Patents

Literature

57results about How to "Easy offline" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

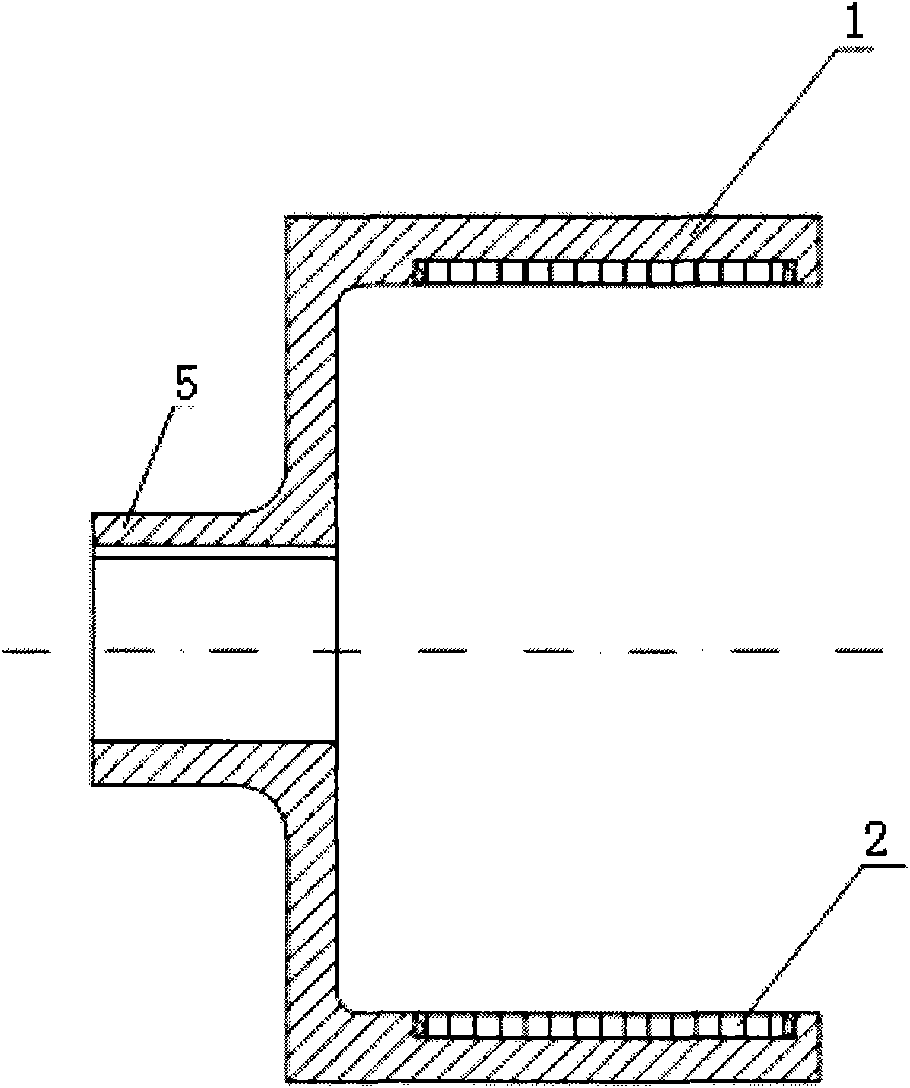

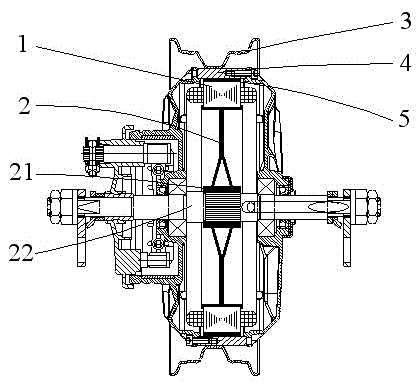

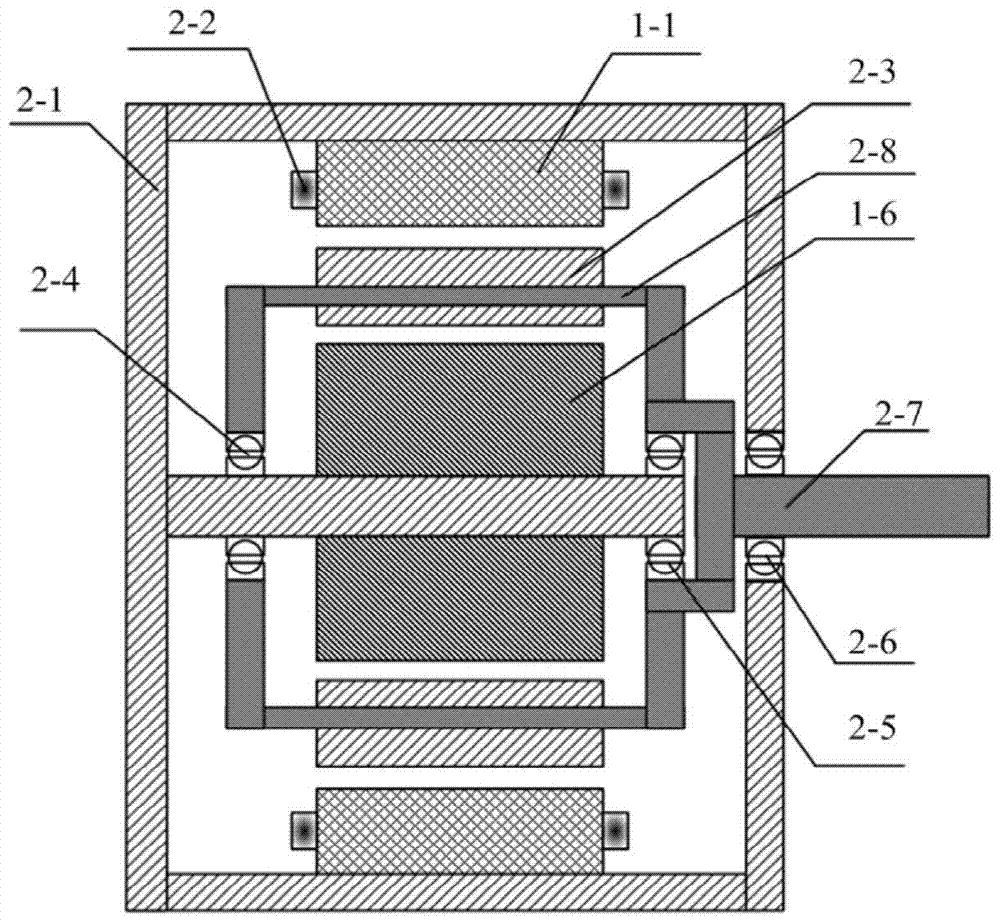

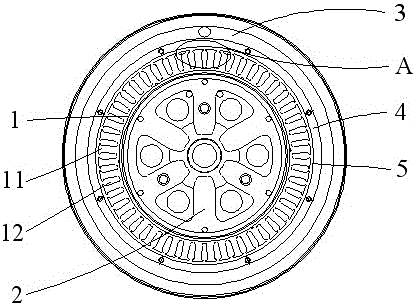

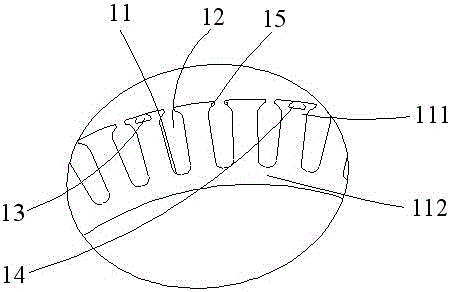

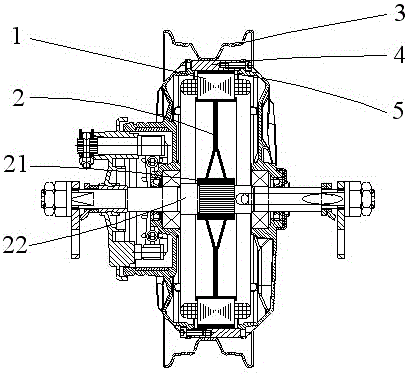

High-capacity non-salient pole nest plate type synchronous generator

ActiveCN101227129AEasy offlineGuaranteed accuracySynchronous generatorsMagnetic circuit rotating partsEngineeringDynamo

