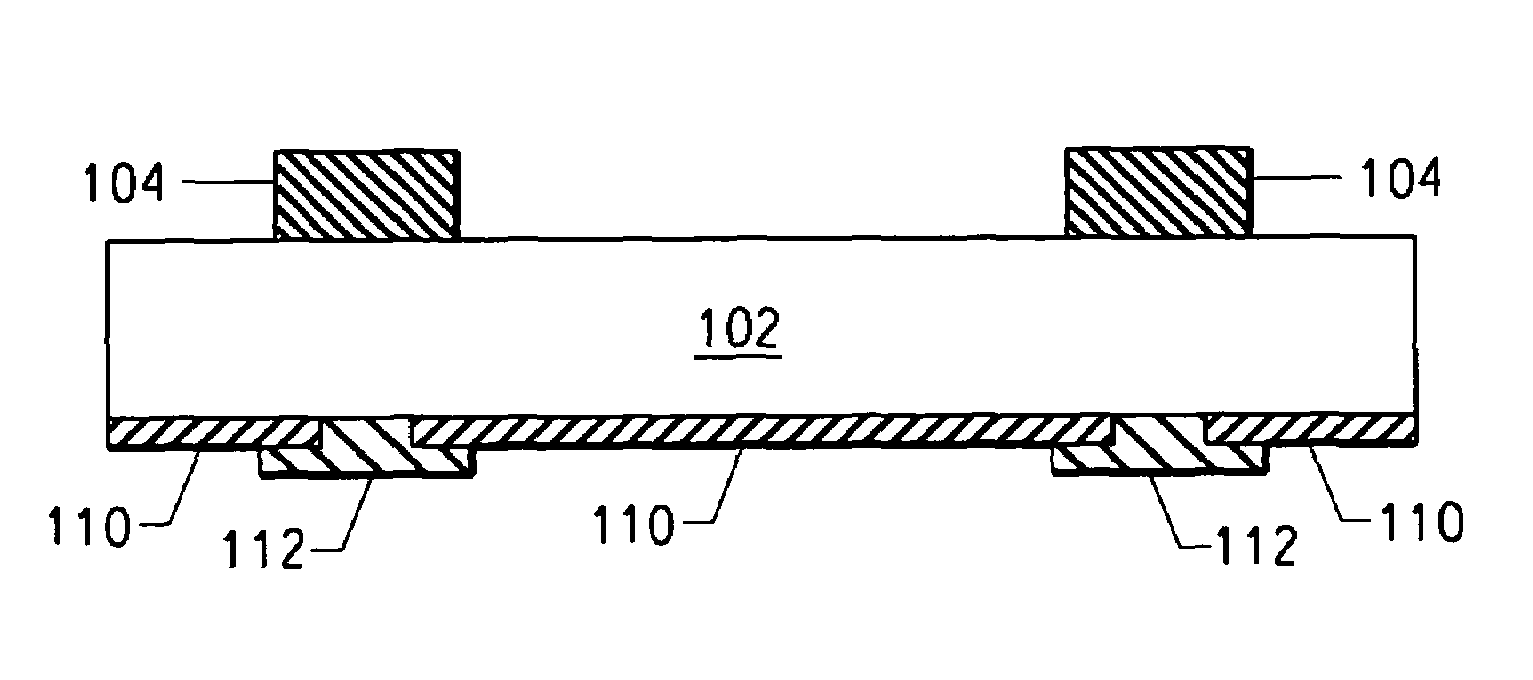

Aluminum thick film compositions(s), electrode(s), semiconductor device(s) and methods of making thereof

InactiveUS20070079868A1Significant bow reduction tendencyDusting tendency is decreasedConductive materialNon-conductive material with dispersed conductive materialElectrical conductorDevice material

The present invention is directed to a thick film conductor composition comprised of (a) aluminum-containing powder; (b) amorphous silicon dioxide (c) and one or more optional glass frit compositions; dispersed in (d) organic medium. The amorphous silicon dioxide contributes to significant bow reduction tendency for solar cells thinner than 270 microns and larger than five inches square without significant effect on reducing the electrical performance of the fired solar cell. In addition and as preferred by solar cell manufacturers, the addition of glass frit reduces the dusting tendency of the aluminum thick film composition.

Owner:EI DU PONT DE NEMOURS & CO

Method of manufacture of semiconductor device and conductive compositions used therein

The present invention is directed to a thick film conductive composition comprising: (a) electrically conductive silver powder; (b) Zn-containing additive wherein the particle size of said zinc-containing additive is in the range of 7 nanometers to less than 100 nanometers; (c) glass frit wherein said glass frit has a softening point in the range of 300 to 600° C.; dispersed in (d) organic medium.The present invention is further directed to a semiconductor device and a method of manufacturing a semiconductor device from a structural element composed of a semiconductor having a p-n junction and an insulating film formed on a main surface of the semiconductor comprising the steps of (a) applying onto said insulating film the thick film composition as describe above; and (b) firing said semiconductor, insulating film and thick film composition to form an electrode.

