Patents

Literature

100results about How to "Won't strain" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

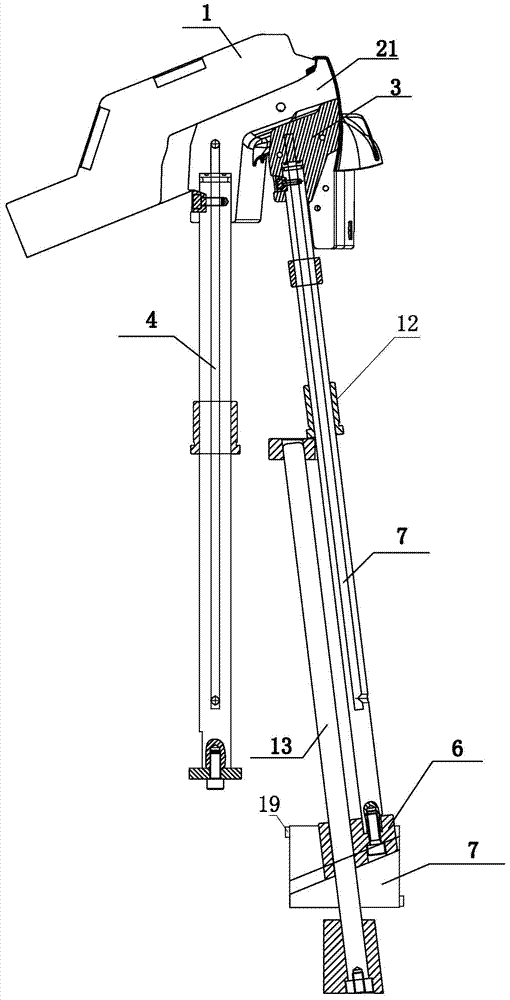

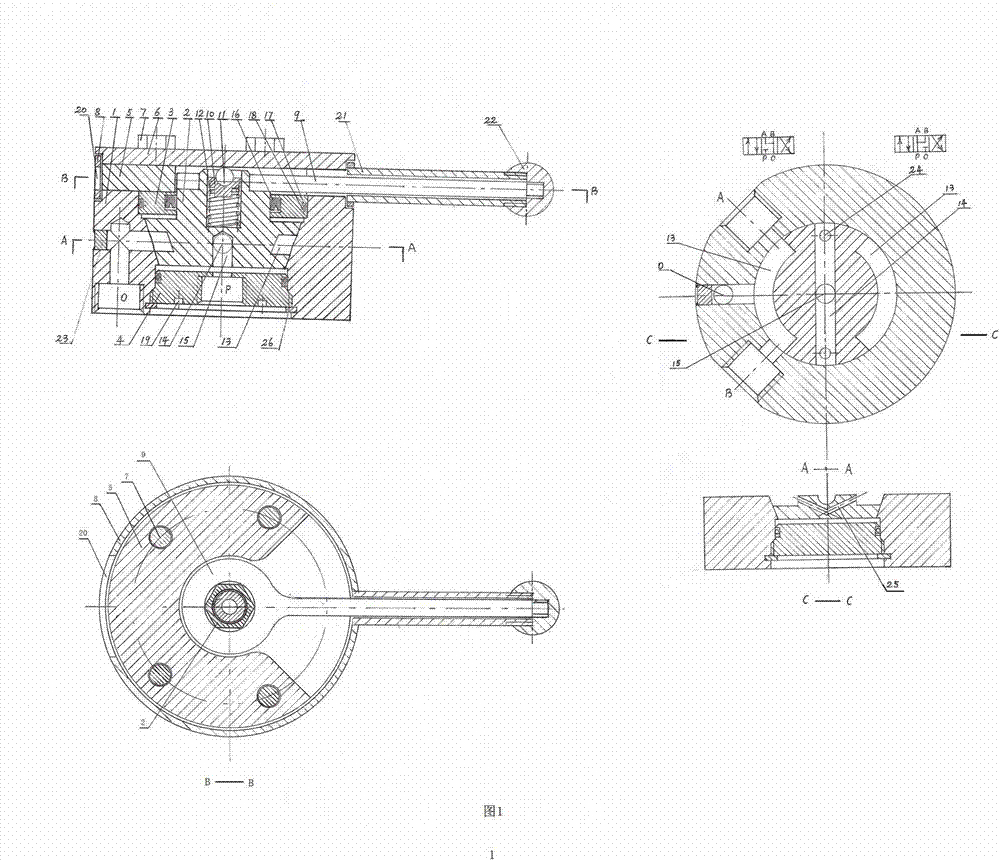

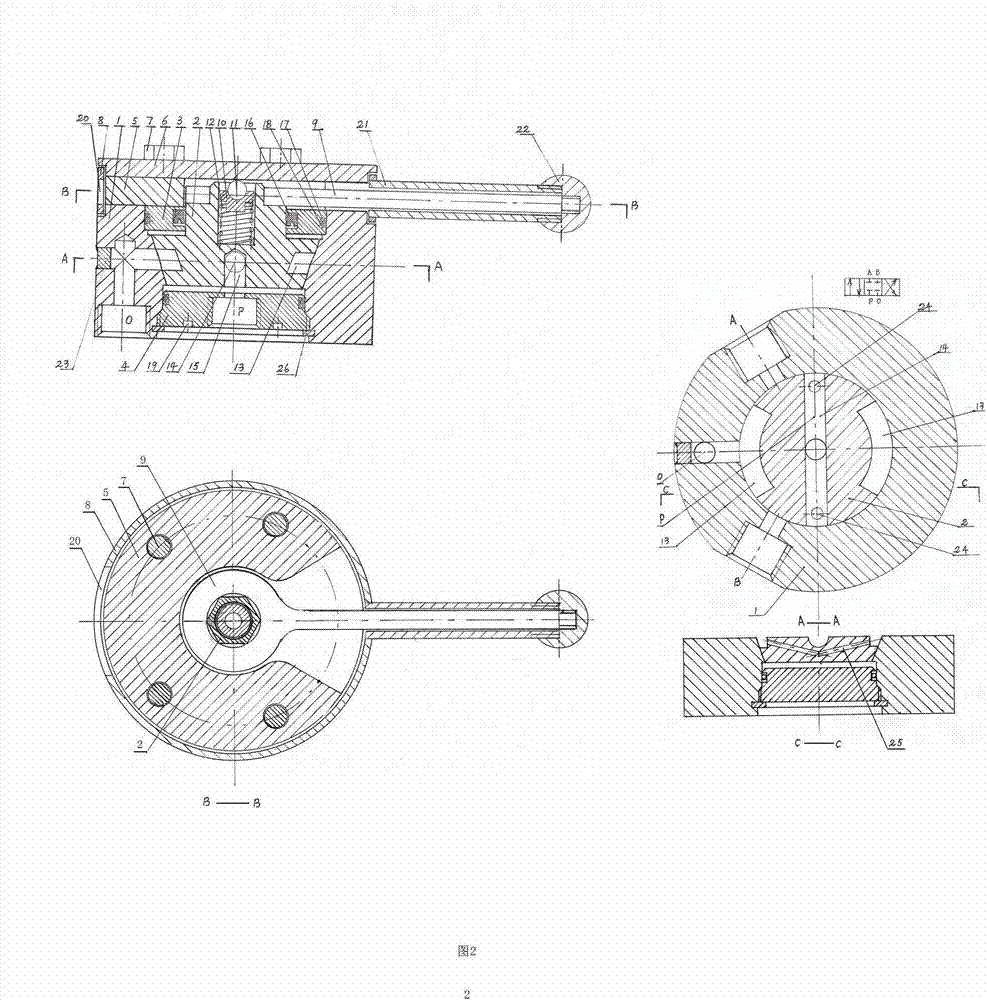

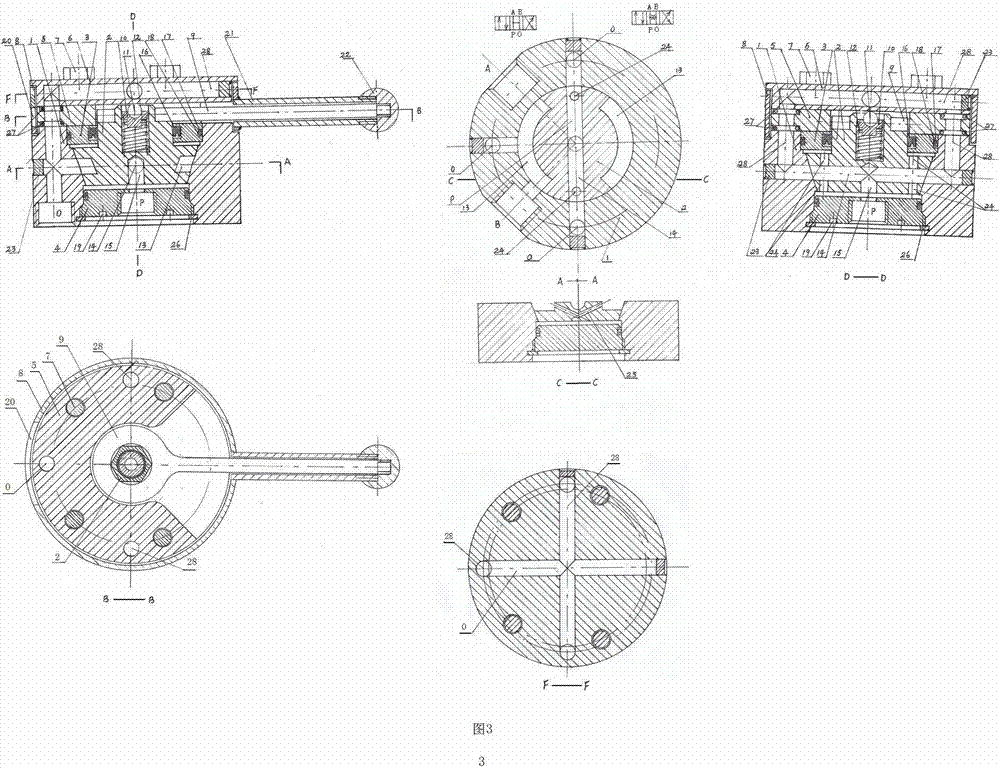

Inertia friction welding machine

InactiveCN101224522AAxial welding is convenientPrecise positioningWelding/cutting auxillary devicesAuxillary welding devicesFriction weldingEngineering

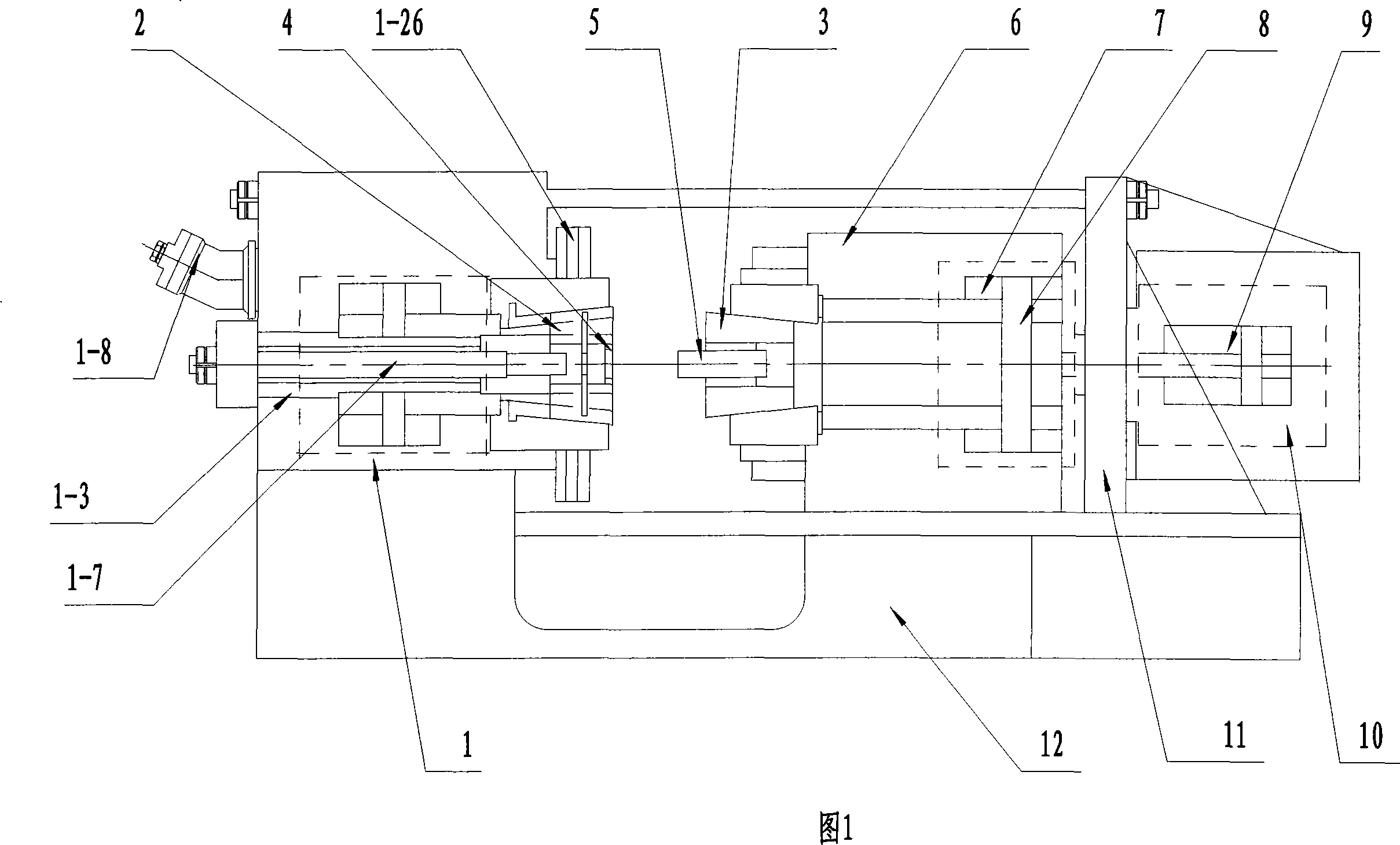

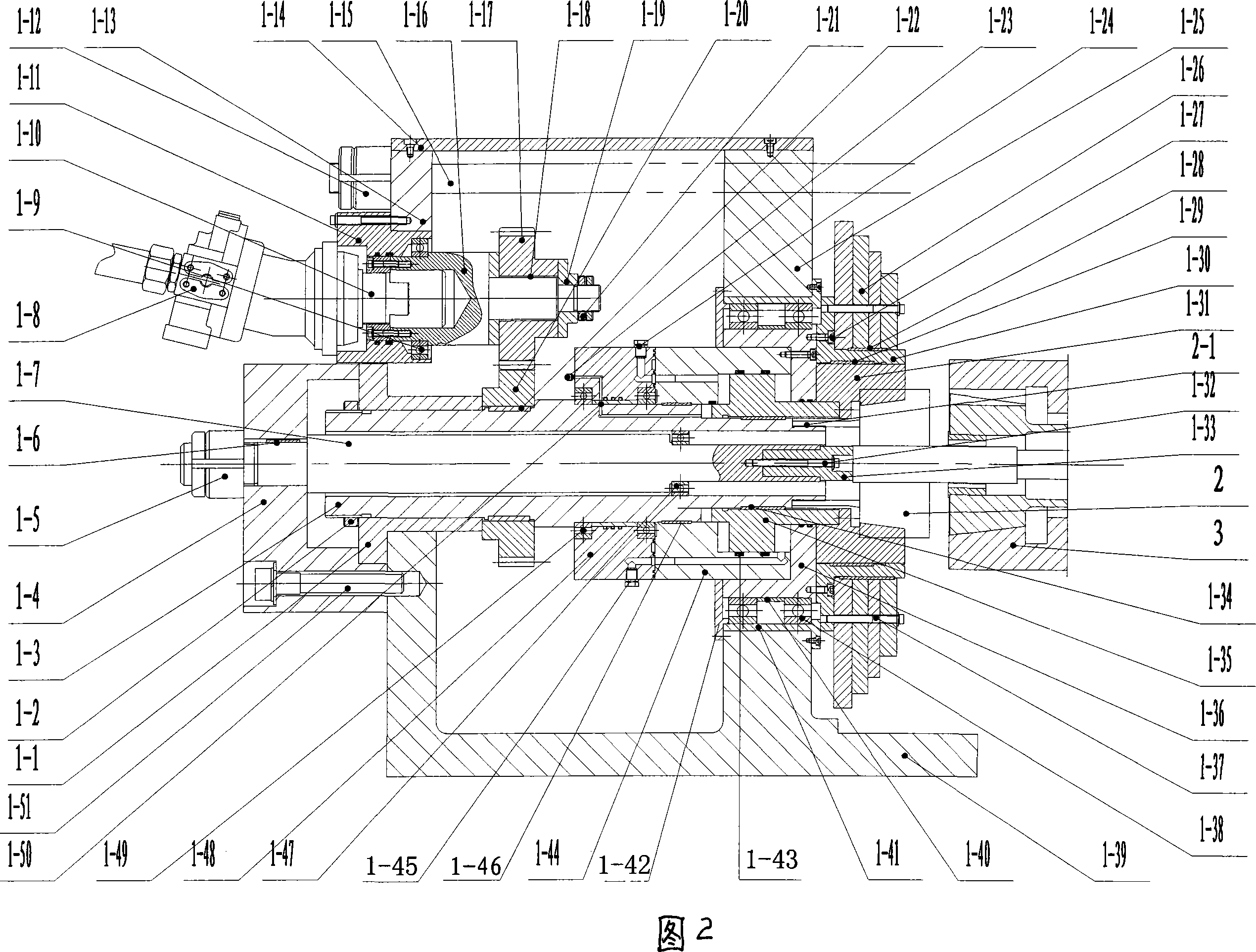

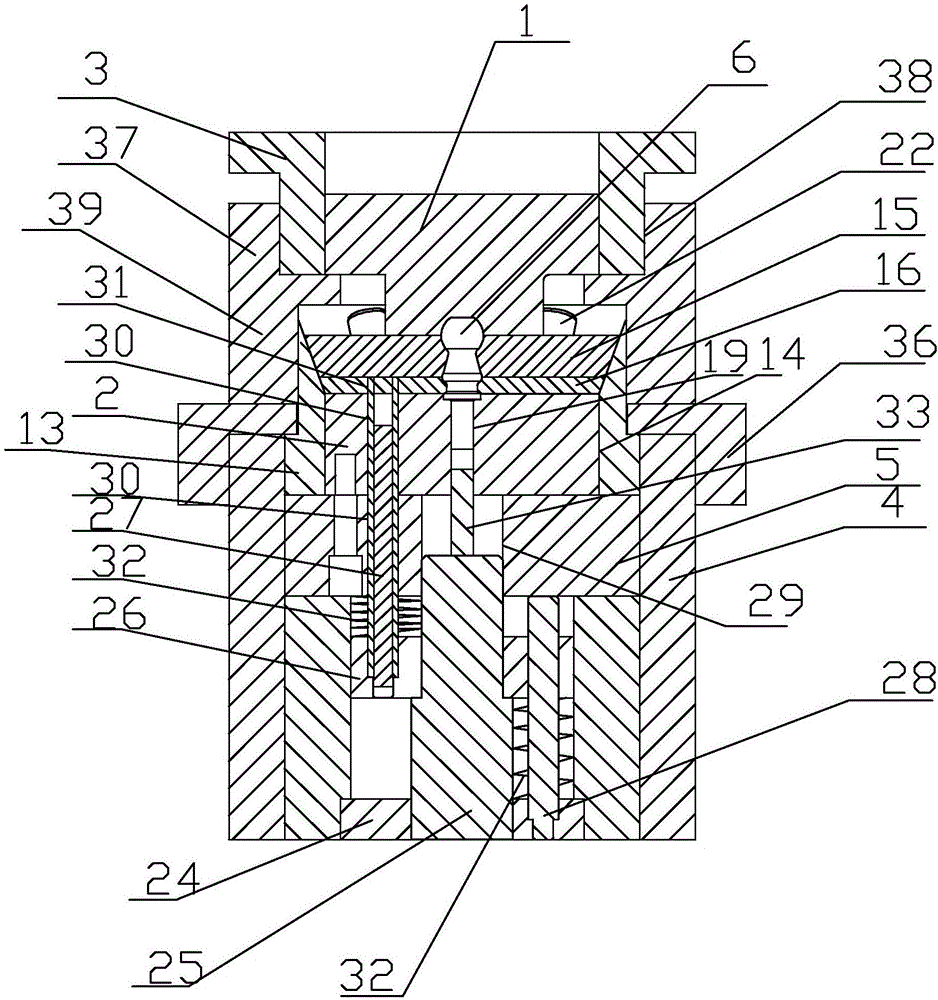

The invention relates to an inertia friction welding equipment, comprising a frame (1-39), a mainshaft box (1) which is formed by the connecting of a left bracket (1-13) and a right bracket (1-25), a transmission mainshaft (1-3) arranged in the mainshaft box (1), and a flywheel (1-26) which is rotated together with the transmission mainshaft (1-3); the invention is characterized in that the front circumference of the transmission mainshaft (1-3) is provided with a hydraulic device which rotates with the transmission mainshaft (1-3) and is pressed axially. The equipment which is provided by the invention and can be used for the radial inertia friction welding on the circumference surface of a cirque part and a cylindrical and round pipe-shaped part has simple and reasonable structure, and safe and convenient application, can realize the radial pressurization in the rotation, realizes the pre-clamping and the exact positioning of any positions of the cirque welding part, controls the welding deformation, ensures that the surface of the clamped workpiece is not damaged by the rotation inertia of the frock device in the welding process, thus greatly improving the working efficiency.

Owner:NO 59 RES INST OF CHINA ORDNANCE IND

Novel foam composite wound dressing

ActiveCN103637877AStrong ability to lock waterWounds heal fasterNon-adhesive dressingsAdhesive dressingsMoistureBackflow

The invention relates to a medical dressing, in particular to a novel foam composite wound dressing. The novel foam composite wound dressing includes a water absorbing layer and a water locking layer arranged above the water absorbing layer in a covering manner, wherein a transitional layer is arranged between the water absorbing layer and the water locking layer, a waterproof layer is arranged above the water locking layer in a covering manner, and a polyurethane film layer is arranged below the water absorbing layer. The novel foam composite wound dressing is neither toxic nor irritating to human bodies; moisture around a wound can be quickly absorbed through the water absorbing layer, and absorbed and locked through the water locking layer, which prevents the moisture backflow, guarantees a suitable temperature and a suitable humidity of the wound, prevents the soaking reaction of the skin at the application position, and achieves rapid healing of the wound; the application through silica gel achieves good fixation effect and low falling possibility, and avoids the skin injury by pulling.

Owner:吴康平

Refrigerator door liner sealing groove forming die

InactiveCN101462356AAvoid local deformationThe demoulding process is safe and stableDomestic articlesMovable typeEngineering

Owner:昆山市三建模具机械有限公司

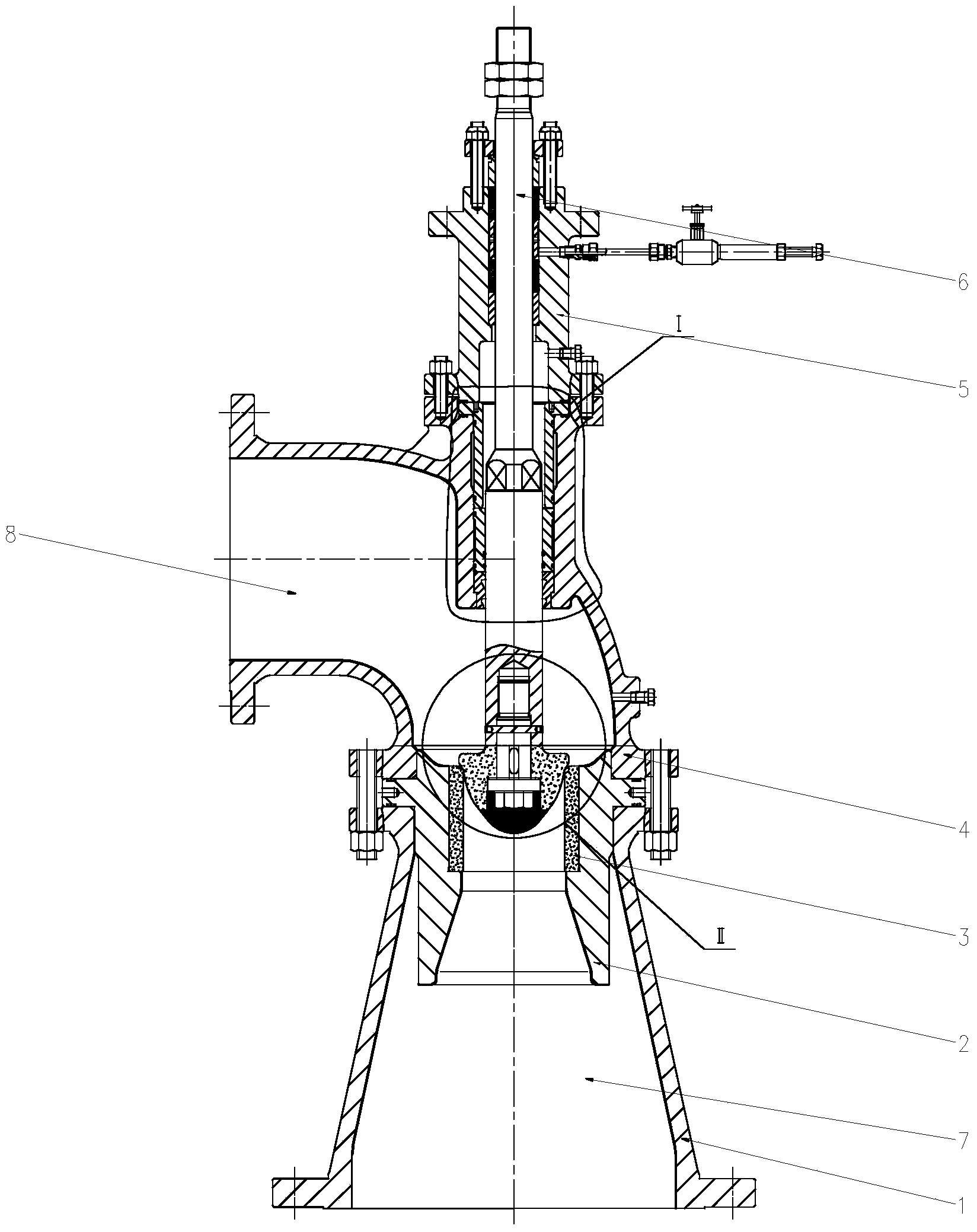

Black water coking-preventing impact-resistant shockproof regulating angle valve special for coal chemical industry

ActiveCN103591303AImprove anti-blocking performanceAvoid vortexLift valveValve housingsFluid controlControl valves

The invention relates to a regulating angle valve, in particular to a black water coking-preventing impact-resistant shockproof regulating angle valve special for the coal chemical industry, and belongs to the field of fluid control valves. The black water coking-preventing impact-resistant shockproof regulating angle valve comprises a diffusion tube and a valve body, wherein the lower end of the valve body is connected with the diffusion tube through a bolt. An inlet flowing channel is arranged in the valve body, an outlet flowing channel is arranged in the diffusion tube and is communicated with the inlet flowing channel, and the inlet flowing channel is perpendicular to the outlet flowing channel. A valve carrier base is arranged in the outlet flowing channel and is clamped through the diffusion tube and the valve body, and a valve carrier is arranged in the valve carrier base. The black water coking-preventing impact-resistant shockproof regulating angle valve is simple in structure and novel in design, can effectively solve the technical problems that a traditional black water regulating angle valve is easy to coke, poor in impact resistant performance, undesirable in shockproof effect and the like in a use process, is widely applied in sites of customers, and effectively lowers production operation cost of the customers.

