Patents

Literature

278 results about "Slab caster" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

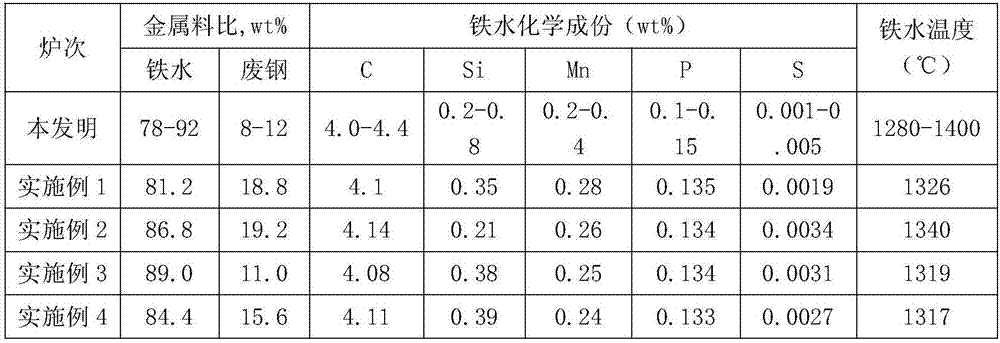

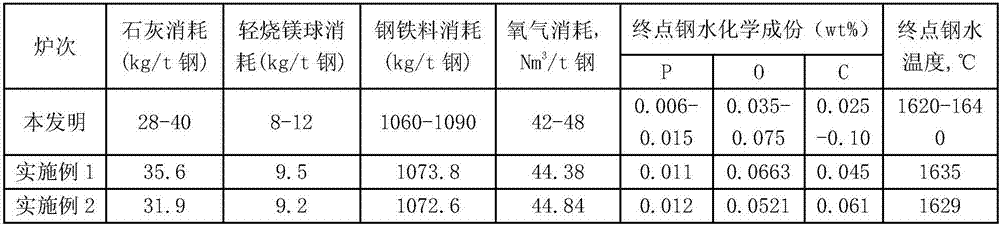

Method for producing hot rolled steel strip for automotive frame

The invention discloses a method for producing a hot rolled steel band used for an automotive frame, comprising the following steps: the pretreated liquid iron is smelt conventionally in a top and bottom combined-blowing revolving furnace, argon is blown at the bottom of the furnace in the whole process, the contents of carbon, phosphorus, silicon and manganese at the terminal of the liquid iron are controlled; the liquid iron discharged from the furnace is refined by an LF furnace, argon is blown to the liquid iron and is stirred and decarbolized at the same time of blowing the argon at the bottom of the LF furnace in the whole process, the liquid iron is subjected to microalloying by adding vanadium, titanium, niobium alloy or niobium and titanium alloy, the content of the microalloy in the liquid iron is controlled to between 0.15 and 0.20 percent, the refined liquid iron is continuously cast into a casting blank through a CSP sheet billet conticaster, the casting blank is soaked in a roller-hearth type soaking furnace and is rolled initially through a vertical miller as well as is sent to a finishing mill set to be rolled, the rolling force of each stander and the finishing temperature of the steel band are controlled, and the hot rolled steel band is cooled through a laminar flow and is cut by a pair of flying shears as well as is wound into a steel coil through a recoiling machine. The produced steel band in 510 L and 590 L or 610 L used for the automotive frame has excellent comprehensive mechanical property, and technique processing and welding performances, can be taken as the automotive frames of a light truck, a medium truck and a heavy truck as well as an agricultural automobile and has remarkable benefits.

Owner:湖南华菱涟源钢铁有限公司

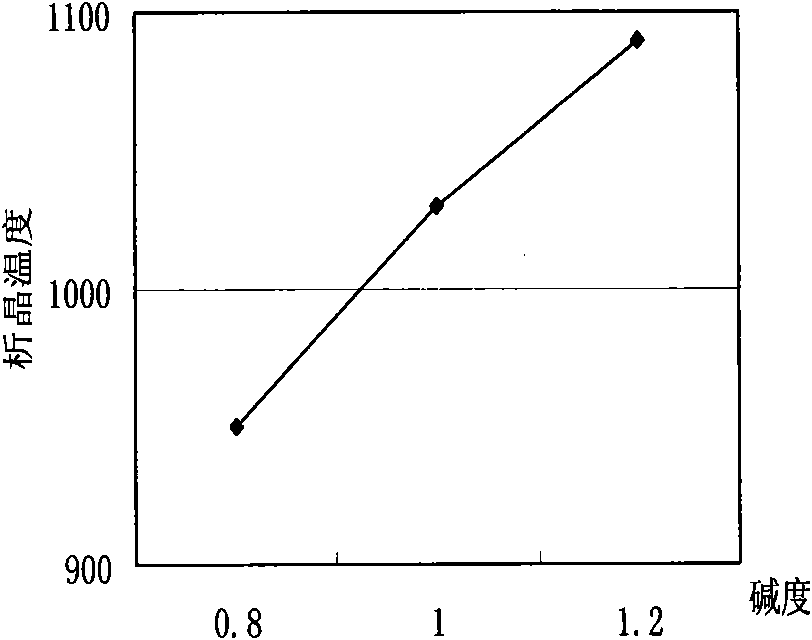

Method for producing low-alloy peritectic steel by medium-thickness slab caster

ActiveCN101586205AEliminate longitudinal cracks on slab surfaceEliminates lateral depressionsManufacturing convertersSlab casterFully developed

The invention provides a method for producing low-alloy peritectic steel by a medium-thickness slab caster, which comprises the following steps: firstly, converter smelting: alkalinity of molten steel is increased during the tapping, top slag is modified after the tapping so as to realize the tapping without slag, tapping final phosphorus is controlled within ingredient range, and other ingredients are lower than the upper limit value; secondly, LF furnace refining: deep deoxidation is performed, the mixing is performed by adopting argon; thirdly, casting: the casting is performed by adopting the medium-thickness slab caster, the slag is protected by adopting a high-alkalinity crystallizer with high melting speed, and the blowing argon protection of the crystallizer is realized. The method for producing the low-alloy peritectic steel lightens the fluid level fluctuation caused by peritectic reaction during the casting production, eliminates longitudinal division and transverse depression on the surface of a low-alloy peritectic steel casting blank so that the qualification rate of the casting blank reaches 100 percent, and fully develops the capacity of the medium-thickness slab caster producing the low-alloy peritectic steel massively at high pulling rate.

Owner:ANGANG STEEL CO LTD

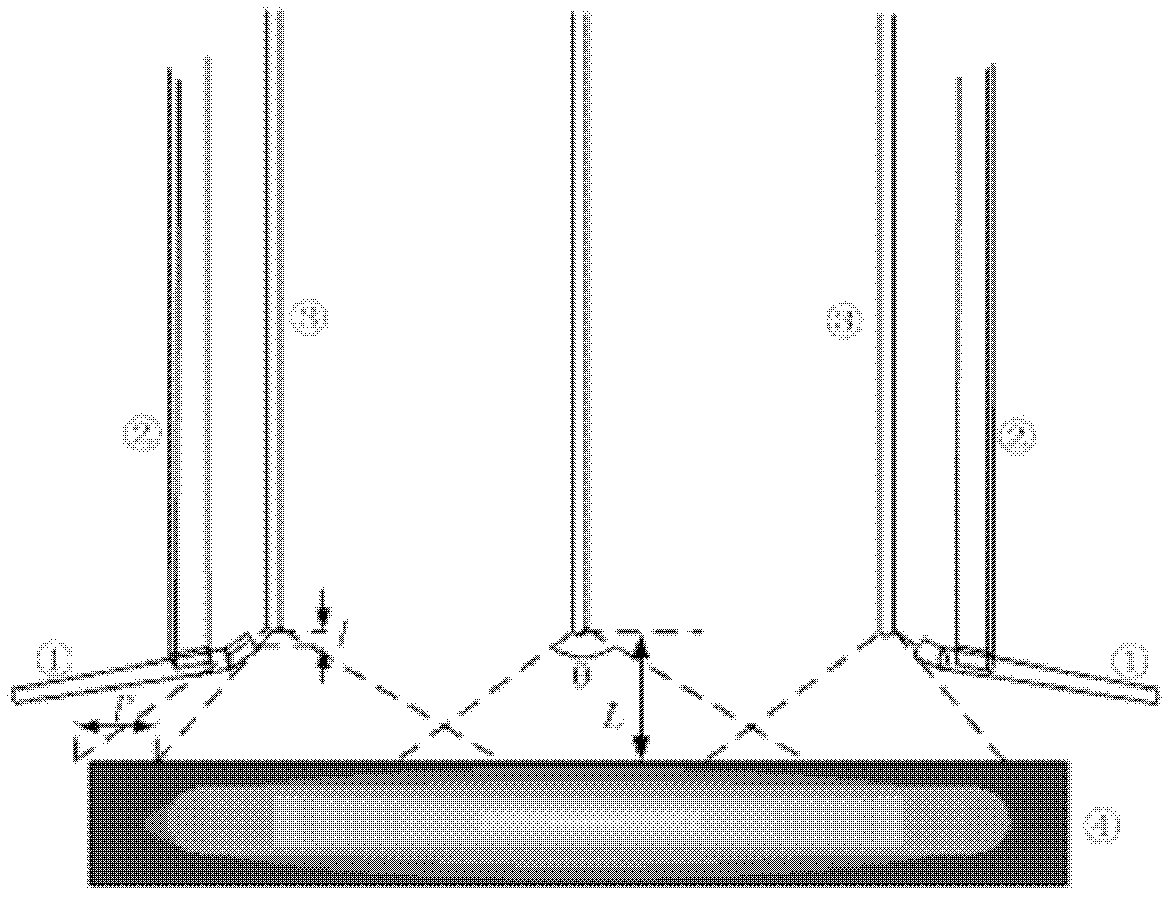

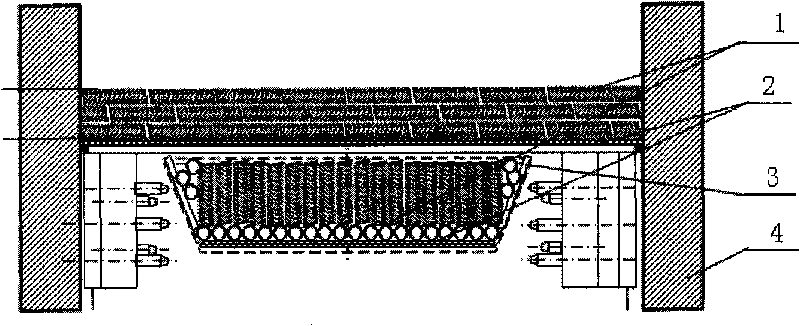

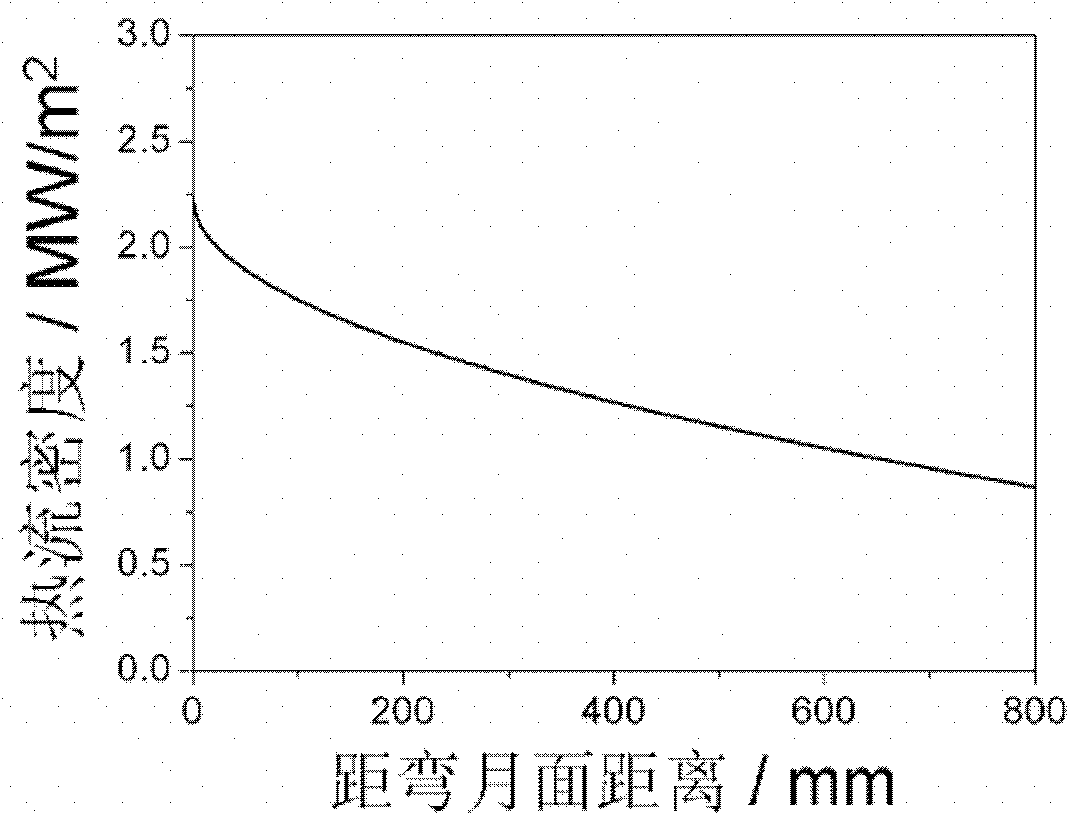

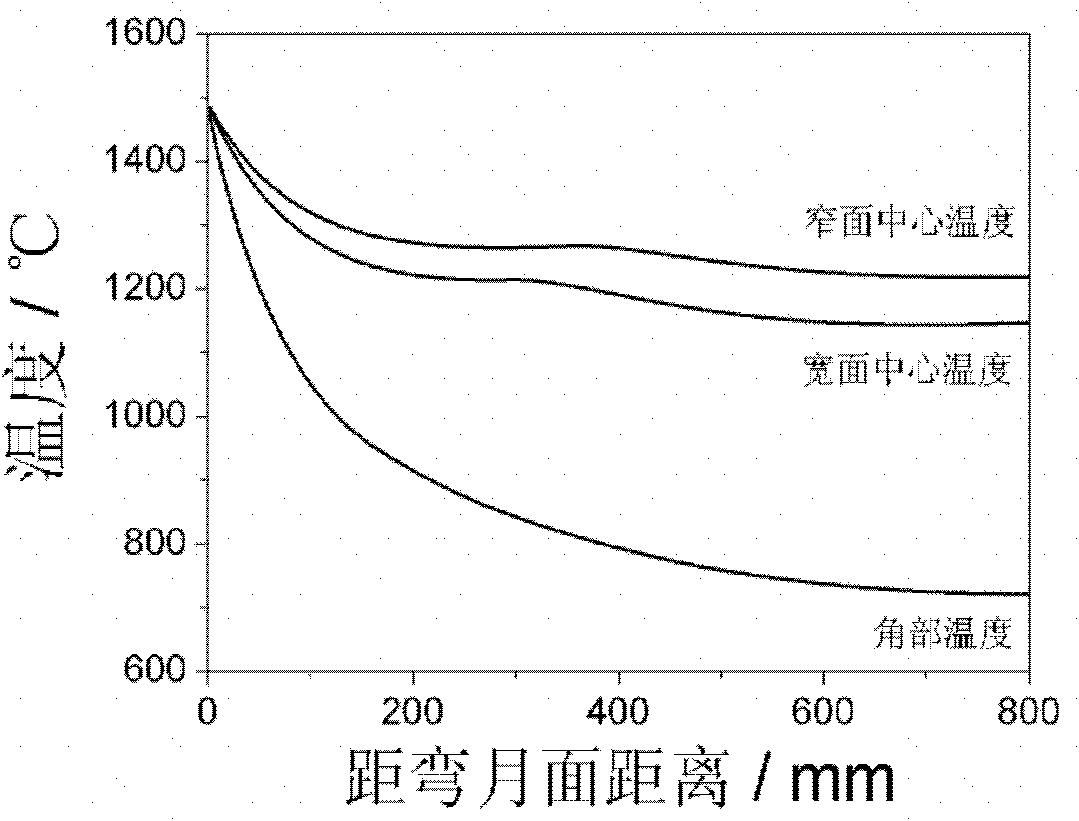

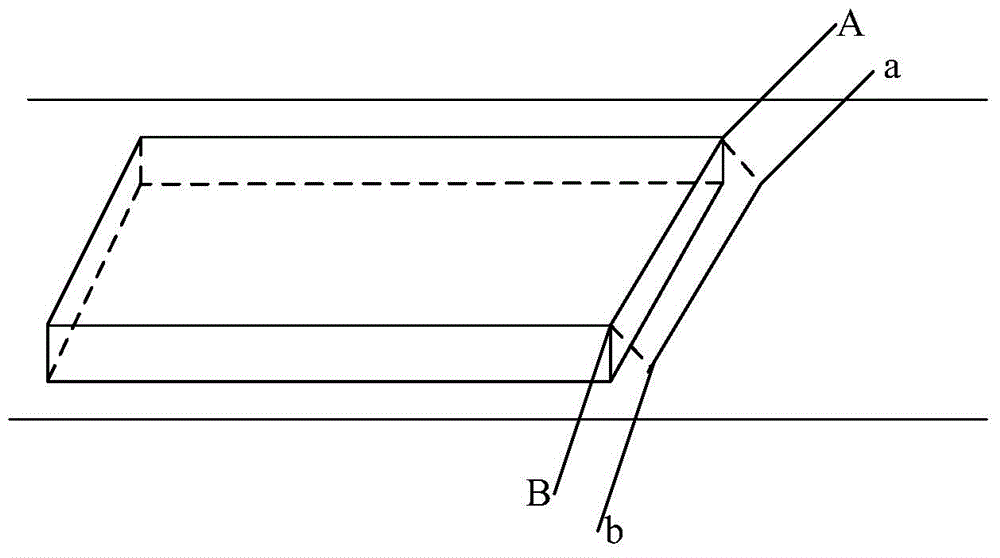

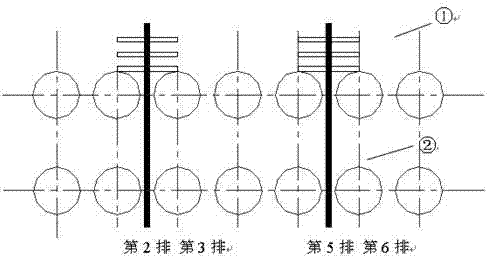

Secondary cooling water amplitude-cutting control method of slab continuous casting machine

ActiveCN102430733AAvoid the third brittle temperature zoneRealize collection and diversionSlab casterField tests

The invention provides a method for carrying out online automatic accurate amplitude-cutting control on spraying width of secondary cooling water of a wide and thick slab, belonging to the technical field of control over cooling water for continuous casting and aiming at overcoming the defects of large engineering modification of a cooling water supply loop, higher cost or poorer control precision of manually adjusting spraying width and the like existing in the prior art. The method mainly comprises the following steps of: taking secondary cooling water spraying widths of different steel types and different width specifications of casting blanks, which are determined through temperature field simulation computation of secondary cooling water regions of the casting blanks and field tests,as references, driving a guide device mainly consisting of a support frame and a collecting guide pipe to collect and guide out redundant cooling water which is sprayed from spray pipes at edge partsof rows of the inner arc of the sector section so as to realize online accurate amplitude-cutting to spraying width of the secondary cooling water of the inner arc of the sector section. Due to adoption of the method disclosed by the invention, temperature of the corner of a continuous casting blank can be stably controlled at 870-900 DEG C, a third brittleness temperature region of steel is effectively avoided, the micro transverse crack defect rate of the corner of the micro alloy steel continuous casting blank is controlled within 1 percent.