Owner:EI DU PONT DE NEMOURS & CO

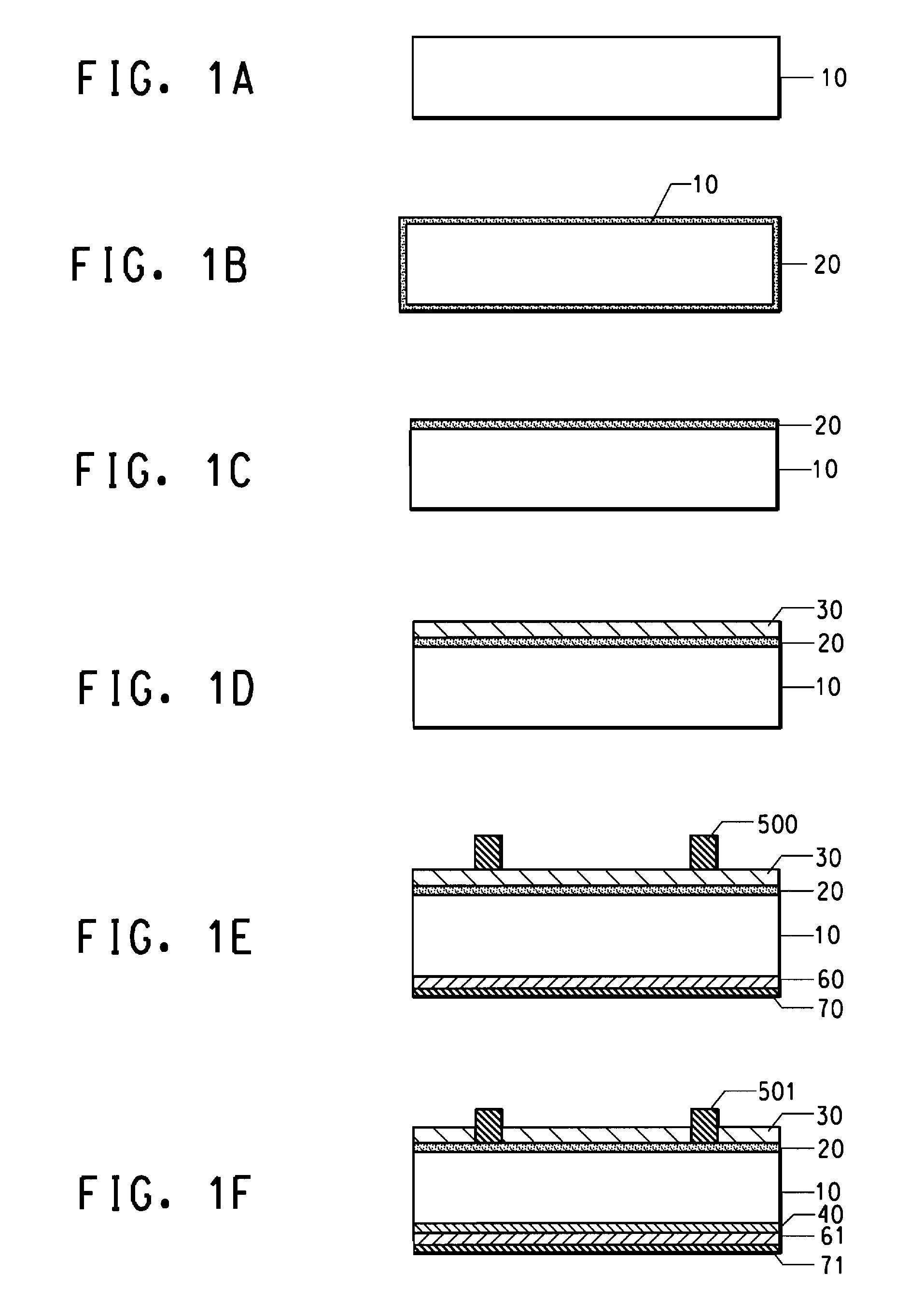

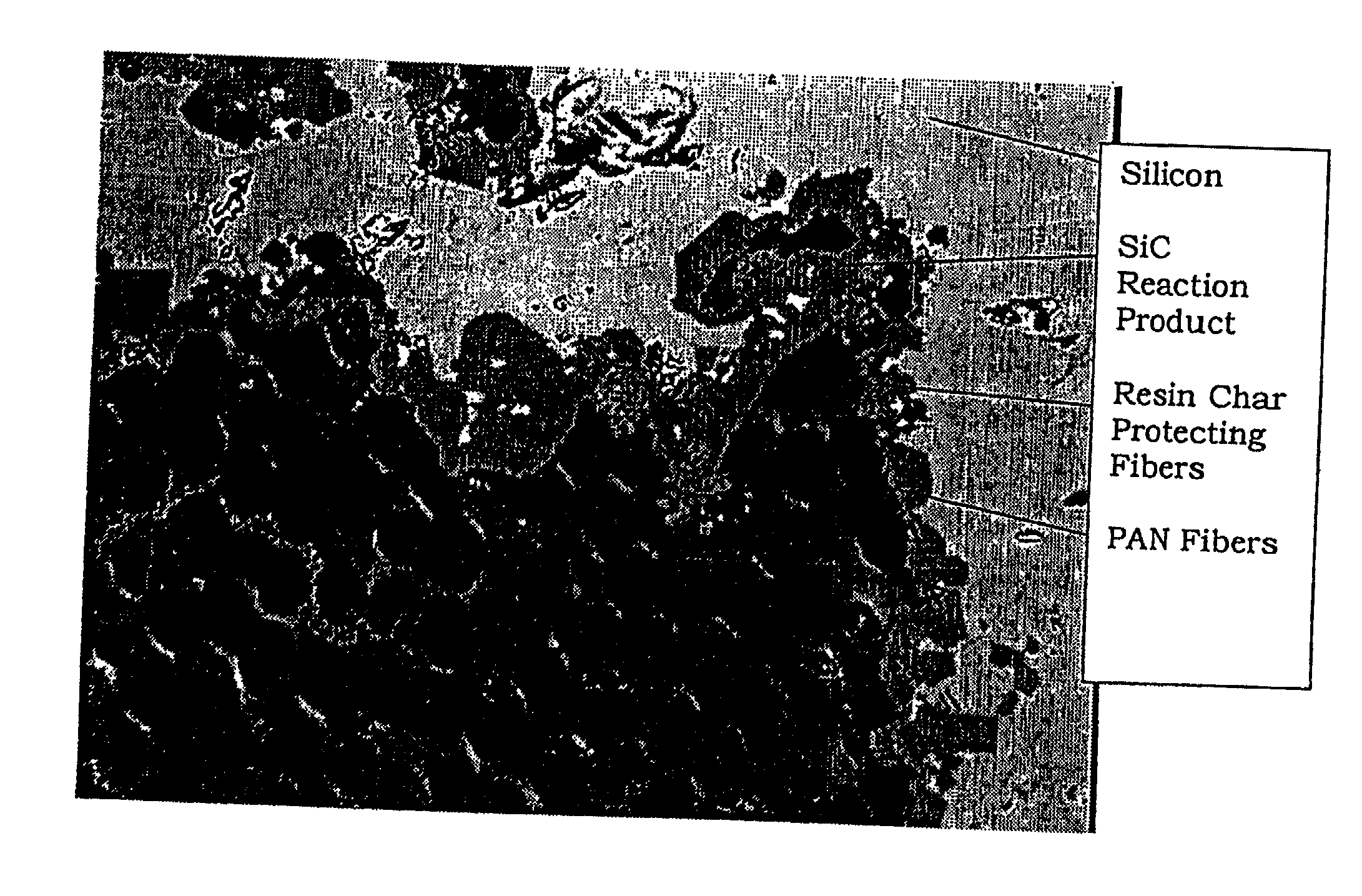

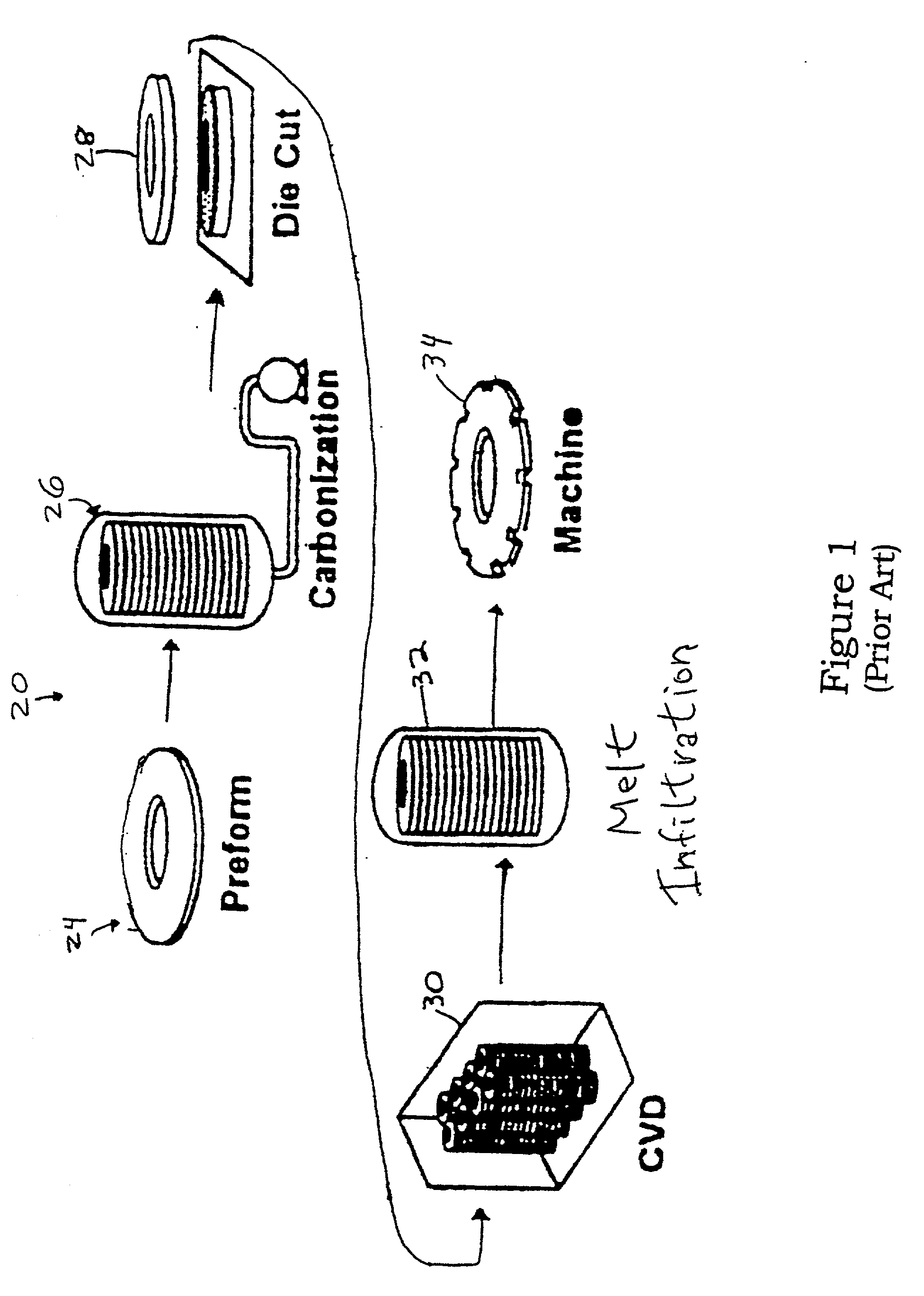

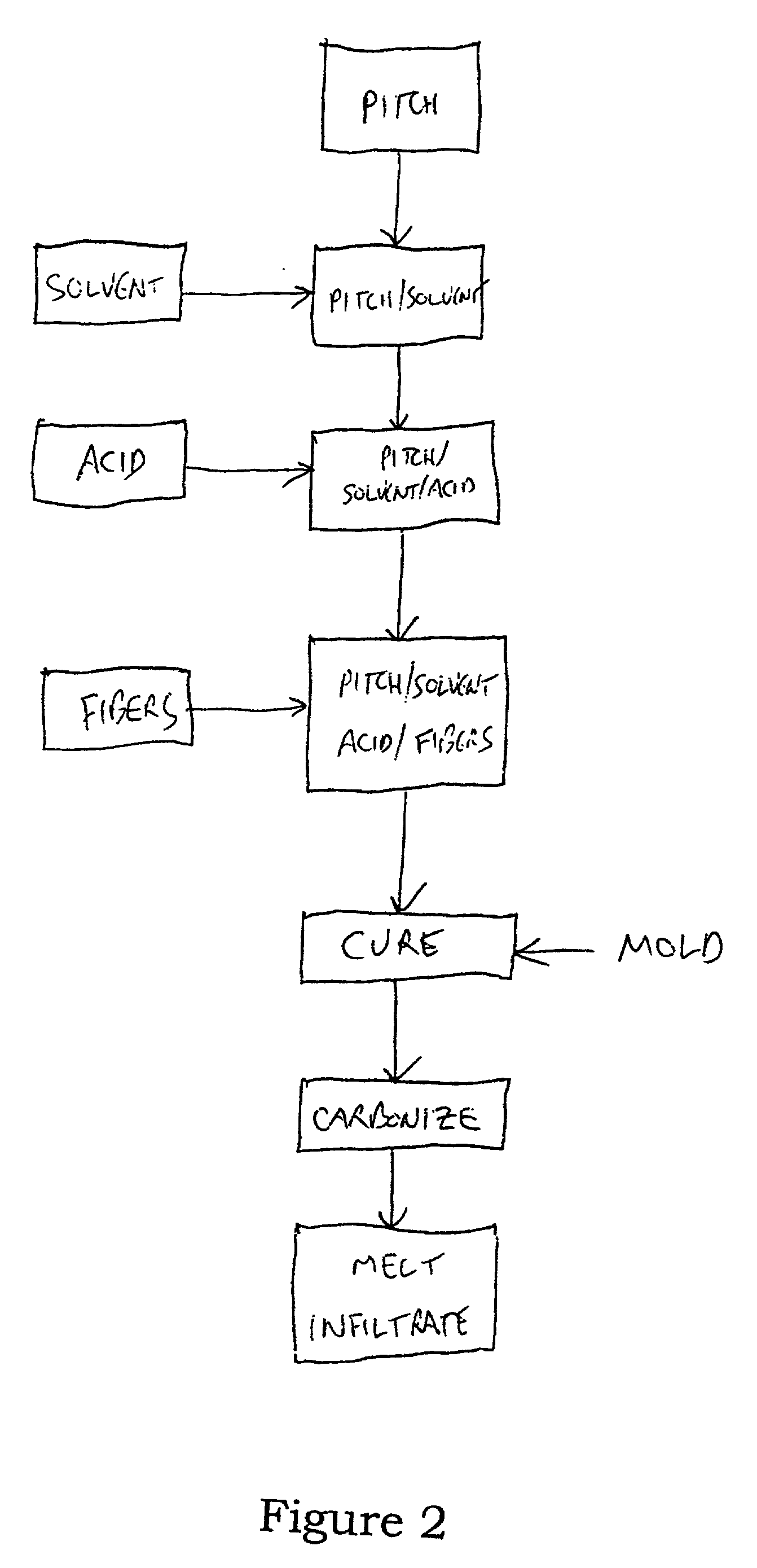