Owner:WUXI SMART AUTO CONTROL ENG CO LTD

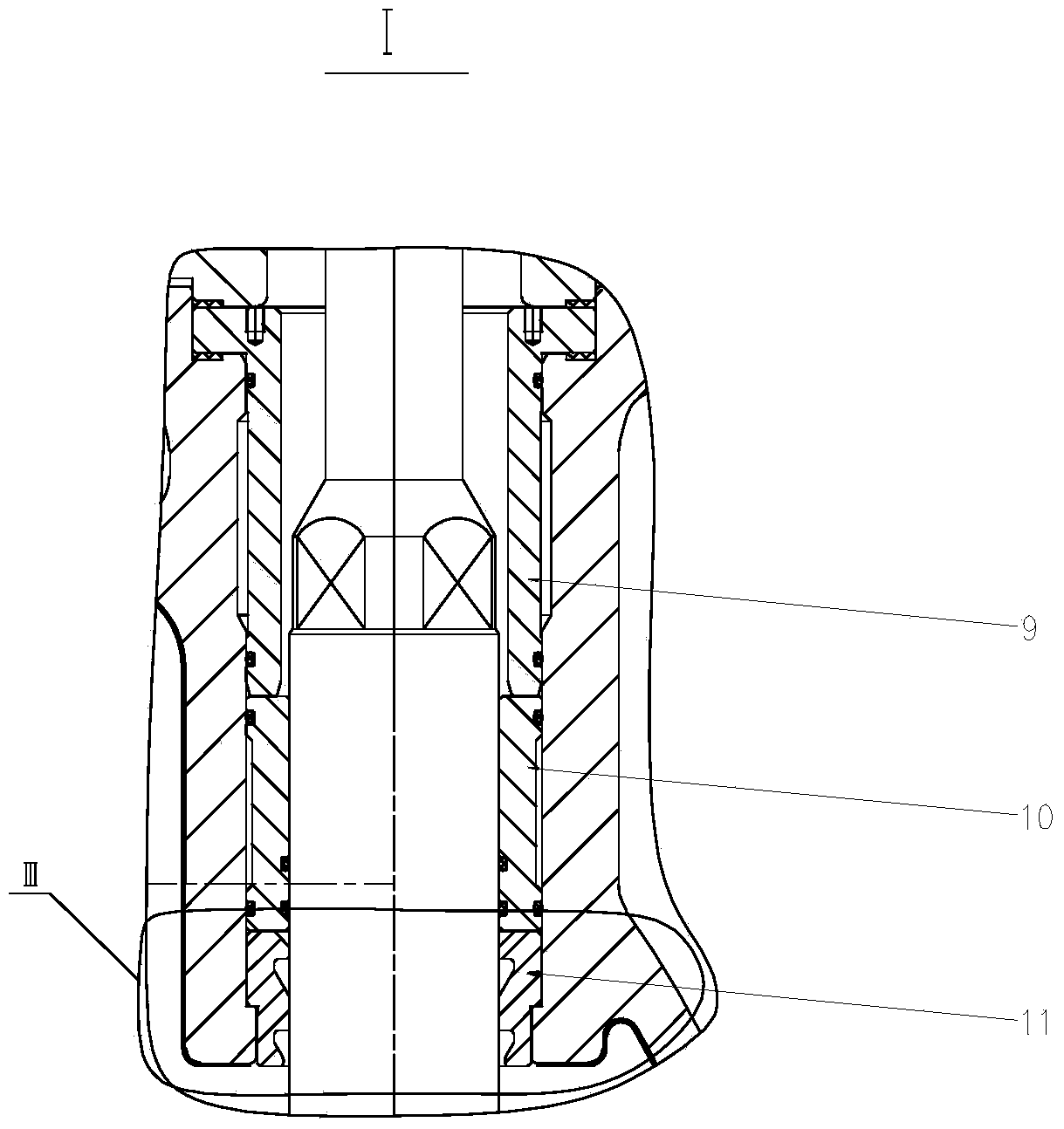

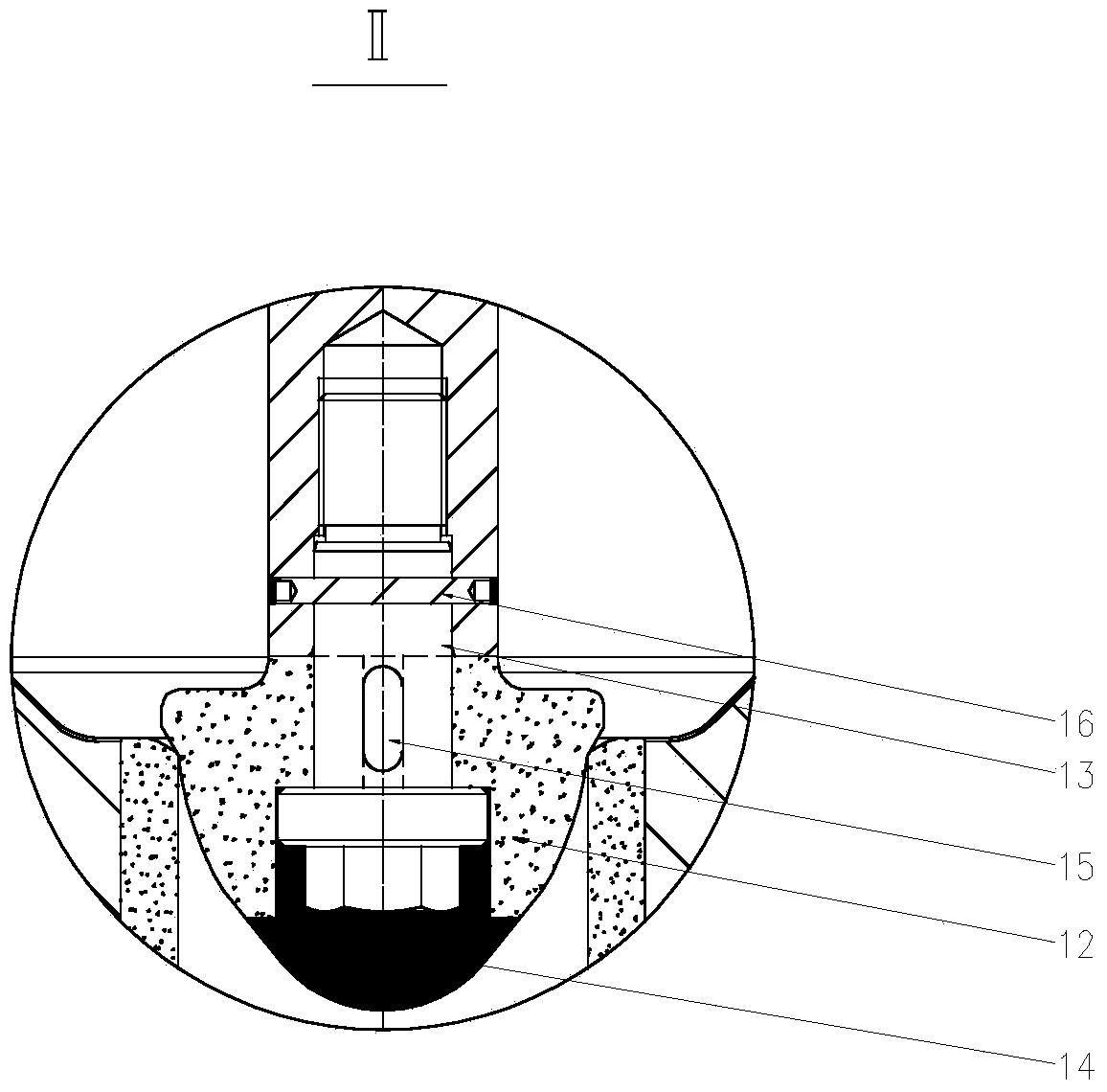

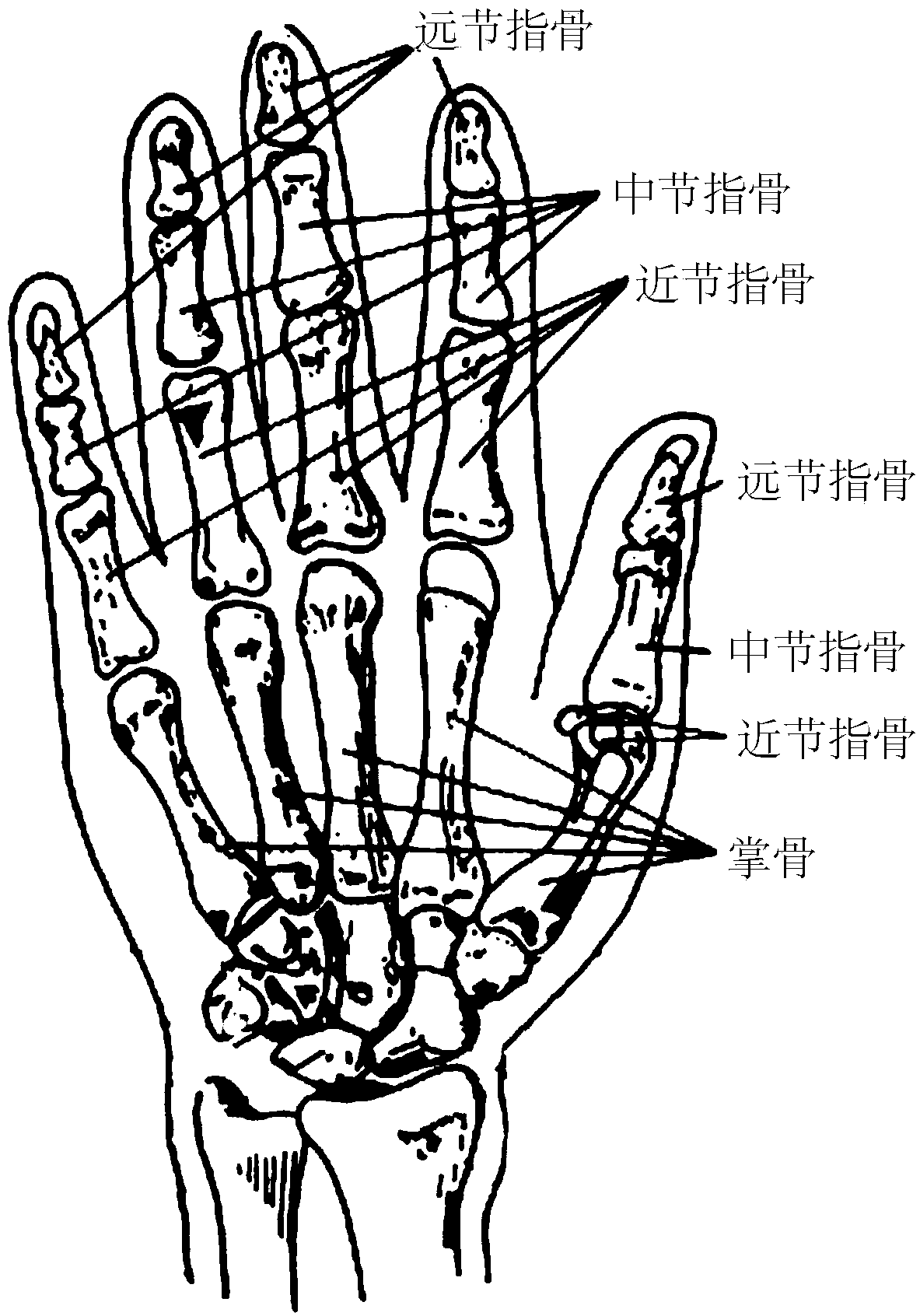

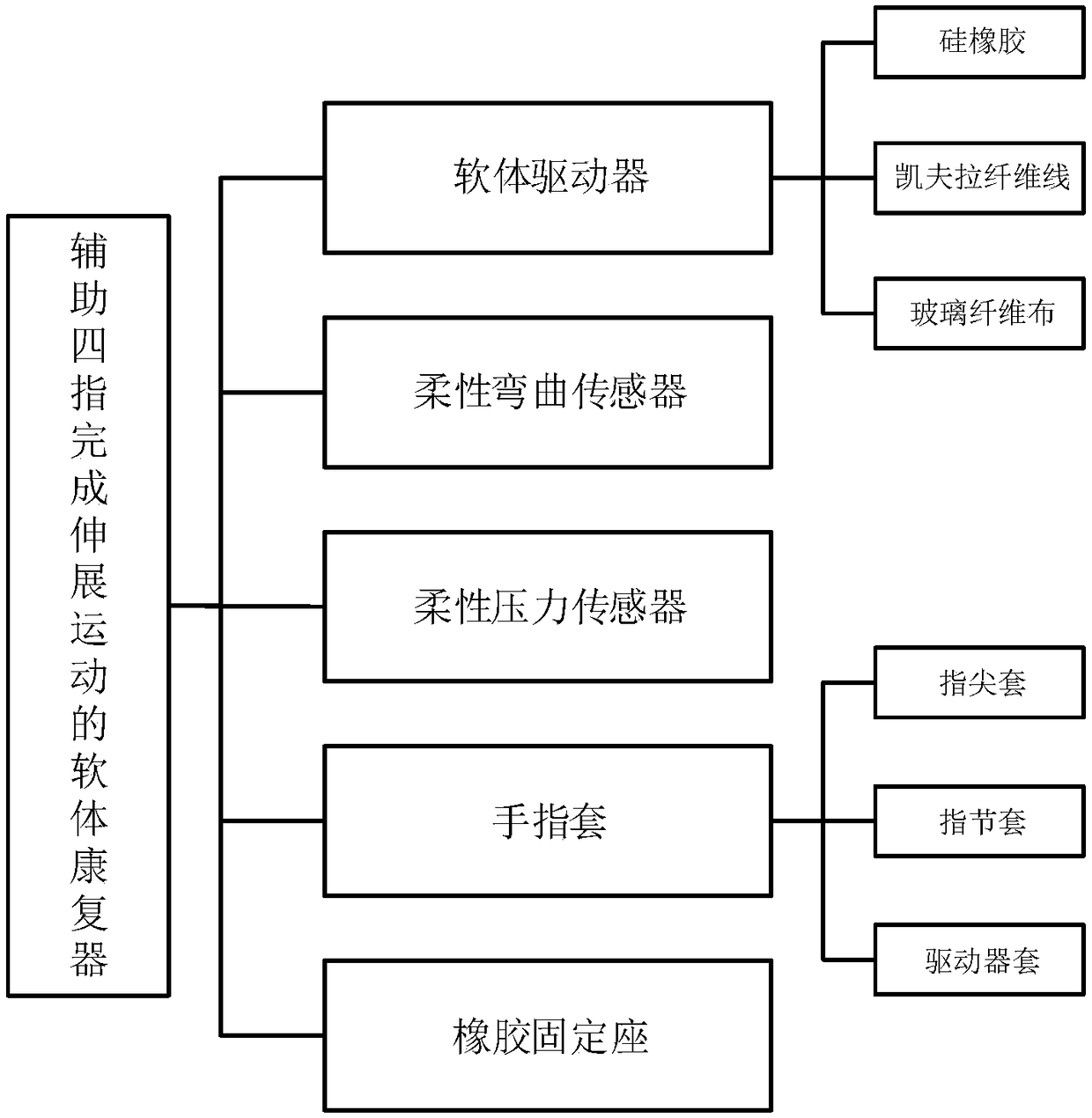

Software driver for assisting four-finger stretching of human hand

The invention discloses a software driver for assisting four-finger stretching of a human hand. The software driver includes an inner layer silicone tube, an outer layer silicone tube, a Kevlar fiberline and three-section glass fiber cloths. The front end of the inner layer silicone tube is closed, the rear end of the inner layer silicone tube is provided with an opening which is used for being connected with an air pressure or hydraulic driving device, the Kevlar fiber line is wound around a portion of the outer wall of the inner layer silicone tube corresponding to four-finger phalanges ina double helix mode, the three-section glass fiber cloths are attached to the side of the inner layer silicone tube deviated from the fingers, the positions respectively correspond to a connecting joint for the four-finger phalanges and proximal phalanges, a connecting joint for the proximal phalanges and intermediate phalanges and a connecting joint for the intermediate phalanges and distal phalanges; the outer layer silicone tube sleeves the inner layer silicone tube and is closely combined with the inner layer silicone tube, and the Kevlar fiber line and the glass fiber cloths are fixed onthe outer wall of the inner layer silicone tube. By loading the drive, a glove achieves simulation of four-finger stretching exercise and assists the four fingers in stretching training.

Owner:HUAZHONG UNIV OF SCI & TECH +1

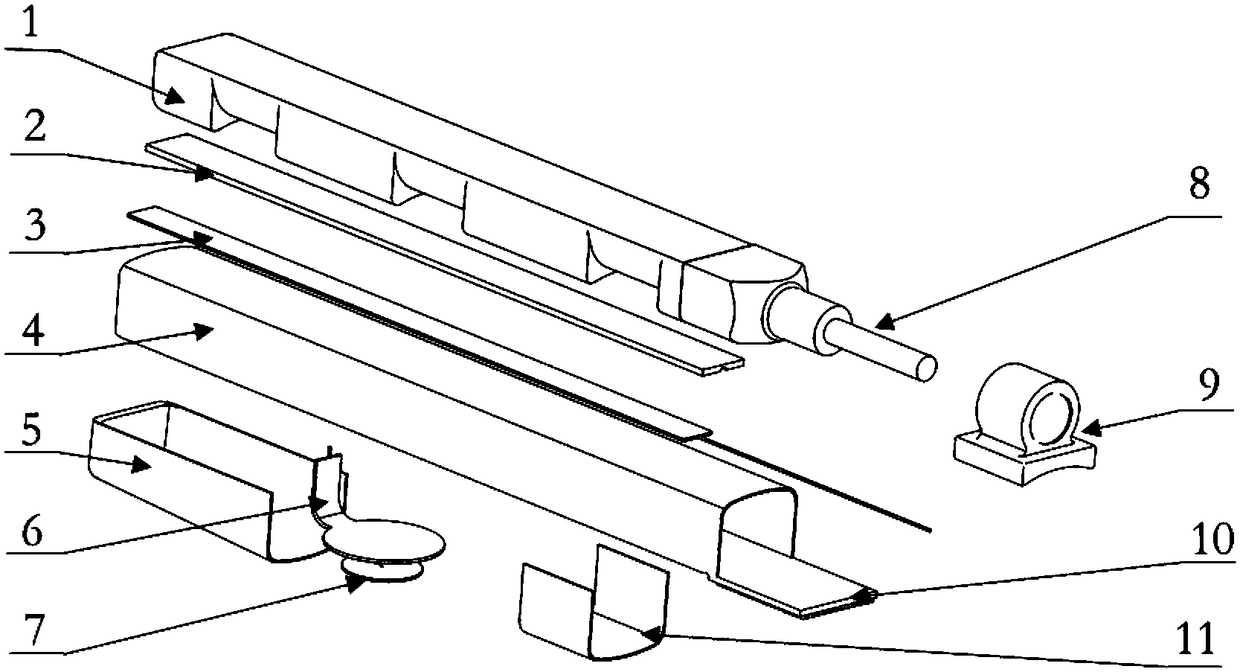

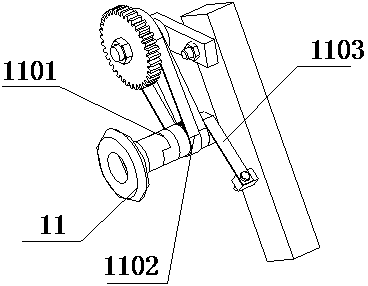

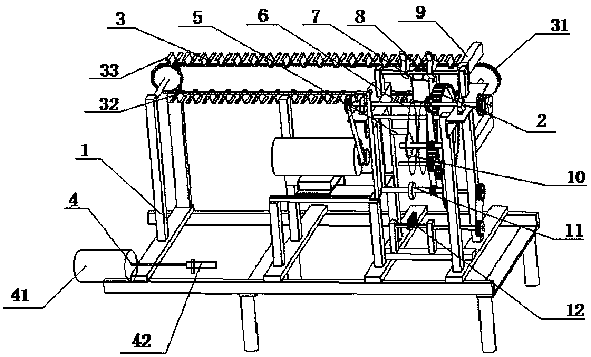

Intestine removing device of automatic shrimp sheller

The invention provides an intestine removing device of an automatic shrimp sheller. The intestine removing device is characterized by comprising a bush shaft and an intestine removing brush arranged at one end of the brush shaft, wherein a brush driving wheel is sleeved on the brush shaft, an elastic element is arranged on the tail portion of the brush shaft, and the other end of the elastic element is fixed on a rack. The intestine removing device is simple in structure and more thorough in intestine removing by adopting the arc brush. Due to the pressure control of the elastic element on the brush, intestines of differently shaped ship raw materials can be removed. The pressure of intestine removing lines between the brush and shrimp bodies can be ensured to be constant, catguts on the shrimp bodies can be ensured to be removed clear without pulling shrimp meat off, and therefore the shelled shrimp bodies can be guaranteed to be intact.