Owner:TIANJIN IRON & STEEL GRP

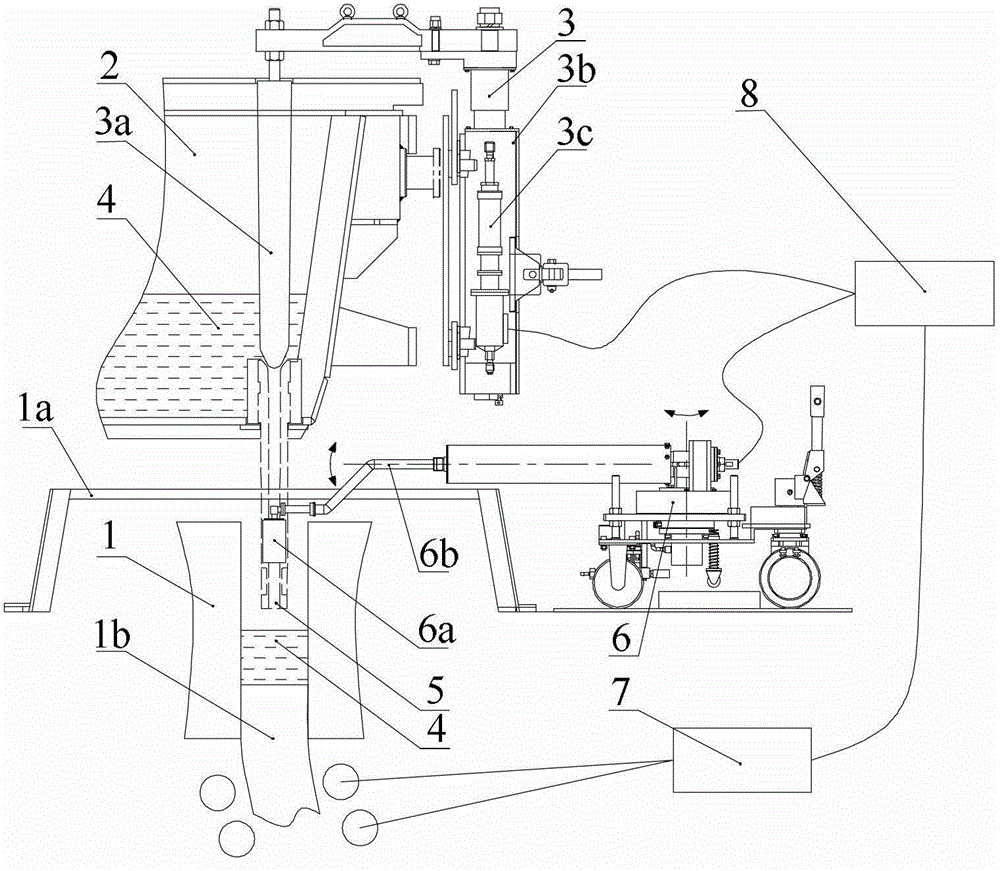

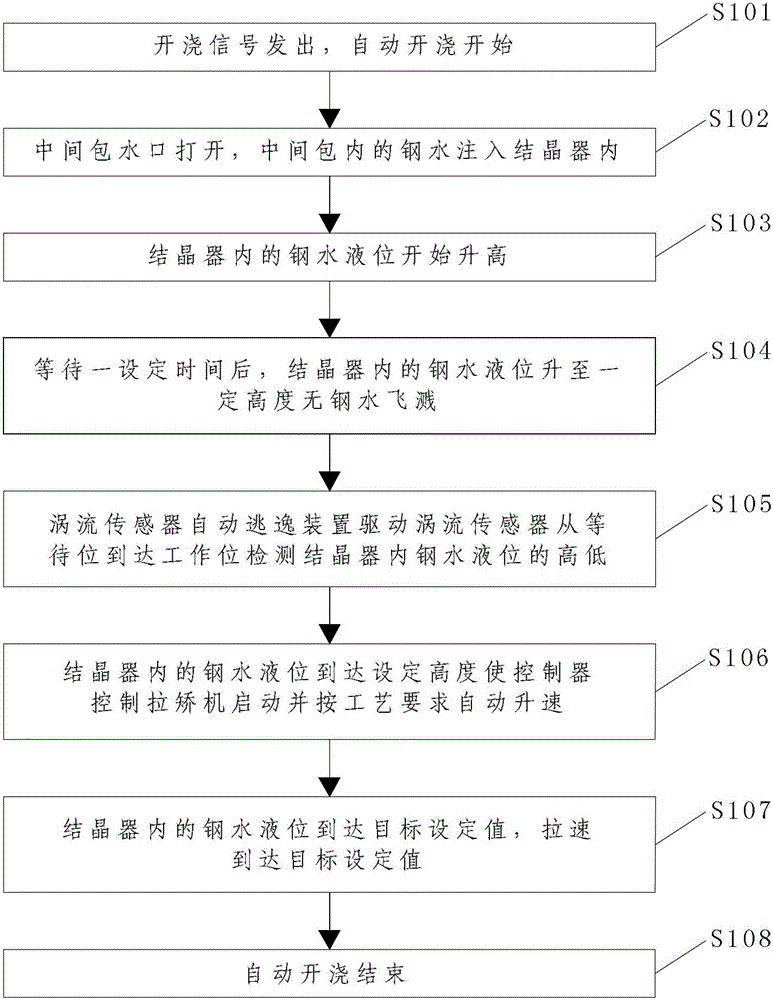

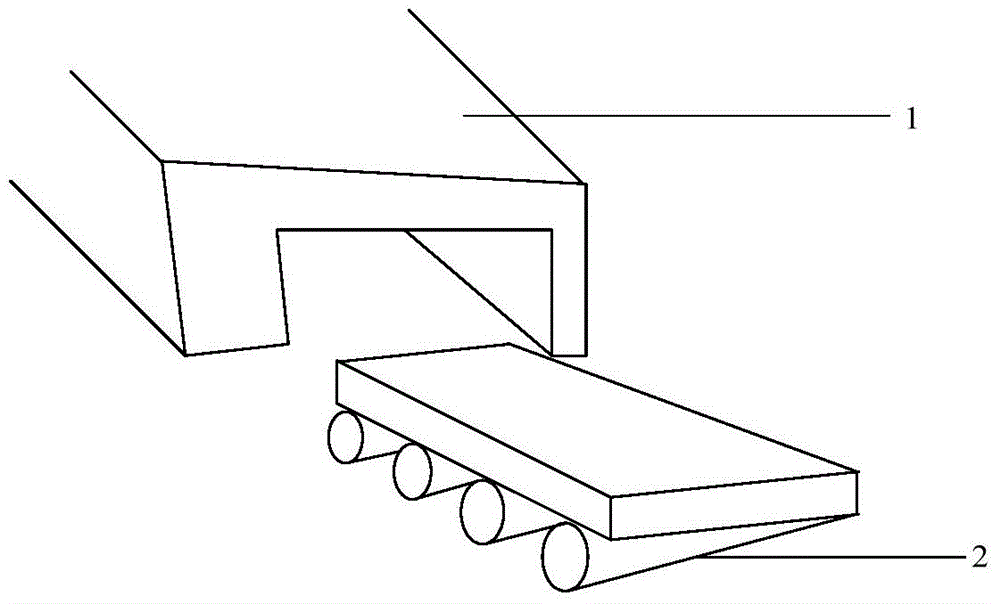

Automatic plate blank continuous casting machine tundish pouring method and automatic pouring system

InactiveCN102717039AReduce the risk of breakoutsImprove the success rate of pouringFlow transducerSlab caster

The invention discloses automatic plate blank continuous casting machine tundish pouring method and an automatic pouring system. The pouring method comprises the following steps of: a) opening a water gap of a tundish, and pouring molten steel in the tundish into a crystallizer; b) after the water gap of the tundish is opened for certain time, leading a vortex flow transducer to automatically move to a work station from a waiting station so as to detect height of the molten steel level in the crystallizer by utilizing an automatic escape device; and c) when the vortex flow transducer detects that the molten steel level in the crystallizer reaches a set height, starting a withdrawl and straightening machine and promoting the casting speed to a target set value according to the process requirement. The automatic plate blank continuous casting machine tundish pouring method and the automatic pouring system can solve the problem that the plate blank continuous casting machine of the existing vortex flow molten steel level detector can not realize automatic pouring, reduce the risk on pouring breakout, improve the pouring success rate, and saving the cost.

Owner:田志恒 +2

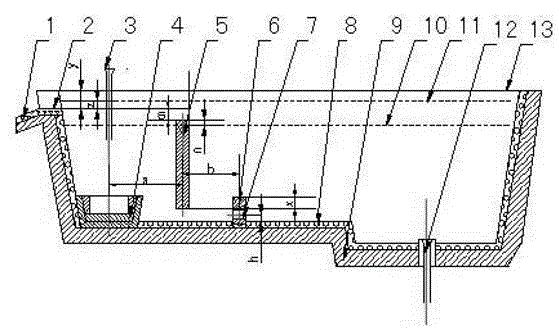

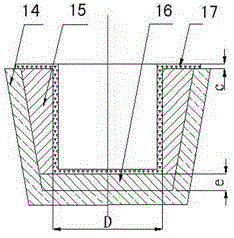

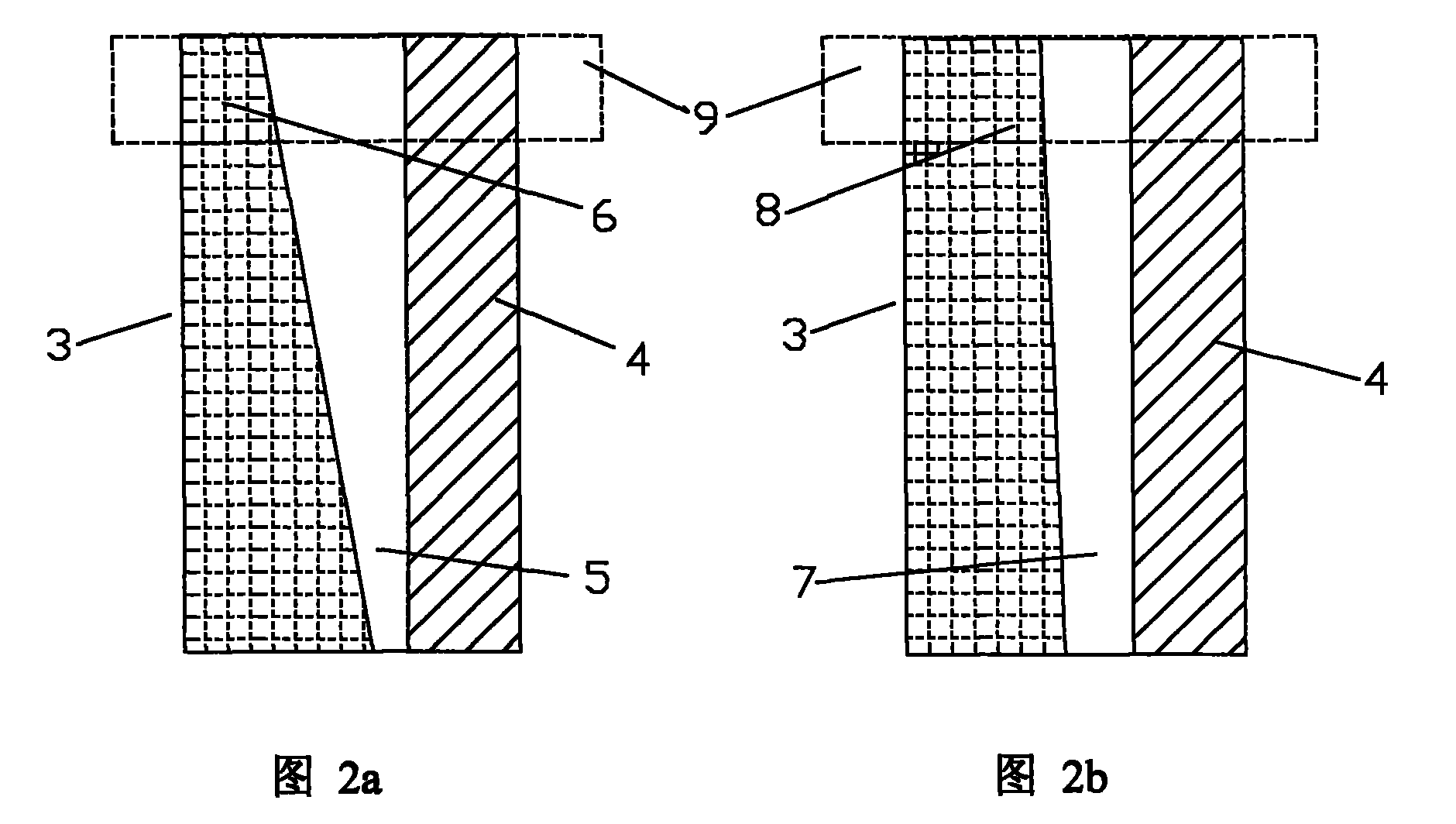

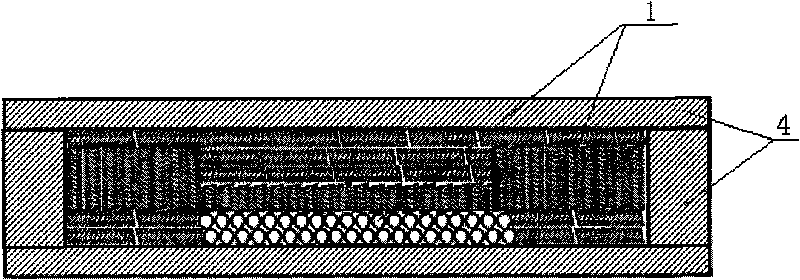

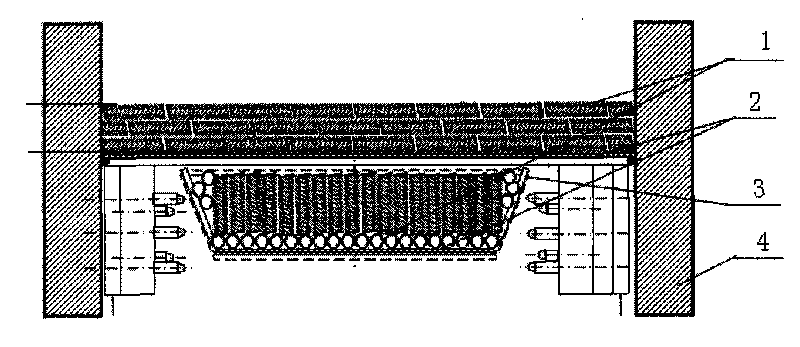

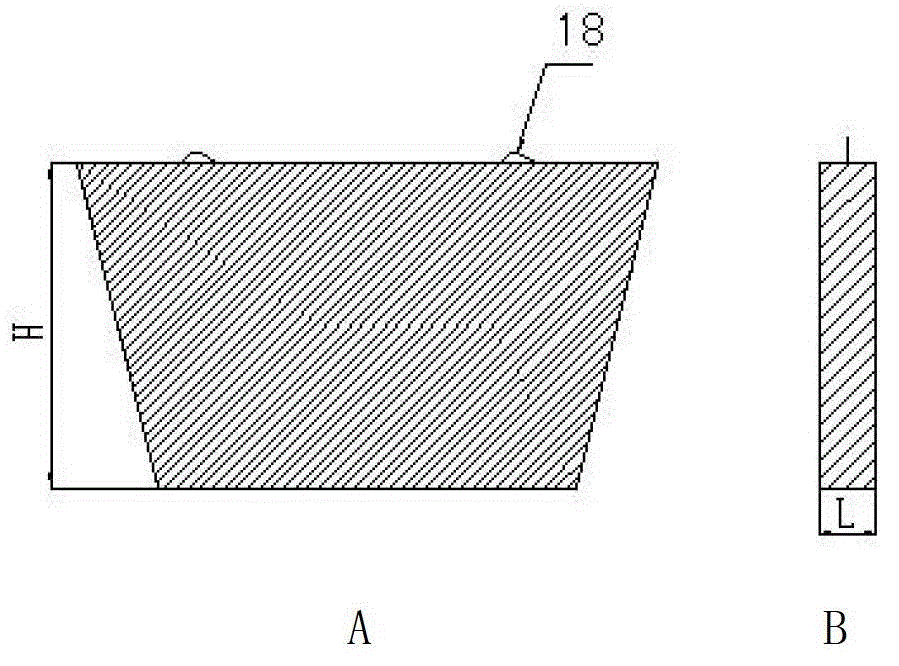

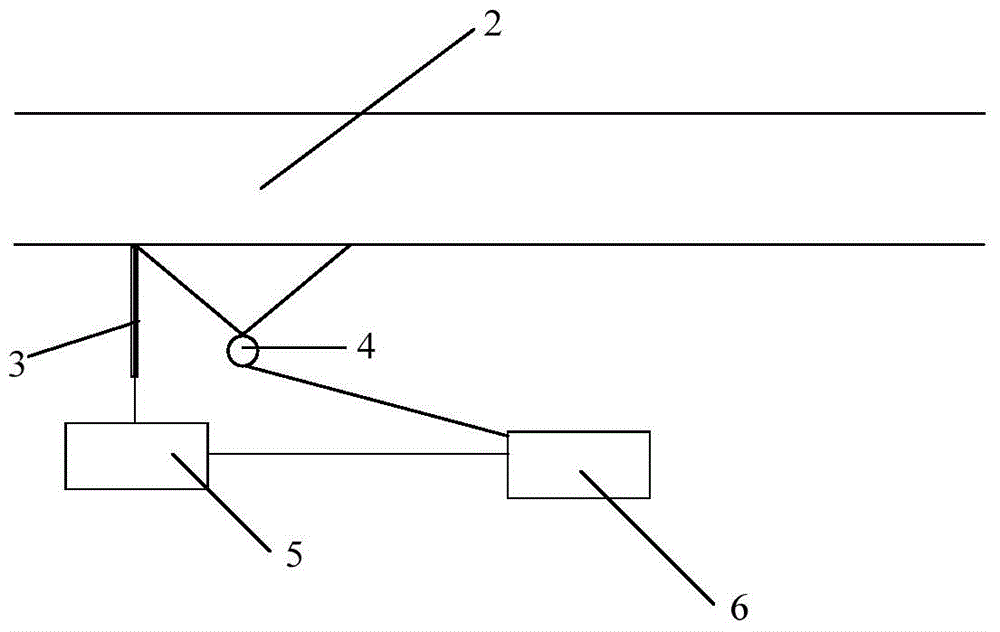

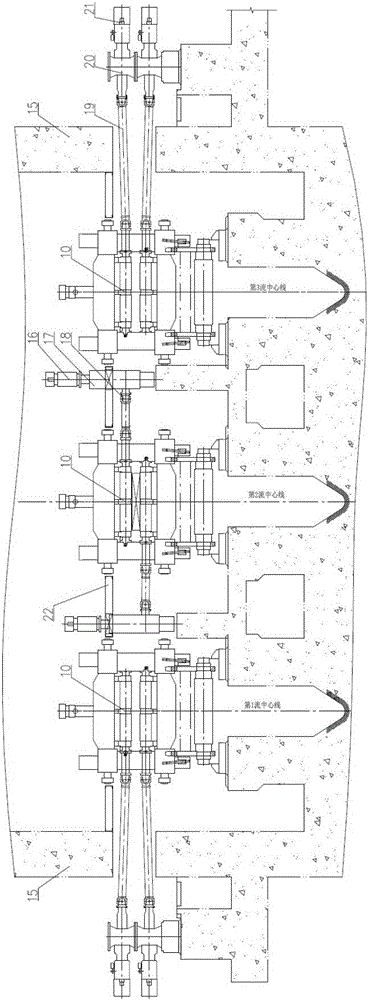

Tundish flow control device for slab casting machine, preparation method thereof and slagging method using tundish flow control device

