Patents

Literature

82results about How to "Reduce binding force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

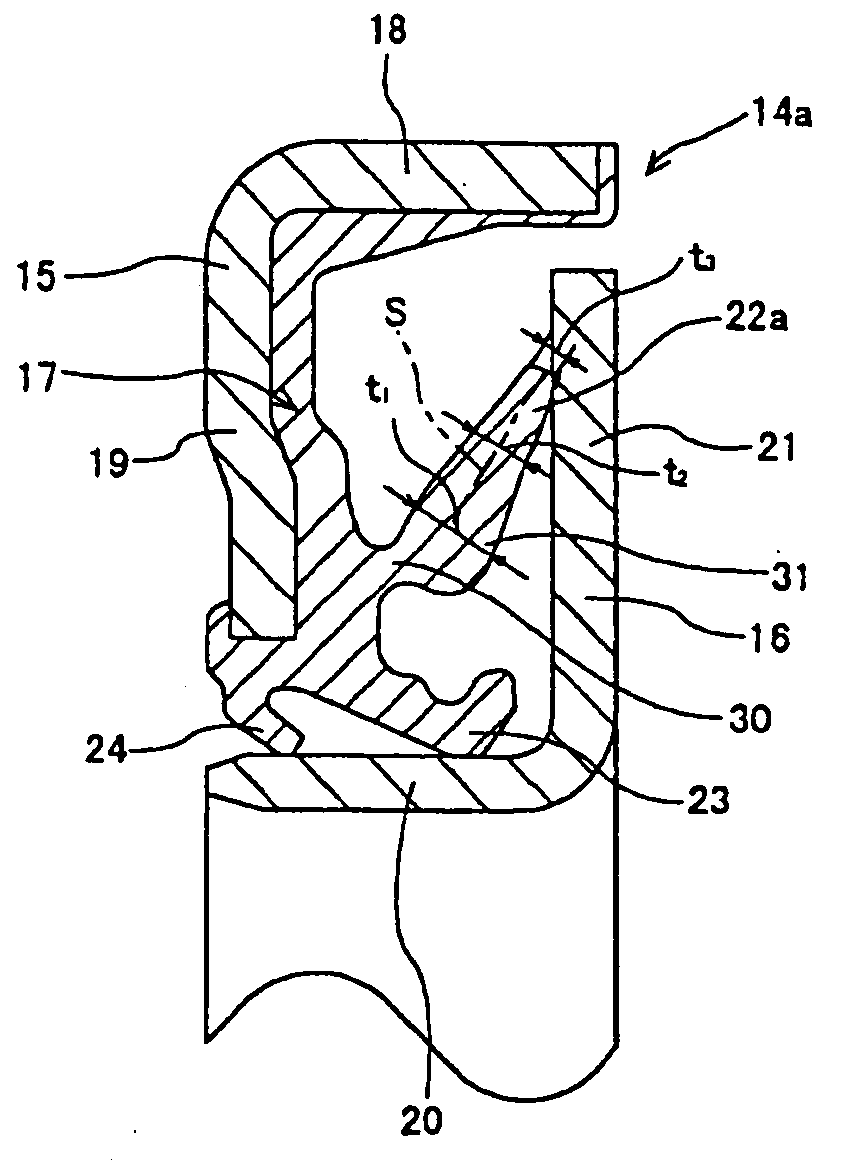

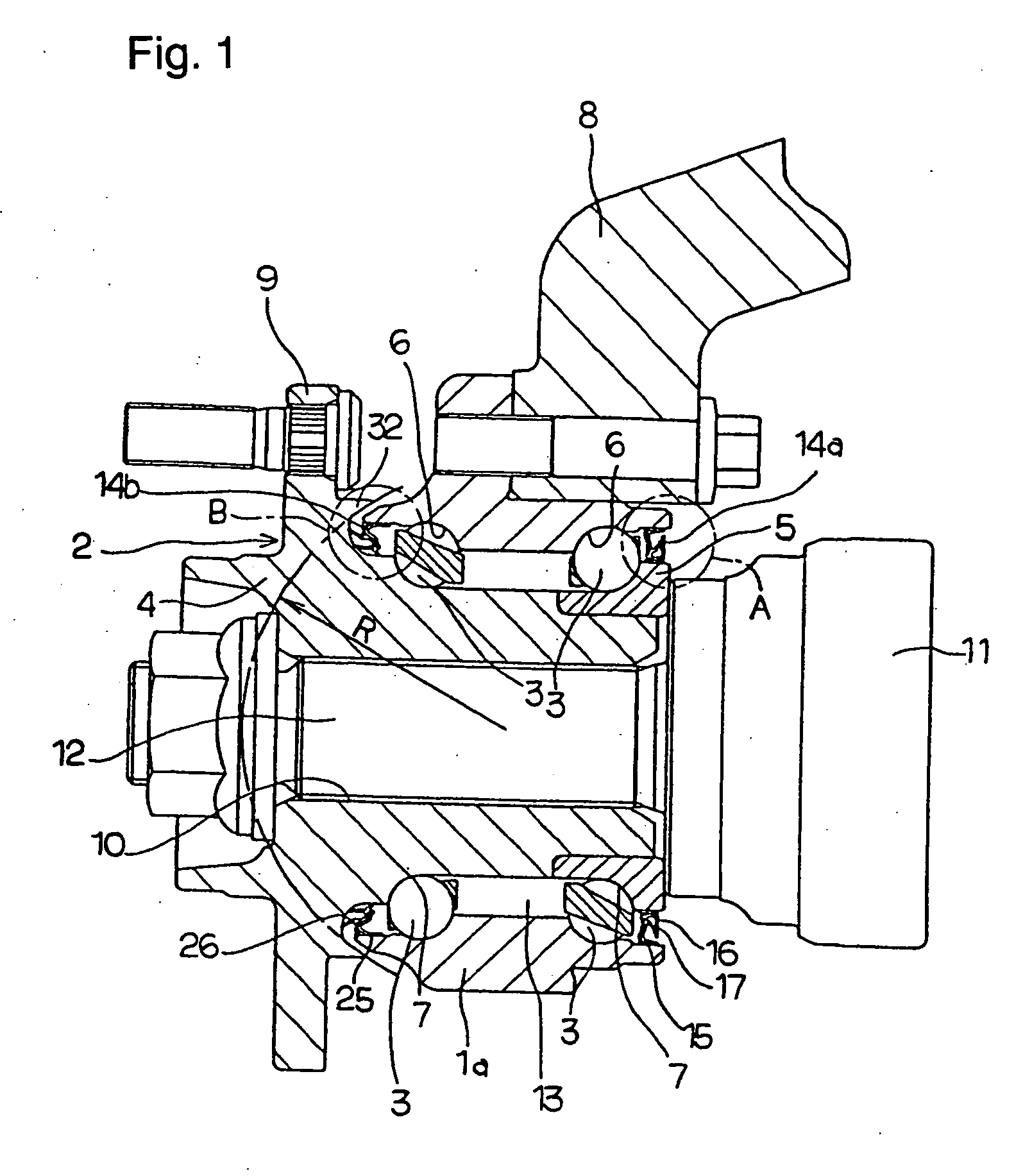

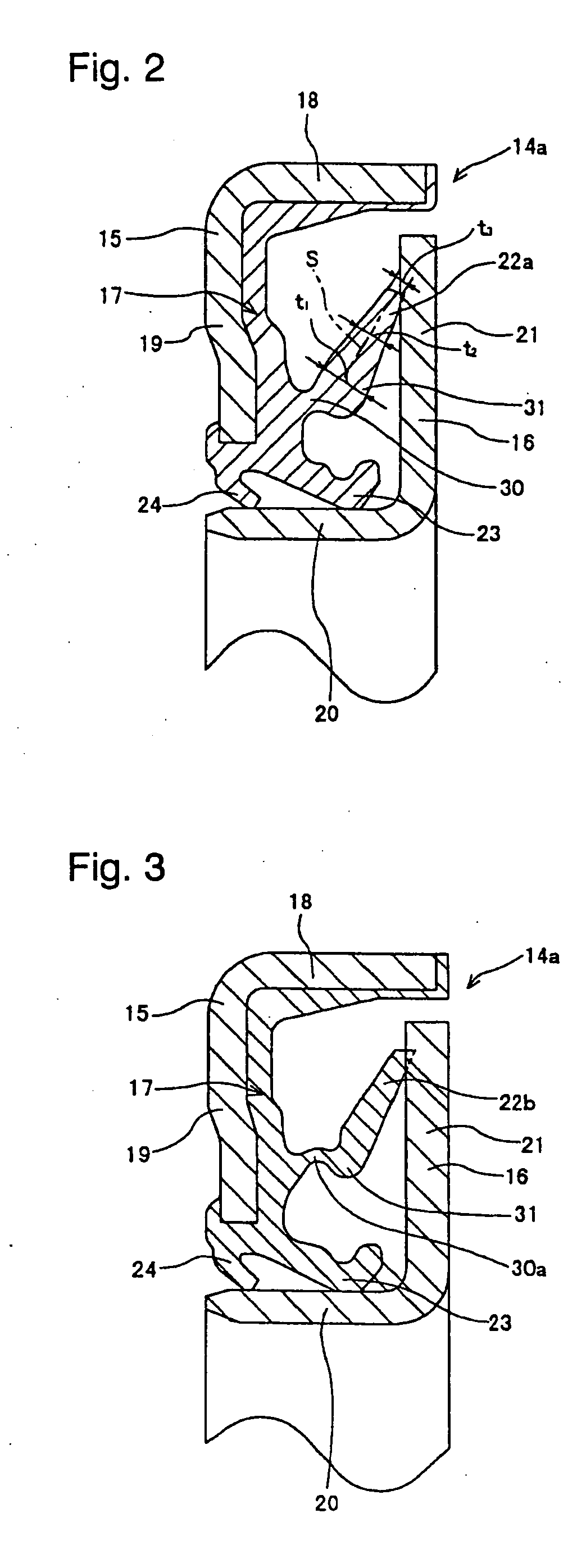

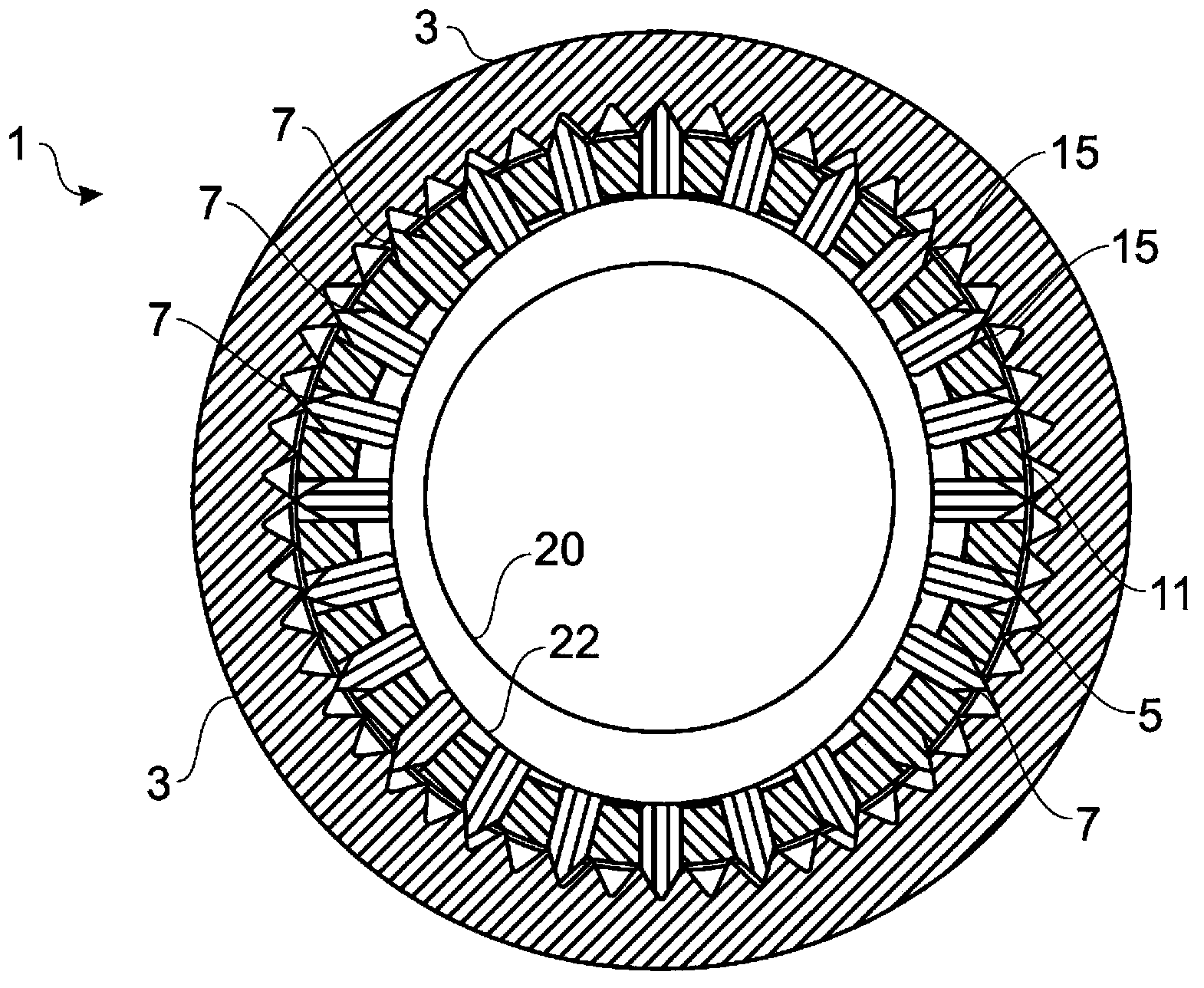

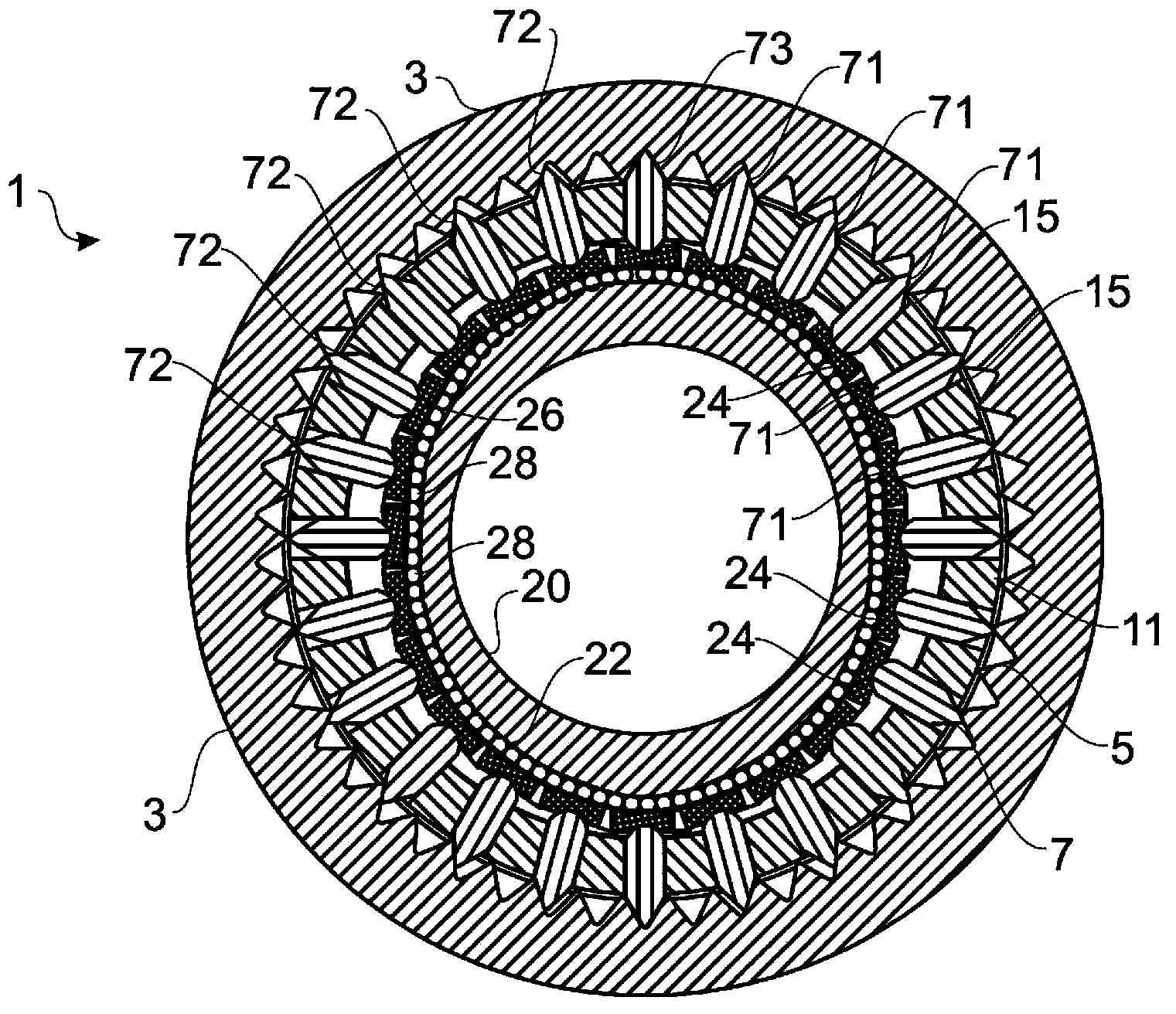

Seal ring and rolling bearing unit with seal ring

InactiveUS20050089254A1Reduce binding forcePromote generationEngine sealsRolling contact bearingsRolling-element bearingEngineering

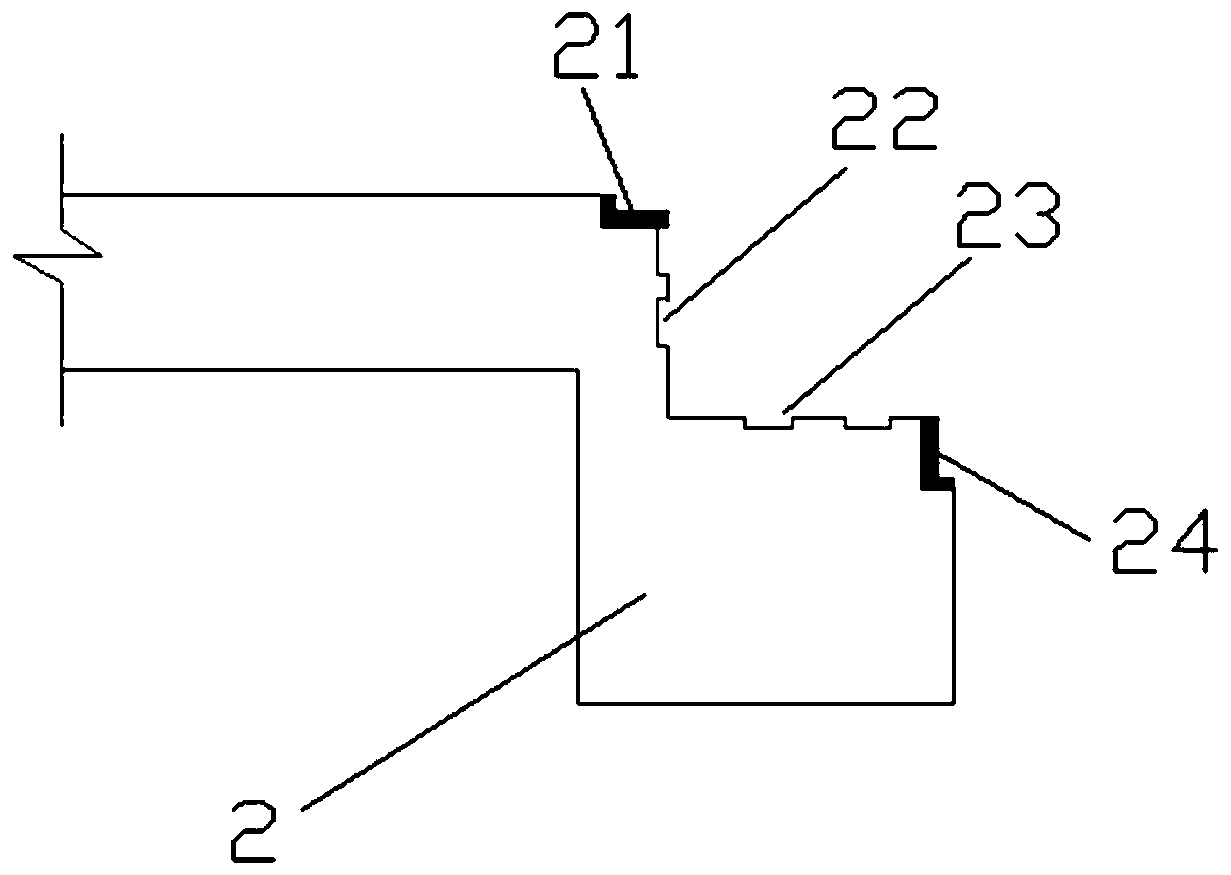

It is intended that the rotation resistance is decreased while the durability and seal performance are kept in the rolling bearing unit with seal ring. The most thin wall-thickness portion 30 is provided in the vicinity of the base end of the seal lip 22a projecting laterally in sliding contact with the mating surface. The most thick wall thickness portion 31 is provided adjacent to the most thin wall thickness portion 30 on the tip end side. The thickness is gradually decreased from the most thick wall thickness portion 31 to the tip end. Further, the ratios of thickness in the respective portions 22a are properly controlled.

