Non-strengthening heat treatment construction technology for over-sized device aerial strength weld

A technology for carrying weld seam and heat treatment temperature, applied in heat treatment furnace, heat treatment equipment, heat treatment process control, etc., can solve problems such as lowering crane parameter level, cylinder deformation, etc. The effect of degree deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0022] Example: Two propylene rectification towers at a certain site were installed using the aerial assembly process. According to the distribution of the four welds of the two towers, the stress on the section ring seam at the bottom 17.13 meters of the most dangerous T4007 was analyzed.

[0023] 1. First of all, after the butt welding of the overrun equipment is completed in the air, the stress of the bearing weld is calculated and checked at the heat treatment temperature;

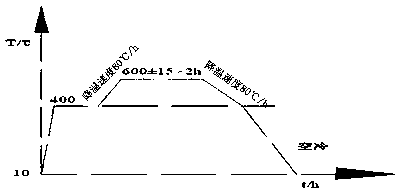

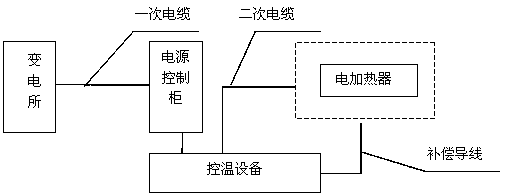

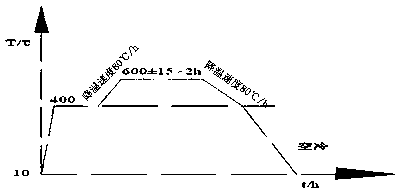

[0024] 1. Equipment heat treatment technical parameters

[0025]

[0026] The main technical conditions are detailed in Table 1 below

[0027] Table 1

[0028] Annular seam heat treatment process requirements table 2

[0029]

[0030]

[0031] Table 2

[0032] 2. Tower stability calculation

[0033] The stress on the circular joint of the section at the bottom 17.13 meters of the most dangerous T4007 is analyzed.

[0034] The overall weight of the tower body is 480t, the weight of the tow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| weight | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com