Low-carbon steel continuous casting and rolling production line and production technology thereof

A technology of continuous casting, continuous rolling and production process, applied in the field of steel rolling, can solve the problems of insufficient temperature control ability, unable to meet temperature control at the same time, unable to guarantee the outlet temperature and coiling temperature requirements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

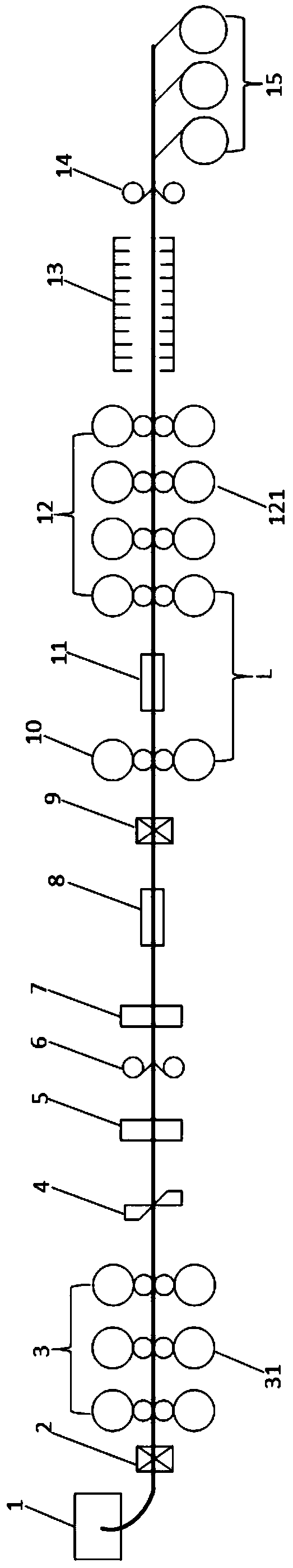

Embodiment 1

[0029] The mass percentages of the chemical composition of the low carbon steel billet raw materials are: C: 0.04%, Mn: 0.07%, Si: 0.03%, P: 0.012%, S: 0.002%, Als: 0.022%, and the balance is Fe and impurities, After the raw materials are smelted, they are cast into billets in a continuous casting machine with a casting speed of 5.5 m / min and a thickness of 90 mm.

[0030] The cast slab at the exit of continuous casting is roughly descaled by 20MPa high-pressure water, and then enters the rough rolling unit for rolling. The rough rolling inlet temperature is 1010°C, and then performs pendulum shearing, pushing out, stacking plates, drum flying shears, and waste removal in sequence. and other devices, and then enter the induction heating furnace 8 for heating, the temperature of the induction heating outlet is controlled to 1010°C, and then 20MPa high-pressure water is used for descaling, and then enters the middle rolling stand 10, and the middle rolling inlet temperature is 97...

Embodiment 2

[0033] The mass percentages of the chemical composition of the low carbon steel billet raw materials are: C: 0.013%, Mn: 0.08%, Si: 0.03%, P: 0.013%, S: 0.001%, Als: 0.028%, and the balance is Fe and impurities, After the raw materials are smelted, they are cast into billets in a continuous casting machine with a casting speed of 5.5 m / min and a thickness of 90 mm.

[0034] The cast slab at the exit of continuous casting is roughly descaled by 20MPa high-pressure water, and then enters the rough rolling unit for rolling. The rough rolling inlet temperature is 1010°C, and then performs pendulum shearing, pushing out, stacking plates, drum flying shears, and waste removal in sequence. and other devices, and then enter the induction heating furnace 8 for heating, the induction heating outlet temperature is controlled to 1010°C, and then 20MPa high-pressure water is used to descale, and then enter the middle rolling stand 10, the middle rolling inlet temperature is 960°C, and then ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com