Owner:NSK LTD

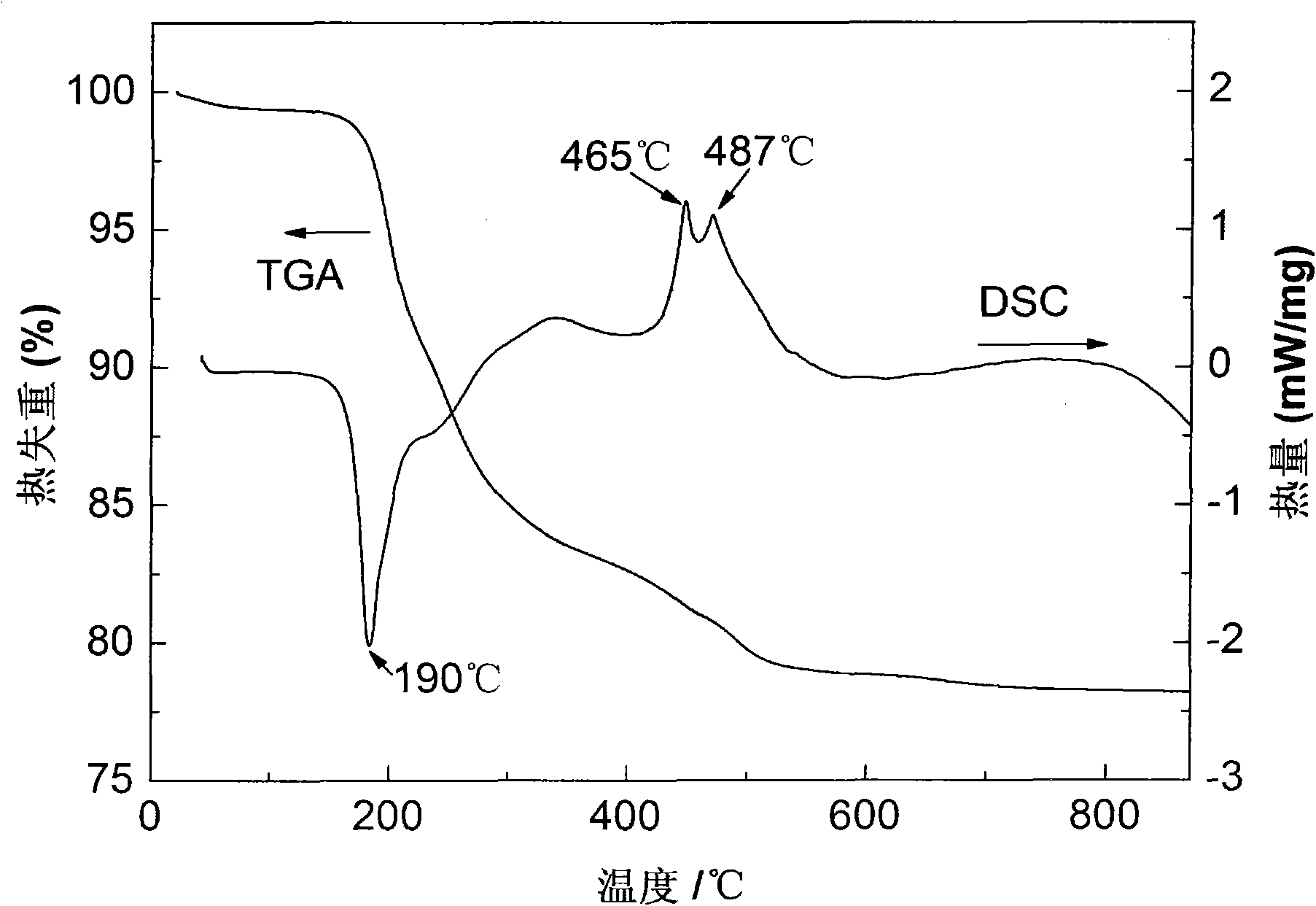

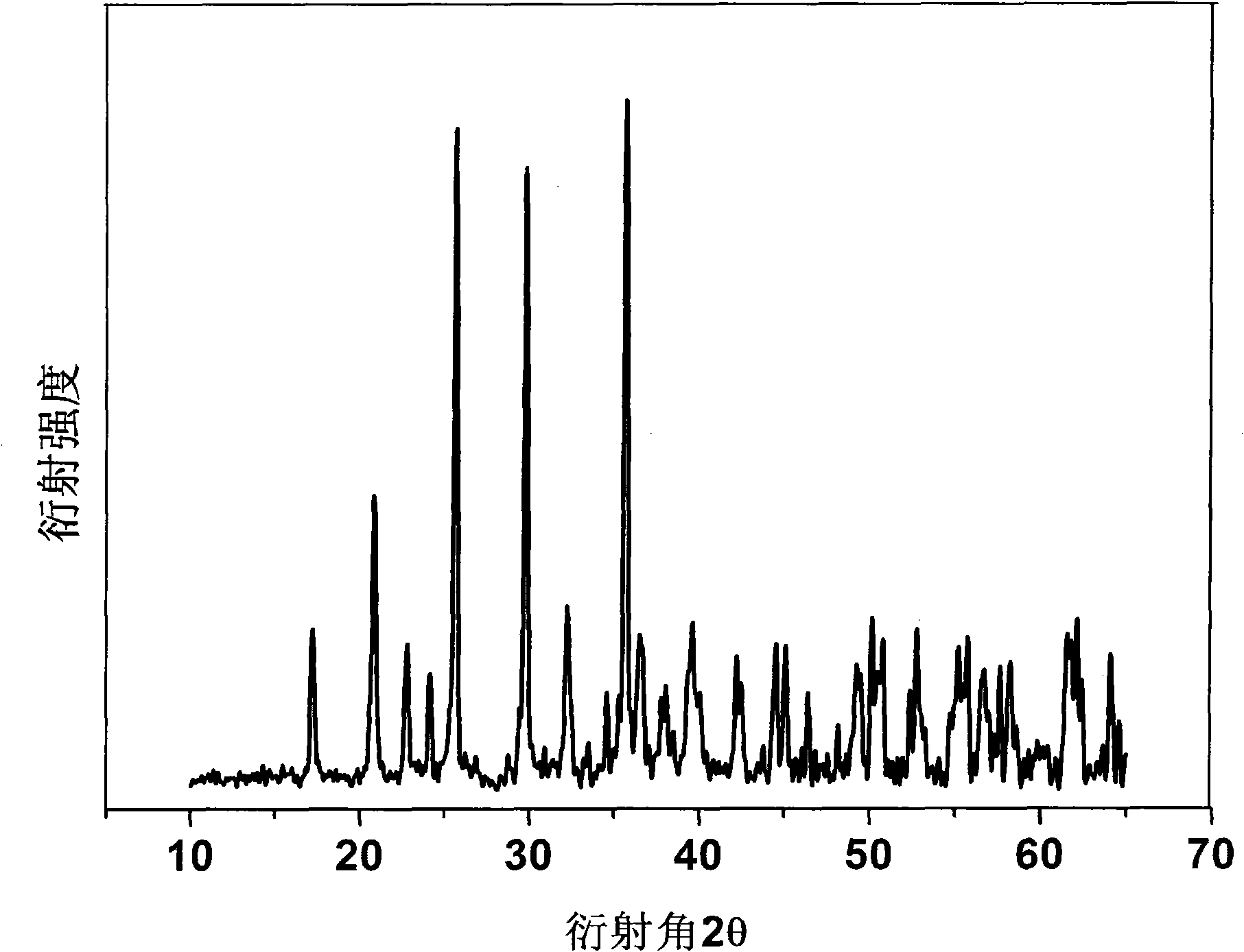

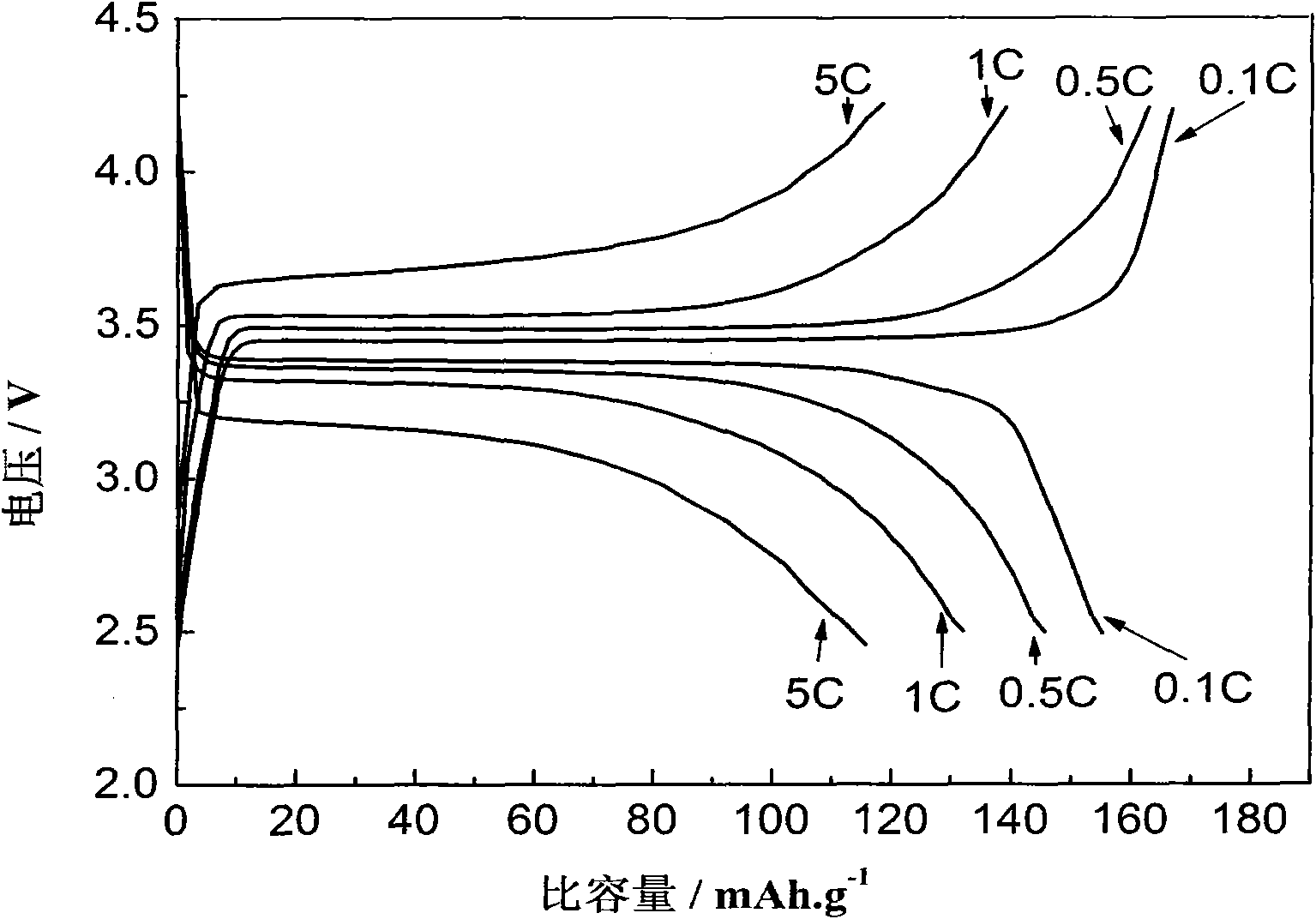

Fluorinion-doped lithium iron phosphate material and preparation methods thereof

InactiveCN102024951AEasy accessImprove electrochemical performanceCell electrodesIron saltsPhosphate

The invention discloses a fluorinion-doped lithium iron phosphate material and preparation methods thereof. The fluorinion-doped lithium iron phosphate powder material has a chemical formula: LiFe(PO4)1-xF3x / C, wherein x is larger than 0 and smaller than 0.2. The fluorinion-doped lithium iron phosphate powder material can be prepared by two preparation methods of adding fluoride before pre-sintering and directly sintering or adding after pre-sintering and roasting fluoride, i.e. mixing lithium salt, iron salt and phosphate with fluoride, adding a carbon source, primarily mixing, pre-sintering and roasting or firstly mixing the lithium salt, the iron salt and the phosphate, adding the carbon source, mixing, pre-sintering, mixing with fluoride and roasting to obtain the fluorinion-doped lithium iron phosphate material. By adopting a low-temperature solid phase method, the fluorinion-doped lithium iron phosphate material is synthesized, an electrode material prepared by using the fluorinion-doped lithium iron phosphate material has excellent electrochemic performance and multiplication charging and discharging performance; the invention has the advantages of simple process, lower energy consumption and low raw material cost; and the obtained material has good electrochemic performance and excellent multiplication charging and discharging performance and is convenient for industrial mass production.

Owner:SOUTH CHINA UNIV OF TECH

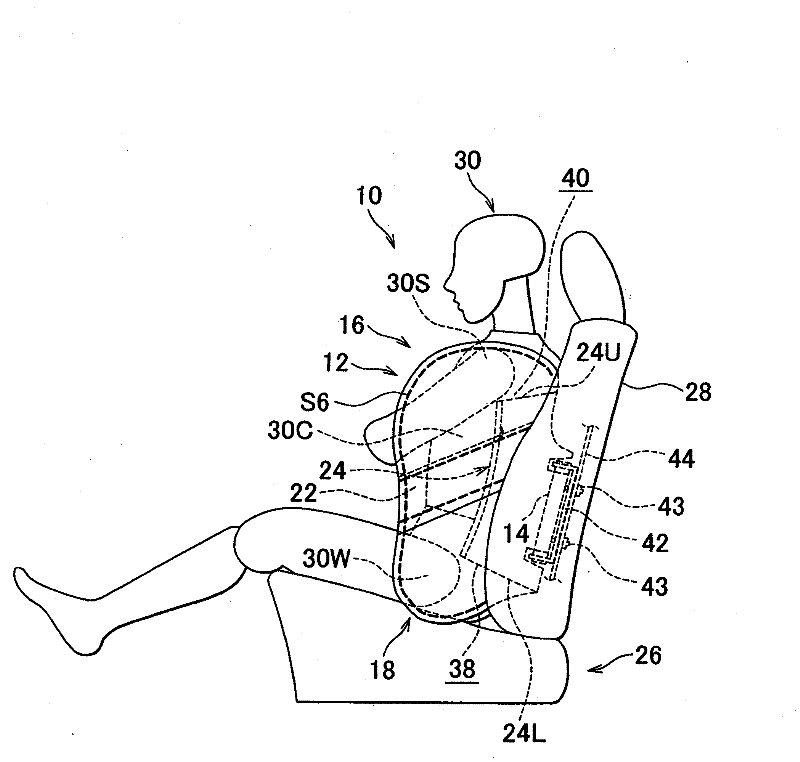

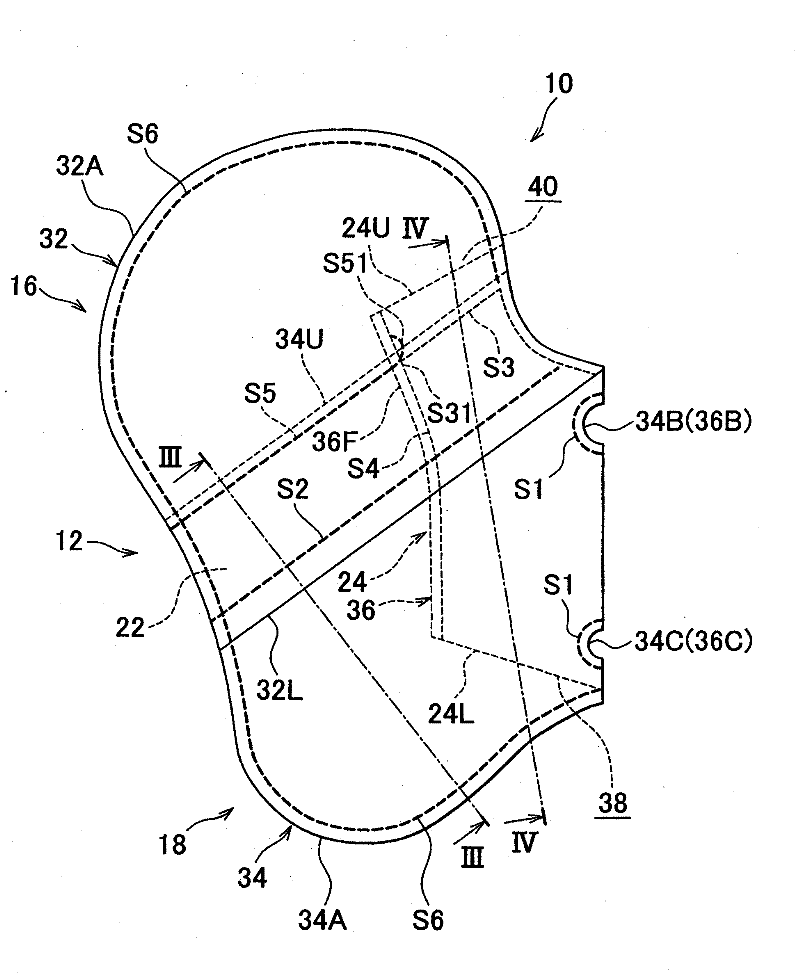

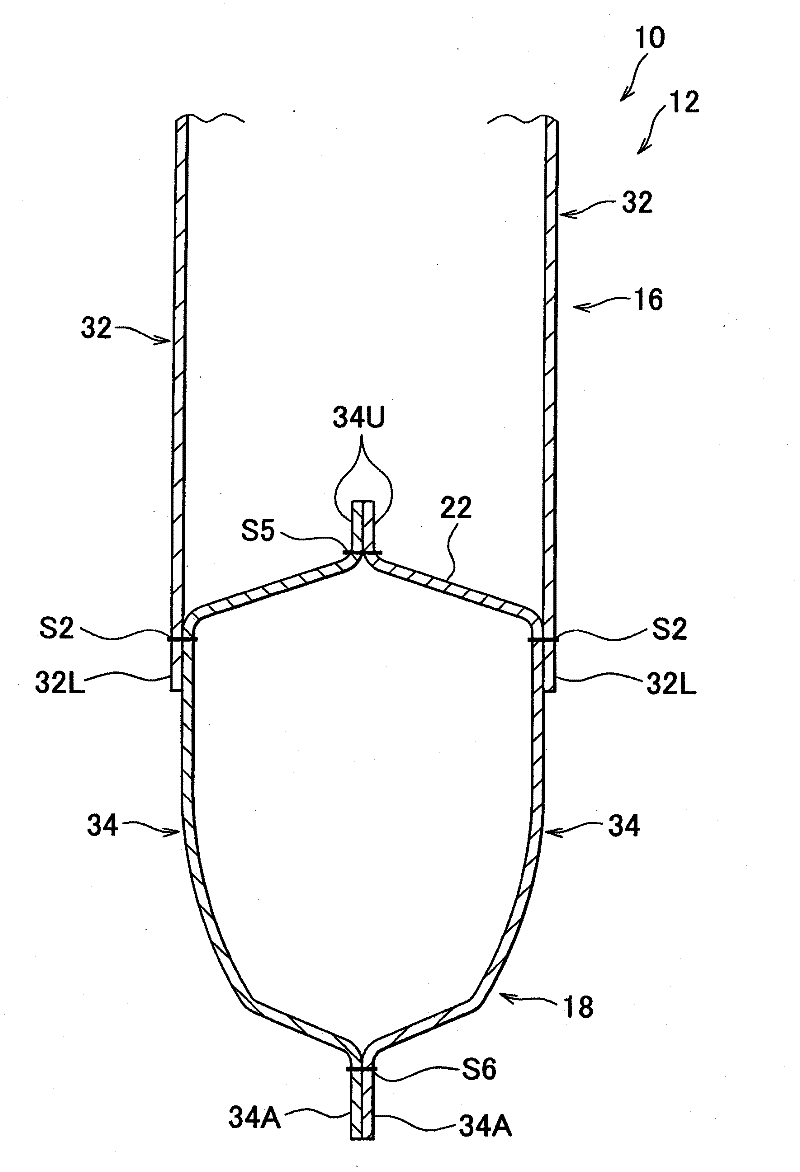

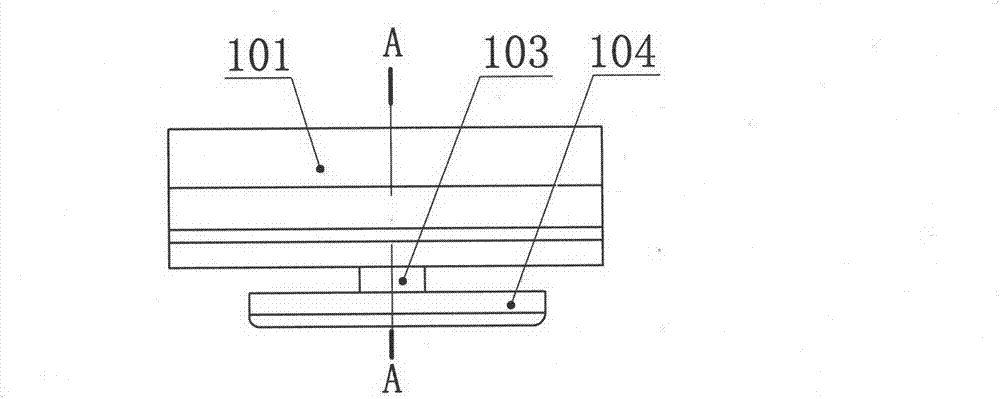

Side airbag system and method of manufacturing side airbag

InactiveCN102317122AEasy to sutureImprove air tightnessPedestrian/occupant safety arrangementLateral airbagMechanical engineering

In a side airbag system (10), a tether portion (22), which serves as a partition between an upper bag portion (16) and a lower bag portion (18), is formed of upper regions (34U) of a piece of lower base fabric (34), and is formed by sewing the upper regions (34U) of the lower base fabric (34), folded toward a vehicle front side along a fold axis, together. In addition, a tube (24) that distributes inflation gas between the upper bag portion (16) and the lower bag portion (18) extends through the tether portion (22) to the lower bag portion (18) and to the upper bag portion (16). The tube (24)is formed into a cylindrical shape in such a manner that a piece of tube base fabric (36) is sewed to the upper regions (34U) of the lower base fabric (34) and folded toward a vehicle front side along the fold axis and then front ends (36F) of the folded tube base fabric are sewed together in a tube longitudinal direction.

