Integral non-hooking sparking plug for electric trolley bus

A technology of trolleybus and electric nozzle, which is applied in the direction of electric vehicles, collectors, vehicle parts, etc., can solve the problems of automatic hanging trolleybus, etc., and achieve the effect of expanding the use and increasing the degree of freedom

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

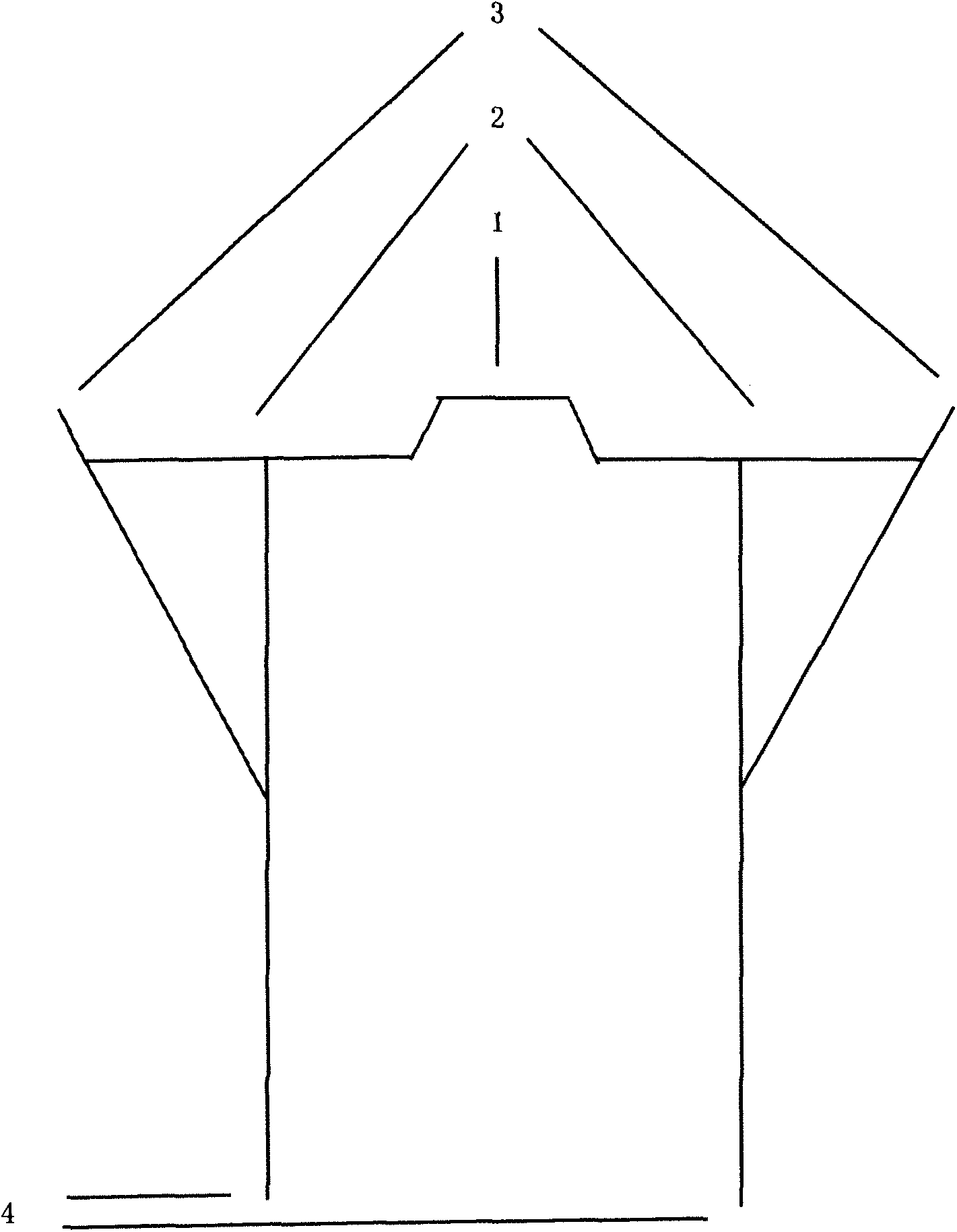

[0008] In the attached drawing, when the pole (4) rises up, insert the insulating cap (1) between the two power lines, and the conductive cross bar (2) forming a groove can be an insulating bracket protruding upward on both sides (3) with the aid of hooking up with the power line. Otherwise, the connecting rod (4) descends, and the conductive cross bar (2) breaks away from the power line.

[0009] Due to the overall closed and integrated design, the conductive cross bar (2) is connected to the electric pole (4), and the insulating brackets (3) on both sides form a closed triangle with the conductive cross bar (2) and the electric pole (4). Hooking, hooking mistakes will not pull the wire.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com