High-power electric power electronic capacitor with firm welding spots

A technology of power electronics and capacitors, which is applied in the field of high-power power electronic capacitors, can solve problems such as pulling wires, copper strip deformation, loosening or falling off of solder joints, etc., to improve the pass rate, prevent loosening or falling off, and ensure that it is not damaged Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The following embodiment is used as an example for the power electronic capacitor on the STATCOM / SVG dynamic reactive power compensation and harmonic control device.

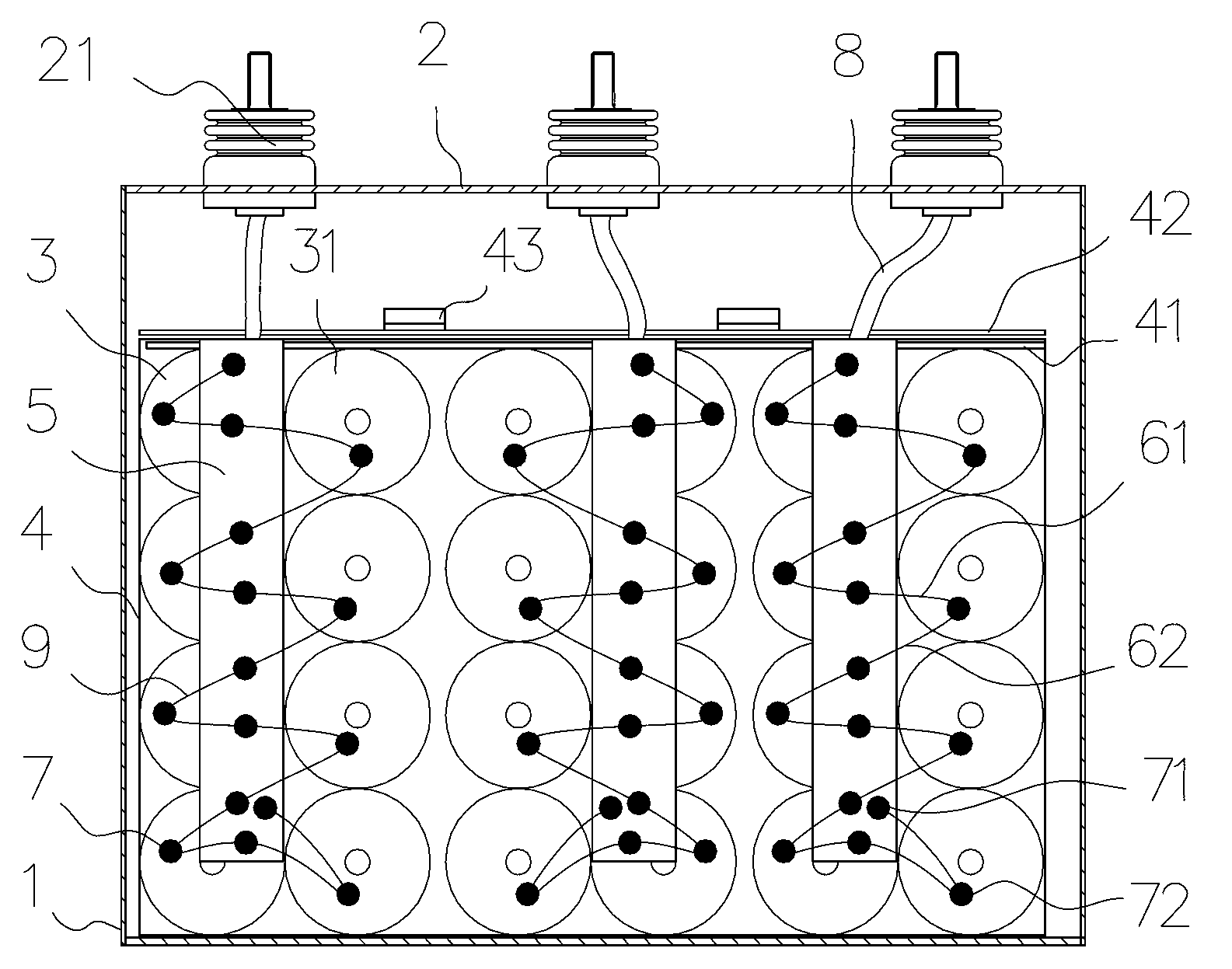

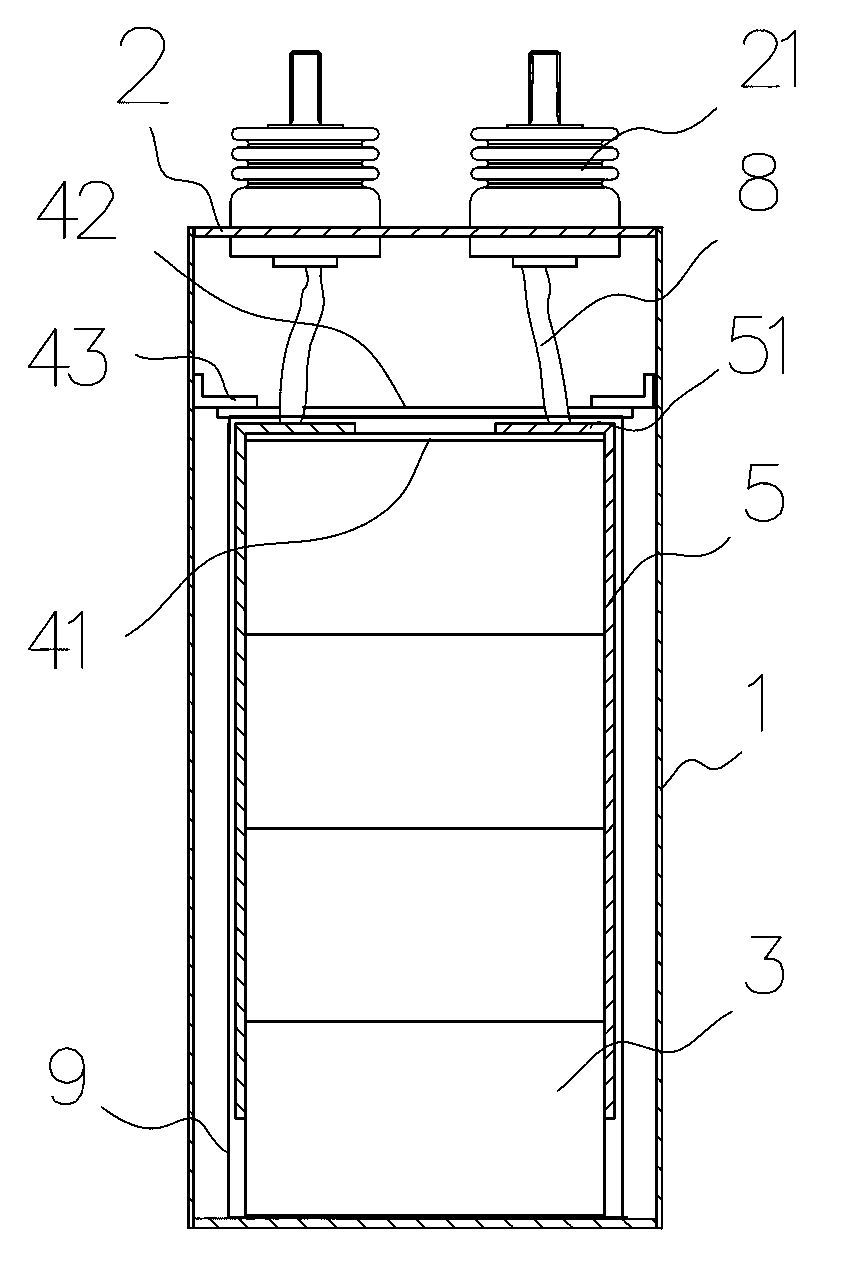

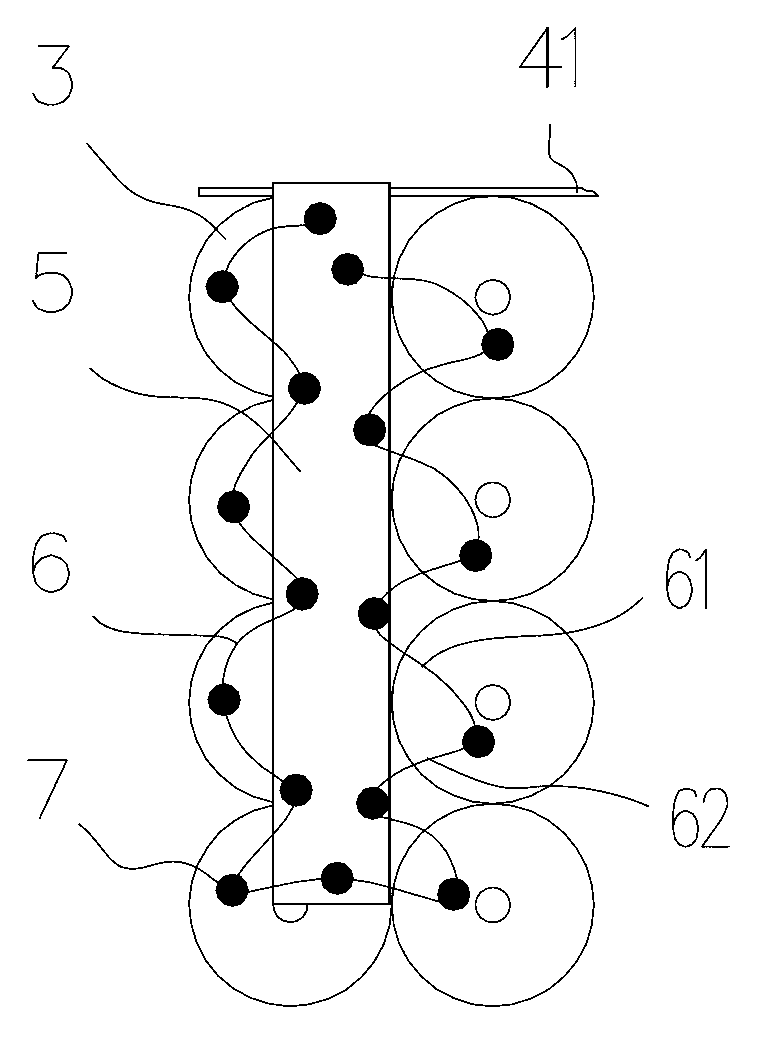

[0017] like figure 1 , figure 2 As shown, the present invention includes a cover plate assembly 2, a shell 1, and a core group 3; there are three groups of core groups 3, and each core group 3 is arranged side by side by two columns of capacitor cores, and each column of capacitor cores is composed of a plurality of capacitor cores 31 It is formed by stacking up and down; each core group 3 has a lead-out copper strip 5 on the gold-sprayed surface on both sides. Electrode 51; the gold-sprayed surface of each capacitor core 31 on each core group 3 is electrically connected with the lead-out copper strip 5 at the corresponding end respectively through a metal copper wire 6, and the wire 6 is electrically connected at two electrical connection solder joints 71, 72 The length between them is greater than th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com