Owner:TOYOTA JIDOSHA KK +1

A transmission

ActiveCN103363027AImprove transmission stiffnessAvoid constraintsPortable liftingToothed gearingsTooth segmentEngineering

Owner:WITTENSTEIN GROUP

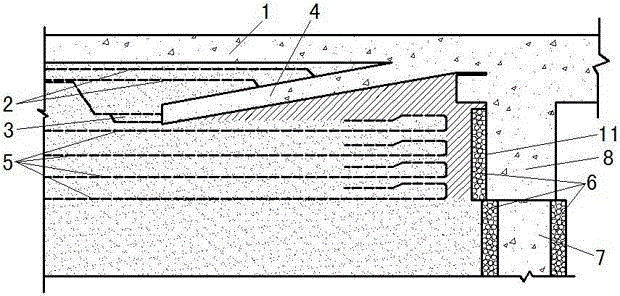

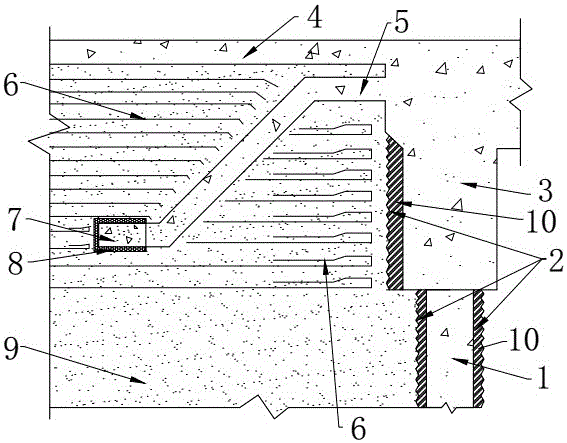

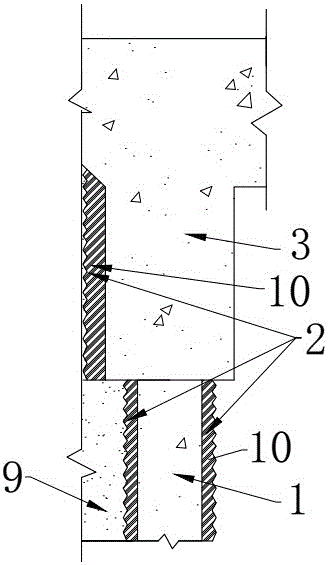

Structure and method for controlling jointless abutment back subsidence and pavement cracking by using reinforcement geotextile

InactiveCN103981802AImprove integrityIncrease stiffnessPaving detailsBridge structural detailsAbutmentRoad surface

The invention relates to a structure and a method for controlling jointless abutment back subsidence and pavement cracking by using reinforcement geotextile. The bridge abutment of a jointless bridge is connected with an access board, backfill reinforced by multilayer reinforcement geotextile is arranged above the access board, backfill reinforced by multilayer reinforcement geotextile is also arranged under the access board, spacing is formed between the backfill reinforced by multilayer reinforcement geotextile and under the access board, and the wall body of the bridge abutment, an elastic material layer in the spacing is wrapped on the abutment back of the abutment, the wall body of the abutment is supported on a single rank of piles, the periphery of the single rank of piles is also wrapped by an elastic material layer, and the access board is obliquely arranged, and a discrete material layer is arranged at the tail end of the access board. With the reinforcement principle of the reinforcement geotextile and ingenious structural arrangement, a flexible structural layer with good overall integrity and higher rigidity is formed, so that the abutment back subsidence and pavement cracking of the jointless bridge are effectively controlled, the rigid-and-flexible stable transition of the road and bridge transition section is realized, and the structure and method are particularly applicable to jointless bridges with integral type abutments.

Owner:FUZHOU UNIV

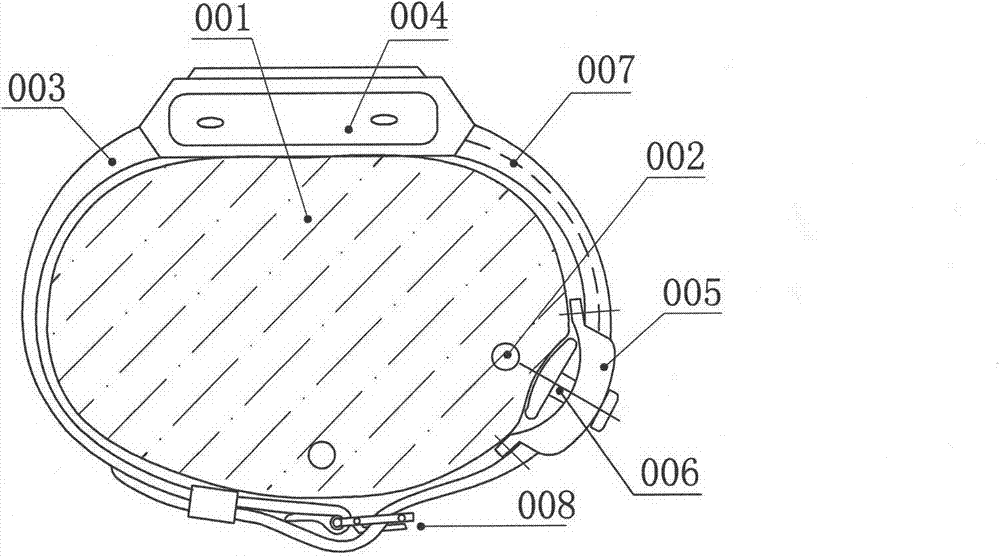

Wireless monitoring device and blood pressure detecting device

InactiveCN103565420AReduce labor intensityEasy accessTransmission systemsDiagnostic recording/measuringWireless transmissionBlood pressure

The invention discloses a wireless monitoring device. The wireless monitoring device comprises a wireless transmission unit, a signal processing unit, a tying band and a vibrating unit arranged on the tying band. A blood pressure detecting device comprises a sensor unit, a signal processing unit and a tying band, wherein at least one part of the tying band comprises a part which bends from the side close to the limbs to the outer side in the length direction of the tying band, the sensor unit is arranged on the inner side of the bend part and at least comprises two sensor elements, a preset included angle is formed between the vertical lines of the sensitive faces of the sensor elements, and a movable connecting component is arranged between the sensor unit and the tying band. According to the blood pressure detecting device, signals which are changed along with changes of pulse or changes of the blood pressure can be accurately obtained within a large detecting range, and blood pressure detecting values are stable and reliable.

Owner:许建平

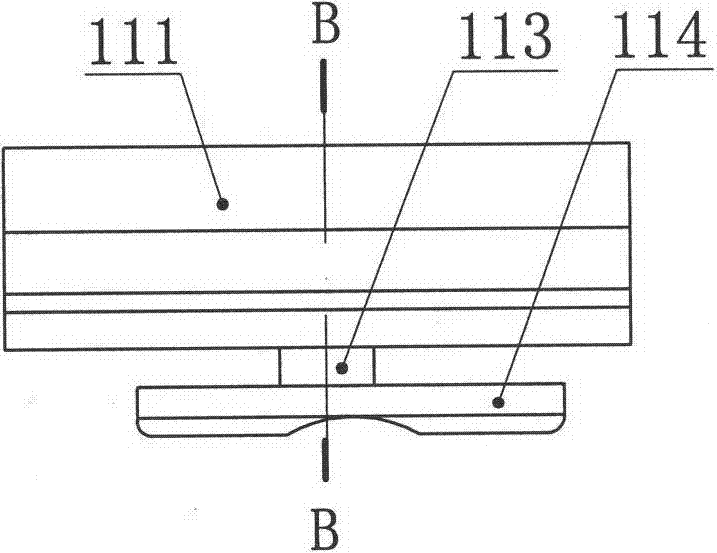

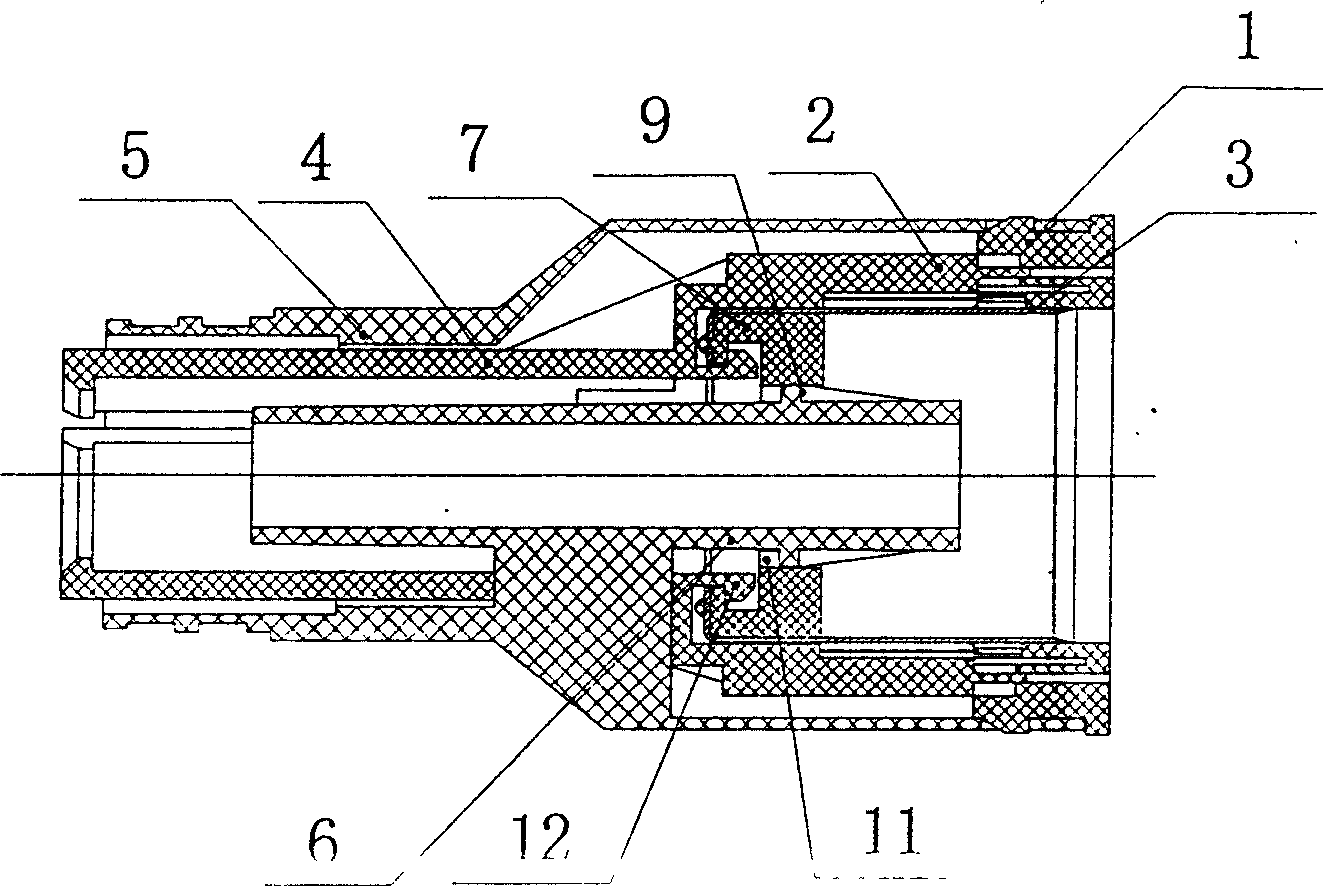

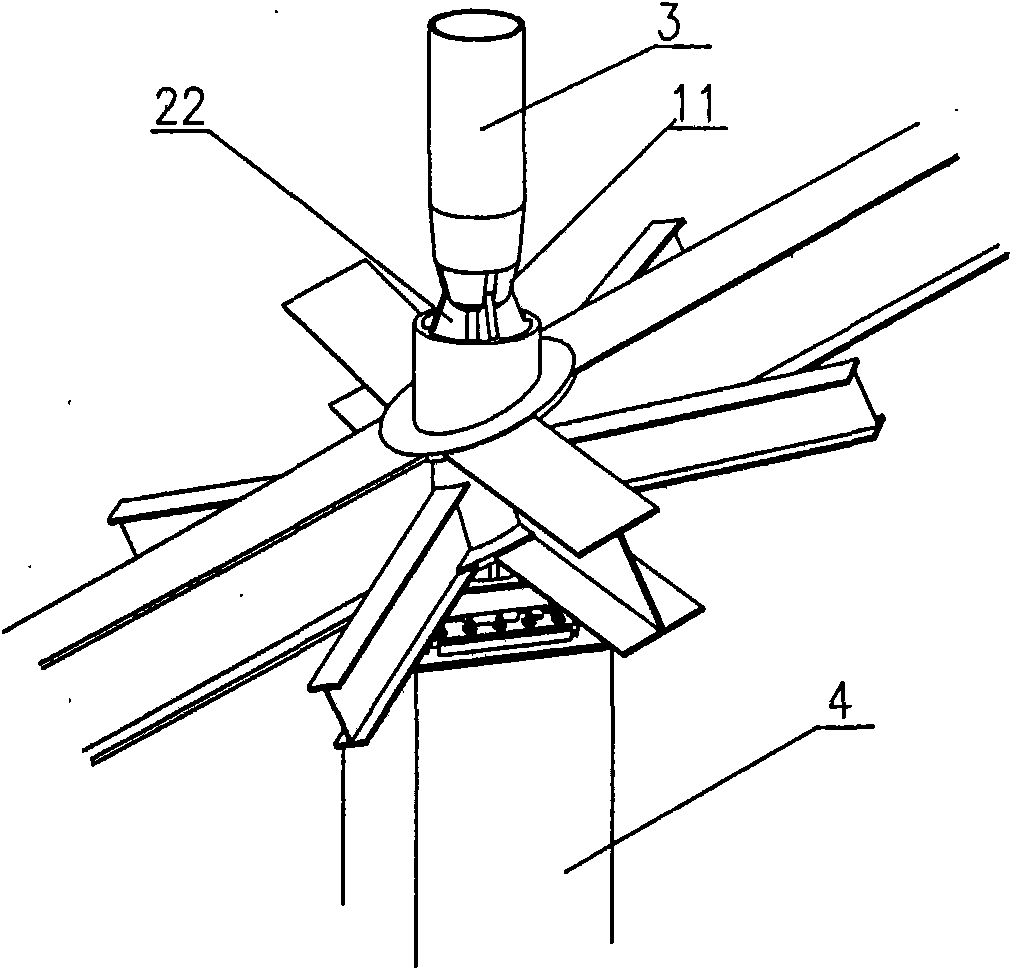

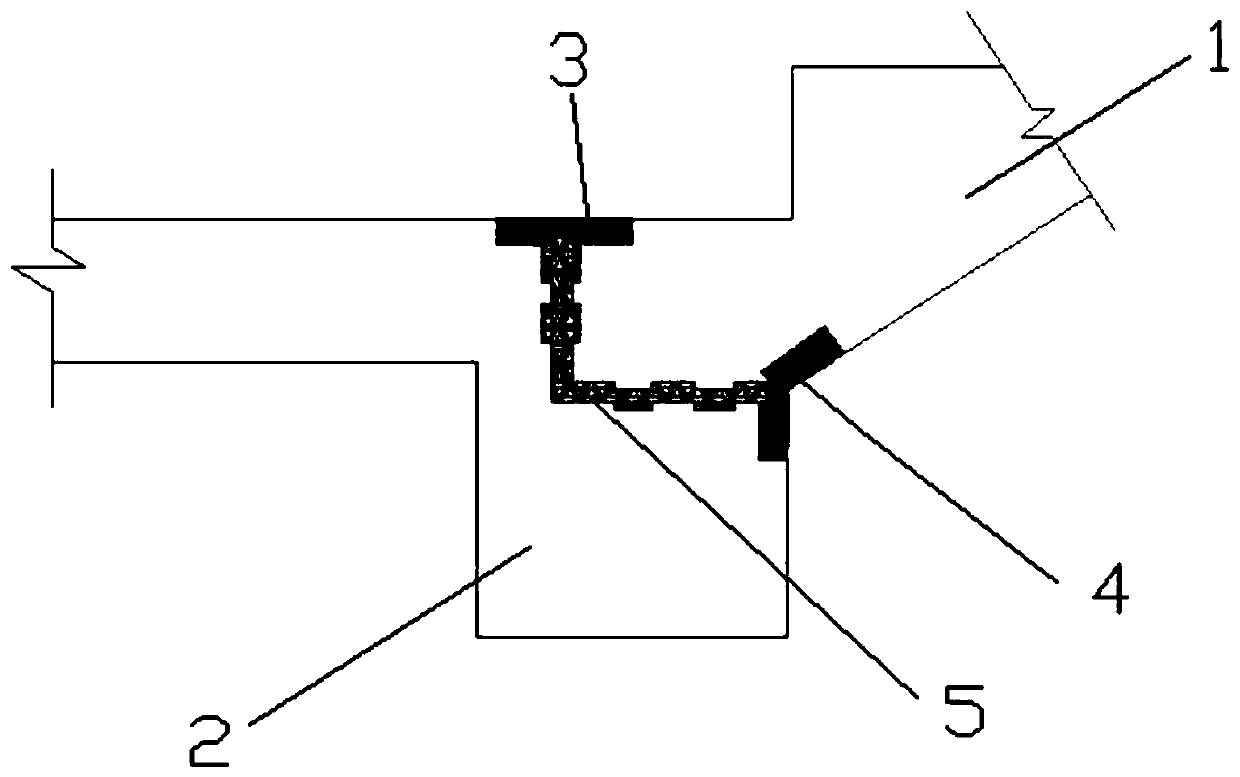

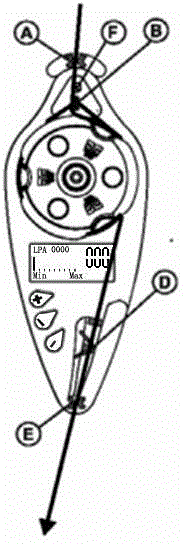

Rotary scalpel head for surgical binder

InactiveCN1891166AReduce resistanceReduce binding forceSurgical staplesSurgical operationEngineering

The present invention relates to a rotary cutter head of binding apparatus for surgical operation. It includes the following several portions: nail chamber, nail-pushing piece, cutter, nail-pushing column and nail tube, it also includes rotating component. The cutter feeding device composed of the described nail chamber, nail-pushing piece, cutter, nail-pushing column, nail tube and rotating component is a rotary feeding device. Said invention also provides the concrete connection mode of all the above-mentioned portions, and also provides the working principle of said rotary cutter head of binding apparatus and its operation method.

Owner:TOUCHSTONE INTERNATIONAL MEDICAL SCIENCE CO LTD

Method for recovering glucomannan and protein in konjac flying powder by enzyme process

InactiveCN102020856AImplement resourcesRealize harmless useFood processingAnimal feeding stuffAmylaseNutrition

The invention relates to a method for recovering glucomannan and protein in konjac flying powder by the enzyme process, which comprises the following process steps: (1) liquification: adding alpha-amylase into water solution of the konjac flying powder and liquifying till starch is fully degraded; (2) saccharification: adding amyloglucosidase into solution in the step (1) for saccharification; (3) centrifugation: regulating the pH of the solution in the step (2) to 3.5-5.0, centrifugating and getting precipitate; (4) acid washing: adding water into the precipitate in the step (3), regulating the pH of the solution to acidic condition, stirring, centrifugating, and getting the precipitate; and (5) drying: regulating the pH of the precipitate after the acid washing of the step (4) to be neutral, drying and finally getting a final extract. The process flow is simple, the operation is easy, the content of the glucomannan and crude protein in the got extract is high, and the extract can be used as a high-quality feed or a protein raw material and the like; and a stinking matter of trimethylamine and an antinutritional factor of tannin can be effectively removed.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

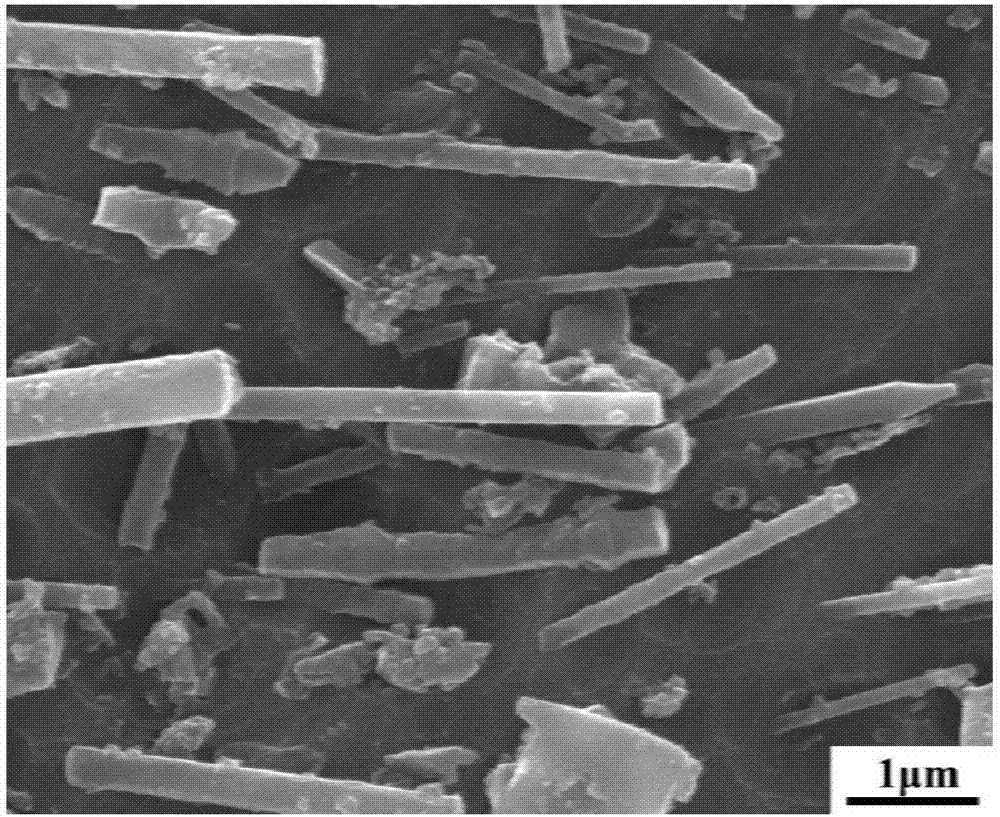

Method for preparing directionally-arranged SIC nanowire reinforced aluminum matrix composite material based on semi-solid extrusion

The invention relates to a method for preparing a directionally-arranged SIC nanowire reinforced aluminum matrix composite material based on semi-solid extrusion. The problem that by adopting conventional hot extrusion treatment, damage to SIC nanowires is serious in the directional arrangement process of the SIC nanowires is solved. The method comprises the steps that firstly, a non-directional SIC nanowire reinforced aluminum matrix composite material is prepared; secondly, the non-directional SIC nanowire reinforced aluminum matrix composite material and a hot extrusion die are preheated; and thirdly, the directionally-arranged SIC nanowire reinforced aluminum matrix composite material is prepared through semi-solid extrusion. According to the method, the SIC nanowire reinforced aluminum matrix composite material is subjected to hot extrusion treatment above a solid phase line and below a liquid phase line; the grain boundary of an aluminum matrix is melted, the aluminum matrix is located in the solid-liquid mixing state, constraining force to the SIC nanowires is small, and the SIC nanowires can achieve low-damage directional arrangement.