ActiveCN102744393AReduce the balanceImprove erosion resistanceMelt-holding vesselsCasting cleaning apparatusSlab casterSlag

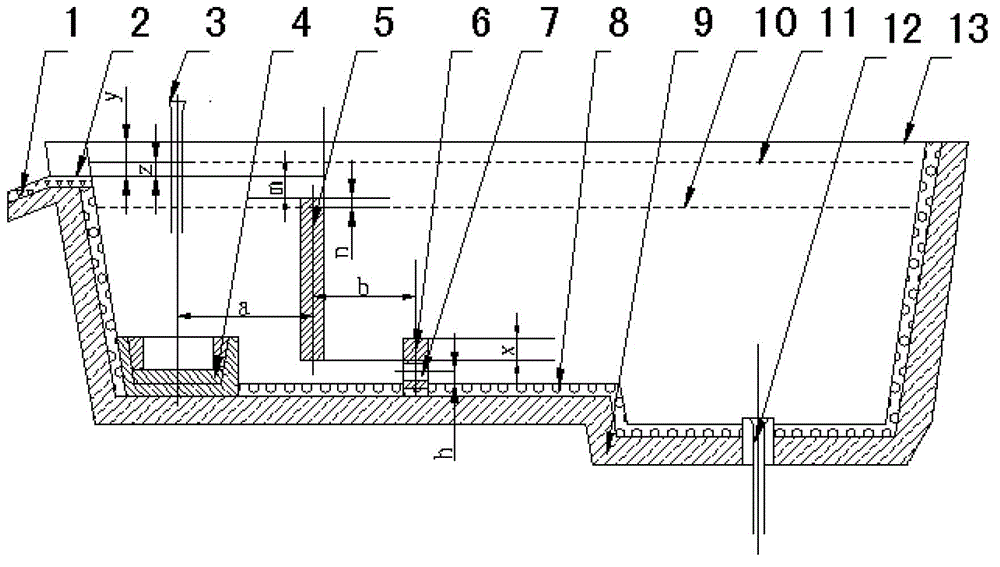

The invention relates to a tundish flow control device for a slab casting machine, a preparation method of the tundish flow control device and a slagging method using the tundish flow control device, and belongs to the technical field of the ferrous metallurgy slab casting tundish technology. The tundish flow control device for the slab casting machine comprises a turbulence controller, a slag blockage weir and a slag blockage dam, and is characterized in that the upper edge of the slag blockage weir (5) is higher than the highest liquid level (10) of molten steel normally poured by the tundish, but is lower than the working face of tundish overflow port coating (1); the slag blockage weir (5) and the slag blockage dam (6) are vertically staggered; two ends of the slag blockage dam (6) are respectively provided with a through hole; a center distance a between the slag blockage weir (5) and the turbulence controller (4) is 400-600mm; and a center distance b between the slag blockage weir (5) and the slag blockage dam (6) is 300-400mm. After the tundish flow control device for the slab casting machine is adopted, slab tundish injection residue can be reduced by more than 25%, the service life of the flow control device is improved by one time and is above 14 hours, and the production cost of continuous casting refractory material is lowered by more than 30%.

Owner:LAIWU IRON & STEEL GRP

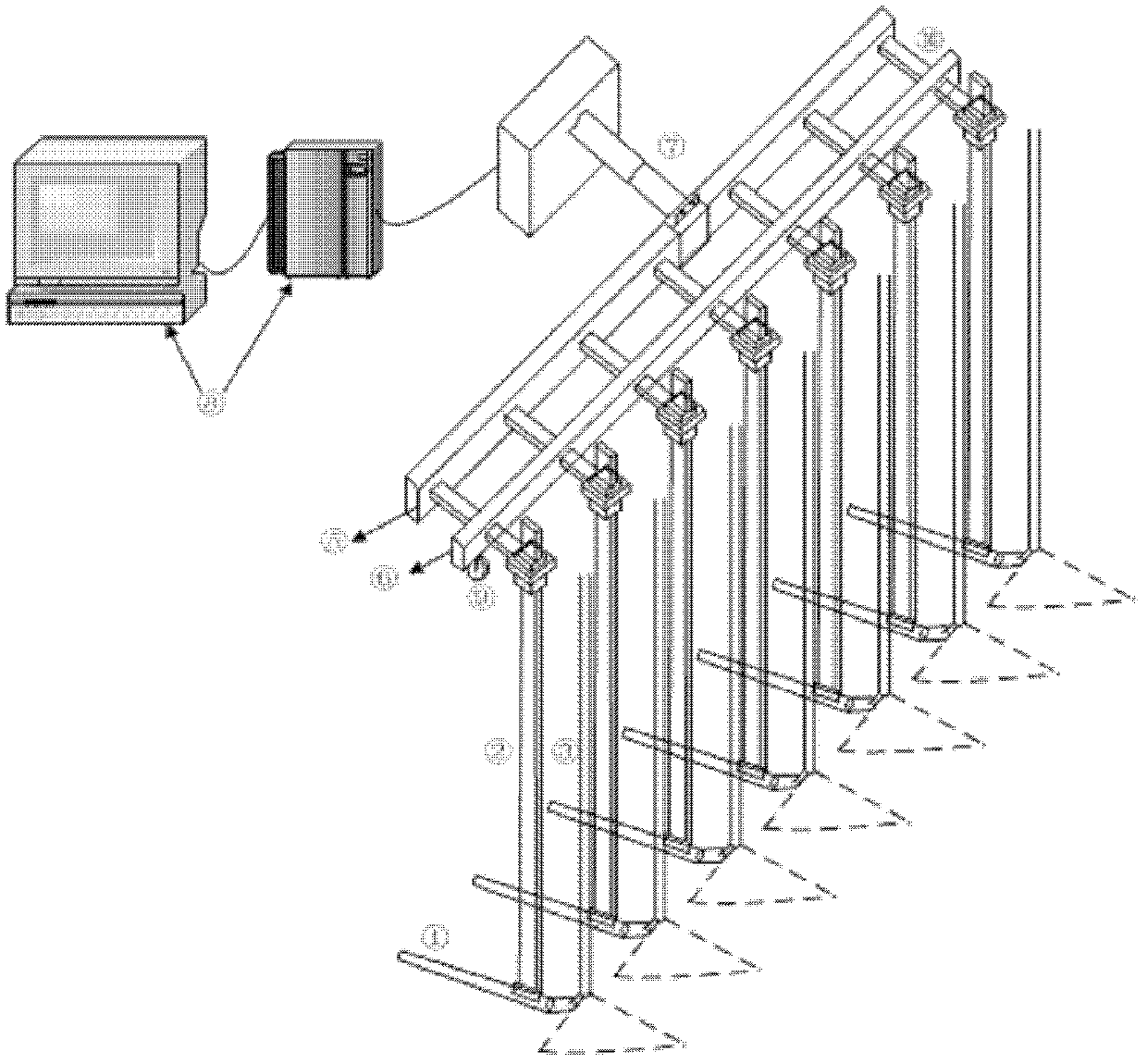

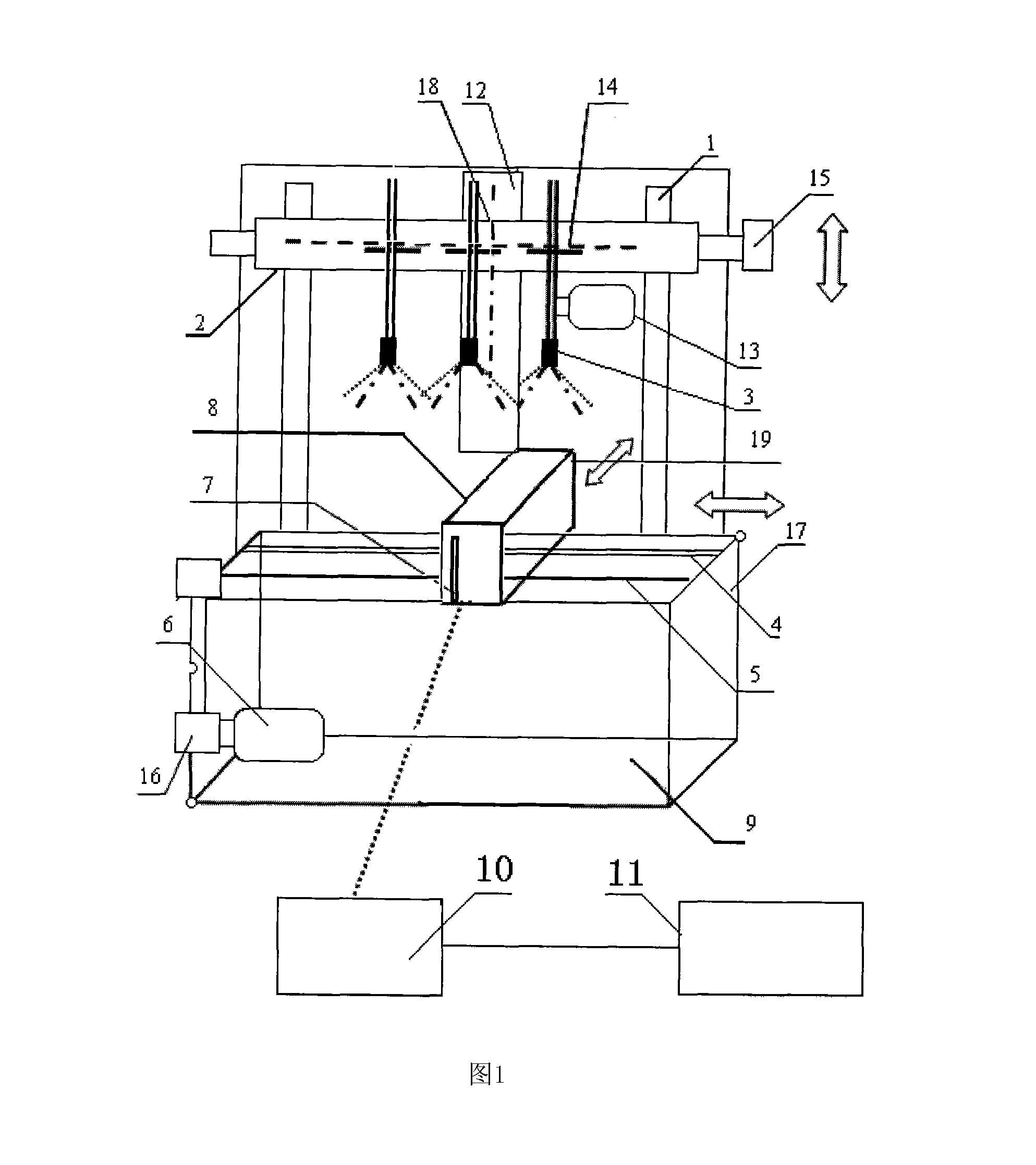

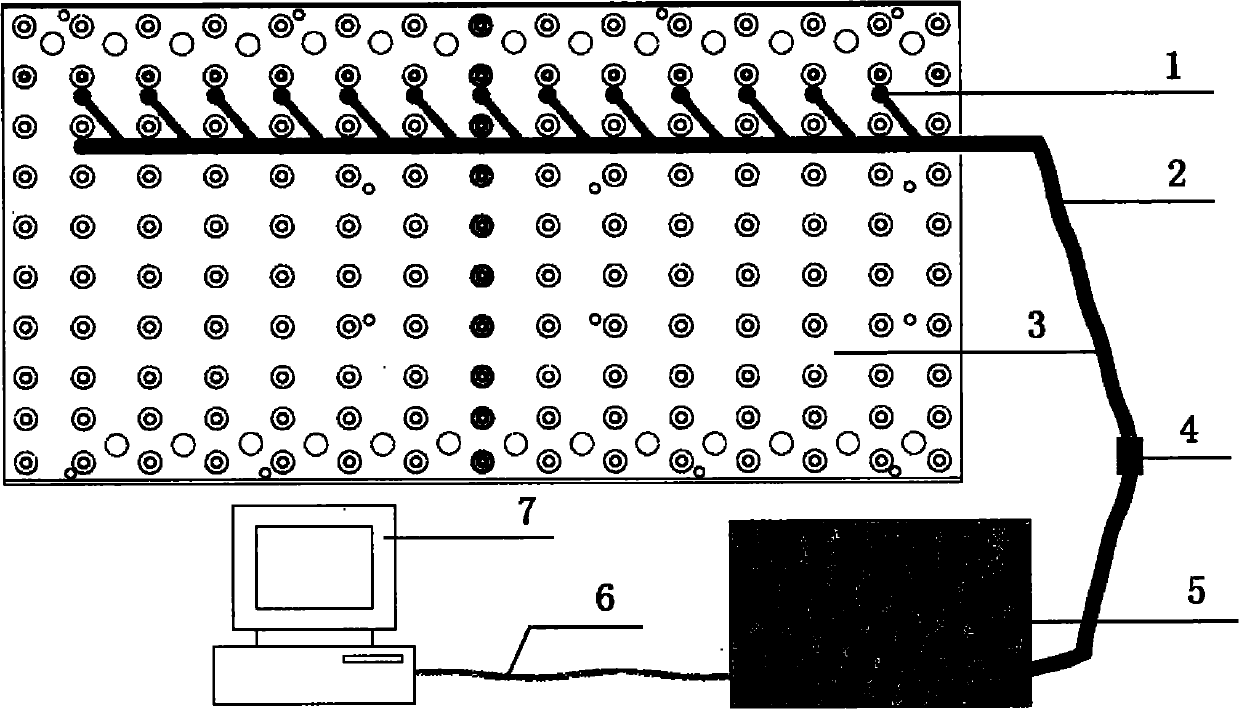

Slab caster two cold nozzle impact measuring system

InactiveCN101187587AMeasuring Impact CharacteristicsAccurate measurementForce measurementStructural/machines measurementSlab casterSignal conditioning

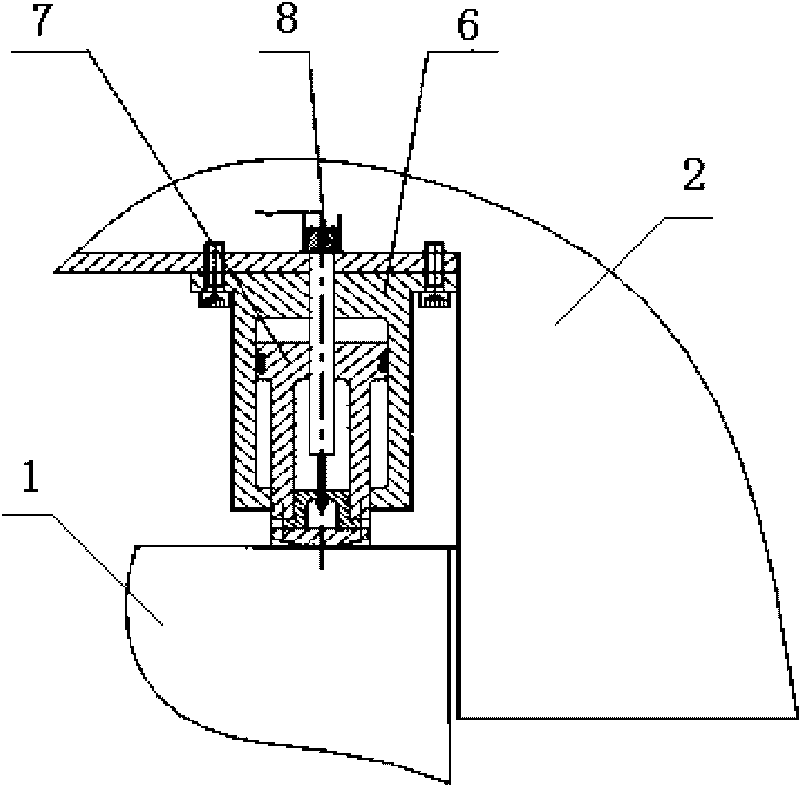

The invention belongs to the metallurgical equipment field, which relates to a testing system for an impact force of a secondary cooling nozzle of a slab caster. The invention is characterized in that a waterproof strain type micro force value sensor (8) is fixed on a sensing shift mechanism, the waterproof strain type micro force value sensor (8) is driven to shift to a testing position through the sensing shift mechanism, a nozzle is fixed on a nozzle shifting mechanism, a nozzle (3) is arranged downwards, the nozzle (3) is shifted to the upper portion of the waterproof strain type micro force value sensor (8) through the nozzle (3) shifting mechanism, the nozzle (3) sprays water, the waterproof strain type micro force value sensor (8) is driven to shift through the sensing shift mechanism, a strain type electric signal is produced by a spraying percussive force in different space which is given by the waterproof strain type micro force value sensor (8), the signal is amplified through a signal conditioner 10, a data which is output by the signal conditioner 10 is transmitted to a data collecting and analyzing unit (11) of a computer, and an inundation distributing graph of three-dimensional water spraying percussive force is given. The invention can accurately measure the percussive force characteristics of a nozzle, which improves measuring accuracy, and reduces measuring cost.