Owner:南通宝泰机械科技有限公司

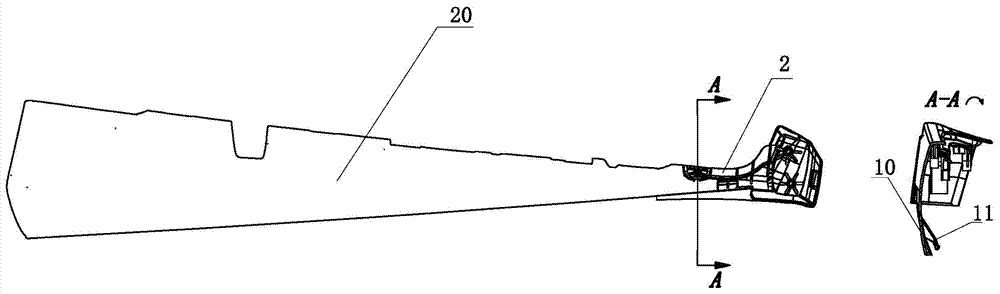

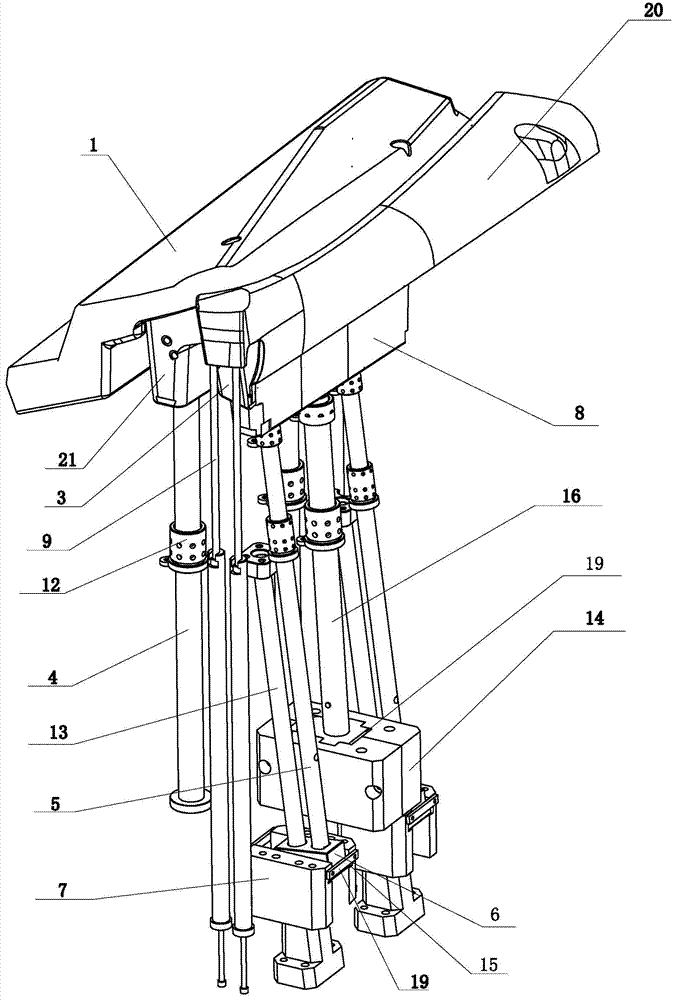

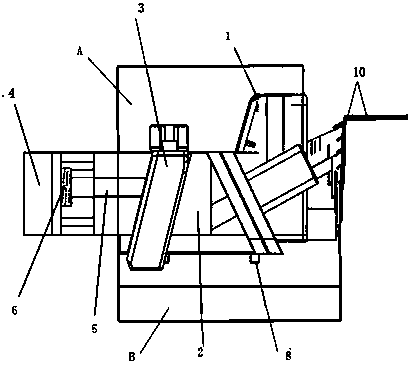

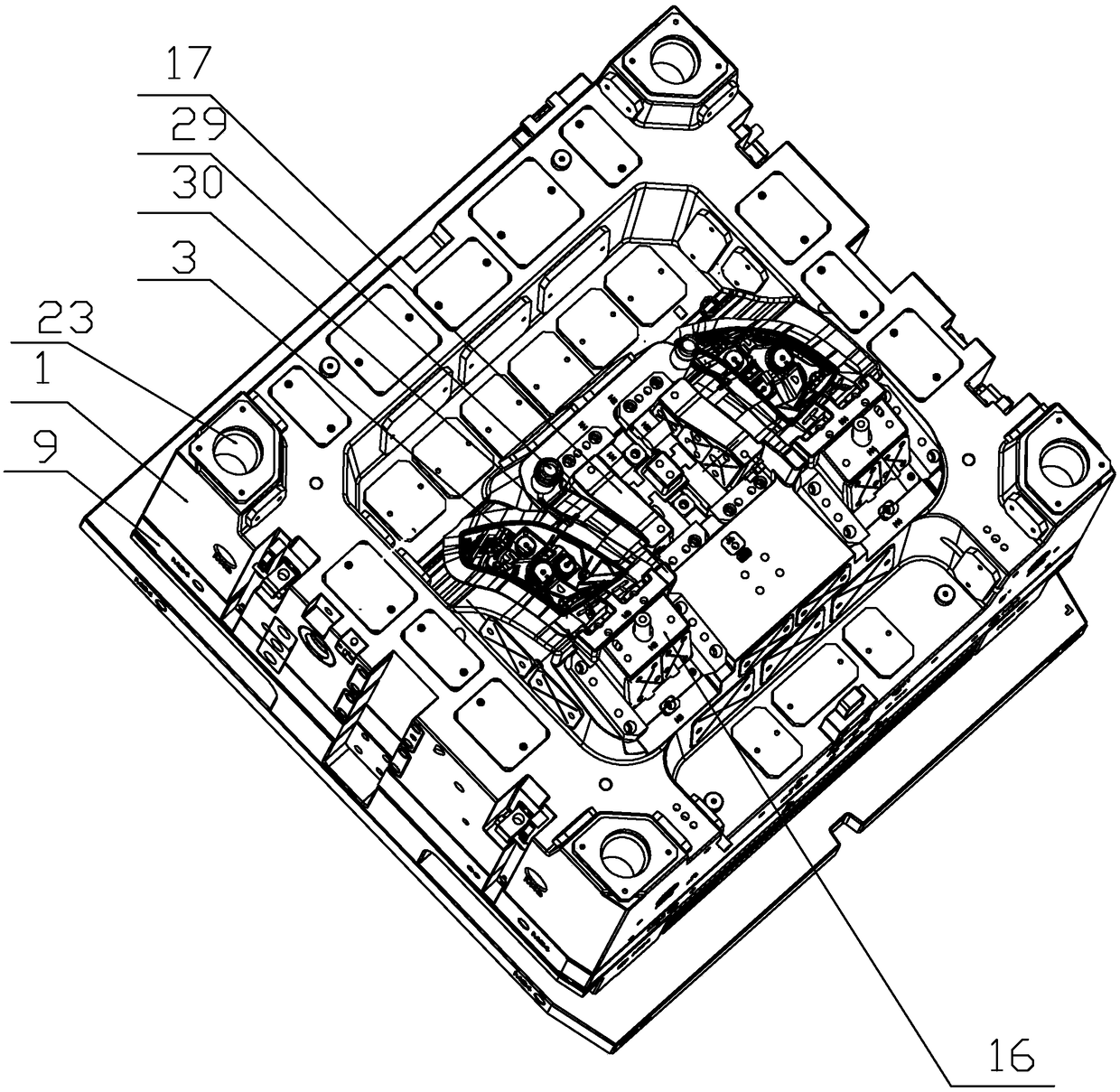

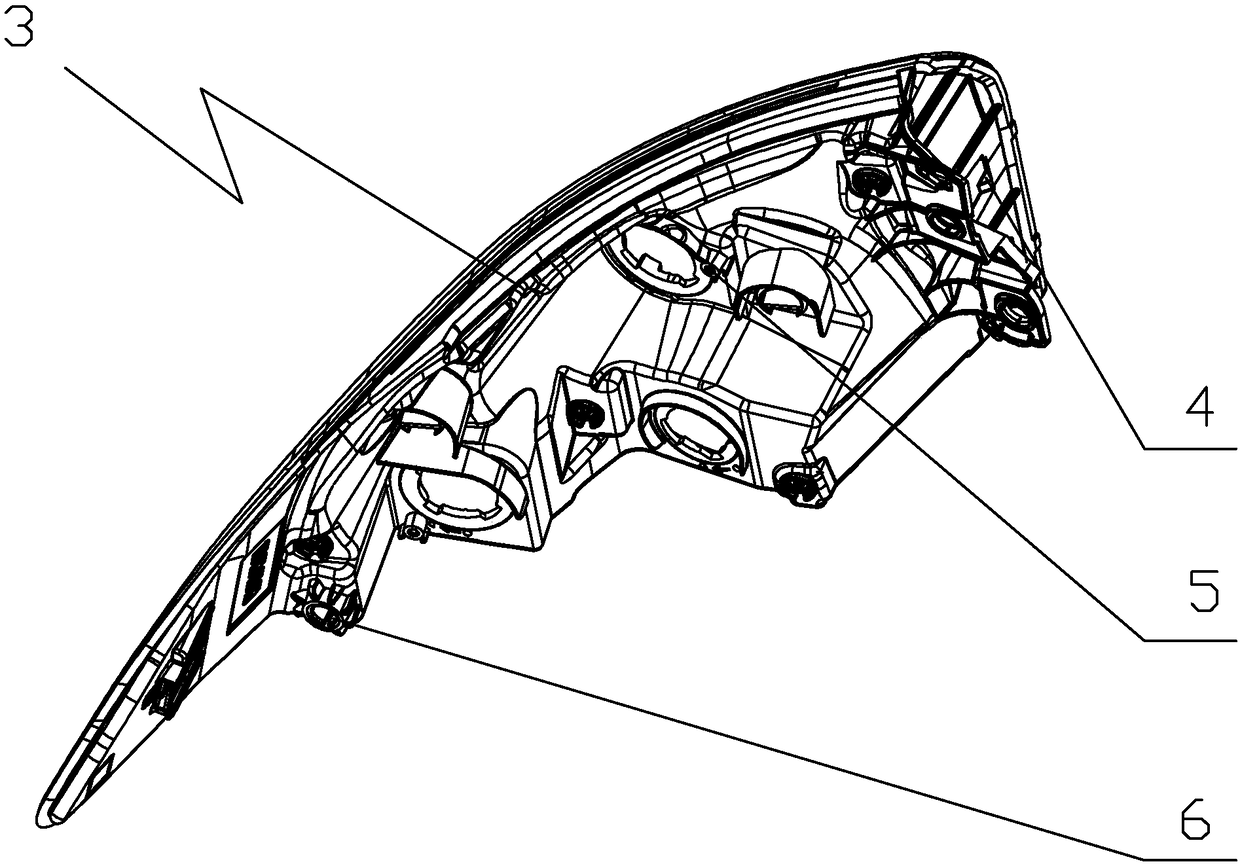

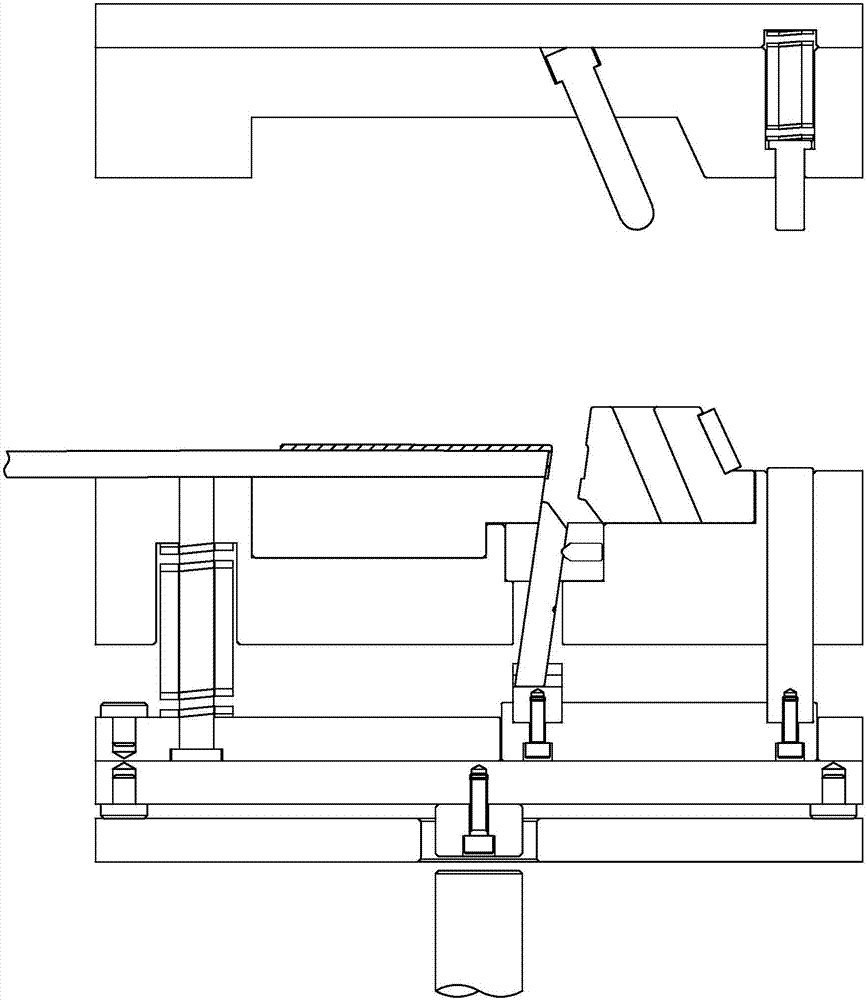

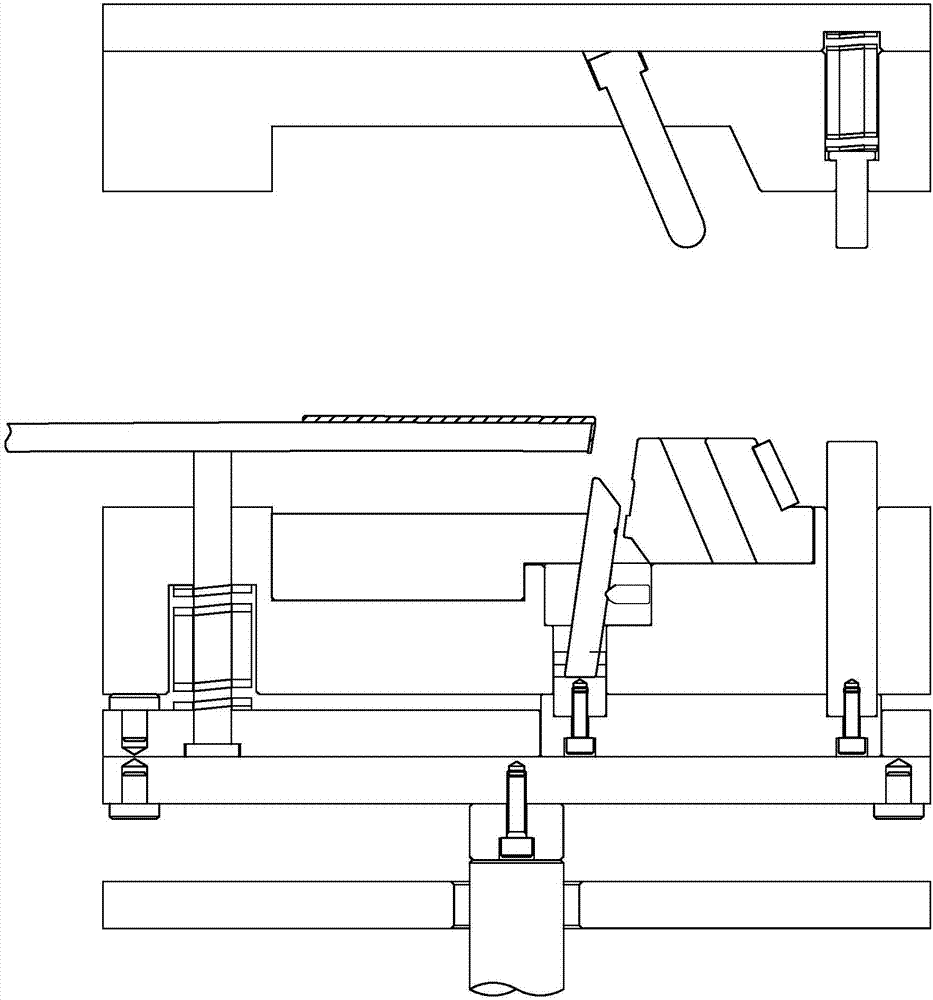

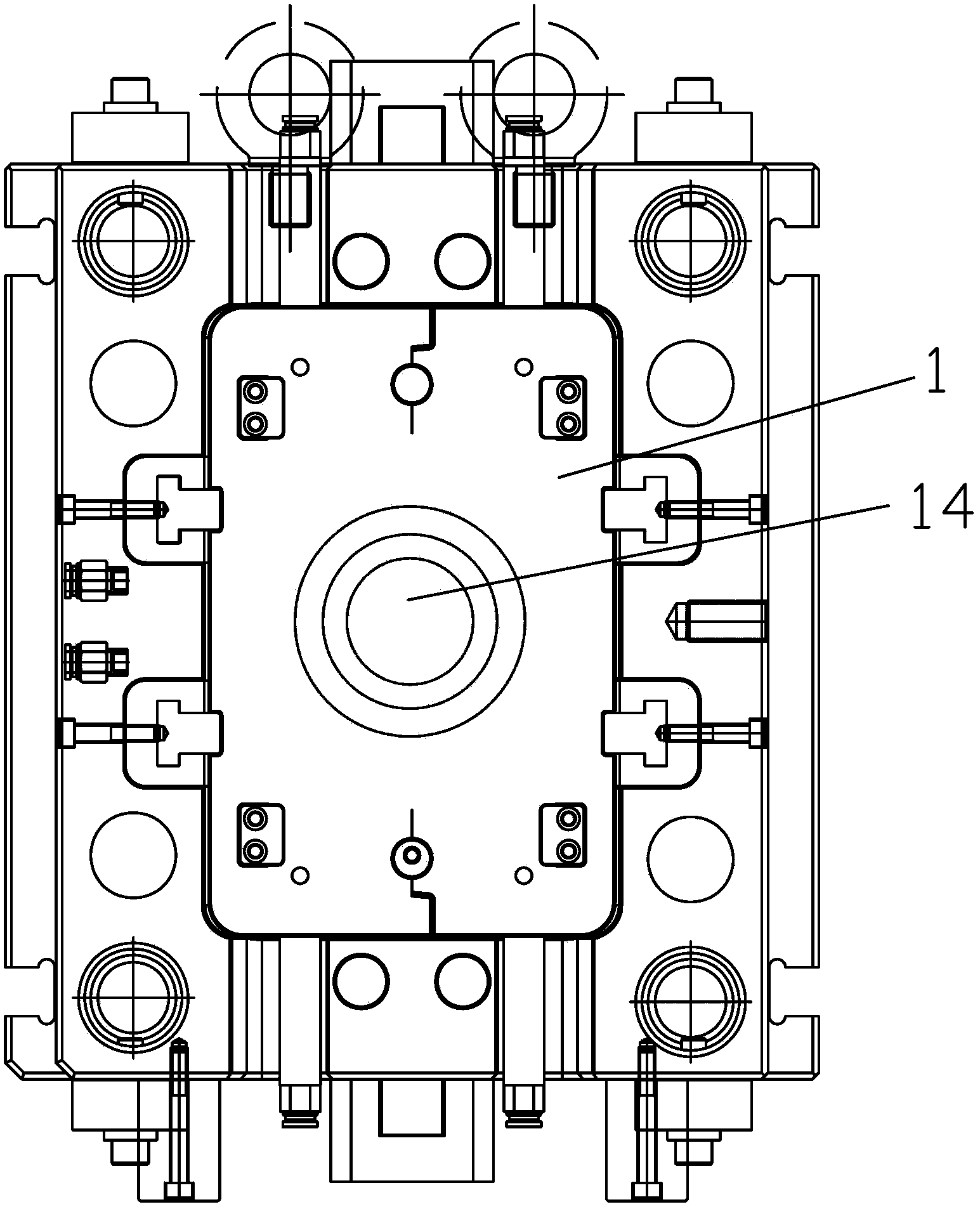

Core pulling mechanism of automobile front door upper framework

The invention discloses a core pulling mechanism of an automobile front door upper framework. The core pulling mechanism comprises a product (20), wherein the product (20) comprises a small end (2); the lower part of the small end (2) is provided with a warped surface (10); the inner side of the warped surface (10) is provided with an inverted buckle (11); an included angle between the inverted buckle (11) and the vertical direction is 50 degrees-65 degrees; the product (20) also comprises a core pulling mechanism for pulling a core of the small end (2); the core pulling mechanism comprises a slide block (1), a straight ejector (21), an oblique ejector (3), an oblique ejector body (8), a first oblique ejector slide base (7) and a second oblique ejector slide base (14), wherein the straight ejector (21) is positioned on the inner side of the upper part of the small end (2); the lower end of the straight ejector (21) is provided with a straight ejector bar (4); the slide block (1) is matched with the oblique surface of the upper end surface of the straight ejector (21). The invention provides the core pulling mechanism of the automobile front door upper framework, which is large in oblique ejector walking angle, can guarantee no seizing and self-locking in the walking process, and is beneficial to core pulling.

Owner:NINGBO FANGZHENG TOOL

Slide block demolding mechanism

The invention discloses a slide block demolding mechanism, and belongs to the field of demolding apparatuses in mold processing. The slide block demolding mechanism comprises an upper template, a lower template, a slide block, a slide block seat, a shovel base, a positioning seat, a hexagonal socket head cap screw, springs, two horizontal guiding briquettes, pins and two inclined guiding briquettes, the slide block, the slide block seat and the positioning seat are arranged between the cavity of the upper template and the cavity of the lower template, the slide block seat is provided with an inclined T-shaped chute, the slide block is correspondingly provided with an inclined slide projection, the slide block seat is movably connected with the slide block through the cooperation of the inclined T-shaped chute and the inclined slide projection, the two horizontal guiding briquettes and the two inclined guiding briquettes are symmetrically arranged at two sides of the slide block and the slide block seat and are fixed on the lower template through the pins, and the shovel base is arranged in the slot of the slide block seat. The shovel base releases locking force on the slide block under the action of a mold opening machine of an injection machine in order to make the slide block and the slide block seat rapidly slide away from a product under the driving of the reset force of the springs in order to make the product nondestructively demolded.

Owner:HUNAN ZHONGZHENG CONSTR MATERIALS

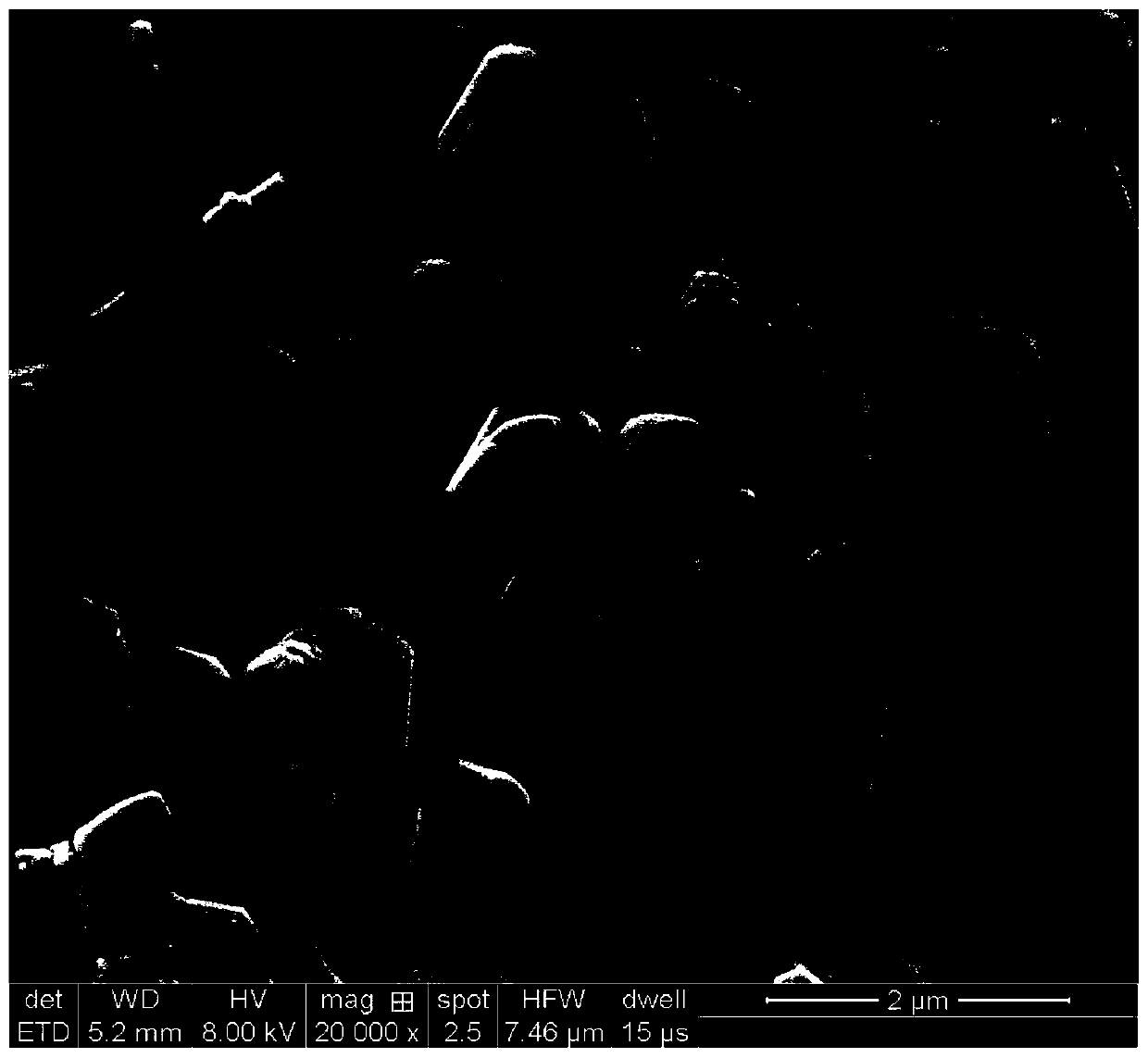

Alumina ceramic and preparation method thereof

The invention provides an aluminum oxide ceramic. The aluminum oxide ceramic is prepared from aluminum oxide, calcined kaolin, bentonite, heavy magnesium carbonate, calcium carbonate, barium carbonate, glycerol, emulsified wax, titanium dioxide, zirconium dioxide and lanthanum oxide. The invention also provides a preparation method for the aluminum oxide ceramic. The preparation method comprises the following steps: mixing all the raw materials, adding water, carrying out ball milling, adding an aqueous polyvinyl alcohol solution with a mass fraction of 10%, continuing ball milling to obtain slurry, carrying out spray granulation to obtain a ceramic material, carrying out dry pressing molding, and performing roasting to obtain the aluminum oxide ceramic. According to the invention, Al2O3-SiO2-MgO-CaO composed of aluminum oxide, kaolin, bentonite, heavy magnesium carbonate and calcium carbonate is used as a basic system; barium carbonate, zirconium dioxide and lanthanum oxide are addedto serve as grain inhibitors; titanium dioxide serves as a solid solvent; glycerol and emulsified wax serve as dispersing agents; so the aluminum oxide ceramic with high bending strength is prepared.

Owner:陕西澳华瓷业科技有限公司

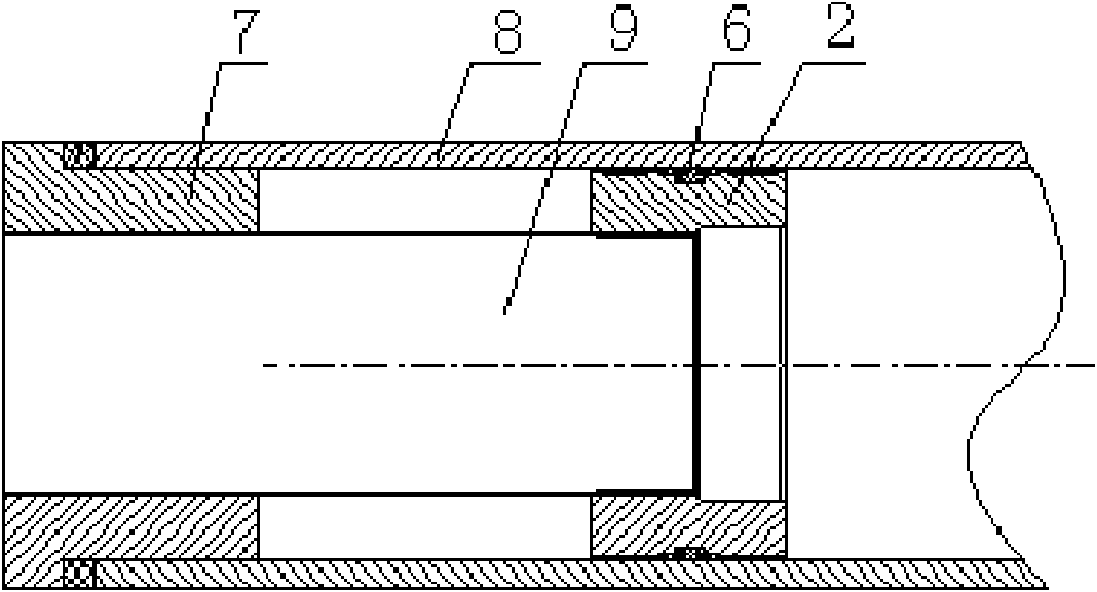

Tapered-surface reversing rotary valve

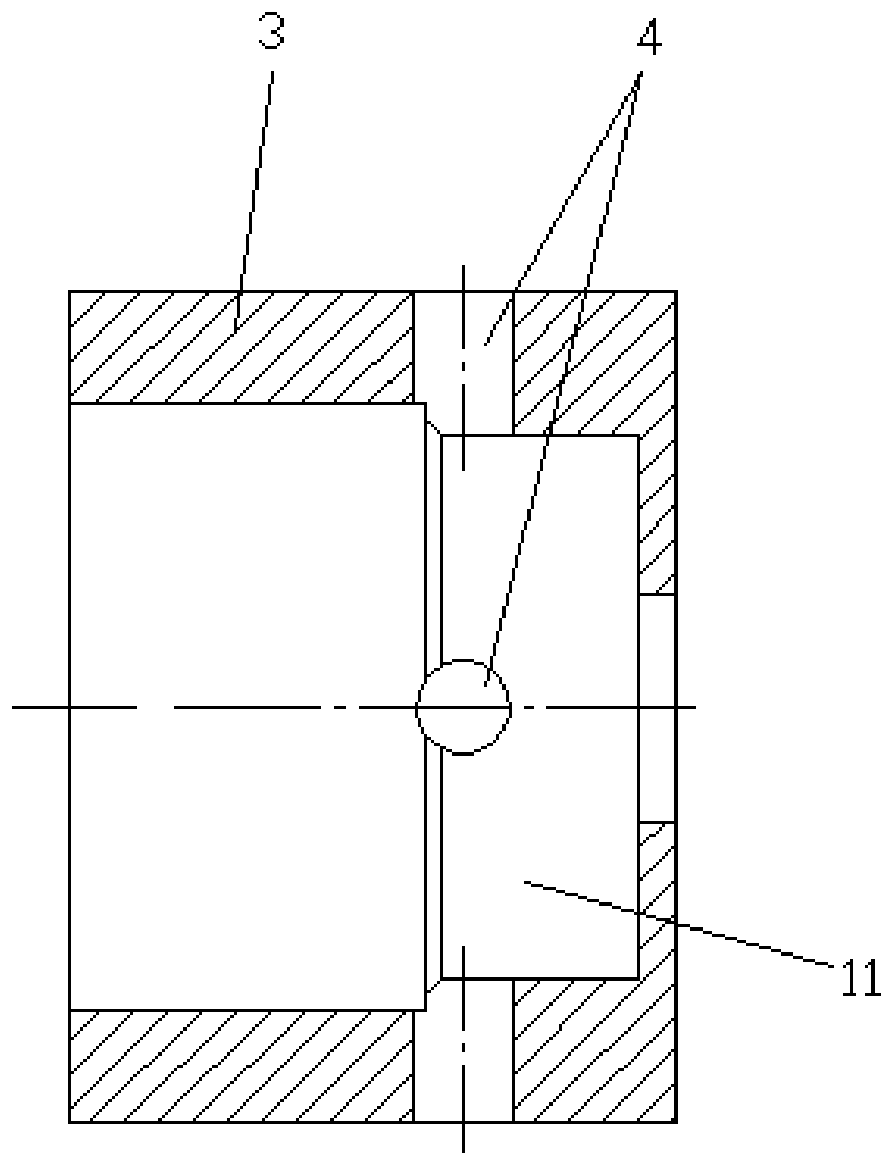

InactiveCN103697003AWear self-compensating extra longSmall drainServomotor componentsRotary valveHigh pressure

The invention relates to a tapered-surface reversing rotary valve and belongs to the technical field of fluid pressure transmission. The tapered-surface reversing rotary valve has the main technical characteristics that radial force and axial force acting on a valve core by fluid are balanced, and the valve core and a valve seat are in close fit under the action of a compression spring force; a rotational torque mainly depends on spring pressure and is independent of fluid pressure; the rotary valve can be designed as a two-position valve with different functions or a three-position valve with different functions; the rotary valve can be manual or electric and can also be a valve group. The tapered-surface reversing rotary valve has automatic wear compensation, the seal between internal high pressure and internal low pressure of the valve is gapless spaced seal, the internal leakage is little or zero, the service life is super-long and can reach up to several million times, and the tapered-surface reversing rotary valve has the performance of being applicable to any fluid. According to the tapered-surface reversing rotary valve, a three-position four-way valve with the coded name of Y-valve is taken as an example, the structure of a valve / valve group is introduced, and the valve core structures of eleven kinds of relatively-common three-position four-way valves with different functions and one kind of three-position six-way valve and the valve group structure of the three-position four-way valve with the coded name of Y-valve are designed and drawn.

Owner:王瑞林

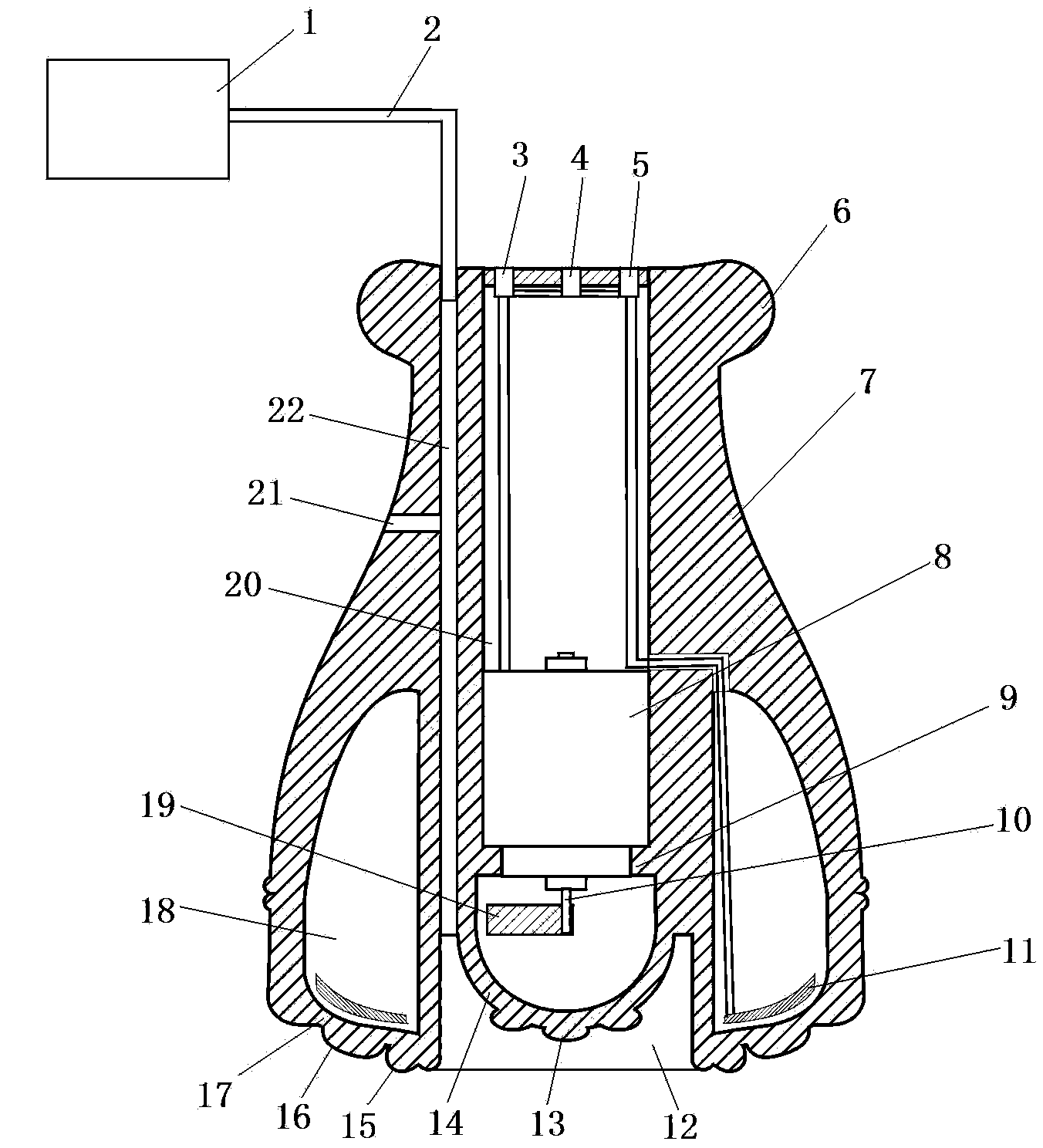

Multifunctional moxa warming pot

ActiveCN103961257AFunction increasePromote absorptionDevices for heating/cooling reflex pointsDevices for pressing relfex pointsTemperature controlEngineering

The invention provides a multifunctional moxa warming pot, and relates to medical instruments for traditional Chinese medicine. The multifunctional moxa warming pot comprises a shell, a micro-motor, an eccentric cam, a getter pump, heating wires, a 12V power interface, a speed regulator switch and a temperature control switch. The whole shell is in the shape of a circular truncated cone, the middle of the bottom end of the shell sinks inwards to form a cupping cavity, the periphery of the cupping cavity is provided with an annular heating cavity, a vibration cavity is further formed in the upper side of the cupping cavity, the top wall of the shell extends downwards and is provided with an air inlet communicated with the cupping cavity, the getter pump is connected with the air inlet through an air pipe, the heating wires are evenly arranged on the wall of the bottom end of the inner side of the heating cavity, the micro-motor is arranged in the vibration cavity, and the eccentric cam is installed on an output shaft of the lower side of the micro-motor. The 12V power interface, the speed regulator switch and the temperature control switch are arranged at the positions, located on the upper side of the vibration cavity, of the top wall of the shell. The speed regulator switch and the temperature control switch are connected with the 12V power interface respectively, the temperature control switch is connected with the heating wires, and the speed regulator switch is connected with the micro-motor.