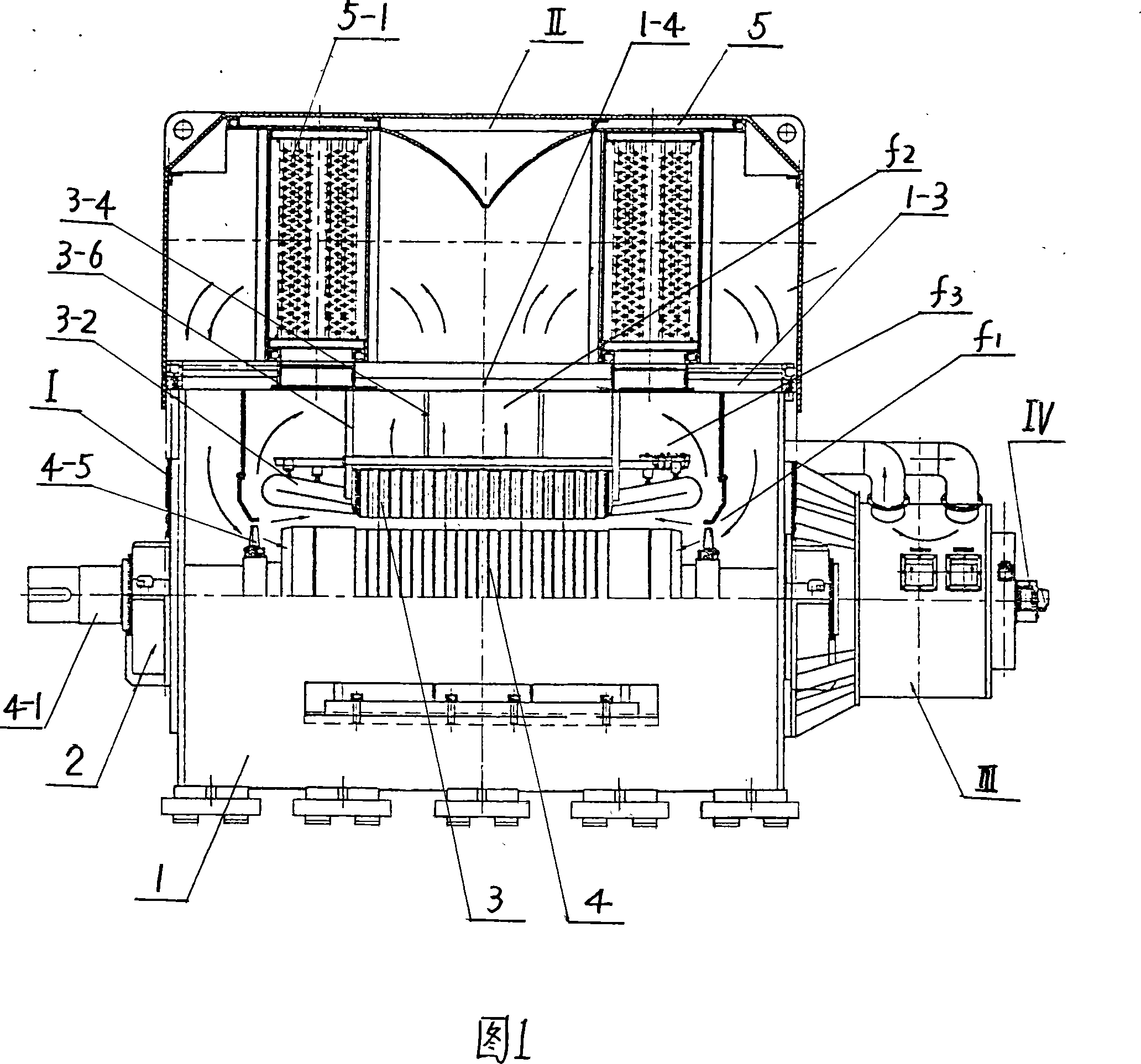

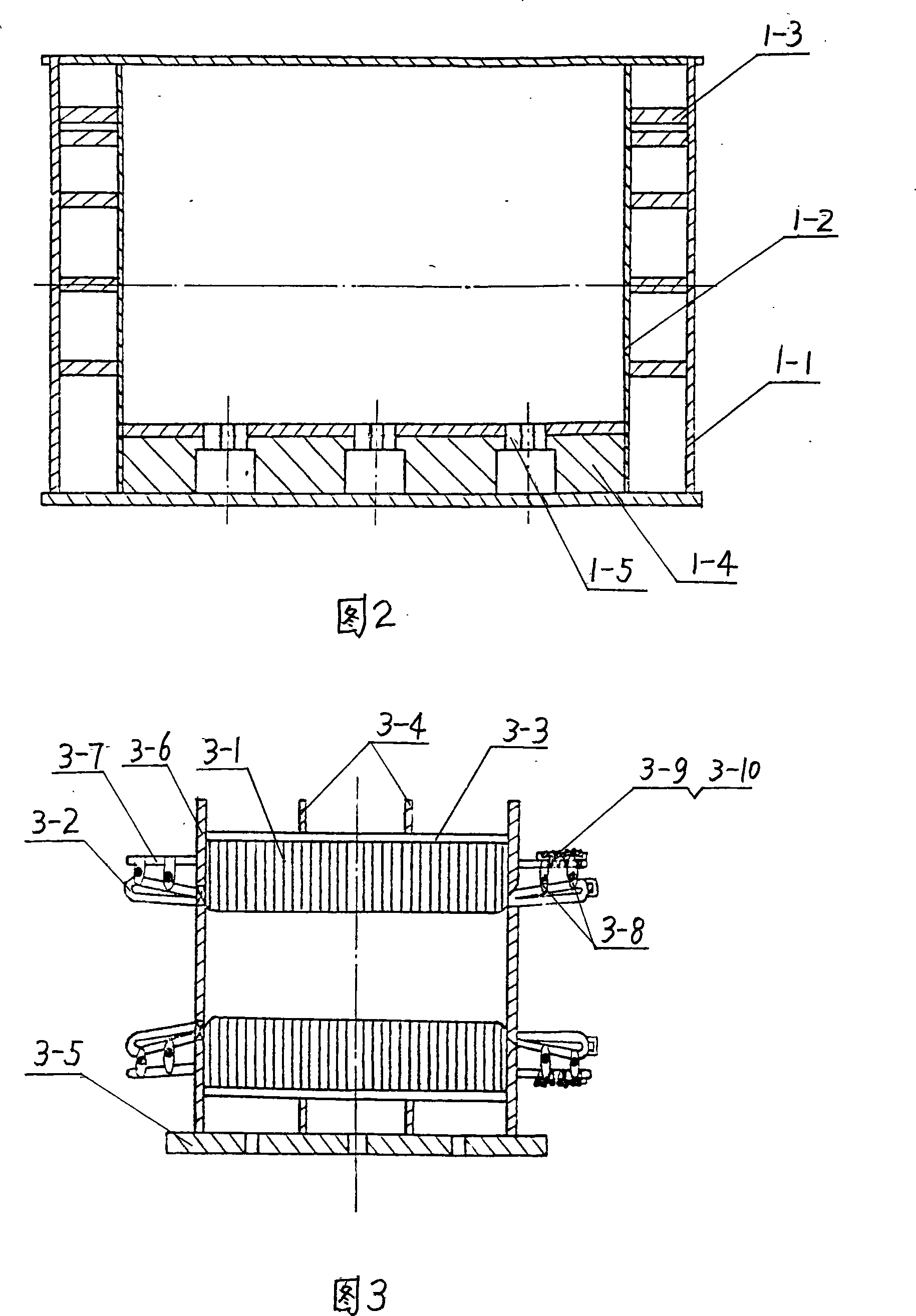

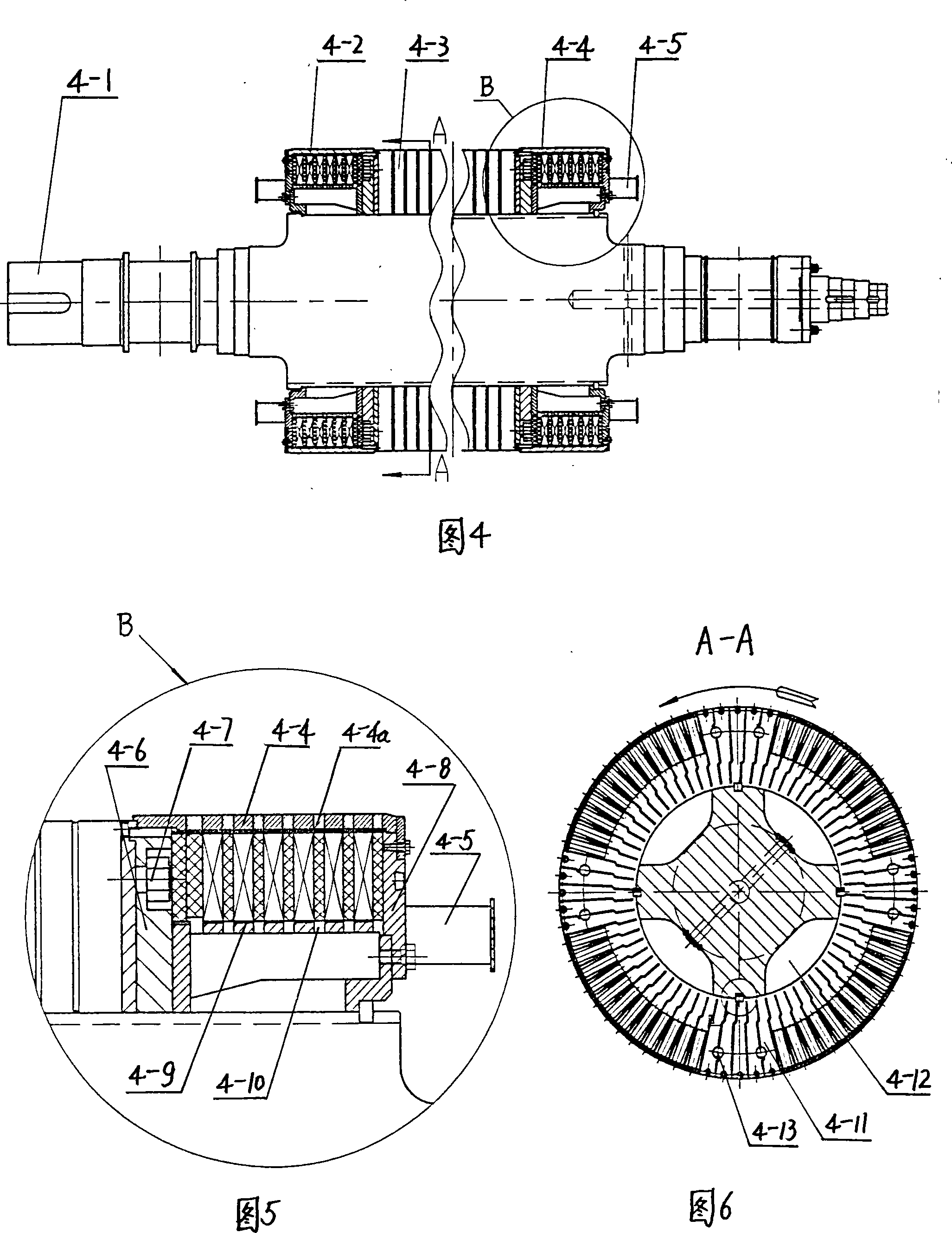

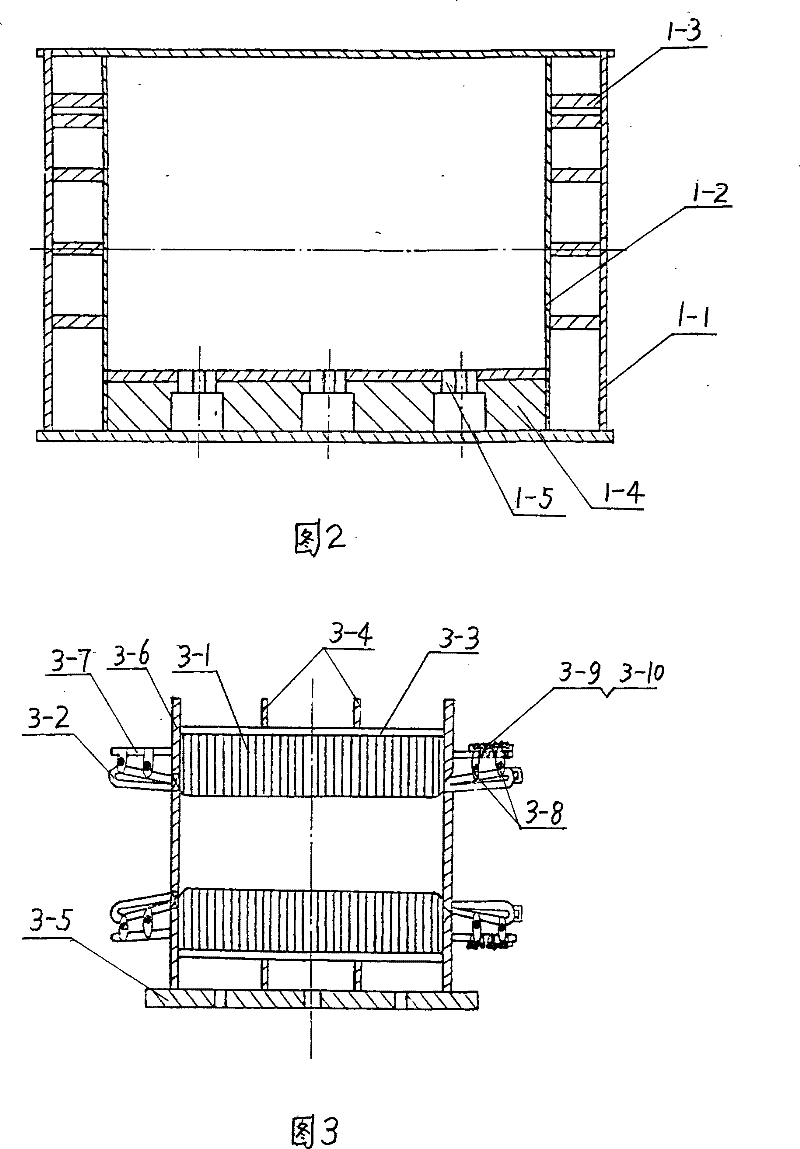

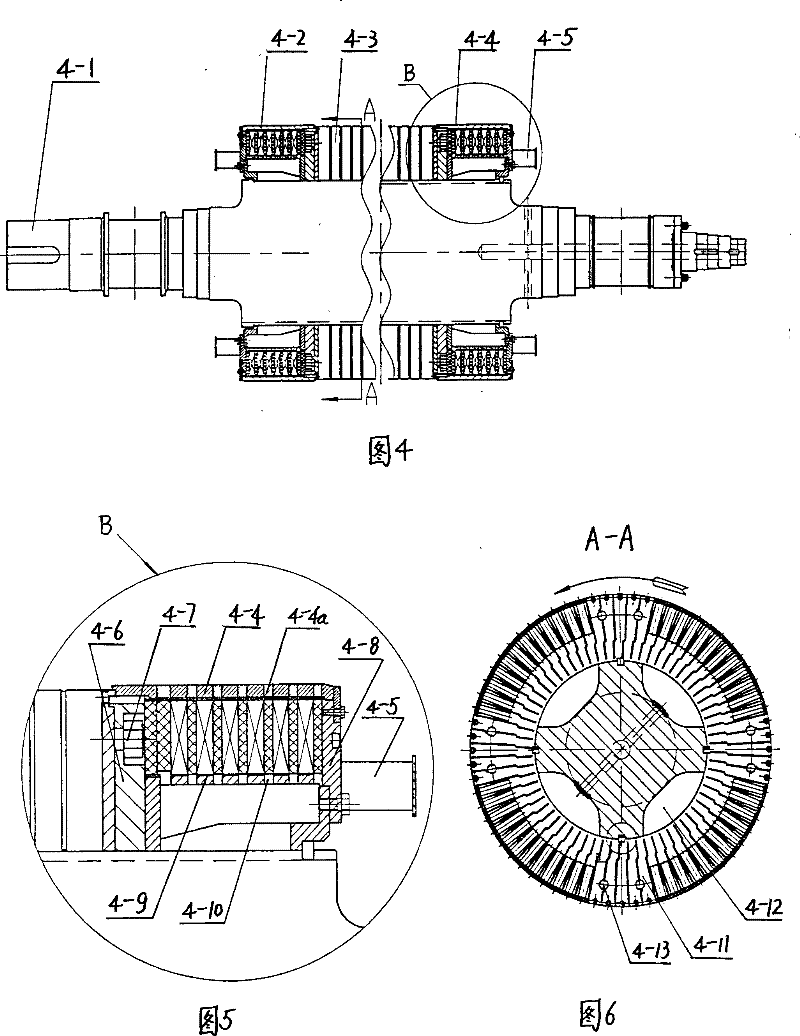

The invention relates to a large capacity non-salient pole plate fine type synchronous generator, which is characterized in that a main generator is provides with a stator which is sleeved with a motor base split unit and a rotor which is connected with a motor base through an end cover bearing, an exciting end of a rotor rotating shaft is provided with a brushless excitation system with a high pole number, the tail end of the system is provided with a grounding detecting device, and a cooling system comprises a cooling device which is positioned on the main generator, four ducted cooling paths which circulates in multiply return circuits and is formed by a stator ventilating circuit, a rotor ventilating circuit, an air gas ventilating circuit and an exciting dynamo ventilating circuit of the main generator. The generator has the advantages of reasonable design of the whole system, compact structure, complete function of each portion, convenient installation and maintenance, reliable operating property, high quality of voltage and electric current which are produced and the like, which saves manufacturing cost.