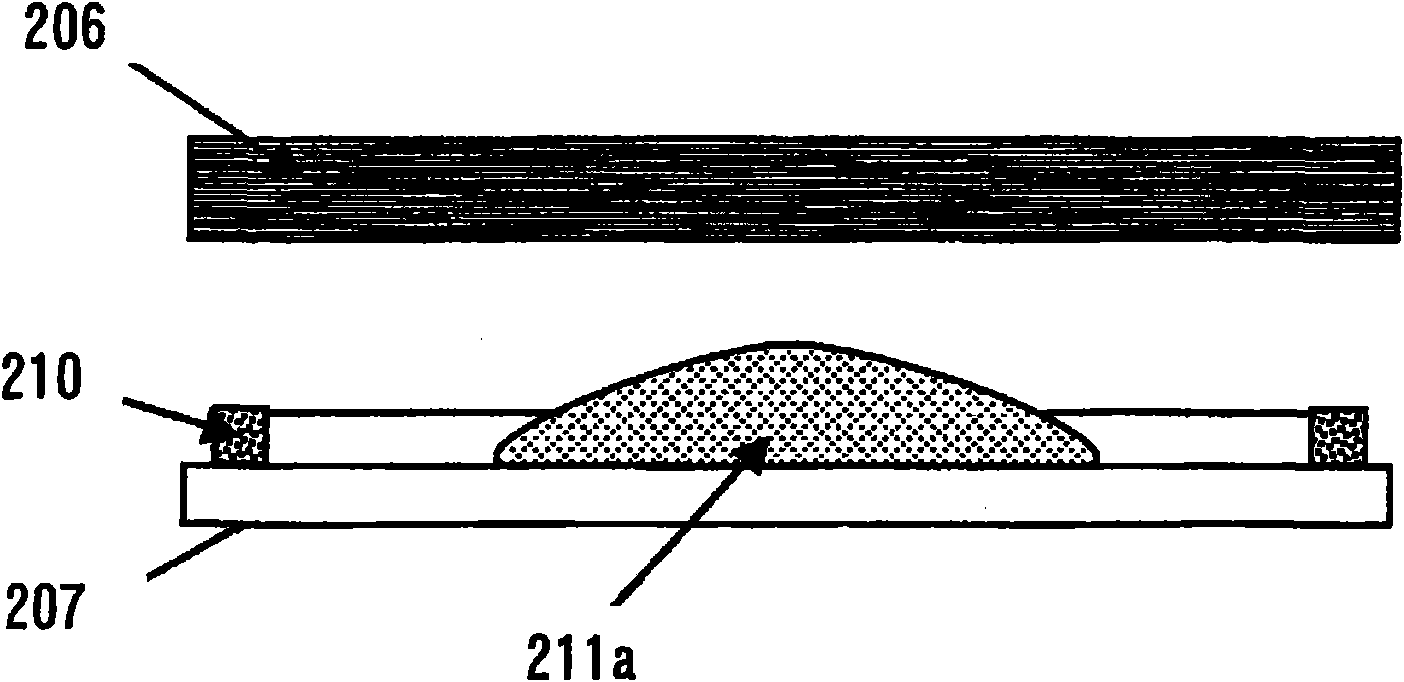

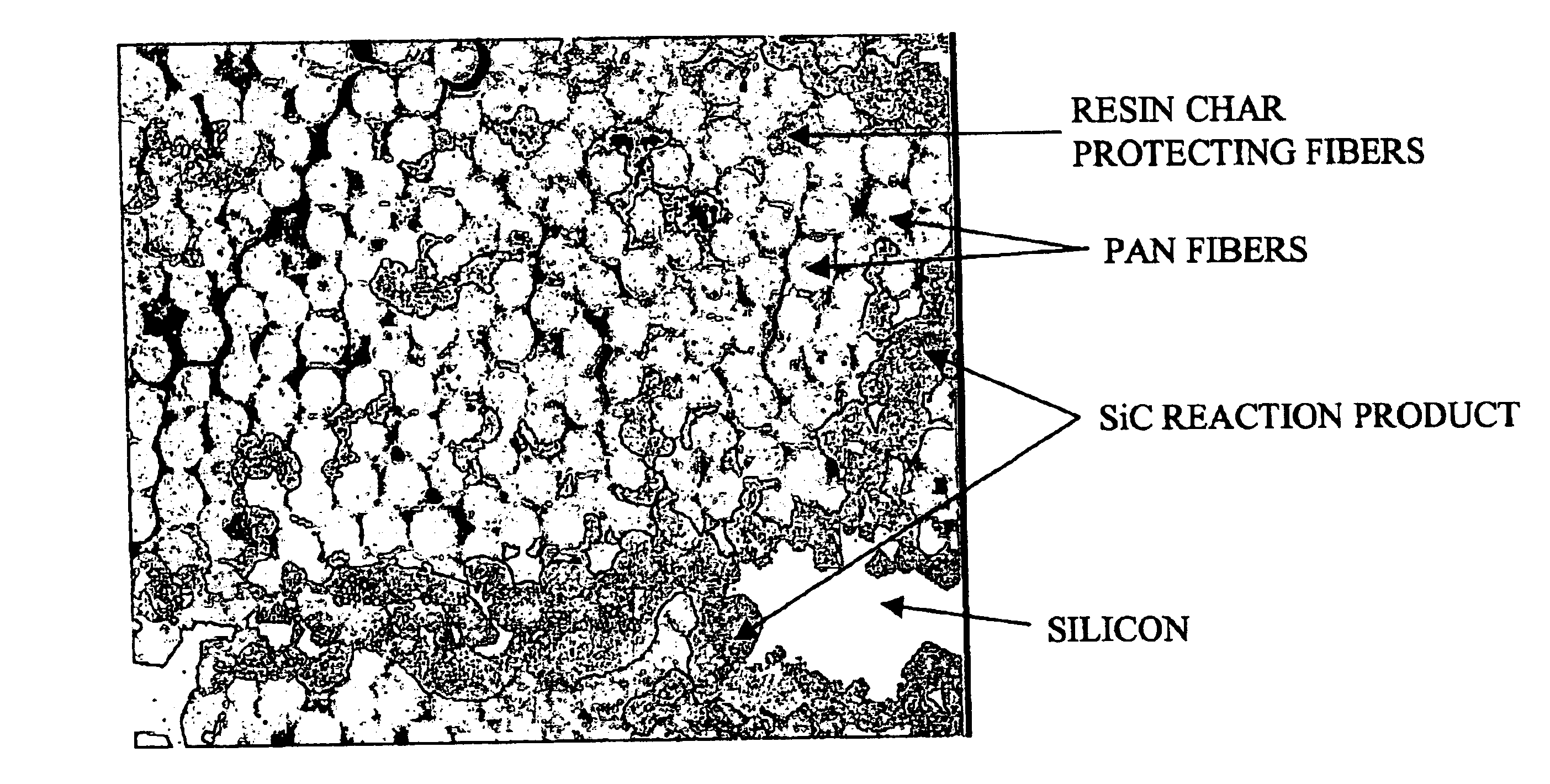

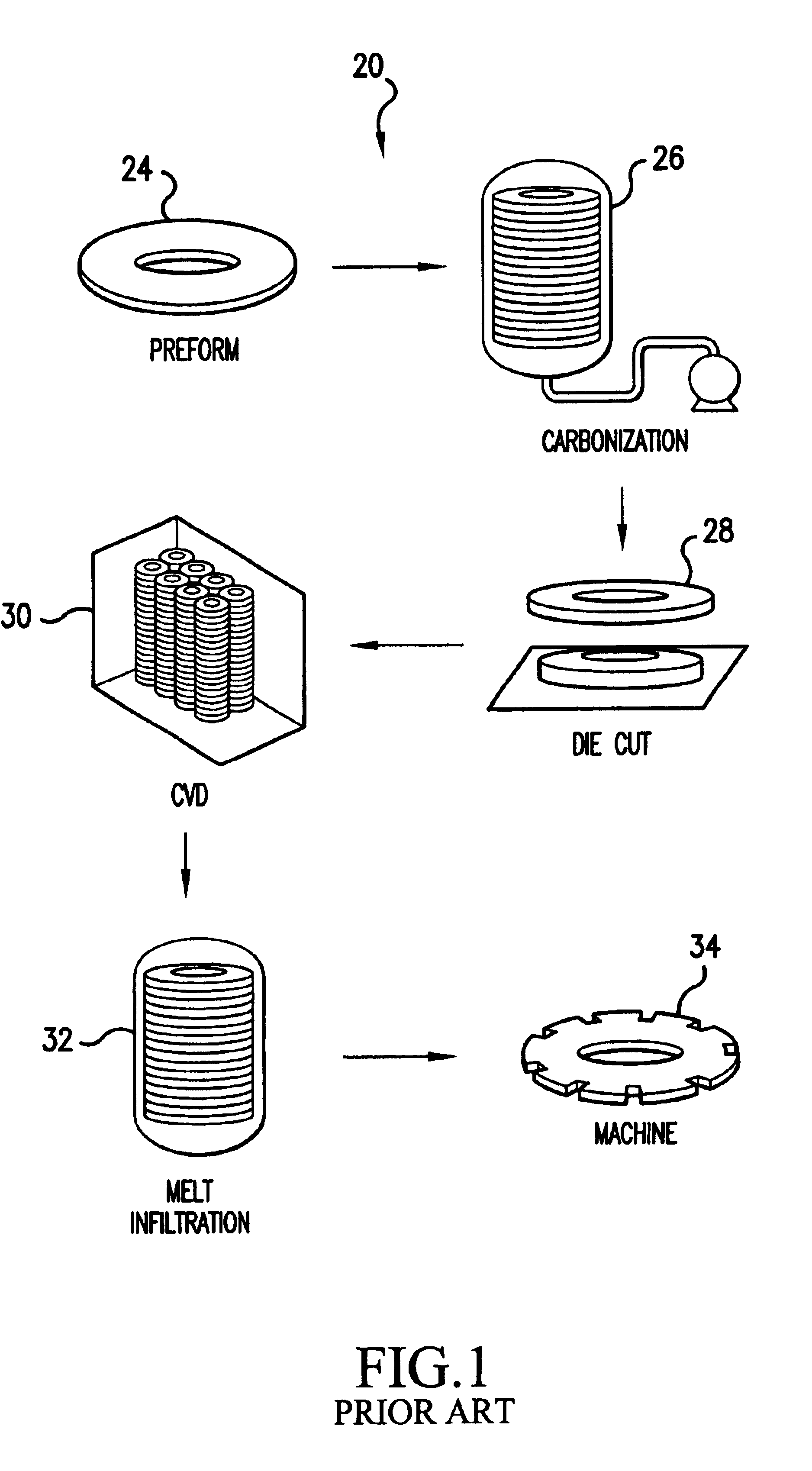

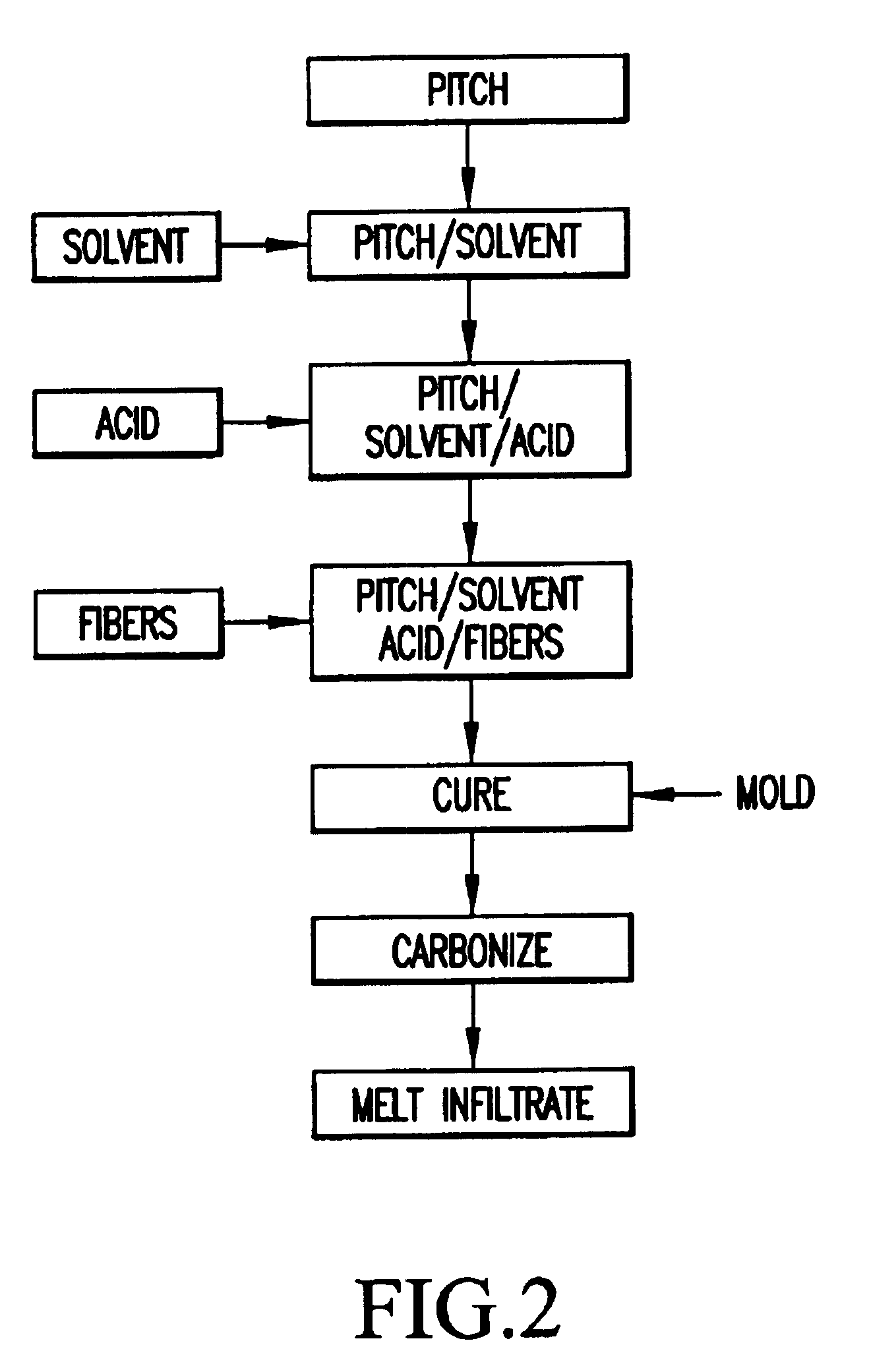

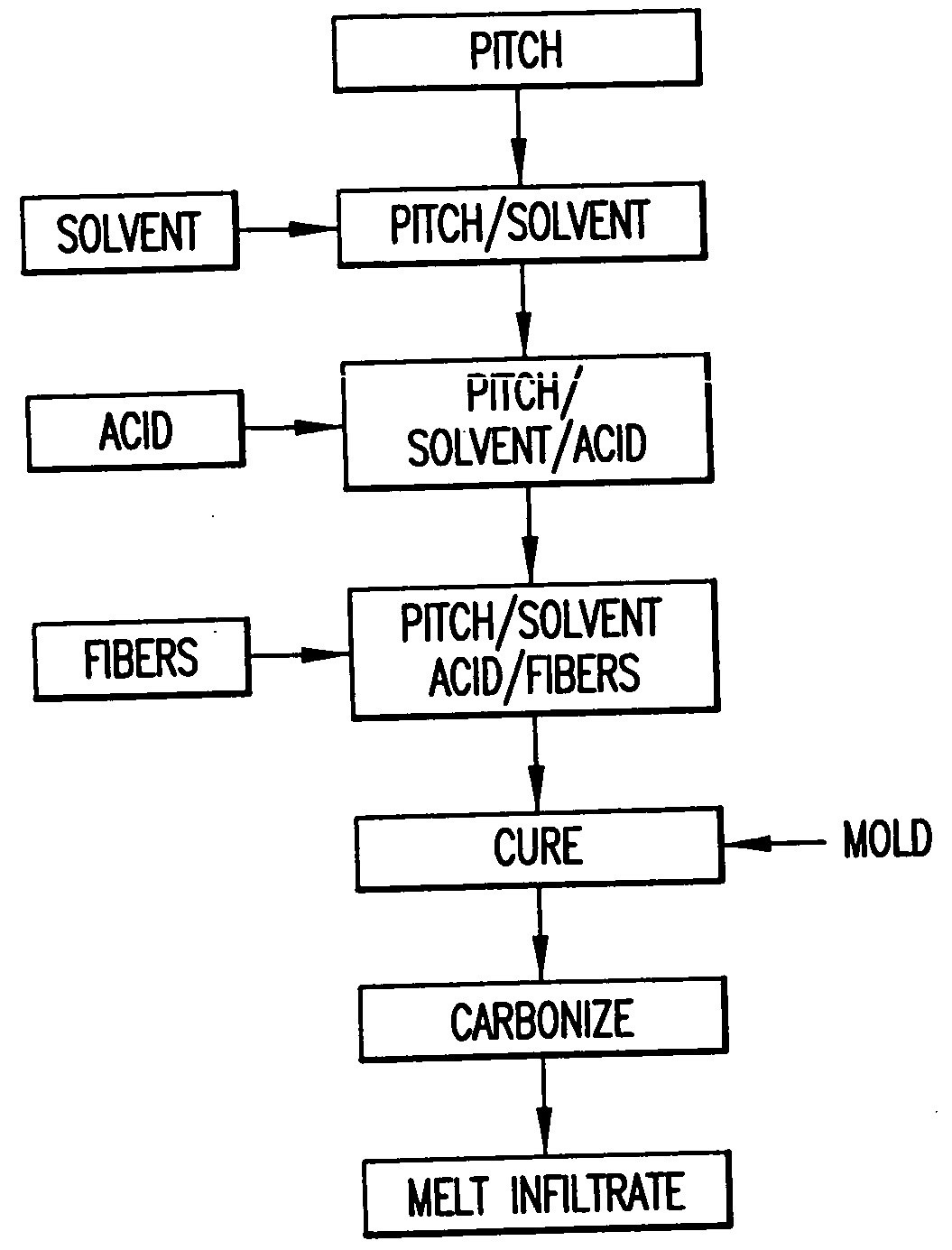

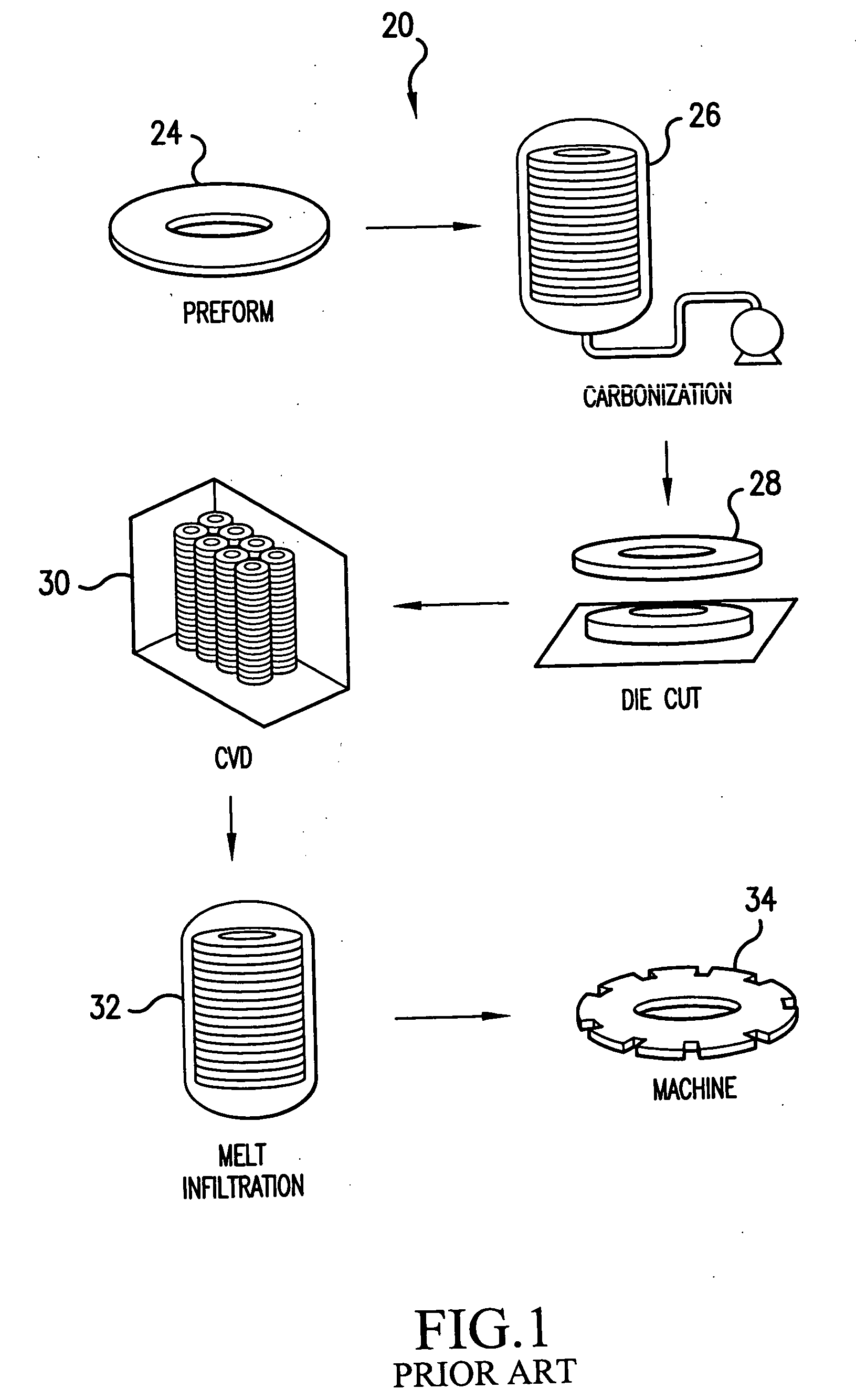