Owner:黄广文

Injection mold for automobile back light shell body

The invention discloses an injection mold for an automobile back light shell body. The injection mold comprises an upper template, a lower template and a mold leg which fixed below the lower template,wherein the upper template is located on the upper surface of the lower template; a push plate is arranged between the mold leg and the lower template; the push plate is arranged in the mold leg in asliding match manner; a mold cavity for molding a product is arranged between the upper surface of the lower template and the lower surface of the upper template; a first opening groove and a secondopening groove are formed in the lower surface of the product respectively; the first opening groove is located above the second opening groove; a first included angle is formed between the central line of the first opening groove and a vertical plane; a second included angle is formed between the central line of the second opening groove and the vertical plane. The injection mold provided by theinvention has the advantages that the cost is low, oil does not seep into the mold and the size of the mold is not increased.

Owner:宁波如强模塑有限公司

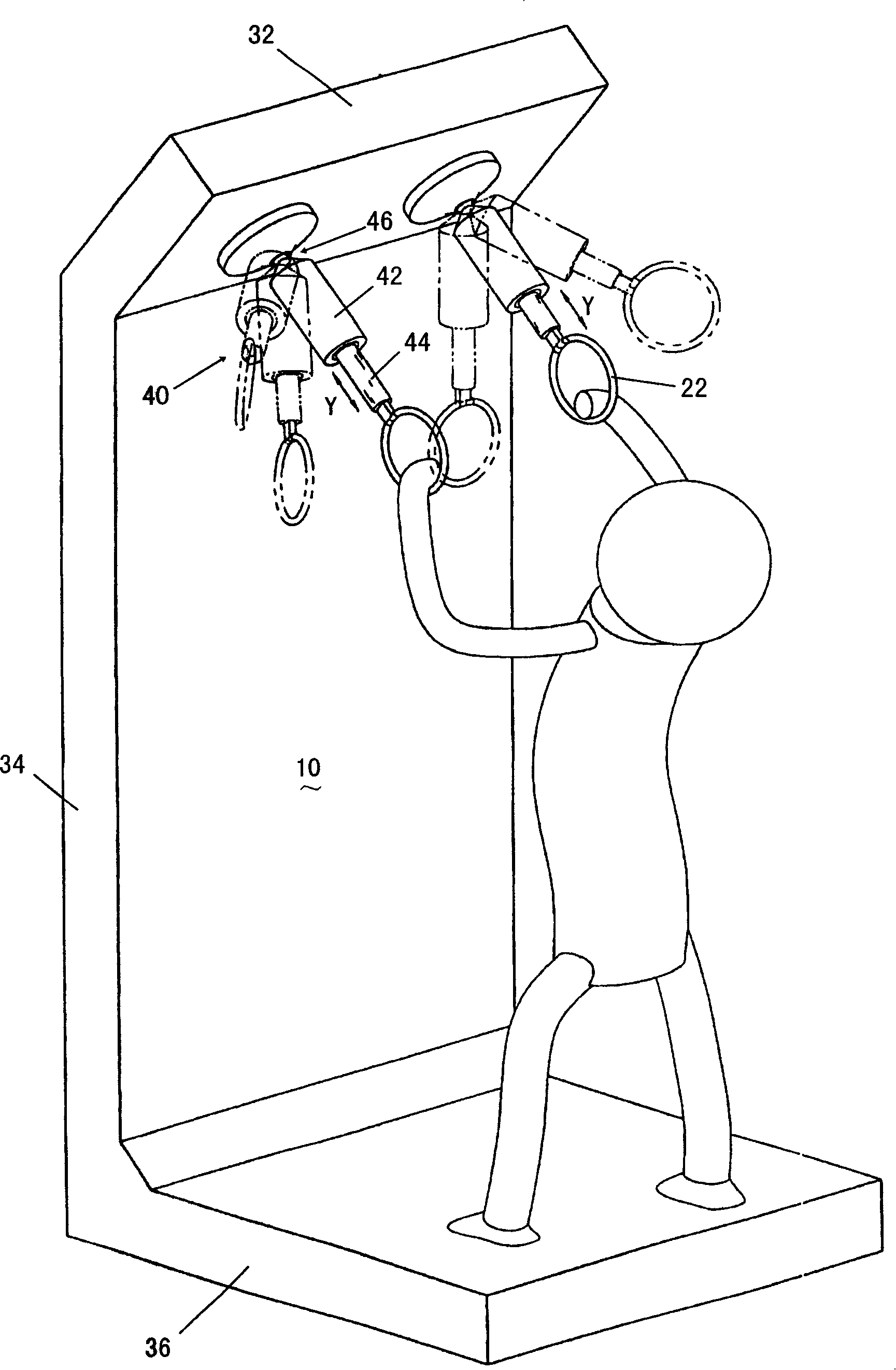

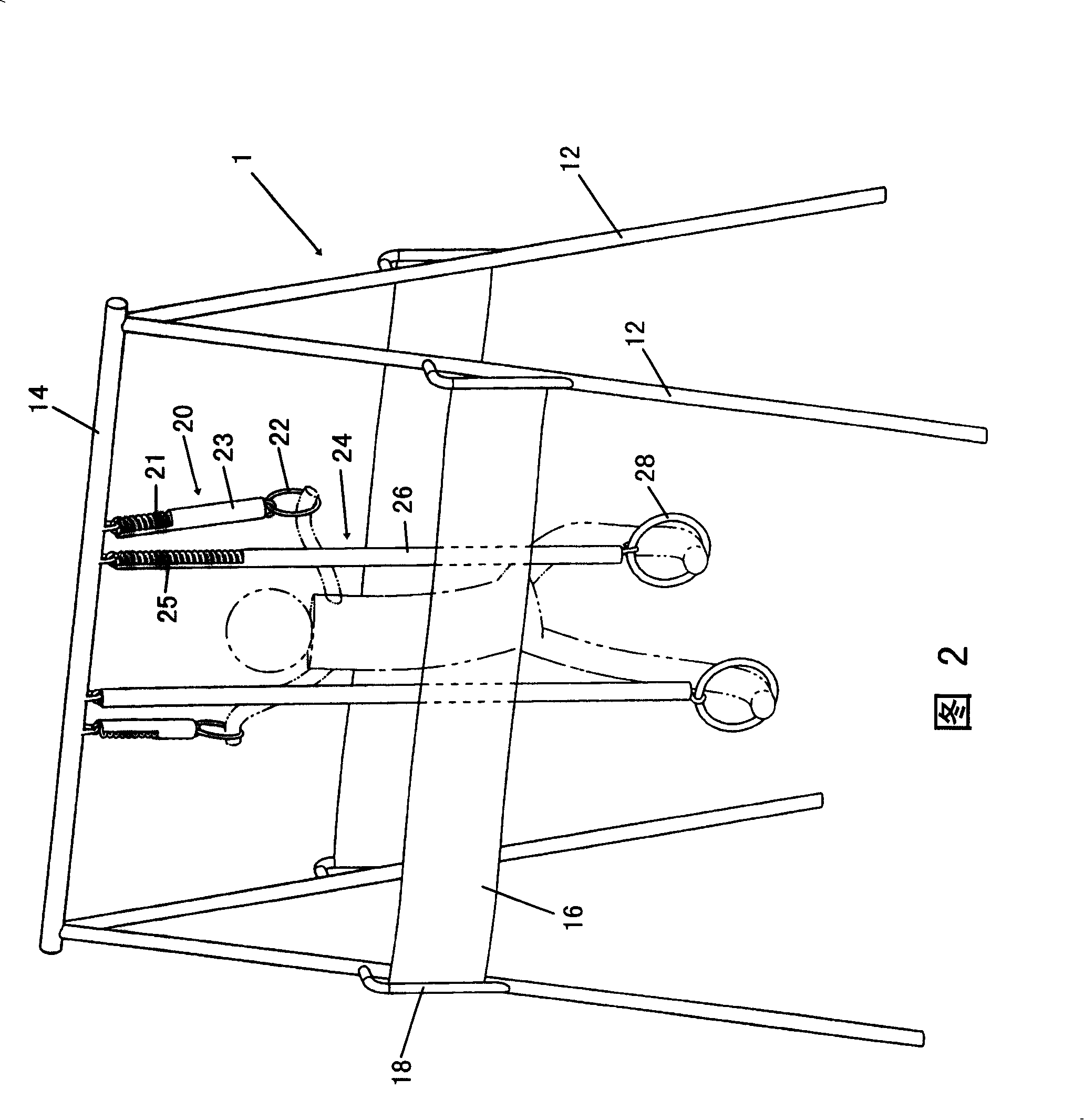

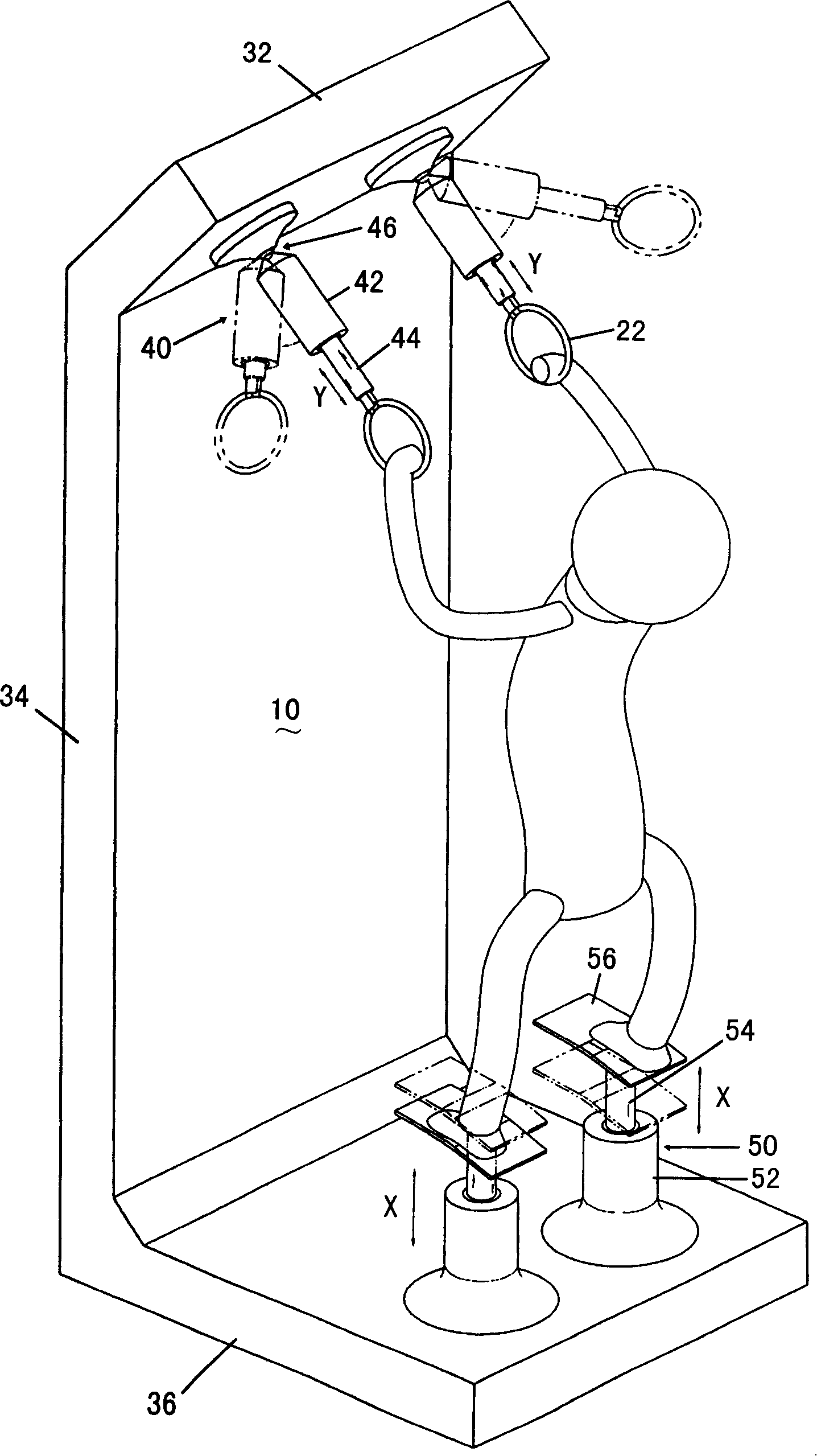

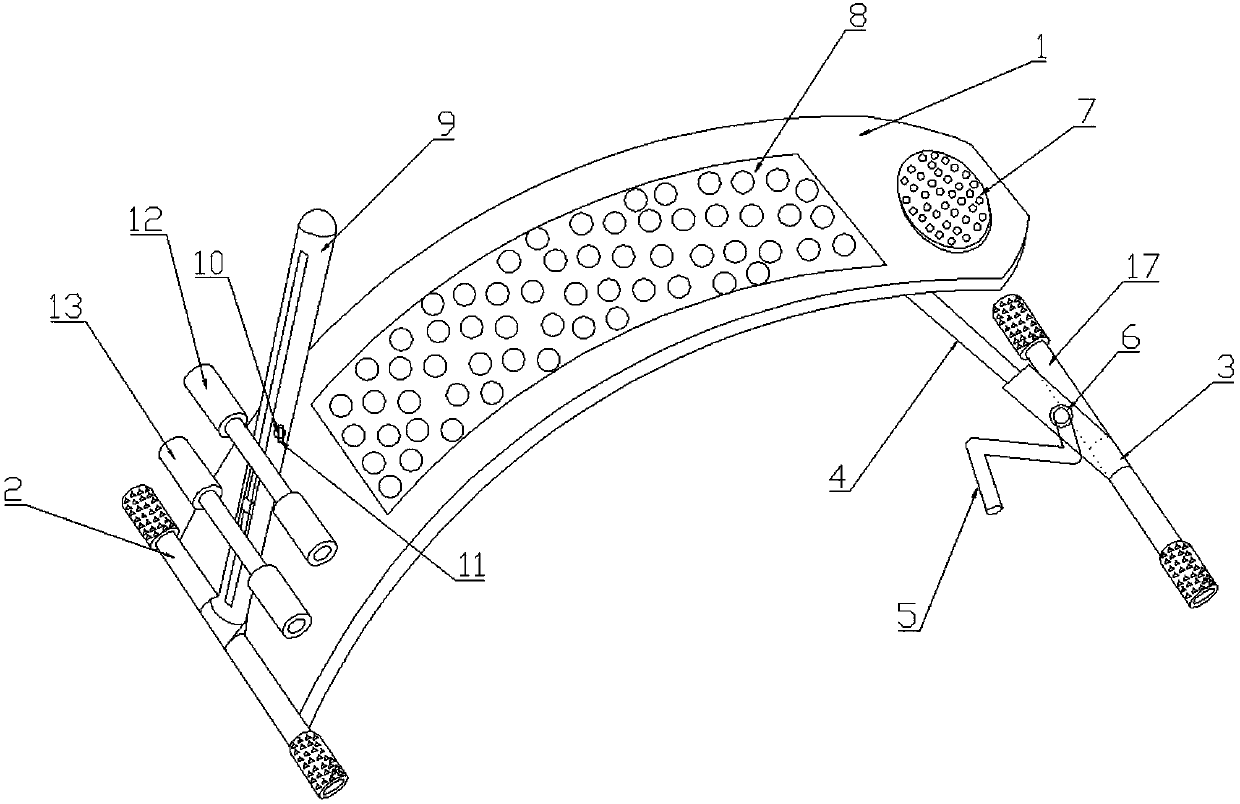

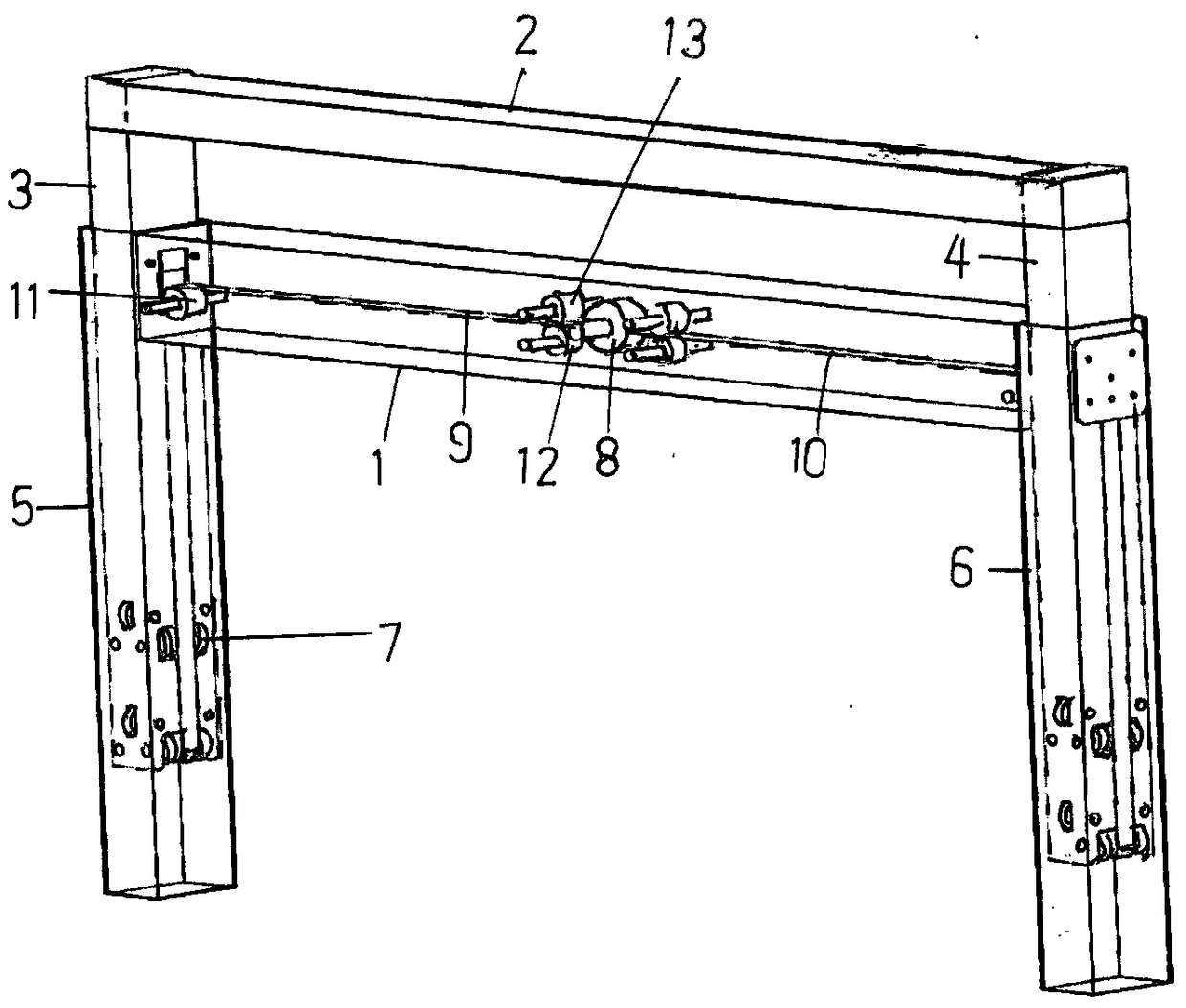

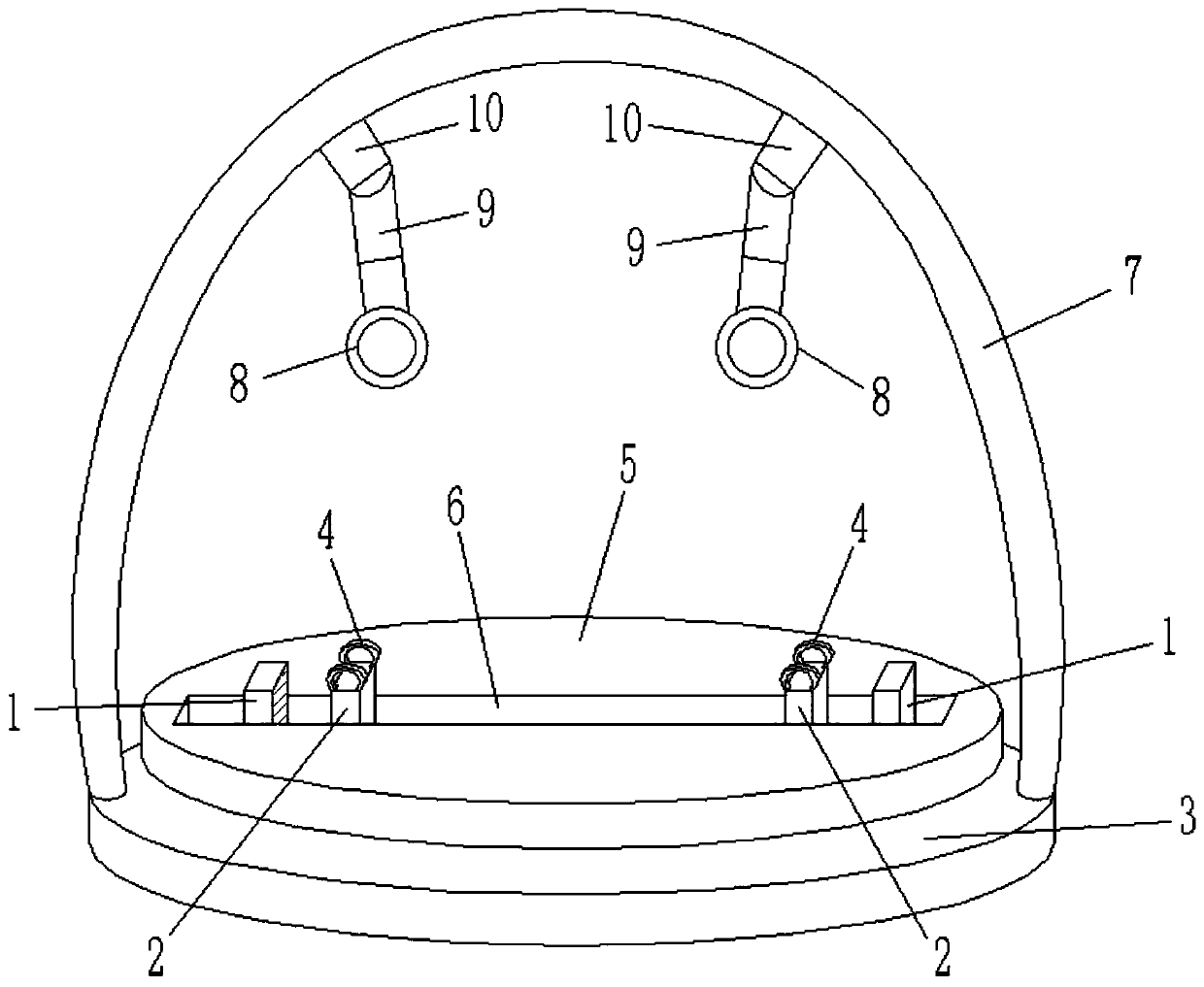

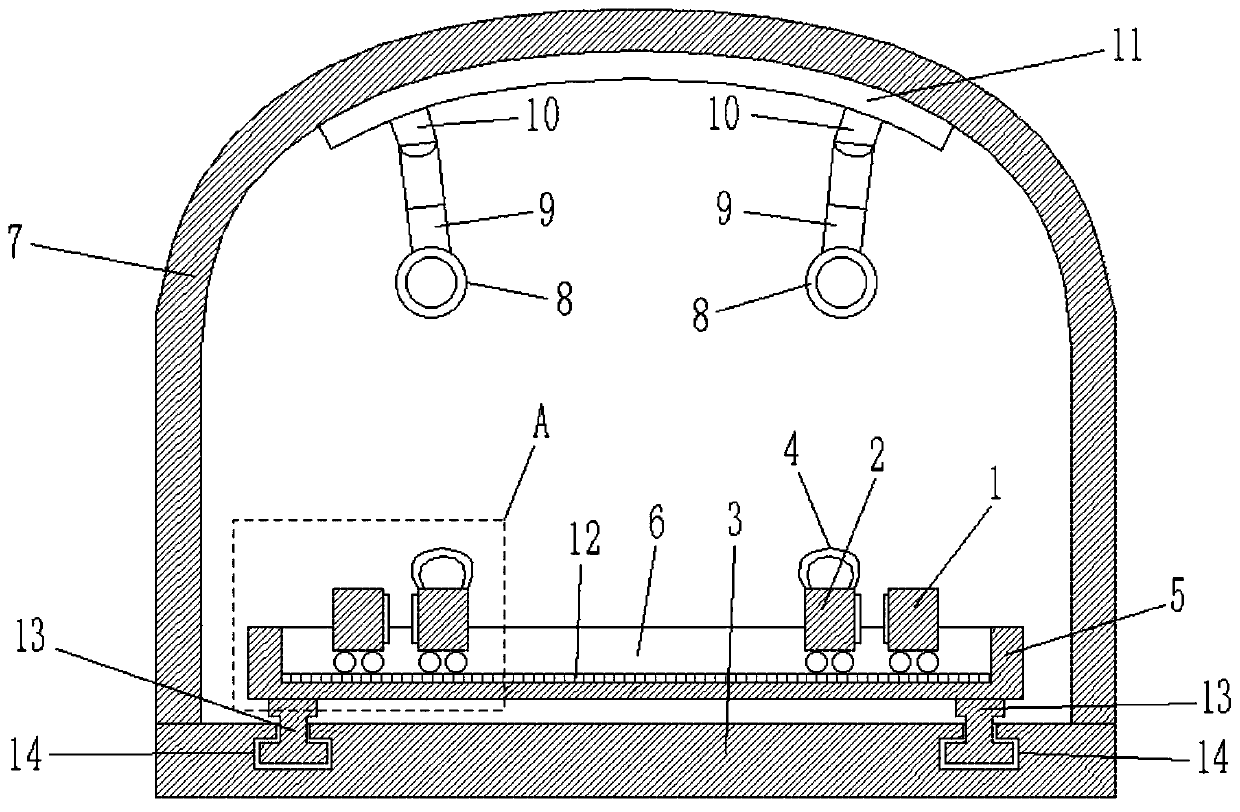

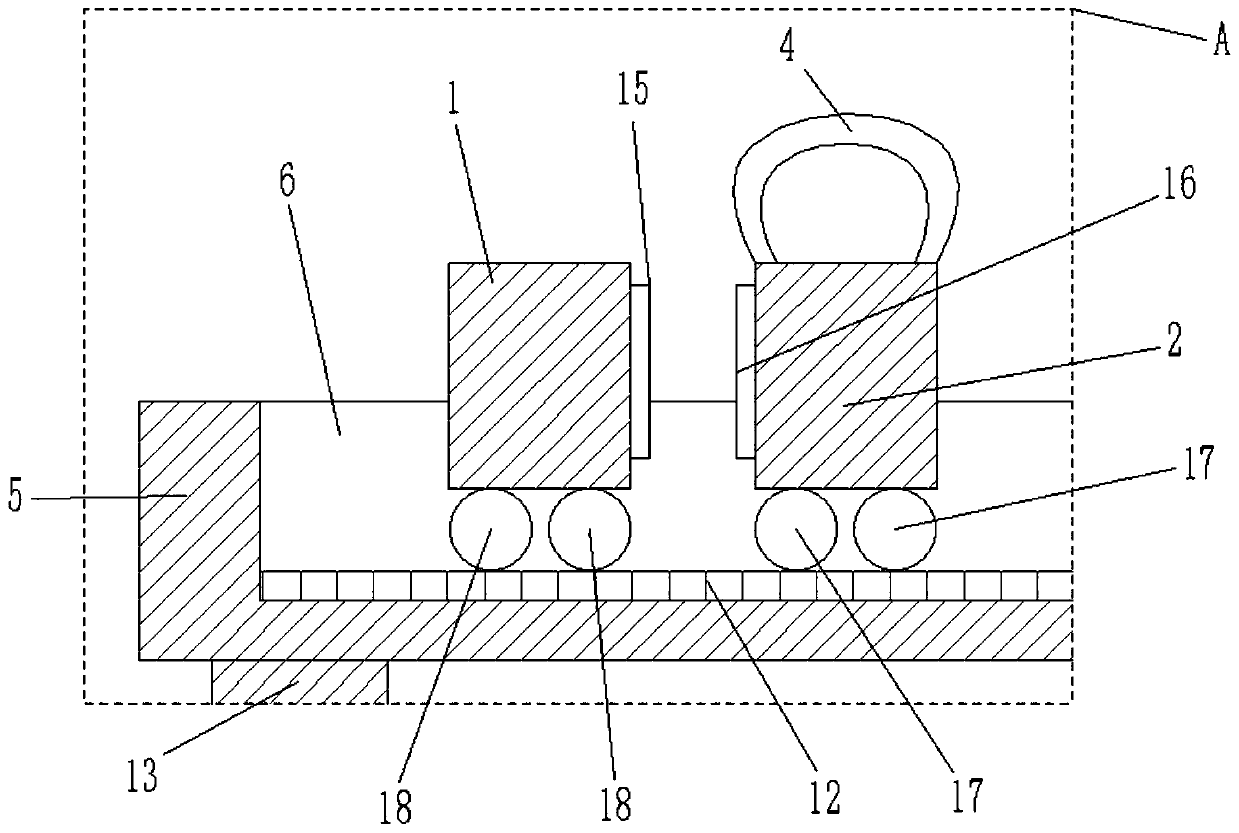

Telescopic limb sports equipments

InactiveCN101224331AWon't strainExercise flexibilityResilient force resistorsExtreme fatigueSports equipment

The invention provides a flexible limb exercise apparatus, comprising a frame fixed on the ground and at least one flexible upper limbs exercise device connected with the frame. The upper limbs exercise device comprises a handle for hand-holding of users and a flexible component which is provided with a moving buffer and is connected between the frame and the handle. With the exercise apparatus, users can exercise the upper limbs without need of using large force of the upper limbs so as to avoid the strains of the limbs of users and extreme fatigue in a short time. The flexible limb exercise apparatus also can comprise at least a flexible lower limb exercise device connected with the frame which comprises a foot support part used for supporting feet of users and a flexible component which is provided with the moving buffer and is arranged between the frame and the foot support device. Therefore, users can exercise the upper and lower limbs at the same time.