Owner:CHINA NAT HEAVY MACHINERY RES INSTCO

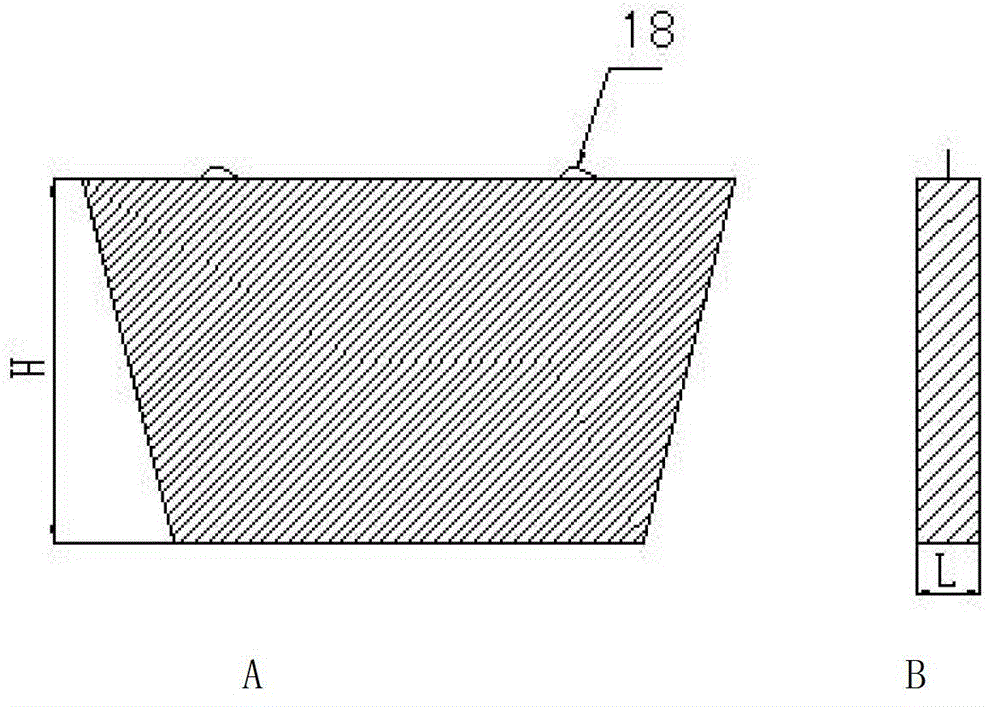

Final-pouring capping method for reducing abrasion of copper plate of crystallizer of moderate-thickness slab caster

The invention provides a final-pouring capping method for reducing abrasion of a copper plate of a crystallizer of a moderate-thickness slab caster. The method comprises the following steps of casting speed reducing, residue salvage, final pouring, capping, width regulating of the crystallizer and opening of the copper plate. The method has the advantages that by controlling speed reducing, and speed and time of residue salvage, and by changing a capping mode, blasting accidents easily caused by capping misoperation are eliminated, and production safety is improved; by means of design of opening of the copper plate of the crystallizer and the pulling speed, supercooling tail blanks are prevented from making contact with the copper plate of the crystallizer, abrasion to the copper plate of the crystallizer is reduced, and service life of the crystallizer is prolonged by more than 20%, and good popularizing value is achieved.

Owner:JIGANG GRP

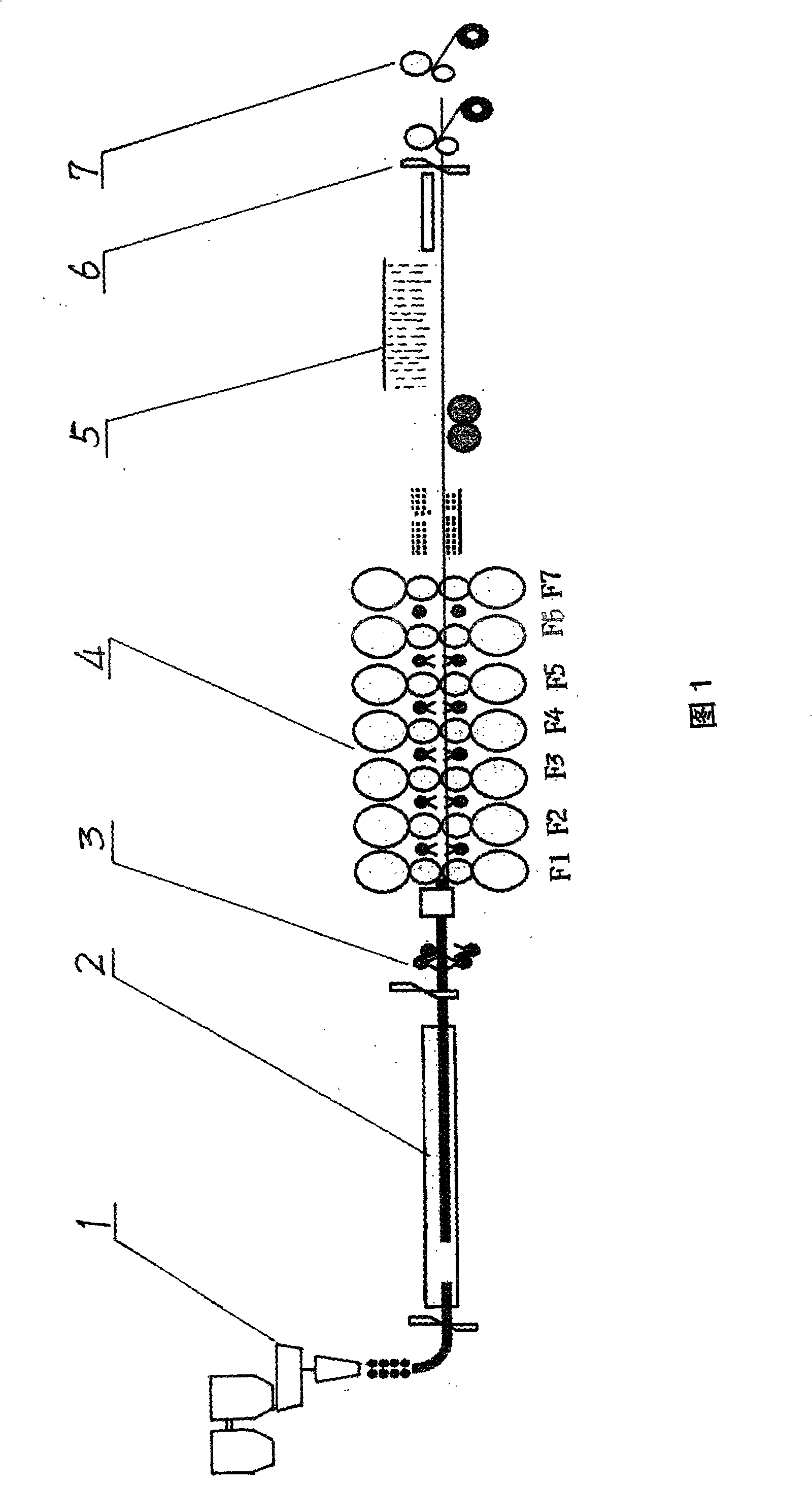

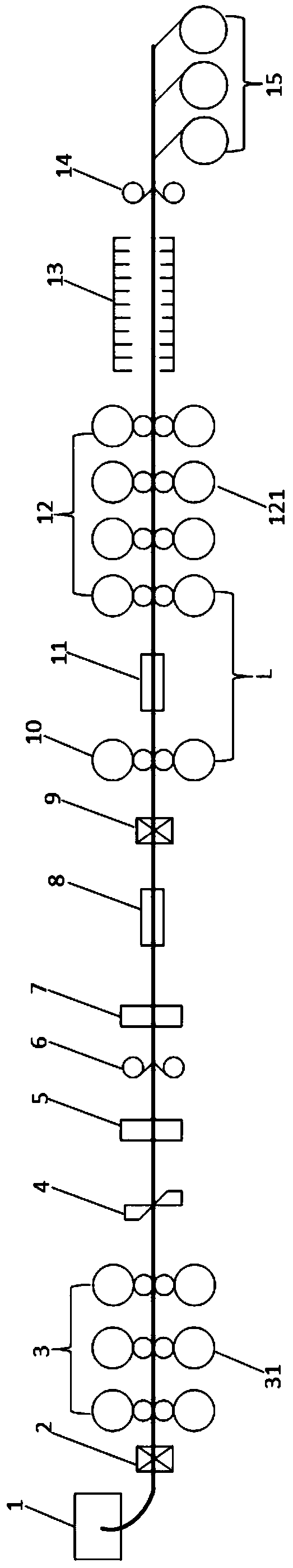

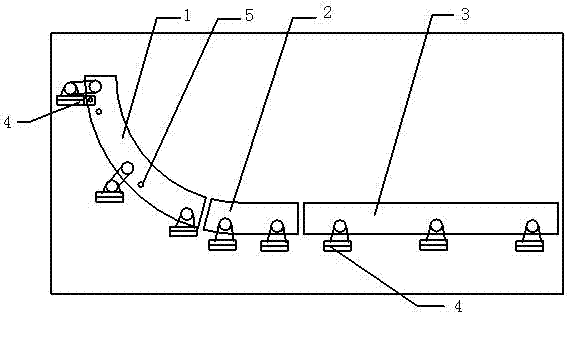

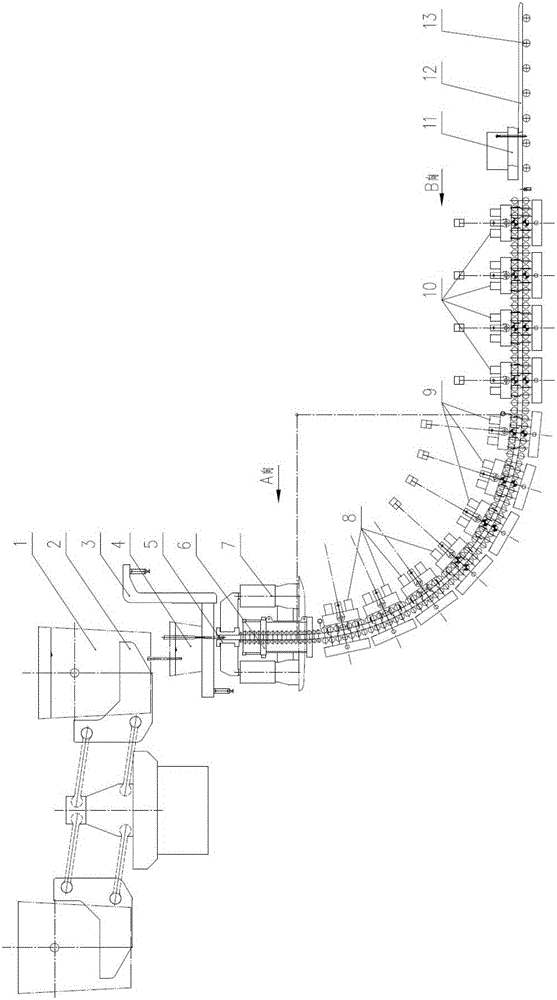

Low-carbon steel continuous casting and rolling production line and production technology thereof

PendingCN108526221AMeet the temperatureFulfil requirementsMetal rolling arrangementsSlab casterHigh pressure water

The invention discloses a low-carbon steel continuous casting and rolling production line and a production technology thereof. The low-carbon steel continuous casting and rolling production line and the production technology thereof are applied to the technical field of steel rolling. The production line comprises a slab continuous casting machine, a high-pressure water rough descaling device, a roughing rolling unit, a swing shear, a pushing-out and sheet stacking device, a rotating drum flying shear, a waste material removal device, an induction heating furnace, a high-pressure water fine descaling device, a middle rolling rack, a middle water cooling device, a finishing rolling unit, a laminar flow cooling device, a high-speed flying shear and a recoiling machine. The finishing rollingunit comprises four finishing rolling racks. The distance L between the middle rolling rack and the centre line of the first finishing rolling rack ranges from 10 m to 20 m. According to the low-carbon steel continuous casting and rolling production line and the production technology thereof, by means of reasonable production line arrangement and the proper production technology, the low-temperature rolling and high-temperature recoiling requirements for ferrite rolling are guaranteed; the sufficient finishing rolling total reduction rate is guaranteed; complete transforming, from austenite toferrite, of strip steel before being subjected to finishing rolling is completed; the finishing rolling is conducted in a ferrite zone, and thus real-sense ferrite rolling conducted through the continuous casting and rolling production line is achieved.

Owner:CISDI RES & DEV CO LTD

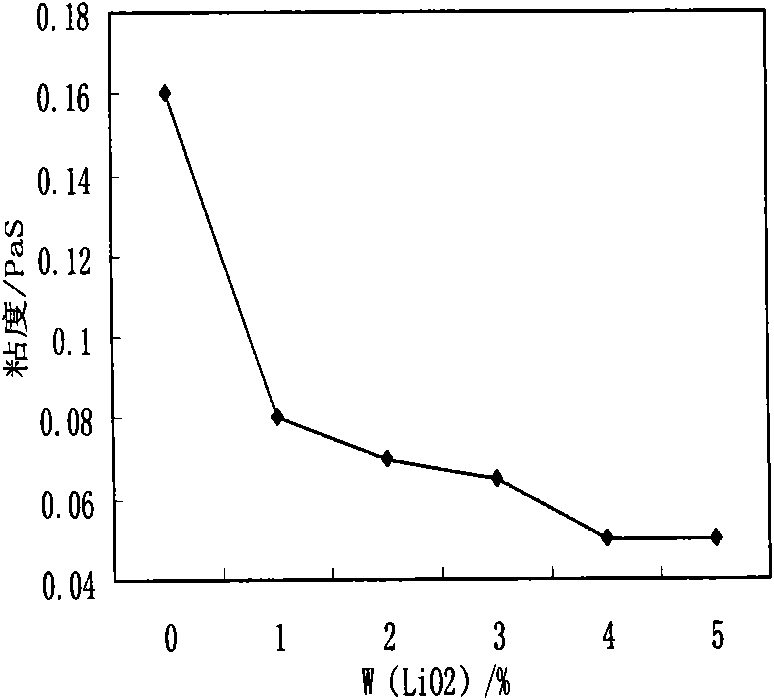

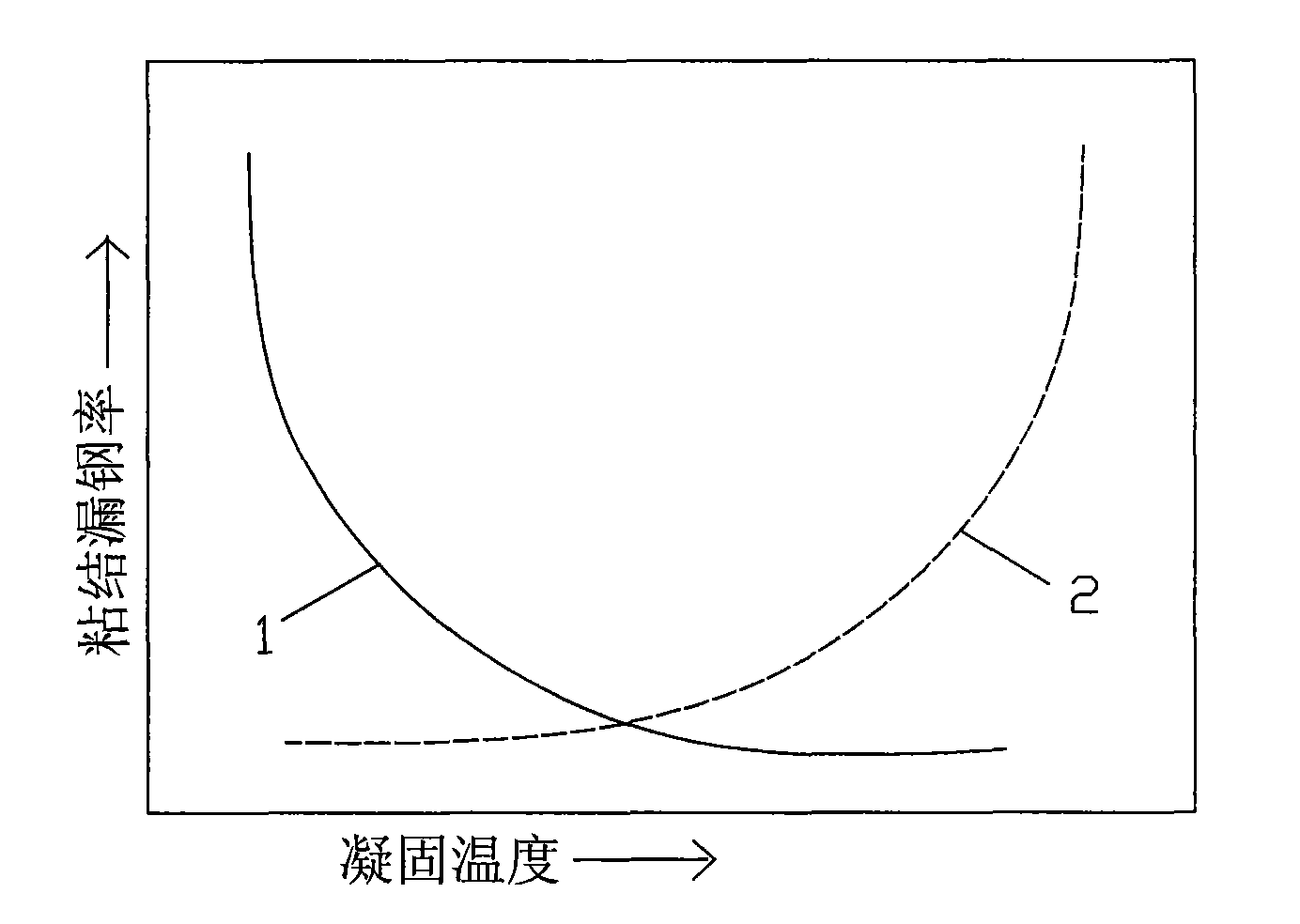

High-casting speed mold flux

The invention relates to a continuous casting mold flux, in particular to a high-casting speed mold flux, which solves the problem that the flux consumption is low and the mold bonding alarm rate is high when the casting speed is higher than 1.2 m / min in the prior art. The high-casting speed mold flux comprises the following components in percentage by weight: 32.0 to 34.0 percent of SiO2, 39.0 to 41.0 percent of CaO, 4.0 to 5.0 percent of Al2O3, 7.5 to 9.5 percent of Na2O, 5.0 to 6.0 percent of F, 2.0 to 3.0 percent of MgO, 0.5 to 1.5 percent of Fe2O3, 2.5 to 3.0 percent of C, 0.7 to 1.0 percent of Li2O and 0.9 to 1.4 percent of B2O3. A binary basicity (CaO / SiO2) in the flux is 1.15 to 1.25. The high-casting speed mold flux is mainly used for protecting the high-casting speed mold for slab caster continuous casting peritectic steel under electromagnetic brake technology.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

Mould powder for manganese-containing low content alloy peritectic steel subjected to continuous casting by thick slab caster

The invention relates to metallurgical auxiliary material mould powder, in particular to mould powder for manganese-containing low content alloy peritectic steel which is subjected to continuous casting by a thick slab caster. The mould powder for the manganese-containing low content alloy peritectic steel which is subjected to the continuous casting by the thick slab caster comprises cement clinker, wollastonite, fluorite, sodium carbonate, lithium carbonate, slaked lime, refining slag powder and carbon black; the mould powder comprises the chemical components in percentage by weight: 4.0 to 5.0 percent of Li2O, 28.0 to 31.0 percent of SiO2, 48.0 to 51.0 percent of CaO, 3.0 to 6.0 percent of Al2O3, 0.5 to 1.5 percent of Na2O, 6.0 to 8.0 percent of F<->, 1.0 to 2.0 percent of MgO, 0.5 to 1.0 percent of Fe2O3 and 1.5 to 2.0 percent of C. The mould powder solves the problem of high incidence of longitudinal cracks on the surface of a casting blank in the process of the continuous casting for the manganese-containing low content alloy peritectic steel by the thick slab caster, and has the advantages of low melting point and solidification temperature, and short crystallization incubation time.