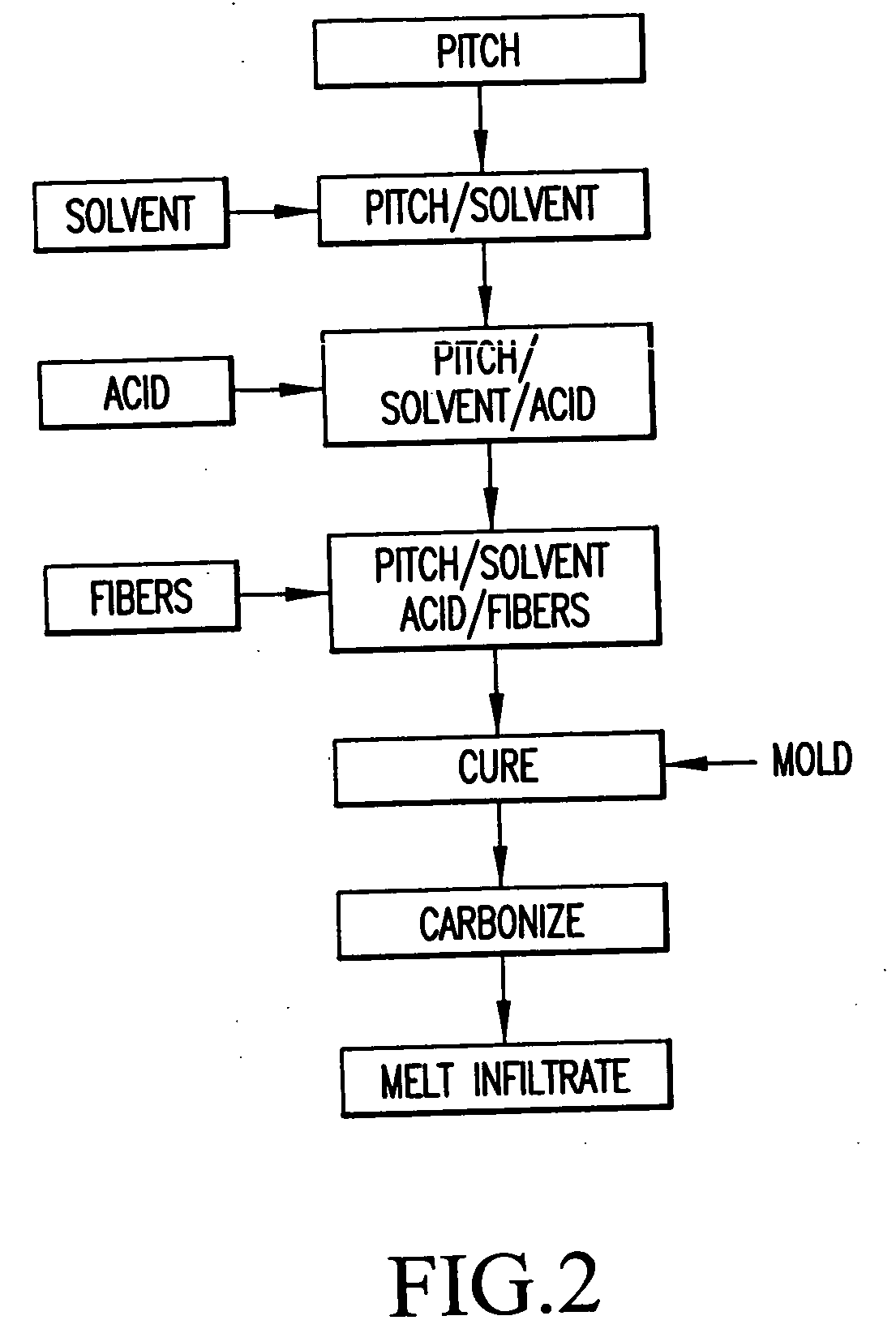

Melt-infiltrated pitch-pan preforms

InactiveUS20030180538A1Omission of costly CVD stepGood adhesionBraking discsCeramic layered productsPorosityCarbon fibers