Owner:WORLD WIDE STATIONARY MFG CO LTD

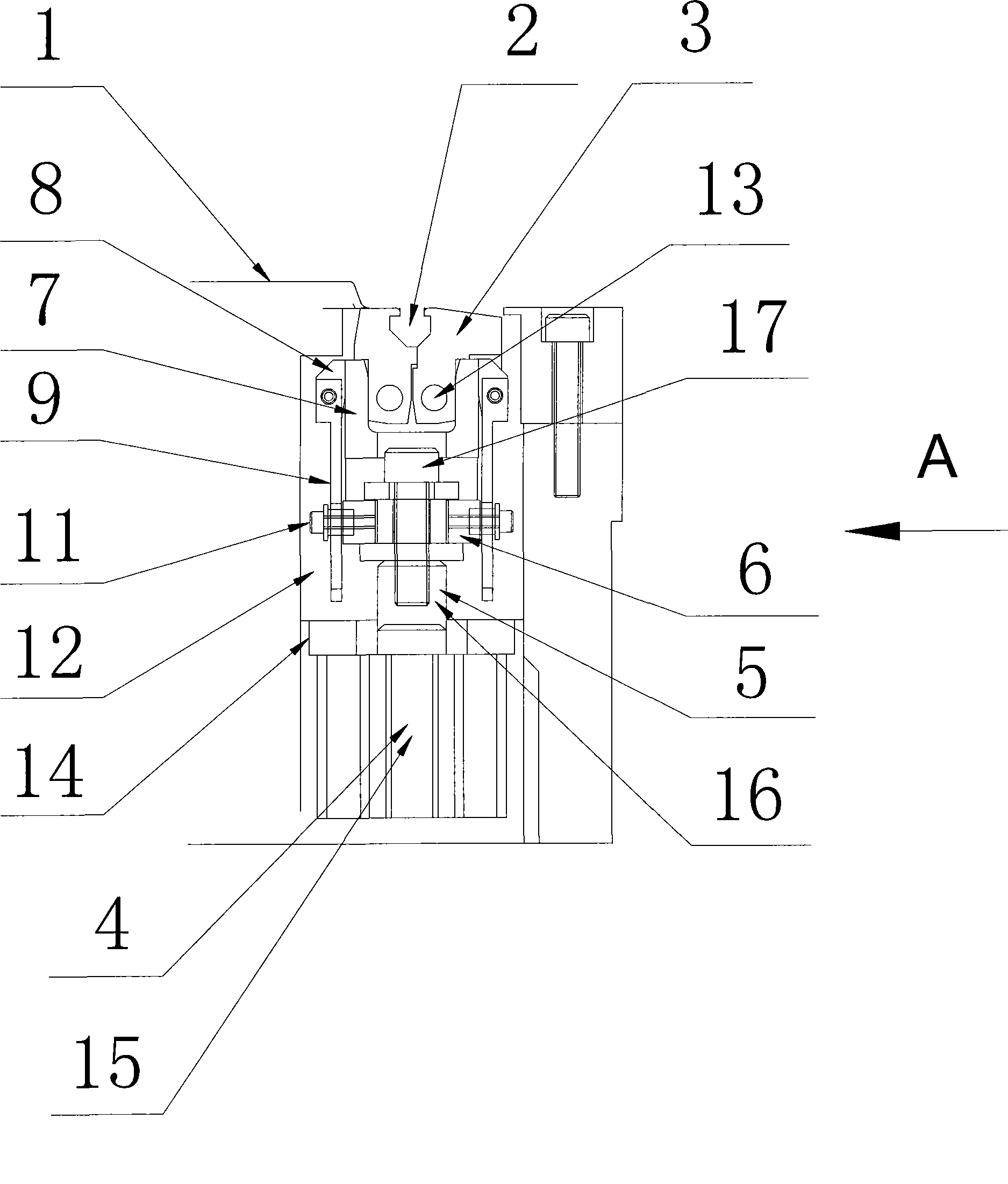

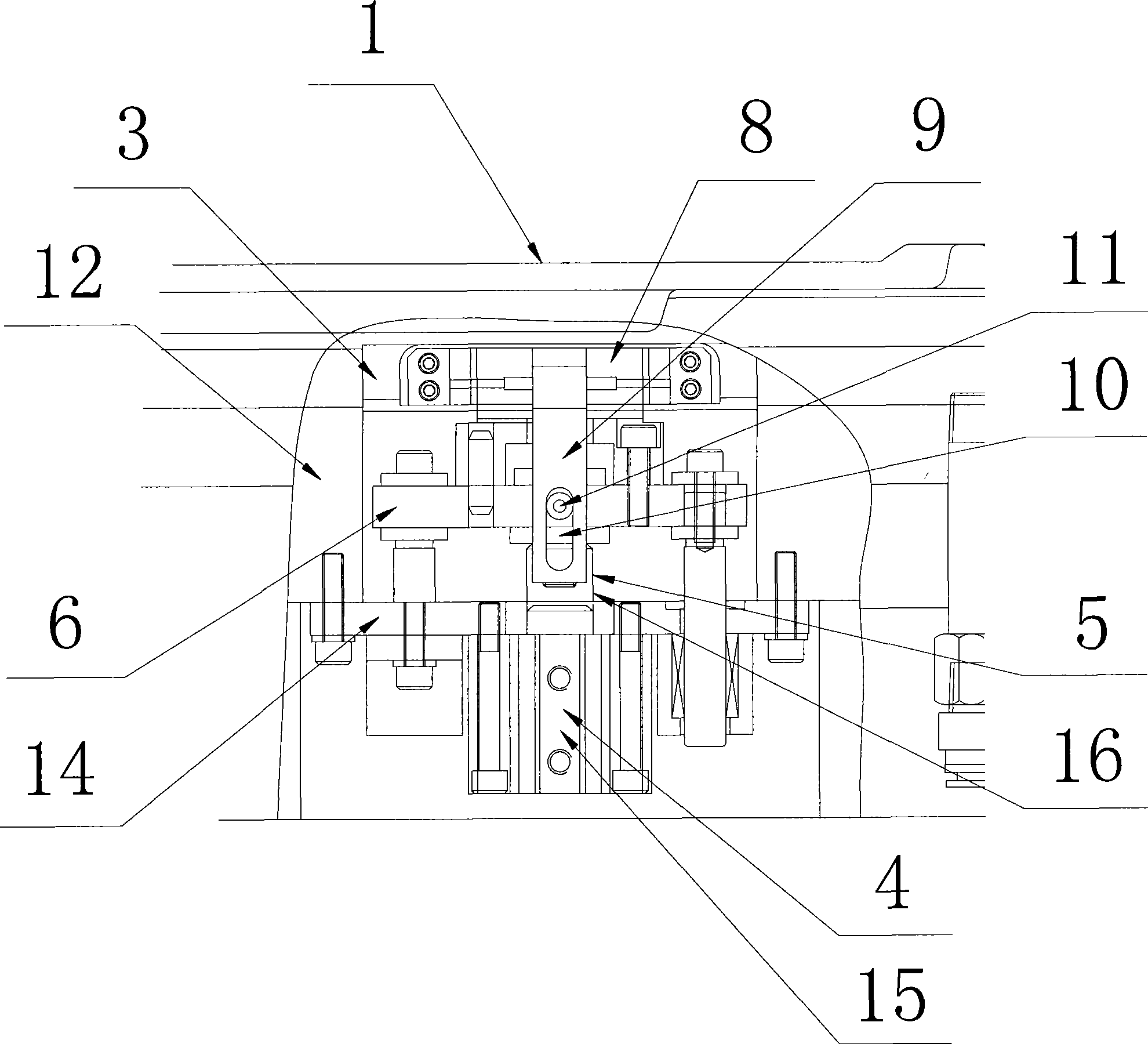

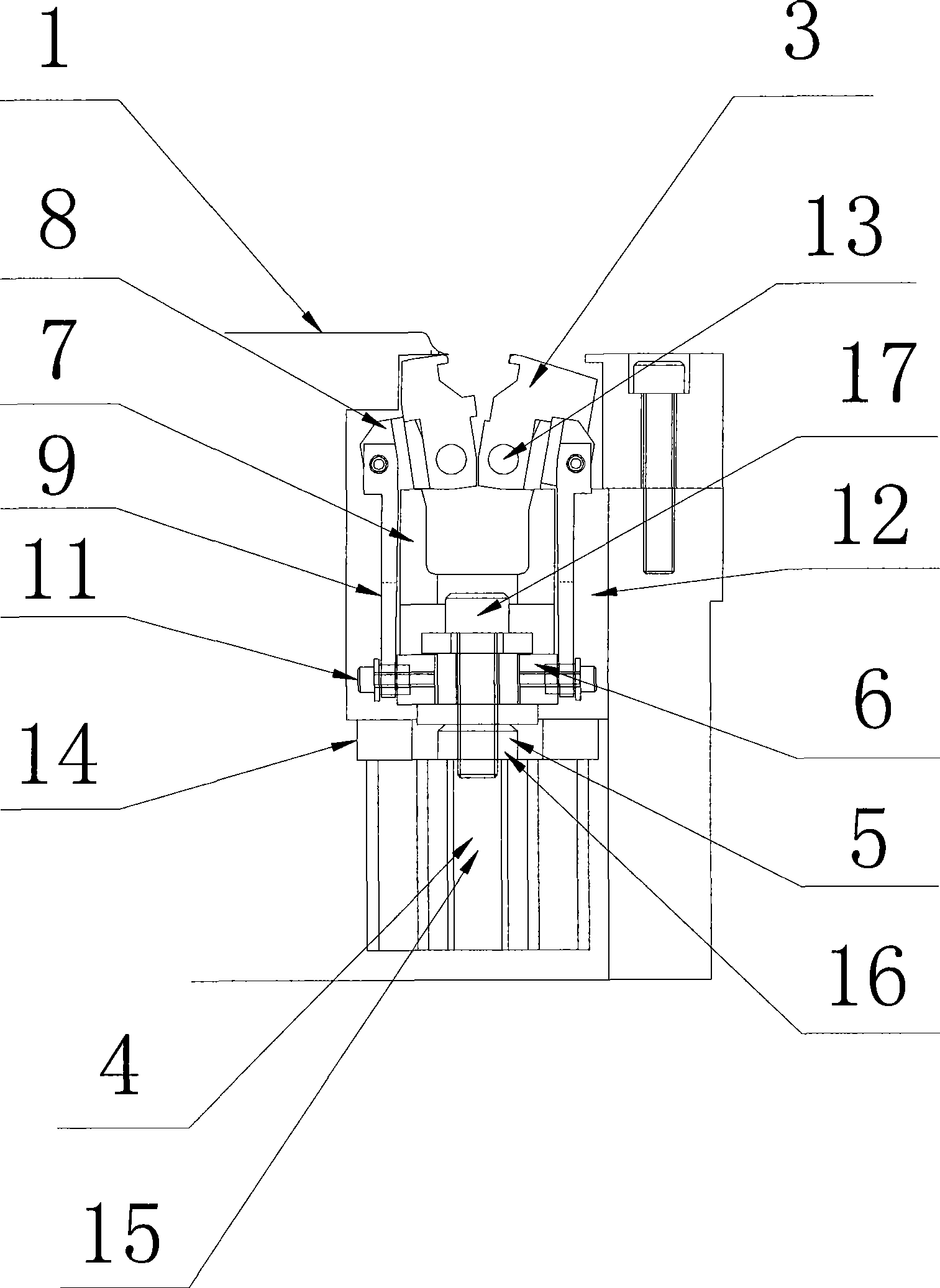

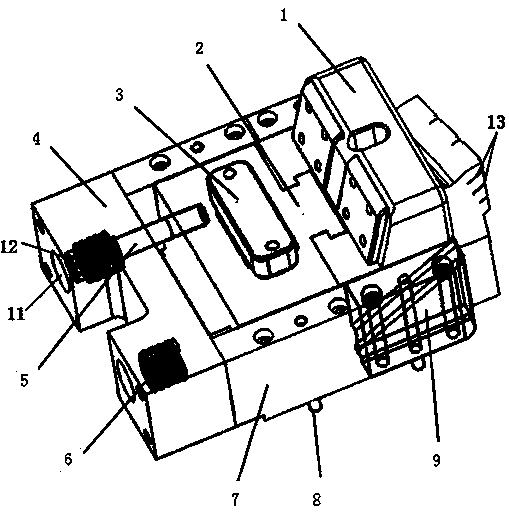

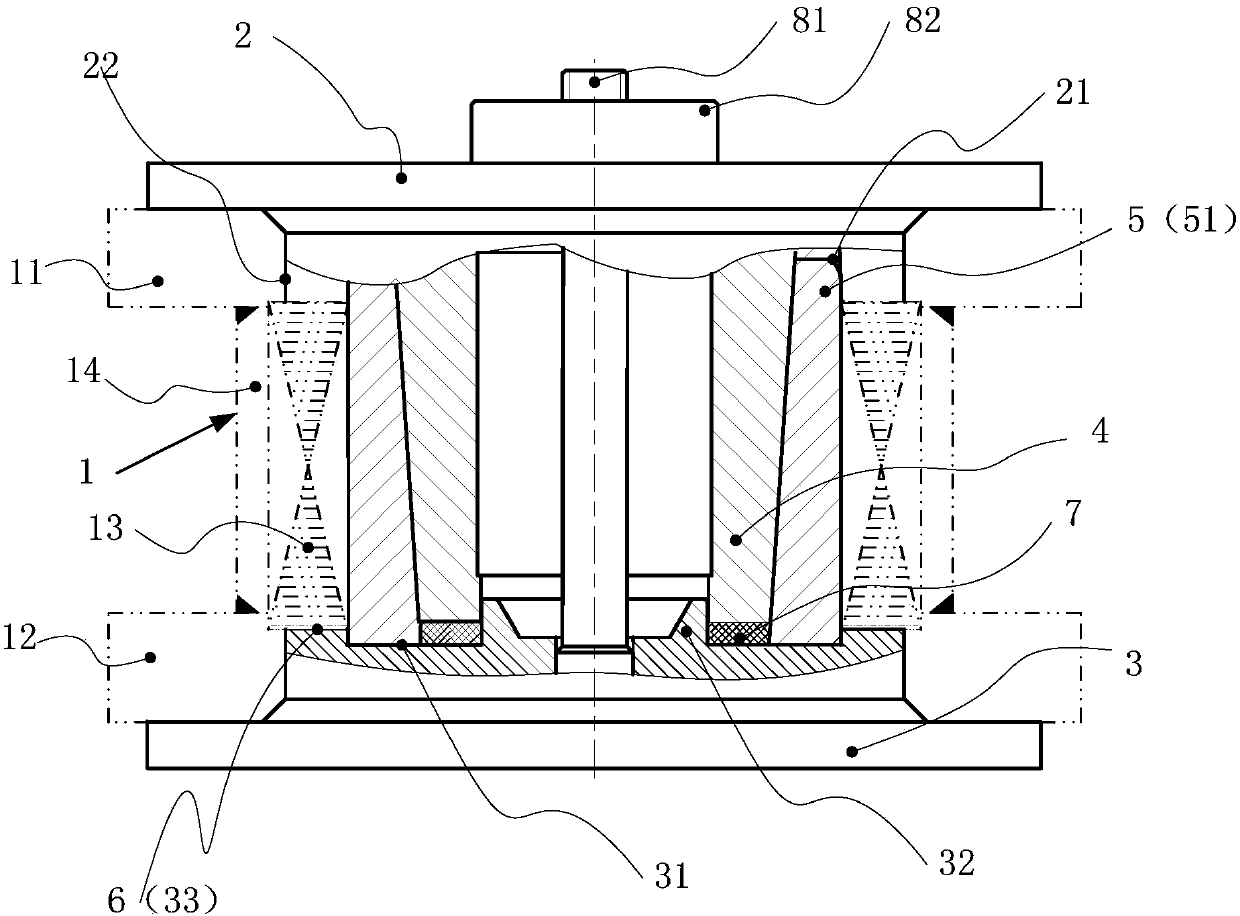

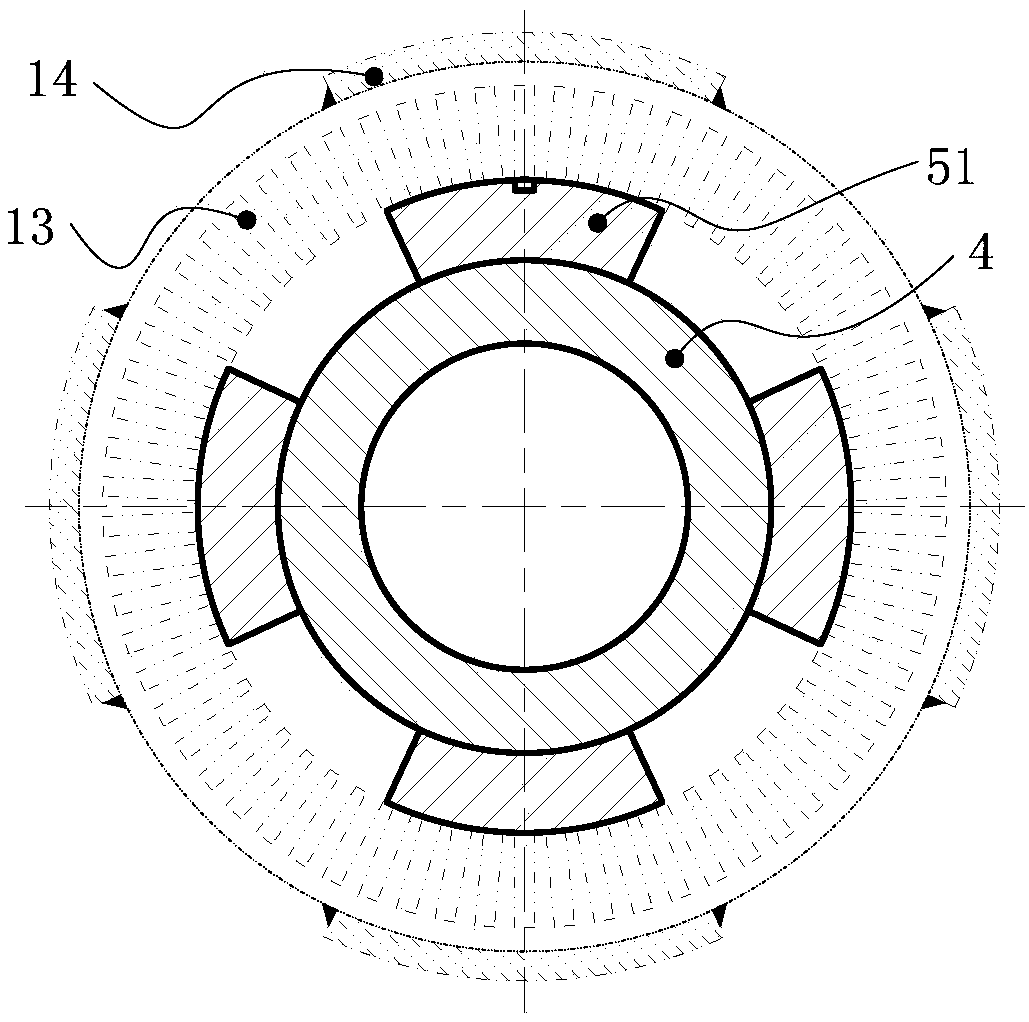

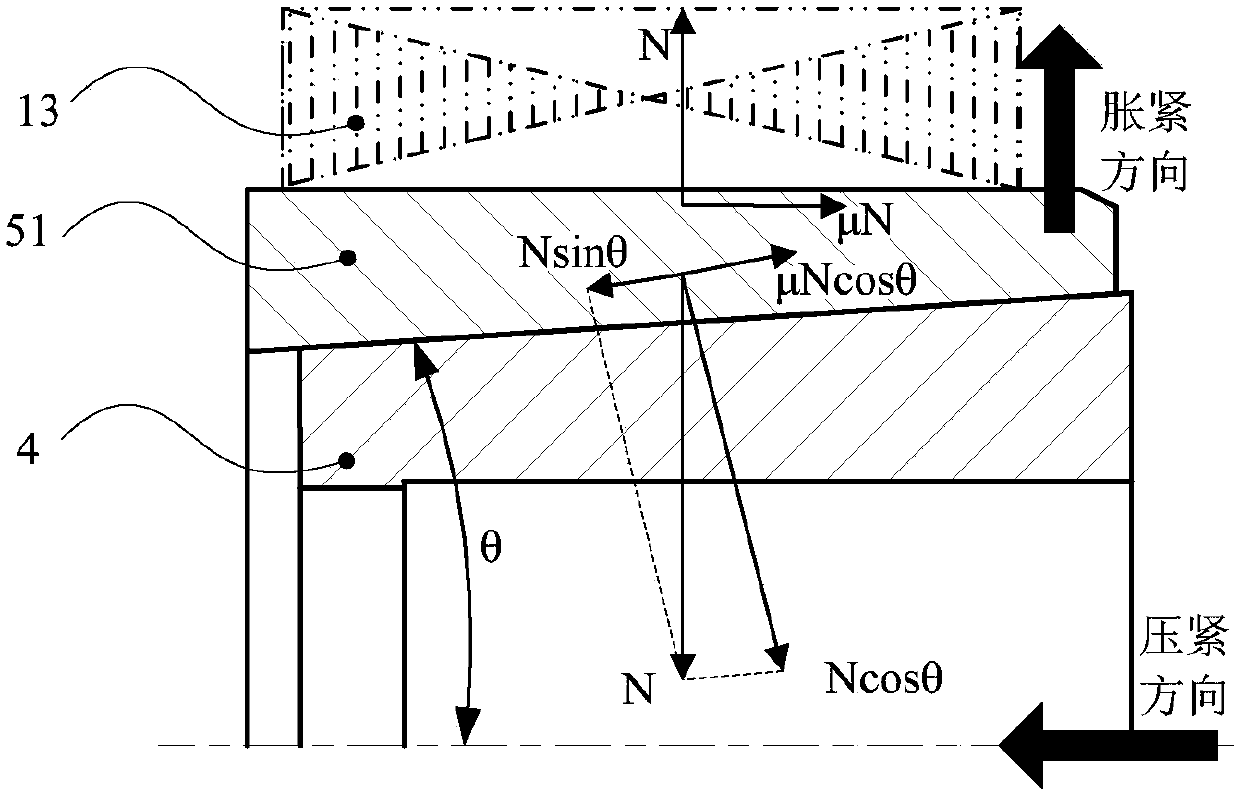

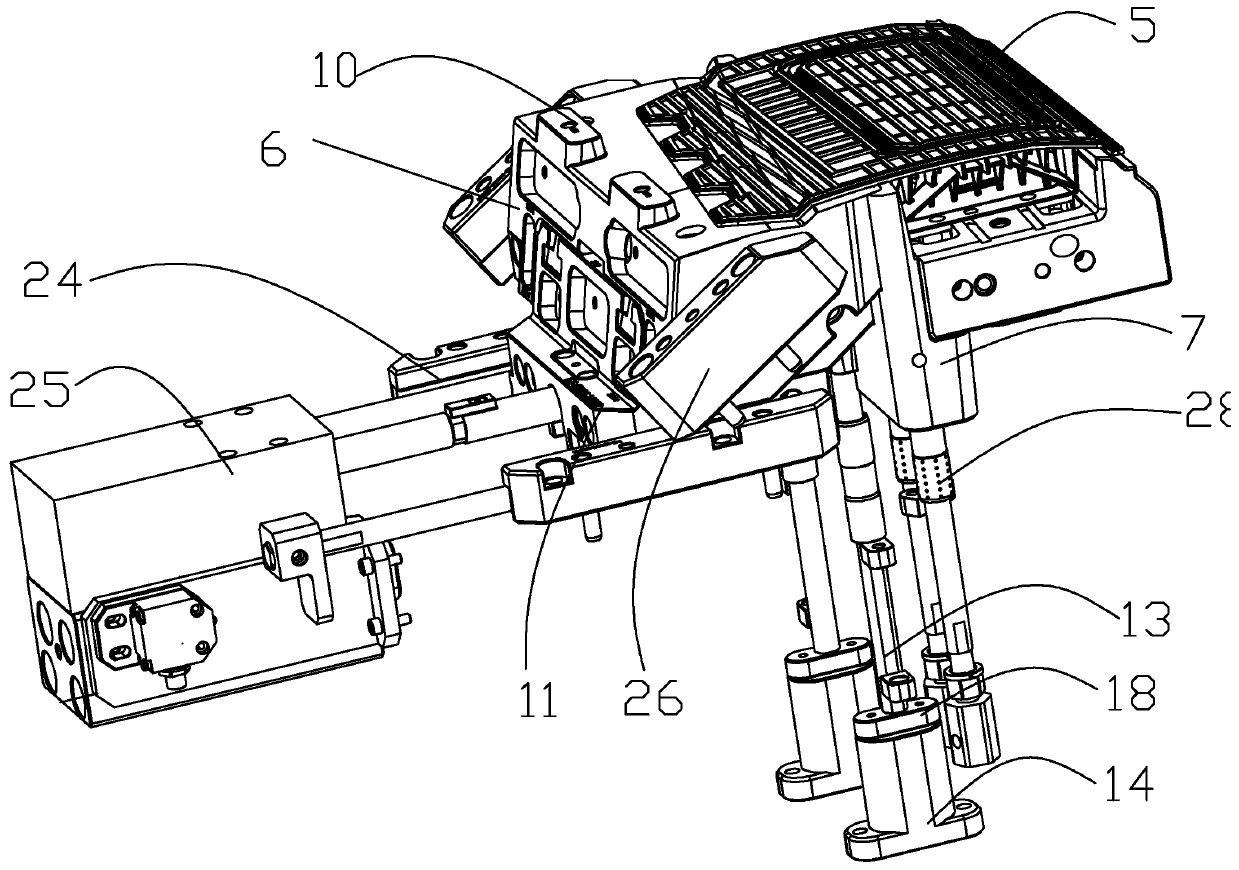

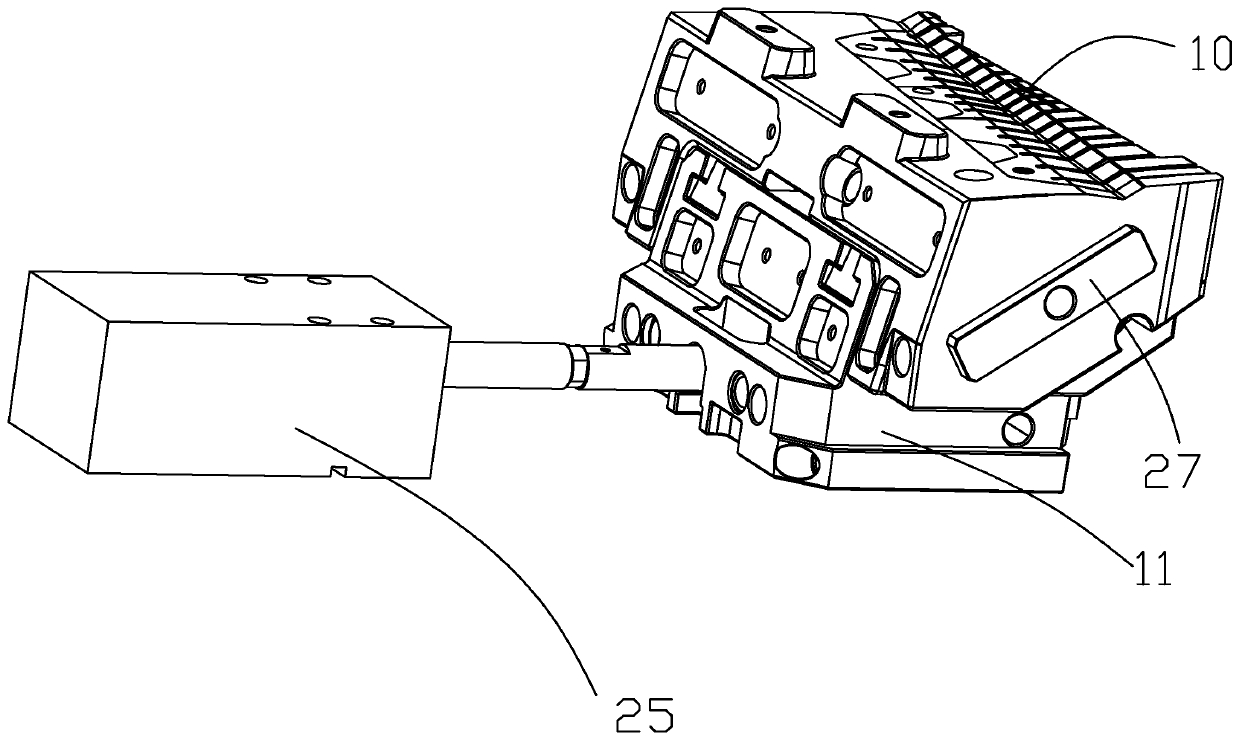

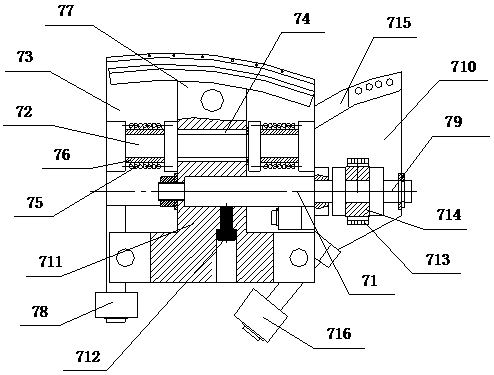

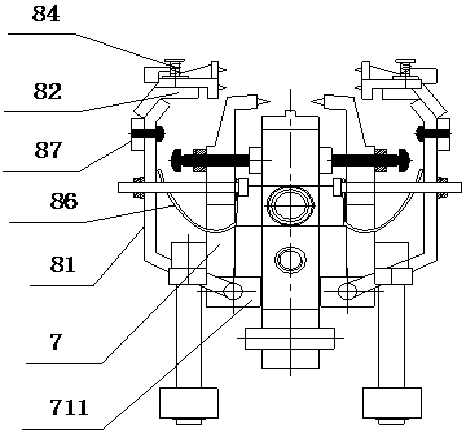

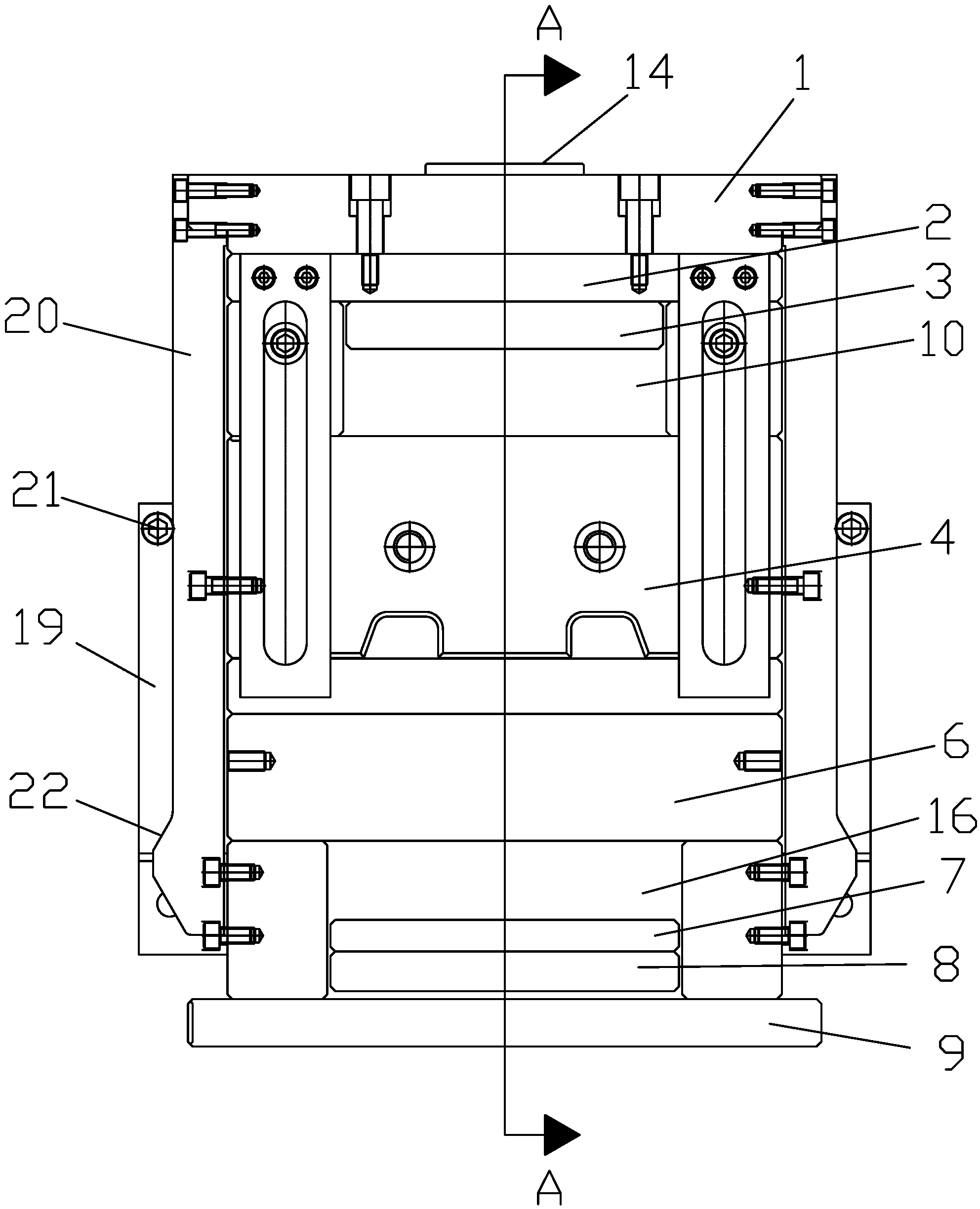

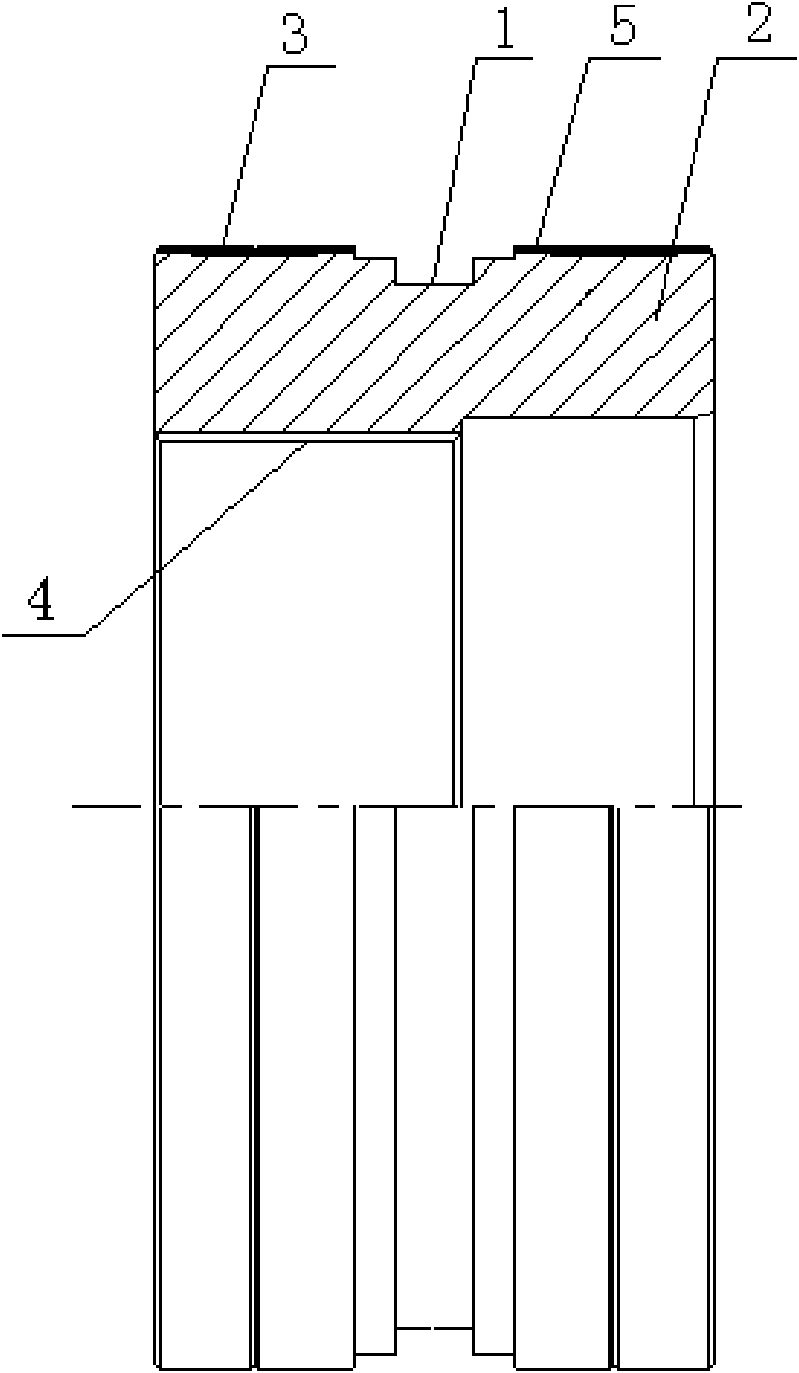

Stator iron core overlaying welding mold

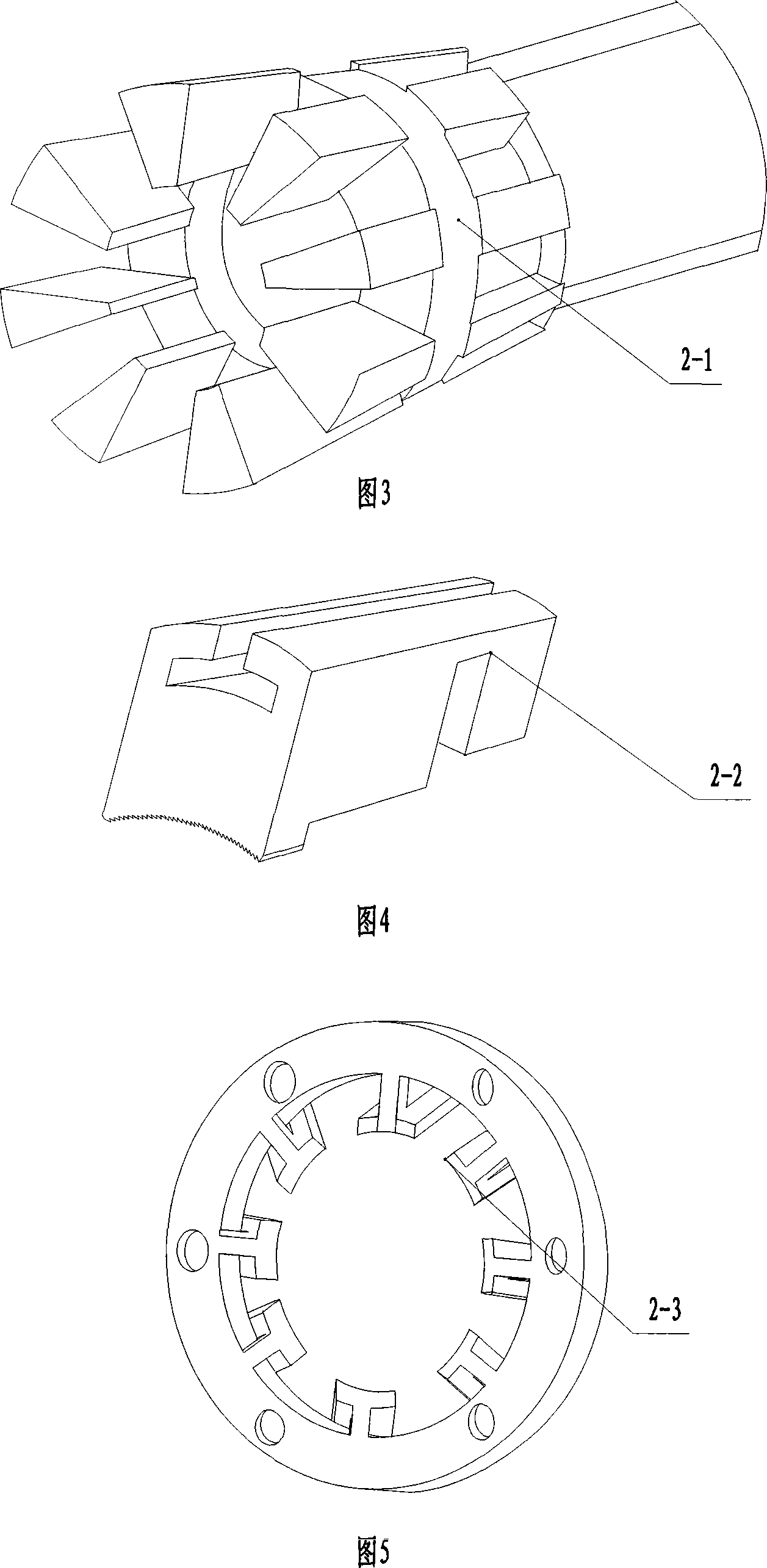

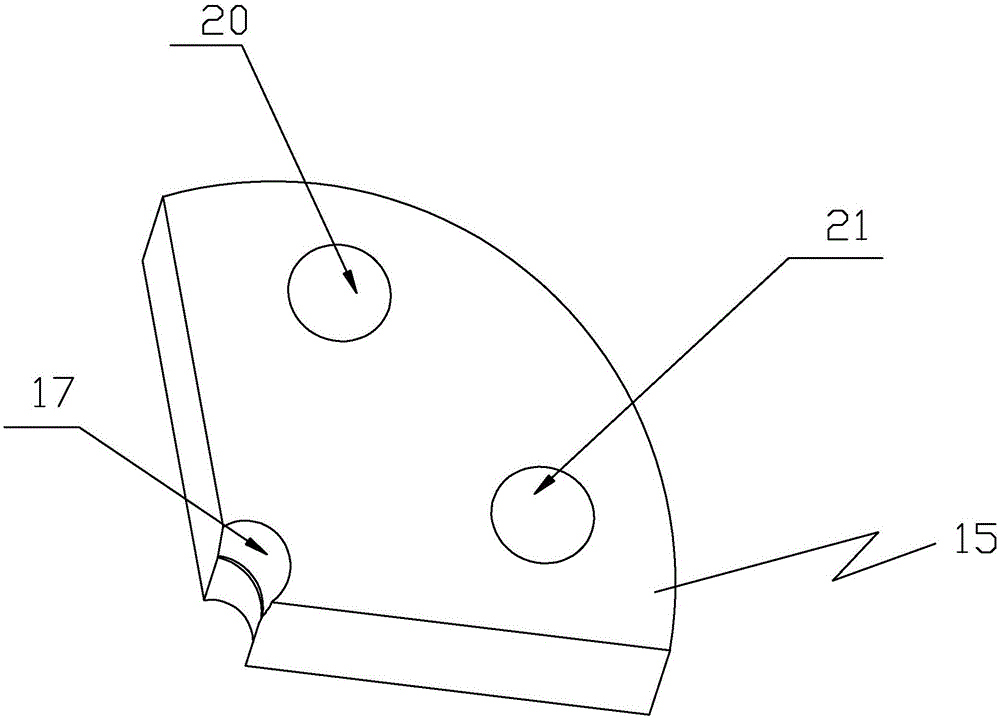

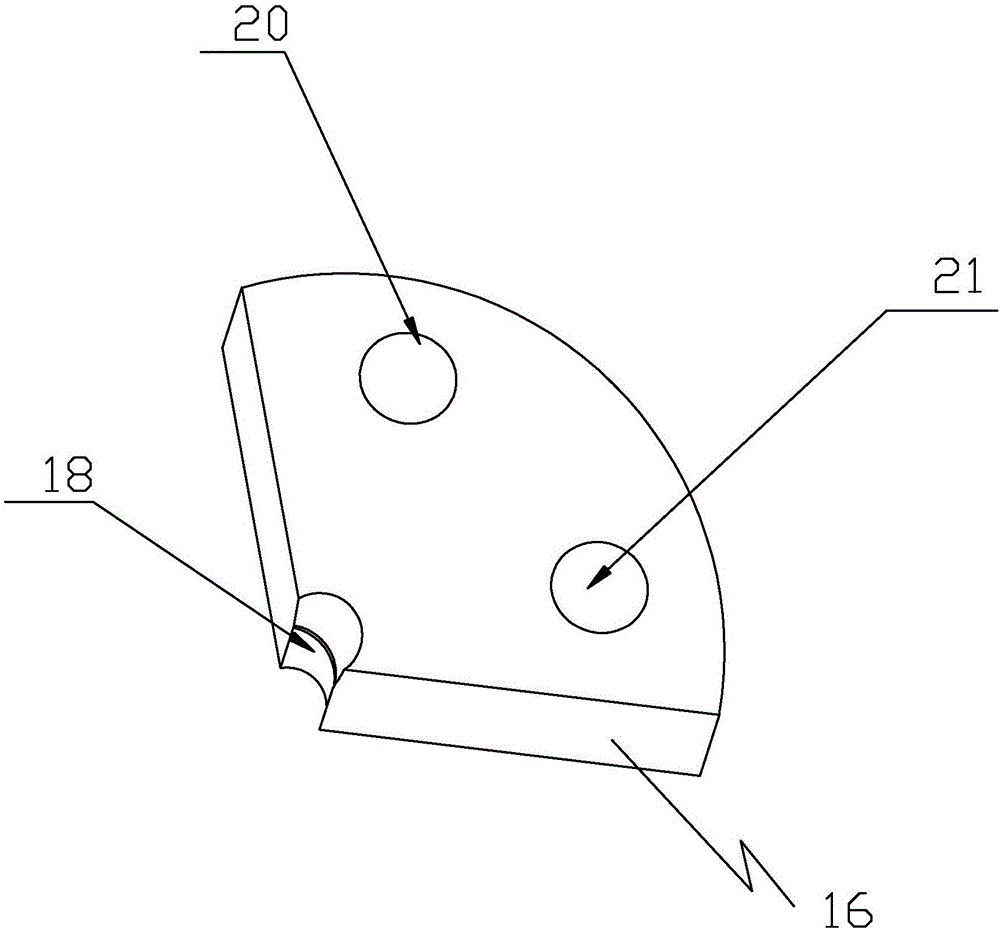

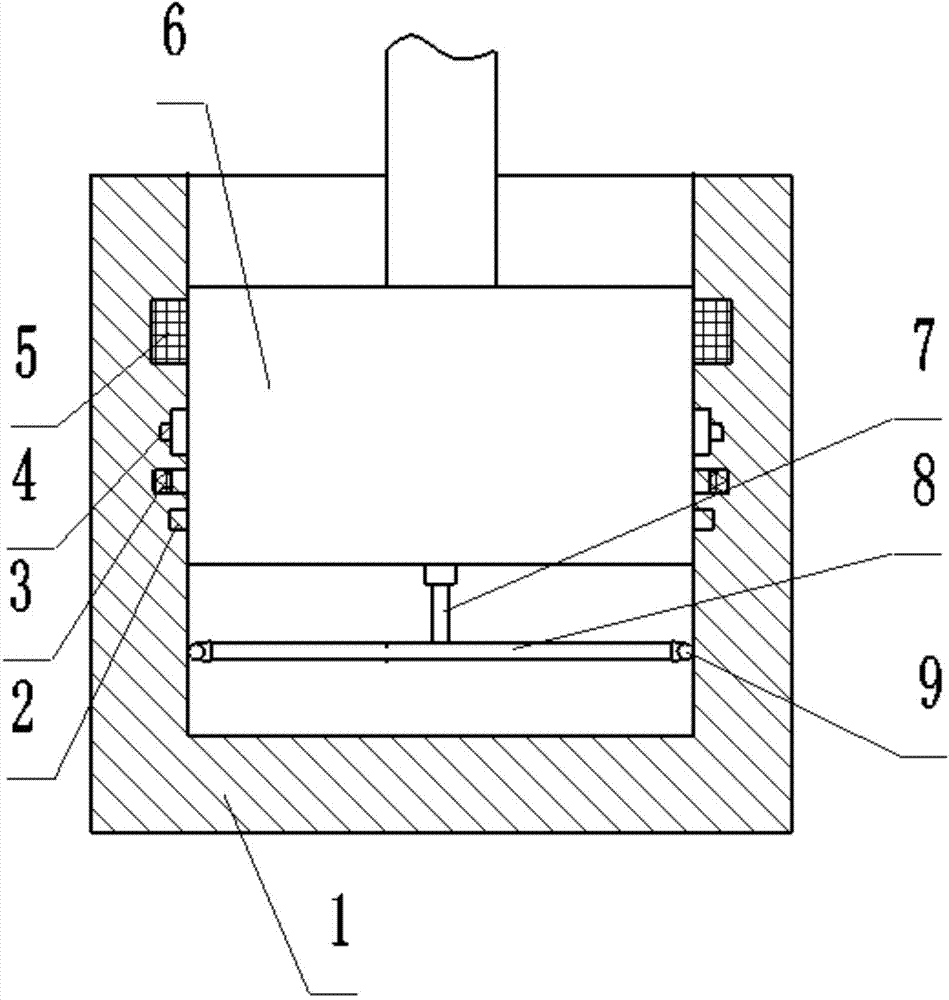

ActiveCN109702403AGuaranteed roundnessWon't strainWelding/cutting auxillary devicesAuxillary welding devicesPunchingWelding deformation

The invention discloses a stator iron core overlaying welding mold. A stator iron core comprises a stator upper pull ring, a stator lower pull ring, a stator punching piece and multiple stator pull plates; the stator punching piece is arranged between the stator upper pull ring and the stator lower pull ring; the multiple stator pull plates are uniformly distributed at the outer periphery of the stator punching piece; the welding mold comprises an upper pressing plate, a lower pressing plate, an inner mold and an outer mold; the inner mold and the outer mold are arranged between the upper pressing plate and the lower pressing plate; the outer mold comprises multiple fan-shaped blocks; the fan-shaped blocks are as many as the stator pull plates; the inner surfaces and the outer surfaces ofthe fan-shaped blocks are arcs; the multiple fan-shaped blocks are uniformly arranged at the outer periphery of the inner mold; limiting pieces are arranged at the outer peripheries of the multiple fan-shaped blocks; the outer surface of the inner mold is an inner mold conical surface; the inner surfaces of the fan-shaped blocks are outer mold conical surfaces matched with the inner mold conical surface; and the outer surfaces of the fan-shaped blocks are matched with the inner surface of the stator punching piece. The reversible deformation is only applied to welding deformation positions ofthe stator pull plates, so that the welding deformation is effectively counteracted, and the inner circle roundness of the stator iron core can be guaranteed.

Owner:湖南中车商用车动力科技有限公司

Automobile safety airbag cover ejection mechanism

InactiveCN111267302AWon't strainImprove reliabilityDomestic articlesStructural engineeringAutomobile safety

