Gem cone awning processing technique

A processing technology and cone technology, applied in the field of gemstone cone awning processing technology, can solve problems such as poor visual effect, influence architectural design effect, single effect, etc., achieve good lighting effect, increase architectural effect, and beautiful appearance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The preferred technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0023] Gem cone awning processing technology of the present invention comprises the following steps:

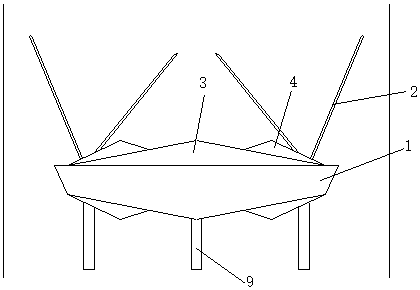

[0024] 1-Processing the overhang support surface 1, the overhang support surface 1 is a plate-shaped plane or a large-diameter arc-shaped surface;

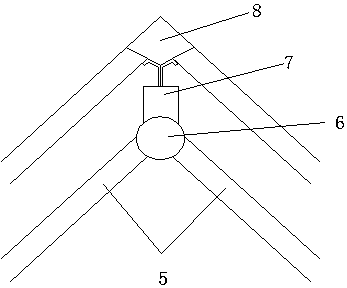

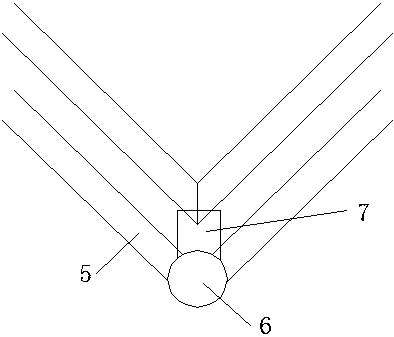

[0025] 2-Set a support pipe 5 above the overhang support surface 1, connect a seamless steel pipe 6 at the upper end of the support pipe 5, set a support connection structure 7 on the seamless steel pipe 6, connect the support connection structure 7 to a glass or aluminum plate, and overhang the support surface 1 A plurality of quadrangular glass cones 3 arranged in parallel are formed on the top, and triangular aluminum plate cones 4 are arranged at the gaps on both sides of every two quadrangular glass cones 3;

[0026] 3-Set V-shaped corner closing material 8 at the gap between t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com