Owner:BAOSHAN IRON & STEEL CO LTD +1

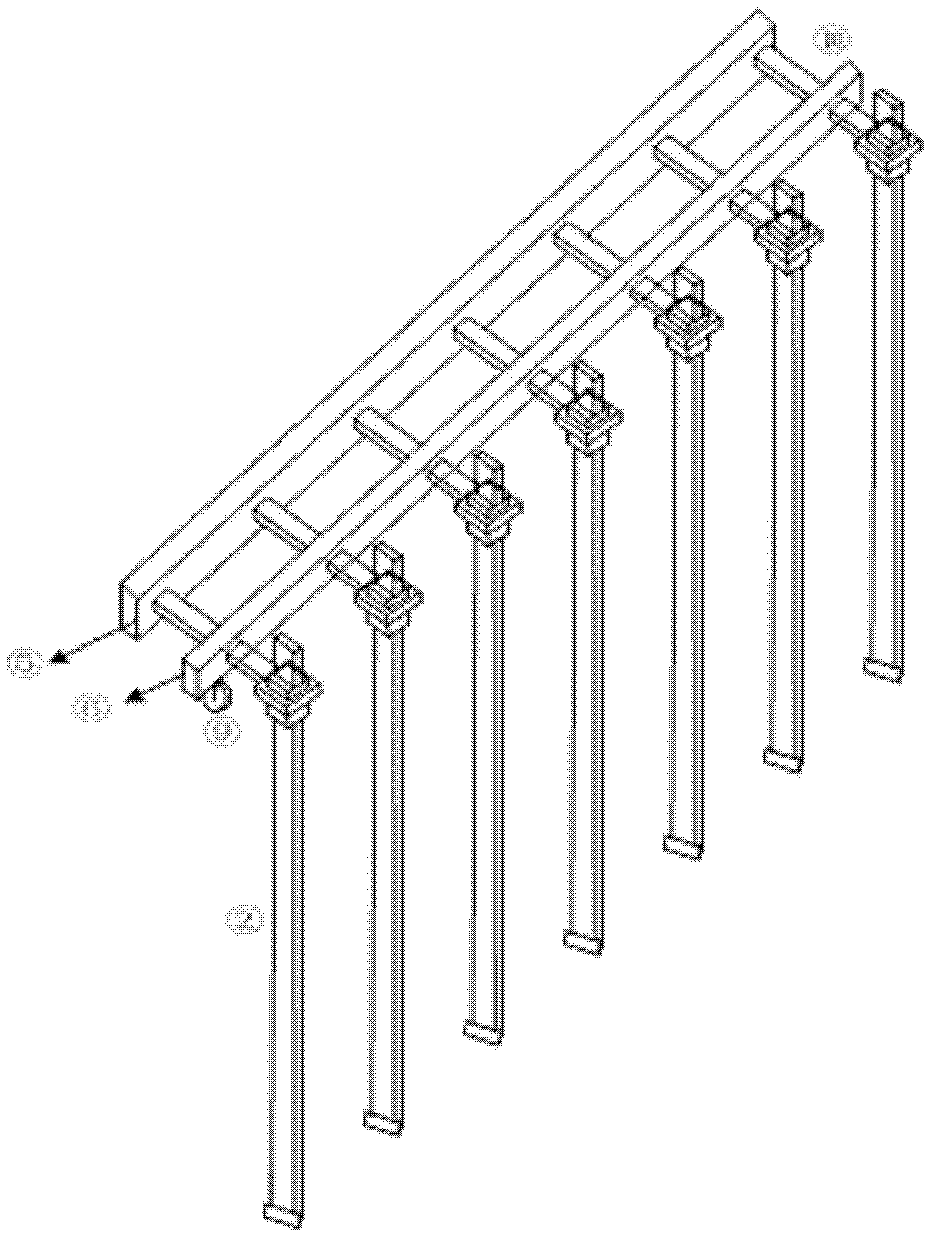

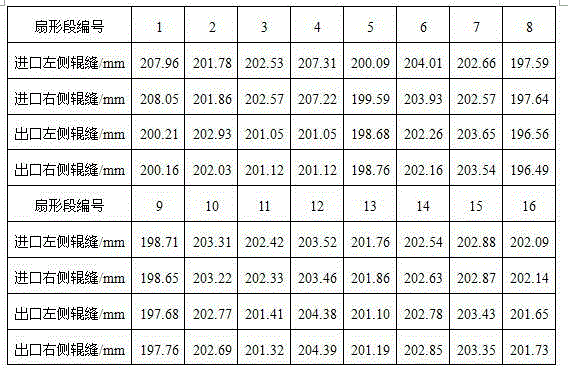

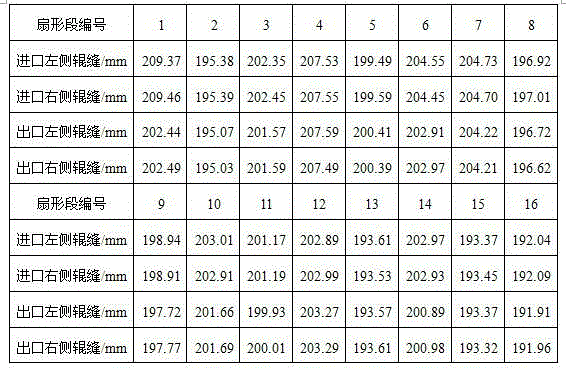

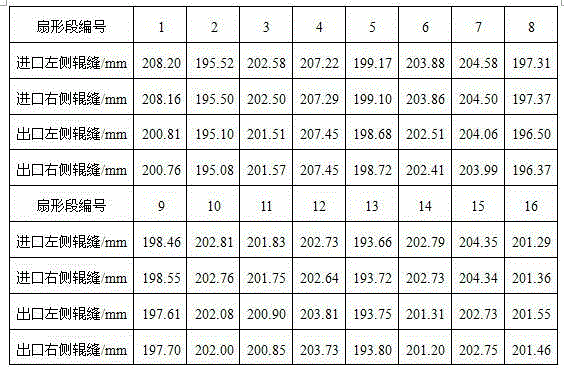

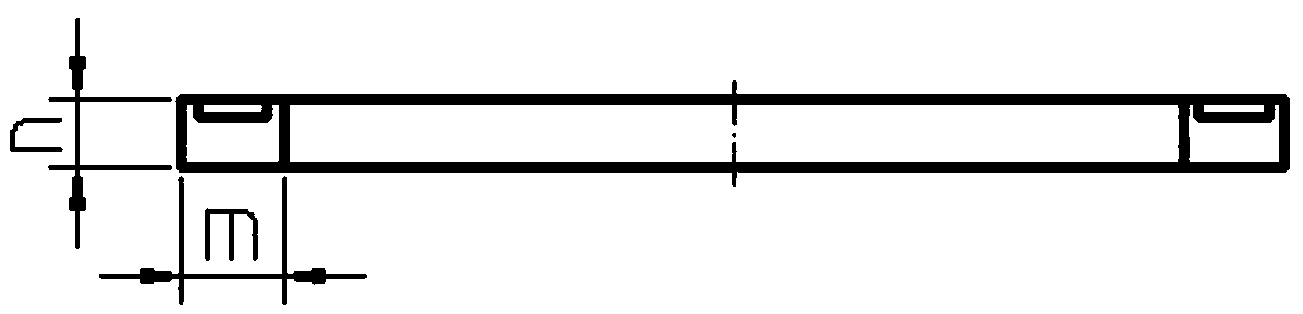

Method for calibrating sector sections of slab continuous casting machine online

The invention provides a method for calibrating sector sections of a slab continuous casting machine online, and belongs to the technical field of roll gap calibration methods of continuous casting machines. The method is used for calibrating the sector sections of the slab continuous casting machine online. According to the technical scheme, the method includes the steps that (1) two pairs of hydraulic cylinders at an inlet and an outlet of each sector section are leveled through gaskets respectively; (2) upper frames of the sector sections are pressed through pressure ranging from 800 kN to 4000 kN; (3) roll gap values of the inlets and the outlets of the sector sections are measured respectively; (4) displacement sensors in the hydraulic cylinders are calibrated according to the actually-measured roll gap values. By means of the method for calibrating the sector sections of the slab continuous casting machine online, the control precision of roll gaps of the continuous casting machine can be increased and reach 0.20 mm. The method can be used for calibrating all the sector sections at the same time, the calibrating efficiency is high, and the operating efficiency of the continuous casting machine can be improved. The hydraulic cylinders of the sector sections, calibrated through the method, of the continuous casting machine bear force uniformly, and the interior quality of casting blanks and the production stability of the continuous casting machine are improved. By means of the method, the labor intensity of workers can be greatly reduced.

Owner:HEBEI IRON AND STEEL

Method for plugging dummy bar head of slab caster

The invention discloses a method for plugging a dummy bar head of a slab caster. The technological process is characterized in that a steel chisel plugs a paper string in the gap between the dummy bar head and a crystallizer, two sheet iron plates are placed at the corner of a hook head, nail scraps are used to cover the periphery of the paper string, springs are horizontally placed at the bottom layer in a groove and springs are vertically upward placed; and other parts outside the groove are transversely placed in a staggering way. The invention has the advantages that the molten steel filling state in the dummy bar head plugged by adopting the method is good, the plug and the dummy bar head are reliably connected, no starting unhook or slab clamping accidents occur, the situation of starting breakout is avoided, the heavy ladle return refining is avoided, the normal field production rhythm is guaranteed and the safety factors of personnel and devices are improved.

Owner:ANGANG STEEL CO LTD

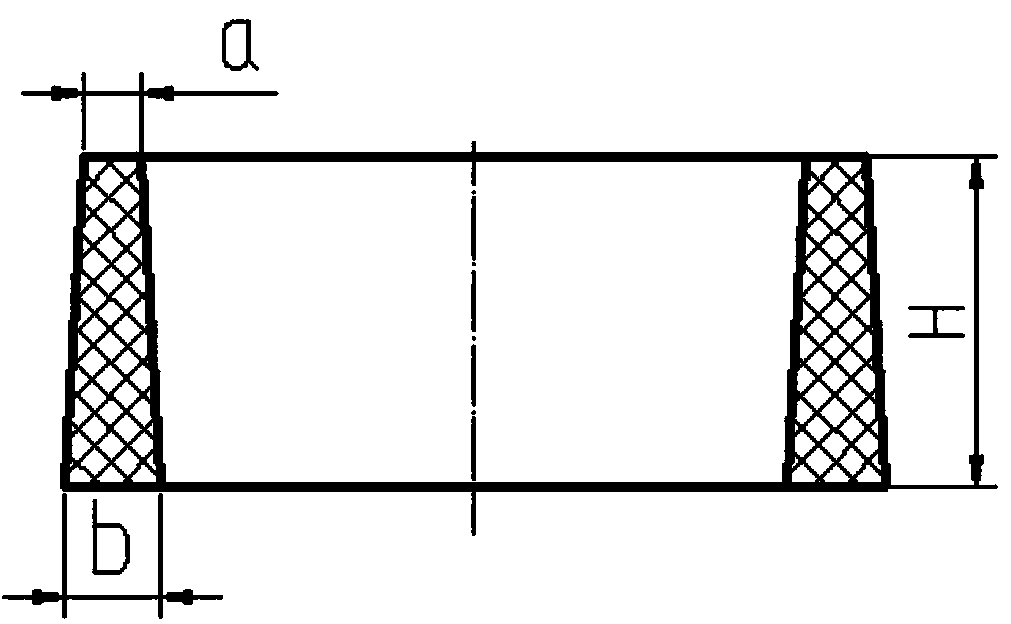

Flow control device for tundish of slab continuous caster and deslagging method thereof

The invention relates to a flow control device for a tundish of a slab continuous caster and manufacturing method thereof. The flow control device comprises a turbulent flow controller, a slag weir and a slag dam, wherein the upper edge of the slag weir is higher than the normally poured liquid steel highest liquid surface of the tundish but lower than the working surface of overflow port coating materials of the tundish, the slag weir and the slag dam are arranged in vertically staggered mode, and a through hole is respectively arranged at two ends of the slag dam. The centre distance a between the slag weir and the turbulent flow controller is 400-600mm, the centre distance b between the slag dam and the slag weir is 300-400mm, and the distance y between the working surface of overflow port coating materials of the tundish and the edge of the tundish is 120-160mm. The turbulent flow controller is of a structure made of combined composite materials, and the slag weir and the slag dam is respectively formed by molded pouring materials through casting molding in the intermediate temperate sintering process. By aid of the flow control device, injection residues of the tundish of slabs are reduced by more than 25% on year-on-year basis, service life of the flow control device is prolonged by one time on year-on-year basis, and continuous casting refractory material production cost is reduced by more than 30% on year-on-year basis.

Owner:LAIWU STEEL YINSHAN SECTION CO LTD

Combined-box alloy plating process of continuous casting crystallizer copper plate

The present invention provides a crystallizer copper plates group box-type nickel-cobalt alloy electroplating process for high-effectively continuously-casting plate blank, which includes: using two cleaned copper plate working surfaces oppositely arranged and other two non-metallic end plates to form a bottom less tank, placing said bottomless tank on the electroplating work platform to form electroplating bath, placing anode into the electroplating bath and injecting the sulfamate system electroplating solution with low cobalt content, powering-on to make electroplating, when the coating thickness is reached to 0.1-0.3 mm, discharging 20-60% of electroplating solution, raising cobalt content in the residual electroplating solution to 15-30%.

Owner:鞍山冶金集团工业有限公司鞍山一炼钢分公司

Method for installing fan-shaped sections of slab continuous casting machine

The invention discloses a method for installing fan-shaped sections of a slab continuous casting machine. The slab continuous casting machine comprises a steel ladle rotary table, a middle tank truck, a crystallizer, the fan-shaped sections, a secondary cooling chamber and the like. The method is characterized by comprising the following steps of: a, checking and accepting basis equipment of the fan-shaped sections; b, setting a sizing block; c, installing a guide rail; d, installing bottom plates of the fan-shaped sections; e, installing foundations of the fan-shaped sections; f, installing an arc frame; g, installing a process platform; h, assembling a lifting appliance; i, installing the fan-shaped sections; and j, installing a transmission device. The method for installing the fan-shaped sections of the slab continuous casting machine has the advantages that: installation steps are scientific and reasonable in design, the method is easy to operate, construction quality is safe and reliable, and installation engineering cost is reduced greatly.