Owner:HARBIN INST OF TECH

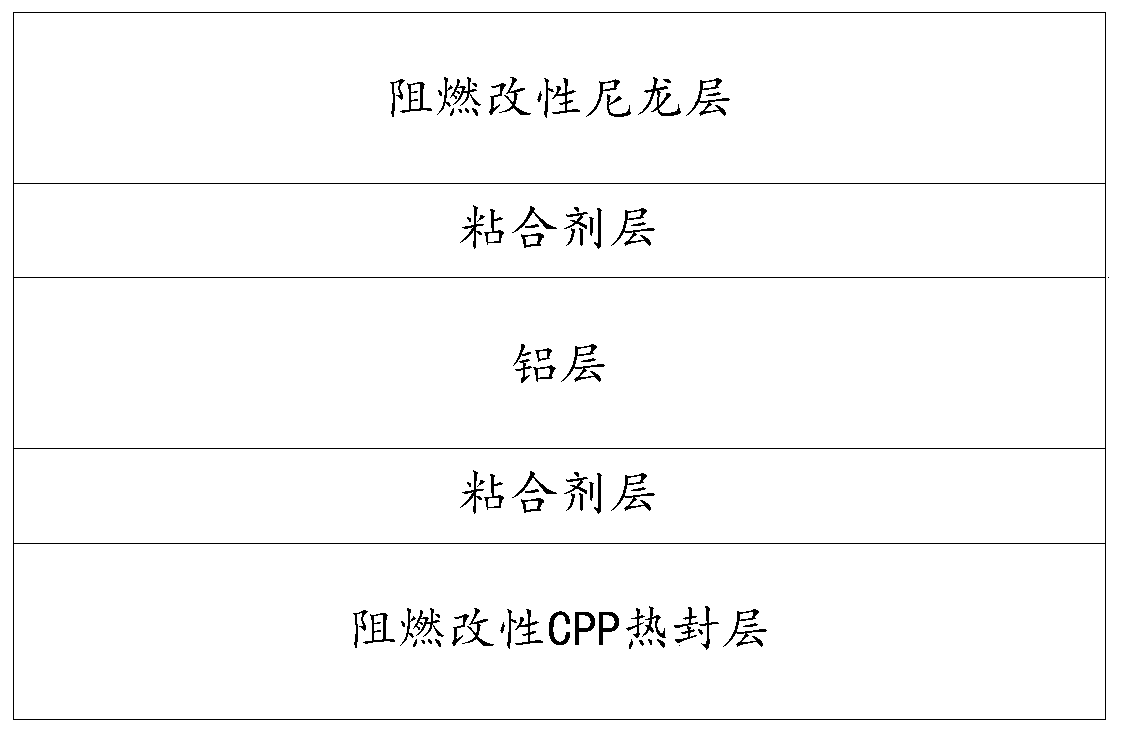

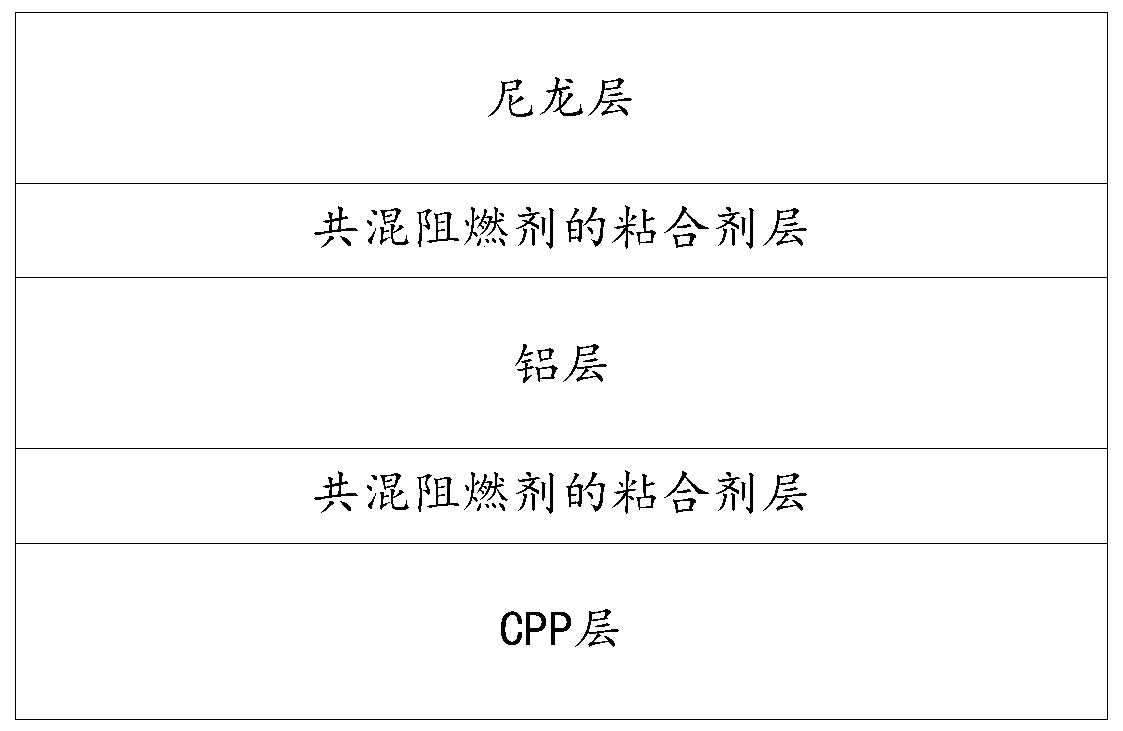

Antiflaming aluminum plastic film and preparation method thereof

ActiveCN109822999AFlame retardantDoes not affect mechanical propertiesSynthetic resin layered productsMetal layered productsSurface layerPlastic film

The invention relates to the field of lithium batteries, and discloses an antiflaming aluminum plastic film and a preparation method thereof. The aluminum plastic film comprises an antiflaming modified nylon layer as a surface layer, an aluminum layer and an antiflaming modified CPP heat sealing layer as an inner layer; the antiflaming modified nylon layer as the surface layer, the aluminum layerand the antiflaming modified CPP heat sealing layer as the inner layer successively bond with one another through a bonding agent. The aluminum plastic film achieves a quite good antiflaming effect, and the safety performance of a lithium ion battery is greatly improved.

Owner:桑顿新能源科技(长沙)有限公司

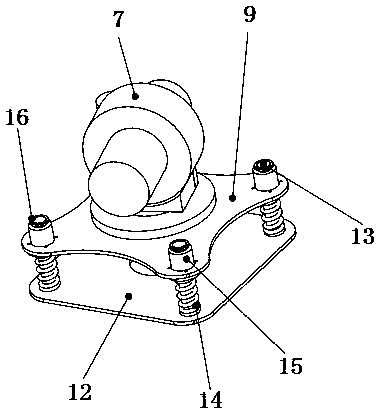

Universal spherical joint supporter with anti-loosening position-limiting structure

ActiveCN101560793AGood architectural effectSmall building effectBuilding constructionsPull forceVertical edge

A universal spherical joint supporter with an anti-loosening position-limiting structure comprises a main spherical joint structural part consisting of a main top base with a concave spherical surface and a main bottom base with a convex spherical surface; the main bottom base consists of a base body, at least three reinforced plates and a steel ball; the steel ball is a convex ball component arranged in the bottom base; the reinforced plates are distributed in the bottom base radially and vertically by taking the vertical middle axis line of the steel ball as a central line; each reinforced plate is provided with a vertical edge closely to the middle axial line of the steel ball; a spherical concave position used for bearing the steel ball is arranged on an upper plate of the reinforced plate closely to the middle axis line by taking the spherical center of the steel ball as a center, and a convex claw is arranged in a space between every two adjacent reinforced plates on the main bottom base correspondingly to the lower circumference of the main top base, thus forming the position-limiting structure of the spherical joint. The position-limiting structure can play roles of preventing loosening, restricting the rotation of the top base around the axis line and bearing the pulling force and has excellent bearing performance; and when the position-limiting structure bears the pulling force, the spherical joint part can rotate slightly and simultaneously.

Owner:ARCHITECTURAL DESIGN RES INST OF GUANGDONG PROVINCE

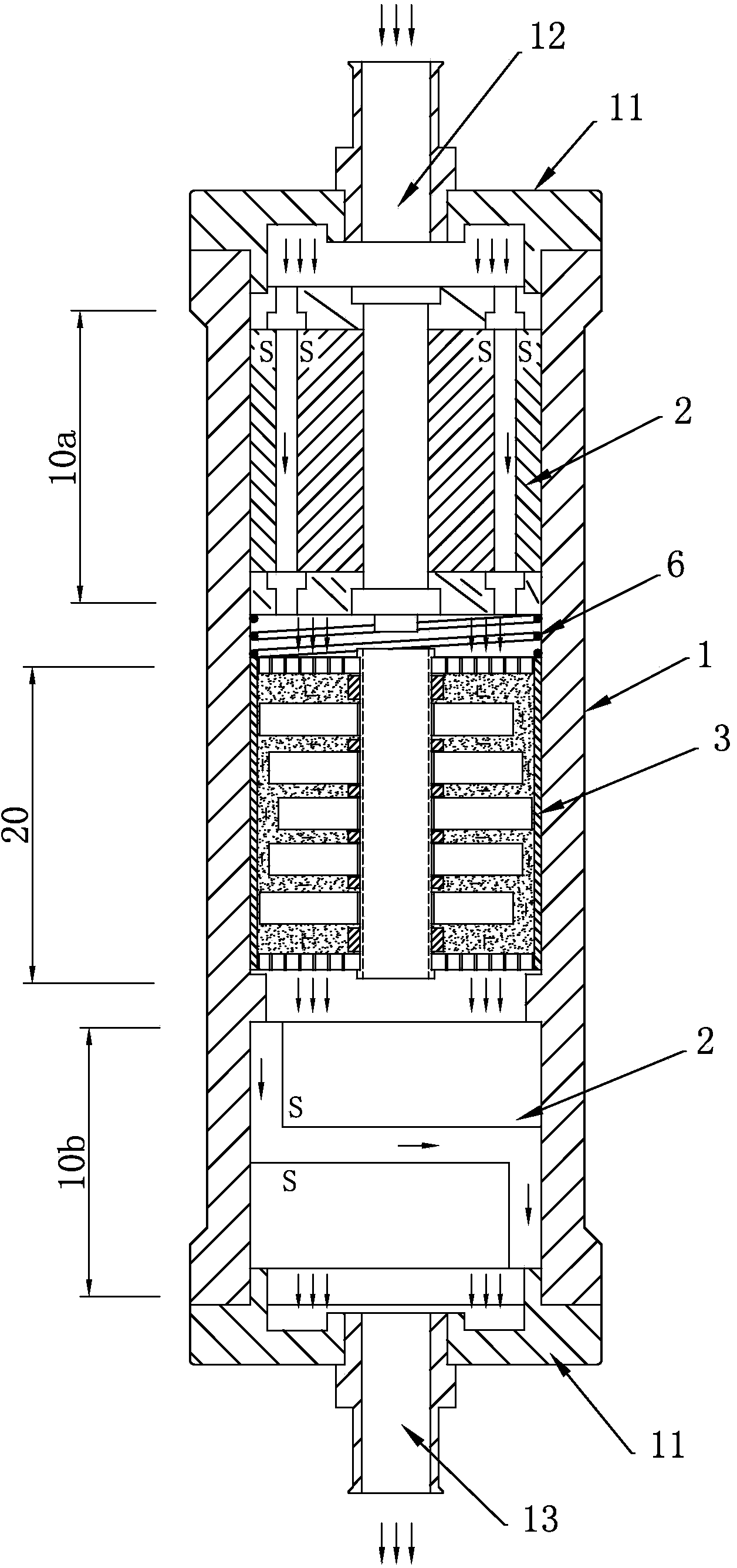

Magnetic-field-strengthening iron-carbon-microelectrolysis method for treating organic pollutants in landfill leachate

InactiveCN105236518AIncreased degradation rateHigh speedWater/sewage treatment by magnetic/electric fieldsWastewaterOrganic matter

The invention relates to a magnetic-field-strengthening iron-carbon-microelectrolysis method for treating organic pollutants in landfill leachate. The method comprises the steps of externally applying a magnetic field to the surrounding of a reaction tank, adding zero-valent iron and granular activated carbon into organic matter polluted wastewater in the reaction tank, and purifying the water under external-force stirring. According to the method, the organic pollutants in the landfill leachate can be effectively removed, the utilization ratio of the iron and the carbon is increased, the consumption of reagents is lowered, and the rate of reaction is accelerated. Once the reaction starts, the operation is simple and convenient and is easy to control; and the method is economical.

Owner:BEIJING VOCATIONAL COLLEGE OF AGRI +1

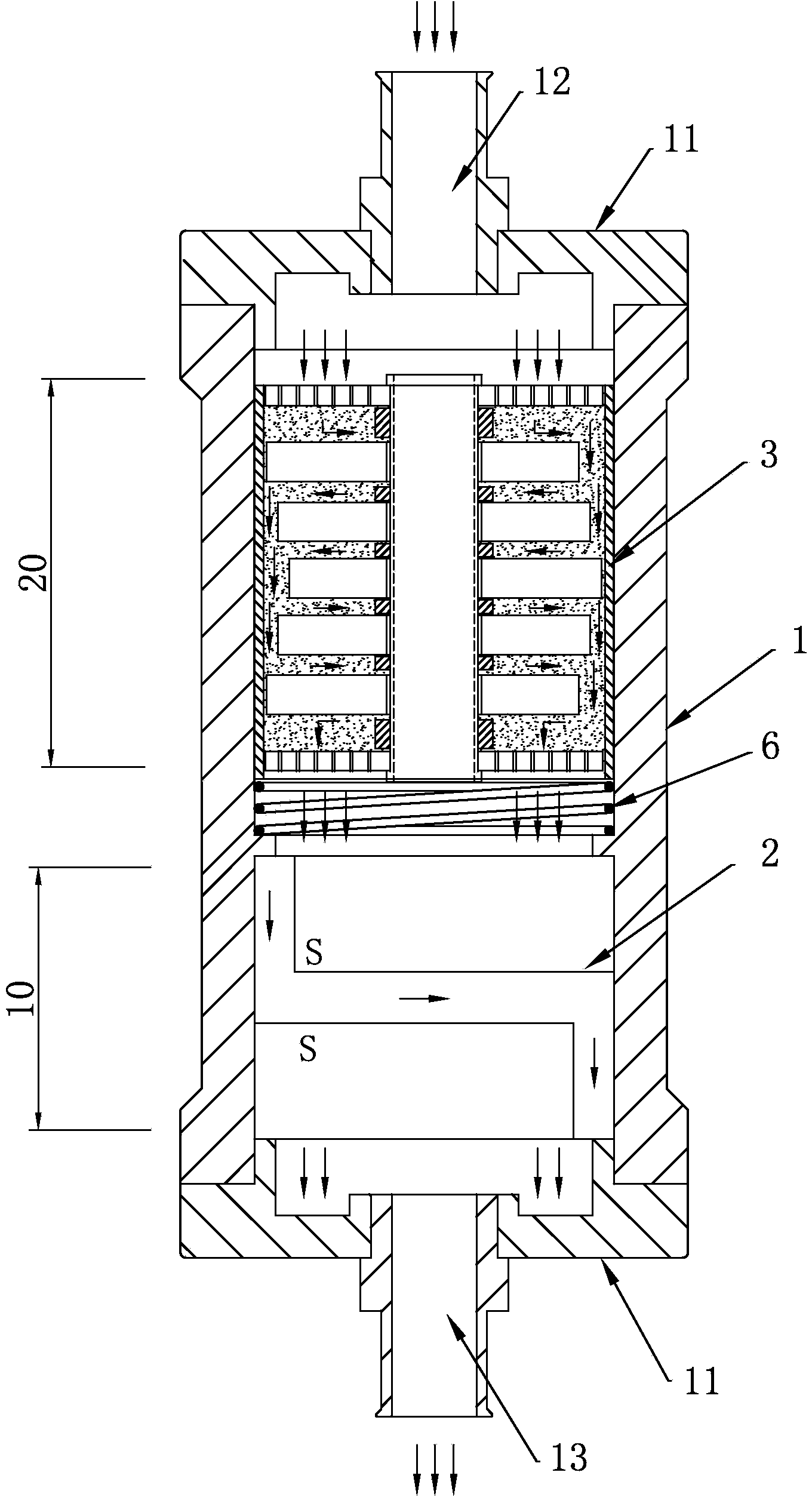

Oil-saving emission-reduction device for automobile

ActiveCN104018959AChanges in macroscopic physical propertiesBurn fullyInternal combustion piston enginesCombustion-air/fuel-air treatmentNMR - Nuclear magnetic resonanceRare earth

The invention discloses an oil-saving emission-reduction device for an automobile. The strong magnetic and nuclear magnetic resonance principle is utilized to change the activity of fuel, the rare earth catalyzing effect is improved to improve the fuel utilization rate and reduce pollutant emission. The oil-saving emission-reduction device for the automobile comprises a shell made of a non-permeability-magnetic material. A strong magnetic area and a strong catalyzing area are arranged in an inner cavity of the shell, wherein the fuel can pass through the strong magnetic area and a strong catalyzing area. Two magnetic parts with magnetic poles of the same polarity facing to each other are arranged in the strong magnetic area, the magnetic inductive strength of the surfaces of the magnetic parts ranges from 0.34T to 0.38T, and the fuel flows through a gap between the two magnetic parts. A fuel catalyzing assembly through which the fuel passes is arranged in the strong catalyzing area, wherein the magnetic sheets and a nanometer material are arranged in the fuel catalyzing assembly. The oil-saving emission-reduction device for the automobile conducts at least one time of strong magnetization and one time of strong catalytic activation on the fuel flowing through the oil-saving emission-reduction device, after the fuel leaves a magnetic field, binding force of the fuel is reduced, intermolecular interaction force is also reduced, and little increment of the intermolecular distance will greatly reduce intermolecular cohesion force. The oil-saving emission-reduction device for the automobile can enable the fuel to be sufficiently combusted, improve the fuel utilization rate and greatly reduce emission of waste gas.

Owner:苏悦熙

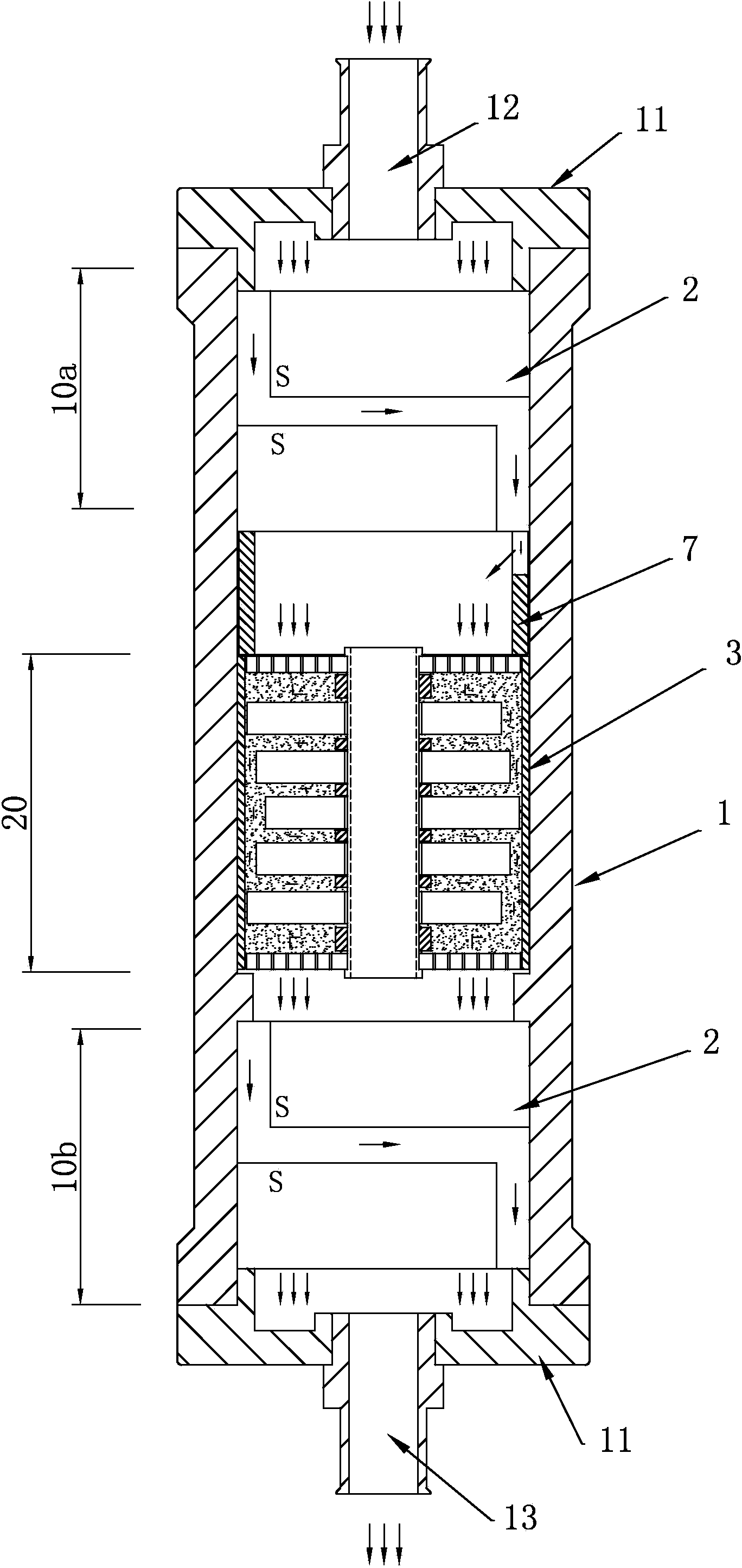

Cold repairing, asphalt mixture and its manufacturing method

InactiveCN1195021CReduce binding forceImprove performanceIn situ pavingsBuilding insulationsKerosenePetroleum resin

An asphalt mixture for cold repair of asphalt pavement is prepared from heavy oil, C5 or C9 petroleum resin, C1-C10 solvent oil, butadiene-styrene rubber, diesel oil or kerosene or gasoline, thermoplastic butadiene-styrene rubber, naphthenic oil, mineral oil RC-10, petroleum asphalt and minerals through preparing 3 predymers, preparing cold repair additive, and adding petroleum asphalt for making asphalt mixture and minerals. Its advantages are convenient application, and no environmental pollution.