Carbon-silicon carbide brake preforms are manufactured by carbonizing a blend of carbon (e.g., polyacrylonitrile) fibers and thermosetting pitch resin, optionally along with a lubricant such as graphite, to provide an intermediate product having open porosity and subsequently filling the pores of the intermediate product with silicon by a melt infiltration process. Molded articles that consist principally of carbon, that have relatively high strength and resistance to decomposition by frictional heat, and that are suitable for melt infiltration with silicon, are produced by, e.g.: coating randomly oriented polyacrylonitrile-derived carbon fibers, optionally mixed with finely divided carbon powder, with a thermosetting blend of (a) pitch and (b) an organic medium, at an elevated temperature to form a viscous molding compound; molding the compound at a low pressure and elevated temperature so that a solid compact is obtained; stripping a molded article made of said compound from the mold; optionally heating the molded article at gradually increasing temperatures to insure complete condensation within the article; and carbonizing the condensed molded article in an inert atmosphere at gradually increasing temperatures to produce a molded C / C intermediate article suitable for melt-infiltration with silicon. The preforms may be configured in the form of a disc brake rotor or a disc brake pad.

Owner:HONEYWELL INT INC

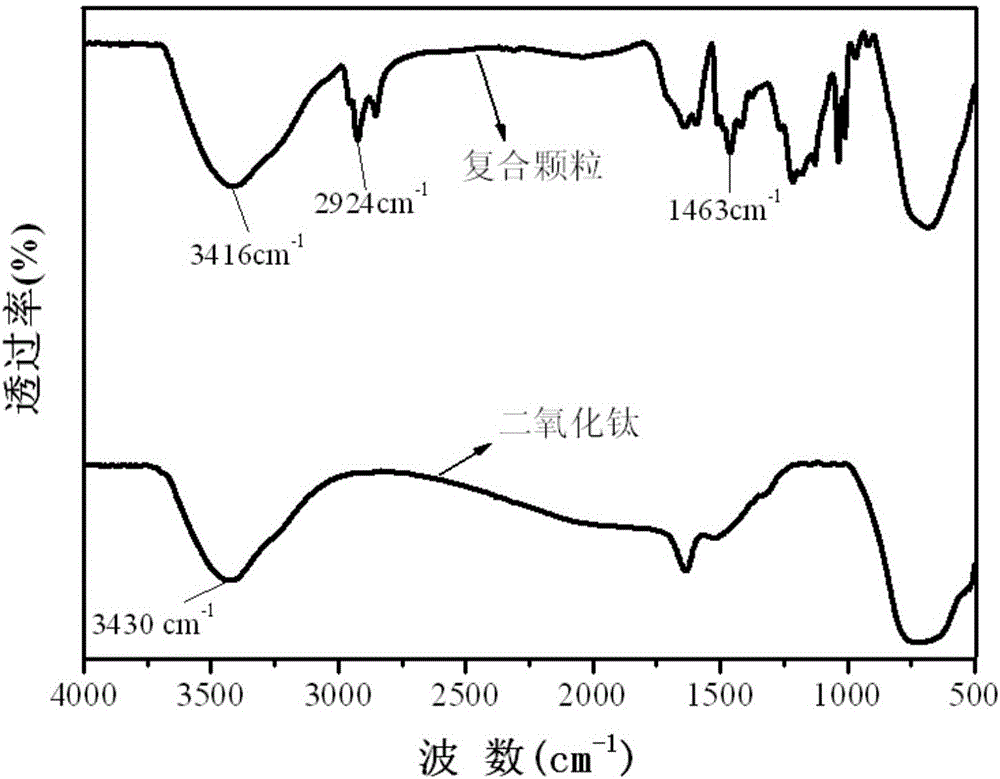

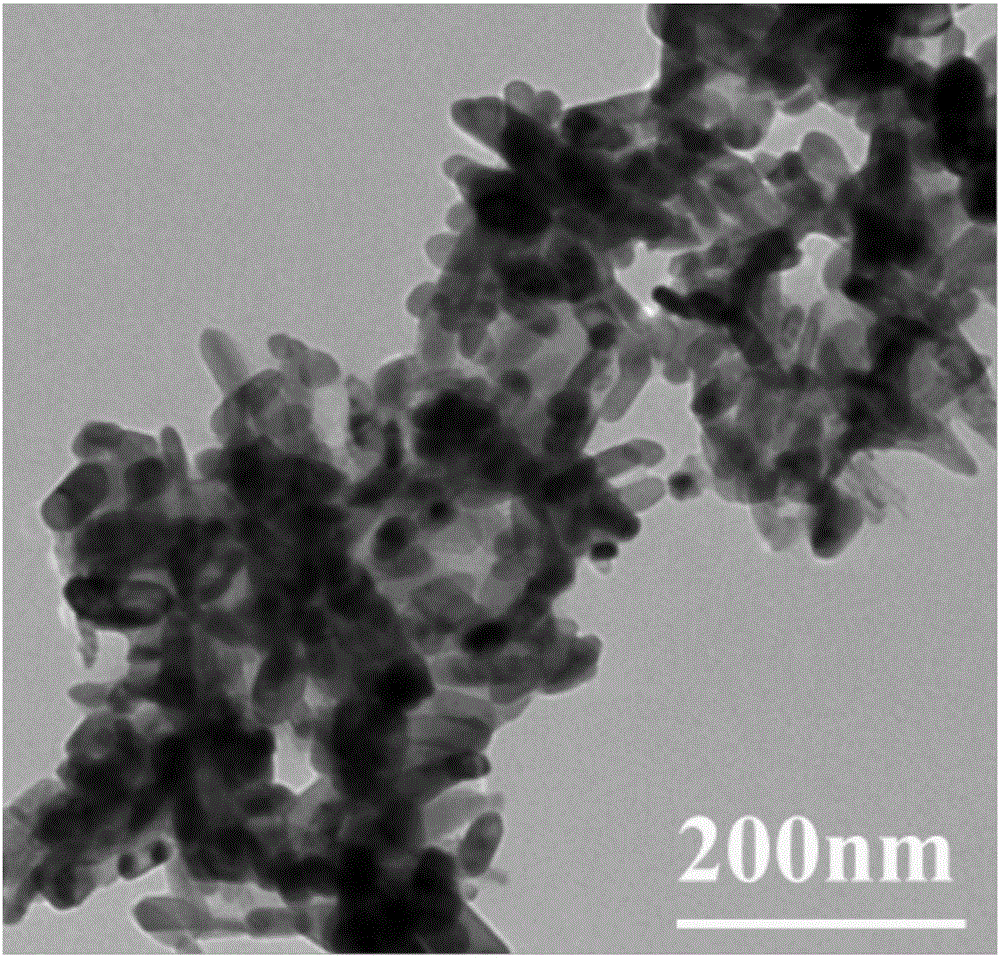

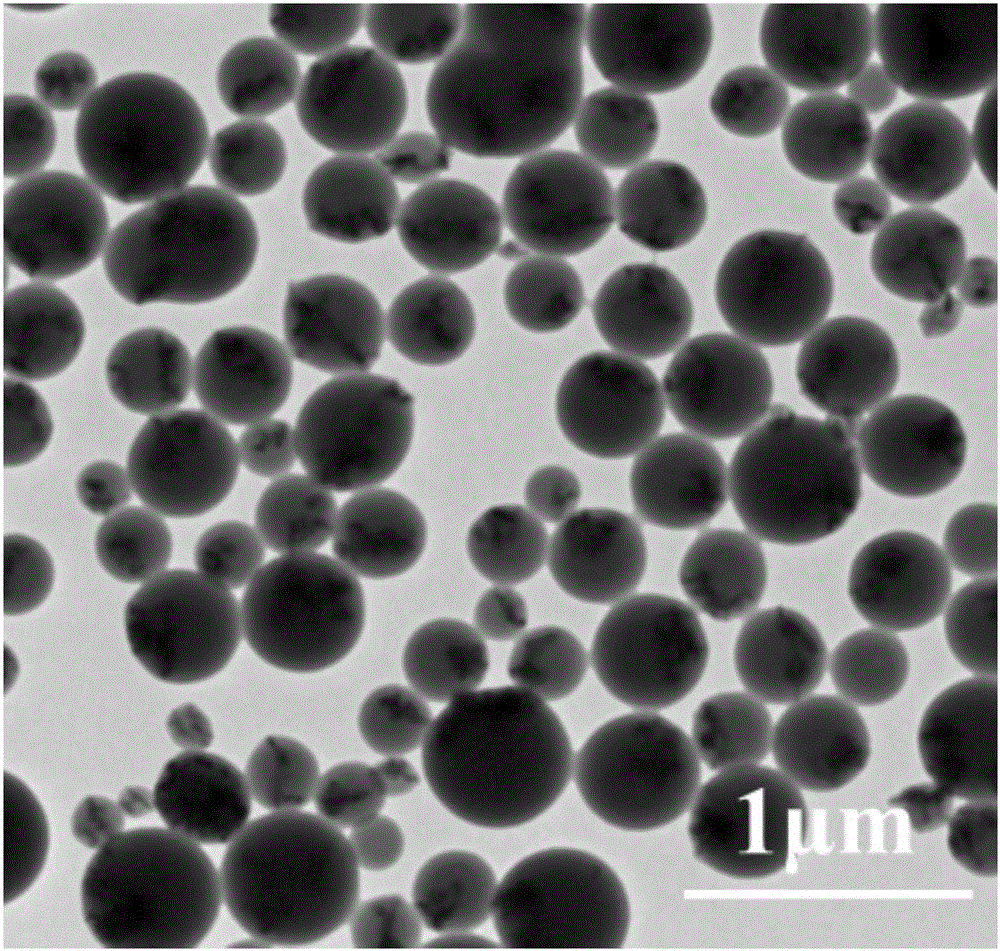

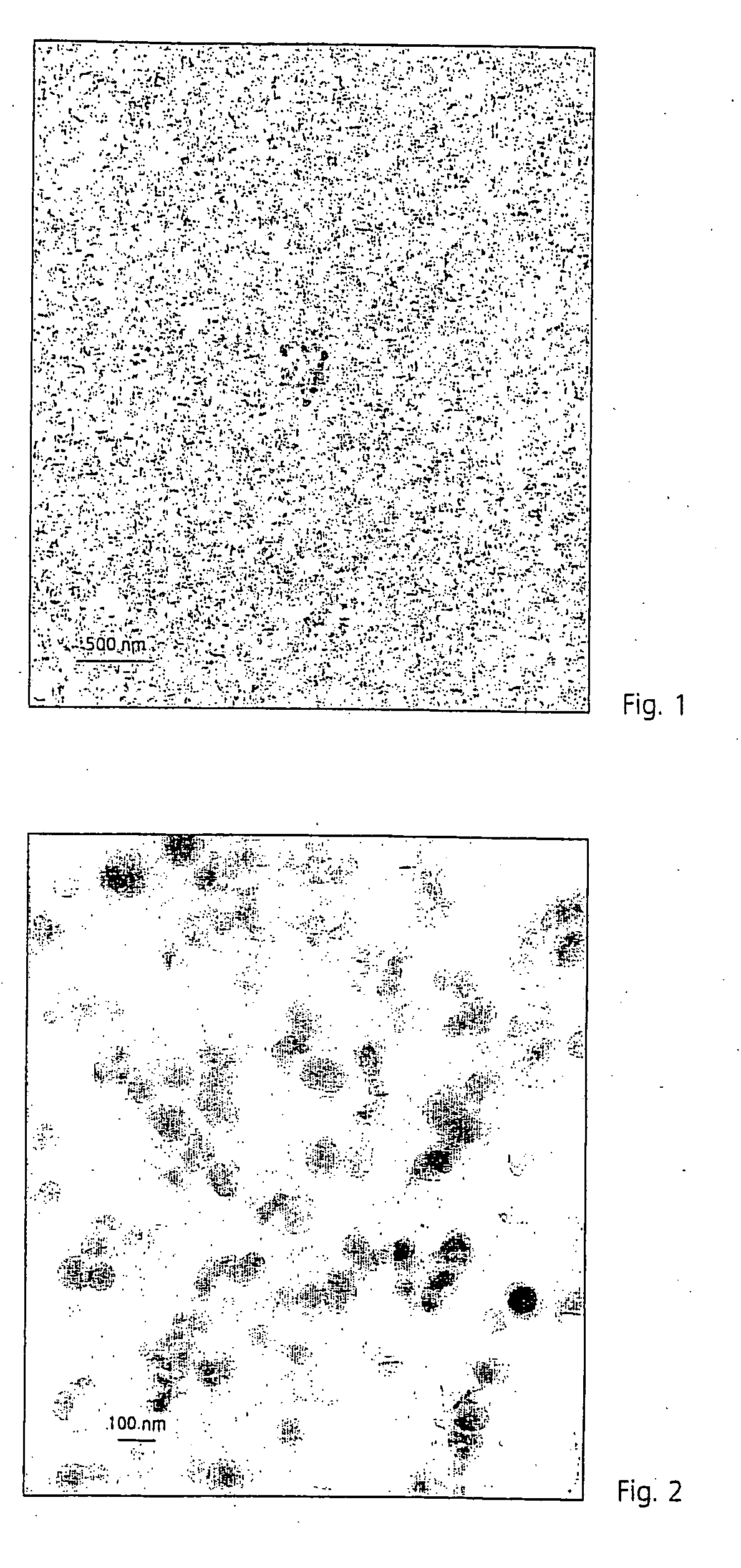

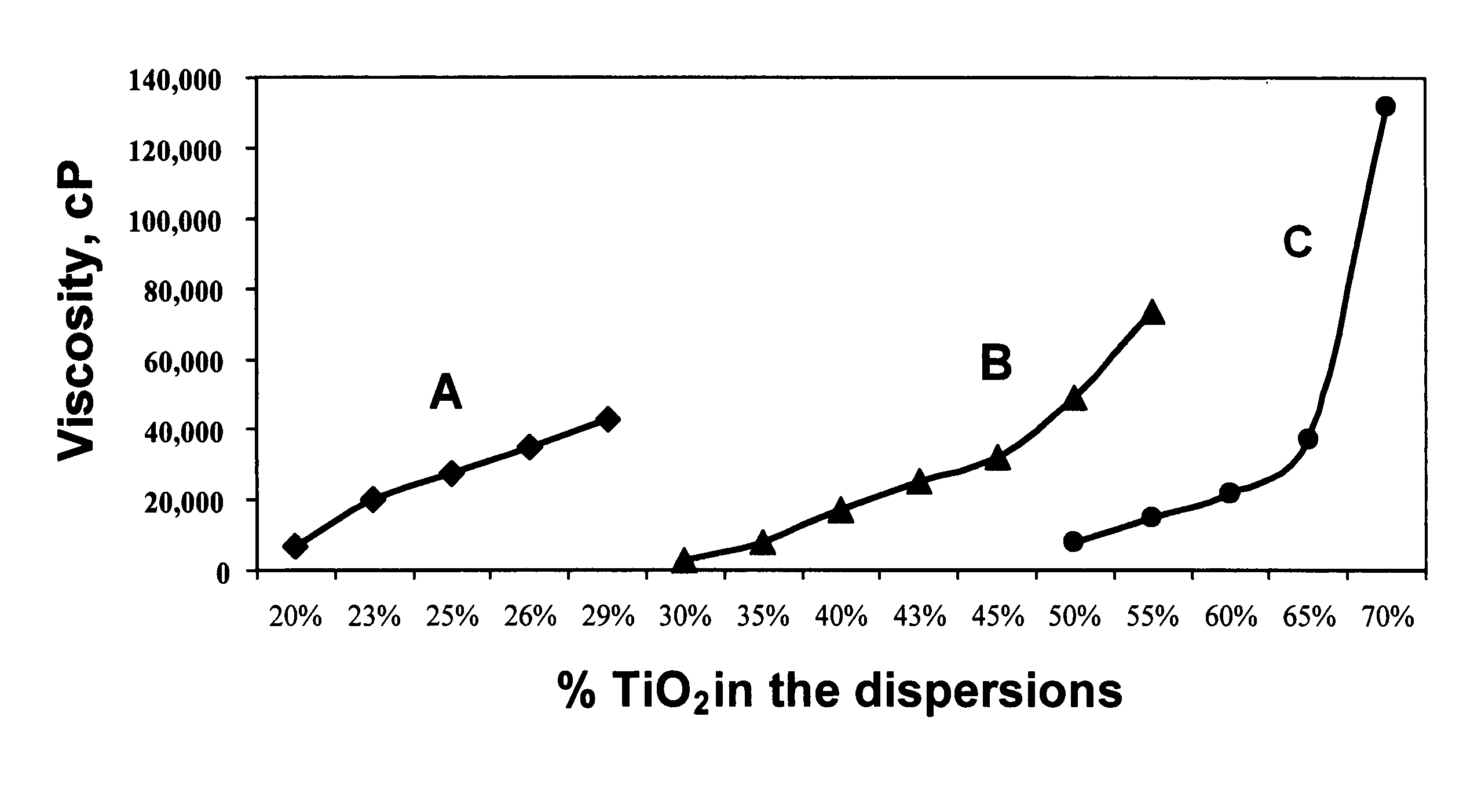

Titanium dioxide/lignin-based composite nanoparticle, and preparation method and application thereof

ActiveCN106633967AEnhanced interactionAvoid reunionCosmetic preparationsToilet preparationsOrganic mediaComposite nanoparticles

The invention discloses a titanium dioxide / lignin-based composite nanoparticle, and a preparation method and application thereof, belonging to the technical field of composite nanoparticles. The method provided by the invention comprises the following steps: adding a quaternization reagent into an alkaline alkali lignin solution for a reaction so as to obtain quaternized lignin; subjecting the quaternized lignin to acid regulation, adding an anionic surfactant so as to obtain a quaternized lignin / anionic surfactant compound, and adding the compound into an ethanol suspension of nanometer titanium dioxide so as to obtain a mixed solution of titanium dioxide / lignin-based compound; and adding water with a pH value of 1 to 7 into the mixed solution and carrying out ageing so as to obtain titanium dioxide / lignin-based composite nanoparticle. The composite nanoparticle is low in cost, uniform in particle size, good in dispersibility and strong in compatibility with organic mediums; when applied to skin care products and anti-UV materials, the composite nanoparticle can substantially improve anti-UV capability; and titanium dioxide wrapped by the lignin-based compound can effectively shield the photocatalytic activity of the composite nanoparticle and improve the photostability of the composite nanoparticle.

Owner:SOUTH CHINA UNIV OF TECH

Thick-film pastes containing lead-tellurium-lithium-titanium-oxides, and their use in the manufacture of semiconductor devices

The present invention provides a thick-film paste for printing the front side of a solar cell device having one or more insulating layers. The thick-film paste comprises an electrically conductive metal, and a lead-tellurium-lithium-titanium-oxide dispersed in an organic medium.

Owner:SOLAR PASTE LLC

Thick-film conductor paste for automotive glass

A thick-film composition comprising:(a) conductive metal;(b) crystallized glass;(c) amorphous glass; and(d) organic medium.

