Slope supporting structure and slope retaining and draining integrated system

A technology for supporting structures and slopes, which is used in foundation structure engineering, sheet pile walls, excavation, etc., can solve the problems of insufficient supporting strength of supporting structures, and achieve strong elasticity and toughness, large shear bearing capacity, large The effect of stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

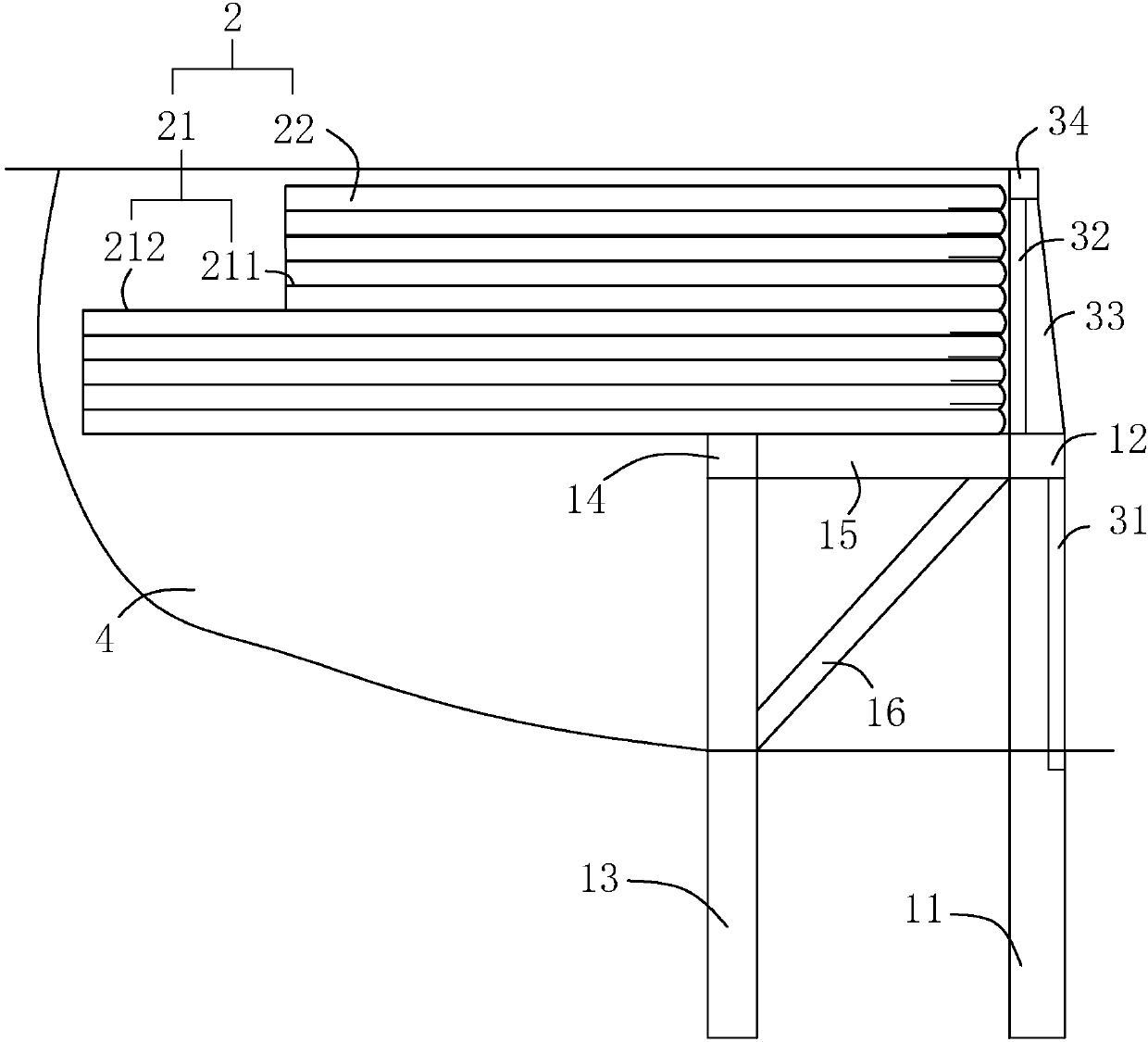

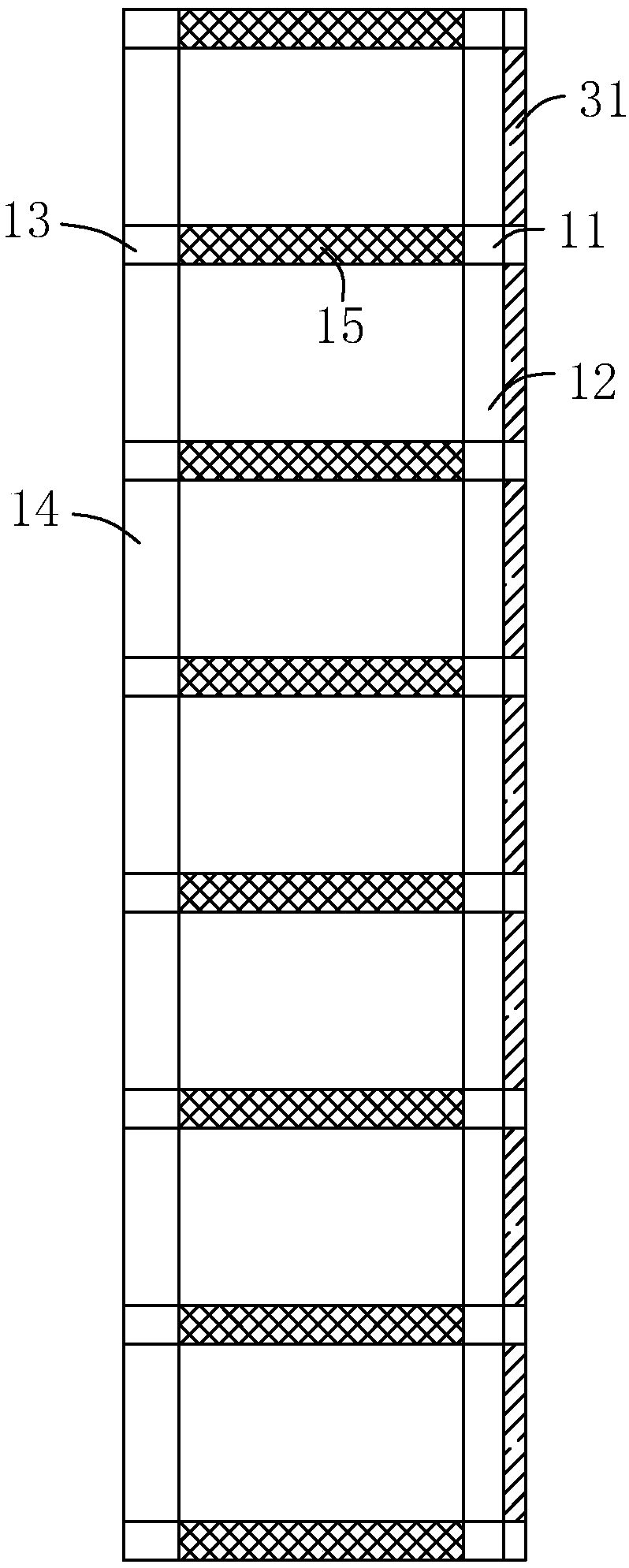

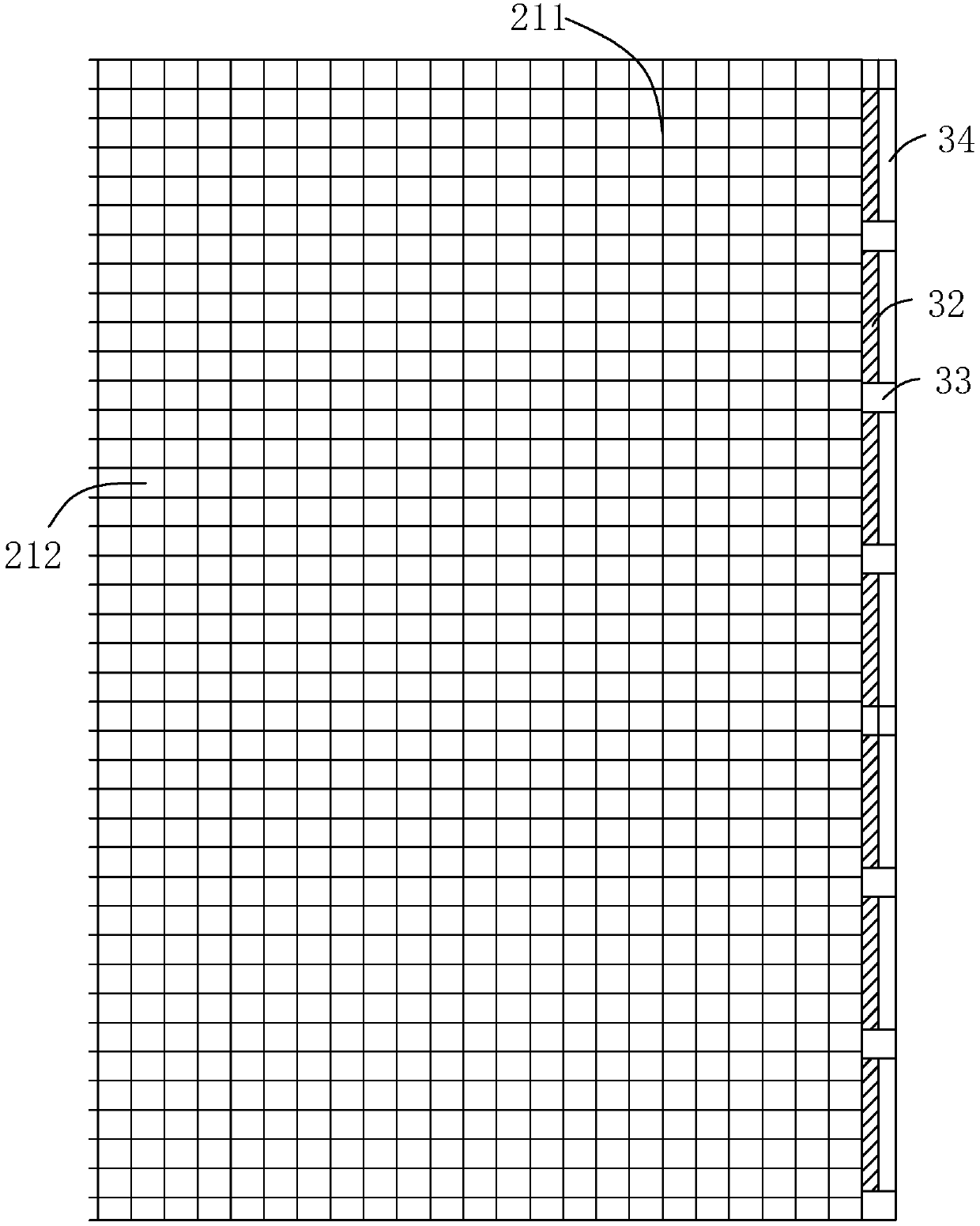

[0052] Embodiment one: a kind of slope support structure, such as figure 1 As shown, it includes: a pile foundation assembly buried in the rock and soil layer of the slope as a supporting base; The flexible reinforced soil component 2 of the body; and the barrier component carried on the pile foundation component for preventing the flexible reinforced soil component 2 and the compacted soil layer 4 from sliding down.