The invention discloses an automobile safety airbag cover ejection mechanism. The automobile safety airbag cover ejection mechanism comprises an upper die, a lower die, a support block and a bottom plate, the support block is located between the lower die and the bottom plate, the lower die is provided with sliding blocks used for forming a first undercut of the side face of a product and a secondundercut of the lower surface of the product and a die core used for forming the lower surface of the other part of the product correspondingly, the automobile safety airbag cover ejection mechanismfurther comprises an ejector pin plate, the ejector pin plate is located between the bottom plate and the lower die, the sliding blocks comprise the first sliding block and the second sliding block, the first sliding block is located on the second sliding block, the first sliding block is matched on the second sliding block through an inclined face, the second sliding block is matched on the uppersurface of the lower die in a sliding mode, the first sliding block is used for forming the first undercut and the second undercut, a first-time ejection mechanism is arranged between the bottom plate and the first sliding block, and a second-time ejection mechanism is arranged between the die core and the ejector pin plate. The automobile safety airbag cover ejection mechanism has the advantagesthat the reliability is high, and the rejection rate is low.

Owner:NINGBO FANGZHENG TOOL

Medical self-adhesive elastic bandage preparation method

InactiveCN107802877AImprove mechanical propertiesStable in natureAbsorbent padsBandagesEmulsionRoom temperature

The invention discloses a medical self-adhesive elastic bandage preparation method. The method includes steps: (1) mixing methacrylic anhydride, methyl methacrylate, methyl acrylate, deionized water and lauryl amine, heating to 75-80 DEG C, and continuously stirring for 60-70min to obtain mixed emulsion; (2) slowly adding a modifying agent into the mixed emulsion obtained in the step (1), heatingthe mixed liquid to 86-90 DEG C, continuously stirring for 300-350min, cooling to the room temperature, and filtering through a 150-mesh filter screen to obtain an adhesive; (3) adding a stabilizing agent into the adhesive obtained in the step (2), well stirring, and coating front and back faces of an elastic bandage with the prepared adhesive to obtain a medical self-adhesive elastic bandage. Themedical self-adhesive elastic bandage prepared according to the method has advantages that the adhesive is nonsticky to skin and free of greasiness, wound pulling in tearing of the bandage is avoided, and excellent breathability is realized.