Owner:WOLONG ELECTRIC NANYANG EXPLOSION PROTECTION GRP CO LTD

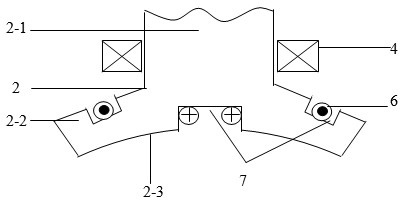

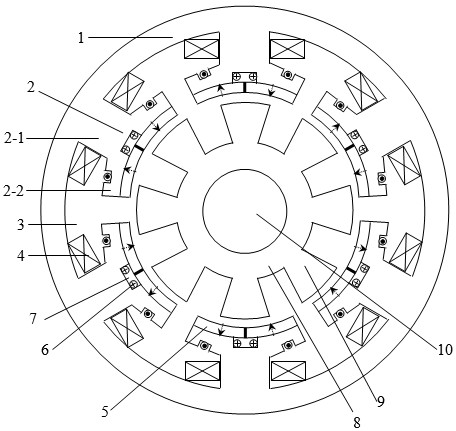

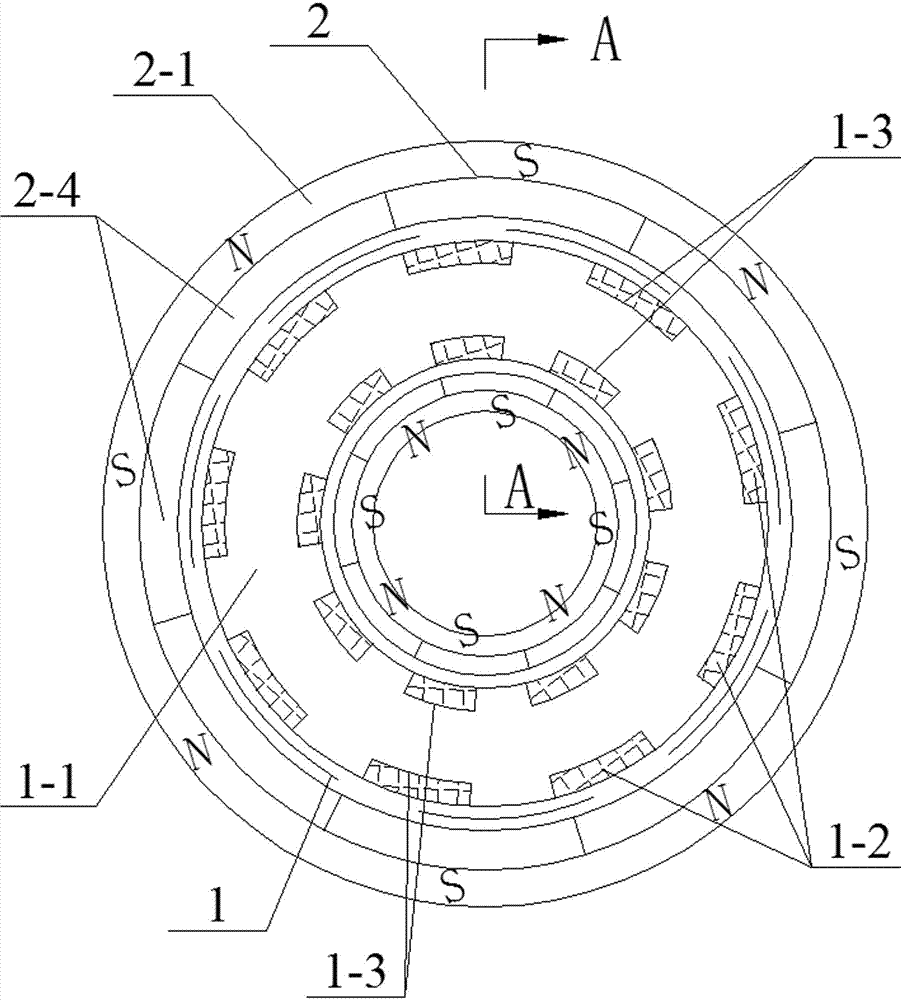

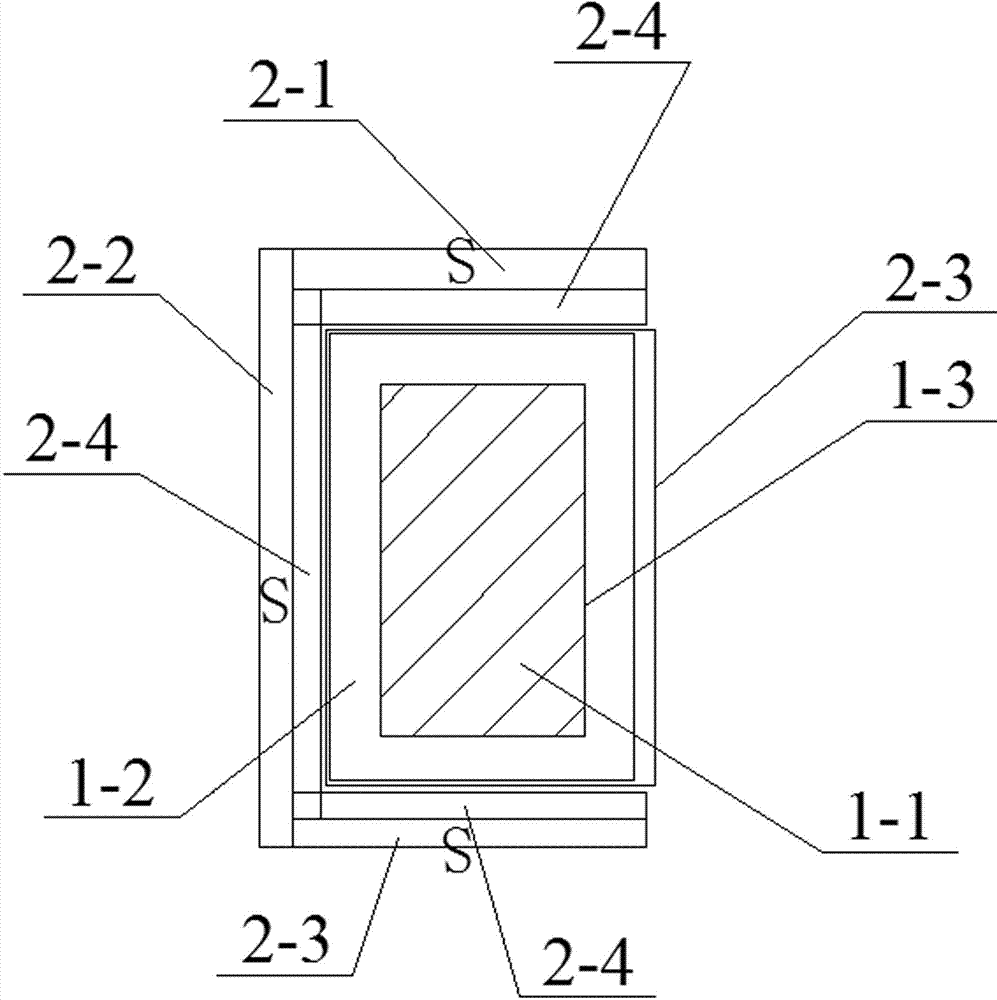

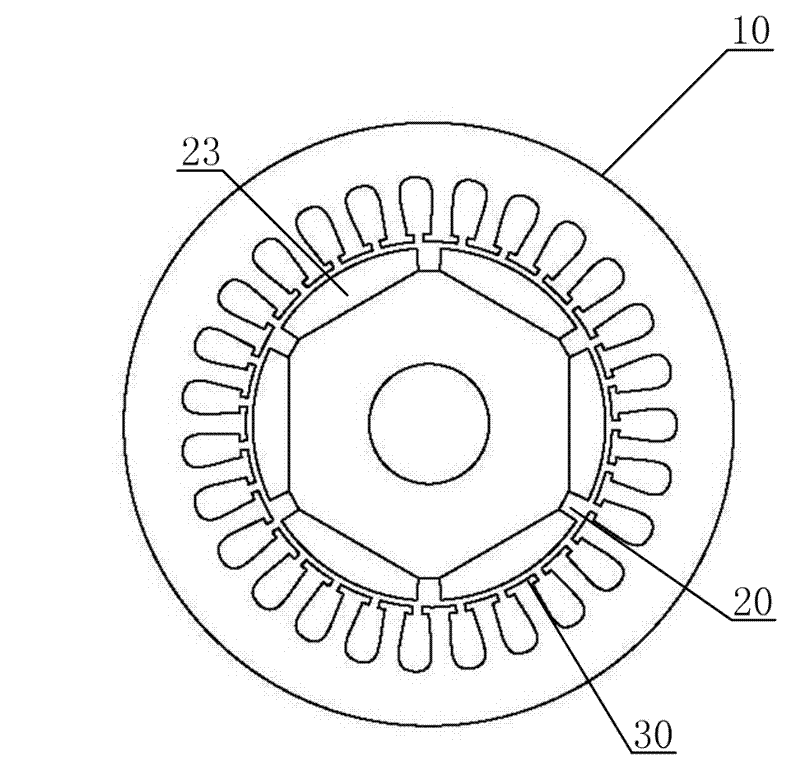

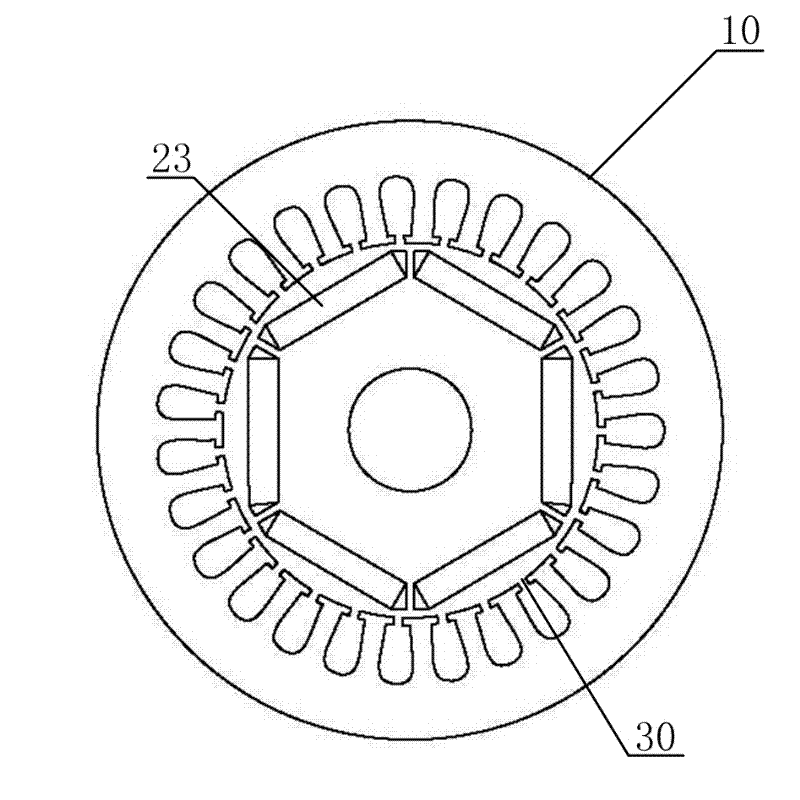

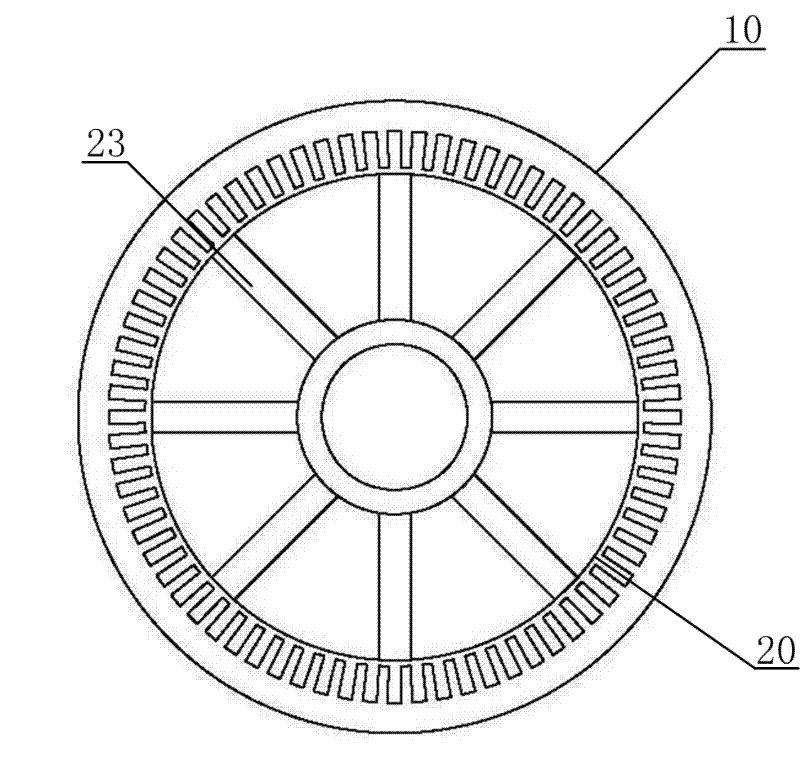

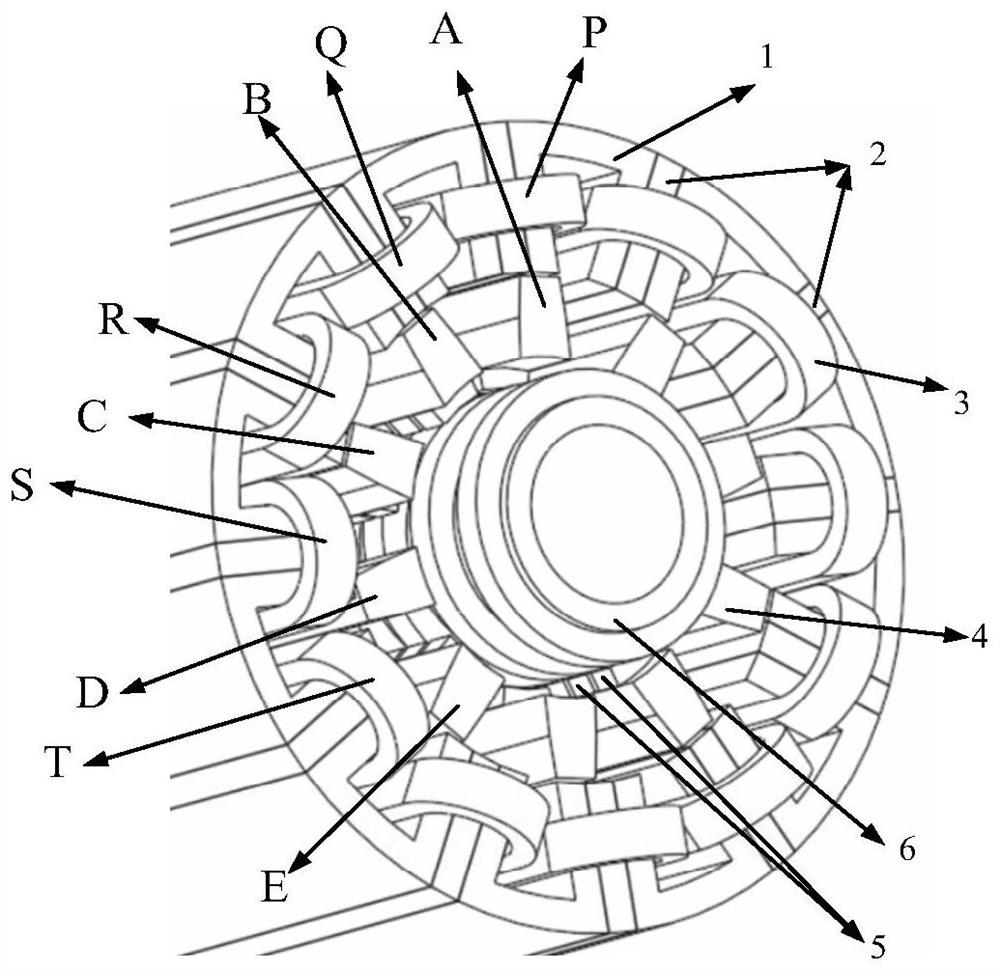

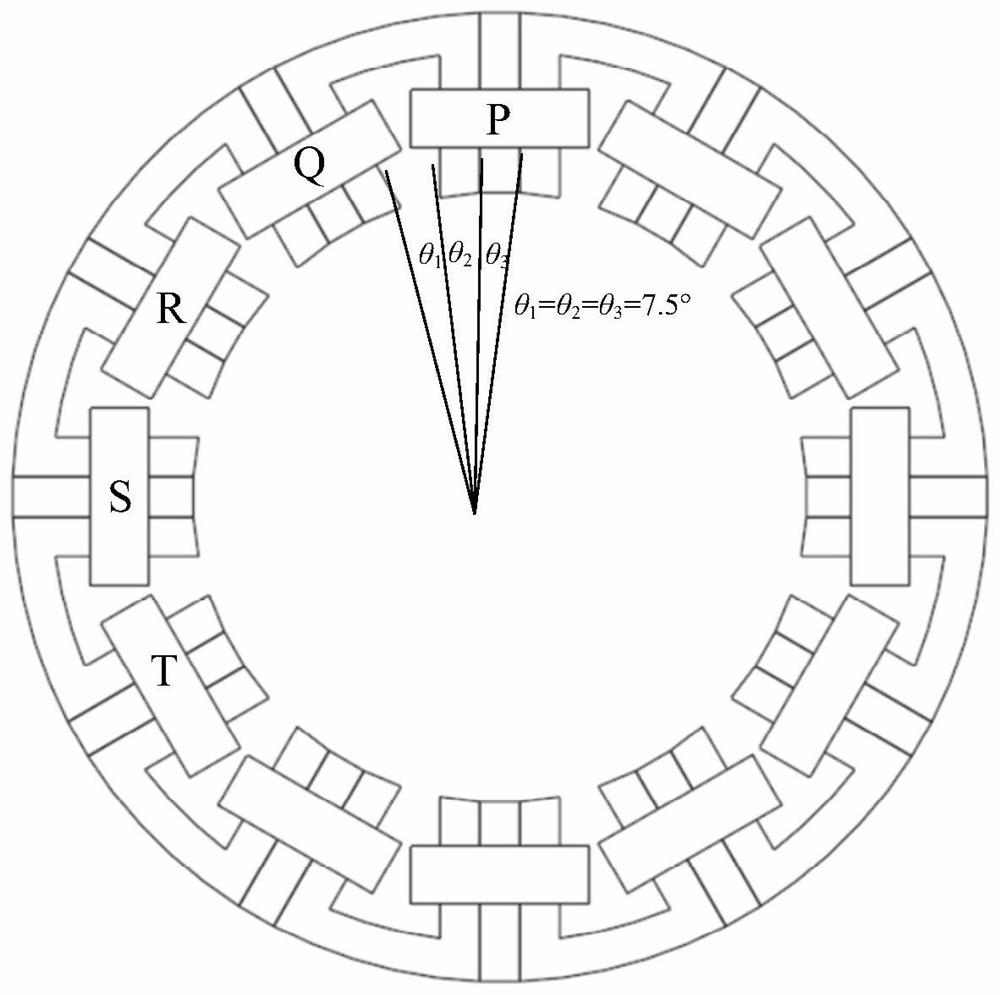

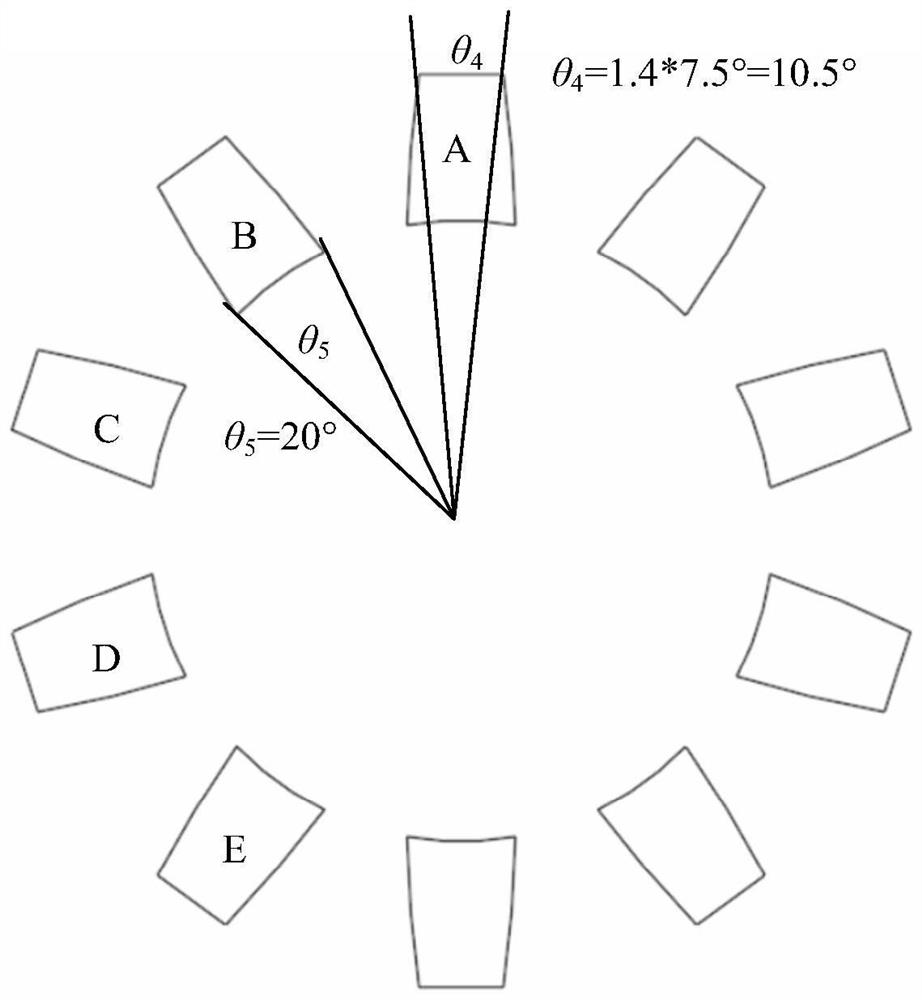

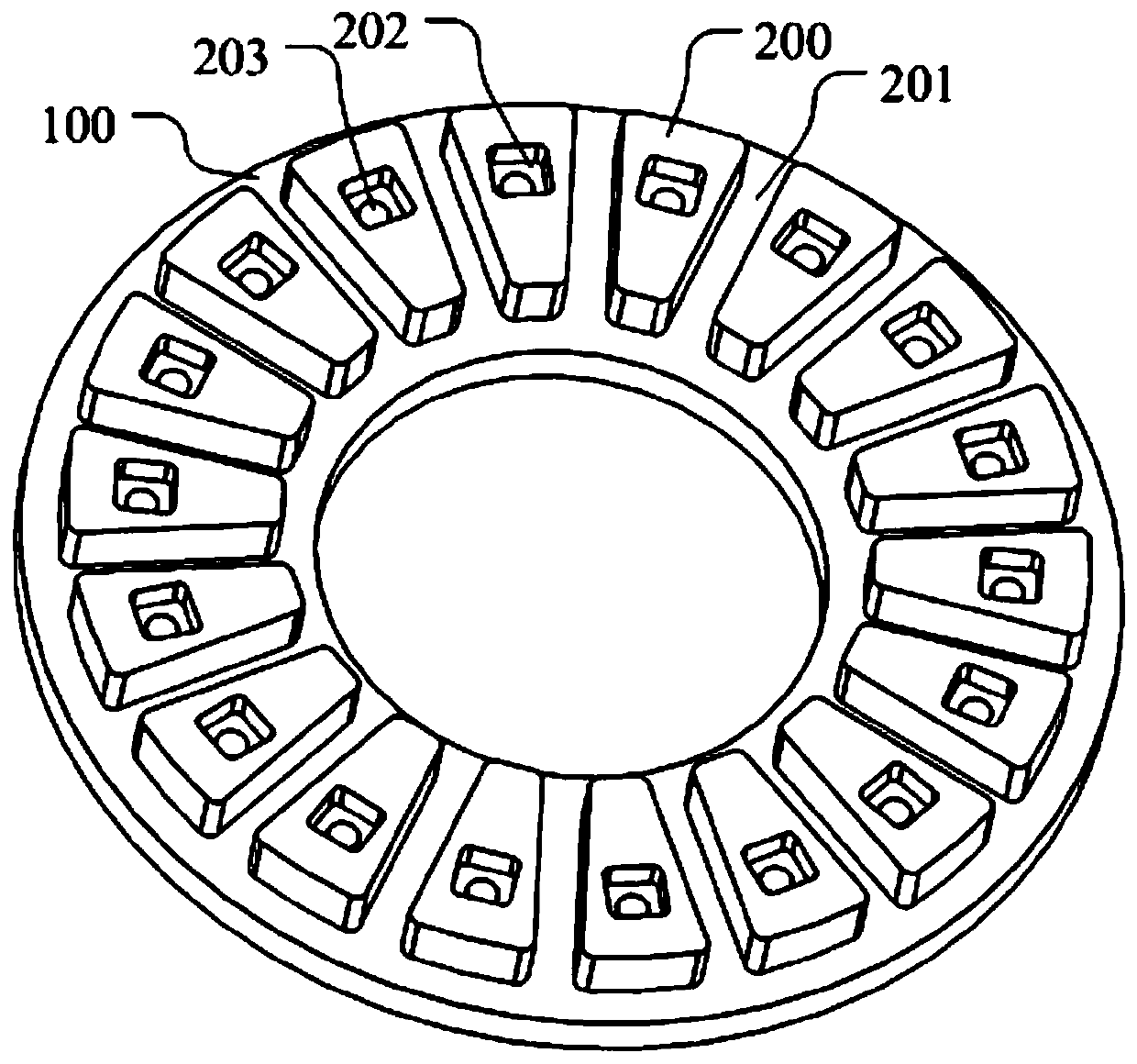

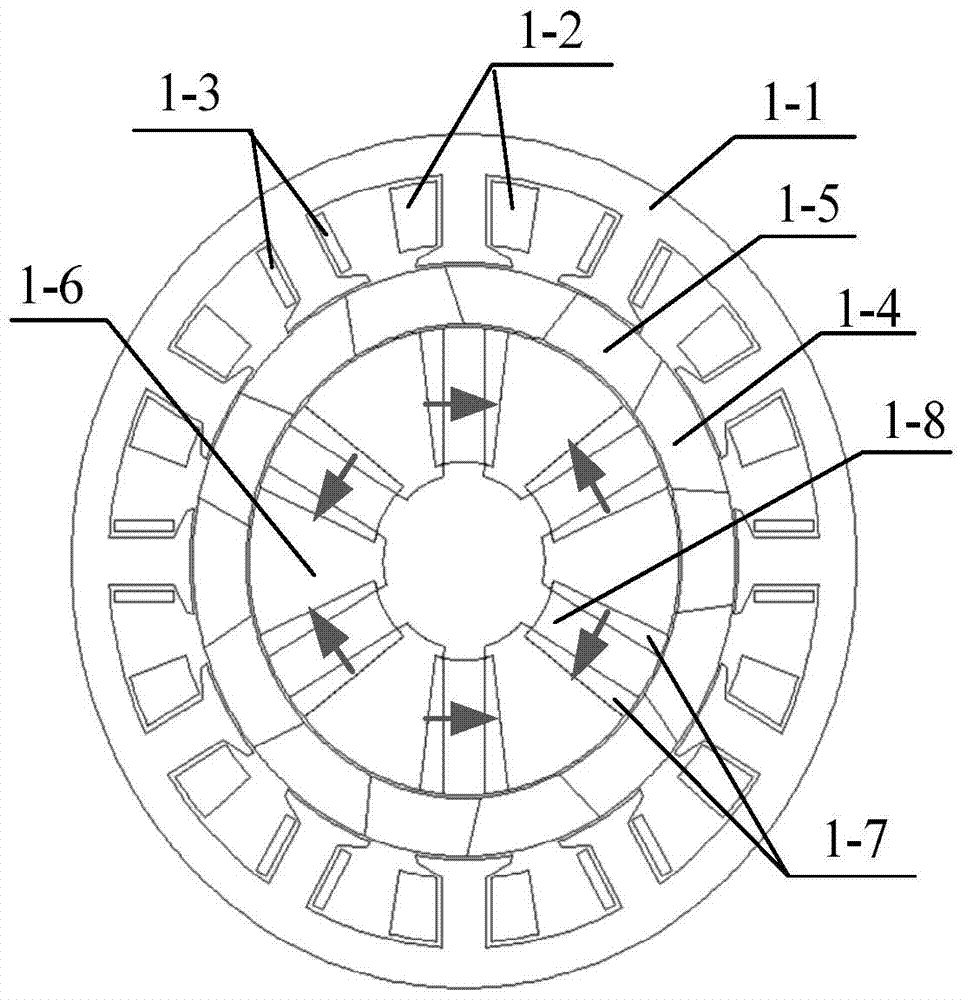

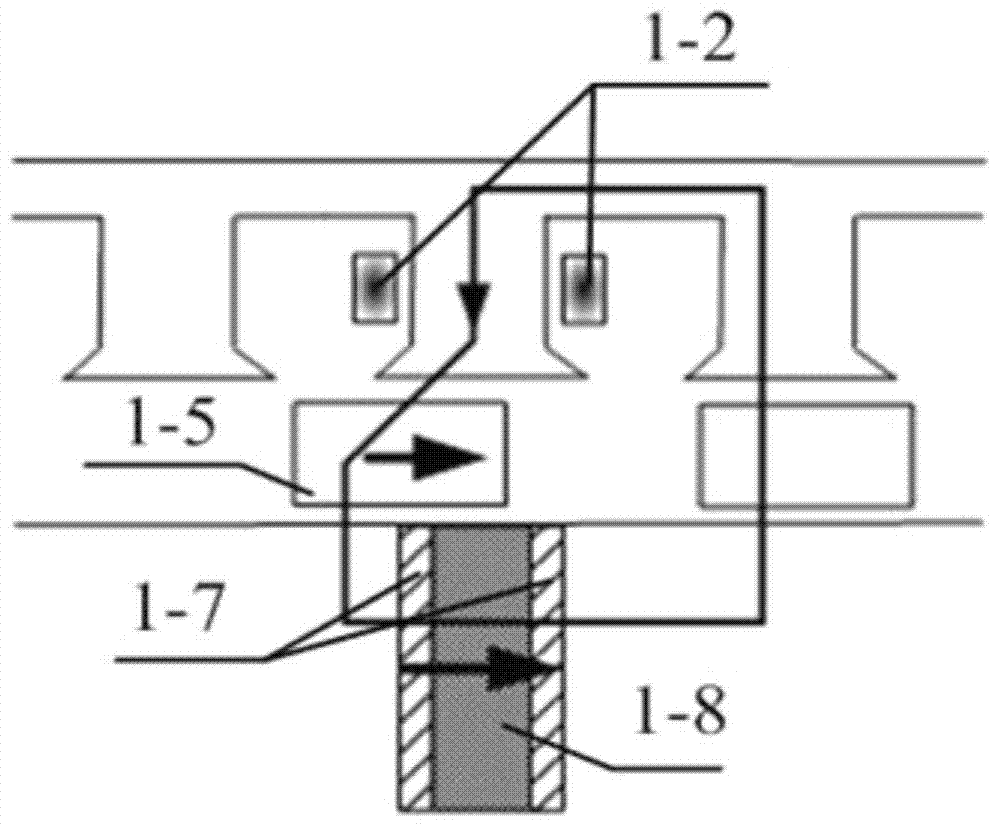

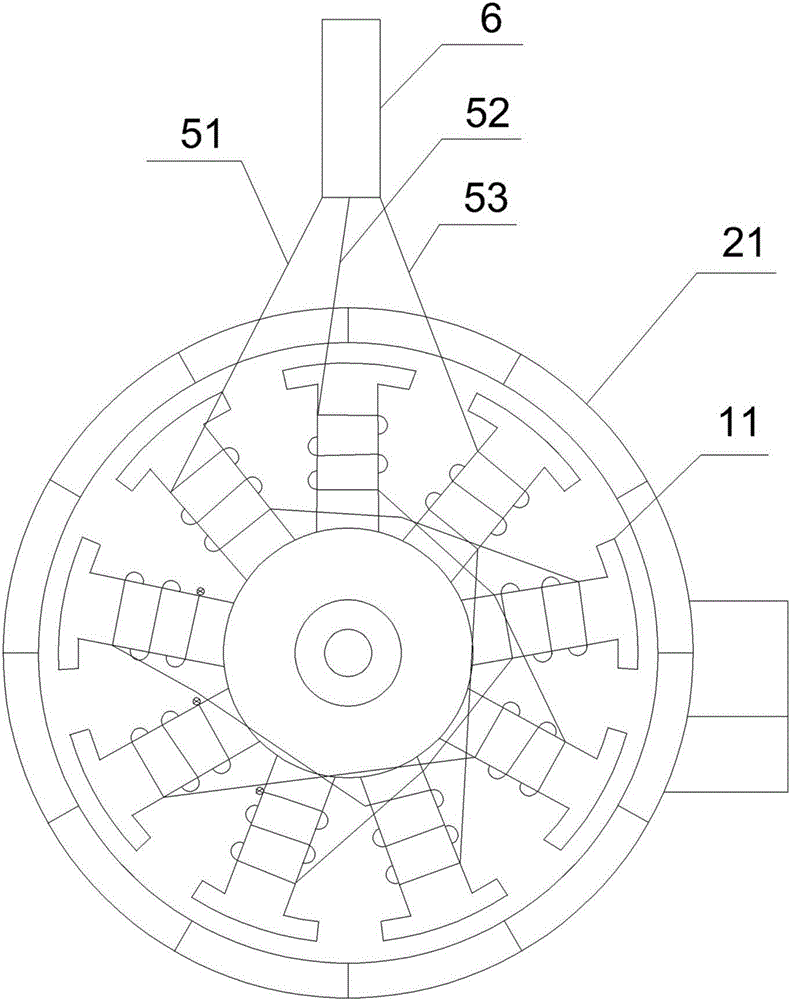

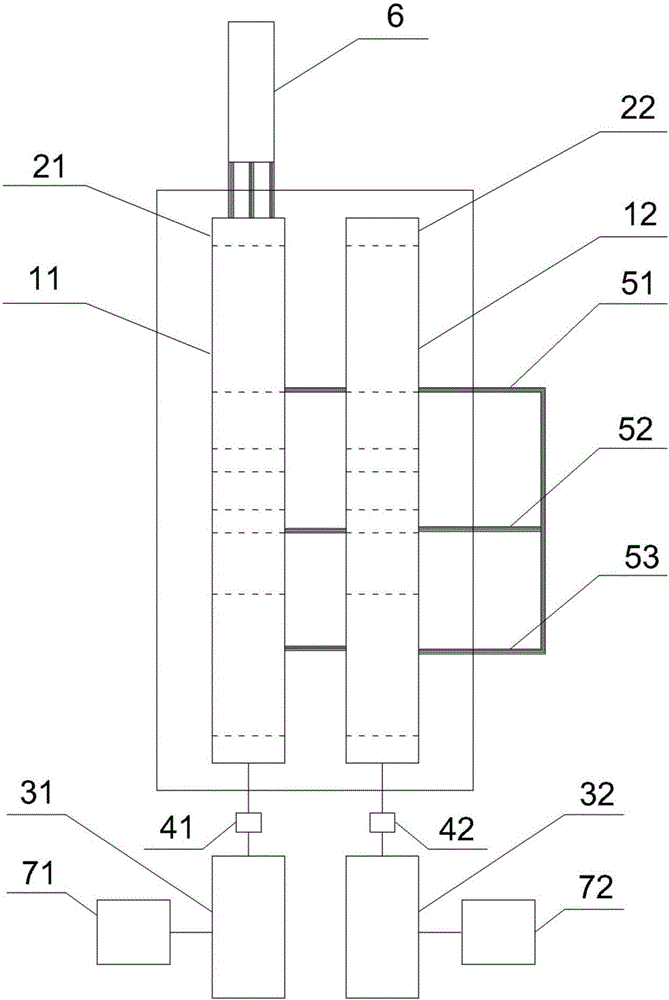

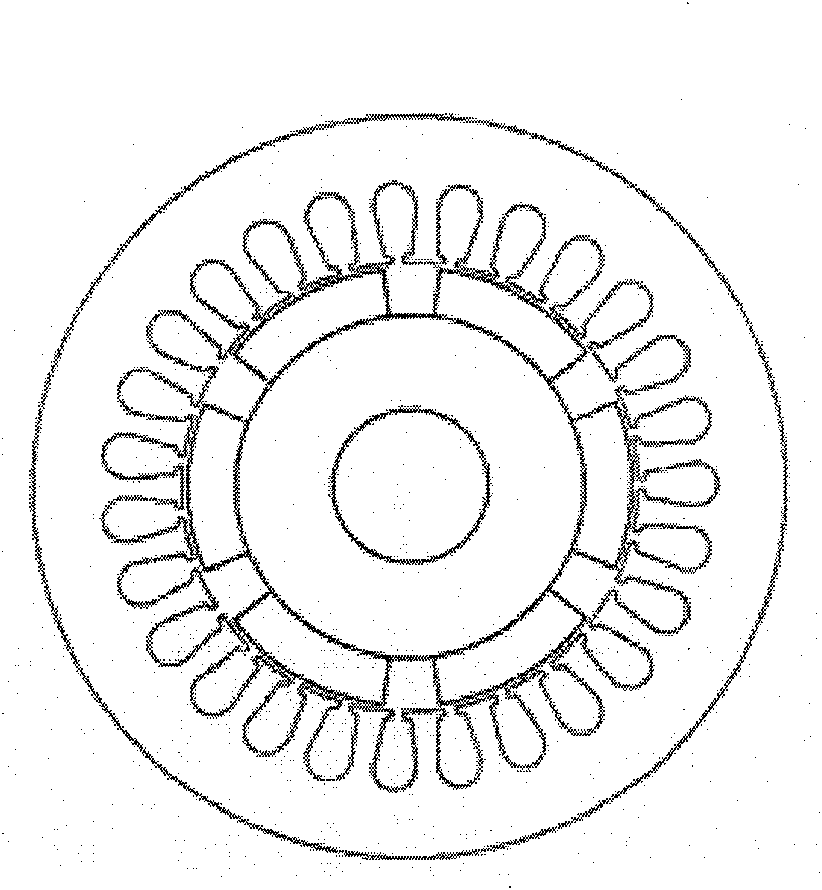

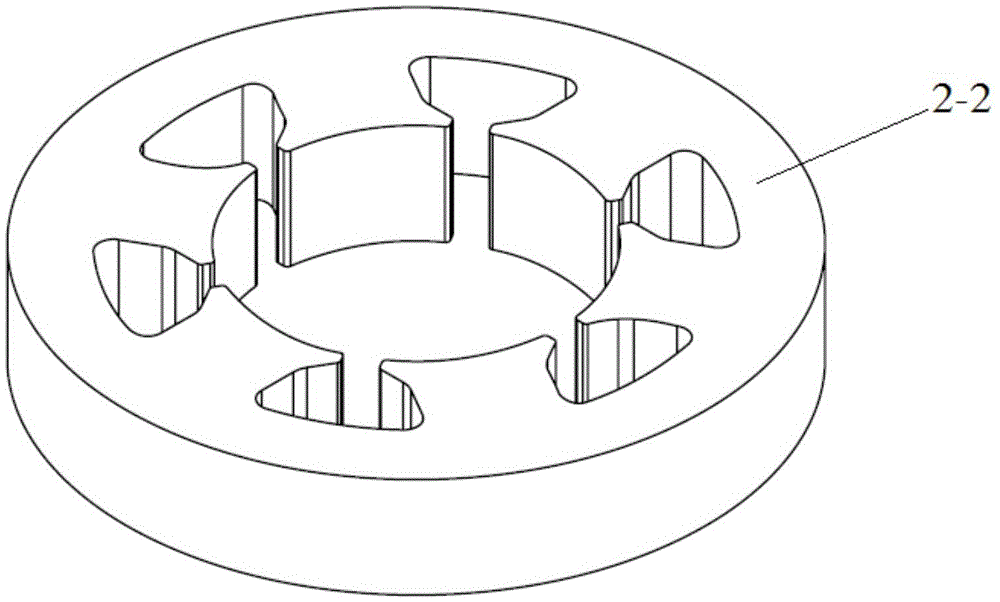

Hybrid excitation flux reversal motor

InactiveCN102570647AAdjust the size of the magnetic fieldRestore magnetismMagnetic circuit stationary partsWindings conductor shape/form/constructionElectrical polarityConductor Coil

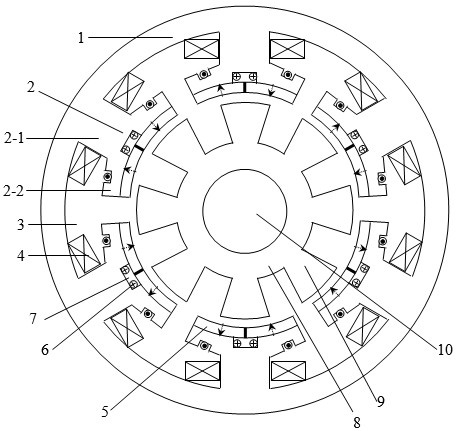

The invention discloses a hybrid excitation flux reversal motor. The motor comprises a stator, a rotor and a rotary axle. The rotor comprises a rotor yoke and a rotor pole. The stator comprises a stator yoke and a plurality of stator poles connected with the stator yoke. Each stator pole comprises a stator pole body, a stator pole shoe and a stator pole arc surface. A stator power winding wire casing is arranged between each two adjacent stator poles. A stator power winding is arranged in the stator power winding wire casing. Two stator permanent magnets with opposite polarity are glued on each stator pole arc surface symmetrically. A stator excitation winding winds the corresponding stator pole shoe relative to each stator permanent magnet, and the two stator excitation windings on each stator pole are connected in series mutually. The hybrid excitation flux reversal motor has the advantages of adjustable excitation magnetic field and a simple structure.

Owner:CHINA UNIV OF MINING & TECH

A method of providing fiber web making furnish with filler, and paper or paper board

ActiveCN105339548AImprove qualityMuch better and even qualityReinforcing agents additionPaper/cardboardFiberCardboard

The present invention relates to a method of producing precipitated calcium carbonate (PCC) where a retention / strength enhancing chemical is added to milk of lime to form a mixture thereof prior to adding the mixture of the retention / strength enhancing chemical and milk of lime to paper making stock in a pipeline leading to a headbox of a paper making machine, whereafter carbon dioxide is introduced to the paper making stock, and the carbonation reaction between milk of lime and carbon dioxide is allowed to proceed in the presence of both fibers and the retention / strength enhancing chemical.

Owner:WETEND TECH +1

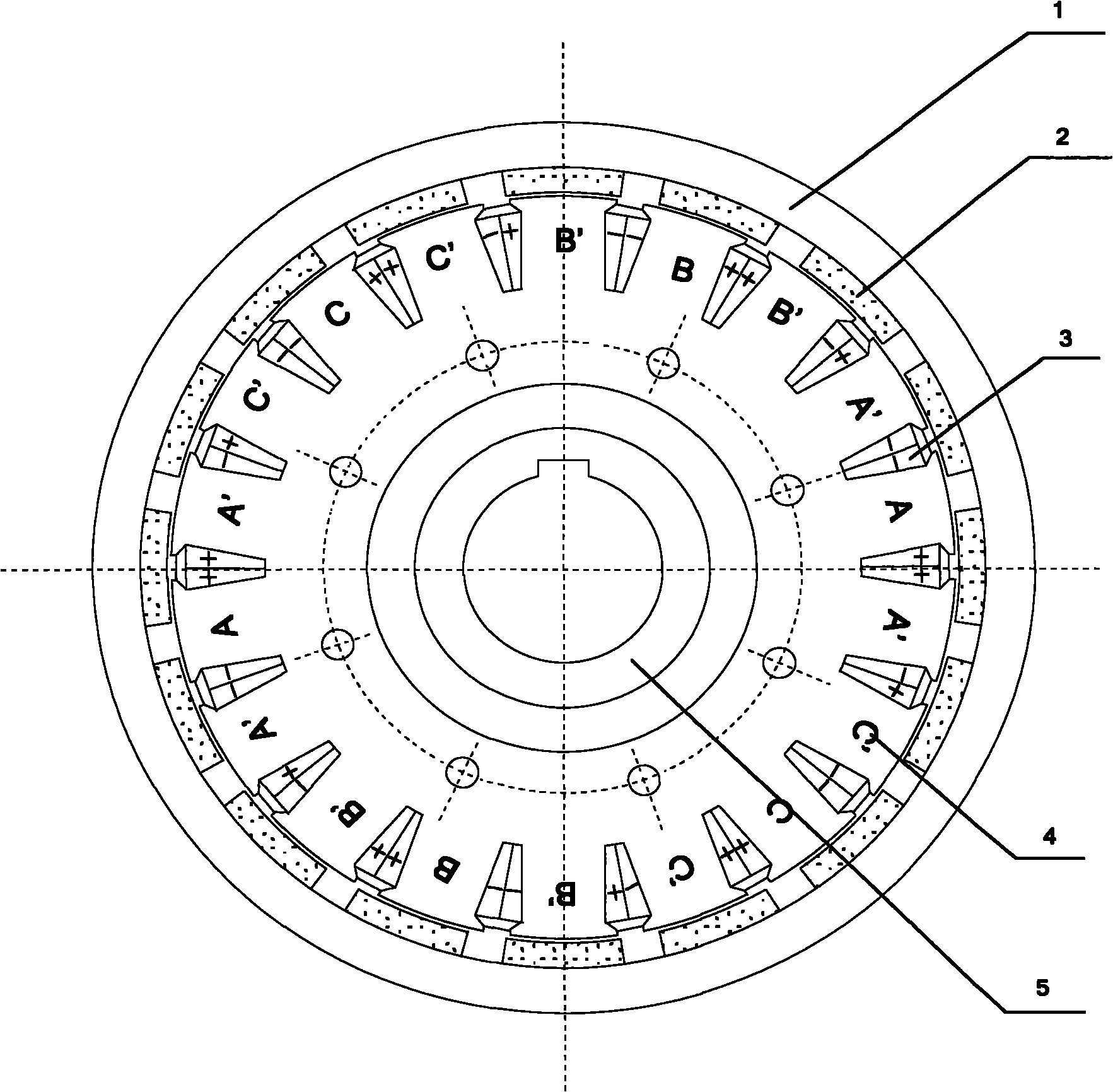

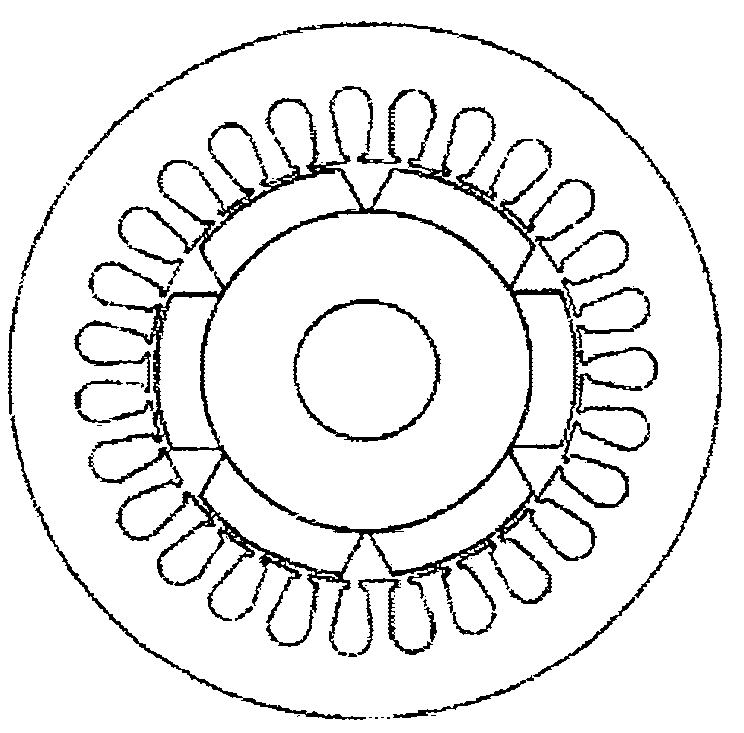

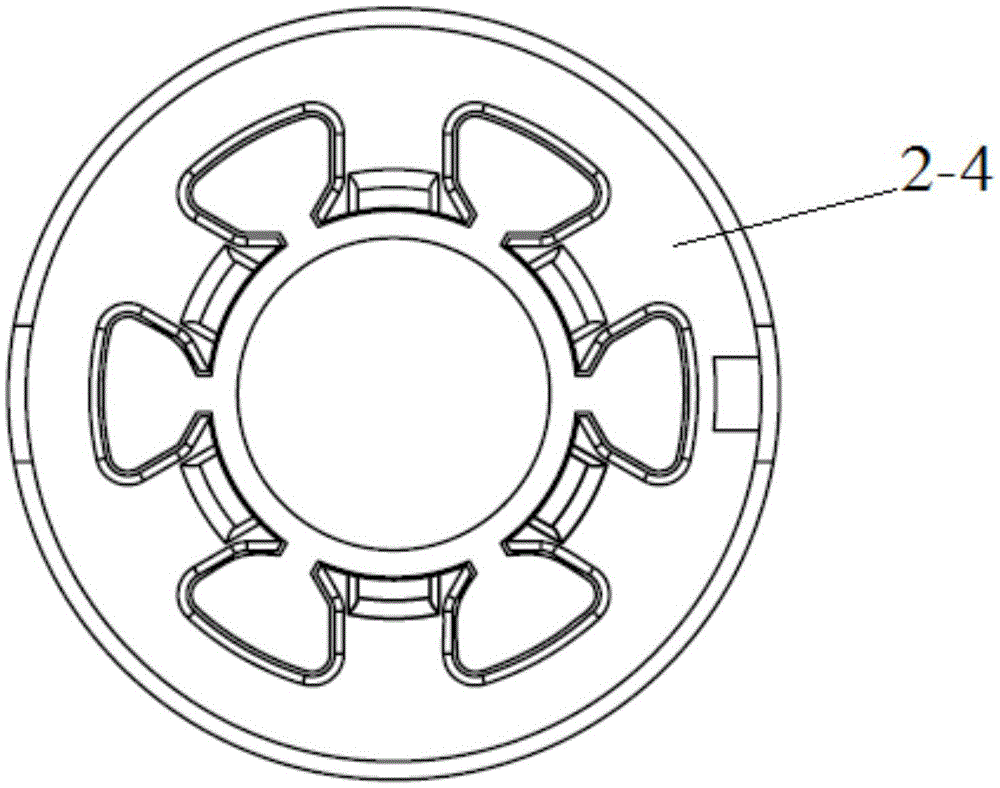

Modularized permanent magnet synchronous generator