Owner:袁永长

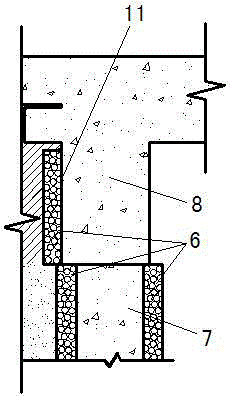

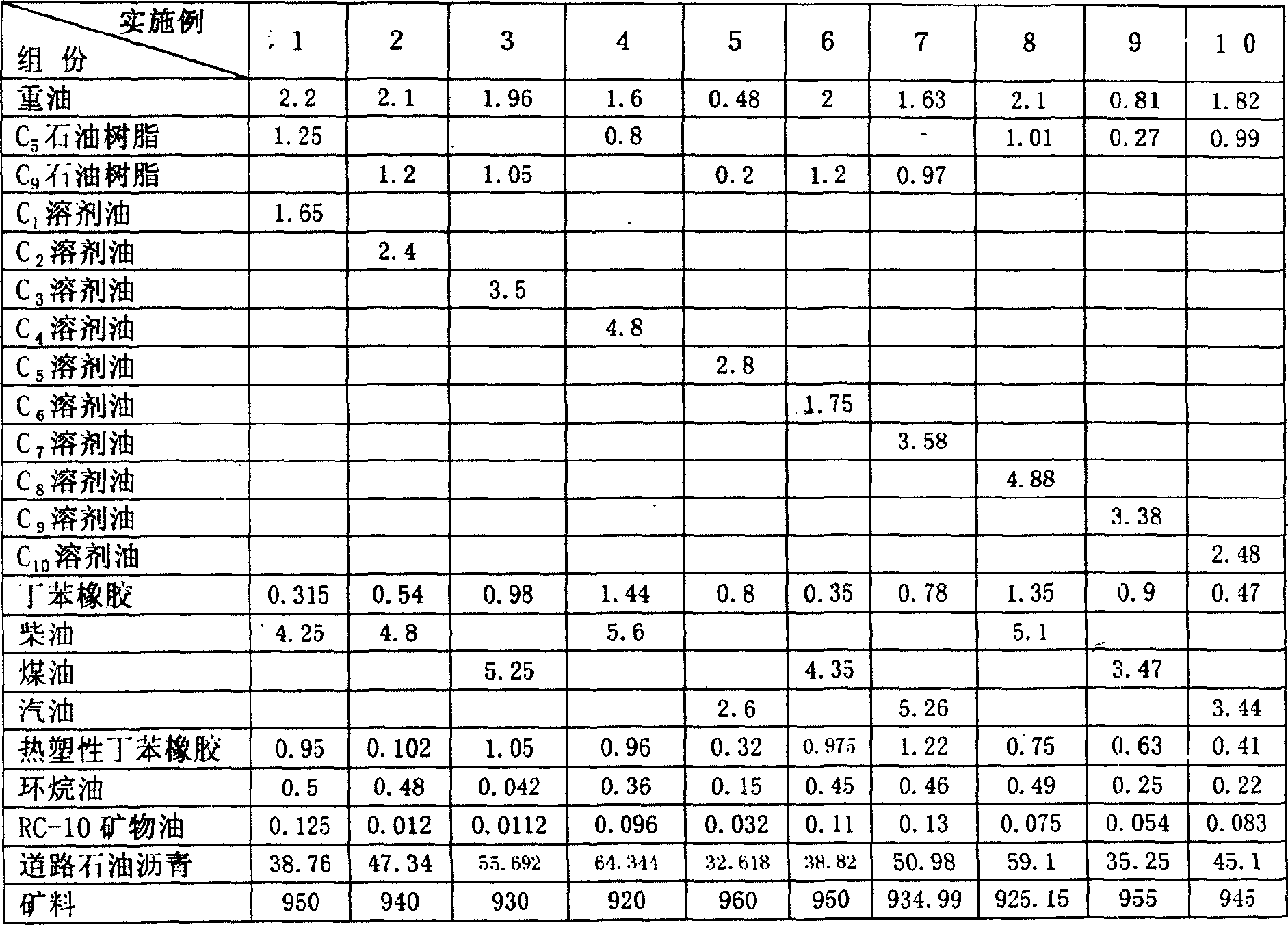

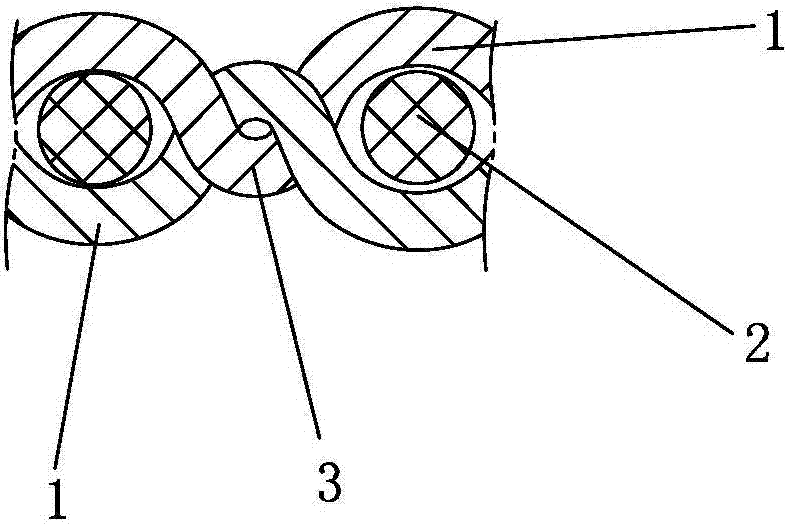

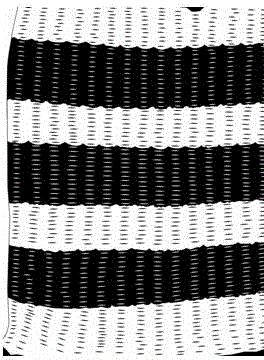

Warp and weft forwards and backwards entwisted white body wide-angle interwoven fabric

InactiveCN103806180AReduce binding forceExtended service lifeWoven fabricsYarnPulp and paper industry

The invention belongs to the technical field of textiles and particularly relates to warp and weft forwards and backwards entwisted white body wide-angle interwoven fabric. The white body fabric is formed by weaving warp and weft in the angle ranging from 20 degrees to 40 degrees or the angle ranging from 140 degrees to 160 degrees. The warp is composed of forwards-entwisted yarn which is formed by twisting raw material yarn and backwards-entwisted yarn which is formed by twisting the raw material yarn. The weft is composed of forwards-entwisted yarn which is formed by twisting the raw material yarn and backwards-entwisted yarn which is formed by twisting the raw material yarn. The warp and the weft are arranged at intervals in the forwards entwisting mode and the backwards entwisting mode or arranged at intervals in the backwards entwisting mode and the forwards entwisting mode. Two strands of the warp form a group and the two strands of the warp of each group are forwards entwisted by 360 degrees and backwards entwisted by 360 degrees to form forwards twisted knots and backwards twisted knots which are arranged at intervals. The weft is compactly arranged at the corresponding forwards twisted knots and the corresponding backwards twisted knots of the two strands of the warp of each group and in closed rings formed by the backwards twisted knots and the forwards twisted knots. According to the warp and weft forwards and backwards entwisted white body wide-angle interwoven fabric, the weft is fixed by means of an entwisted structure, the service life is prolonged, the good warping strength is achieved and internal squirming is little.

Owner:ZHEJIANG GUOLI TECH

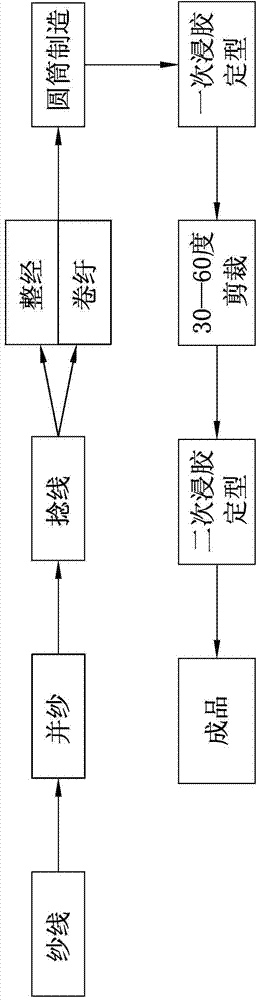

Production technology for impregnated interwoven fabric

InactiveCN103806278AOutstanding and Beneficial Technical EffectsEasy to cutFibre treatmentWoven fabricsTextile technologyPolyvinyl alcohol

The invention belongs to the technical field of textile, and relates to a production technology for impregnated interwoven fabric. The production technology comprises the steps of doubling yarns, twisting yarns, warping and carrying out pirn winding to produce a cylindrical cloth through a cylindrical weaving machine, performing one-time impregnation and setting, shearing strip-shaped fabric according to a 45-degree included angle formed with the edge of the cylindrical cloth, performing secondary impregnation on the shorn strip-shaped fabric, and then carrying out stretching and setting to form an impregnated wide-angled cloth product in which the warp yarns and weft yarns form included angles of 20-40 degrees or wide angles of 140-160 degrees, wherein the formula used in the primary impregnation comprises the following active ingredients in parts by weight: 0.5-2 parts of polyvinyl alcohol and 98-99.5 parts of water; the formula used in the secondary impregnation comprises the following active ingredients in parts by weight: 5+ / -0.1 parts of natural latex, 20+ / -0.1 parts of butadiene-vinyl pyridine latex, 10+ / -0.1 parts of water, and 15+ / -0.1 parts of 6.5% RLF solution. The production technology has the advantages that the shearing accuracy is high after the primary impregnation, the utilization rate of the fabric is high, latex is evenly distributed in the fabric and firmly bonded after primary and secondary impregnations, and the production technology is applicable to production of fabric wrapping layers of a triangular belt or a toothed belt.

Owner:ZHEJIANG GUOLI TECH

Energy dissipation rotating type connecting method for stair joint connection

ActiveCN110700503AImprove seismic performanceHas the function of energy dissipation and shock absorptionProtective buildings/sheltersStairwaysArchitectural engineeringControl theory

The invention relates to the field of fabricated prefabricated stair construction, and particularly discloses an energy dissipation rotating type connecting method for stair joint connection. The method comprises the following steps of 1 prefabricating parts, 2 laying a horizontal damping seismic isolation layer, 3 placing prefabricated stair ends, 4 connecting a bottom rotating steel plate, 5 filling in gaps and 6 connecting a top rotating steel plate. According to the connecting method, the connected rotating steel plate can supply certain rotation and can also supply vertical restraint andhorizontal restraint, when stairs are vibrated, the damping seismic isolation layer supplies certain deformation, the rotating steel plate can supply a certain rotating amount, the damping seismic isolation layer is matched with the rotating steel plate, and the anti-seismic performance of stairs is effectively improved.

Owner:SHAOXING UNIVERSITY +1

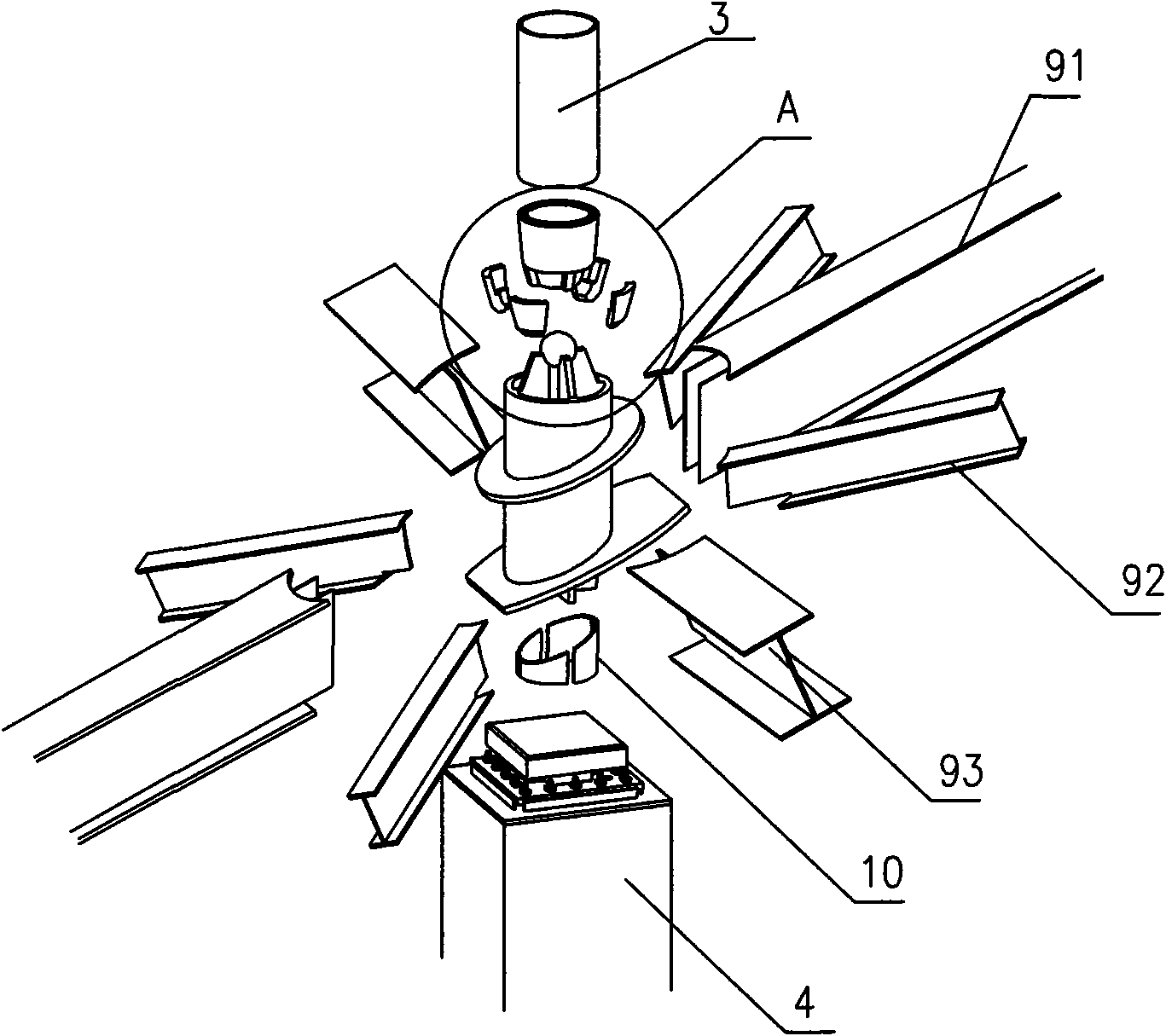

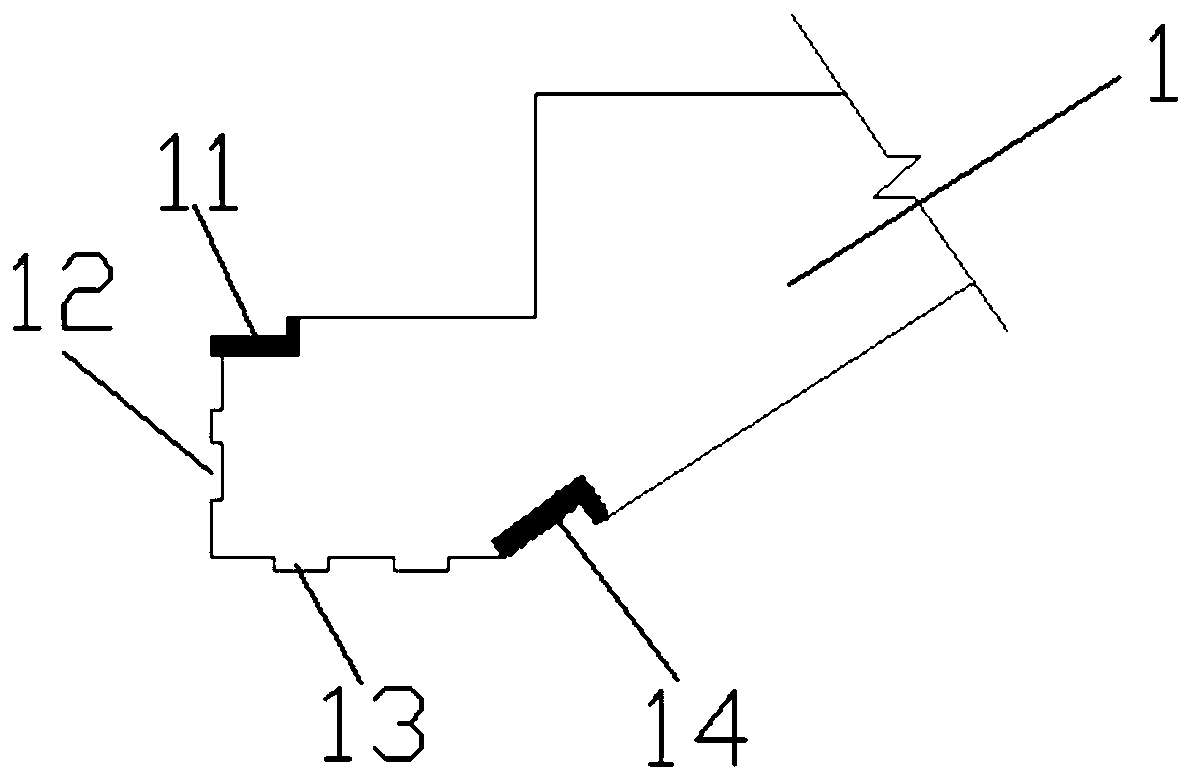

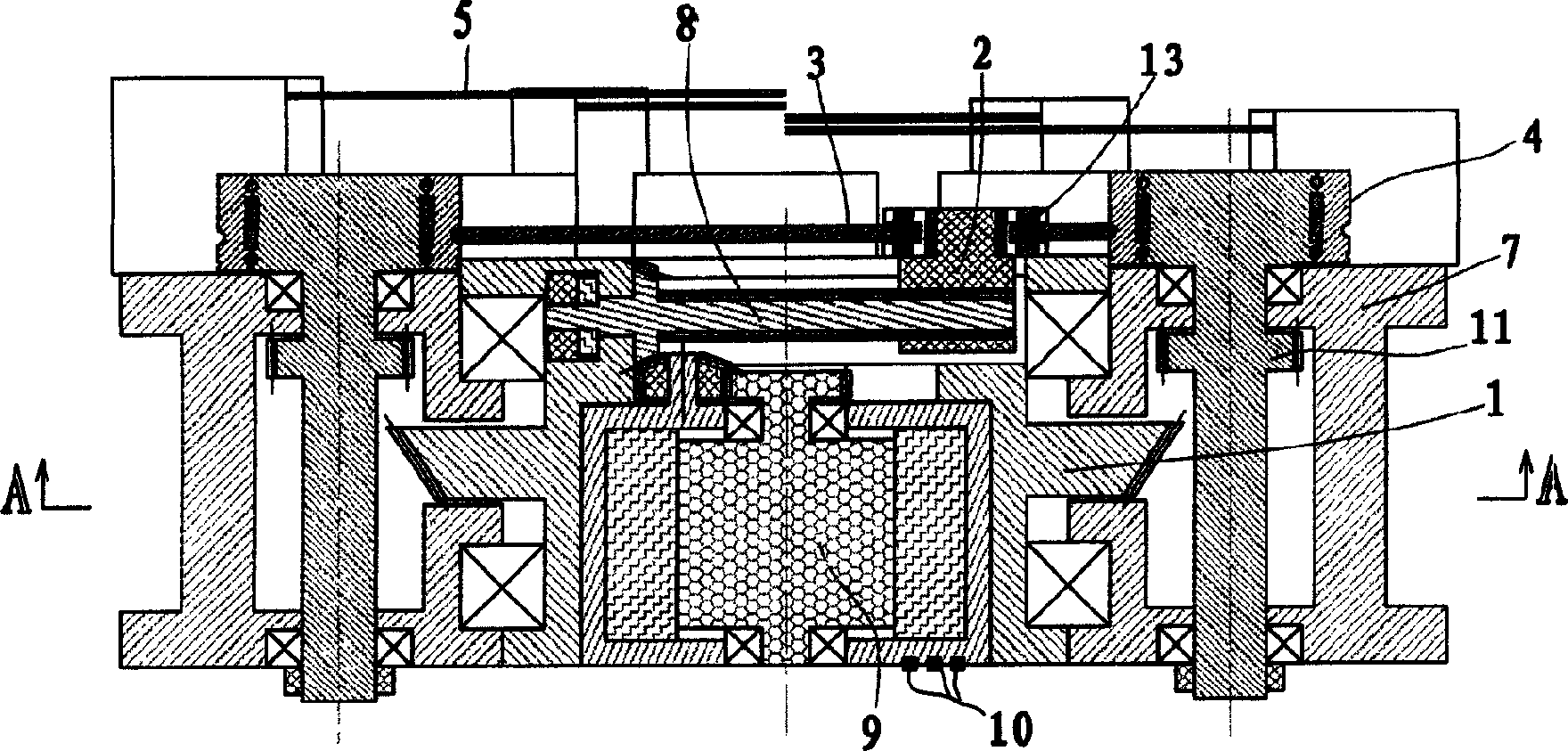

Rotary cutter of binding instrument for surgery

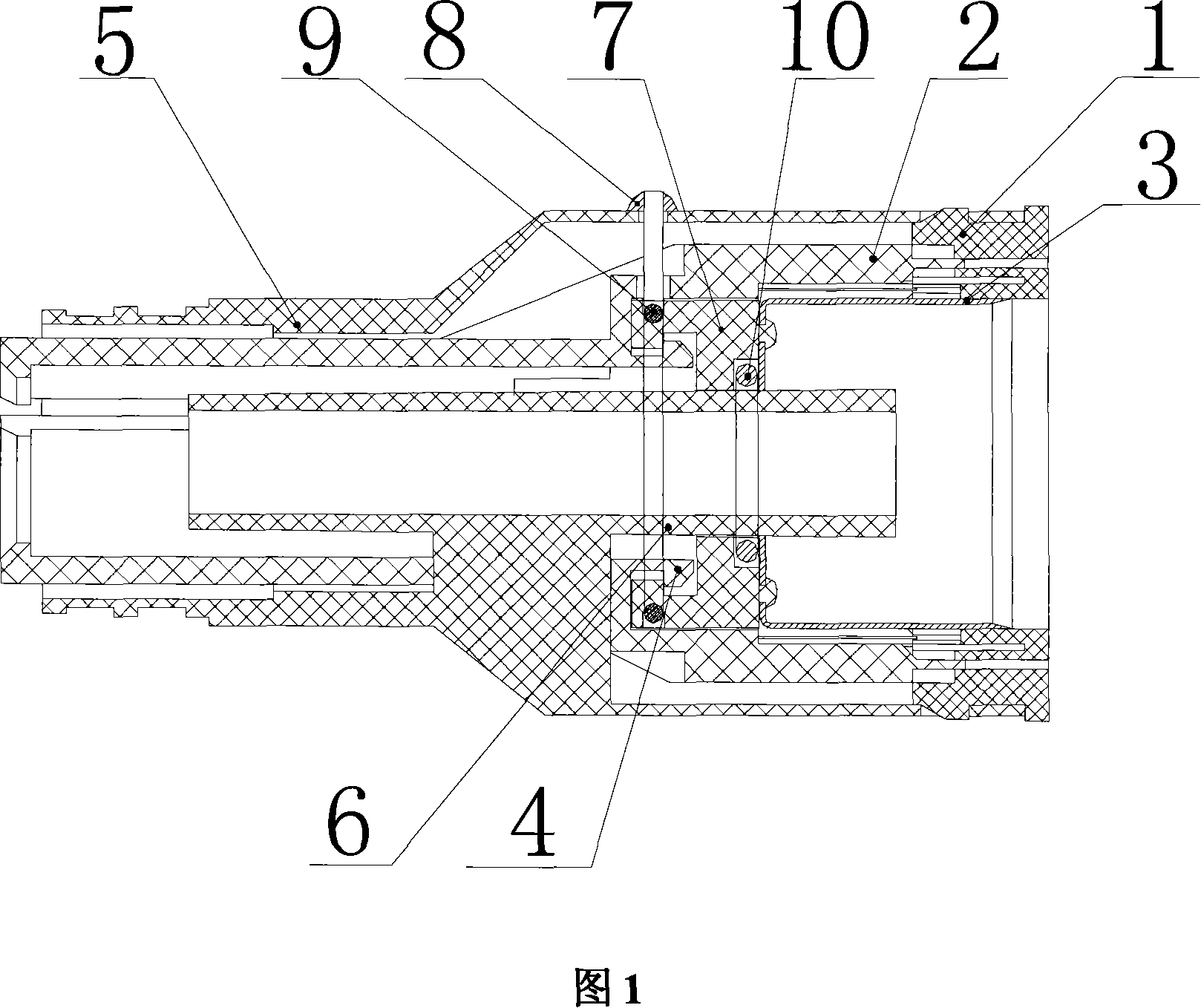

ActiveCN101152099AReduce resistanceReduce binding forceIncision instrumentsSurgical staplesBinding forceSurgical binding

The present invention relates to a rotary cutter for a surgical binding instrument, which comprises a nail box, a nail pusher, a loop-shaped cutter, a nail pushing column, a nail cylinder and a line-pulling turning sleeve module. A feeding device for the loop-shaped cutter is a rotary feeding device, which is formed by the nail box, the nail pusher, the loop-shaped cutter, the nail cylinder and the line-pulling turning sleeve module; the inner of the nail box is provided with an anti-expansion pipe, and a step-shaped round tubular nail pusher is arranged between the anti-expansion pipe and an inner wall of the nail cylinder, which matches the nail cylinder inner wall shape; both a front end of the nail cylinder and a front end of the nail pusher are a cavity matching the loop-shaped cutter that is covered on the anti-expansion pipe and is positioned in the cavity; the front end circumferential edge of the nail cylinder and the nail pusher is connected and touched with the loop-shaped nail box; the loop-shaped cutter is connected with the nail pusher and the anti-expansion through the turning sleeve module. The present invention effectively reduces resistance of cutting a tissue and reduces tissue pulling cuts caused by cutting, which is characterized by cutting the tissue safely and reliably, and reducing a binding force needed by an operation.