[0053] Specifically, the pile foundation assembly includes: a plurality of first supporting piles 11 buried on the side of the rock and soil layer of the slope near the bottom of the slope and arranged along the extending direction of the slope; fixed between the adjacent first supporting piles 11 Between the first crown beam 12; a plurality of second support piles 13 buried in the rock and soil layer of the slope, the second support piles 13 correspond to the first support piles 11 one by one; fixed between the adjacent second support piles 13 Between the seco...

Embodiment 2

[0065] An integrated system for slope support and drainage, comprising: the slope support structure described in Embodiment 1; and a plurality of drainage pipes 5 buried in the compacted soil layer 4 and passing through the barrier assembly; specifically, A through hole is opened on the first barrier part 31, and the drain pipe 5 is plugged into the through hole and arranged obliquely downward, the inclination angle is 5-10°, 10° in this embodiment, and the drain pipe 5 adopts three-dimensional porous The flexible permeable pipe, the permeable pipe is supported by the anti-rust spring steel ring from the inside to the outside, thus forming a high-pressure-resistant soft structure. The inside of the pipe is bonded with non-woven fabric as a lining filter. The outer body is wound with polypropylene filaments, the diameter of the drain pipe 5 is 80-120 mm, and the diameter of this embodiment is 100 mm, and the water permeability coefficient is ≥ 0.02 cm / sec, so that the drain pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com