InactiveCN101951105APrevent flyaway damageLow costSynchronous machine detailsMagnetic circuit stationary partsCopper lossPhysics

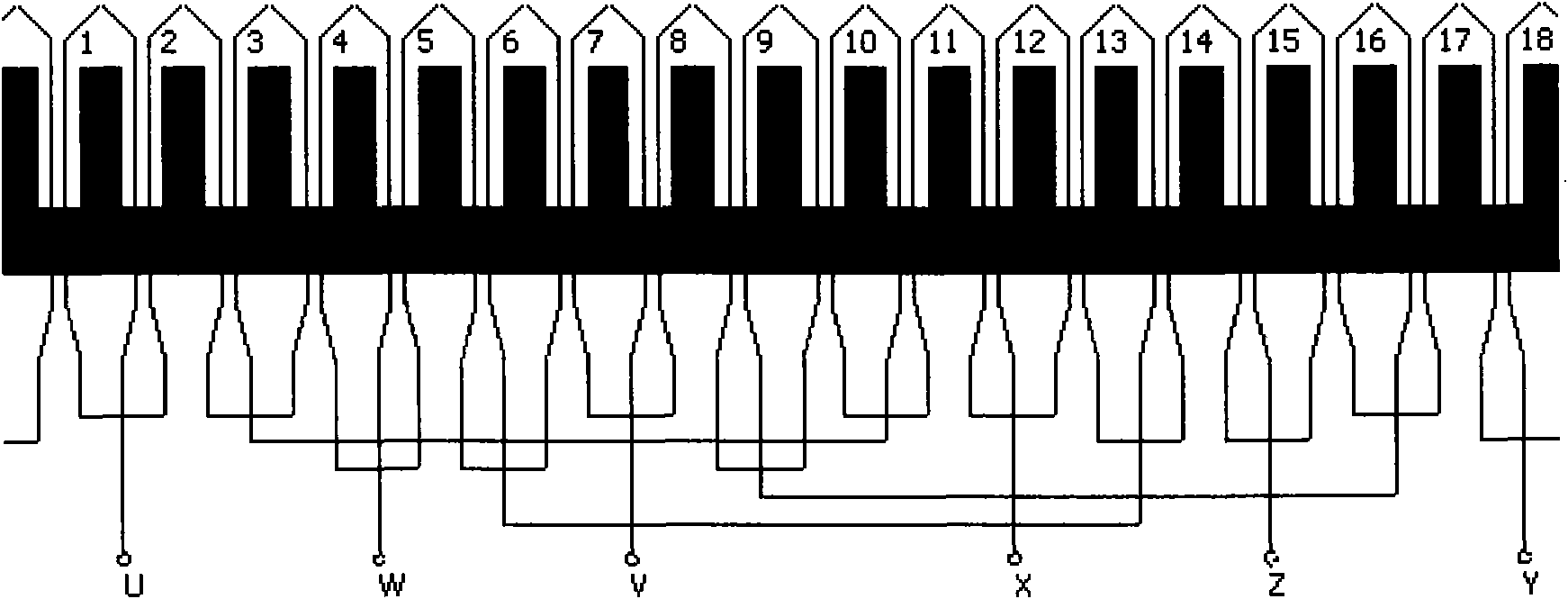

The invention discloses a modularized permanent magnet synchronous generator, comprising a rotor yoke, an rare earth permanent magnet, a triphase stator winding and a stator core, wherein the permanent magnet is evenly adhered on the inner surface of the rotor yoke, the stator tooth number of the stator core is two more than the piece number of the permanent magnet; a slot insulation layer is cladded on the stator teeth, the triphase stator winding is wound outside the slot insulation layer; the stator teeth of the stator core are evenly divided into six parts, winding of each phase is provided with two opposite parts and wounded on the corresponding slot, out-phase windings are only wounded in the six slots between two adjacent parts and same-phase windings are wounded in the rest of the slots. The invention can overcome the defects such as the large tooth space of the traditional permanent magnet synchronous generator and the like. Meanwhile, as the special centralized winding is utilized, the generator of the invention can greatly improve sine degree of voltage waveforms, reduce generator copper loss and improve generator power density.

Owner:SOUTHEAST UNIV

Radio and axial hybrid magnetic circuit permanent-magnet synchronous-side rotor motor

InactiveCN104753291ASmall sizeIncrease torqueSynchronous machine detailsSynchronous machines with stationary armatures and rotating magnetsElectric machineMagnetic poles

The invention discloses a radio and axial hybrid magnetic circuit permanent-magnet synchronous-side rotor motor and belongs to the technical field permanent-magnet motors with an aim to solve problems that improvement of motor efficiency is limited due to rapid increasing of eddy current loss of motor cores when power density of existing permanent-magnet motors are increased by increasing rotating speed and pair of poles. The radio and axial hybrid magnet circuit permanent-magnet synchronous-side rotor motor is characterized in that a winding is embedded in each rectangular ring groove, and a solid circular ring is made of soft magnetic composite (SMC); the outer circular edge of a magnetic-side wafer covers the left port of a magnetic outer circular ring, and the internal circular edge of the magnetic-side wafer covers the left port of a magnetic inner circular ring; magnetic poles of magnetic steel on the magnetic outer circular ring and the magnetic inner circular ring are identical to that of magnetic steel on the aligning magnetic-side wafer; a rotor sheaths a stator from the outer periphery with clearance so as to enable the axial lead of the rotor to be coincided with that of the stator. An axial magnetic field and a radial magnetic field are allowed to pass through a main magnetic circuit simultaneously, and the pair of poles is allowed to be increased without causing rapid increasing of eddy current loss.