Owner:MCC5 GROUP CORP SHANGHAI

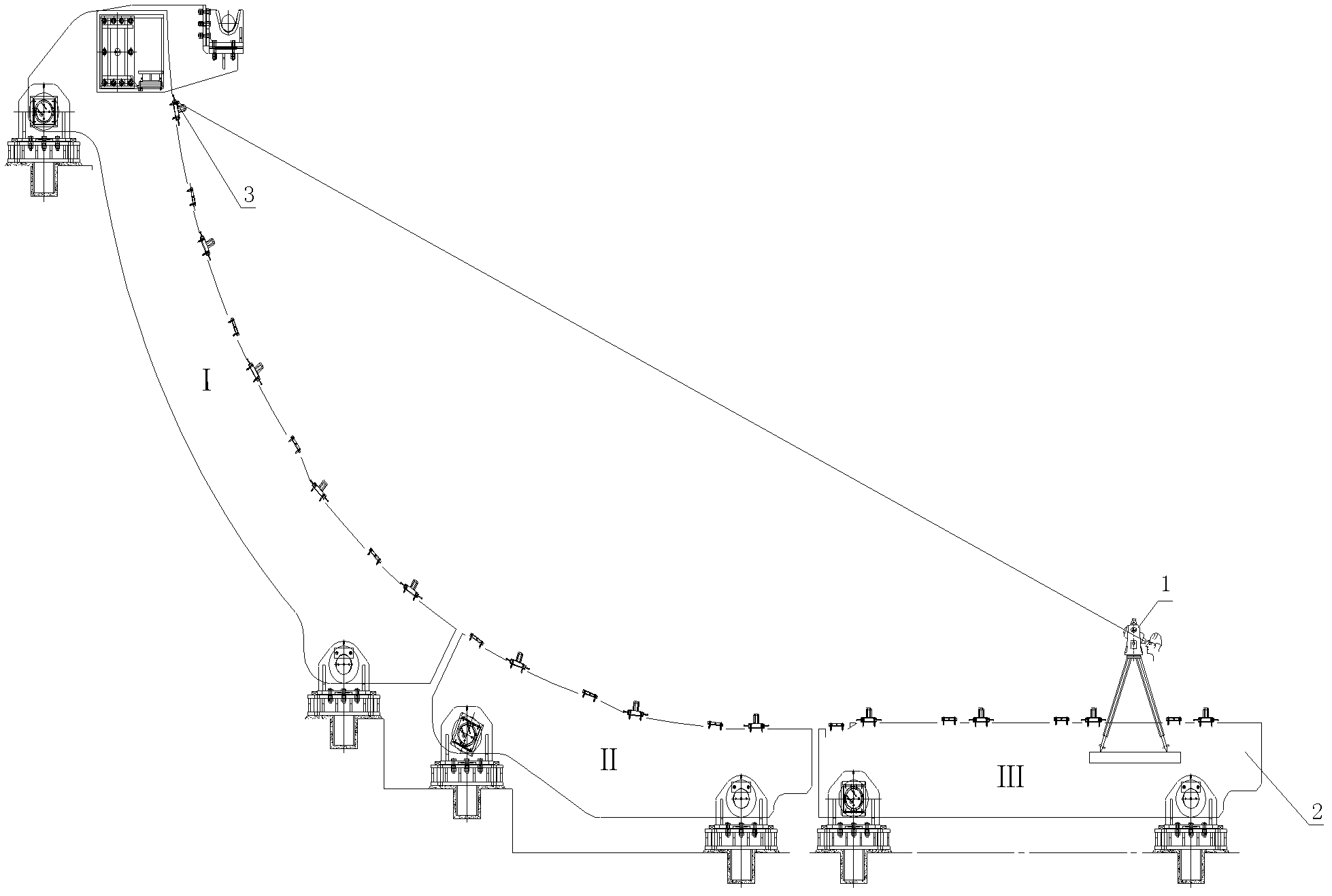

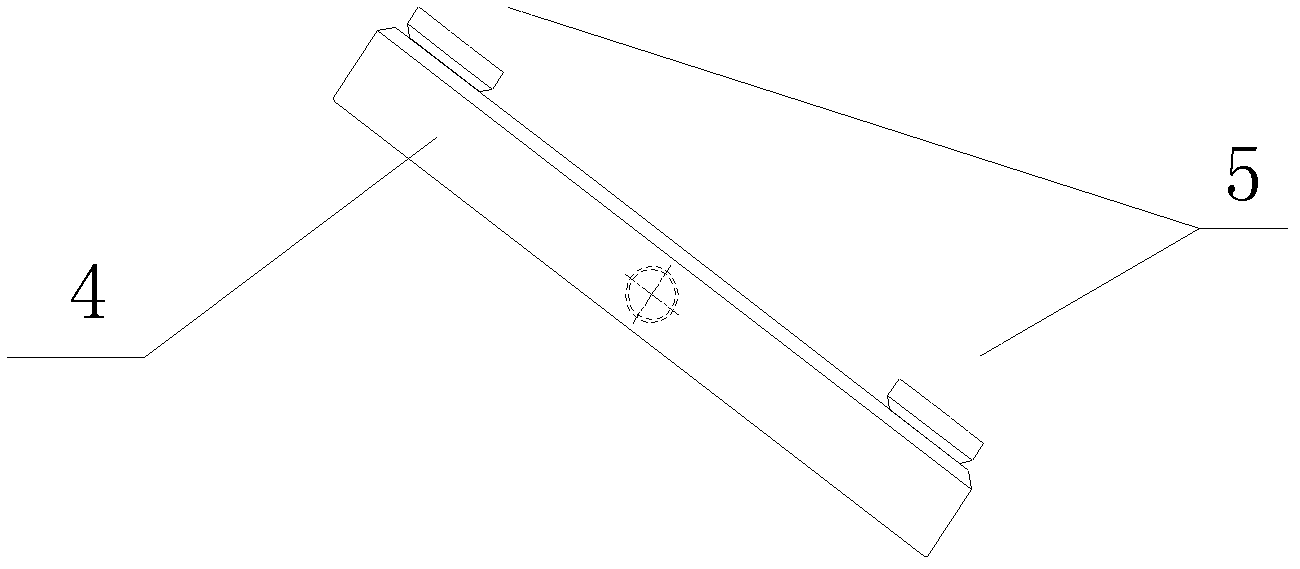

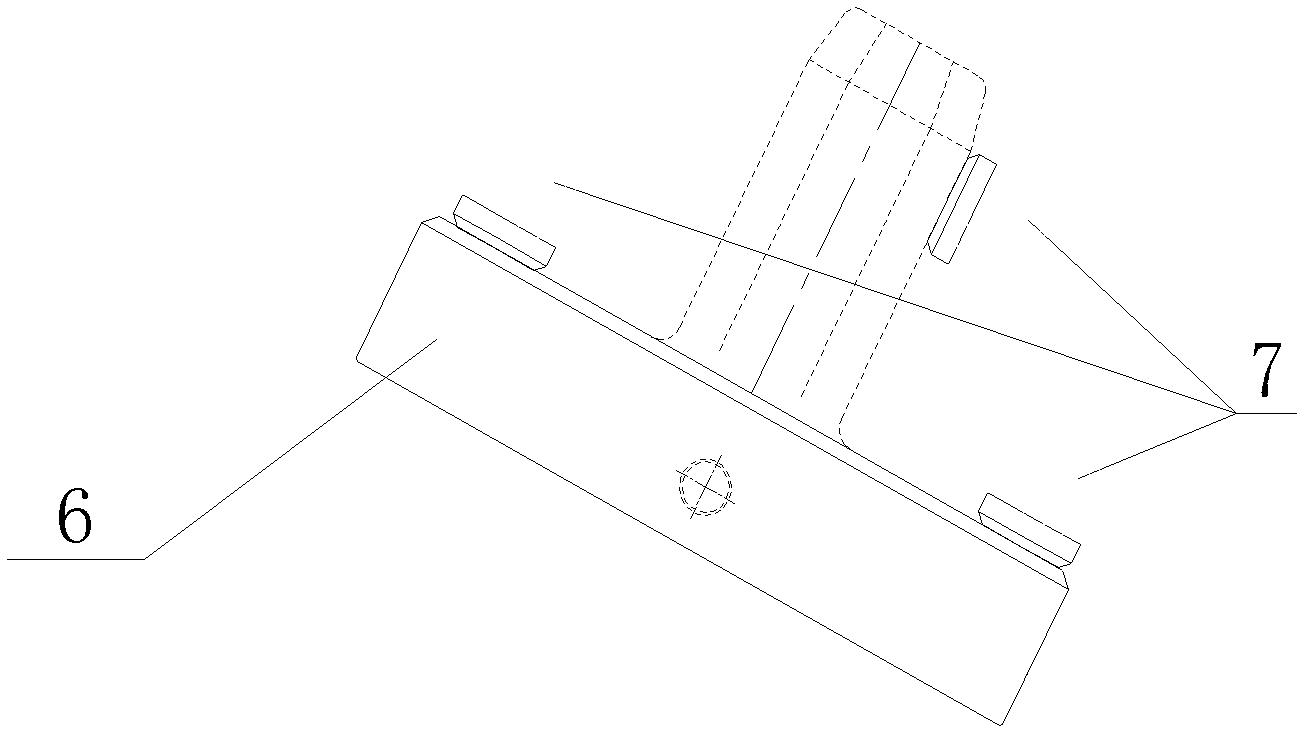

Arc detection method for slab casting machine based on holographic method

The invention provides an arc detection method for a slab casting machine based on a holographic method, belonging to the technical field of measurement control. The method comprises the following process steps: erecting a total station in the middle of a horizontal section III of a sector section supporting frame, and ensuring that all sector section supports can be observed through the instrument; transforming coordination systems; and acquiring the coordinates of supporting positions of the supports and simulating the positions. The industrial grade total station is utilized to detect the arc section of the slab casting machine in combination with sphere prisms, and the method is used for detecting the arc of the casting machine during the installation and maintenance of the casting machine so as to determine the adjustment quantity of each support, thereby ensuring the arc to achieve the ideal state. By comprehensively acquiring the raw data of the acting surfaces of the supports and utilizing a computer model to simulate the deviation states of the measuring positions, the problem of how to accurately position all the positions of the supports on the sector section of the slab casting machine is solved. The method has the following advantages: by knowing the sector section supporting structure, the industrial grade total station is utilized to detect the arc section of the slab casting machine in combination with the sphere prisms; and the arc adjusting efficiency and accuracy are greatly improved.

Owner:BEIJING SHOUGANG CONSTR GROUP

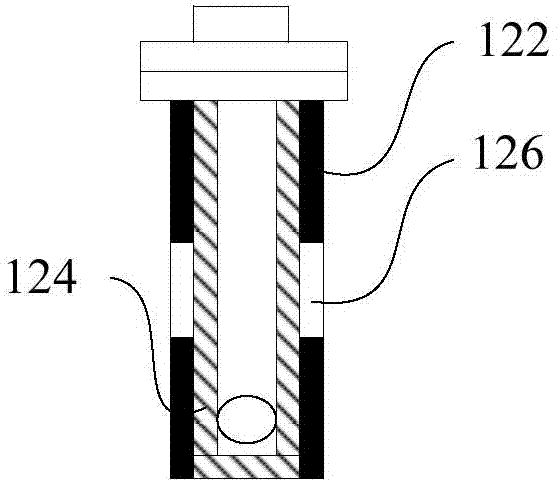

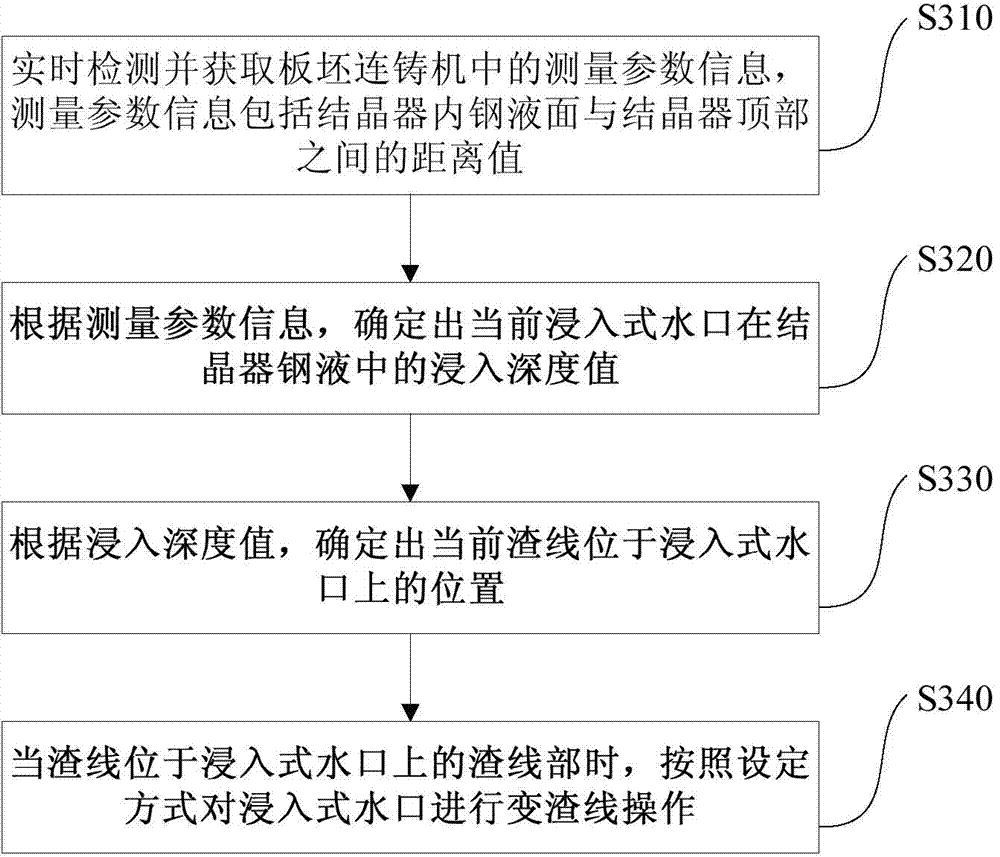

Method and device for submersed nozzle slag line of automatic adjusting slab caster

The invention provides a method and a device for a submersed nozzle slag line of an automatic adjusting slab caster, relates to the technical field of slab casting, and solves the problems that the slag line changing operation carried out by a manual way, a submersed nozzle cannot be accurately controlled, and the service life of the submersed nozzle can be severely affected by the partially excessive corrosion of the submersed nozzle in a crystallizer. The method comprises the following steps: detecting and acquiring measurement parameter information in the slab caster in real time, wherein the measurement parameter information comprises a distance value between the molten liquid surface of the crystallizer and the top part of the crystallizer; determining an immersion depth value of the existing submersed nozzle in the molten liquid in the crystallizer; determining the position of an existing slag line in the submersed nozzle according to the immersion depth value; carrying out slag line changing operation to the submersed nozzle according to a set way when the slag line is located on a slag line part above the submersed nozzle. The method for the submersed nozzle slag line of the automatic adjusting slag caster is mainly applied to a production process of steelmaking.

Owner:SHANDONG IRON & STEEL CO LTD

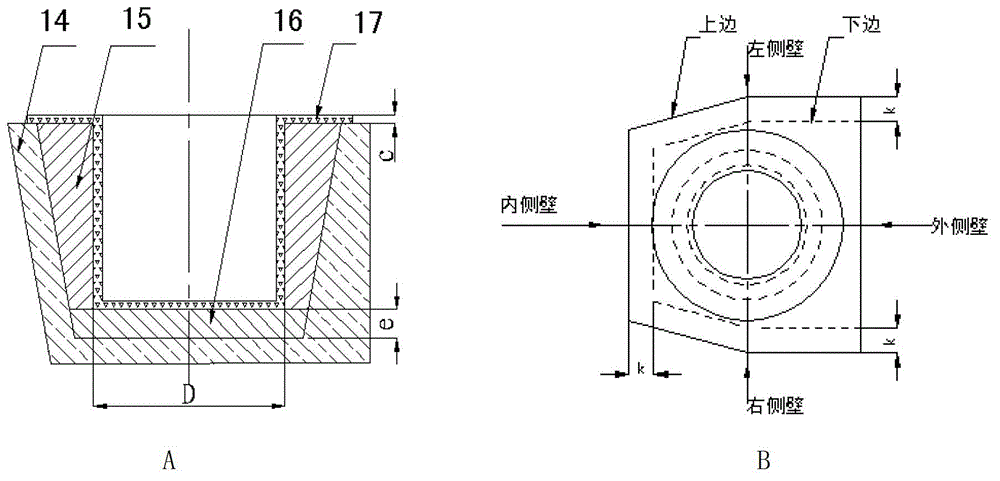

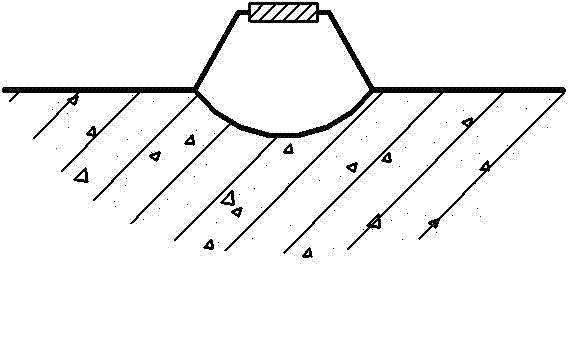

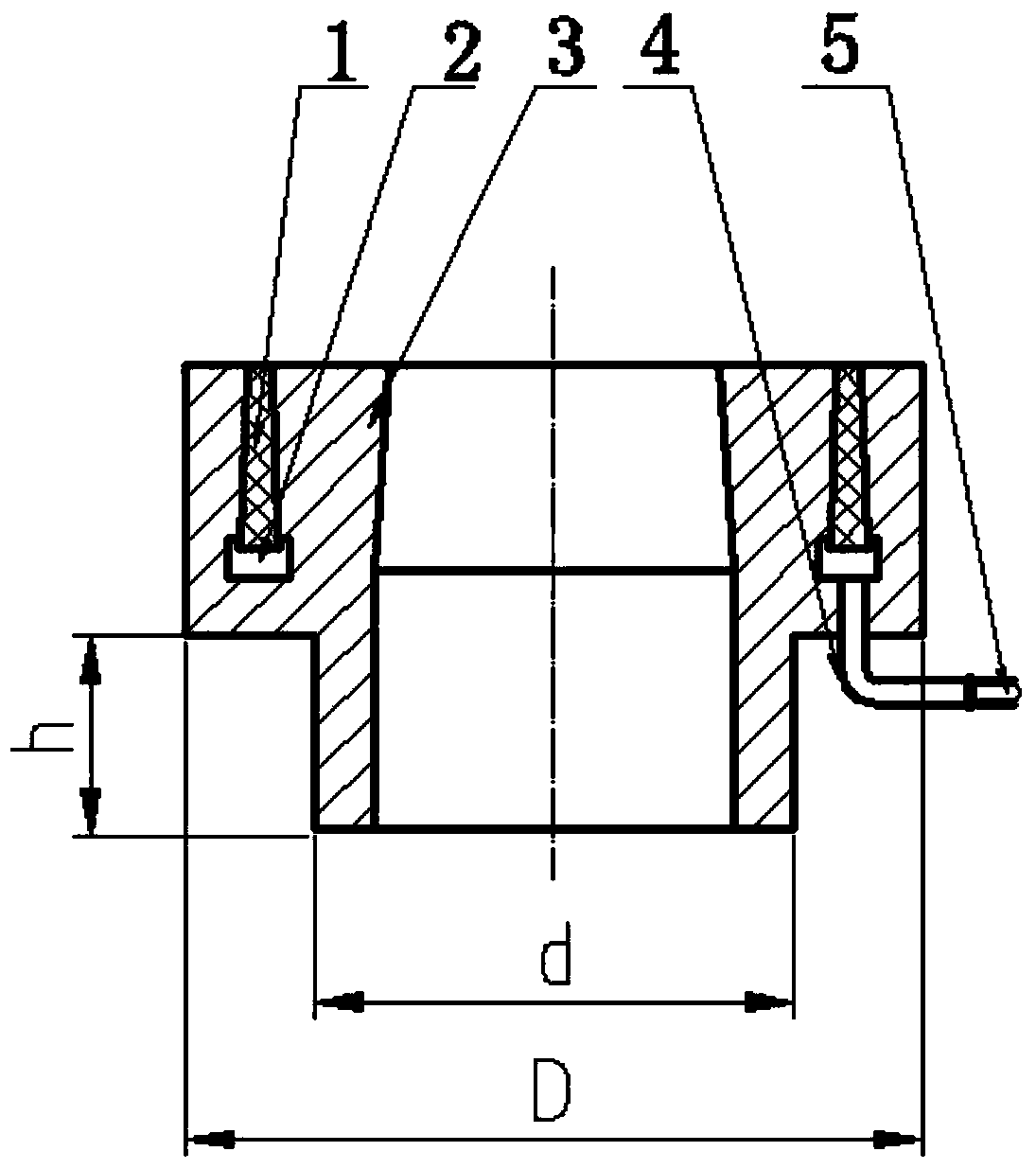

Breathable upper pocket block of continuously-cast intermediate ladle and installation method thereof

ActiveCN103862028AAlleviate over-eye problemsTo promote floatingMelt-holding vesselsSlab casterEngineering

The invention relates to a breathable upper pocket block of a continuously-cast intermediate ladle and an installation method thereof. The breathable upper pocket block comprises an upper pocket block body, wherein the upper pocket block body comprises an upper boss and a lower boss which are integrally formed; the outer diameter of the lower boss is less than that of the upper boss; a breathable ring and an air chamber are positioned in the upper boss of the upper pocket block body; The circular ring width of the breathable ring is gradually reduced from bottom to top; an air inlet pipe is L-shaped; after argon gas is blown in, an annular air curtain barrier is formed around an upper pocket, air washing is performed on molten steel which is about to enter into the upper pocket, floating and removal of impurities are promoted, meanwhile the problem of sleeve holes caused by the impurities attached to the inner wall of the upper pocket of the intermediate ladle in the process of producing low-carbon aluminum killed steel by virtue of a slab caster is reduced, the continuous casting furnace quantity of the intermediate ladle is improved, the continuous casting furnace quantity is improved from 6-8 to 10-12, and the continuous casting refractory material cost is proportionally reduced by more than 40%.