Owner:DU PONT CHINA LTD

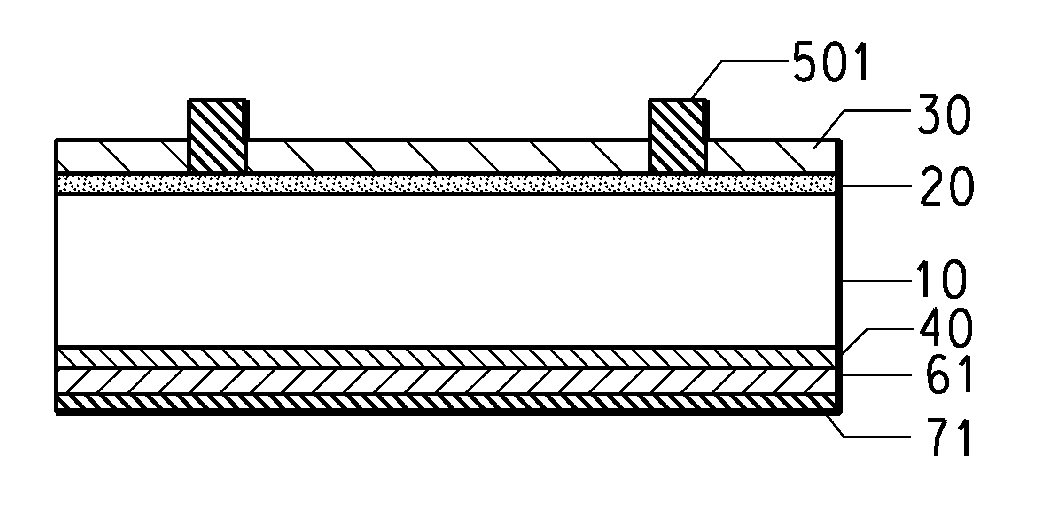

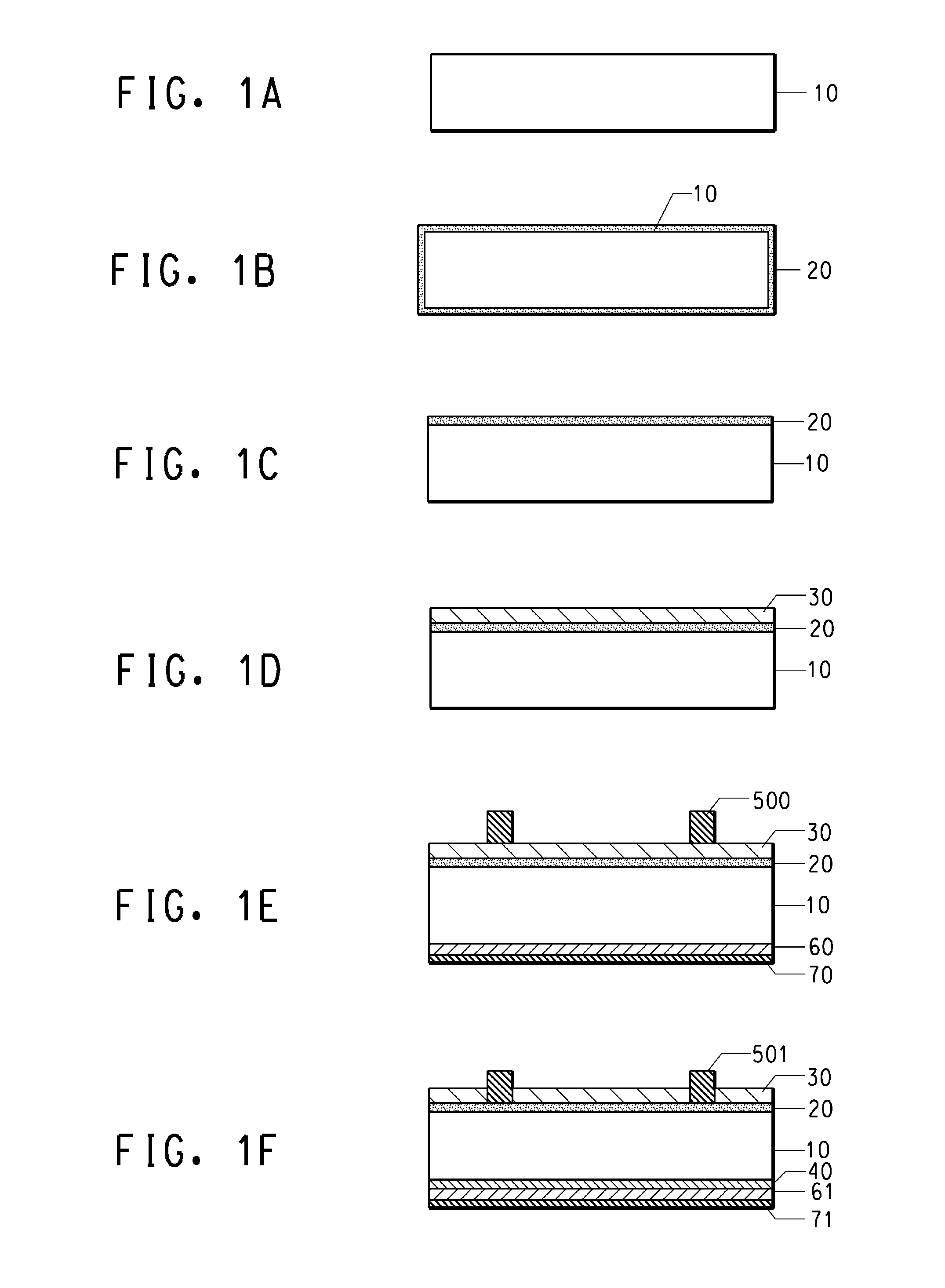

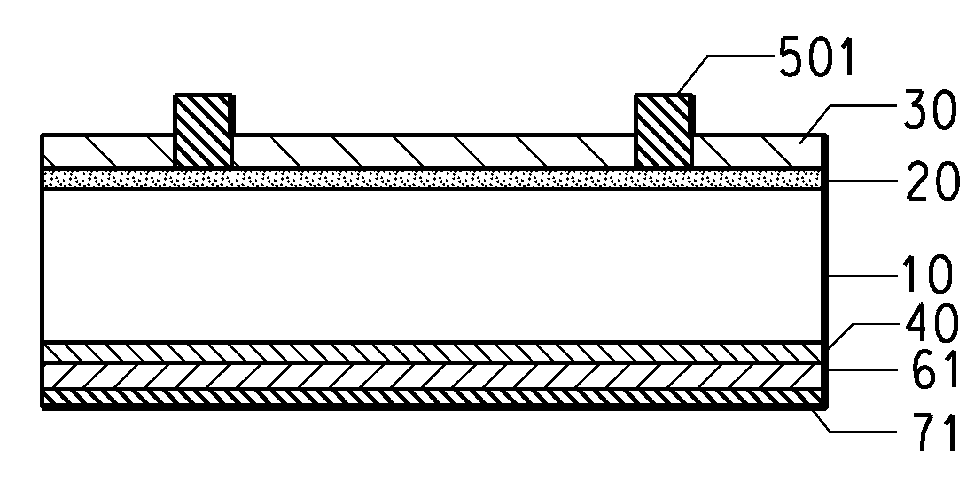

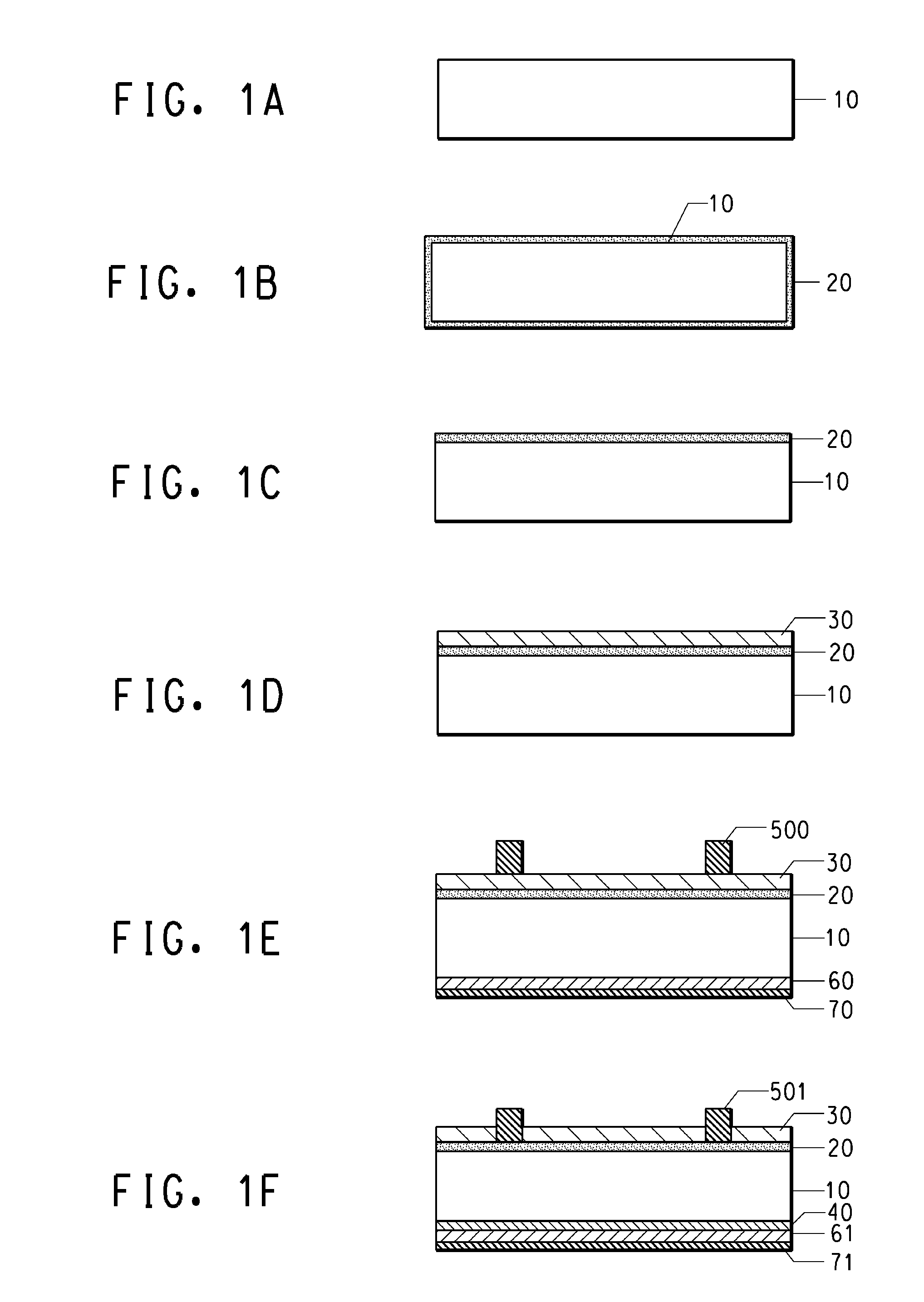

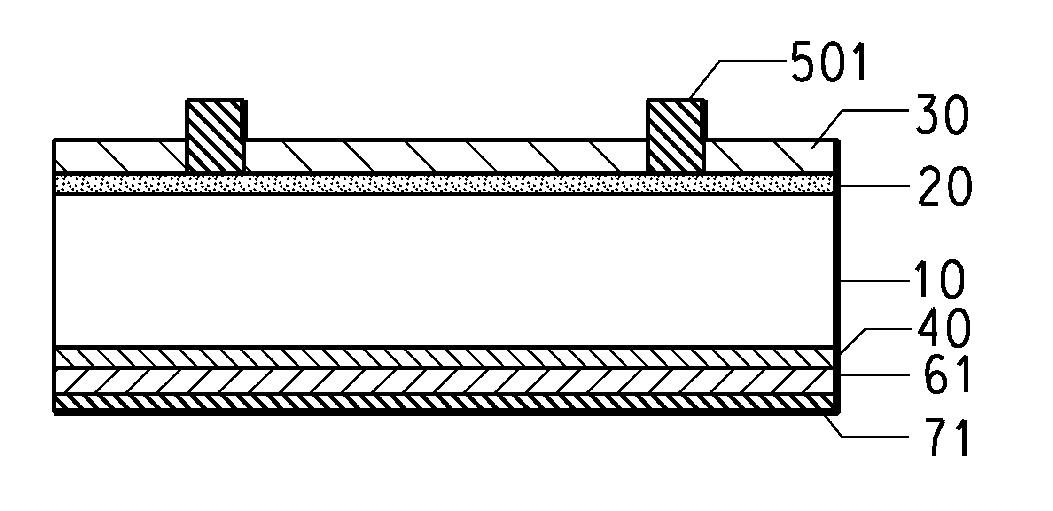

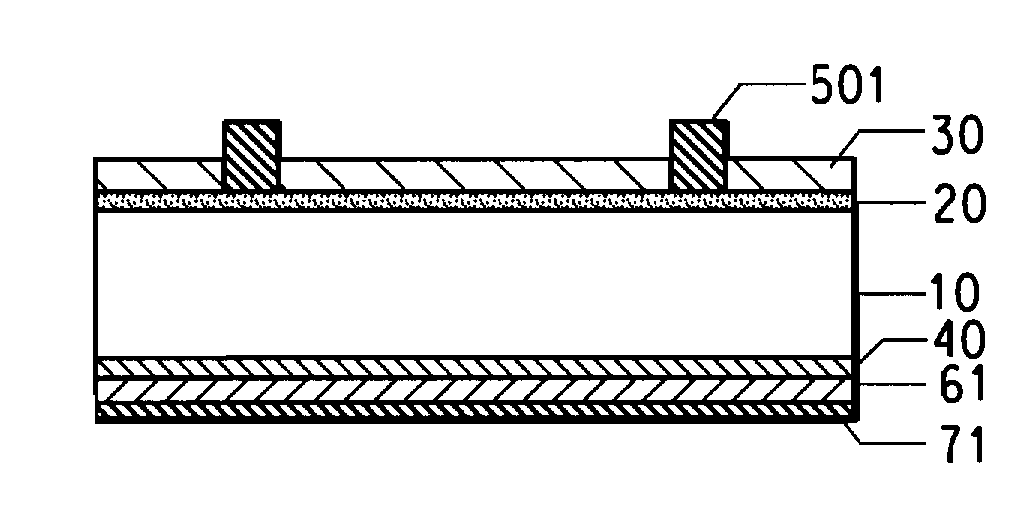

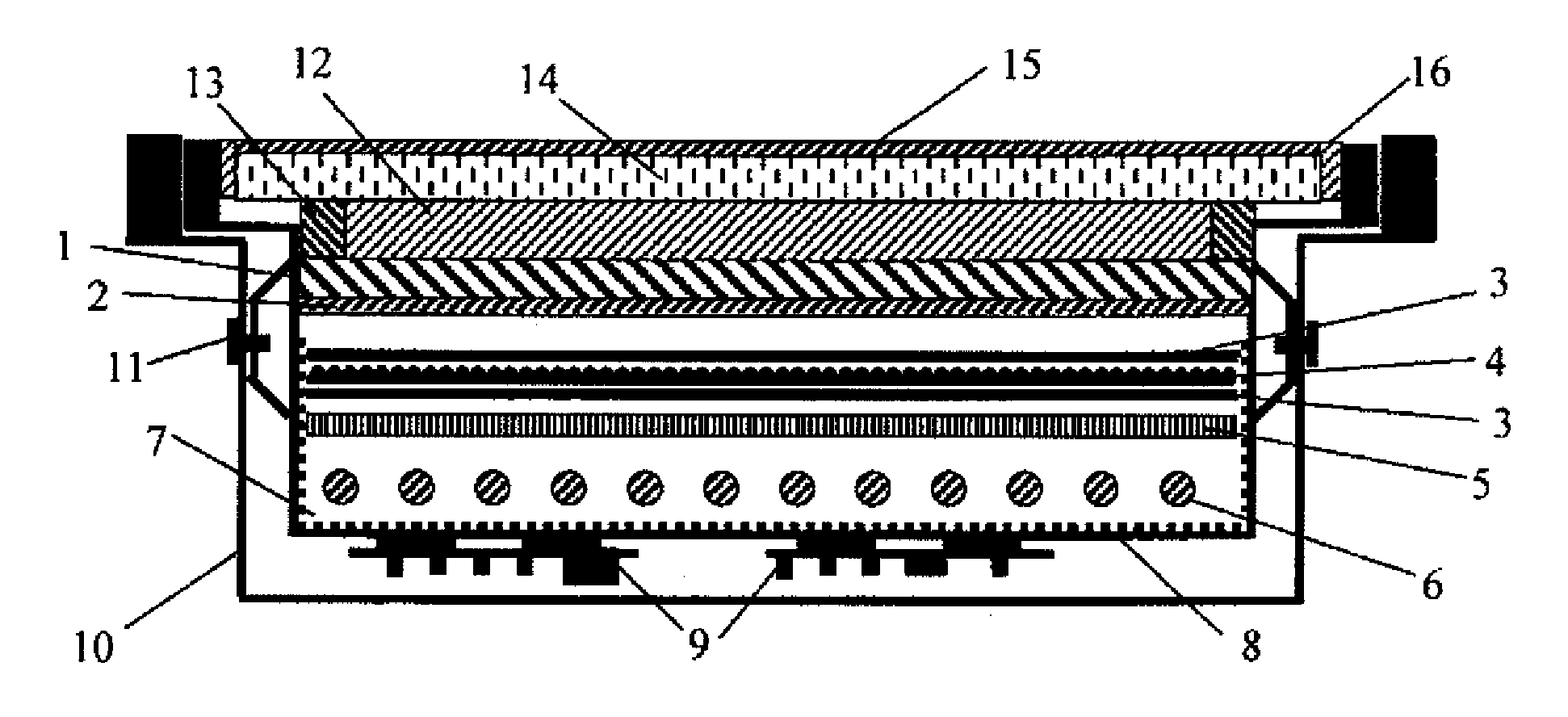

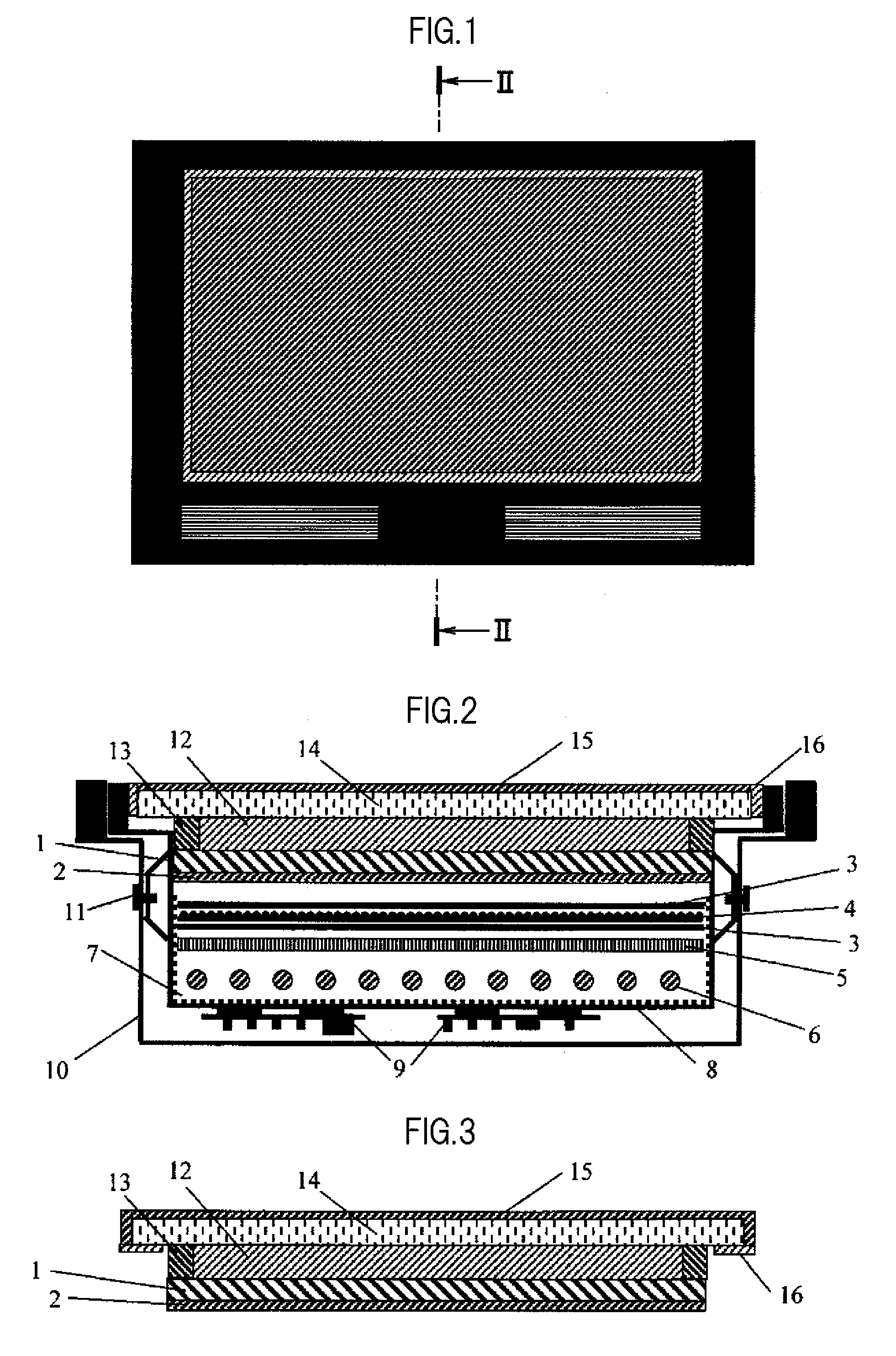

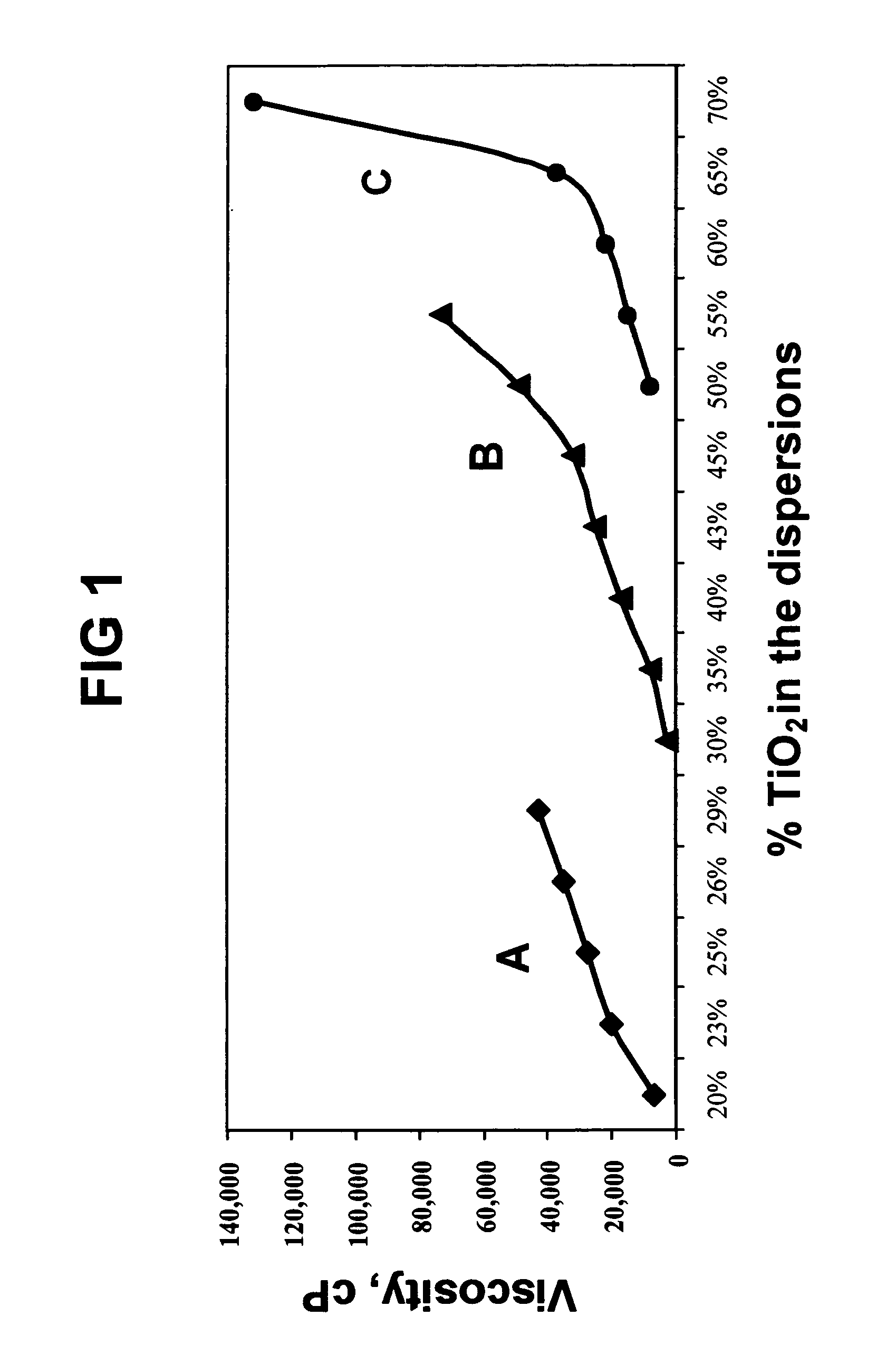

Liquid crystal display device

ActiveUS20100053499A1Layer structure is simpleBig burden to solveNon-linear opticsLiquid-crystal displayPolarizer