Owner:HARBIN INST OF TECH

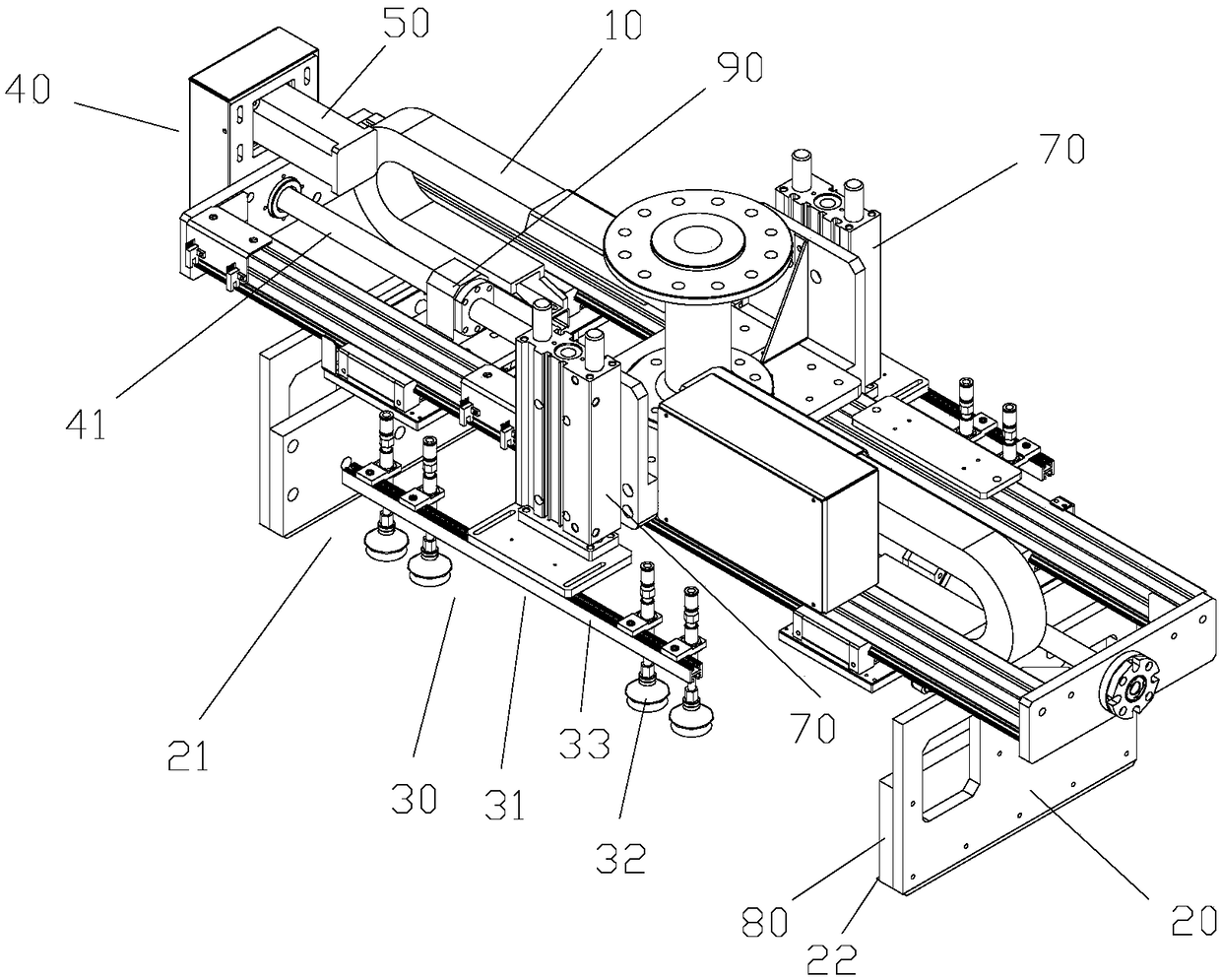

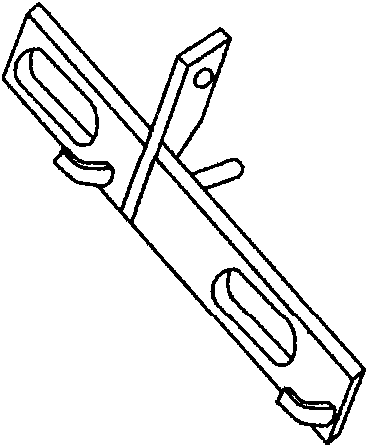

Fixture

Owner:ZHUHAI GREE INTELLIGENT EQUIP CO LTD +1

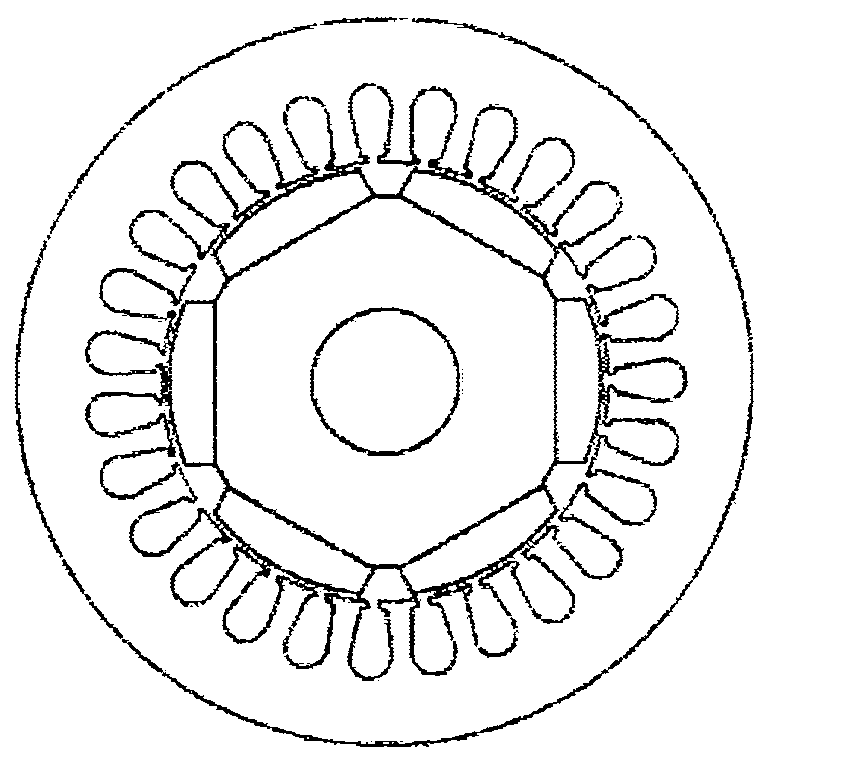

Permanent magnet synchronous machine (PMSM) possessing assembled magnetic effect

InactiveCN102255460AImprove distributionImprove approachMagnetic circuit rotating partsMagnetic circuit stationary partsPermanent magnet synchronous machinePermanent magnet synchronous motor

The invention provides a permanent magnet synchronous machine (PMSM) possessing an assembled magnetic effect. The PMSM comprises a stator and a rotor. Air gaps exist between the stator and the rotor. The stator includes a stator core and a stator winding. The rotor includes a rotor core, a rotating shaft and permanent magnet steel. The stator winding is a centralized winding. The rotor is an eccentric rotor. Ends of the permanent magnet steel are directly connected with each other. The air gaps between the stator and the rotor are non-uniform air gaps. The invention has the following positive effects that: (1) distribution of air-gap flux density can be optimized through improving a rotor structure and the air gap flux can be very close to a sinusoidal waveform by using the non-uniform air gaps; (2) magnetic flux leakage on the ends can be effectively reduced because the ends of the permanent magnet steel are directly connected with each other, and simultaneously a magnetic isolation bushing is not needed to be installed on a rotating shaft side so that a requirement of a rotating shaft material can be reduced, wherein the rotating shaft can adopt a magnetic conductive material and / or a non magnetic conductive material.