Owner:LAIWU IRON & STEEL GRP

Alloy structure steel 42CrMo slab and production method thereof

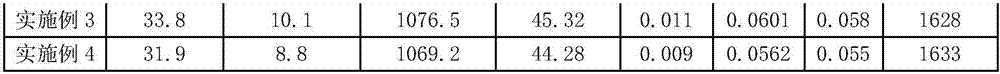

The invention relates to an alloy structure steel 42CrMo slab and a production method thereof. The method comprises the following steps: (1) charging molten iron containing less than or equal to 0.030% of S, less than or equal to 0.120% of P and less than or equal to 0.85% of Si into a furnace; (2) smelting steel rods containing more than or equal to 0.10% of C and less than or equal to 0.008% of P in the converter at the temperature of 1650-1680 DEG C; (3) performing LF (low frequency) refining and adjusting the target values of the components, so that C is 0.41-0.43% of C, Si is 0.23-0.27%, Mn is 0.58-0.62%, S is less than or equal to 0.010%, P is less than or equal to 0.015%, Cr is 0.92-0.98%, Mo is 0.17-0.19%, Cu is less than or equal to 0.20% of Cu and Ni is less than or equal to 0.30%, wherein the discharge temperature of molten steel is 1560+45 DEG C in a first furnace and 1550+45 DEG C in a continuous casting furnace; (4) performing VD (vacuum degassing) refining under the vacuum of less than or equal to 67Pa for 15 minutes, meanwhile, performing weak argon blowing stirring of 0.15-0.20MPa, feeding 140-150m of CaSi wire with the diameter of phi13mm after breaking, and then performing weak argon blowing for more than or equal to 10 minutes, wherein the discharge temperature is 1560+ / -5 DEG C in the first furnace and 1550+ / -5 DEG C in the continuous casting furnace; and (5) performing continuous casting: controlling the water distribution of each secondary cooling zone of a slab caster by adopting a primary water meter, wherein the light pressing interval fs is 0.45-0.95, the distribution coefficients are shown in table 2, and the pressing quantity is 3.8mm. The method meets the production requirements of large-section 42CrMo slabs.

Owner:TIANJIN IRON & STEEL GRP

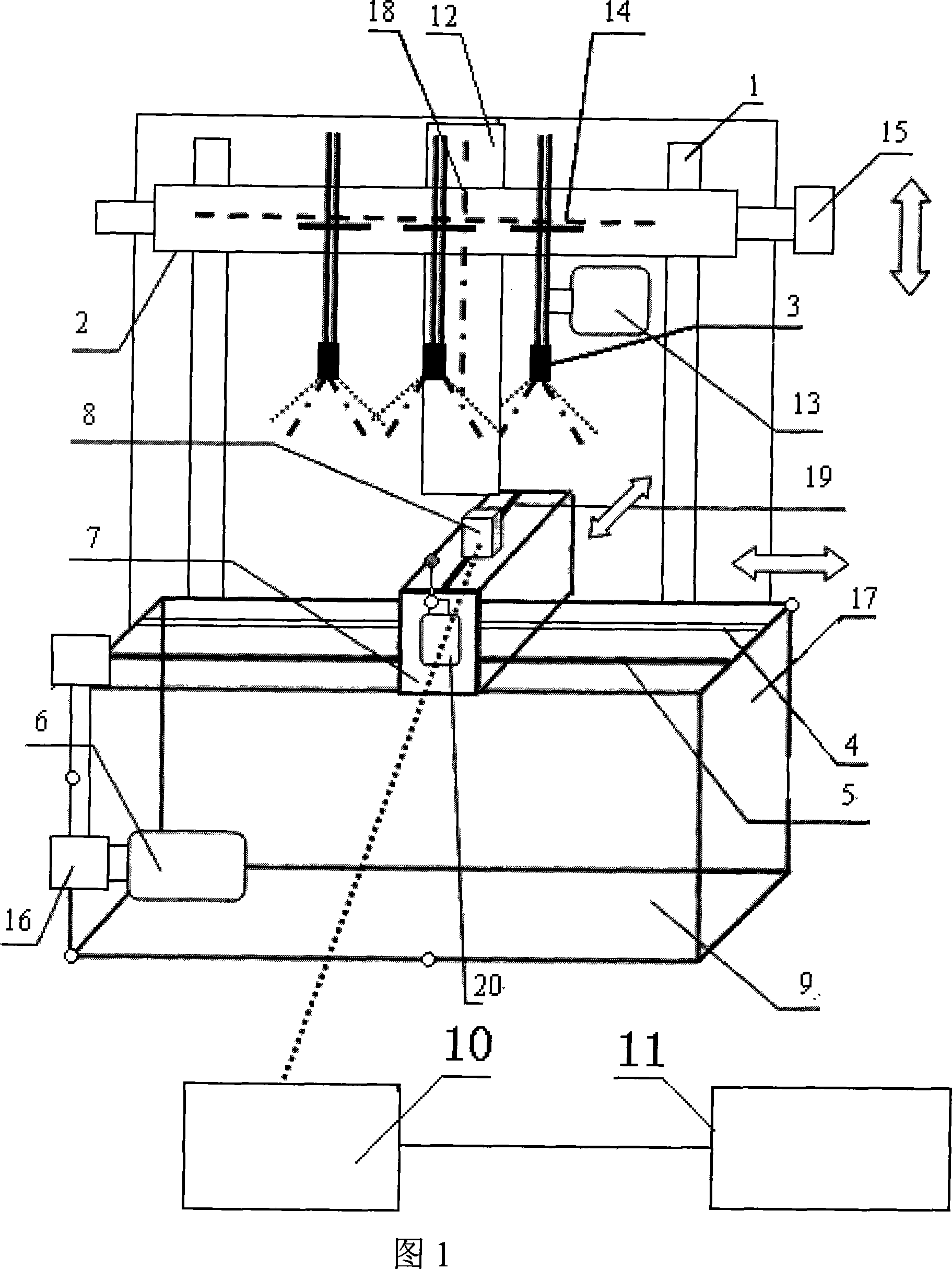

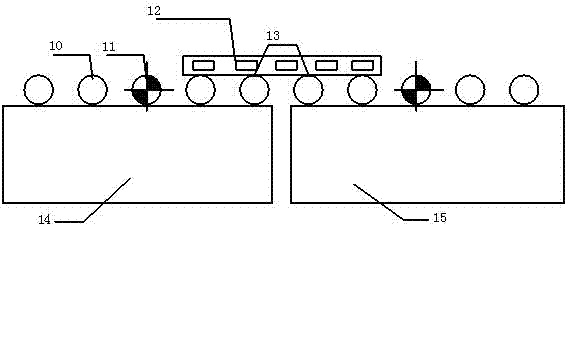

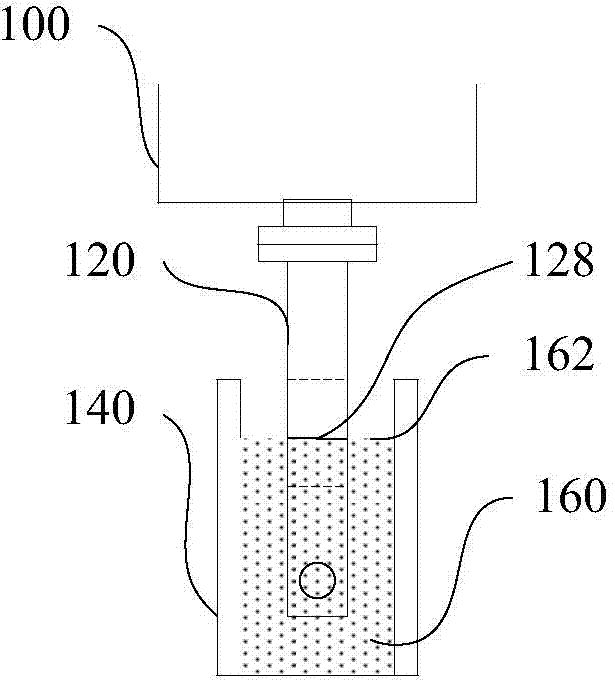

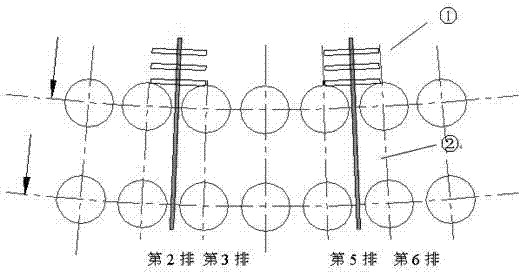

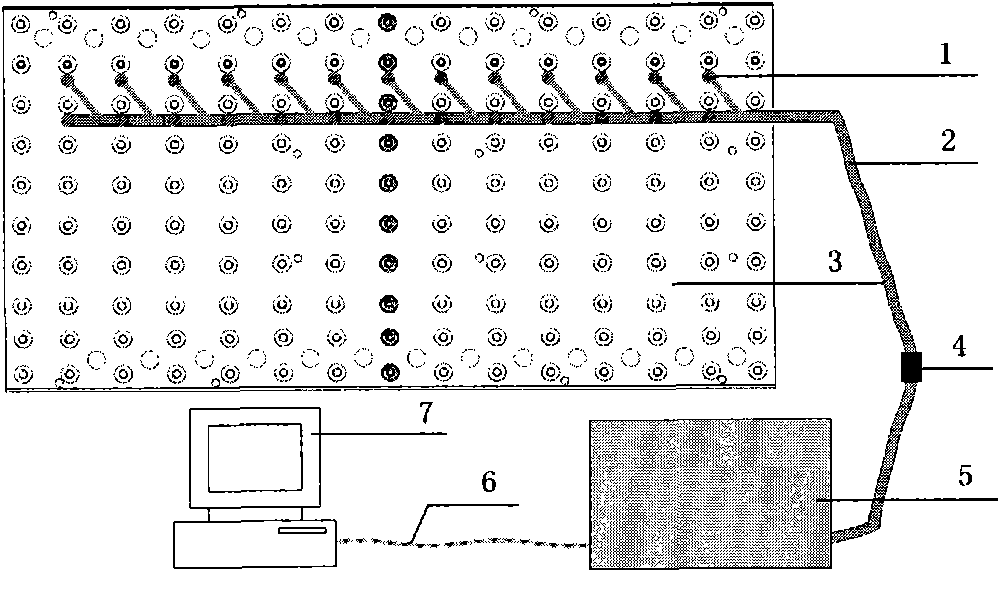

Slab caster two cold nozzle density measuring system

InactiveCN101187618AAccurate measurementShort measurement timeStructural/machines measurementSpecific gravity measurementSlab casterSignal conditioning

The invention belongs to the field of metallurgy equipments, and relates to a water flow density measuring system for a two-cooling nozzle of a slab caster. The invention is characterized in that the invention at least comprises a nozzle moving mechanism, a nozzle (3), a signal conditioning device (10), a data collecting and analyzing unit (11) of a computer, a water collector (8), and a sensing moving mechanism. The water collector (8) is fixed on the sensing moving mechanism and driven (8) to a checking position through the sensing moving mechanism, the nozzle (3) is fixed downwards on the nozzle moving mechanism and driven to the upper portion of the water collector (8) through the nozzle moving mechanism, water is sprayed by the nozzle (3), spraying densities of different spaces are given by a liquid level sensor (7) inside the water collector (8), a signal is used to output data to the data collecting and analyzing unit (11) of a computer after being amplified through the signal conditioning device (10) and gives a three-dimensional water spraying density inundation distributing map. The invention has precise measurement, short measuring time, and low measuring cost.

Owner:CHINA NAT HEAVY MACHINERY RES INSTCO

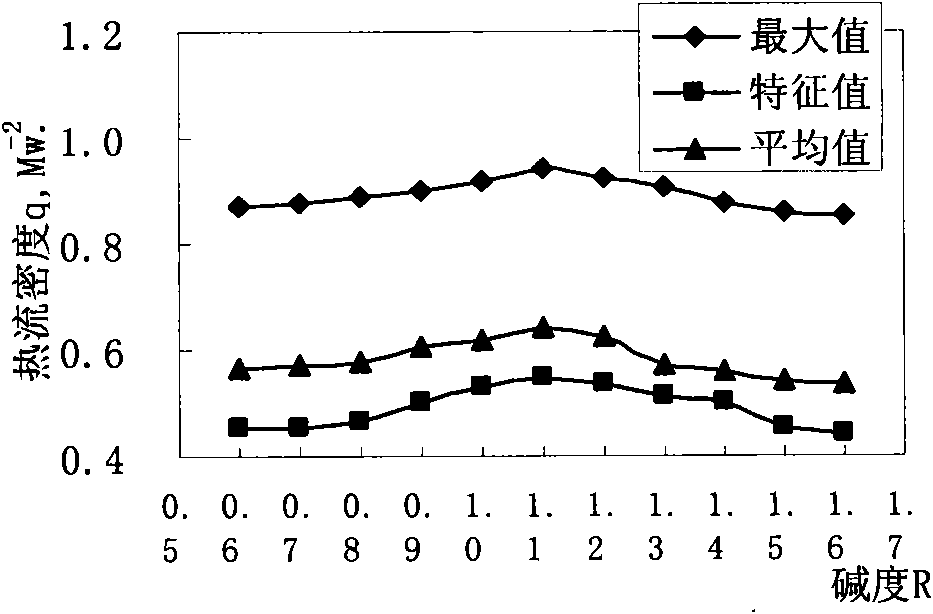

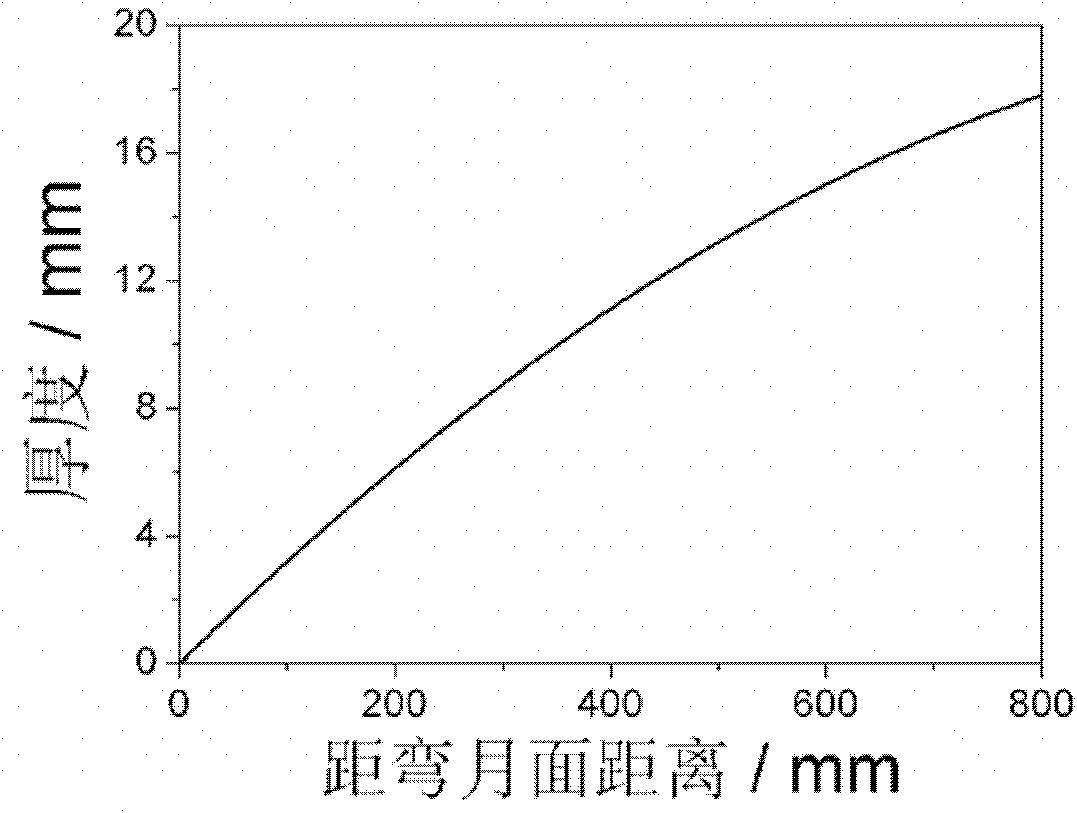

Multi-point continuous measurement and simulation method for solidification heat transfer process of molten steel in continuous casting crystallizer

InactiveCN102228973AGuaranteed uptimeComply with continuous casting operation requirementsContinuous measurementSlab caster

The invention discloses a multi-point continuous measurement and simulation method for a solidification heat transfer process of molten steel in a continuous casting crystallizer. Based on temperature distribution data measured in real time by a copper plate thermocouple of a slab casting machine crystallizer, the instantaneous heat flow density boundary condition of the crystallizer in unit areais converted by using casting machine parameters, steel grade data parameters and production process parameters, so that the solidification heat transfer process of the molten steel in the crystallizer is calculated. The method is simple, convenient, feasible, high in practicability and high in reliability, can be used for on-line multi-point continuous measurement of the solidification heat transfer process of the molten steel in the slab casting machine crystallizer, and provides a convenient path for regulation of a continuous casting production process in large-scale production.

Owner:WISDRI ENG & RES INC LTD

Cutting method and system for improving cutting precision of slab casting machine

The embodiment of the invention discloses a cutting method and system for improving the cutting precision of a slab casting machine. The method comprises the steps that slab cutting calibration coordinates are preset and stored in a database, slab head lower edge coordinates are obtained in real time and compared with the slab cutting calibration coordinates, an instruction signal is sent to a cutting machine if the slab head lower edge coordinates are the same as the slab cutting calibration coordinates, and the cutting machine receives the instruction signal and then cuts a slab. The lower edge of the head of the slab is detected through a camera, the coordinates of the lower edge are obtained in real time, and therefore the head position of the slab can be tracked accurately; when the coordinates of the lower edge are the same as the preset slab cutting calibration coordinates, the cutting machine is controlled to cut the slab. By the adoption of the method, the slab cutting precision of the slab casting machine is greatly improved.