Owner:TOUCHSTONE INTERNATIONAL MEDICAL SCIENCE CO LTD

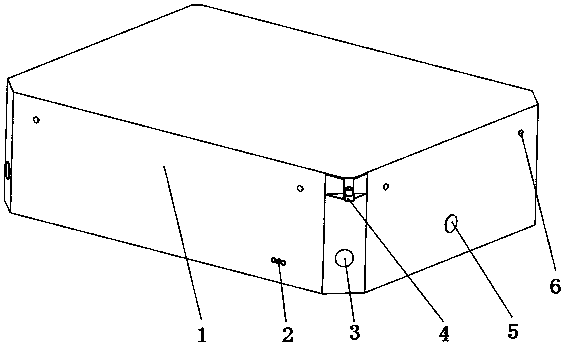

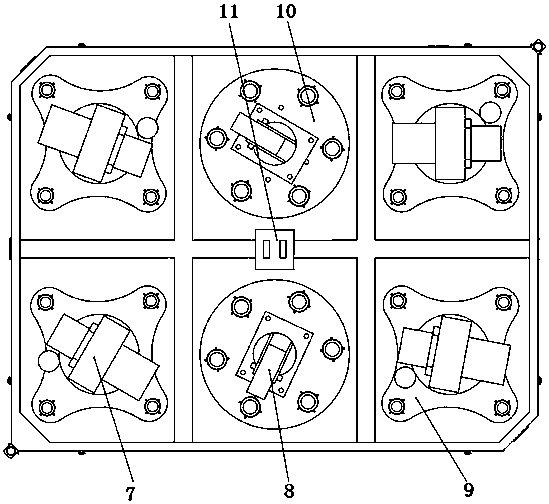

AGV (automated guided vehicle)

PendingCN108622193AStrong driving forceGuaranteed steering performanceResilient suspensionsNon-deflectable wheel steeringVehicle frameSteering wheel

The invention relates to the field of automatic transporters and particularly provides an AGV (automated guided vehicle). The AGV comprises a frame and wheels arranged on the frame and is characterized in that the wheels are arranged at the corners of the frame, and the wheels are the driving steering wheels for driving the AGV to move. The AGV has the advantages that when the AGV turns, each driving steering wheel at the corresponding corner of the frame can provides power for the turning of the AGV, the driving torque of the driving steering wheels is large, each driving steering wheel can be independently controlled, the four driving steering wheels can be coordinated to form the overall direction of the turning of the AGV, the problem that the universal wheels, which cannot actively change directions, of an existing AGV affect the motion of the AGV during turning in the prior art is avoided, the multiple driving steering wheels work at the same time during the turning or in-situ turning of the AGV, the driving force output by the AGV is strong, and the turning effect of the AGV can be guaranteed.

Owner:HENAN SENYUAN ELECTRIC CO LTD

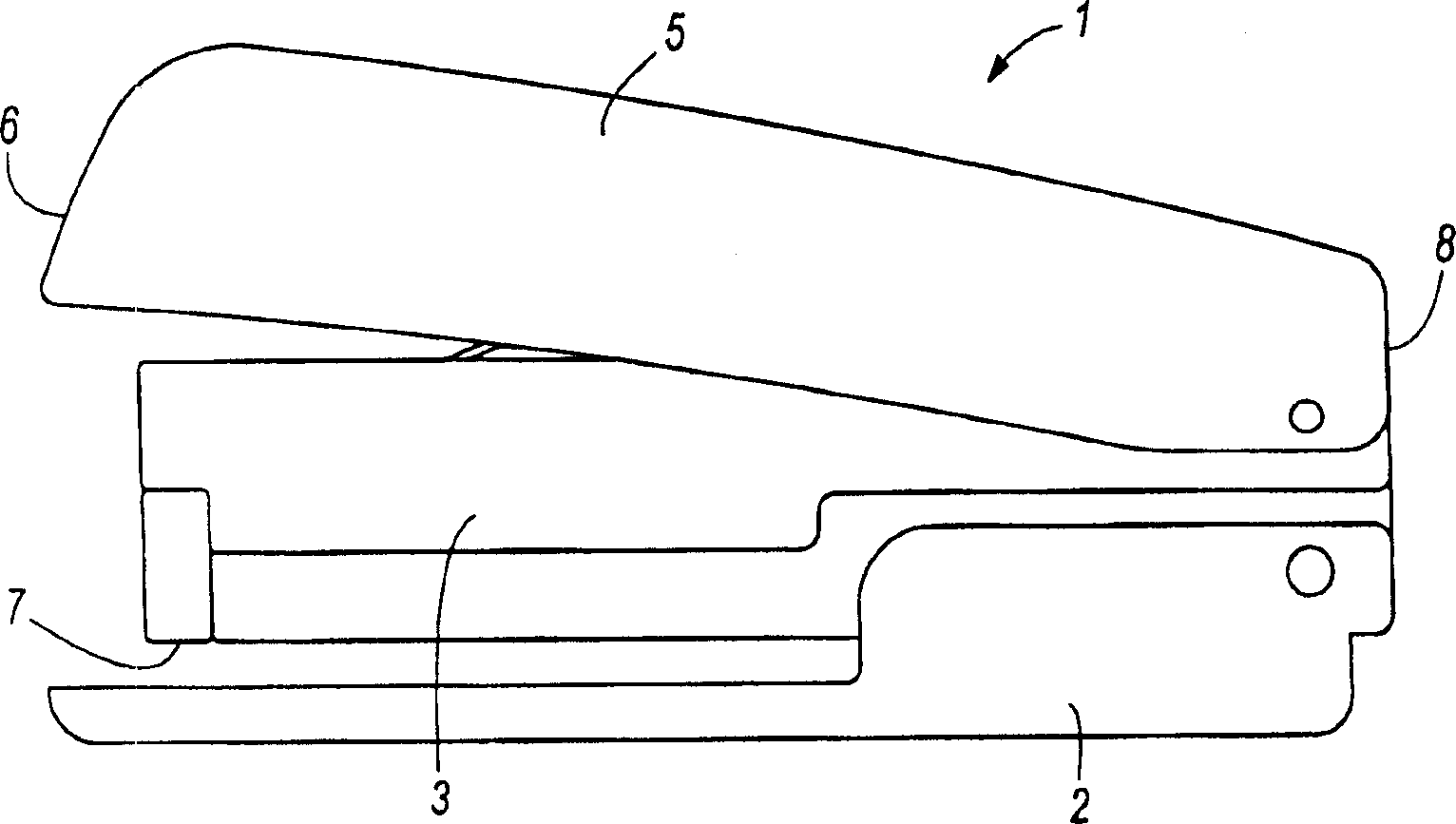

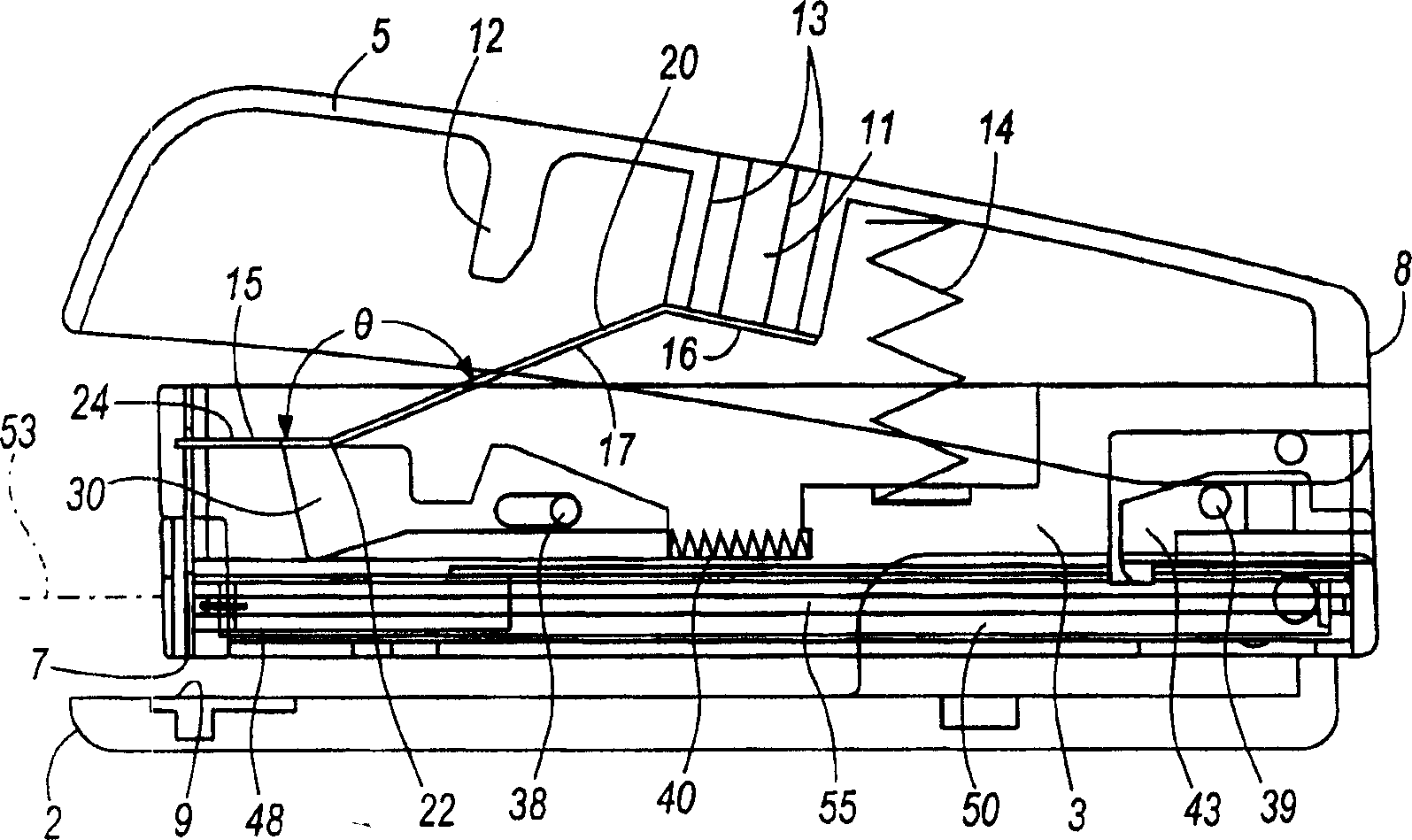

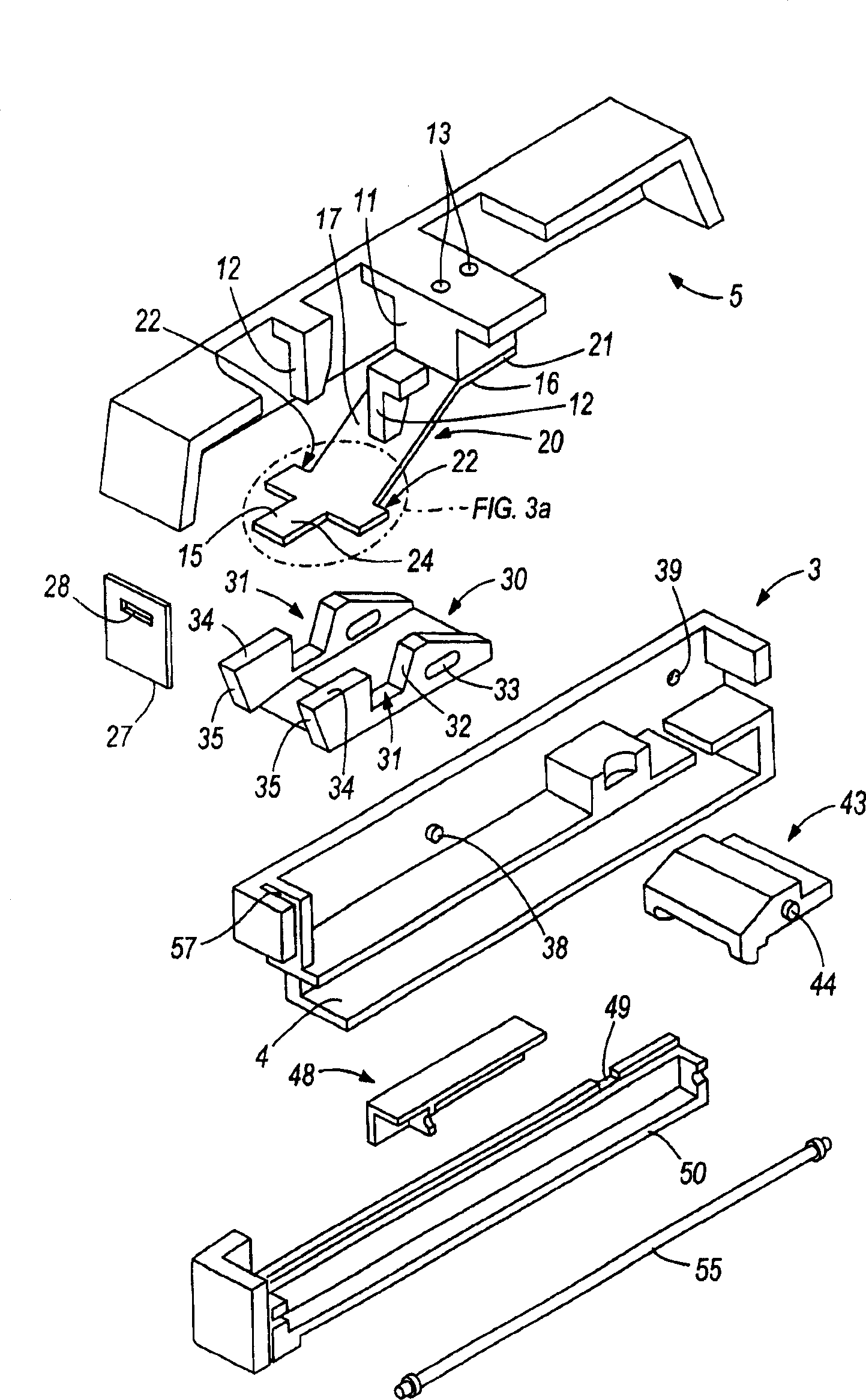

Stapler

InactiveCN1895909AReduce noiseIncrease the number ofStapling toolsSheet bindingRest positionFront and back ends

A stapler movable between a rest position and a stapling position and having a front end and a rear end. The stapler includes a base, a staple magazine coupled to the base and configured to hold staples, and a driver blade operable to drive staples out of the staple magazine during stapling operations. The stapler further includes an elastic member coupled to the driver blade and operable to move the driver blade during stapling operations. The elastic member utilizes potential energy to move the driver blade during stapling operations. The driver blade is positioned above the staple magazine when the stapler is in the rest position and the magazine is extendable from the front end of the stapler to allow a user to load staples in the magazine. The stapler is configured such that only the potential energy of the elastic member can operate the driver blade during stapling operations.

Owner:阿科布兰兹美国有限责任公司

Method for treatment of mercury-containing wastewater by superconducting magnet magnetic field intensified sulfuration process

InactiveCN105174393AImprove removal efficiencyIncrease profitWater/sewage treatment by magnetic/electric fieldsWater/sewage treatment by flocculation/precipitationFiltrationWater quality

The invention relates to a method for treatment of mercury-containing wastewater by a superconducting magnet magnetic field intensified sulfuration process. The method adopts a completely mixed reactor, a metal sulfide is added into mercury-containing wastewater, a magnetic field is applied around the completely mixed reactor to realize rapid precipitation reaction of the metal sulfide and mercury, so that the water can be purified. According to the invention, under the action of the superconducting magnet strong magnetic field, the conductivity of the solution increases, the electric potential decreases, the flocculating settling speed and filtration speed of sulfide residue are enhanced, and the utilization rate of sulfurizing agent is also increased. The method for treatment of mercury-containing wastewater by the superconducting magnet magnetic field intensified sulfuration process provided by the invention can be used for removal of mercury pollutants in groundwater, industrial wastewater and other water bodies.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI +1