Owner:SHANGHAI DIANJI UNIV

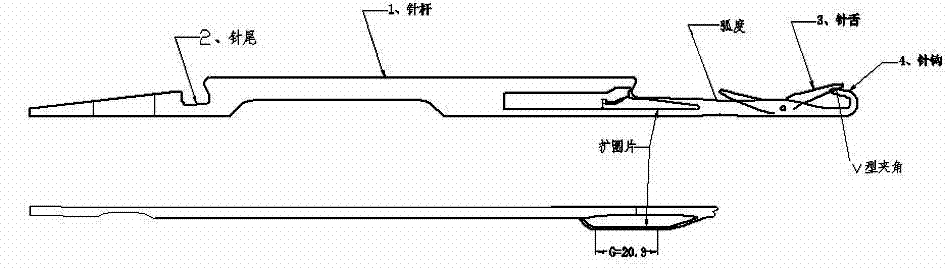

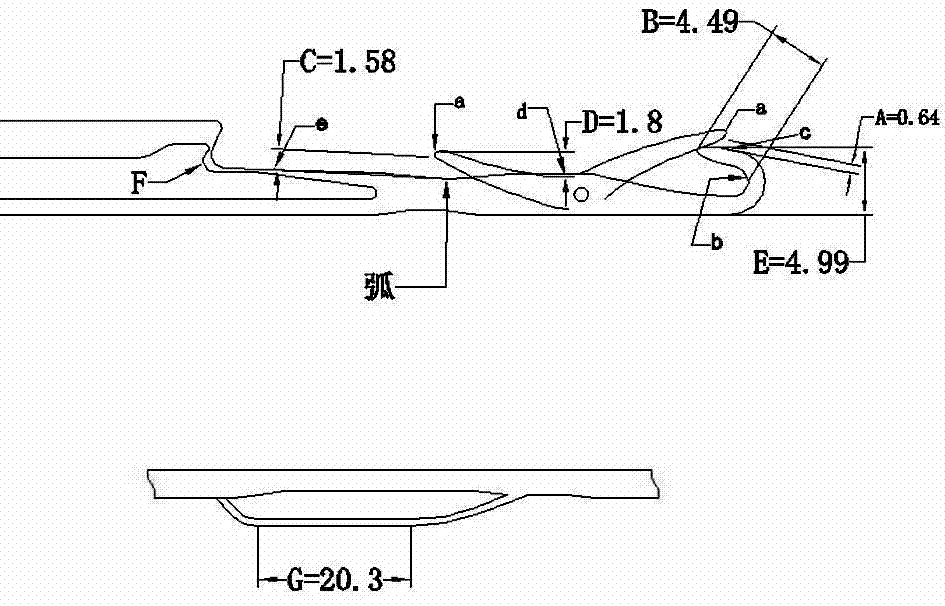

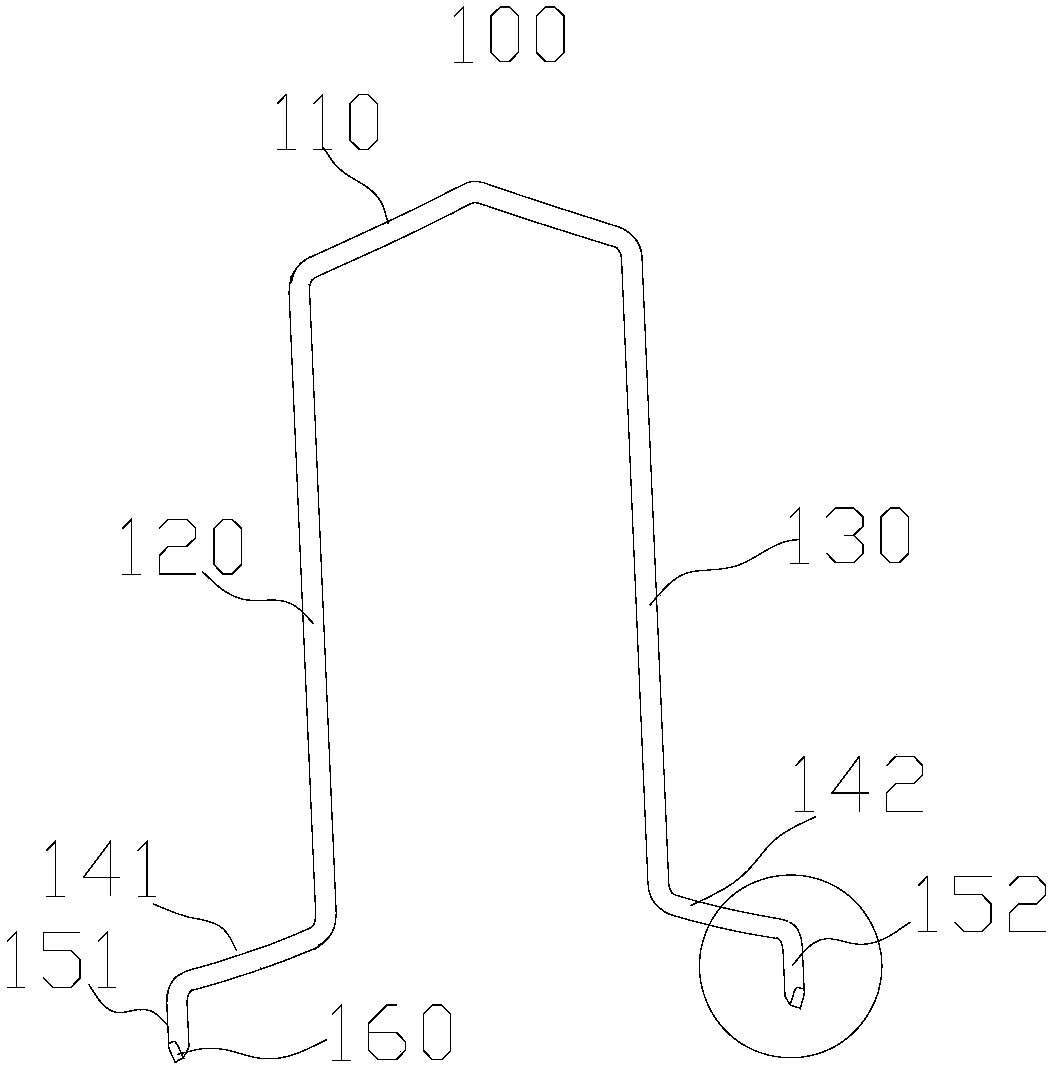

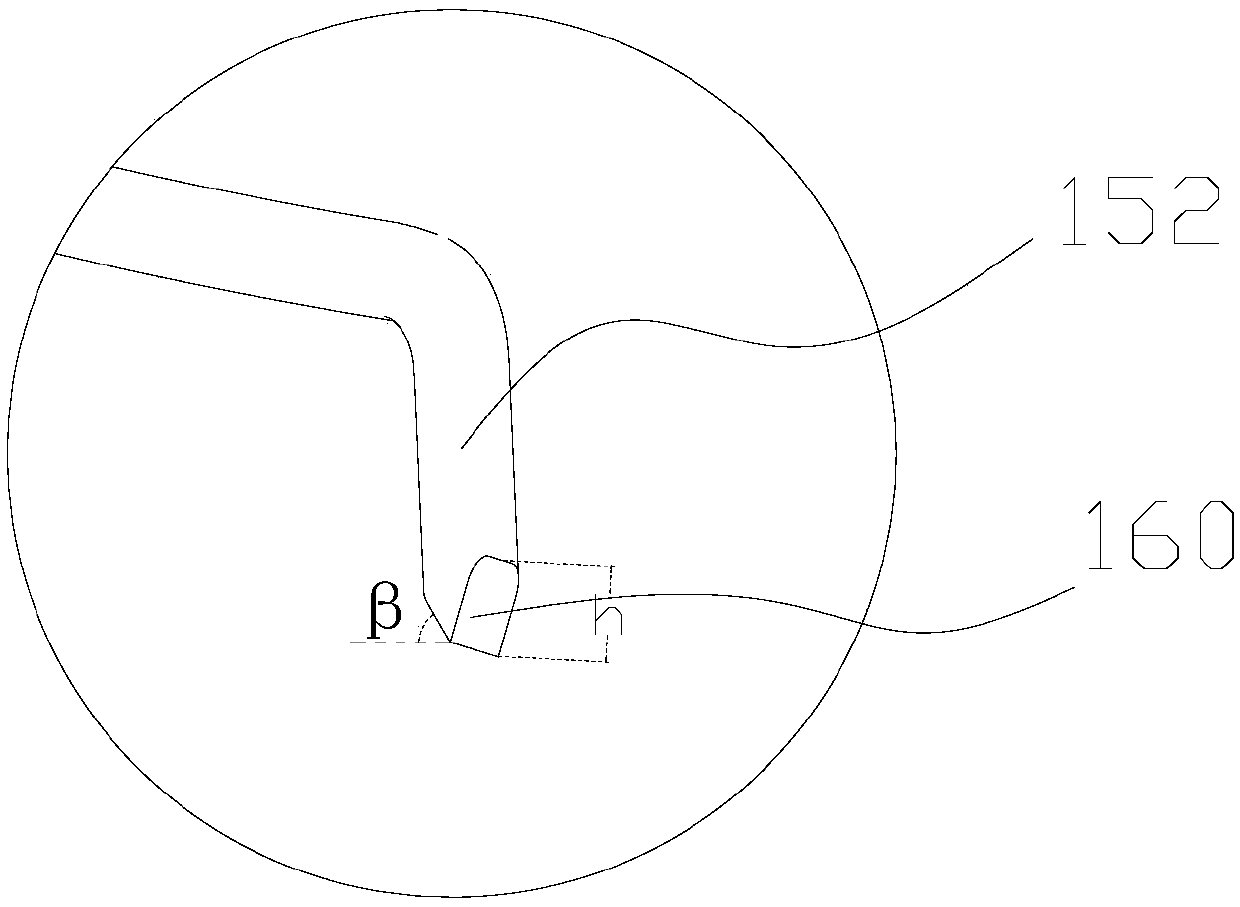

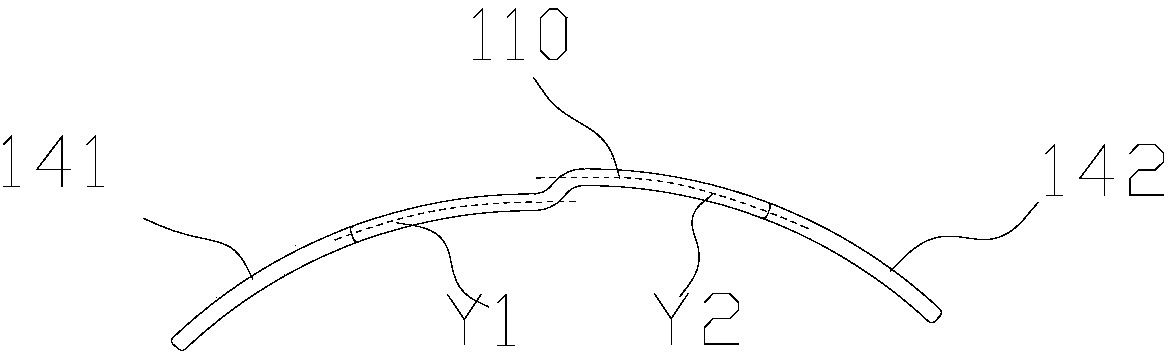

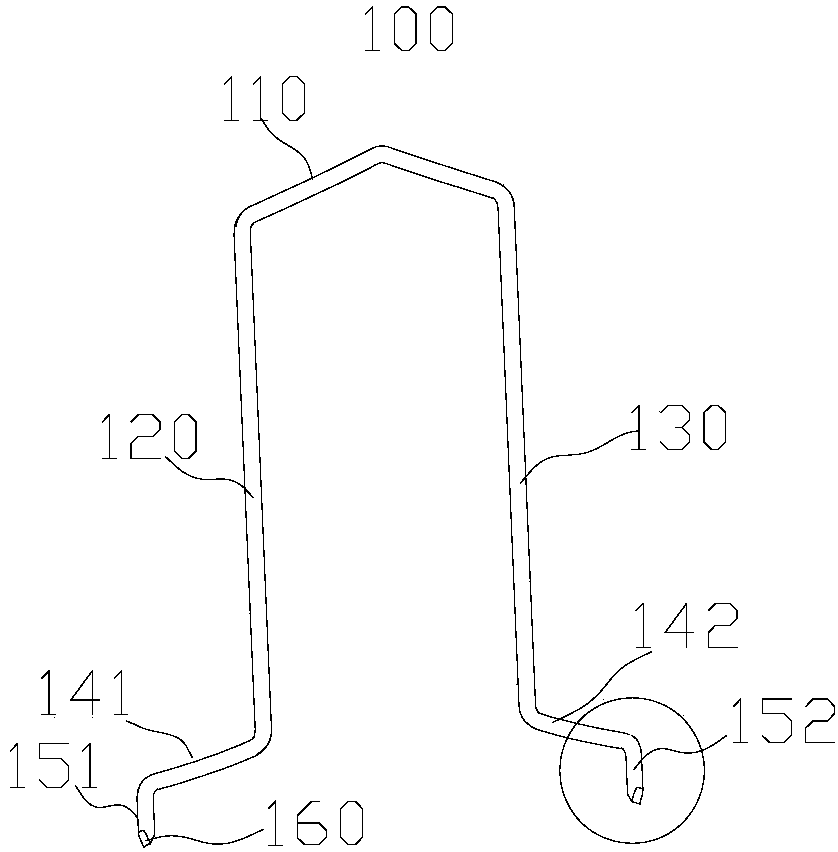

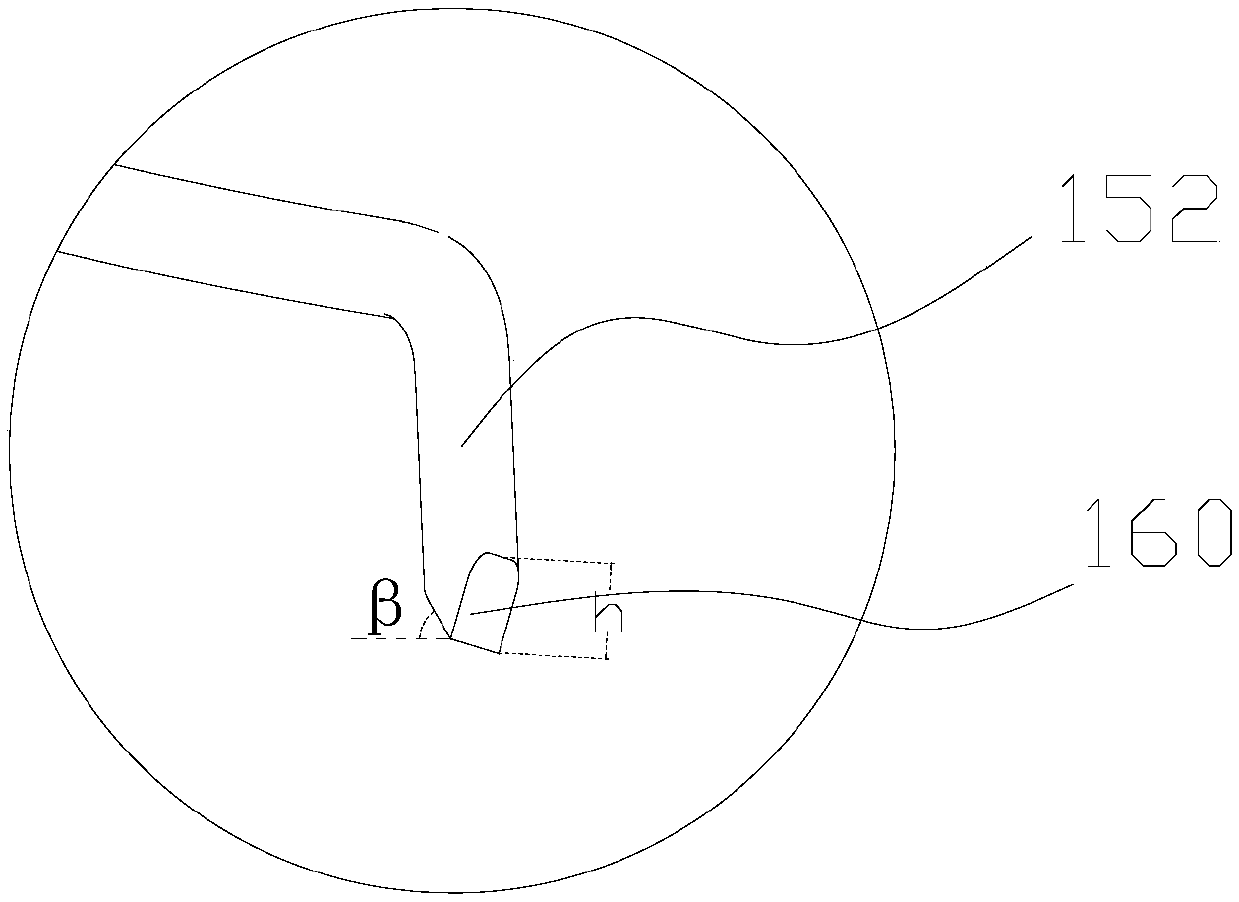

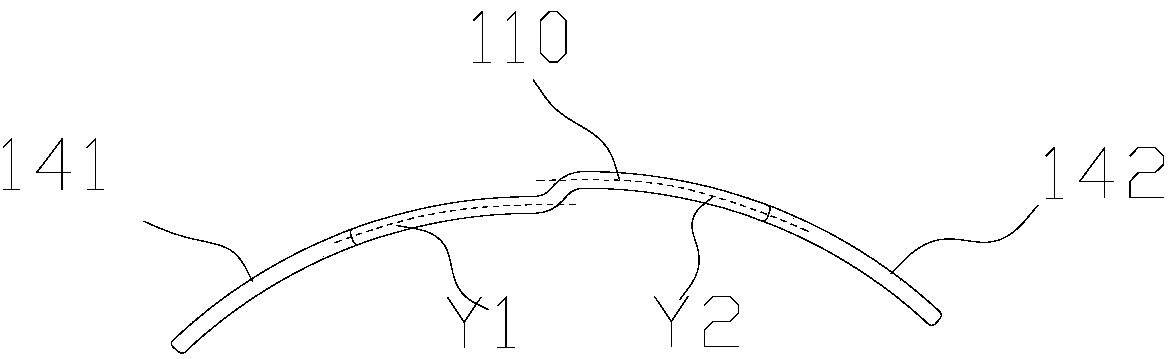

Flat knitting machine needle

The invention relates to a flat knitting machine needle comprising a needle bar, a needle latch and a needle end. One end of the needle bar bends to form a needle hook, the other end of the same forms the needle end, and the needle latch is pivoted at the front end of the needle bar to be in formation of opening or closing with the needle hook; when the needle latch looses thread, the perpendicular distance between the tip a of the needle latch and the top end d at an elastic place where the needle latch is pivoted to the needle bar ranges from 1.5mm to 1.8mm; the perpendicular distance between the tip a of the needle latch and the top end f at a place where the needle latch is pivoted to the needle bar ranges from 1.8mm to 2mm; when the needle latch looses the thread, a certain camber is formed on the opposite side of the needle latch on the needle bar; when the needle latch and the needle hook are closed, the needle latch forms a V-shaped included angle with the needle hook, and the needle latch faces upwards relative to a horizontal line; the perpendicular distance between the tip a of the needle latch and a bent point c of the needle hook is 0.64mm; the distance between the tip a of the needle hook and a bent center b of the needle hook is 4.49mm; the flat bit length of circle expanding piece on the needle bar is 20mm. By the arrangement, the defects that an existing needle is hard to loosen from the thread, less easily to pick up, prone to spewing and the like are overcome, and the flat knitting machine needle is more stable in performance, so that operating efficiency is improved.

Owner:LENSING IND

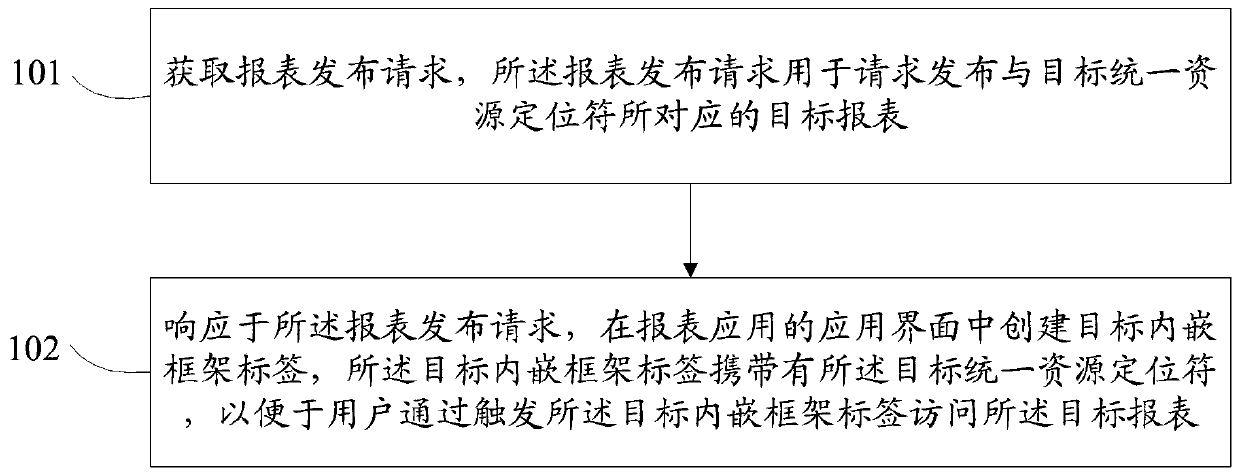

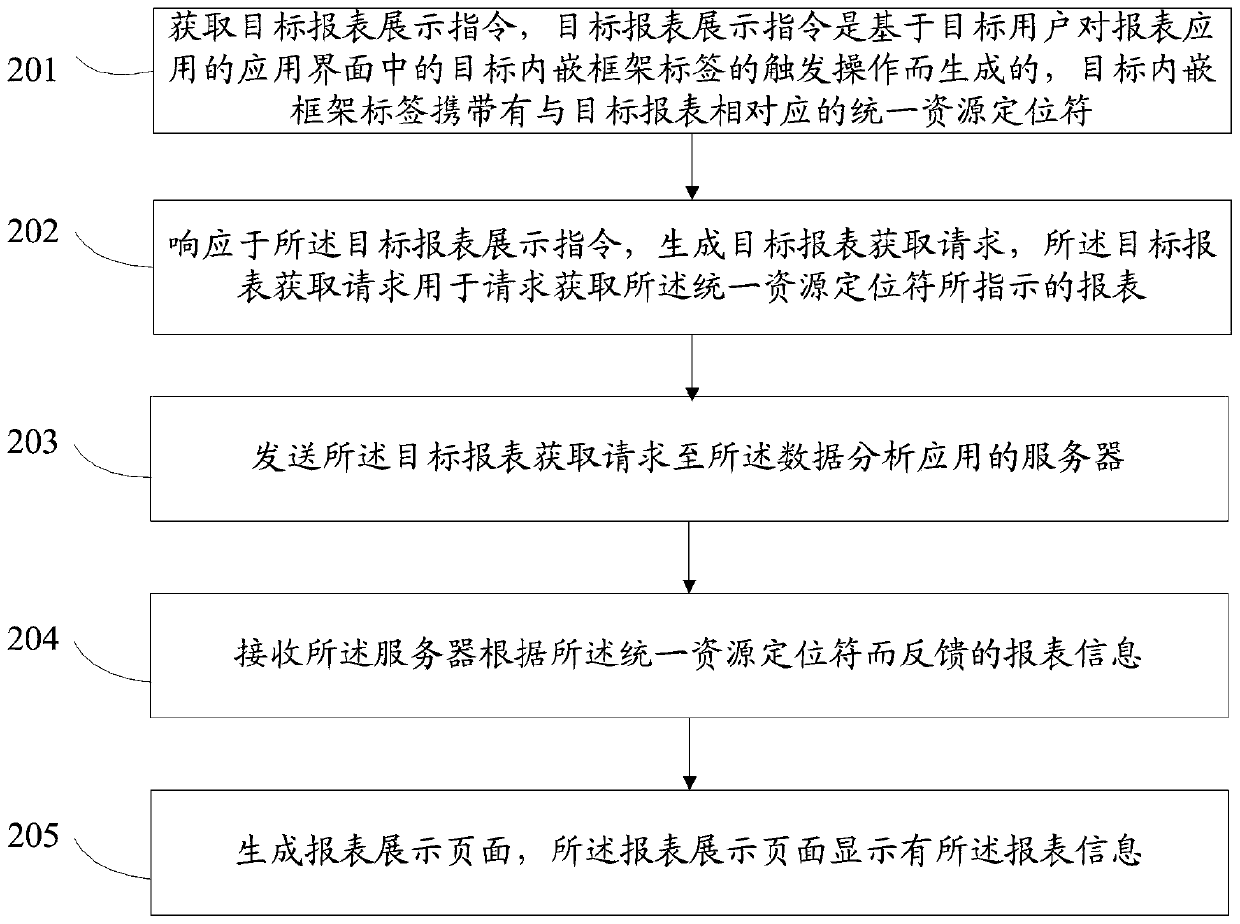

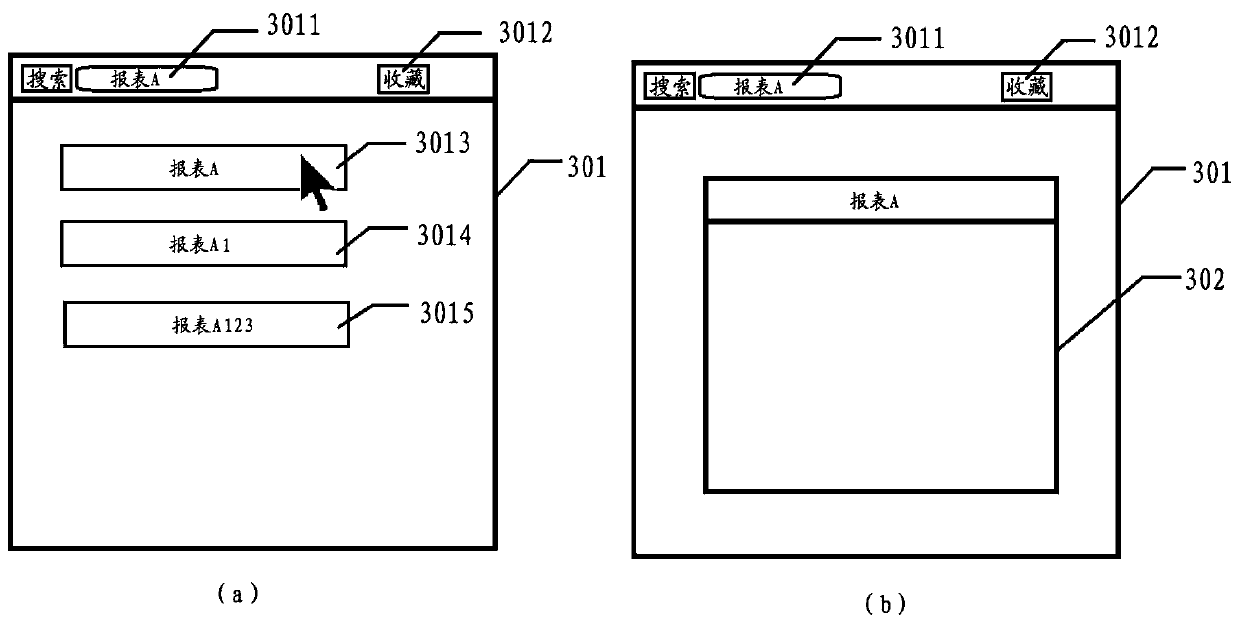

Report publishing method, device and apparatus

PendingCN110555200AEasy accessReduce workloadDigital data information retrievalSpecial data processing applicationsUniform resource locatorDatabase

The embodiment of the invention discloses a report release method, device and apparatus. The report publishing scheme comprises the steps that a report publishing request is acquired, the report publishing request is used for requesting to publish a target report corresponding to a target uniform resource locator, and the target report is a report generated based on a data analysis application. Inresponse to the report release request, a target embedded frame label is created in an application interface of the report application, the target embedded frame label carrying a target uniform resource locator, so that a user can access a target report by triggering the target embedded frame label.

Owner:北京思维造物信息科技股份有限公司

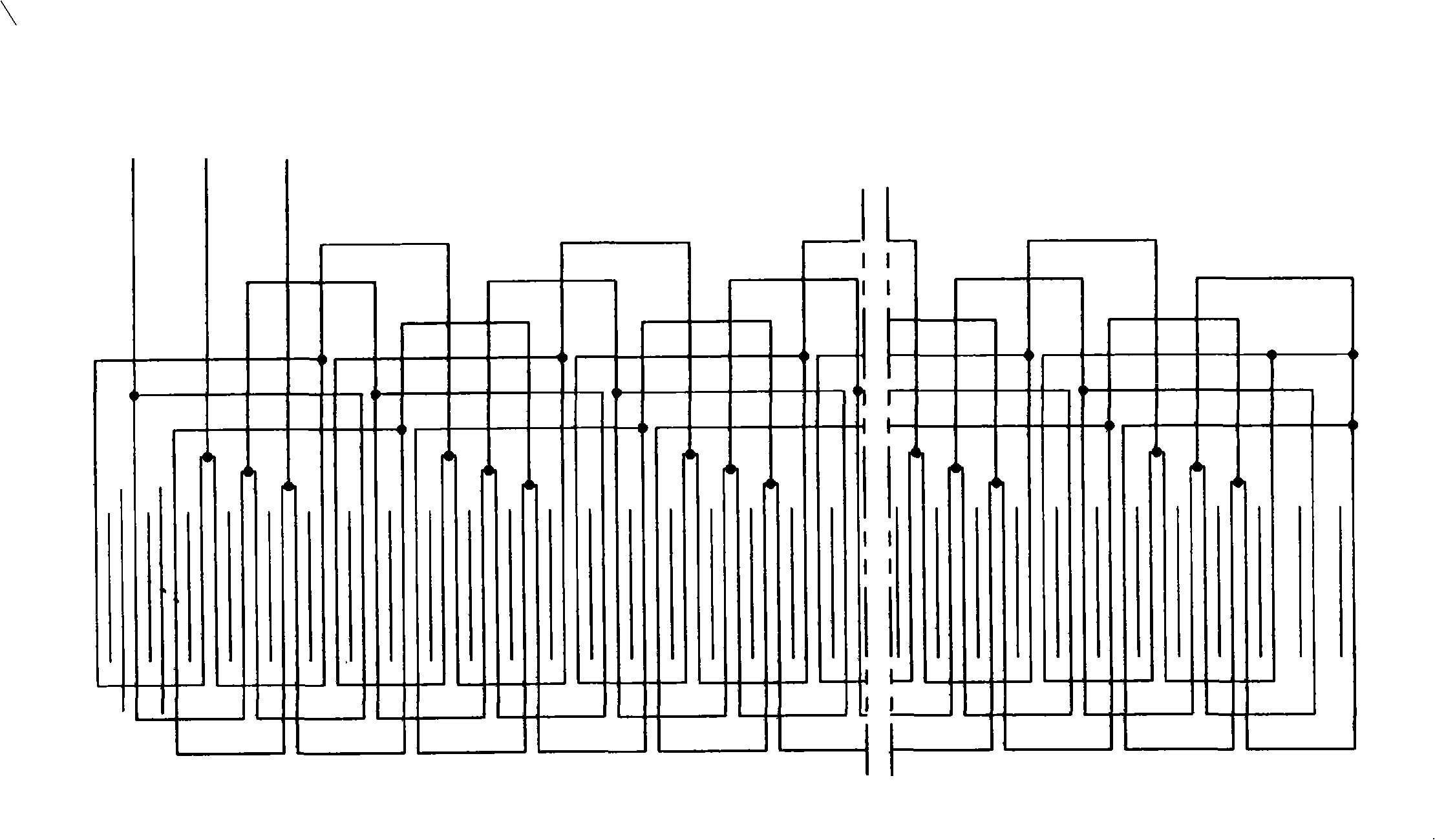

Conductor section and stator assembly with same, and motor

InactiveCN109586445AReduces the risk of scratching the paintwork of adjacent copper wiresDoes not affect altitudeWindings conductor shape/form/constructionElectrical conductorEngineering

The invention provides a conductor section and a stator assembly with the same, and a motor. The conductor sections are adapted to be inserted into the same slot layer of different stator slots of a stator core; each conductor section is formed in a general U-shaped shape and comprises a bending portion, and a first groove inner portion and a second groove inner portion which are connected to thebending portion separately; the end part of the first groove inner portion is connected with a first welding part; the end part of the second groove inner portion is connected with a second welding part, wherein the free ends of the first welding part and the second welding part are both provided with chamfering parts; the bending part comprises a first layer section, a second layer section, and aconnecting section connected between the first layer section and the second layer section, wherein one of the first layer section and the second layer section is twisted, relative to the connecting section, in the radial direction of the stator assembly, or the first layer section and the second layer section are twisted, relative to the connecting section, in a direction opposite to the radial direction of the stator assembly separately. According to the conductor section provided by the embodiments of the invention, the offline is reliable, and the welding is convenient.

Owner:BYD CO LTD

Conductor section and stator assembly with same, and motor

InactiveCN109586448AImprove reliabilityEasy to weldWindings insulation shape/form/constructionMagnetic circuit stationary partsElectrical conductorWelding

The invention provides a conductor section and a stator assembly with the same, and a motor. The conductor sections are adapted to be inserted into the same slot layer of different stator slots of a stator core; each conductor section is formed in a general U-shaped shape and comprises a bending portion, and a first groove inner portion and a second groove inner portion which are connected to thebending portion separately; the end part of the first groove inner portion is connected with a first welding part; and the end part of the second groove inner portion is connected with a second welding part, wherein the free ends of the first welding part and the second welding part are both provided with chamfering parts. According to the conductor section provided by the embodiments of the invention, the offline is reliable, and the welding is convenient.

