Universal spherical joint supporter with anti-loosening position-limiting structure

A technology of limiting structure and universal spherical hinge, applied in building structure, construction and other directions, can solve the problems of low bearing performance, shortened bearing life, poor reliability, etc., and achieve high shear and compressive bearing capacity , the effect of enhanced compressive bearing capacity and good bearing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

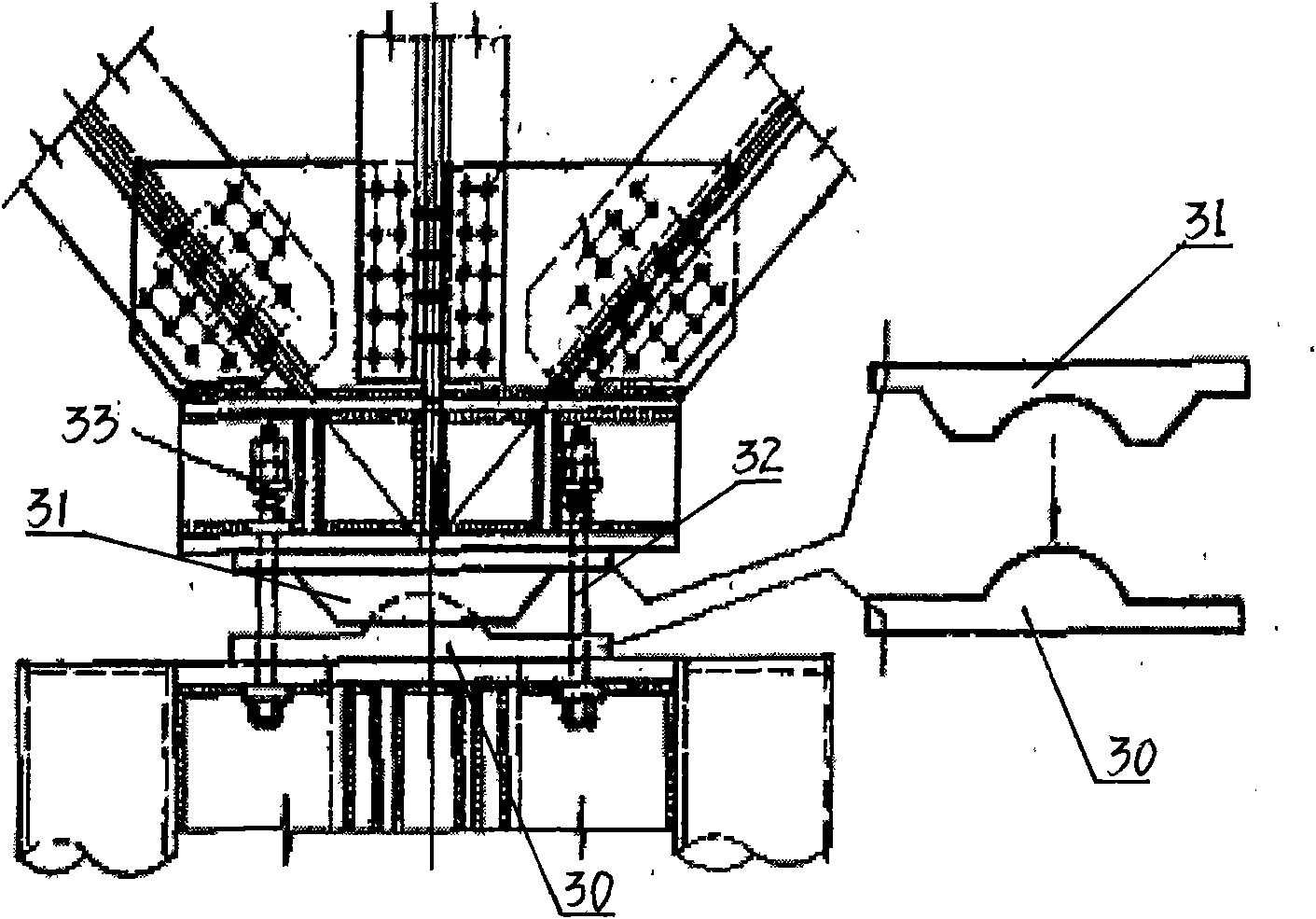