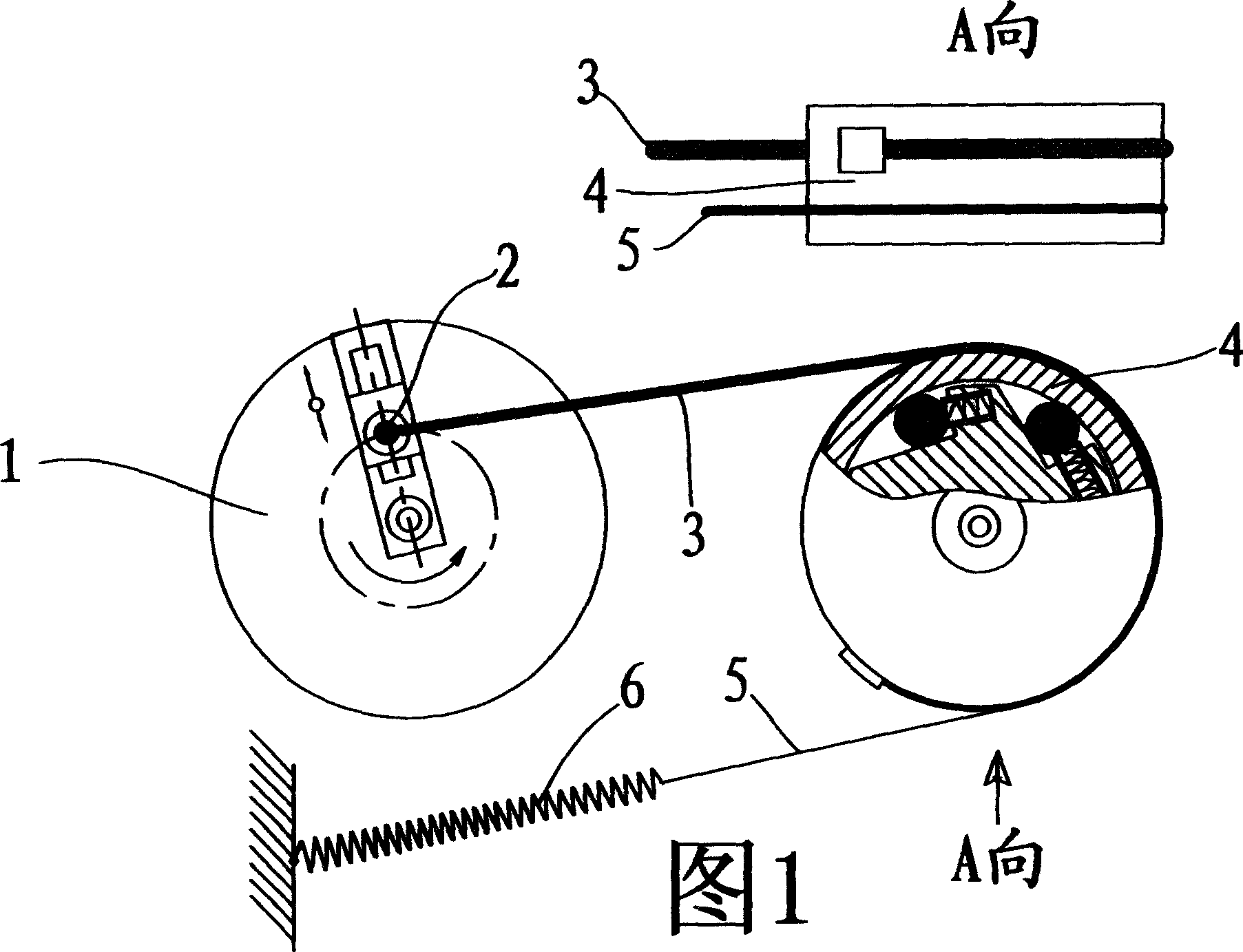

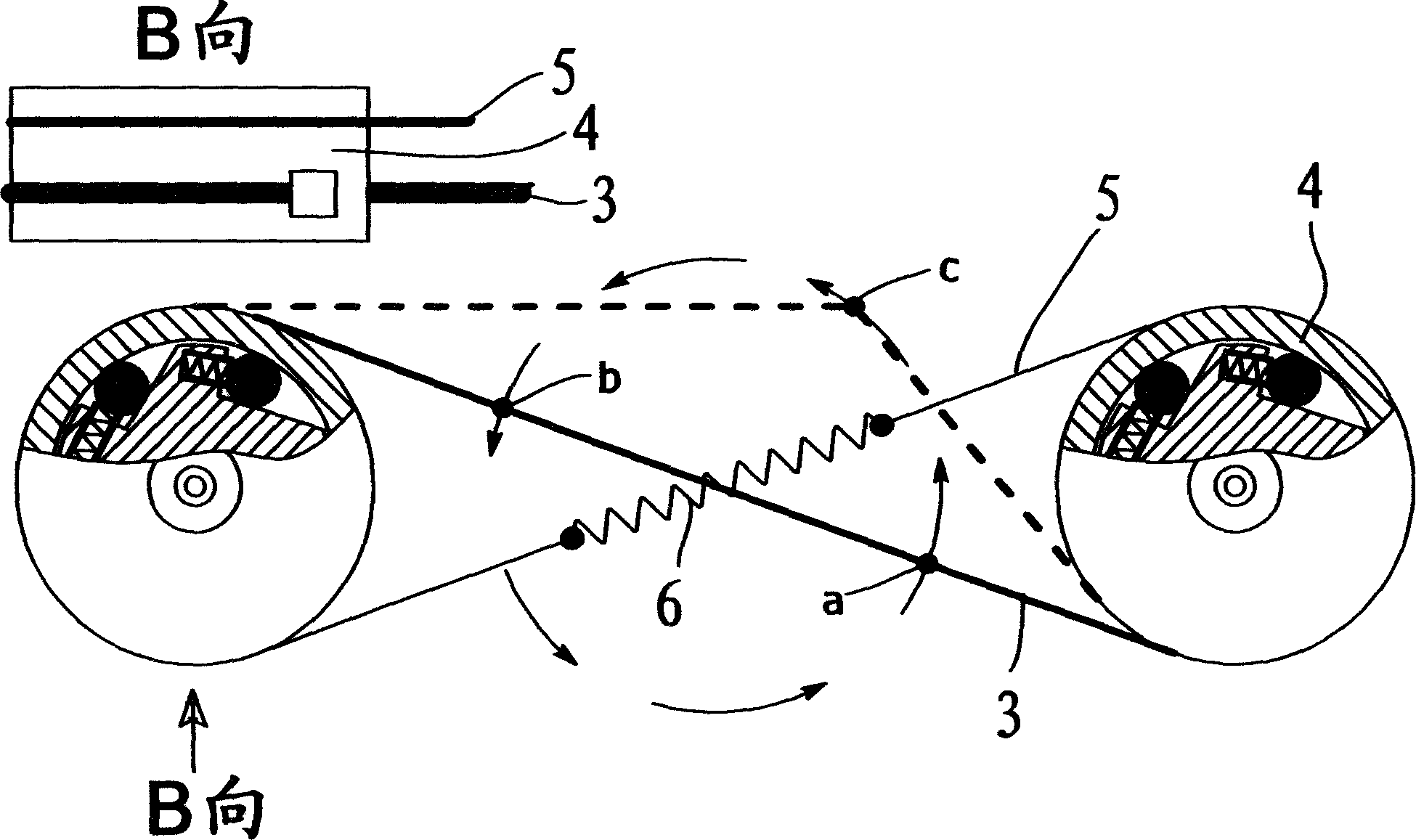

Cable type impulse stepless gear box

InactiveCN1607343AIncrease input speedImprove efficiencyGearingGearing controlControl theoryVariator

The invention discloses a rope-type pulsating stepless transmission, which uses an adjustable crank to pull the active ring of the output mechanism through the rope to do work, and uses a spring to pull the return stroke to realize the whole transmission. The pulsating continuously variable transmission has high input speed, low vibration and high efficiency, and is mainly used in continuously variable transmission systems of automobiles and outdoor mechanical equipment.

Owner:林志贺

Integrated bridge abutment structure for controlling earth pressure behind abutment and filled earth settlement and construction method

InactiveCN106638280AIncrease stiffnessAvoid crackingRoadwaysBridge structural detailsRoad surfaceAbutment

The invention relates to an integrated bridge abutment structure for controlling earth pressure behind an abutment and filled earth settlement and a construction method. The integrated bridge abutment structure comprises an abutment body and a lapping plate, wherein an upper filled earth layer and a lower filled earth layer which are reinforced and firmed by a plurality of layers of geogrids are laid above and below the lapping plate respectively in the vertical direction, the upper filled earth layer upward extends to be laid on the road surface, and the lower filled earth layer downward extends to be laid on the abutment. A first gap is reserved between the upper filled earth layer and the lower filled earth layer and the surface of the lapping plate and the surface of the abutment body respectively. An end opening formed in the upper horizontal end of the lapping plate is in rigid connection with the abutment body. The end portion of the lower horizontal end of the lapping plate is sealed by a rectangular steel sleeve, a second gap is reserved between the inner side of the rectangular steel sleeve and the outer side of the lower horizontal end of the lapping plate and is filled with a rubber layer immersed with grease, and the outer surface of the rectangular steel sleeve is coated with an anticorrosive coating. The integrated bridge abutment structure utilizes good deformation of the lapping plate and reinforcement and firming of the geogrids, is good in integrity, improves pavement strength and effectively controls settlement behind the integrated bridge abutment.

Owner:FUZHOU UNIV

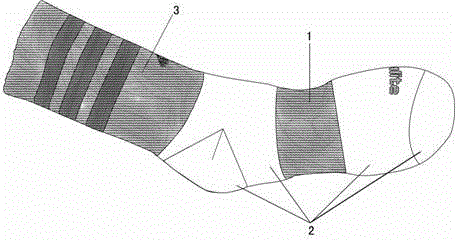

Unwrapped spandex yarn sock production method

The invention relates to an unwrapped spandex yarn sock production method. The production method is characterized in that during the concrete weaving process, a Lonati G615L type sock machine is employed and weave from a collar to the sock toe; for the collar, main yarn cotton yarns with 1.4cm are fed and a sock leg is weaved by material with the length of 22.6cm and has the same position as the collar; the whole sock leg is weaved by cotton yarns and spandex yarns; the sock heel is weaved by cotton yarns; the sock surface is weaved by cotton yarns with the length of 20.5cm; hand linking is employed for sewing linking; the linking is fixed via a steam fixing machine; the concrete parameter of the steam fixing machine are that pressure is 0.13MPa, the temperature is 120 DEG C and dwelling time is 5s; traditional weaving technology is changed; a specific protection structure is added; the whole structure is designed according to the features of sport socks; the sock main body is weaved by combed cotton, nylon yarns and exposed spandex yarns in a blend way via the special transmission weaving technology; full-rubber strings are replaced by the spandex yarns, so enough elasticity is provided; the spandex yarns can be seen with naked eyes; the sock toe, the full foot palm and the heel are pile-loop weaved, so the sock is tightly attached to the heel part; obvious damping effect is achieved upon sports; sports wounds can be prevented; and novel socks with light weight, small pressure and protecting performance is realized.

Owner:吉林省东北袜业园织袜有限公司 +1

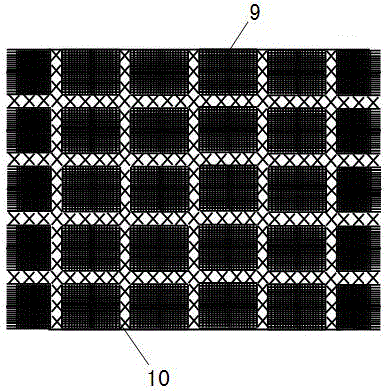

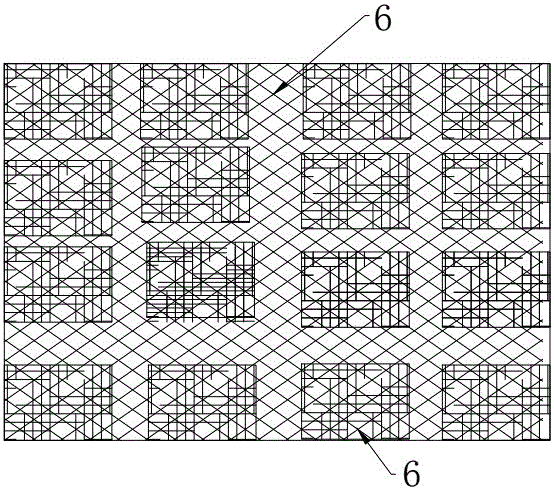

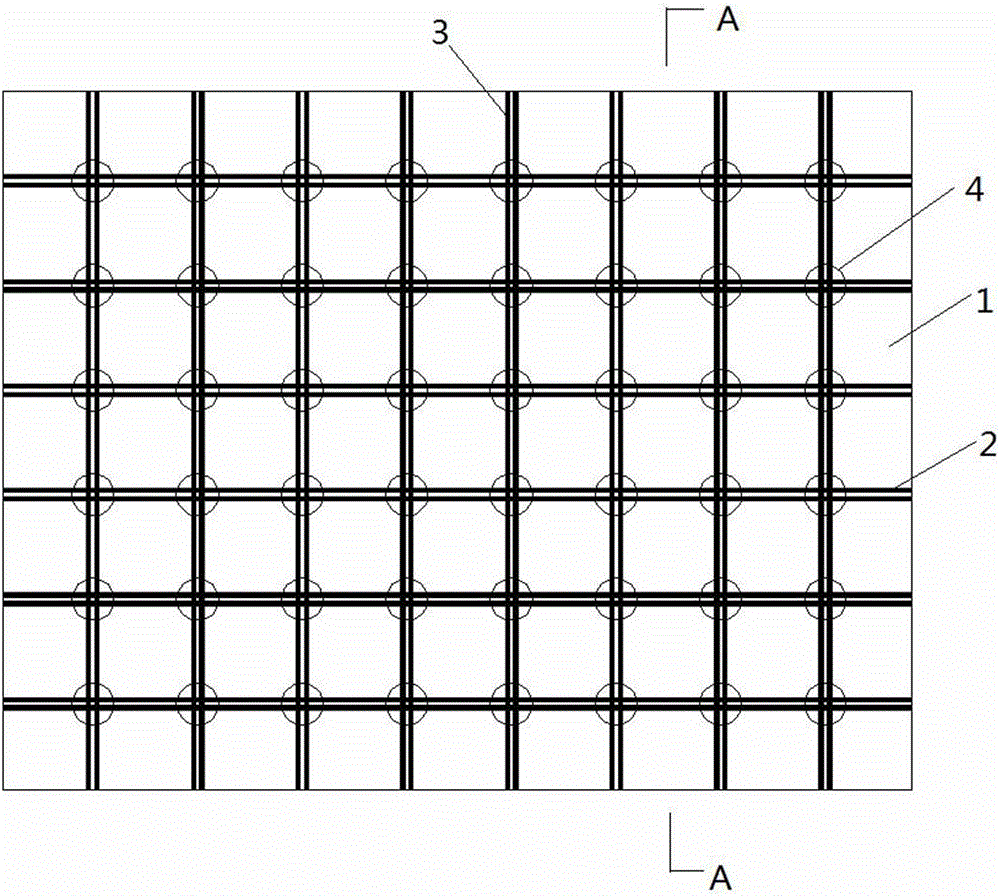

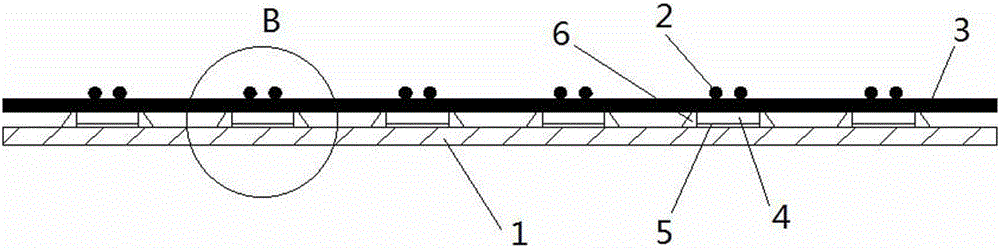

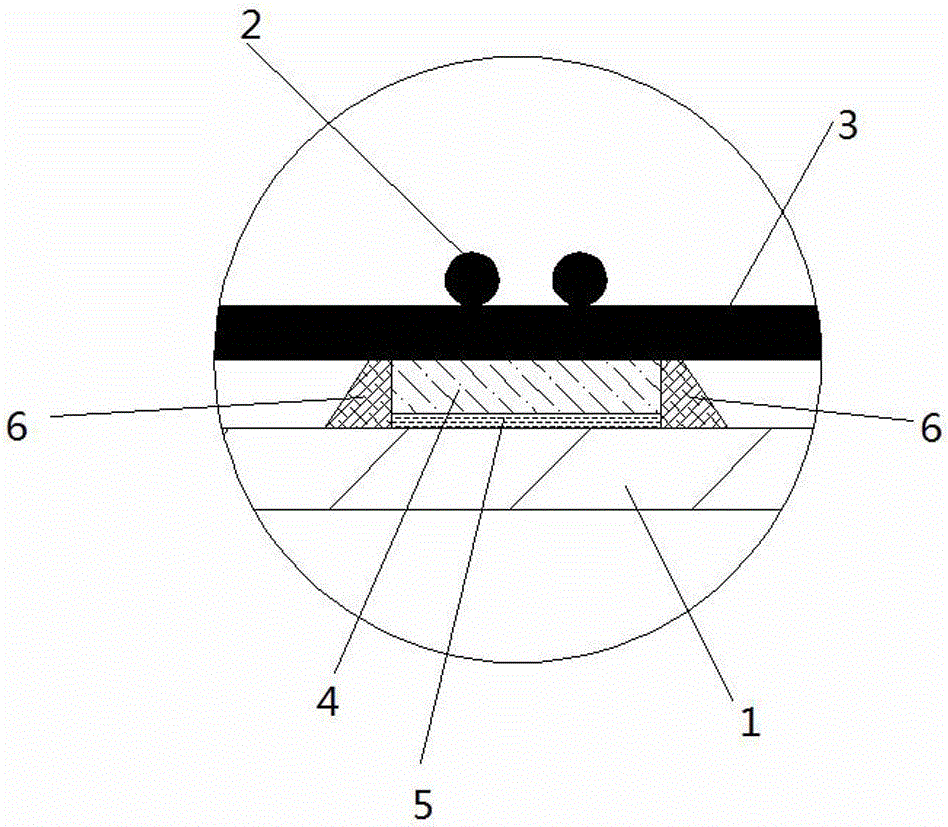

Reinforced fiberglass geogrid for subgrade and manufacturing and construction methods thereof

ActiveCN105951555AShrink does not driveReduce binding forcePaving reinforcementsPolyesterGlass fiber

The invention discloses a reinforced fiberglass geogrid for a subgrade. The reinforced fiberglass geogrid comprises polyester fiberglass cloth (1) and a fiberglass geogrid body. The fiberglass geogrid body is formed through warp knitting, an expanding joint (4) is arranged on the bottom surface of each knitting point, and the surface of the fiberglass geogrid body is coated with a coating. The upper surface of the polyester fiberglass cloth (1) is provided with a plurality of clamping structures (6); the shapes of the clamping structures (6) are matched with those of the expanding joints (4), and the positions of the clamping structures (6) correspond to those of the expanding joints (4); and the expanding joints (4) are clamped in the clamping structures (6). In the manufacturing process of the reinforced fiberglass geogrid for the subgrade, the fiberglass geogrid body and the polyester fiberglass cloth (1) are matched only in a clamping mode and do not need to be fixed through bonding. During construction, the clamping structures are fused under the high temperature environment, the constraining force of the clamping structures to the fiberglass geogrid body is reduced, and shrinkage produced by the polyester fiberglass cloth (1) cannot drive shrinkage of the fiberglass geogrid body; and the fiberglass geogrid body and the polyester fiberglass cloth are tightly composited together at the construction site after being ground and cooled, and the mechanical properties of the fiberglass geogrid body can be fully played.

Owner:山东大庚工程材料科技有限公司

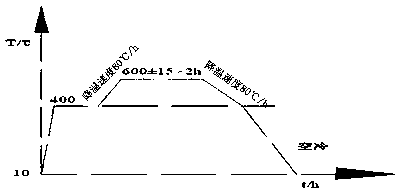

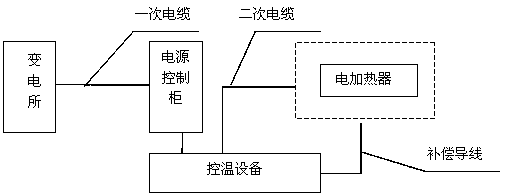

Non-strengthening heat treatment construction technology for over-sized device aerial strength weld

InactiveCN107043849AGuarantee the quality of heat treatmentGuaranteed feasibilityFurnace typesHeat treatment process controlTemperature stressPetrochemical

The invention relates to a non-strengthening heat treatment construction technology for an over-sized device aerial strength weld. Along with the fast development of maximization, modularization and automation of a petrochemical device, compared with an overall lifting technology, an over-sized device aerial assembling technology can relieve the pressure of field plane arrangement and can also reduce the parameter grade of a crane; however, high-temperature stress will be certainly generated at the weld position to cause cylinder deformation when the aerial weld is affected by the factors such as the heating temperature, the constant-temperature time, the weld upper portion device weight and the wind load during heat treatment. By means of the non-strengthening heat treatment construction technology for the over-sized device aerial strength weld, targeted safety technological measures are implemented through data mastered through a material high-temperature test under the premise that the device aerial heat treatment weld is not strengthened, the heat treatment quality of the weld is ensured, feasibility of the technology is forcefully verified, and the non-strengthening heat treatment construction technology is worthy of being applied and popularized in the same industry.

Owner:陕西化建工程有限责任公司

Correction method for angle-inclined telegraph pole signboard

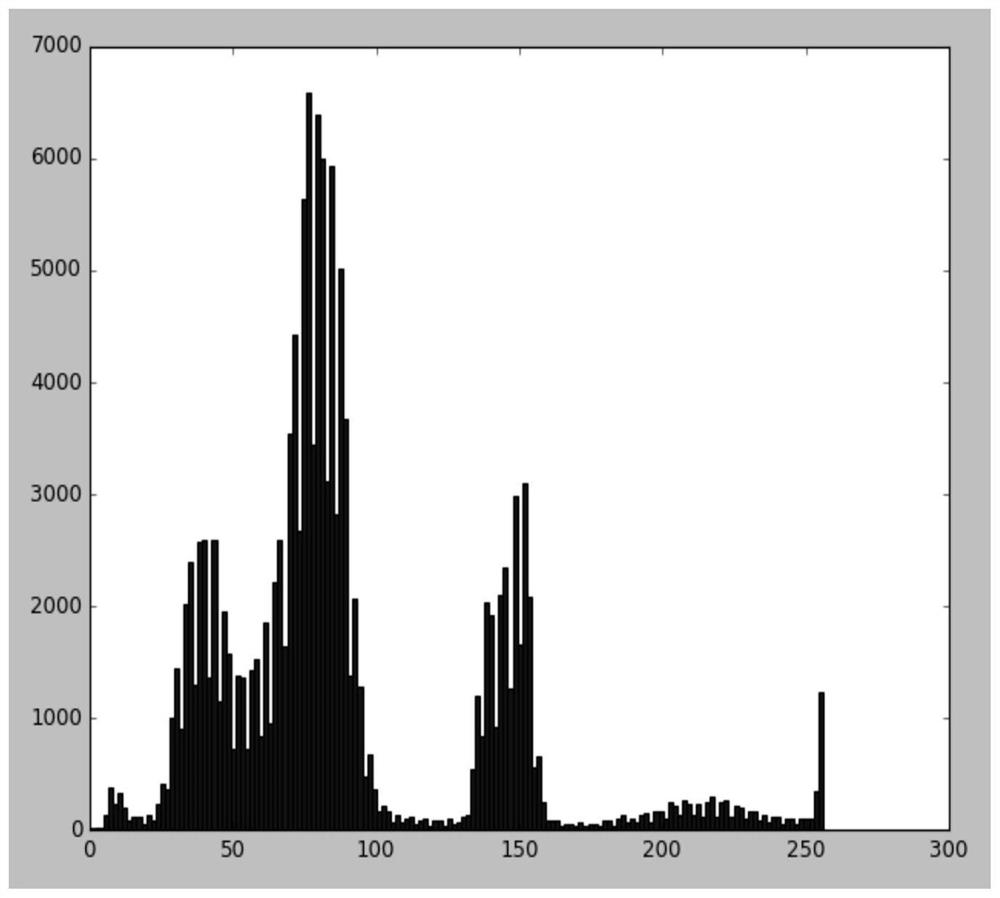

PendingCN111783773AReduce binding forceIncrease flexibilityCharacter and pattern recognitionImaging processingComputer graphics (images)

The invention discloses a correction method for an angle-inclined telegraph pole signboard, and belongs to the field of image recognition technology application. According to the method, an image processing technology is used for carrying out preliminary selection on a suspected target area, and the suspected area is separated from other areas through different thresholds; according to the characteristics of the telegraph pole signboard, noise reduction processing is carried out on all suspected areas to screen out the most suspicious area contour; a minimum enclosing rectangle of the area contour is searched, coordinates and rotation angles of four vertexes are extracted, and vertex coordinates of the inclined signboard are solved by utilizing the coordinates of the rectangle according toa geometrical similarity relation; and finally, inclination correction of the telegraph pole signboard is realized through correlation matrix transformation. The method has very high robustness, canquickly and accurately correct the inclined telegraph pole signboard, and improves the recognition speed and accuracy of the telegraph pole signboard.