Owner:BYD CO LTD

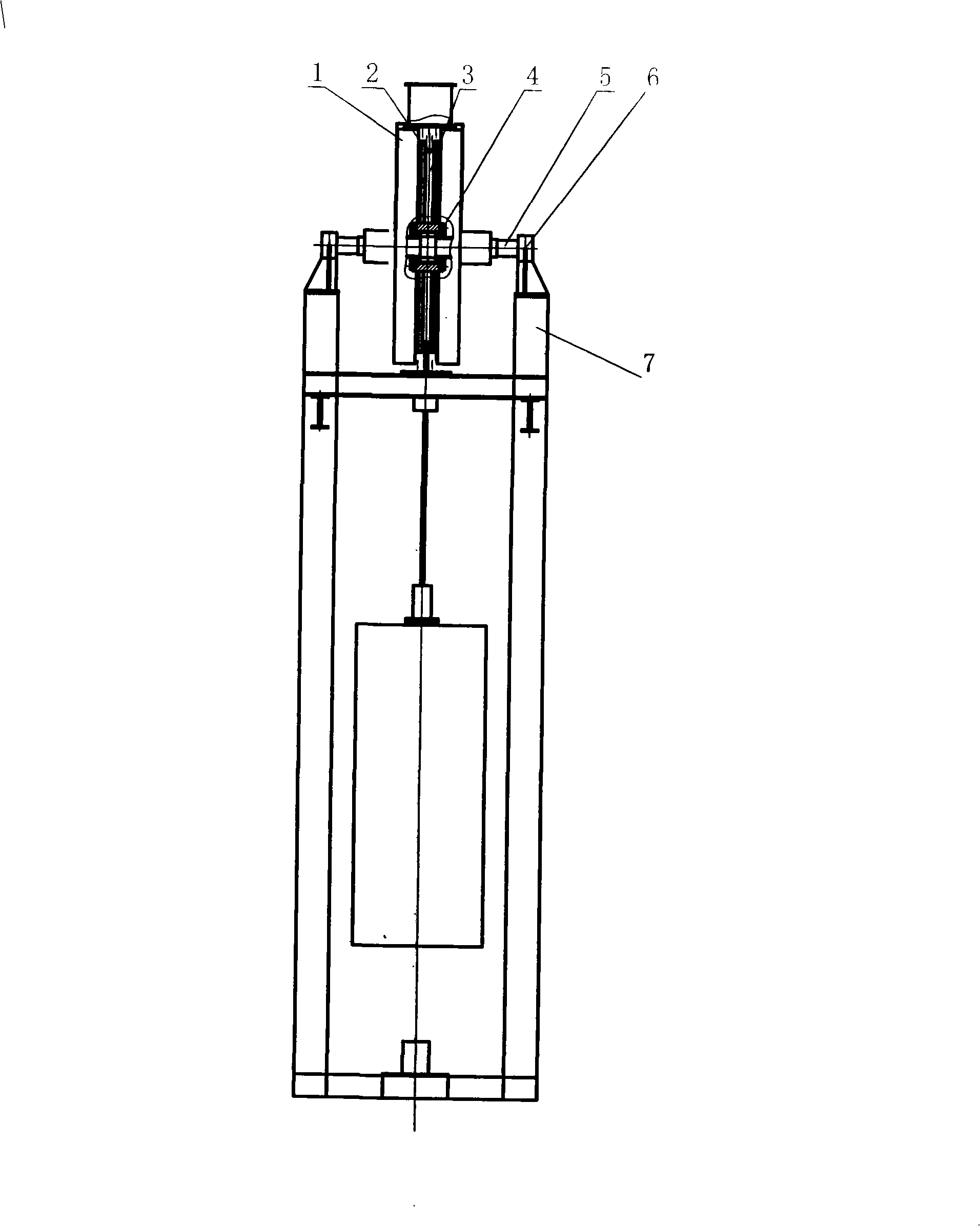

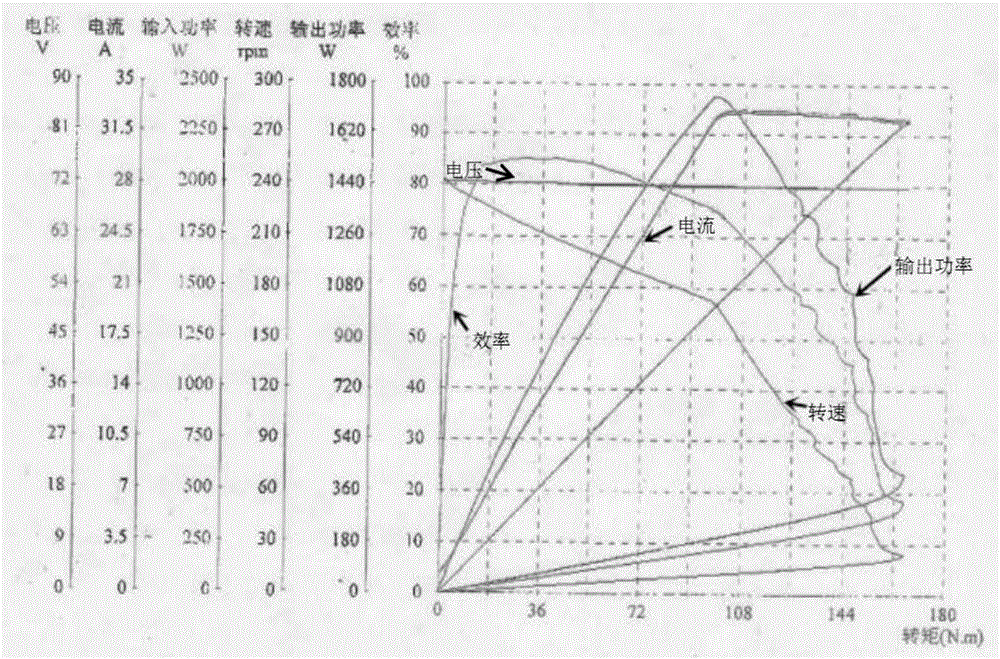

Circular disc permanent magnetism wind water double cold linear motor oil pumping machine

ActiveCN101289930AStroke can be adjusted freelyReasonable forceFluid removalPropulsion systemsCircular discRolling-element bearing

The invention relates to a pumping unit with a disk permanent magnet water-cooled and air-cooled linear motor. Two sides of a rope pulley are respectively provided with a set of disk permanent magnetic water-cooled and air-cooled synchronous three-phase linear motor drive set the primary of which is a stator, the secondary of which is a motor and the secondary is a permanent magnet; the motor adopts water-cooled and air-cooled motor. The secondary is respectively fixed on the two sides of the rope pulley to form a whole; the primary is fixed on the same shaft outside the secondary; a gap is arranged between the primary and the secondary; the primary drives the secondary which drives the rope pulley to rotate; an inner hole of the rope pulley is provided with a rolling bearing; an outer sleeve of the bearing is rotated along with the rope pulley; and an inner sleeve of the bearing is fixed with the shaft. The pumping unit has the advantages of simple structure, multi-pole, low rotating speed, big torque, no environmental pollution, no lubricant, long service life, convenient maintenance, few replaceable parts and easy matching.

Owner:HENGDA ELECTRIC MACHINE GROUP WEIHAI

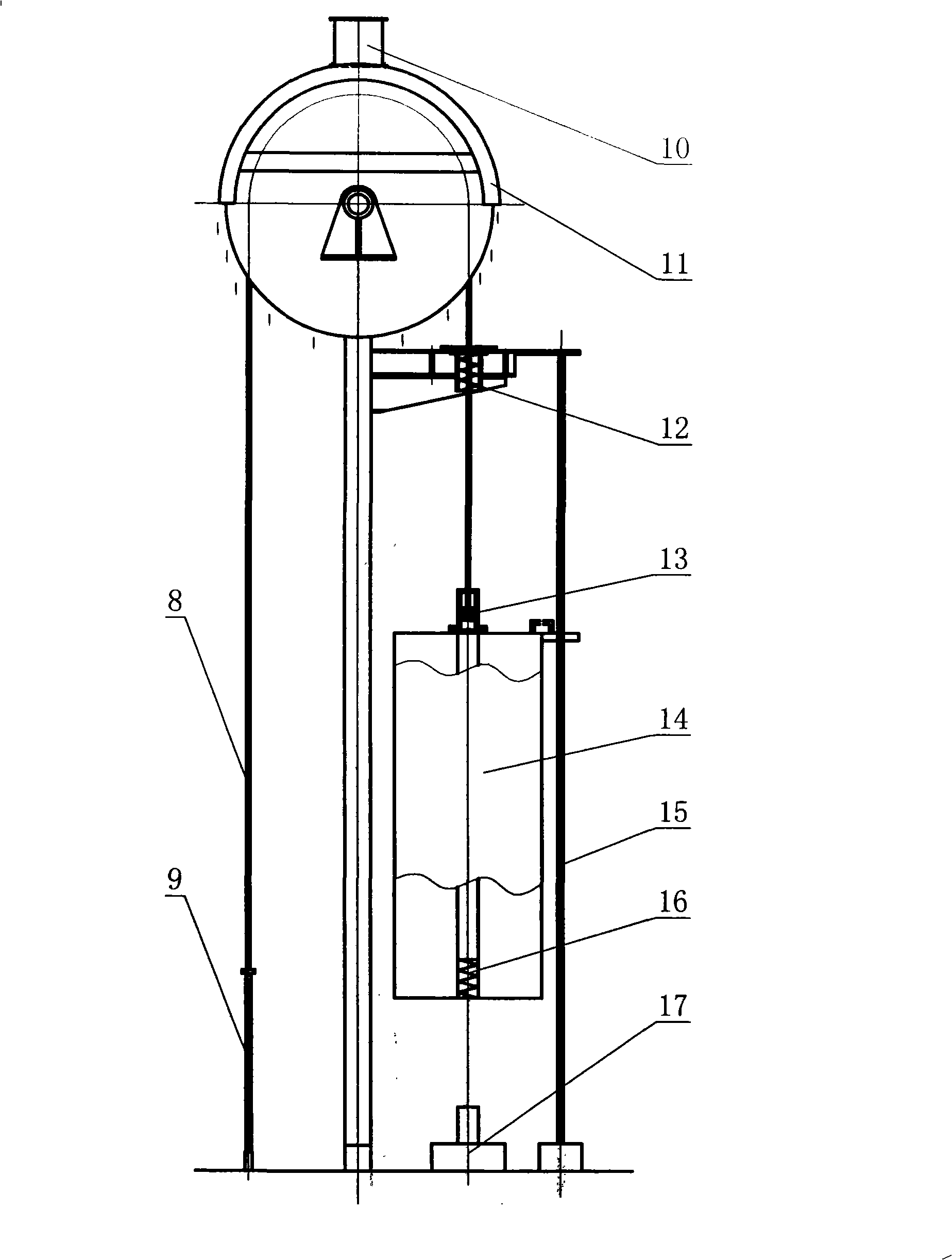

Linear-rotating low-speed cylinder power generator

ActiveCN112865348AReduce processing difficultyLow costReciprocating/oscillating/vibrating magnetic circuit partsMagnetic circuit rotating partsWave power generationElectric machine

The invention discloses a linear-rotating low-speed cylinder motor, and relates to a motor technology suitable for low-speed wave power generation. The linear-rotating low-speed cylinder power generator comprises a stator, a rotor and a mover which are installed from outside to inside and are mutually separated by air gaps, wherein the stator comprises a stator iron core formed by laminating a plurality of U-shaped silicon steel sheets, stator permanent magnets inserted into the middles of the stator iron cores and radially and alternately magnetized along the circumference, and stator windings wound on the stator iron cores and the stator permanent magnets, the rotor comprises a plurality of discrete rotor iron cores, rotor permanent magnets alternately magnetized in the radial direction are attached to the inner wall of each rotor iron core, the mover is made of a whole soft magnetic material, and a plurality of convex teeth distributed in the axial direction are arranged on the peripheral wall face of the mover. Compared with a traditional cylinder motor, the motor of the invention is simple in heat dissipation and machining, longer in stroke and lower in cost, particularly, the flux linkage frequency of a turn chain in the stator winding is higher than the linear motion frequency of the rotor, and the frequency amplification function is achieved.

Owner:ZHEJIANG UNIV

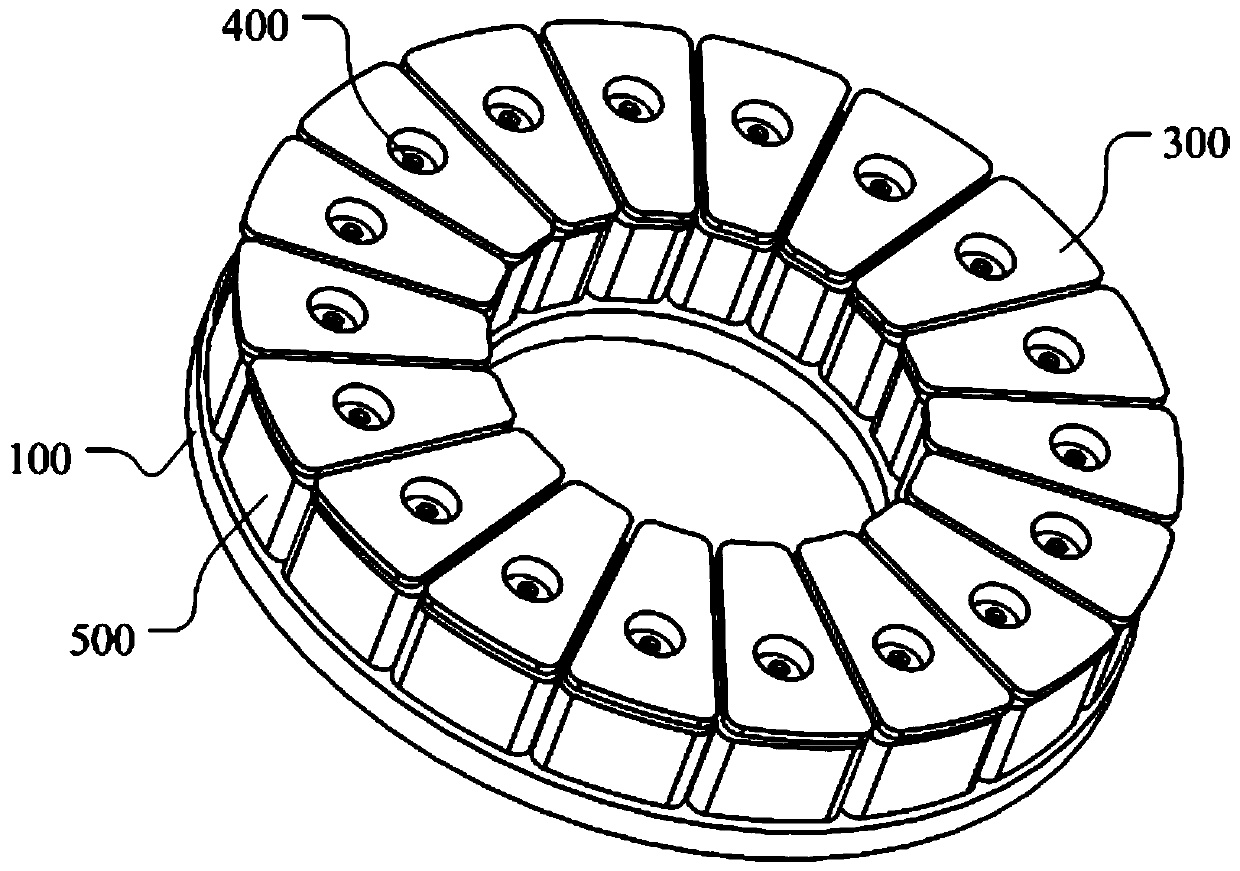

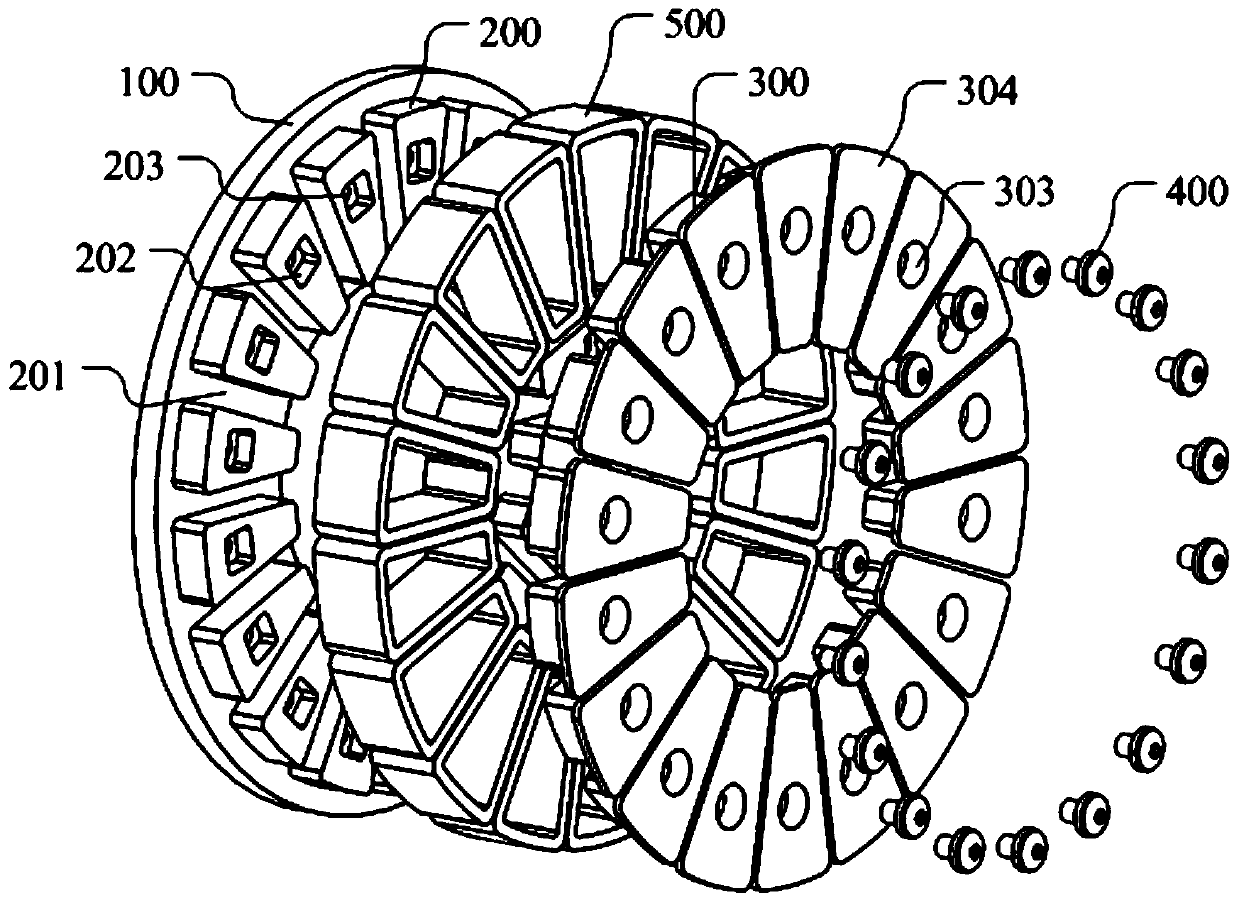

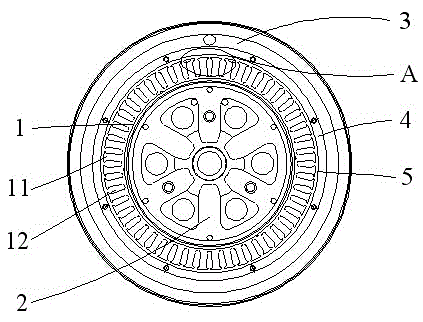

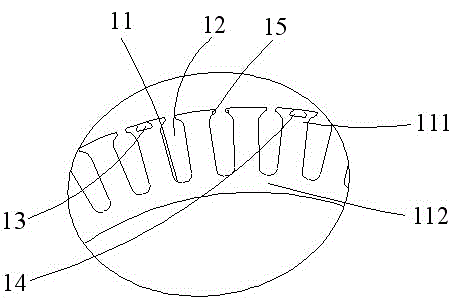

Disk-type iron core and disk-type motor

PendingCN110474452AEasy offlineReduce the difficulty of assemblyWindingsMagnetic circuit stationary partsNuclear engineeringConductor Coil