A liquid crystal display device has a liquid crystal display module including a backlight unit and a liquid crystal panel; a first polarizing plate attached to a side of the liquid crystal panel, the side facing the backlight unit; a transparent front plate mounted on a side of the liquid crystal panel, the side not facing the backlight unit; a transparent organic medium layer placed between the front plate and the liquid crystal panel; and a second polarizing plate attached to a surface of the front plate, the surface opposite from a surface thereof closer to the transparent organic medium layer. An end section of the second polarizing plate is sealed using resin so as not to be directly exposed to air.

Owner:PANASONIC LIQUID CRYSTAL DISPLAY CO LTD +1

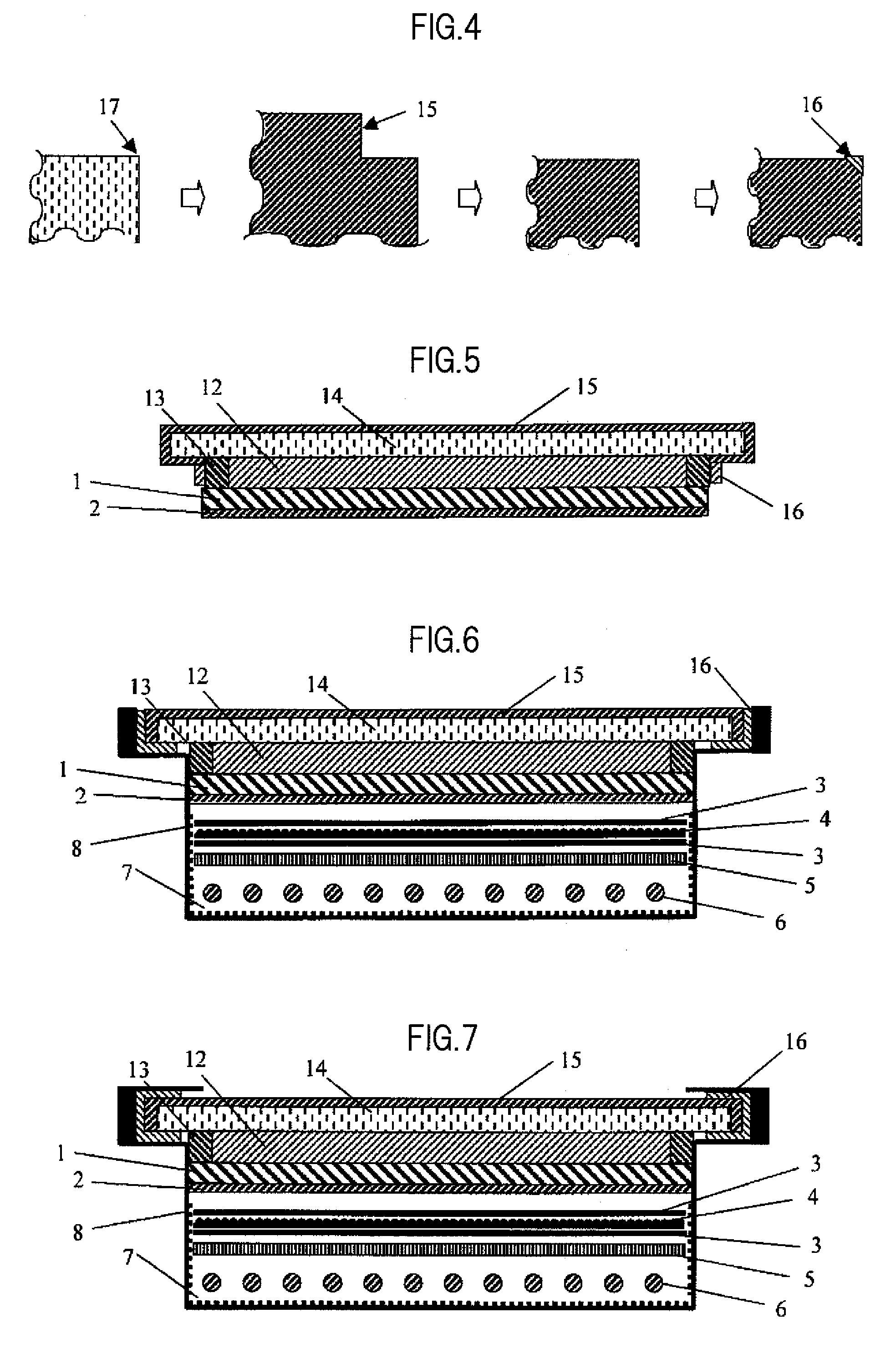

Nanocomposites, method of production, and method of use

InactiveUS20060084723A1Cost-effective methodPigmenting treatmentMaterial nanotechnologyOrganic mediaMethods of production

Method for production of nanocomposites from nanopowders present in agglomerated form and organic binders. Through surface modification of the nanofillers in an organic medium it is possible to divide the agglomerates permanently to such an extent that transparent nanocomposites can be preserved. The modified nanopowder is preferably isolated as a dry intermediate. The production of the disclosed nanocomposites is simpler than the production of nanocomposites by the sol-gel technique and in addition is more flexible and has wider applicability. An important application for the nanocomposites is scratch-resistant paints.

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV

Organic medium special for raising rice by mechanical seedling transplantation and production method for organic medium

The invention discloses an organic medium special for raising rice by mechanical seedling transplantation and belongs to the technical field of rice culture media. The organic medium is characterized by comprising the following components in percentage by weight: 10 to 30 percent of biomass power plant ash, 20 to 40 percent of monosodium glutamate leftovers, 20 to 40 percent of powdered rice hulls, 3 to 8 percent of water retainer, 2 to 5 percent of adhesive and 0.2 to 0.5 percent of root promoter. The organic medium special for raising rice by mechanical seedling transplantation is pollution-free and toxin-free, meets the requirements on environmental protection and low carbon, and is an optimized medium for developing mechanical rice seedling transplanting production.

Owner:CHINA NAT RICE RES INST

Method and compositions for dispersing particulate solids in oil

InactiveUS20080299057A1Easy to manufactureImprove propertiesCosmetic preparationsMake-upParticulatesHydroxystearic Acid

This invention relates to a method for preparing dispersions of solid particles, especially pigments, metal oxides and mineral fillers in organic media, to dispersing compositions used in this method and to dispersions containing these dispersion compositions. The dispersing compositions include an oil soluble surfactant selected from the group consisting of phospholipids, alkyl acids, nonionic surfactants having an HLB less than 10, and mixtures thereof; either an anhydride based polymer selected from the group consisting of polyalkene succinic anhydrides; maleinized polyisoprene; maleinized polybutadiene; maleinized copolymers of isoprene and butadiene; copolymers of styrene and maleic anhydride; derivatives formed by reaction of the anhydride group of the anhydride based polymer with one or more of water, amines, alcohols, and polyols; and mixtures thereof; or a mixture of the said anhydride based polymer with polyhydroxystearic acid; and optionally a liquid oil carrier.

Owner:LIN SAMUEL QCHENG SUN

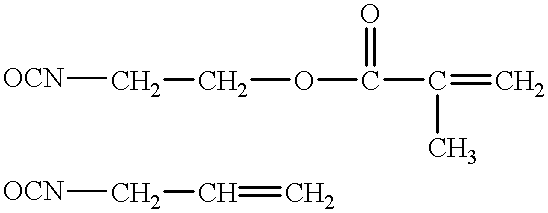

Dispersants and compositions thereof

The present invention provides a dispersant of Formula (1): E-O—(Y)x-T-NR′-A-Z—W0-v, and salts thereof, wherein E is R or R—NR′-T-; R is H or C1-50-optionally substituted hydrocarbyl; R′ is a residue of an optionally substituted alkyl (meth)acrylate or (meth)acrylamide, or a residue of an epoxide, or a C1-8-optionally substituted hydrocarbyl group; Y is C2-4-alkyleneoxy; T is C2-4 alkylene; A is the residue of a dibasic acid or anhydride thereof; Z is the residue of a polyamine and / or polyimine; W is the residue of an oxide, urea or dibasic acid or anhydride thereof; x is from 2 to 90; and v represents an integer variable. The invention further provides a composition comprising a particulate solid, an organic medium and / or water and the dispersant.

Owner:LUBRIZOL LTD

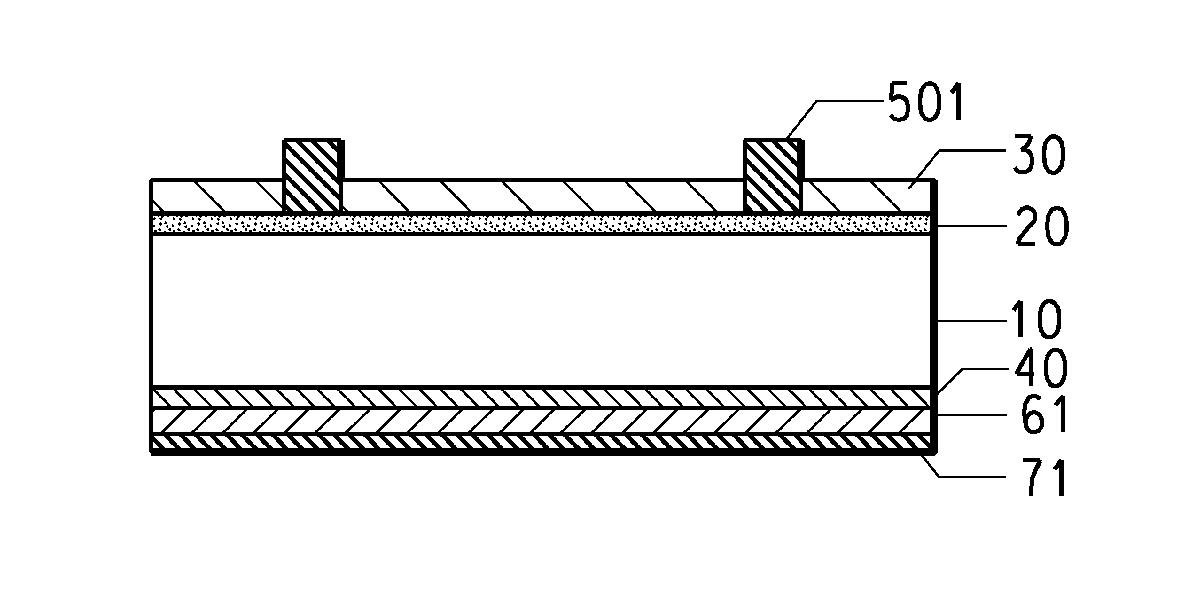

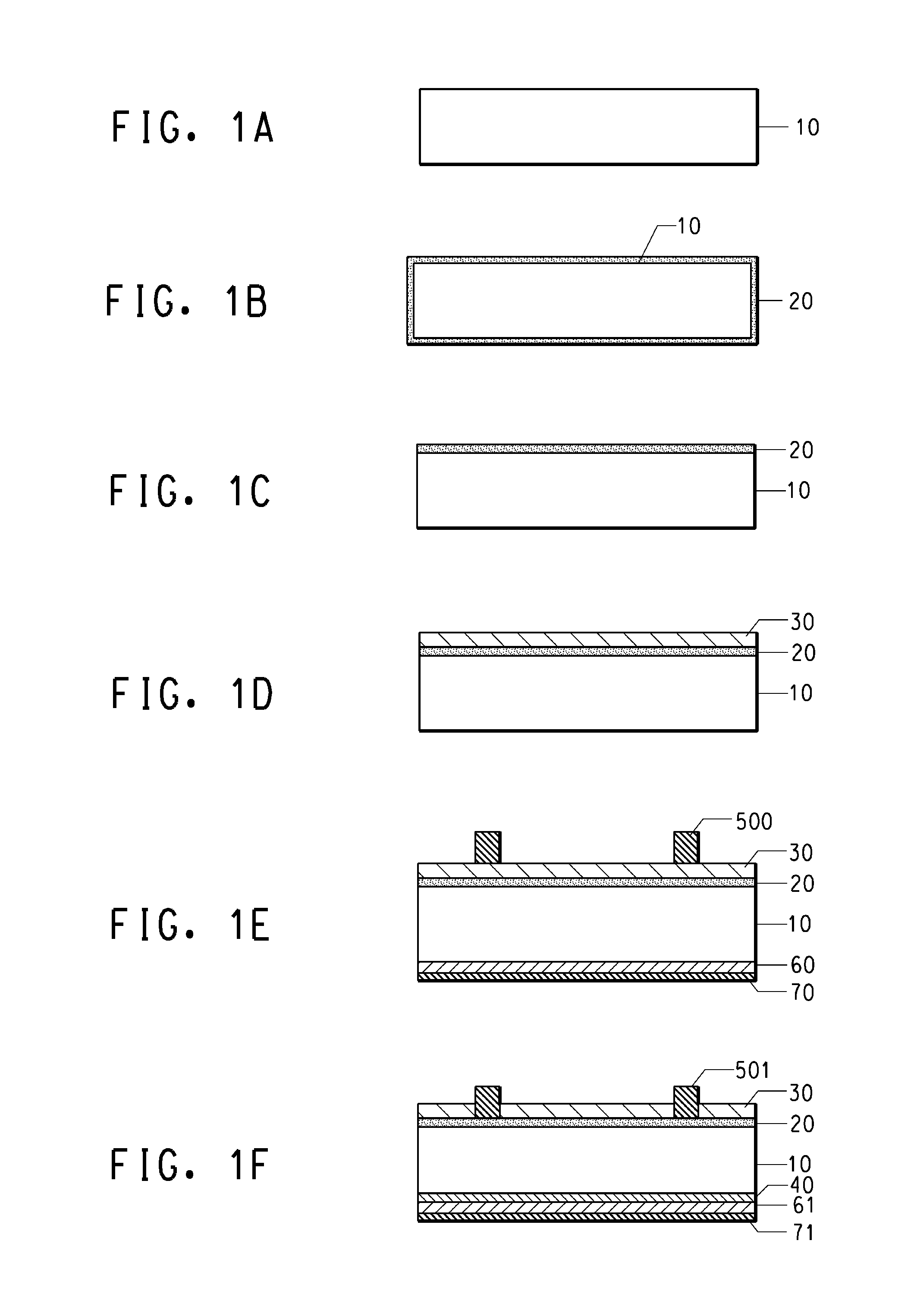

Method for manufacturing image display device, image display device and liquid crystal display device