Owner:BEIJING UNIV OF TECH

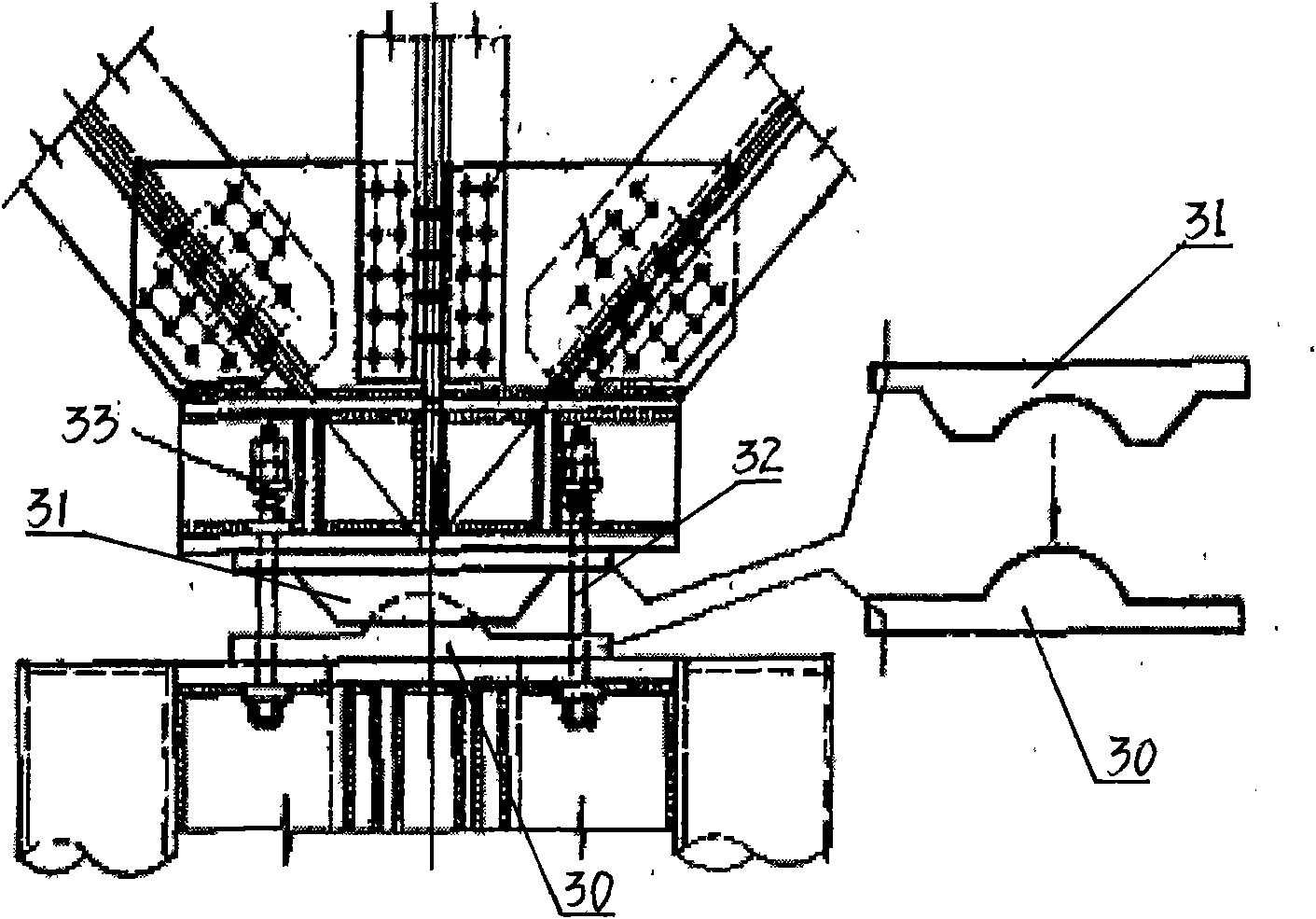

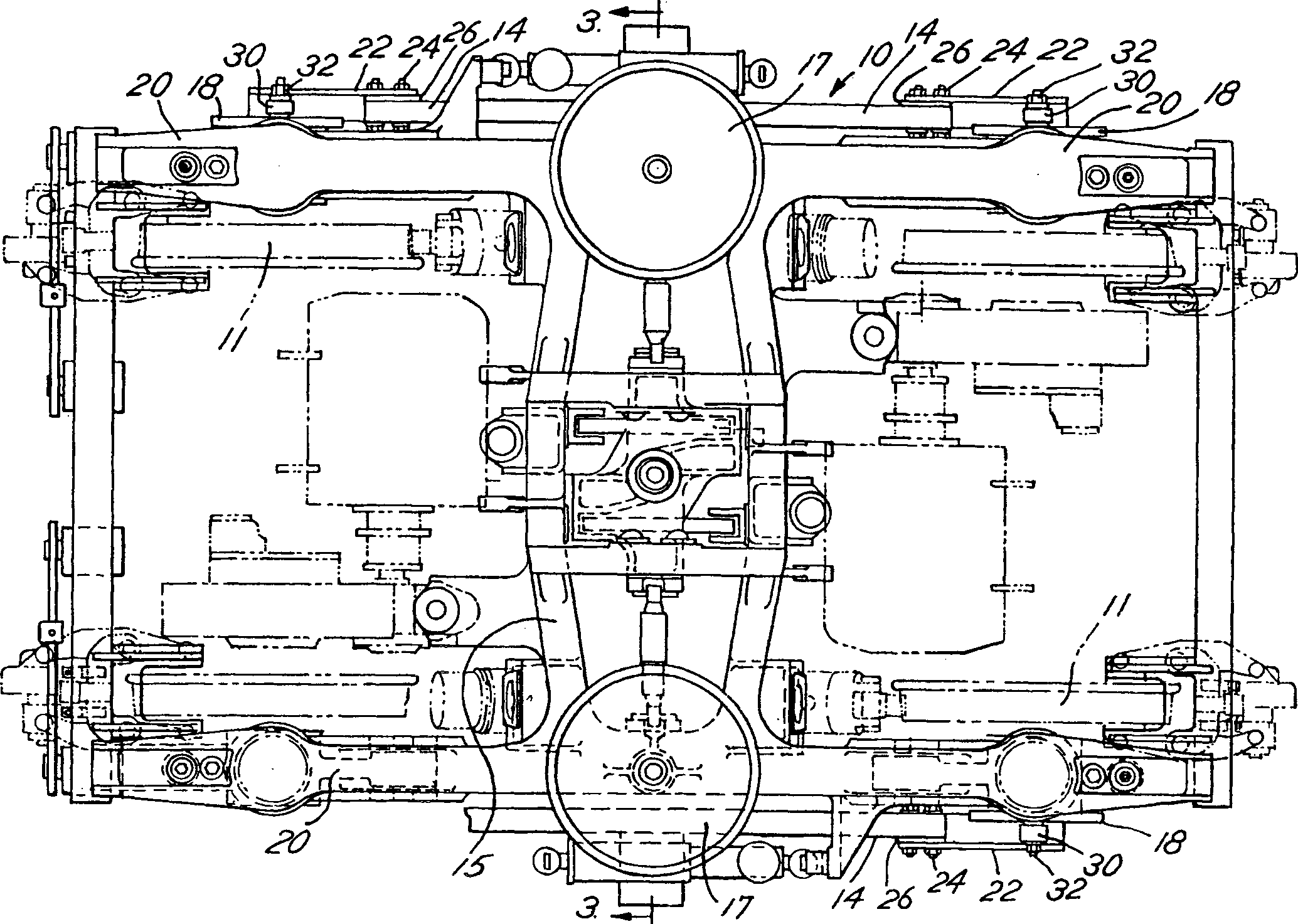

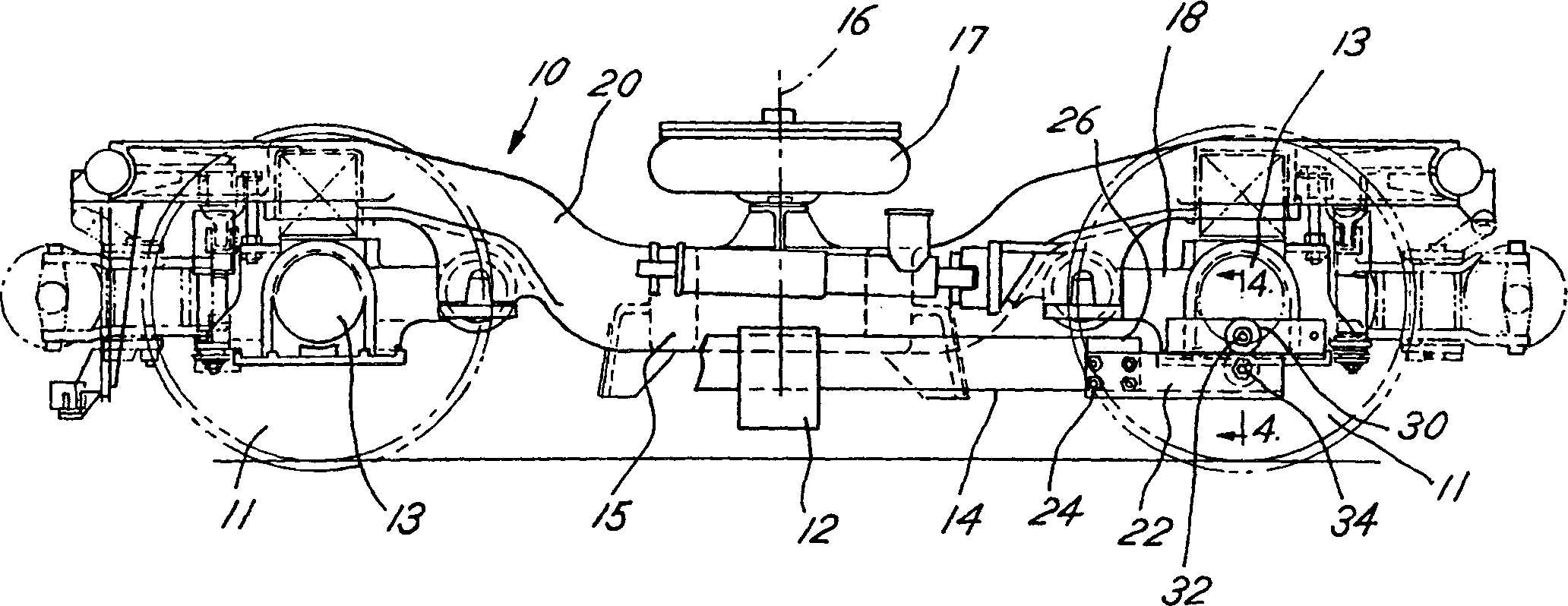

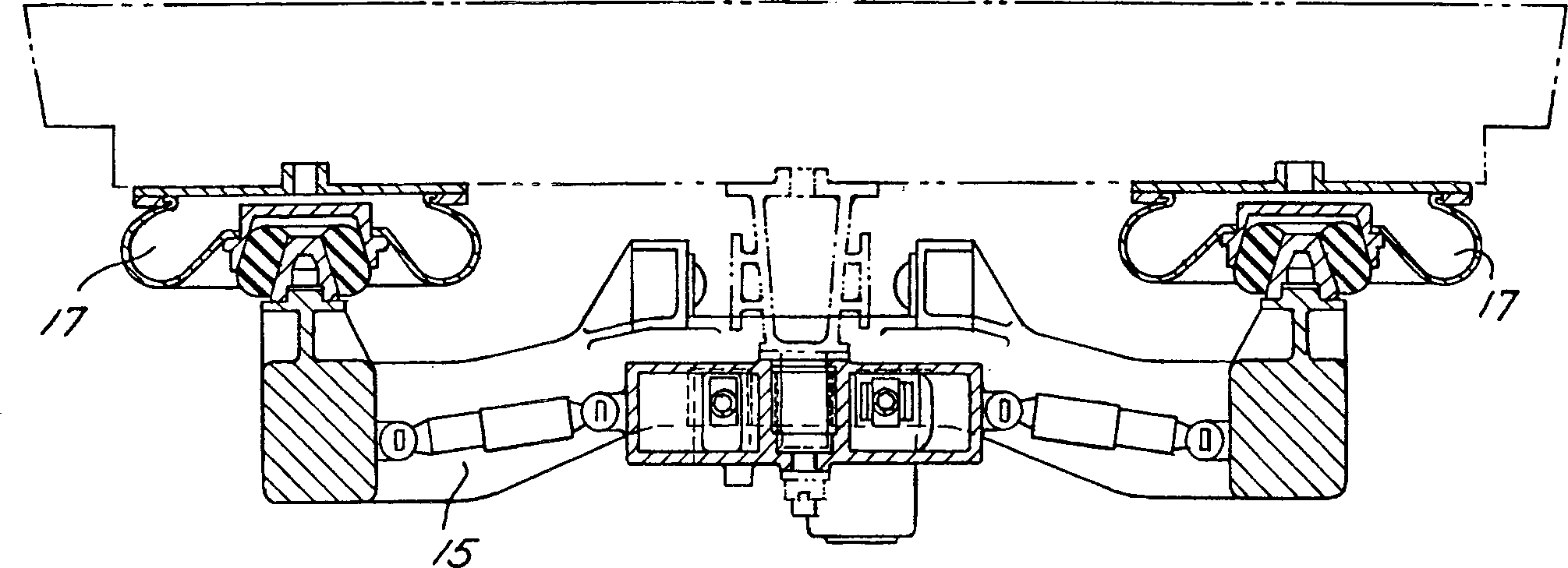

Unsprung third rail collector beam support for a swing arm primary suspension railway truck

An electric railway truck (10) comprises an unsprung third rail collector beam (14) for a swing arm primary suspension. The collector beam (14) and attached current collector (12) are mounted to the truck frame (20) through the use of mounting adapters (22), links (30), and elastomeric bushings (28). Specifically, in the vicinity of the swing arm axle housings (18), the collector beam (14) is secured to the mounting adapters (22) which, in turn, are suspended below the respective axle housings (18) by the links (30) and accompanying elastomeric bushings (28). The torsional deflection of the elastomeric bushings (28) permit the links (30) to swing in the longitudinal direction, thereby accommodating the relatively larger angular and longitudinal axle housing motions created by a swing arm primary suspension.

Owner:BUCKEYE STEEL CASTINGS CO

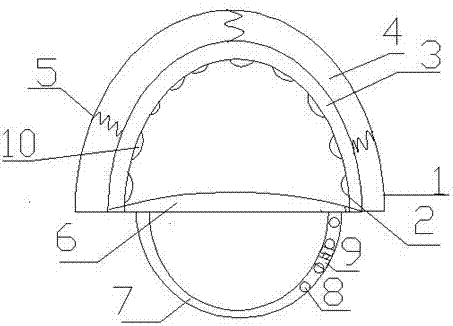

Adjustable comfortable radiating safety cap

InactiveCN107951106AComfortable to useHigh strengthHatsHeadwear capsPlastic materialsTemperature resistance

The invention discloses an adjustable comfortable heat dissipation safety helmet, which comprises an outer layer of a cap shell, an inner layer of the cap shell, an elastic heat dissipation layer, an elastic buffer layer, a buffer spring, a hat brim, a hat strap, an adjustment hole, an adjustment sheet and a massage ball , the inner end surface of the outer layer of the cap shell and the outer end face of the inner layer of the cap shell form an elastic heat dissipation layer and an elastic buffer layer, the lower end of the outer layer of the cap shell is fixed with a brim, and the lower surface of the brim is sewn There is a chinstrap, the surface of the chinstrap is provided with adjustment holes and adjustment pieces, and the lower surface of the inner layer of the hat shell is symmetrically inlaid with massage balls. The cap shell and brim of the adjustable comfortable heat dissipation helmet are made of ABS thermoplastic The plastic material makes the safety helmet have the characteristics of high strength, good insulation performance, high temperature resistance, water resistance, acid, alkali, oil and chemical corrosion. A card slot is arranged on the top to prevent the adjustment piece from slipping off.

Owner:苗强

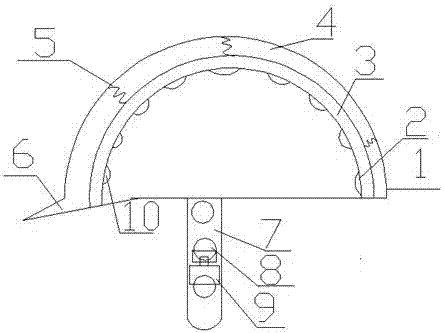

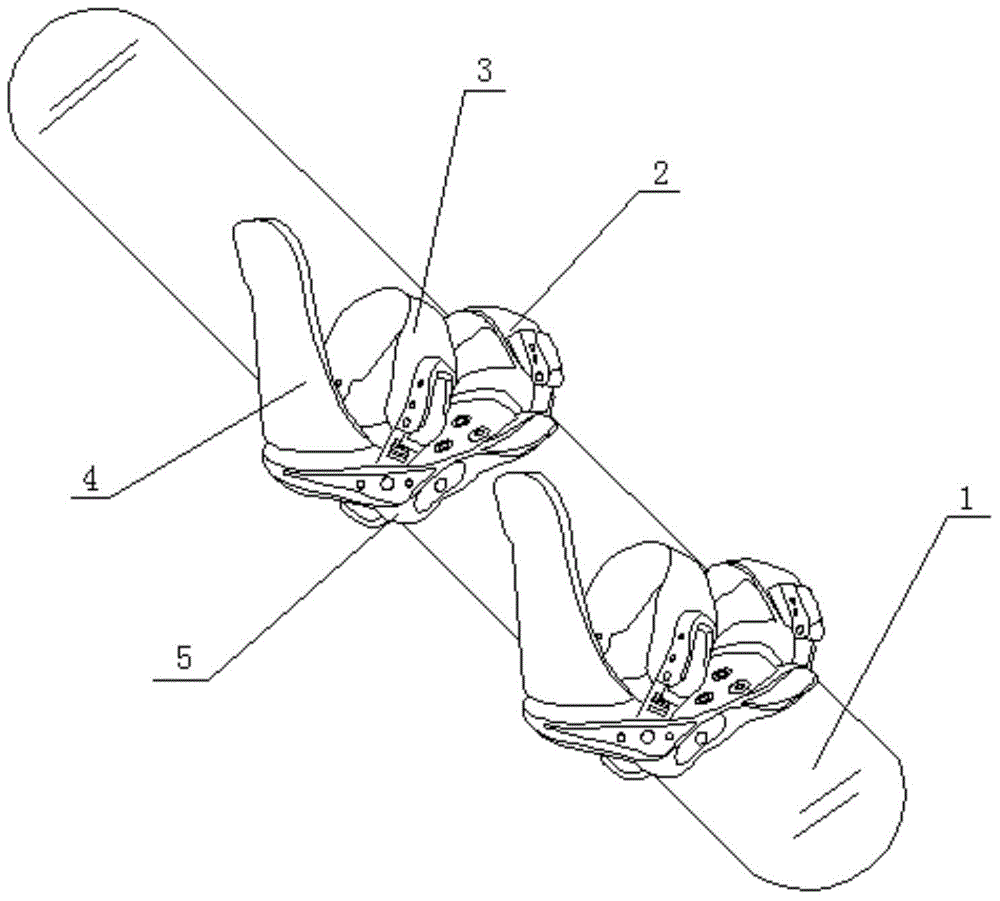

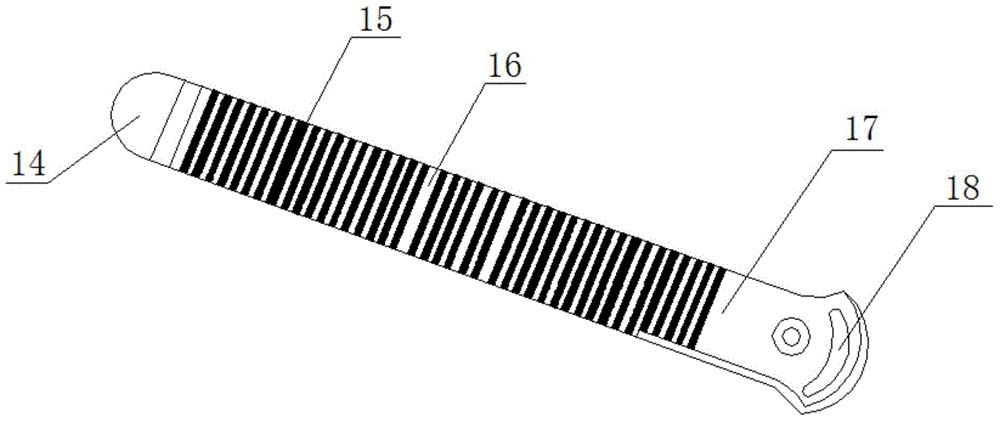

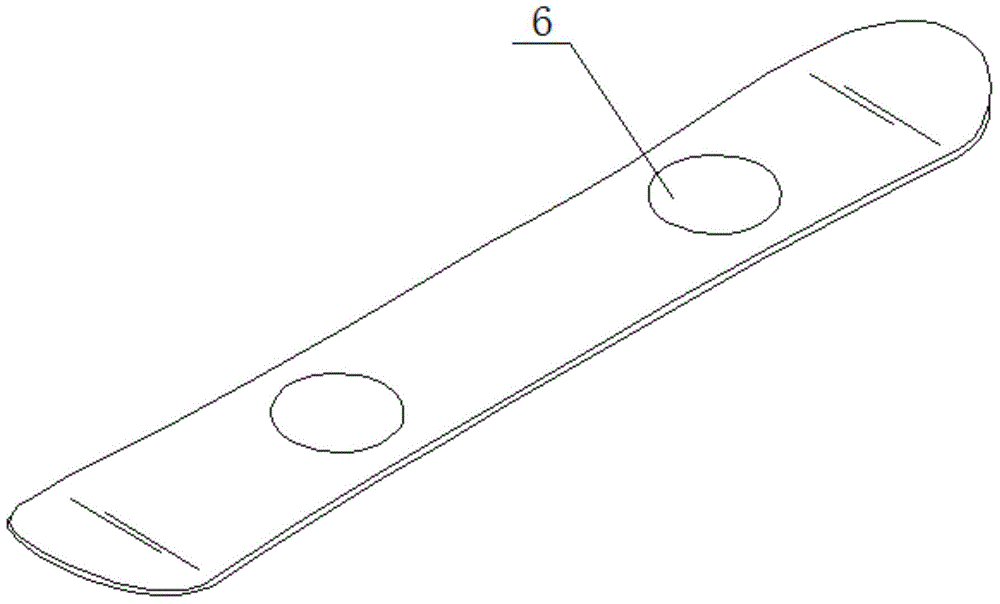

Comfortable ski

InactiveCN105107186AReduce impactReduce binding forceSnowboard bindingsSurface layerMechanical engineering

The invention discloses a comfortable ski, comprising a single board, first buckles, second buckles, foot retainers, fixing devices, fixing holes, notches, adjusting holes, dampers, a surface layer, an interlayer, a bottom layer, lock heads, fastening ridges, fastening grooves, latches, fastening holes, adjusting rings and mating blocks. The comfortable ski has the advantages that after bolts are mounted in the notches, all bolts can be mounted inside the notches, thus the problem that the protruding bolts cause discomfort of feet during sports is avoided; the dampers at the heel parts of the fixing devices are effective in reducing impact of the ski upon the feet during sports and protecting soles; the latches adapt to different people's feet different in size, and even when the soles are different in size, the feet can be secured by adjusting tightness of the latches; the fixing devices allow shoes to be directly secured to the surface of the ski, thereby enabling convenience and simplicity; the first buckle, the second buckle and the foot retainers are effective in reducing binding force of the fixing devices for the soles.

Owner:NINGBO MATRIX SPORT GOODS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com