Owner:安徽斯麦特医学技术开发有限公司

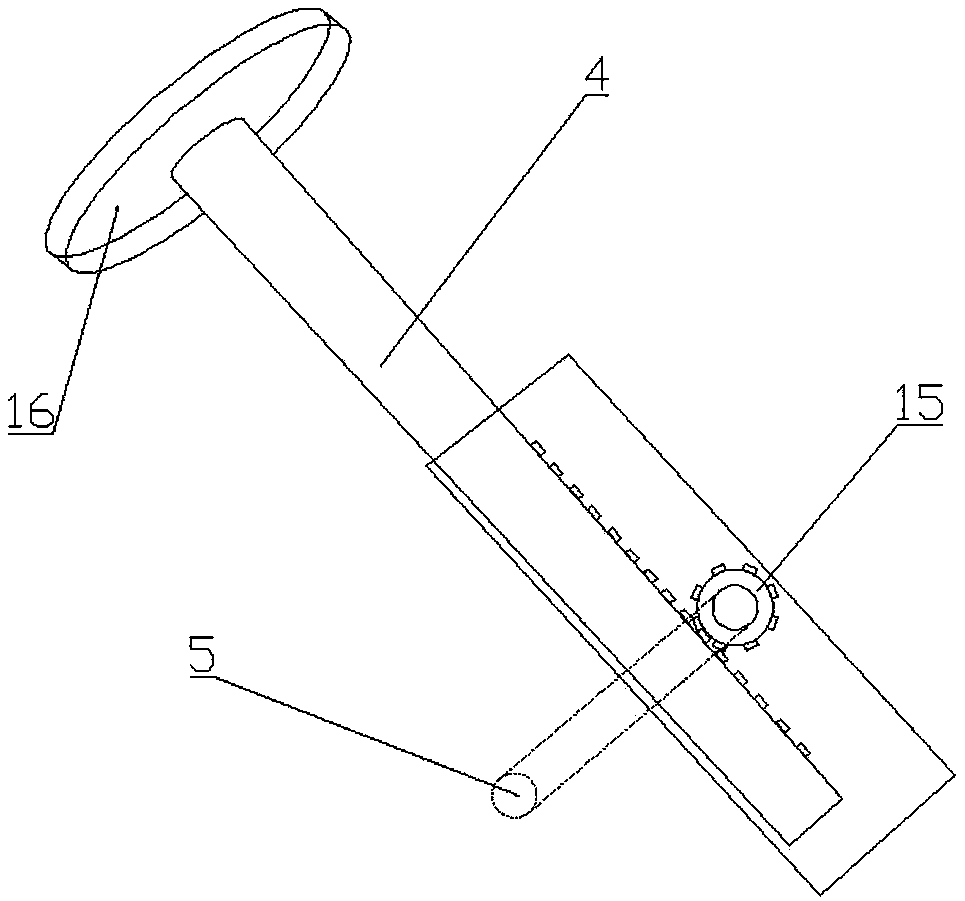

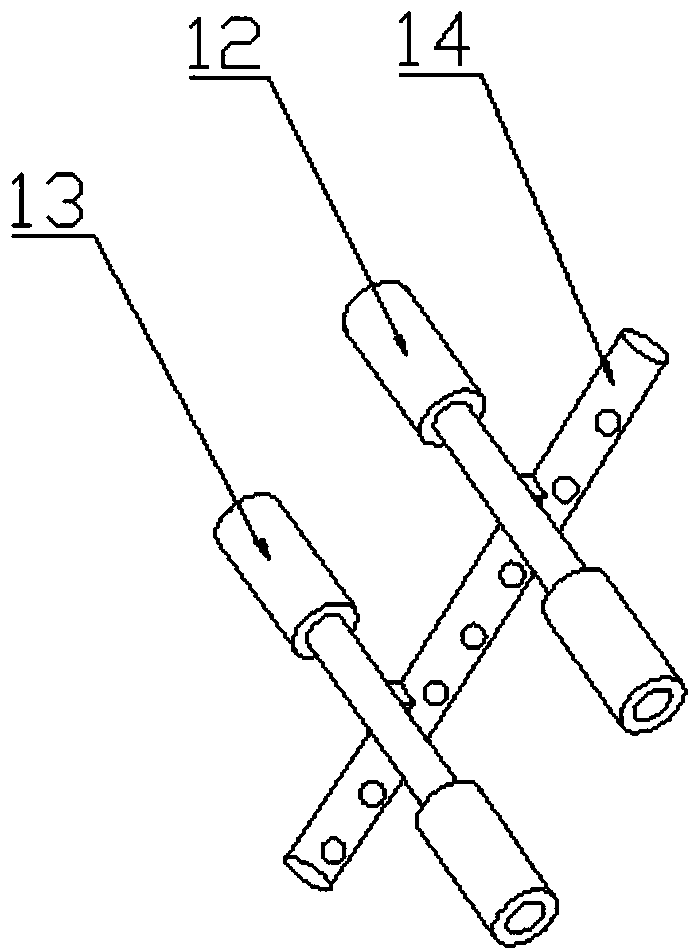

Adjustable supine board

InactiveCN109925661AImprove comfortEasy to stretchDevices for pressing relfex pointsGymnastic exercisingFoot supportsEngineering

The invention relates to the field of fitness equipment, in particular to an adjustable supine board. The adjustable supine board comprises a sit-up board 1, a foot support rod 2 and a head support device 3 at least; one end of the sit-up board 1 is fixedly connected with the foot support rod 2, and the lower surface of the other end of the sit-up board 1 is fixedly connected with the head supportdevice 3. The adjustable supine board is characterized in that the middle of the foot support rod 2 is fixedly connected with a support frame 9 perpendicular to the foot support rod 2, the support frame 9 is located on one side of the upper surface of the sit-up board 1, an included angle of 20-40 degrees is formed between the support frame 9 and the sit-up board 1, a slide groove is formed in the support frame 9 in the vertical direction, the slide groove is internally and slidably connected with a slide rod 14, the outer wall of the slide rod 14 is fixedly connected with a foot hooking rod12 and a foot pad rod 13 which are located outside the slide groove, and a lifting device is arranged on the heat support device 3.

Owner:郭皓

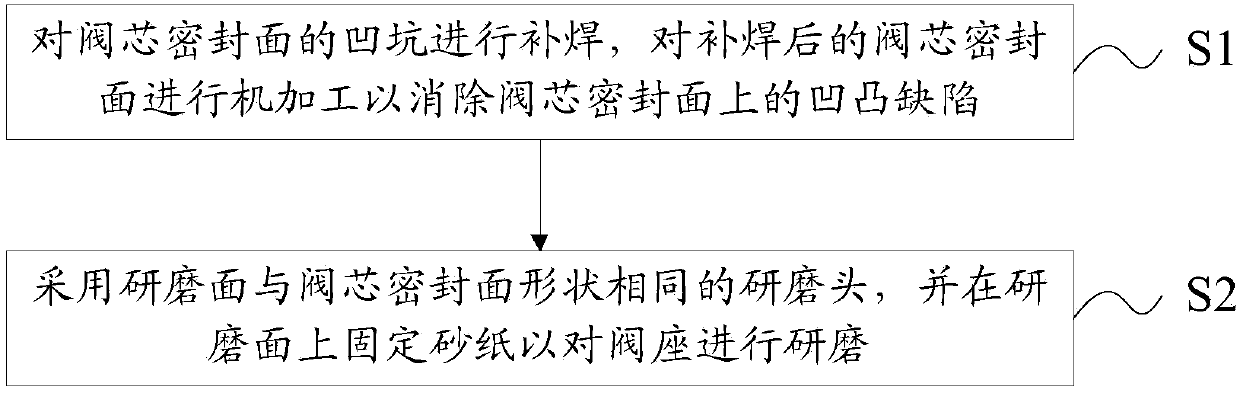

Grinding process of conical surface sealing valve

The invention discloses a grinding process of a conical surface sealing valve. The grinding process comprises the steps that pits in the sealing surface of a valve core are subjected to repair welding, and the valve core sealing surface subjected to repair welding is subjected to mechanical machining so as to eliminate concave and convex defects on the valve core sealing surface; a grinding head with the shape of the grinding surface being the same as that of the valve core sealing surface is adopted, abrasive paper is fixed to the grinding surface to grind a valve seat. By the application ofthe grinding process of the conical surface sealing valve provided by the invention, the grinding quality of the valve core and the grinding quality of the valve seat can be controlled correspondinglyso that the valve core and the valve seat can reach the sealing requirements step by step. Repair welding and mechanical machining are adopted, the work amount and work time are greatly reduced, andthe damage defects of the valve sealing surface can be processed in the limited defect elimination time so that the valve core and the valve seat of the valve can be sealed tightly and reach the operation requirements. Meanwhile, the grinding head is adopted to grind the valve seat, the grinding head with the weight being obviously smaller than that of the valve core can be selected, and thus strain of the sealing surface caused by excessively large grinding resistance in the oppositely grinding process can be avoided.

Owner:CHINA RESOURCES POWER HUBEI

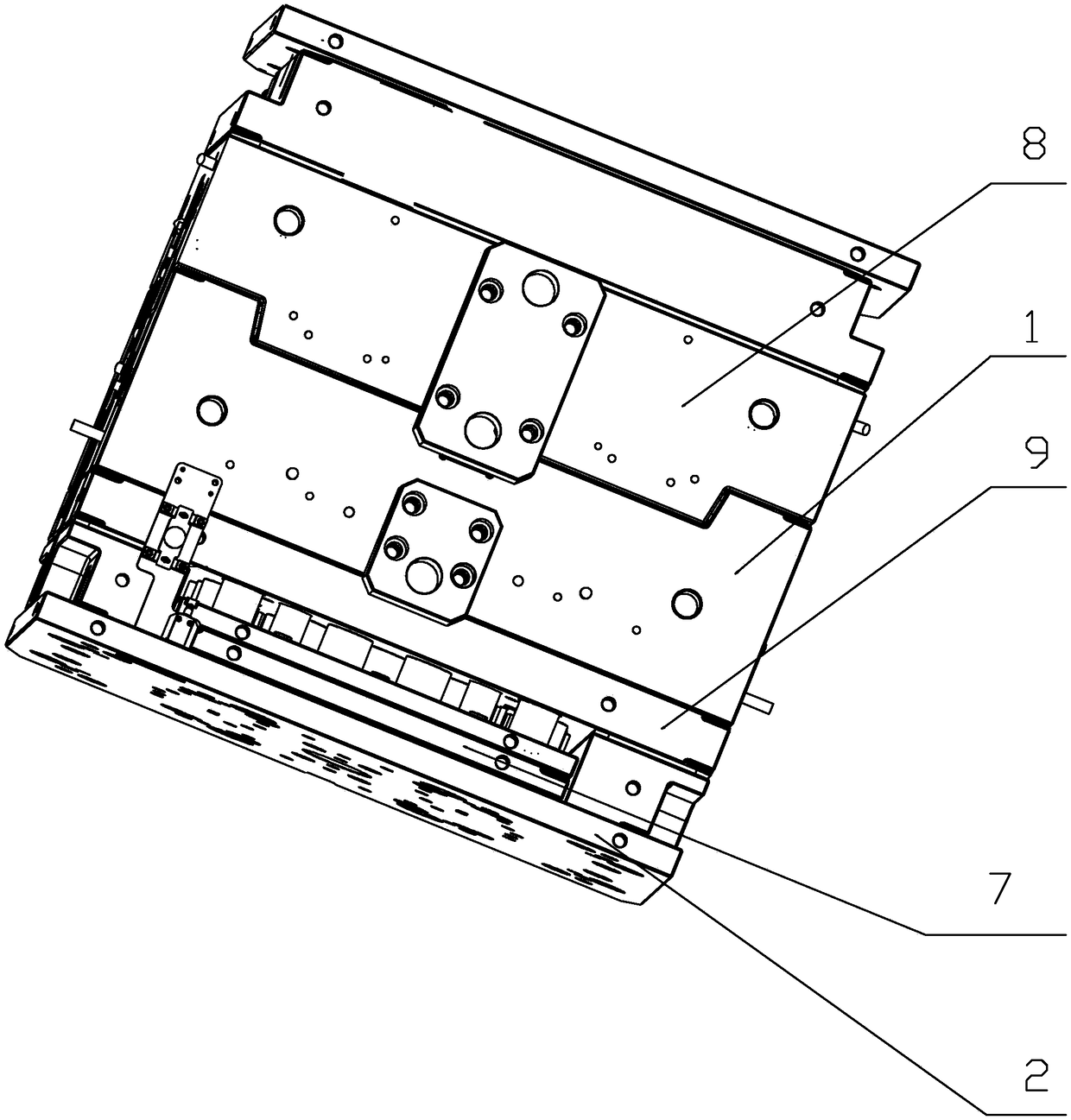

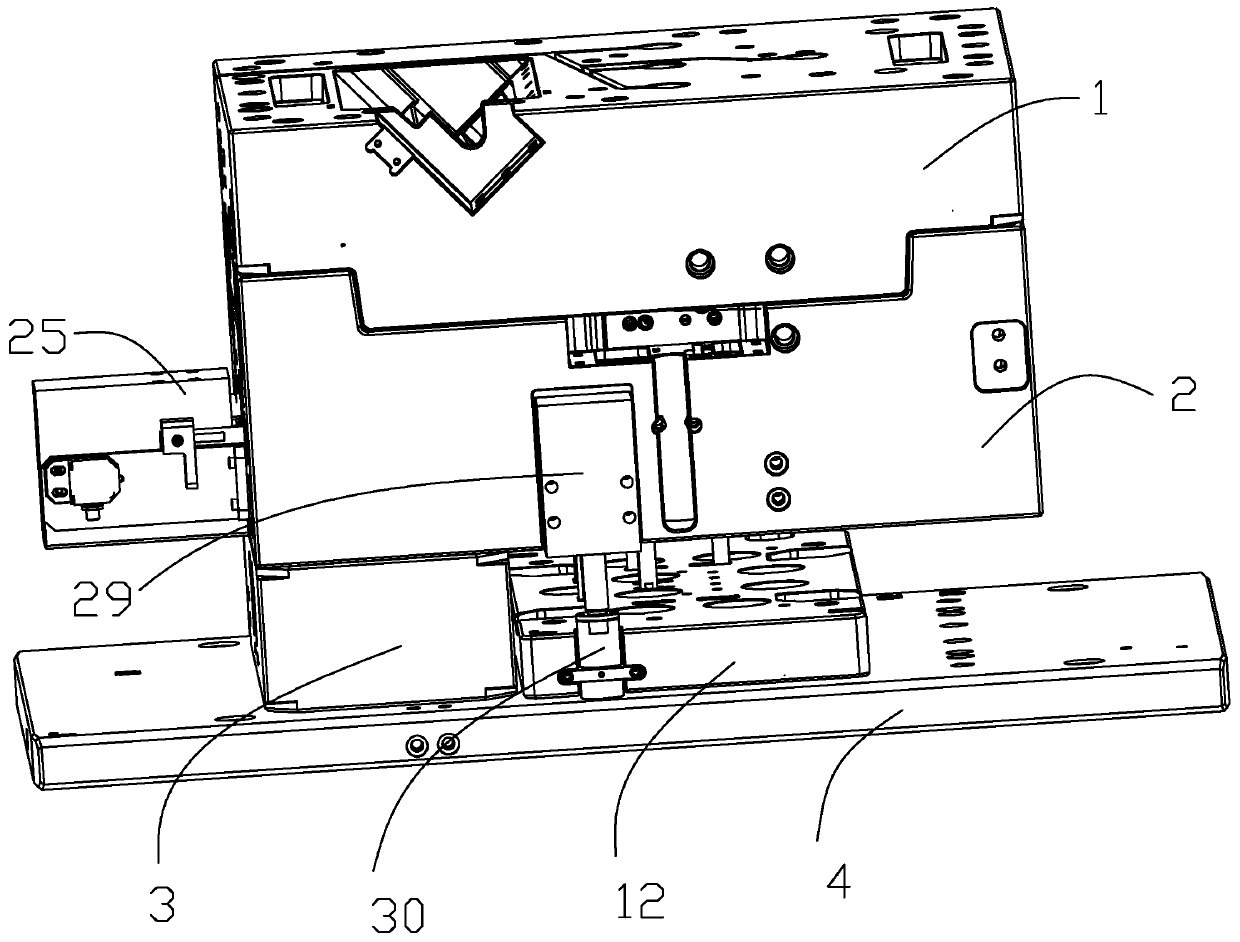

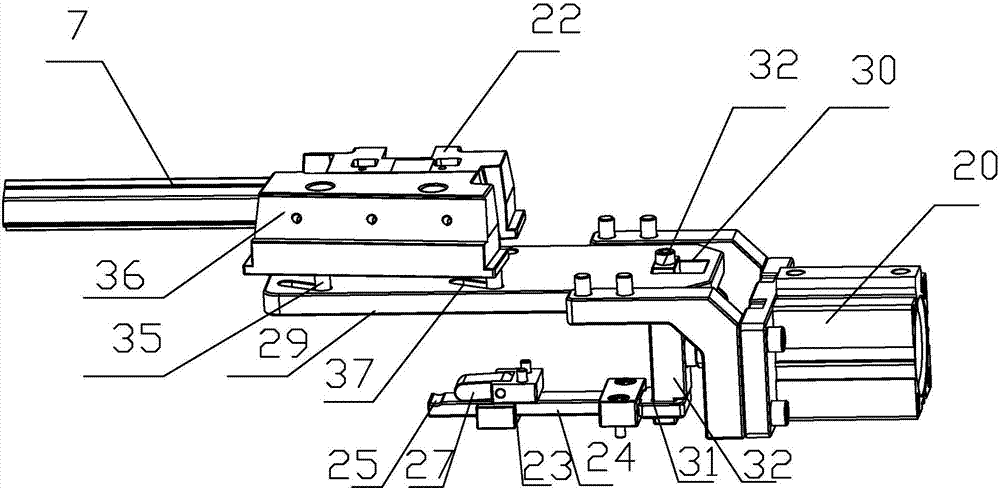

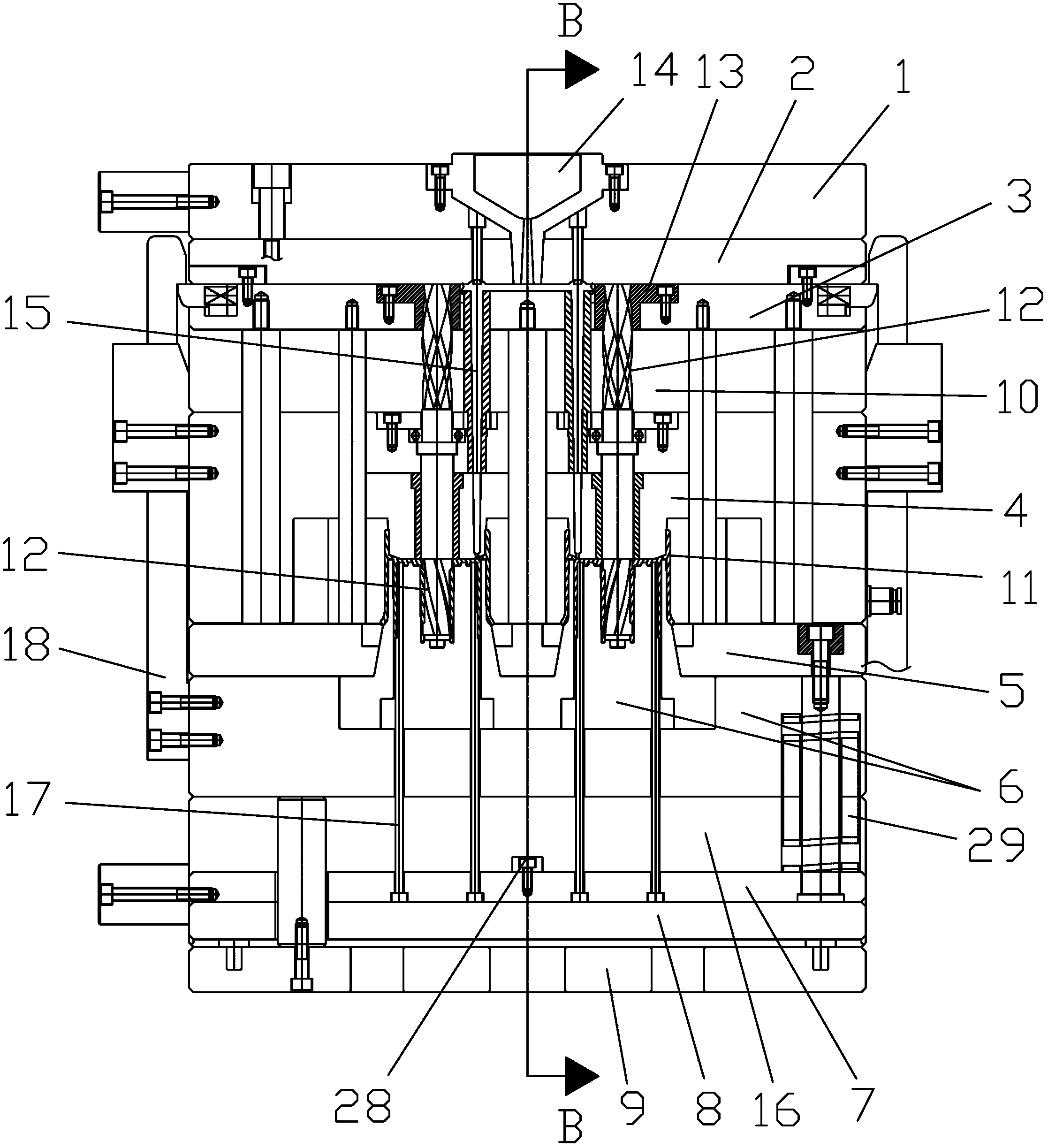

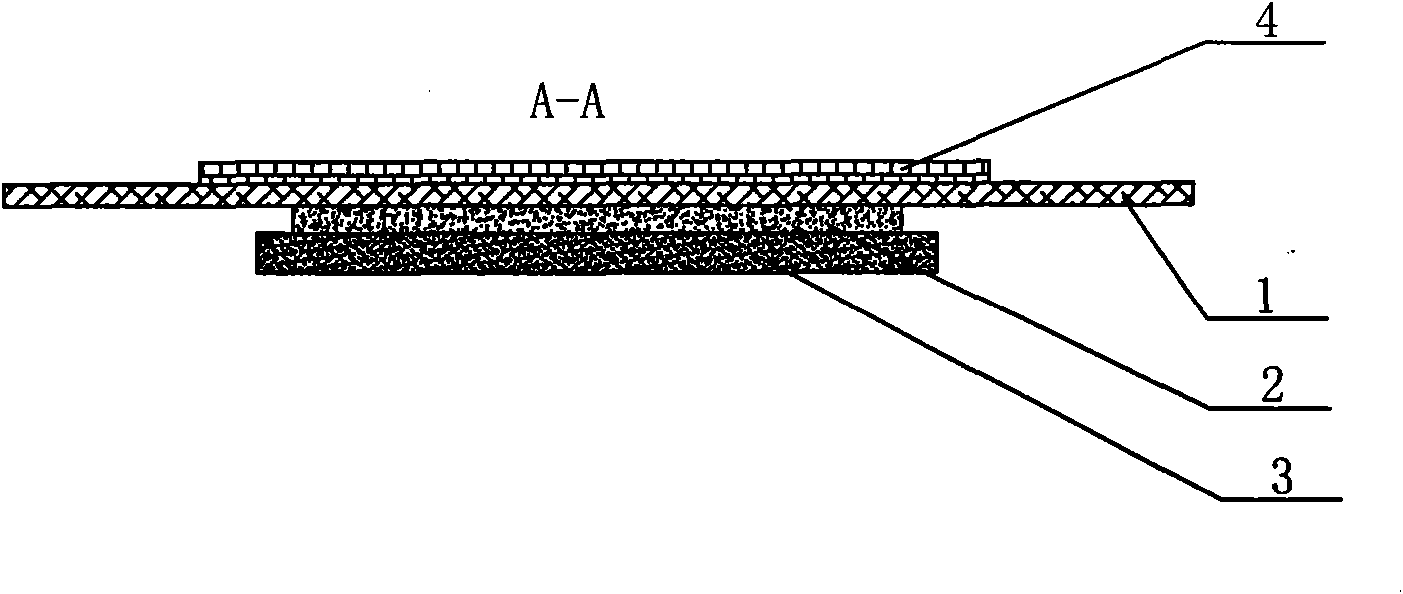

Injection mold for embedding of automobile sealing strip insert

PendingCN107160630AImprove securityNo personal injuryDomestic articlesComposite materialSafety coefficient

The invention discloses an injection mold for embedding of an automobile sealing strip insert. The injection mold comprises an upper mold plate (1), a lower mold plate (2), an ejection plate (3), a base plate (4) and a sealing strip (7). The ejection plate (3) is located on the base plate (4). The lower mold plate (2) is located between the upper mold plate (1) and the ejection plate (3). An upper mold plate (5) is arranged below the upper mold plate (1). A lower mold plate (6) is arranged above the lower mold plate (2). The lower mold plate (2) is provided with an oblique slide block (8) used for forming the rubber coating part of the front end face of the sealing strip (7), a slide block (22) used for forming the rubber coating part of the inner side face of the sealing strip (7) and a mobile slide block (36) positioning the outer side face of the front end of the sealing strip (7). The upper mold plate (1) is provided with an oblique guide column (33) slidably matched with the oblique slide block (8). By adoption of the injection mold for embedding of the automobile sealing strip insert, personal injury cannot be caused, so that the safety coefficient is high.

Owner:NINGHAI HESHI PLASTIC CO LTD

Labor-saving lifting mechanism

InactiveCN108497695AReasonable structureEasy to useOffice tablesVariable height tablesEngineeringSliding contact

The invention discloses a labor-saving lifting mechanism. A left vertical arm and a right vertical arm of an internal n-shaped rack are inserted in a left vertical arm and a right vertical arm of an external n-shaped rack respectively, and pulley mechanisms in sliding contact with the inner walls of the left and right vertical arms of the external n-shaped rack are arranged on the left and right vertical arms of the internal n-shaped rack respectively; a traction belt rolling wheel is arranged in a cross arm of the external n-shaped rack and connected with one end of a left traction belt and one end of a right traction belt, and the other end of the left traction belt and the other end of the right traction belt are fixedly connected with the lower portions of the left and right vertical arms through respective wheel supporting mechanisms respectively; through forward rotation or reverse rotation of the traction belt rolling wheel, the left and right traction belts are rolled or released at the same time, and accordingly the left and right vertical arms of the n-shaped racks are driven to ascend or descend along the external n-shaped rack at the same time. The labor-saving liftingmechanism is reasonable in structure, convenient to use, good in labor-saving performance and particularly suitable for lifting mechanisms of vertical office computer tables; through pulley mechanisms, certain gaps between the vertical arms of the internal n-shaped rack and the vertical arms of the external n-shaped rack are kept, and the vertical arms cannot be collided and damaged.

Owner:李永彬

Aerobics physical training device and method

InactiveCN111530026AWon't strainAdjust stretch limitMovement coordination devicesCardiovascular exercising devicesMuscle strainsPhysical medicine and rehabilitation

The invention discloses an aerobics physical training device and method. The device comprises a long-strip-shaped first chute formed in the upper surface of a chassis in the horizontal direction. Twofirst sliding blocks and two second sliding blocks are slidably connected to the first chute, the two second sliding blocks are both located between the two first sliding blocks, first fixing mechanisms used for fixing the first sliding blocks to the set positions of the first chute are arranged on the first sliding blocks, and second fixing mechanisms used for fixing the feet of a trainee are arranged on the second sliding blocks. The first fixing mechanism comprises a plurality of electromagnets evenly fixed to the bottom of the first chute and iron first rolling wheels located on the electromagnets, and the first rolling wheels are arranged at the bottom of the first sliding block. According to the invention, when a trainee carries out training, setting is carried out according to the stretching limit of the trainee, so that the trainee can carry out training step by step during training, and muscle strain caused by excessive stretching during training of the trainee is avoided.

Owner:SHAANXI INST OF INT TRADE & COMMERCE

An automatic shrimp peeling machine

Owner:南通宝泰机械科技有限公司

High precision machining method for double-head cross hole in bolt shaft

InactiveCN111390216AImprove versatilitySave tooling costsSoldering ironDrill jigsThermal dilatationEngineering

The invention discloses a high precision machining method for a double-head cross hole in a bolt shaft The method comprises the following steps of (1) drill jig manufacturing: designing and manufacturing a pair of overturn cross hole drill jig with 90-degree overturn surfaces; (2) electric soldering iron reforming: reforming the heads of a pair of electric soldering iron to a positioning shaft; (3) drill jig positioning and clamping; (4) first time drilling: drilling one hole in the double-head cross hole in the bolt shaft by a drill bit separately; (5) electric soldering iron gapless positioning: separating the positioning shafts of the pair of electric soldering iron into drilled holes, separately, and connecting a power supply for thermal expansion gapless positioning; (6) drill jig overturning and clamping; and (7) second time drilling: drilling the other hole in the double-head cross hole by the drill bit, separately; and after drilling, unloading the electric soldering iron and the cross hole drill jig after the electric soldering iron is cooled. The method improves the machining precision of the double-head cross hole and is low in implementation cost.

Owner:CHENGXI SHIPYARD

Mold for injection molding of parts with internal threads

The invention discloses a mold for injection molding of parts with internal threads. The mold sequentially comprises a panel, a water gap plate, a front mold needle plate, a fixed mold plate, a push plate, a movable mold plate, a face needle plate, a bottom needle plate and a bottom plate from top to bottom, wherein a space I for up-and-down movement of the front mold needle plate is left between the water gap plate and the fixed mold plate; the upper part of the movable mold plate penetrates through the push plate, and is fitted with the fixed mold plate to form a closed cavity; a threaded core bar is arranged in the closed cavity; the upper part of the threaded core bar penetrates through the fixed mold plate, and is connected with the front mold needle plate; a diagonal pitch is arranged at the upper part of the threaded core bar; the front mold needle plate is provided with an inclined toothed sleeve fitted with the diagonal pitch; a pouring port is formed in the panel; the bottom of the pouring port is communicated into the closed cavity through a sprue sleeve. The mold adopts the front mold needle plate structure to drive the threaded core bar for demolding, has a simple and skillful structure, and greatly improves the productivity.

