Production plant operable in continuous operation and method for operating the production plant in fault situations

A technology for production equipment and equipment, applied in metal processing equipment, manufacturing tools, metal rolling, etc., to solve problems such as unavailability of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

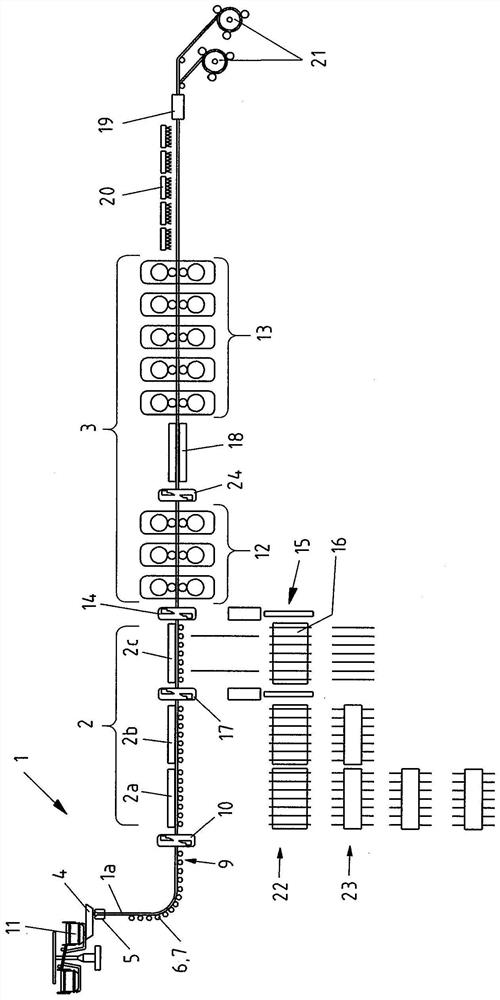

[0018] The drawing shows a schematic side view of a production plant designed as a casting and rolling plant comprising a continuous thin slab casting plant or continuous thin slab caster 1 for producing cast strands 1a, a roller hearth furnace 2 and a rolling mill Column 3, the rolling mill train with associated auxiliary equipment. The devices of the continuous thin slab casting plant or continuous thin slab casting machine 1 are arranged successively in series and form a production line of the continuous thin slab casting plant or continuous thin slab casting machine.

[0019] In the thin slab continuous casting machine 1 upstream of the roller hearth furnace 2, the distribution container 4 is fed from the casting ladle 11, followed by the continuous casting mold 5, the support roll frame 6 with the bending unit 7 and straighteners. A first slab or strip separating device 10 is arranged upstream of the roller hearth furnace 2 on the feed side in the direction of slab trave...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com