InactiveCN101785041AEasy Visual RecognitionExcellent visual recognitionOptical filtersPolarising elementsProduction rateLiquid-crystal display

Provided is a method for manufacturing an image display device having improved impact resistance by arranging a transparent resin layer between an image display panel and a protection panel. By the method, the transparent resin layer having no air bubble can be manufactured with excellent productivity. In the method for manufacturing the image display device, a transparent organic medium is arranged by being adhered between the image display panel and the protection panel arranged on the view side of the image display panel, without having an air layer in between. On the image display panel or the protection panel, a frame having many spaces through which air can pass is arranged. The method includes a step of injecting the liquid-state transparent organic medium inside an area surrounded by the frame on the image display panel or the protection panel; a step of placing the image display panel or the other panel of the protection panel on the frame; and a step of solidifying the liquid-state transparent organic medium.

Owner:HITACHI CHEM CO LTD

Melt-infiltrated pitch-pan preforms

InactiveUS6749937B2Omission of costly CVD stepGood adhesionBraking discsCeramic layered productsPorosityCarbon fibers

Carbon-silicon carbide brake preforms are manufactured by carbonizing a blend of carbon (e.g., polyacrylonitrile) fibers and thermosetting pitch resin, optionally along with a lubricant such as graphite, to provide an intermediate product having open porosity and subsequently filling the pores of the intermediate product with silicon by a melt infiltration process. Molded articles that consist principally of carbon, that have relatively high strength and resistance to decomposition by frictional heat, and that are suitable for melt infiltration with silicon, are produced by, e.g.: coating randomly oriented polyacrylonitrile-derived carbon fibers, optionally mixed with finely divided carbon powder, with a thermosetting blend of (a) pitch and (b) an organic medium, at an elevated temperature to form a viscous molding compound; molding the compound at a low pressure and elevated temperature so that a solid compact is obtained; stripping a molded article made of said compound from the mold; optionally heating the molded article at gradually increasing temperatures to insure complete condensation within the article; and carbonizing the condensed molded article in an inert atmosphere at gradually increasing temperatures to produce a molded C / C intermediate article suitable for melt-infiltration with silicon. The preforms may be configured in the form of a disc brake rotor or a disc brake pad.

Owner:HONEYWELL INT INC

Preparation method of paddy seedling raising medium

InactiveCN102701840AIncrease productionAbundant resources availableFertilizer mixturesFecesOrganic media

The invention discloses a preparation method of a paddy seedling raising medium. In the preparation method, livestock and poultry feces is used as foodstuff for earthworm to provide an environment suitable for growth of earthworm, and the earthworm feces generated by earthworm treatment is screened into earthworm feces with the particle size of 1-4mm, and uniformly mixed with nutrient soil and vermiculite to prepare a novel organic medium, wherein the particle sizes of vermiculite and the nutrient soil are 3-5mm. The medium comprises the components by volume percent: 50-60% of earthworm feces, 30-40% of vermiculite and 10-20% of nutrient soil. The medium is simple in preparation method, rich in resources, inexpensive in materials, sufficient in nutrients and stable in property, changes wastes into valuables, and reduces environmental pollution; and used for paddy seedling raising, the medium improves the paddy plug seedling raising quality, reduces the seedling raising steps (like fertilization) and the cost, and promotes the industrialized development of paddy machine seedling transplanting.

Owner:YANGZHOU UNIV

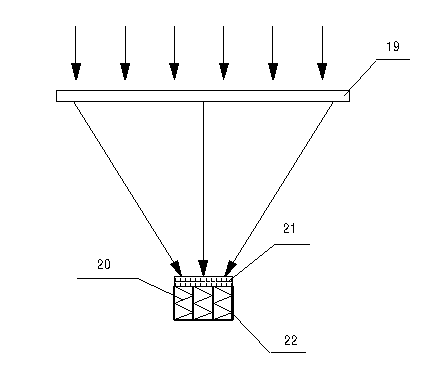

Photovoltaic and organic Rankine cycle coupling combined heat and power supply system

ActiveCN102979588AAchieve provideAbundant resourcesLighting and heating apparatusSteam engine plantsOrganic Rankine cycleOrganic media

The invention relates to a photovoltaic and organic Rankine cycle coupling combined heat and power supply system and belongs to the technical field of energy and environment. The photovoltaic and organic Rankine cycle coupling combined heat and power supply system comprises a heat transfer fluid circulation loop, a biomass burner smoke discharge loop, a heat supply hot water loop and a cooling loop, and further comprises a high temperature stage organic Rankine circulation loop, a low temperature stage organic Rankine circulation loop and a solar cell cooler / organic medium preheater. The high temperature stage organic Rankine circulation loop is connected with the heat transfer fluid circulation loop, the low temperature stage organic Rankine circulation loop is connected with the high temperature stage organic Rankine circulation loop, and the cooling loop is connected with the low temperature stage organic Rankine circulation loop. By adoption of a two-stage overlaid type organic Rankine cycle, the photovoltaic and organic Rankine cycle coupling combined heat and power supply system can achieve gradient heat utilization, greatly lower cost, improve utilization efficiency of energy and photovoltaic power generation efficiency, save materials and cost, and facilitate achievement of an individual distributed power generation system.

Owner:KUNMING UNIV OF SCI & TECH

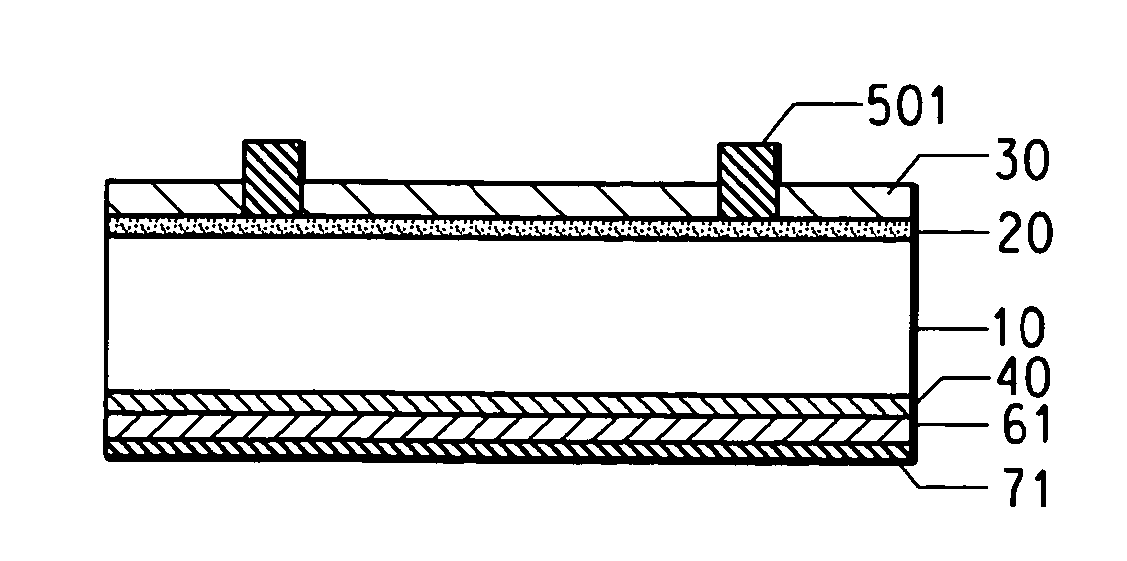

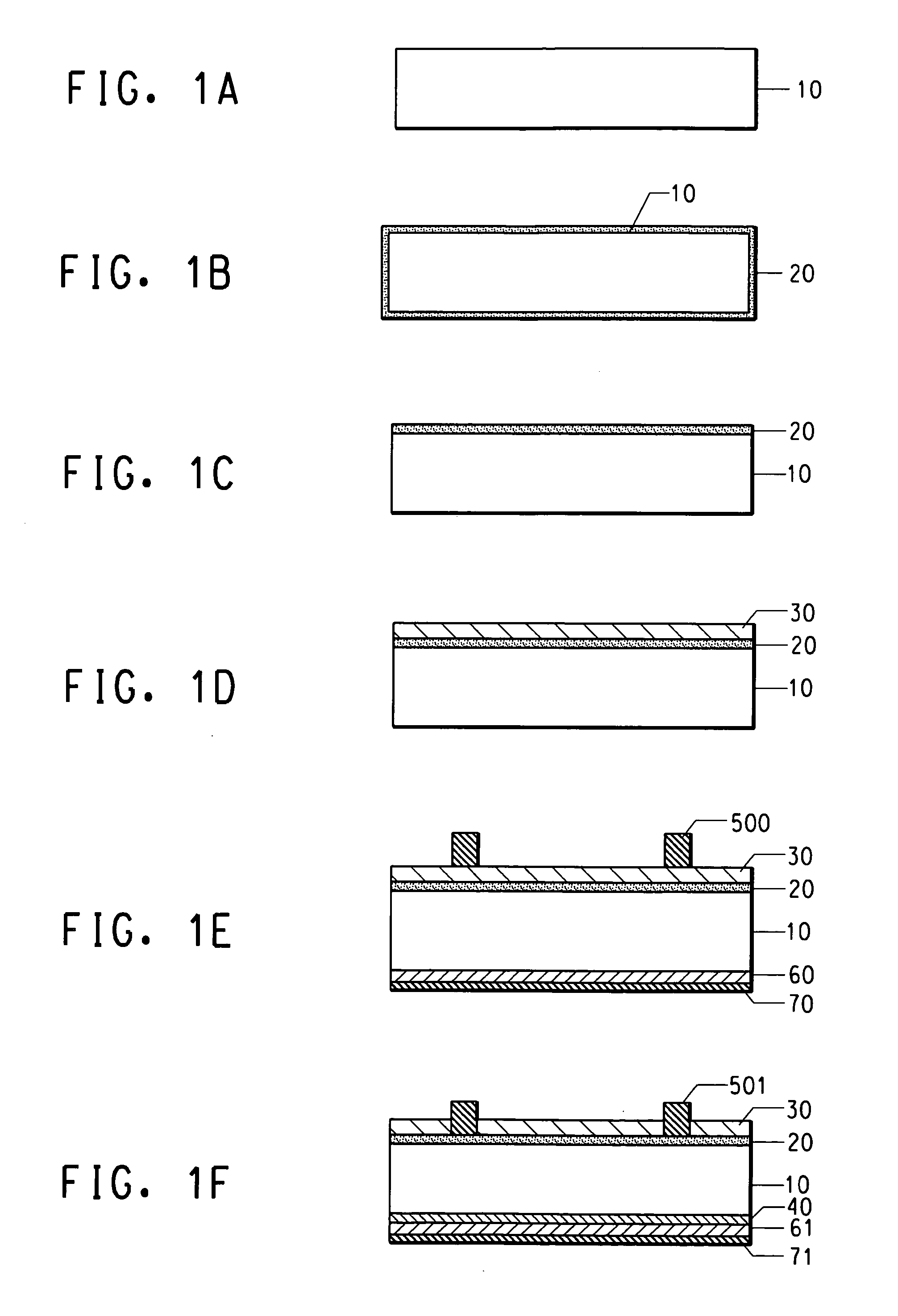

Aluminum thick film composition(s), electrode(s), semiconductor device(s) and methods of making thereof

InactiveUS7718092B2Significant bow reduction tendencyReduction tendencyConductive materialNon-conductive material with dispersed conductive materialElectrical conductorFrit

The present invention is directed to a thick film conductor composition comprised of (a) aluminum-containing powder; (b) amorphous silicon dioxide (c) and one or more optional glass frit compositions; dispersed in (d) organic medium. The amorphous silicon dioxide contributes to significant bow reduction tendency for solar cells thinner than 270 microns and larger than five inches square without significant effect on reducing the electrical performance of the fired solar cell. In addition and as preferred by solar cell manufacturers, the addition of glass frit reduces the dusting tendency of the aluminum thick film composition.

Owner:EI DU PONT DE NEMOURS & CO

Melt-infiltrated pitch-pan preforms

InactiveUS20040202896A1Omission of costly CVD stepGood adhesionBraking discsCeramic shaping apparatusPorosityCarbon fibers

Carbon-silicon carbide brake preforms are manufactured by carbonizing a blend of carbon (e.g., polyacrylonitrile) fibers and thermosetting pitch resin, optionally along with a lubricant such as graphite,.to provide an intermediate product having open porosity and subsequently filling the pores of the intermediate product with silicon by a melt infiltration process. Molded articles that consist principally of carbon, that have relatively high strength and resistance to decomposition by frictional heat, and that are suitable for melt infiltration with silicon, are produced by, e.g.: coating randomly oriented polyacrylonitrile-derived carbon fibers, optionally mixed with finely divided carbon powder, with a thermosetting blend of (a) pitch and (b) an organic medium, at an elevated temperature to form a viscous molding compound; molding the compound at a low pressure and elevated temperature so that a solid compact is obtained; stripping a molded article made of said compound from the mold; optionally heating the molded article at gradually increasing temperatures to insure complete condensation within the article; and carbonizing the condensed molded article in an inert atmosphere at gradually increasing temperatures to produce a molded C / C intermediate article suitable for melt-infiltration with silicon. The preforms may be configured in the form of a disc brake rotor or a disc brake pad.

Owner:HONEYWELL INT INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com