Photovoltaic and organic Rankine cycle coupling combined heat and power supply system

A Rankine cycle and combined heat and power technology, applied in the field of energy and environment, can solve the problems of low power generation efficiency, low energy utilization rate, environmental pollution, etc., and achieve the effect of improving power generation efficiency, saving materials and costs, and reducing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

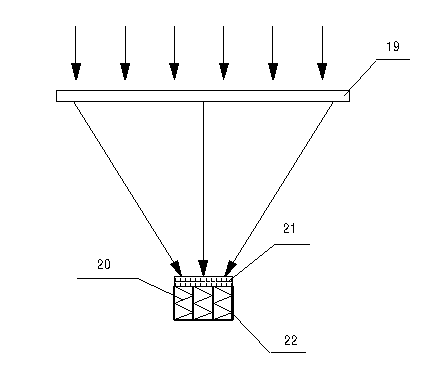

[0028] Example 1: To build a photovoltaic and organic Rankine cycle coupled heat and power system in a certain area, the power of concentrated photovoltaic power generation is 500kw, the output power of the generator in the high-temperature organic Rankine cycle loop is 300kW, and the low-temperature organic Rankine cycle The output power of the generator in the circuit is 200 kw, the total generating power is 1000kW, and the supply of 45~50℃ sanitary hot water is 75m 3 .

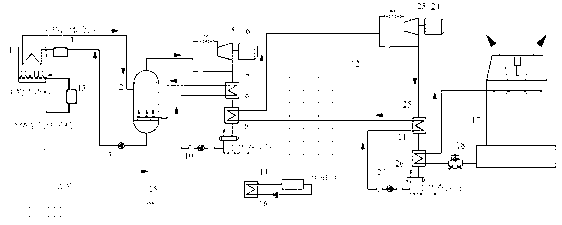

[0029] The photovoltaic and organic Rankine cycle coupled heat and power cogeneration system includes heat transfer fluid circulation loop, biomass combustion furnace smoke exhaust loop, heating hot water loop, cooling loop; one end of biomass combustion furnace exhaust loop and heat transfer fluid circulation The circuit is connected, and the other end is connected to the heating water circuit, which is characterized in that it also includes a high-temperature organic Rankine cycle, a low-temperature organ...

Embodiment 2

[0036] Embodiment 2: This photovoltaic and organic Rankine cycle coupled heat and power cogeneration system is the same as Embodiment 1, and the combustion materials in the biomass combustion furnace 1 used are biodiesel, biomass gasification combustible gas, fuel diesel, heavy oil, Any one or any mixture of methanol, ethanol, methane, natural gas, coal gas, and dimethyl ether.

Embodiment 3

[0037] Example 3: This photovoltaic and organic Rankine cycle coupled heat and power cogeneration system is the same as in Example 1, and the circulating working fluid in the high-temperature organic Rankine cycle loop is R245fa, toluene, butane, isobutane, and pentane , isopentane, cyclopentane, heptane, R113, R11, cyclohexane, benzene, o-xylene, ethylbenzene, 6 methyl 2 siloxane, 8 methyl 3 siloxane, 10 methyl 4 Any one or any mixture of siloxane and 12-methyl-5-siloxane.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Generating power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com