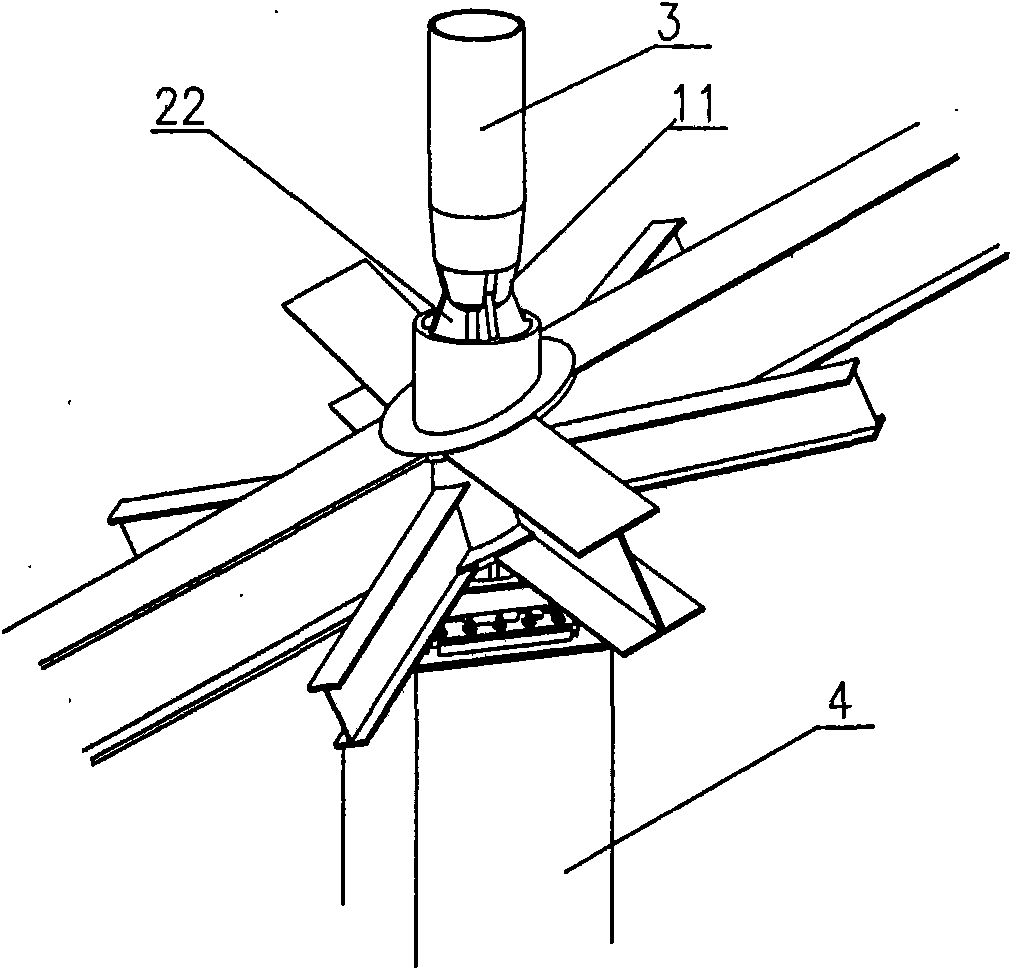

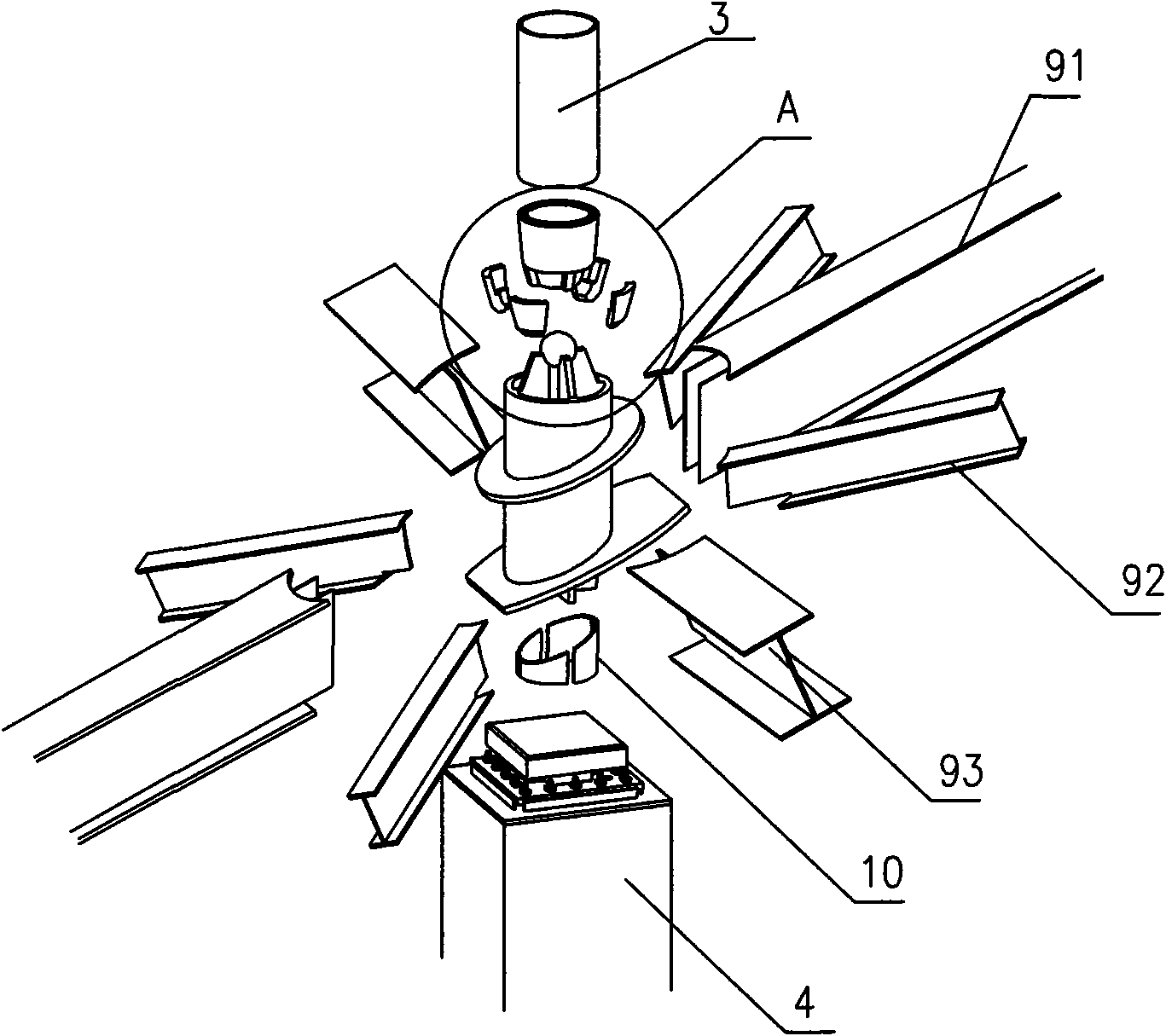

[0049] like Figure 2-6 As shown, the present invention is a kind of universal spherical joint support with anti-loosening limit structure, which includes the main spherical joint structural member composed of the main top seat 1 with a concave spherical surface and the main base 2 with a convex spherical surface. The main base 2 And the connecting structure used on the support to be connected to the grid frame or the cantilever mast 3 and to the pier 4 respectively. The main base 2 is composed of a base body 21, four stiffening plates 22 and steel balls 24. On the base of the main base 2 A steel rod 23 for supporting the steel ball 24 is added at the central axis of the body 21, wherein the stiffening plate 22, the steel rod 23, the steel ball 24 and the base body 21 are integrally cast, and the steel ball 24 is close to a complete spherical shape, which is the main body. The convex ball member in the base 2, the stiffening plate 22 is vertically distributed in the base body ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com