Non-oxidation vacuum annealing furnace for nonferrous metal

A vacuum annealing furnace and non-ferrous metal technology, applied in the field of heat treatment furnaces, can solve the problems of poor uniformity of furnace temperature and inability to guarantee products without oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

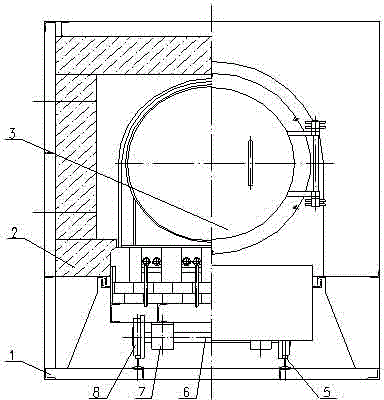

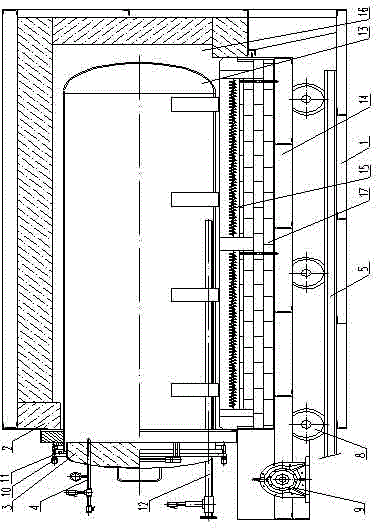

[0011] refer to figure 1 with figure 2 As shown, the non-ferrous metal oxidation-free vacuum annealing furnace of the present invention includes a furnace rack 1 and a trolley 14 . A thermal insulation fiber module 2 is fixed on the upper part of the steel structure grate 1, which is fixed by anchors in this embodiment. The lower part of the grate 1 is fixed with an I-beam rail 5 . Wheel 8 and motor 9 are installed on cart 14 bases, and bearing 7 is installed between wheel 8 and wheel axle 6, and wheel axle 6 is fixed on cart 14 base bottoms by supporting pin, and motor 9 is connected with wheel 8 by transmission belt. The base of the trolley 14 is also fixed with a thermal insulation fiber module 17, an electric heating element 15 and a stainless steel liner 13. The 13 openings of the inner liner are covered with a furnace cover 3, and insulation materials are installed on the furnace cover 3. The 13 openings of the liner and the furnace cover 3 A sealing ring 11 is insta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com