A hybrid hydraulic system and vehicle

A hydraulic system and hybrid technology, which is applied in the layout of power units, vehicle components, and the cooling combination of power units, can solve problems such as increasing system costs and increasing system space layout, and achieve the effect of reducing the number of components and reducing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

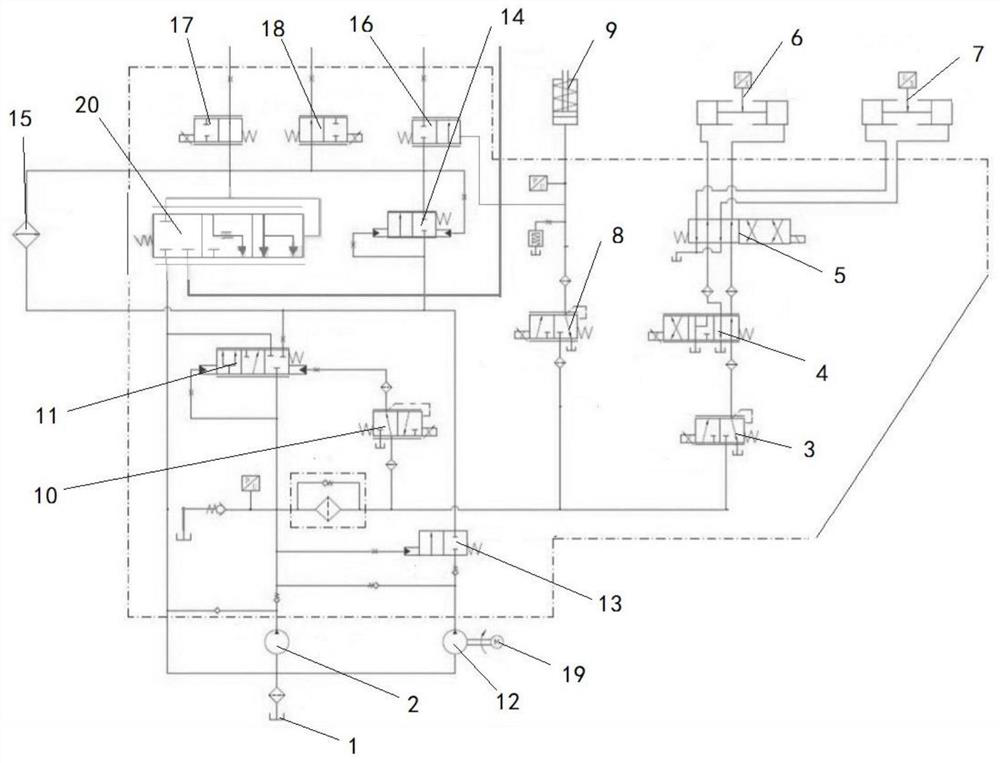

[0030] Hybrid transmission usually adopts the operation method of shifting and cooling separately, such as oil cooling for electric motor cooling, and electronic shifter or clutch operator for clutch and synchronizer shifting operation. Therefore, this mode of operation separates gear shifting and clutch control from motor cooling, which increases system cost and space layout, and uses motor actuators to complete gear shifting and clutch operations. The shifting speed is slow and the smoothness of shifting is average. ; In order to solve the above existing problems, an embodiment of this specification provides a hybrid hydraulic system, which can solve some problems existing in shifting and motor cooling of a two-speed or multi-speed hybrid transmission.

[0031] Specifically, such as figure 1 As shown, it is a schematic structural diagram of a hybrid hydraulic system described in this embodiment. The system is applied to a hybrid vehicle. The system includes a hydraulic oil s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com