Owner:SHANDONG IRON & STEEL CO LTD

Method for regulating fan-shaped section roller seams of continuous casing machine by using mathematical model

The invention relates to a method for regulating fan-shaped section roller seams of a continuous casing machine by using a mathematical model. The method is used for regulating the fan-shaped section roller seams of a Danieli plate blank continuous casting machine of metallurgical enterprises, and belongs to the technical field of continuous casting equipment. The method has the technical scheme that the inlet and outlet roller seams of fan-shaped sections are respectively and practically measured, and the deviation value with the standard roller seam is worked out; a mathematical model among the fan-shaped section inlet roller seam, the outlet roller seam deviation value and the roller seam value to be regulated is built, and the number of gaskets at an inlet clamping hydraulic cylinder part and an outlet clamping hydraulic cylinder part is respectively regulated. The method has the advantages that only the fan-shaped section inlet roller seam and the outlet roller seam need to be measured before the regulation, the difference value with the standard roller seam is worked out and is directly introduced into a mathematic model equation set, and the increase and decrease quantity of the inlet and outlet roller seam gaskets can be obtained. The regulation of the fan-shaped roller seams can be realized in one step, one hour is needed at most, the work efficiency is improved, a great amount of labor is saved, and wide popularization and application prospects are realized.

Owner:HANGANG GRP HANBAO IRON & STEEL

Production method of low-carbon steel

The invention discloses a production method of low-carbon steel. The production method mainly aims to solve the technical problems that normal pouring of a slab caster cannot be satisfied and the production cost of the low-carbon steel is high because inclusions in the low-carbon steel which is smelted by a converter are difficult to control in the prior art. According to the technical scheme, the production method comprises the following steps of performing convertor smelting, converter low-temperature tapping and deoxidation, performing molten steel treatment at an argon blowing station, and refining molten steel in a refining furnace. The molten steel produced by adopting the production method has high cleanliness, the average content of total oxygen in the molten steel is 16.5 ppm, the average content of phosphorus is 95 ppm, the content of phosphorus as a harmful element in the molten steel is greatly reduced, and the production cost of the molten steel per ton steel is reduced by 13 Yuan.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

Dynamic water distribution model of slab caster

The invention discloses a dynamic water distribution model of a slab caster. The dynamic water distribution model comprises seven secondary-cooling areas of the caster. The secondary-cooling areas include a first cooling area, a second cooling area, a third cooling area, a fourth cooling area, a fifth cooling area, a sixth cooling area and a seventh cooling area. The actual water consumptions of the secondary-cooling areas meet the requirement of a formula that Q=AV<2>+BV+C. Products produced by the caster include common-carbon low-alloy steel and high-medium-carbon alloy steel; each year is divided into three stages, and surface temperatures of casting blanks are controlled according to slab equipment and climate changes and based on produced steel products; model parameters of the dynamic water distribution model are adjusted according to the corresponding formula to realize dynamic control. According to changes of climate and external conditions and characteristics of slab production, a crystallizer and a secondary-cooling water distribution model are adjusted in time, the dynamic water distribution model for slabs is created, surface quality and internal quality of the casting blanks of the slabs are stabilized, and accordingly, the quality problems of the casting blanks due to changes of facts such as external climate are solved.

Owner:GANSU JIU STEEL GRP HONGXING IRON & STEEL CO LTD

Method for automatically detecting and controlling segment roll gap by adopting balancing oil cylinder

InactiveCN101704082AAchieving automatic adjustment and maintaining the requirementsDefy gravitySlab casterEngineering

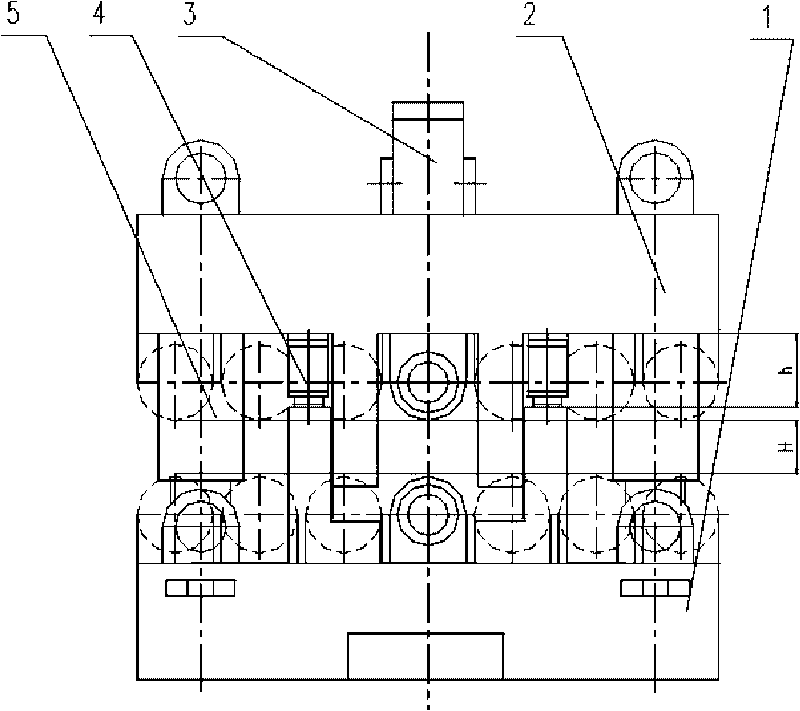

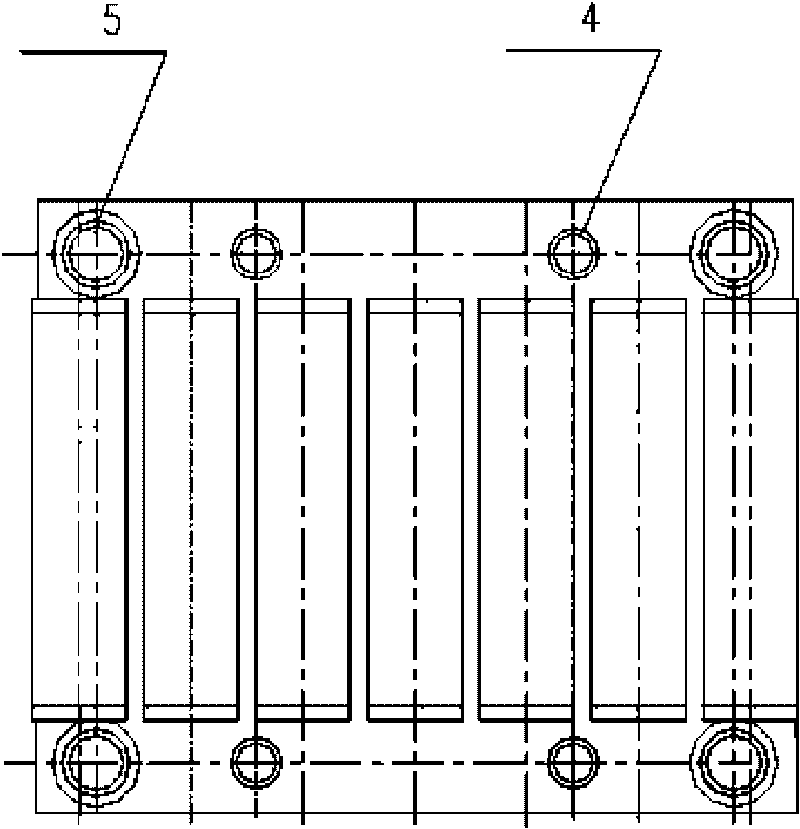

The invention relates to manufacture of large panels, strips, sectional bars and the like in ferrous metallurgy industry, in particular to a method for automatically detecting and controlling a segment roll gap by adopting a balancing oil cylinder, which is characterized by at least comprising a lower frame with a guide roll, an upper frame with a guide roll, a hold down roll device for driving a dummy bar and a casting blank, balancing oil cylinders used for roll gap detection and control, and a clamp oil cylinder for connecting the upper frame and the lower frame and keeping the roll gap, wherein the hold down roll device is fixed in the upper central position of the upper frame, and the balancing oil cylinders are evenly distributed between the upper frame and the lower frame, so that a plate blank continuous casting machine dynamically and lightly presses the solidified end of the casting blank in the production process of pouring steel, the quality defects of center segregation, rarefaction and the like of the casting blank can be effectively avoided, and the steel quality and the metal yield are improved.

Owner:陕西多伦科技发展有限公司 +1

Method for processing blank stop of slab casting machine

The invention discloses a method for processing blank stop of a slab casting machine. The method is characterized in that when blank stop is caused, a fan-shaped section roll gap is widened by 5 to 20mm to reduce blank-pulling resistance, and then a fan-shaped section driving roll is operated to pull casting blanks from two cold rooms at the speed of 0.1 to 1.0m / min; if the casting blanks are still not moved, a part casting blank cutting method is performed to reduce the resistance to bending and straightening of the casting machine, wherein a burning oxygen-blowing steel pipe cutting method is adopted in the part casting blank cutting method, a steel pipe is made from Q235B and is 12mm in wall thickness, 5 to 12mm in inner diameter and 1 to 5mm in length, the tail end of the steel pipe is connected with an oxygen pipe, the purity of oxygen is more than 99 percent, the cut casting blanks are not completely cut, and the residual connecting thickness of the casting blanks is 10 to 60mm. Compared with the prior art, the method has the advantages that the speed of processing blank stop of the slab casting machine can be effectively increased, the damage to equipment by accidents is reduced, and the replacing frequency of a fan-shaped section is reduced.

Owner:ANGANG STEEL CO LTD

Rapid testing device of readiness of thermocouples of crystallizer of continuous casting machine

InactiveCN101905300ATimely processingReduce setup timeCasting parameters measurement/indication devicesSlab casterSignal on

The invention relates to a rapid testing device of readiness of thermocouples of a crystallizer of a continuous casting machine, a bus cable is utilized for sending all thermocouple signals on a copper plate of the crystallizer to a PLC signal acquisition module, the PLC is used for converting the thermocouple signals of all channels into the form of real number values and analyzing analog signals acquired by each channel and sending diagnosis information to a monitoring computer with the OPC technology, the computer is utilized for utilizing the visual graphic technology to display all thermocouple data on a monitor screen in the form of a histogram and the values and displaying the diagnosis information of the thermocouples with problems in the form of alarm information, and the database technology is utilized for filing all the acquired thermocouple data, thereby being capable of playing back the filed historical data, and leading a monitoring program to have the functions of producing statements, outputting and printing. The rapid testing device can directly display the values of all the thermocouples, carry out timely treatment on the thermocouples with the problems according to the diagnosis information and improve the efficiency of the readiness process step of the crystallizer of the slab continuous casting machine.

Owner:杜波

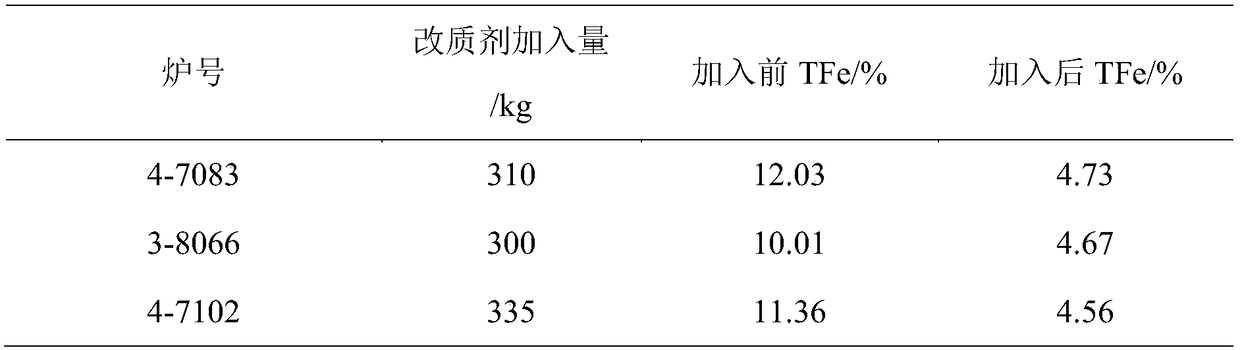

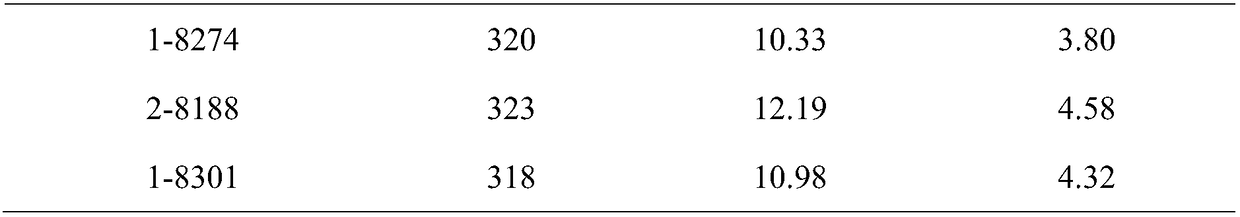

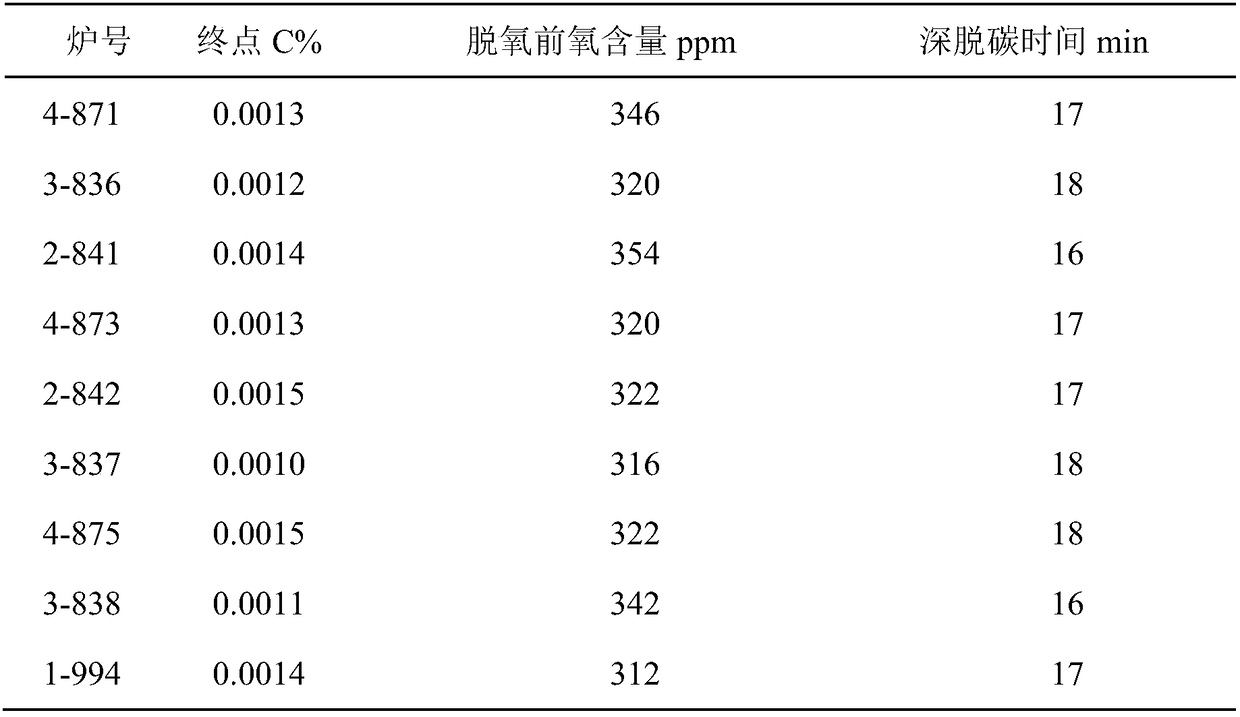

Method for smelting ultra-low carbon steel by low oxygen site in whole process

The invention discloses a method for smelting ultra-low carbon steel by low oxygen site in the whole process. The ultra-low carbon steel comprises the chemical components of, by mass, no more than 0.0030% of C, 0.01% of Si, 0.08-0.18% of Mn, no more than 0.015% of P, no more than 0.010% of S and 0.015-0.055% of Al<sol>. The process of KR stirring desulfuration, a top-bottom combined blown converter, an RH vacuum refining furnace and a slab continuous casting machine is adopted for smelting production. According to the method, the mode of converter terminal low-oxygen and slag modification lowtotal iron, RH furnace low oxygen site deep decarbonization, continuous casting machine fully-protected argon sealing and tundish breathable block brick argon blowing is adopted, the total iron is controlled within 5% after slag modification, end-point oxygen after RH furnace deep decarbonization is controlled to be about 350 ppm, casting blank oxygen is controlled within 20 ppm, the zero-order ratio of inclusions reaches 97% or above, RH end-point carbon is controlled within 20 ppm, and the casting sequence of the continuous casting machine reaches 10 times. The castability and casting blankquality of ultra-low carbon steel such as DDQ-grade cold rolled steel are improved, the number of inclusions in the steel and the shape control level of the steel are improved, and the percent of passof steel blanks is effectively improved.

Owner:SHANDONG IRON & STEEL CO LTD

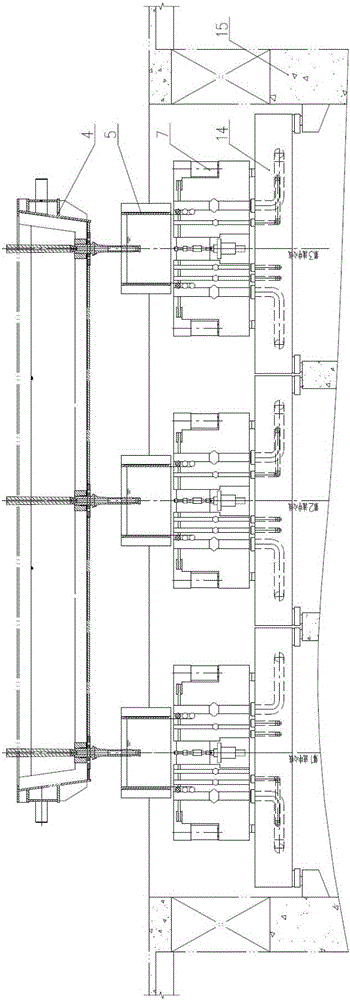

Three-machine three-strand slab continuous casting machine production line

The invention discloses a three-machine three-strand slab continuous casting machine production line which is specially matched with the rapid smelting period of a large converter. Three water outlets are formed in the bottom of an intermediate tank of the production line. A one-strand slab continuous casting machine is correspondingly arranged on the lower portion of each water outlet. The two sides, in the inner and outer arc direction, of each vibration device are each provided with a vibration oil cylinder and leaf springs, wherein the two vibration oil cylinders are set to be the same in motion stroke, and the leaf springs are set to be the same in mounting angle. All loads of the vibration devices are transmitted to a secondary cooling chamber concrete wall through vibration supporting structures. Sector segment transmission devices of the casting machines on the left side and the right side are arranged outside the secondary cooling chamber concrete wall, and motors and speed reducers are directly connected with drive rollers of horizontal sector segments through couplers. A transmission device of the middle slab continuous casting machine is a suspended transmission device. Productivity can be obviously increased, existing two-strand continuous casting machines can be conveniently modified into three-machine three-strand continuous casting machines, the process layout is compact, and the economic performance is excellent.

Owner:CONTINUOUS CASTING TECH ENG OF CHINA

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com