Owner:FOSHAN NANHAI HUADA MOLDS & PLASTICS

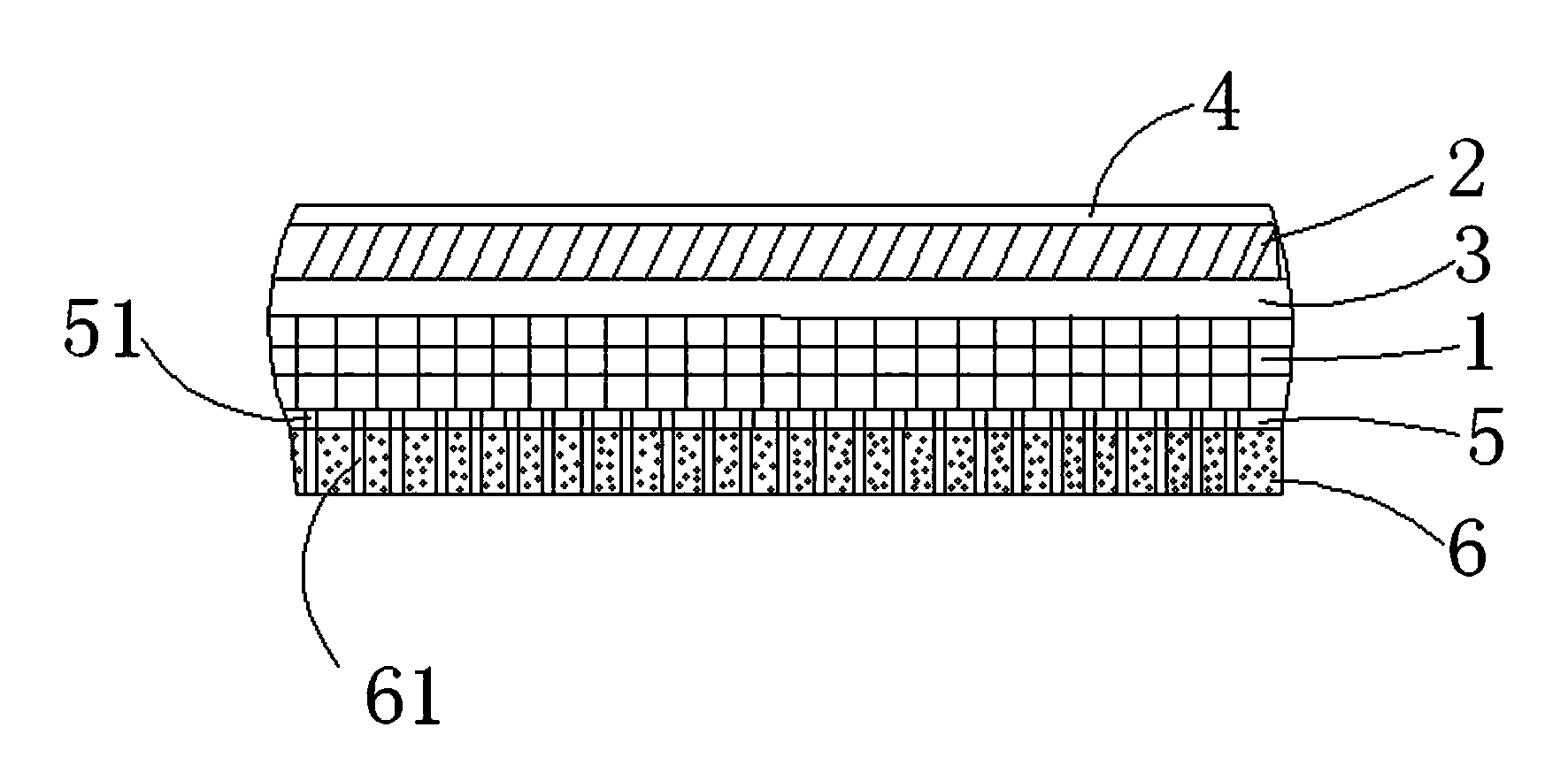

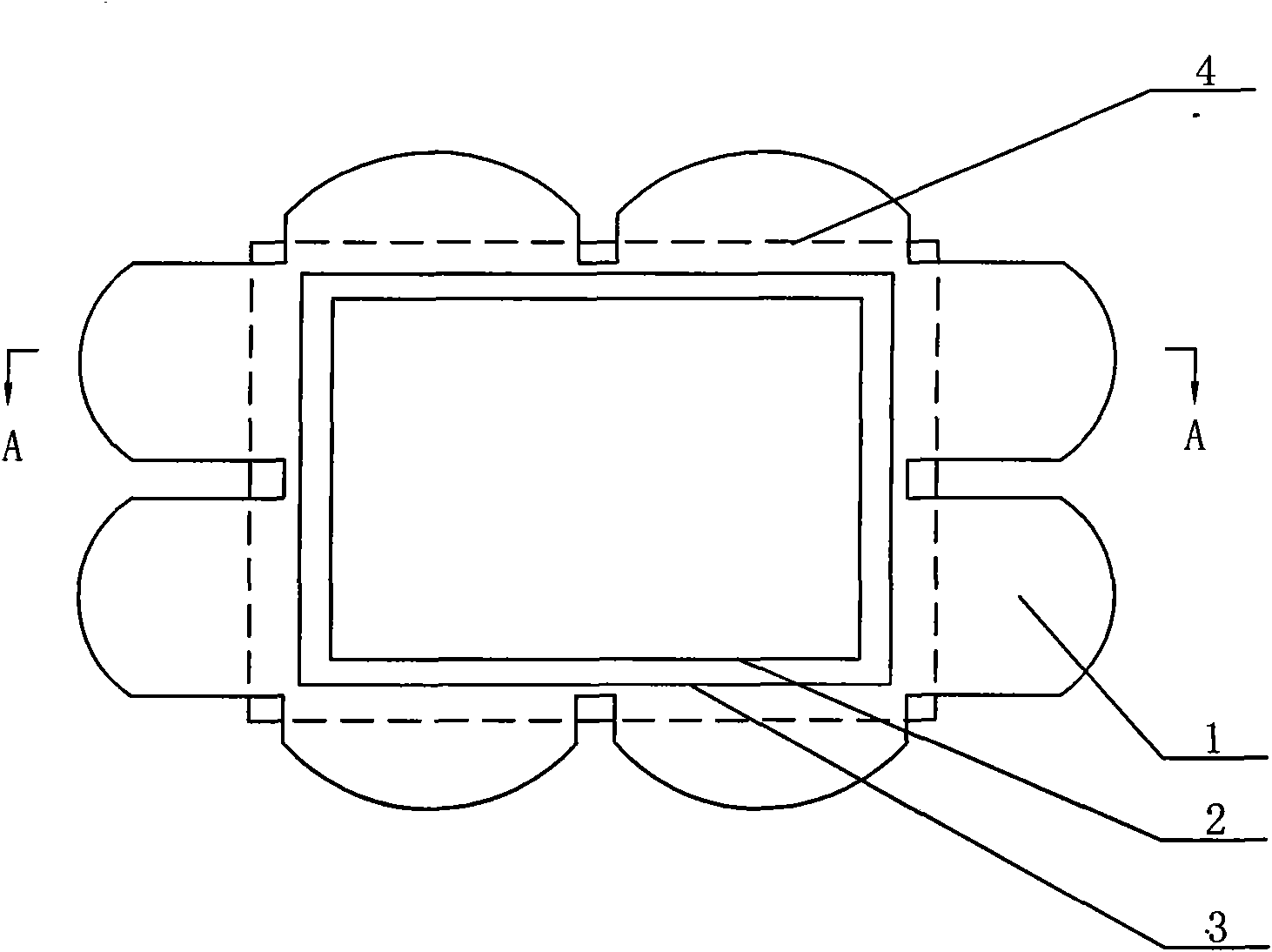

An externally-applied patch

InactiveCN101675920AFast absorptionPromote absorptionSkeletal disorderSheet deliveryThermostatPlastic film

An externally-applied patch relates to an externally-applied patch, which is composed of nonwoven (1), automatic thermostat heater (2), hydrogel transdermal ointment (3) and plastic film (4). The nonwoven (1) and the automatic thermostat heater are tightly connected, the hydrogel transdermal ointment is coated on the back line of the nonwoven, the automatic thermostat heater is arranged in the middle, and the surface of the hydrogel transdermal ointment (3) is covered with the plastic film. The present invention makes the hydrogel transdermal ointment enable to play medical action for a long time at a certain temperature by the continuous heating of the automatic thermostat heater, thereby reducing the effective time of the medicine, and improving the effect of medicine absorption; and thepresent invention has the advantages of convenient and comfortable use, large drug loading, strong penetrability, easy absorption, no residue, and no contaminated clothing.

Owner:倪海军

Landing leg hydraulic cylinder piston and manufacturing process thereof

InactiveCN101644329AExtended service lifeHigh strengthPlungersTrunk pistonsHydraulic cylinderEngineering

The invention relates to a landing leg hydraulic cylinder piston and a manufacturing process thereof. The landing leg hydraulic cylinder piston comprises a piston body and a piston rod, wherein the surface of the middle part of the piston body is provided with an annular gasket groove, a rubber gasket playing the role of sealing is arranged in the annular gasket groove, welding technology annulargrooves are processed on the surfaces of the piston body on both sides of the annular gasket groove, and a copper soluble solder plating is welded in each of the welding technology annular grooves andis projected out from the surface of the excircle of the piston body by 0.8mm to 1.2mm; and the piston body is fixedly connected with the piston rod by internal screw threads. The landing leg hydraulic cylinder piston has long service life, and can not damage the inner wall of a cylinder barrel of a hydraulic cylinder by pulling even under the circumstance of higher unbalance loading.

Owner:李新桥

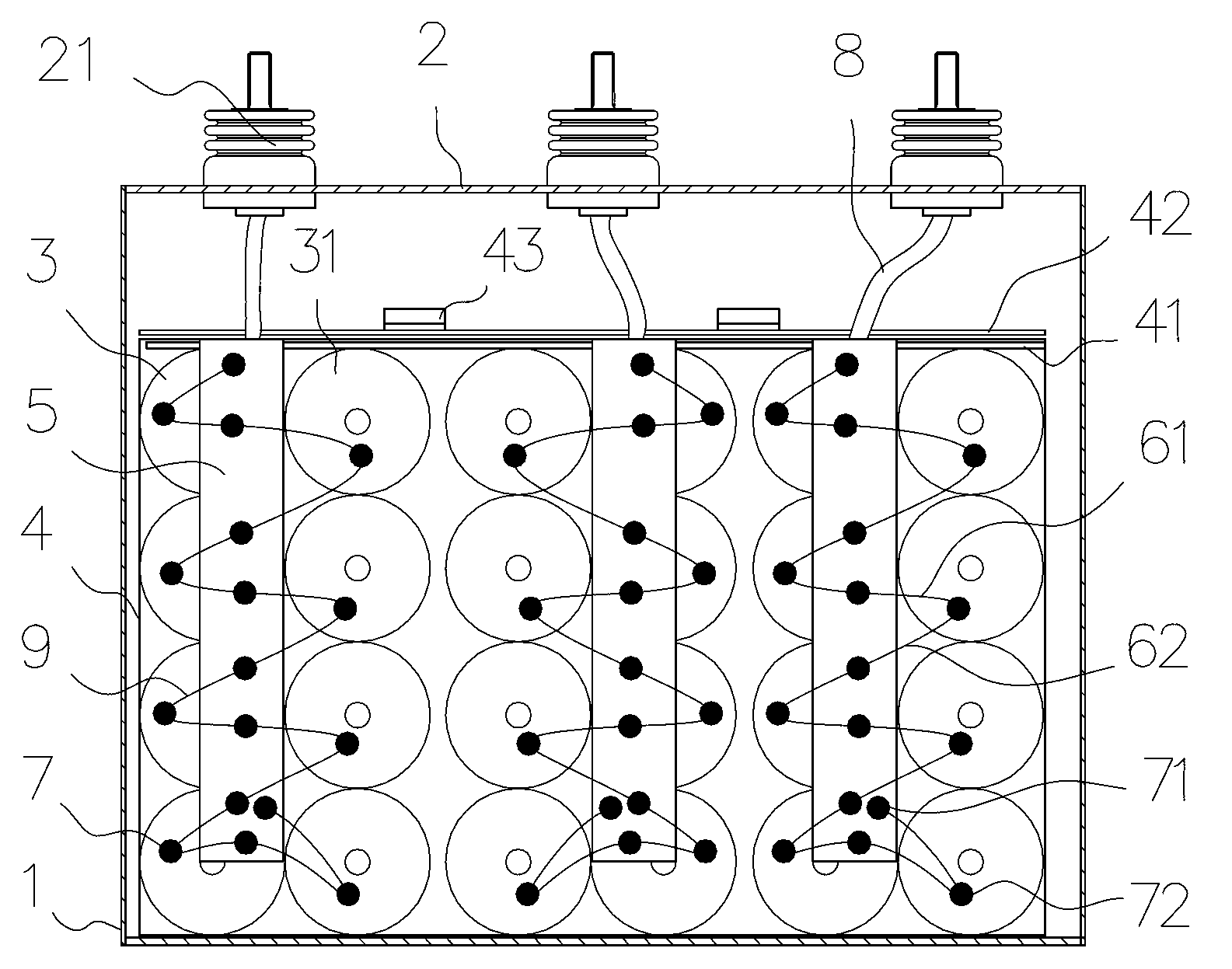

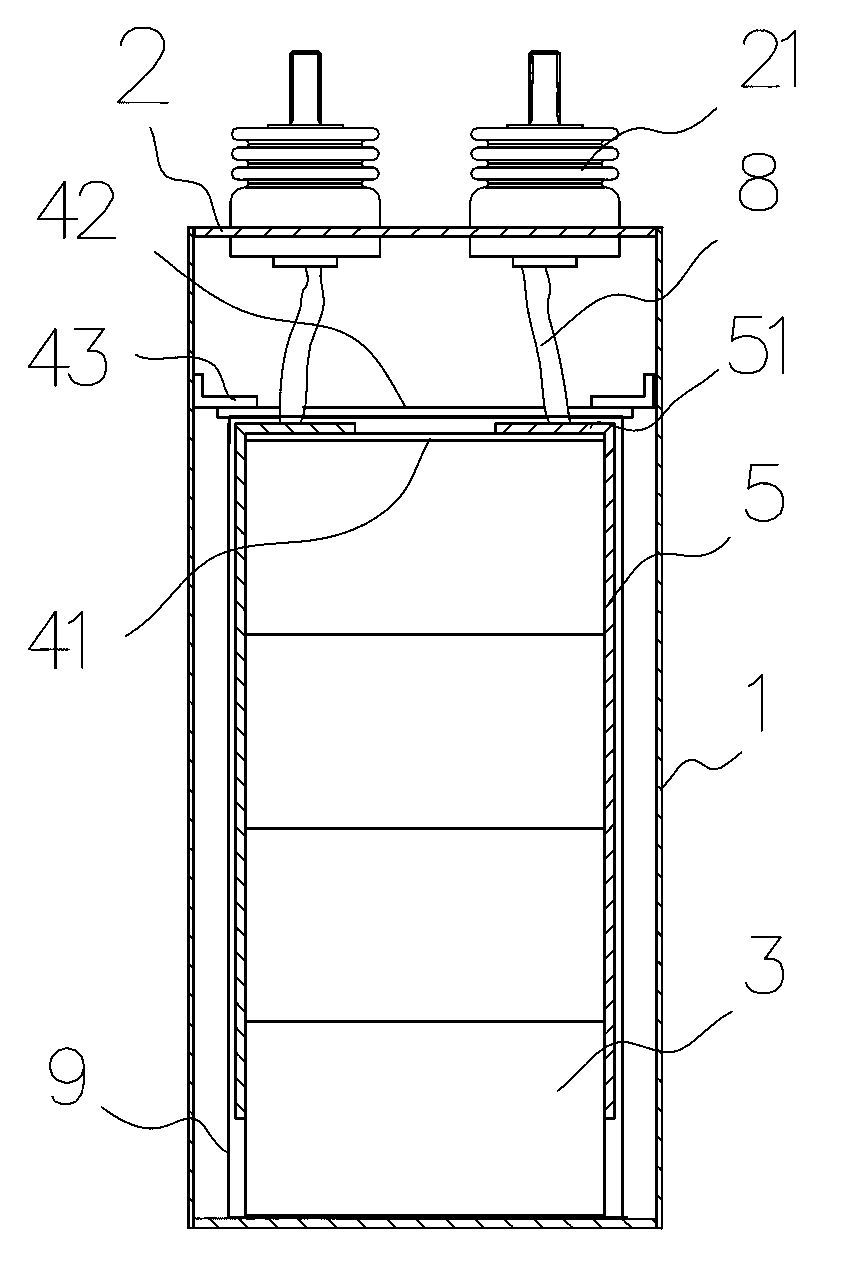

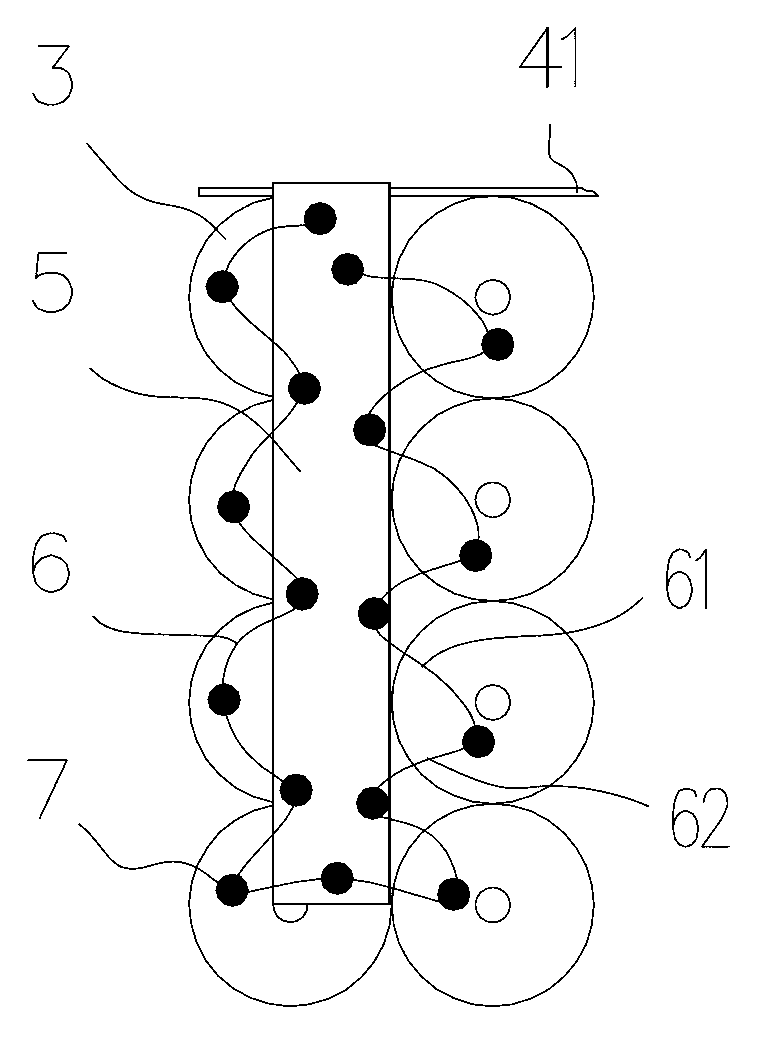

High-power electric power electronic capacitor with firm welding spots

The invention relates to a high-power electric power electronic capacitor with firm welding spots. The high-power electric power electronic capacitor with firm welding spots comprises a cover plate assembly, a casing and core groups fixed in the casing. Each group of the core groups are composed of a row of capacitor cores or two rows of capacitor cores arranged side by side, a lead-out copper strip is respectively arranged on metal sprayed surfaces of two sides of each core group, a metal sprayed surface of each capacitor core on each core group is electrically connected with the lead-out copper strip at the corresponding end through a wire, and length of the wire between the two electrically connected welding spots is longer than straight-line distance between the two welding spots. The lead-out copper strips are in flexible connection with the metal sprayed surfaces of the core groups through wires, displacement of the core groups cannot strain the welding spots on the core groups and the lead-out copper strips, and loosening or dropping of the welding spots can be effectively avoided.

Owner:ANHUI TONGFENG ELECTRONICS

Integral non-hooking sparking plug for electric trolley bus

InactiveCN104325889AIncrease freedomEasy to hang up the linePower current collectorsElectrical conductorPower cable

The invention discloses an automatic hanging sparking plug for use in running of an electric trolley bus. The automatic hanging sparking plug is characterized in that an integral enclosed non-hooking design is adopted; two conducting transverse rods are taken as sparking plug conductors, and are connected through a convex insulating cap; the outer ends of the conducting transverse rods are connected with a wiring rod through insulating brackets, thereby forming an enclosed triangle; a conducting transverse rod groove of a certain width is formed between the insulating brackets extending upwards from both sides of the sparking plug and the insulating cap projecting in the middle. Wire hanging can be performed conveniently by correcting the electric trolley bus below a power cable, lifting the wiring rod and putting the insulating cap in the middle of the sparking plug between two power cables in a sleeving manner; on the contrary, the wires can be separated easily by descending the wiring rod. The integral enclosed non-hooking design is adopted for the sparking plug, so that an electric wire is prevented from being hooked even hanging fails. The automatic hanging sparking plug has the beneficial effects that once the integral automatic hanging sparking plug is arranged on the electric trolley bus, hanging and separation running can be performed conveniently without worrying about the problem of falling of the electric wire or damage to the electric wire by hooking. Therefore, the degree of freedom of running of the electric trolley bus is greatly increased, the application range is expanded, an open type electric road net is built, and various passenger cars, trucks and saloon cars can be modified into electric vehicles or hybrid power vehicles.

Owner:朱大碌

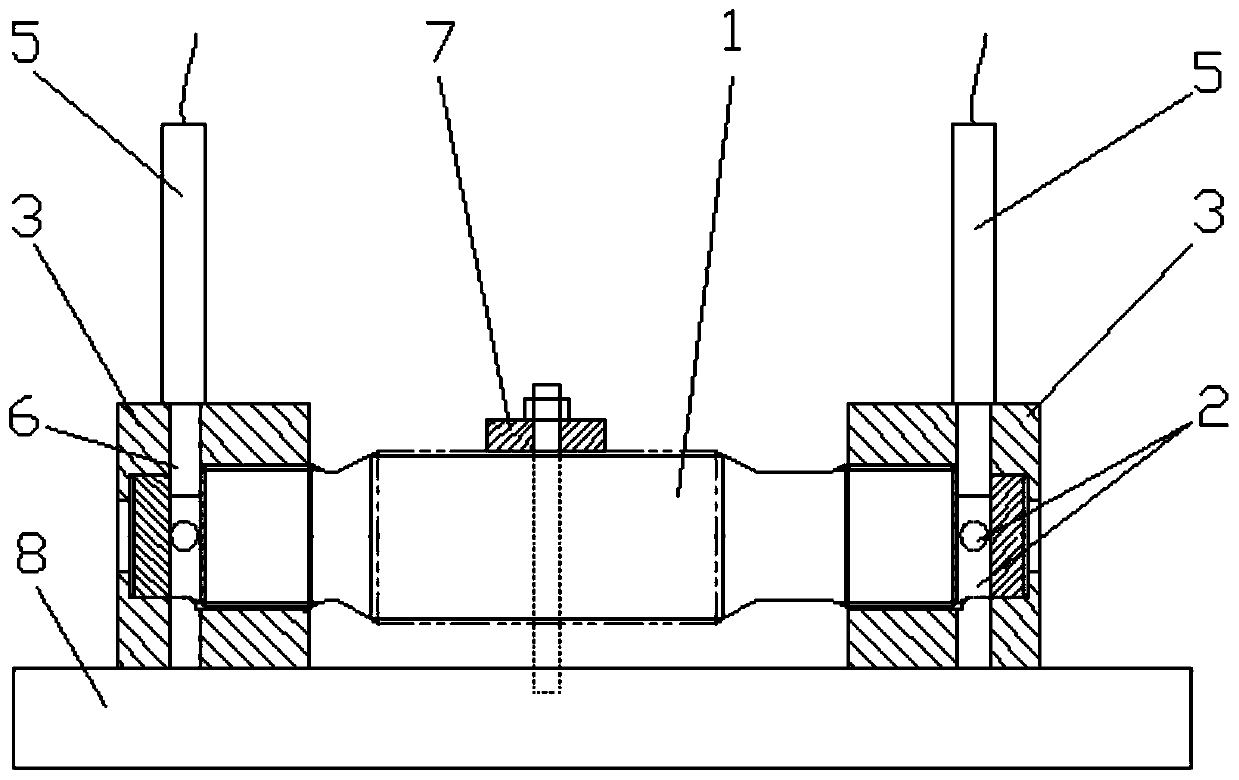

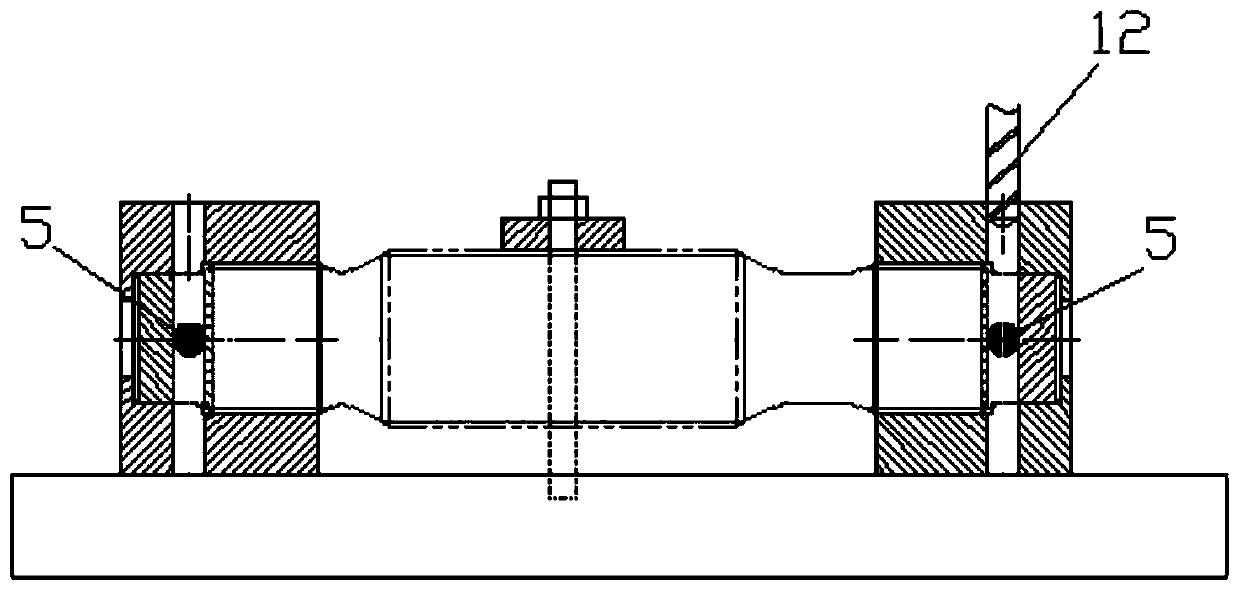

Cold extrusion mold for ball stud

ActiveCN106424192ASmall machining allowanceSave raw materialsExtrusion diesNeck partsUltimate tensile strength

The invention discloses a cold extrusion mold for a ball stud. The cold extrusion mold comprises an upper mold (1), a lower mold (2), an upper mold sleeve (3), a lower mold sleeve (4) and a product (6), wherein the upper mold (1) is fixed in the upper mold sleeve (3); the lower mold (2) is fixed in the lower mold sleeve (4); a lower mold base plate (5) is arranged in the lower mold sleeve (4); the lower mold base plate (5) is located at the bottom of the lower mold (2); the product (6) comprises a bulb (7), a neck part (8) and a rod part (9); a first bulge (10) and a second bulge (11) are arranged on the rod part (9); the first bulge (10) is located between the neck part (8) and the second bulge (11). The cold extrusion mold for the ball stud, provided by the invention, has the advantages of less machining allowance of the ball stud, higher strength, lower cost and convenience in realization.

Owner:宁海县鑫鸿汽车部件有限公司

Anti-thunder anti-shear hydraulic cylinder device

ActiveCN103697015ADoes not produce raised spotsExtend your lifeEngine sealsFluid-pressure actuatorsHydraulic cylinderNitrile rubber

The invention relates to an anti-thunder anti-shear hydraulic cylinder device and belongs to the technical field of application for sealing a wind driven generator brake. The anti-thunder anti-shear hydraulic cylinder device comprises a cylinder body, a piston and a seal ring; the seal ring is arranged between the inner wall of the cylinder body and the outer wall of the piston; the seal ring is made of nitrile rubber and fluorine rubber; a pressure bearing ring protruded out of the surface of the inner wall of the cylinder body is arranged between the inner wall of the cylinder body and the outer wall of the piston; the pressure bearing ring is made of a plastic composite steel plate; the front end of the piston is connected with a vertical screw rod and a horizontal screw rod. Two ends of the horizontal screw rod are connected with a universal iron ball respectively. The universal iron balls tightly cling to the inner wall of the cylinder body. The lateral force generated in the work process of the piston is borne by additionally arranging a guide ring, capable of bearing larger load, in the sealing structure of a piston cavity, so the bias pressure phenomenon of the hydraulic cylinder is greatly reduced, the work condition of the hydraulic cylinder is improved to achieve the aim of prolonging the service life of the hydraulic cylinder, and the maintenance cost of a wind driven generator is reduced.

Owner:贵州新安航空机械有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com