Owner:SHANGHAI PANGOOD POWER TECH CO LTD

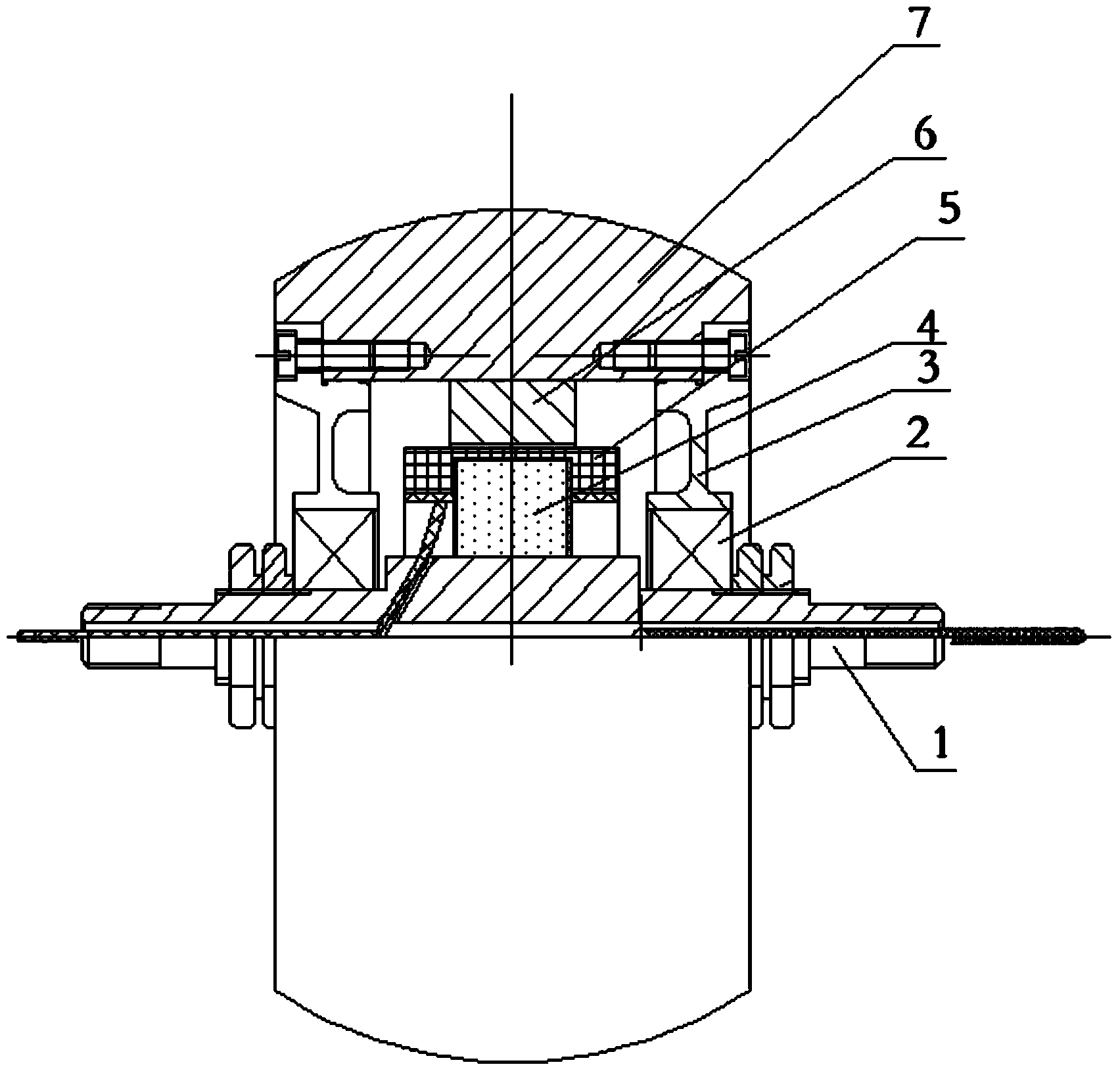

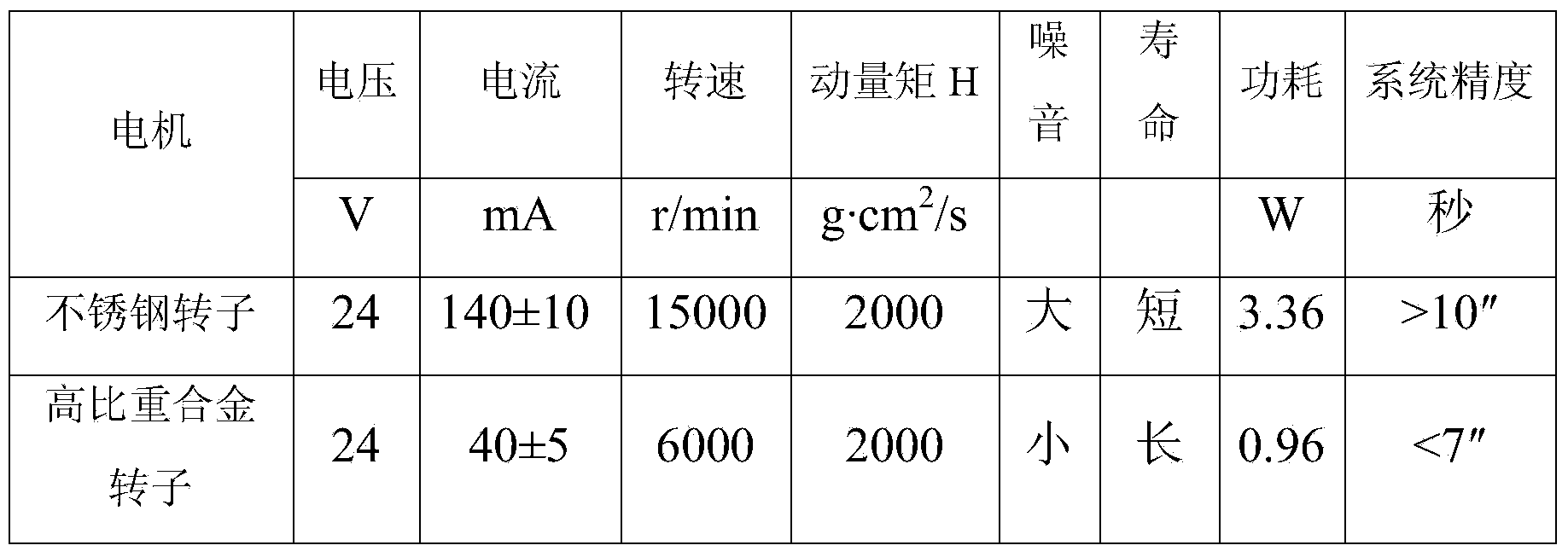

High-specific-gravity permanent magnet brushless direct-current gyro motor

InactiveCN103633804AEasy offlineSimple control circuitMagnetic circuit rotating partsMagnetic circuit stationary partsSpecific gravityPhysics

The invention provides a high-specific-gravity permanent magnet brushless direct-current gyro motor which comprises a rotor component and a stator component. The stator component comprises a stator coil, a stator magnetic core and a shaft. The stator magnetic core is disposed on the boss in the middle of the shaft. The stator coil is disposed on the excircle of the stator magnetic core. The rotor component comprises a rotor ring, a magnetic steel component and an end cover. The rotor magnetic steel component is disposed outside the stator coil. The rotor ring is disposed on the excircle of the rotor magnetic steel component. Bearing inner rings are sleeved on two sides of the boss of the shaft. A bearing outer ring is disposed on an end cover. The high-specific-gravity permanent magnet brushless direct-current gyro motor has the advantages that the rotor ring is made by tungsten-based high-specific-gravity alloy so as to increase the rotational inertia of a rotor and lower the rotation speed of the motor under the set angular momentum value; soft magnetic ferrite is high in resistivity, low in eddy current loss, and low in magnetic loss; the stator magnetic core without an inserting coil slot is free of slot effect, and the motor is stable in operation and low in noise; the two-phase brushless direct-current motor using counter potential control is low in power consumption, stable in rotation speed, low in noise, long in service life and applicable to high-temperature and low-temperature environments.

Owner:TIANJIN LUHANG MOTOR TECH

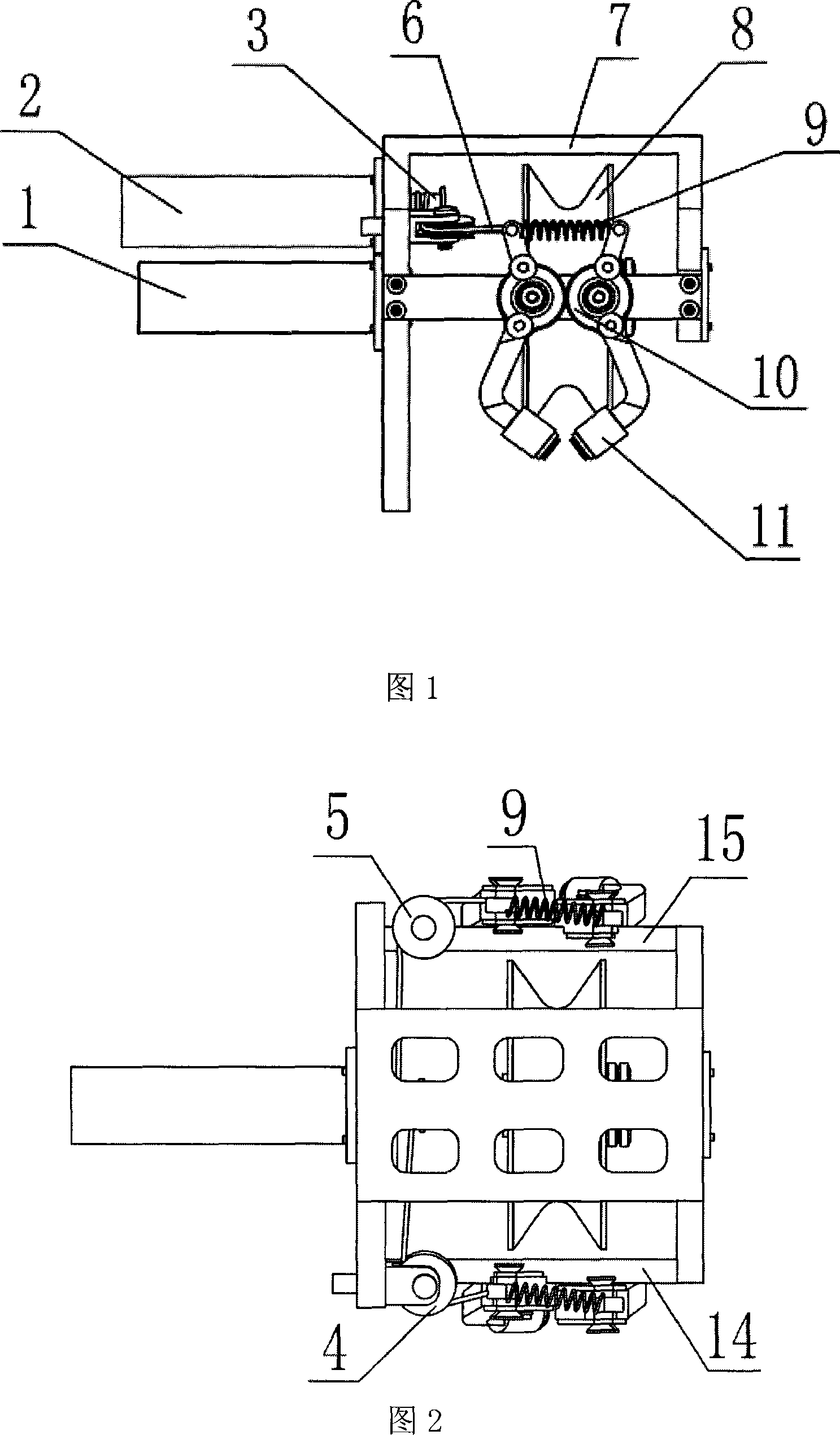

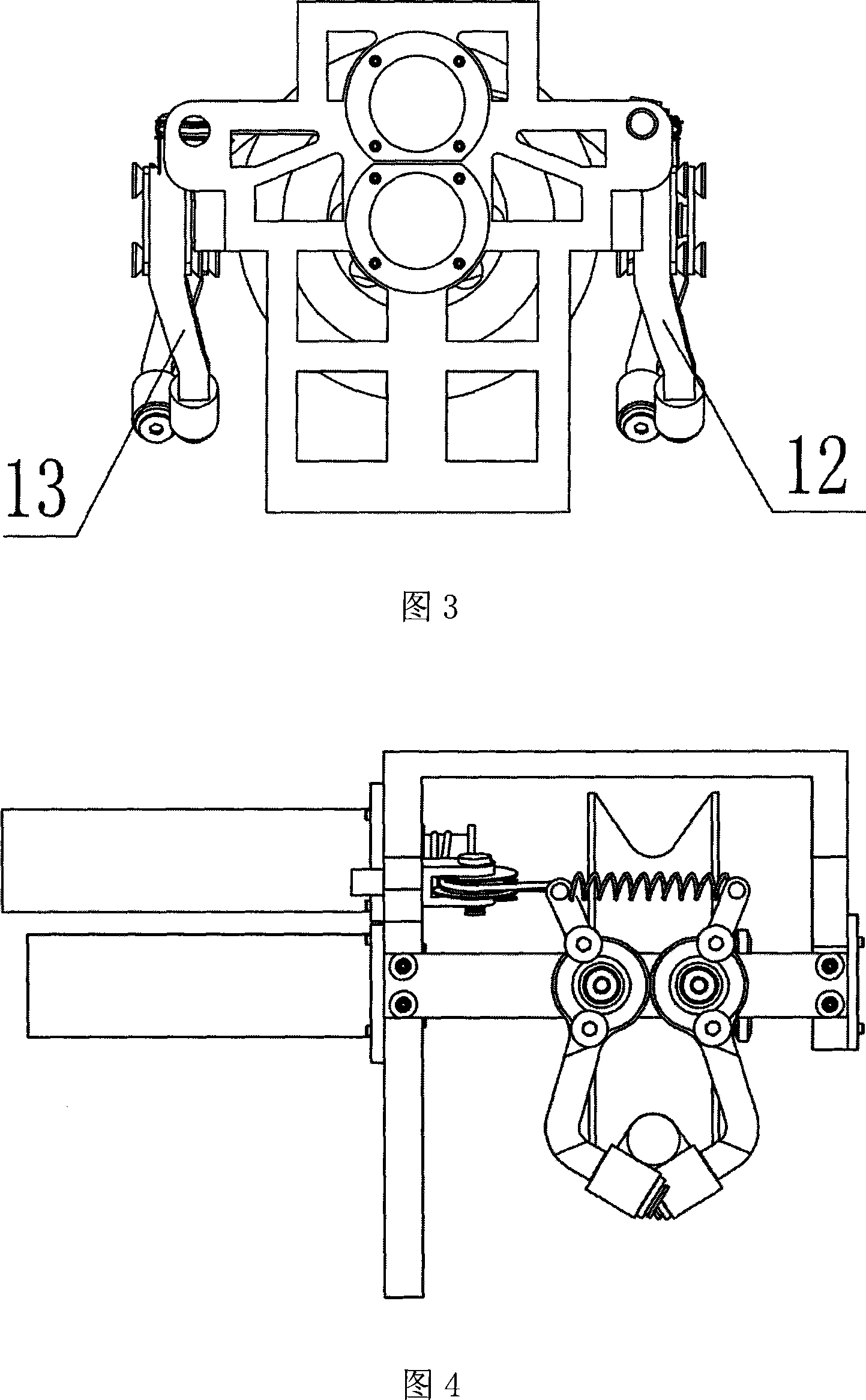

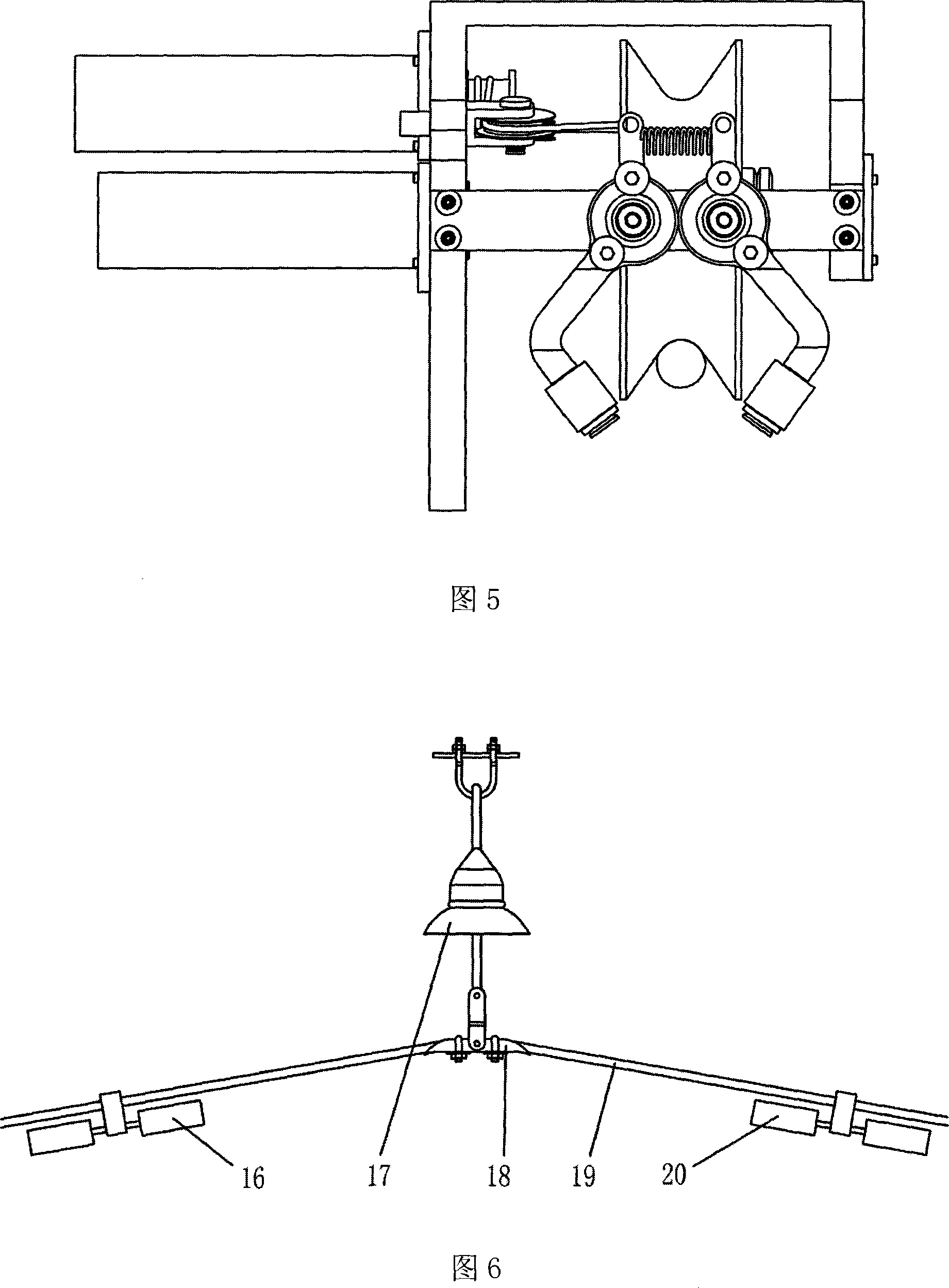

Gripper mechanism with fault release function for walking of patrolling robot

ActiveCN101471546BEasy to walkImprove protectionManipulatorApparatus for overhead lines/cablesPulleyPower transmission

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

Permanent-magnet brushless direct-current hub motor having high efficiency and low material loss for electric vehicle

ActiveCN105099111AImprove conversion efficiencyIncrease profitSynchronous machine detailsElectric machinesEngineeringElectric vehicle

A permanent-magnet brushless direct-current hub motor having high efficiency and low material loss for an electric vehicle comprises a stator assembly and a rotor assembly, wherein the stator assembly comprises a fixed support and a stacked stator steel sheet, the stacked stator steel sheet is formed by laminating a plurality of silicon steel sheets and comprises tooth parts and a tooth groove part, the tooth part comprise tooth ribs and a tooth yoke, the tooth groove part is composed of a semi-closing inner cavity formed between every two tooth parts, a single silicon steel sheet is provided with an automatic-buckling groove, the tooth groove part is of a semi-closing pear-shaped groove structure, a first Hall groove, a second Hall groove and a third Hall groove are arranged on the stacked stator steel sheet, and the stator assembly comprises a rim arranged at the periphery, a magnetic conduction ring and a plurality of magnetic steel sheets. By the permanent-magnet brushless direct-current hub motor, the pole groove ratio is optimized, the performance is improved, the usage of magnetic steel and an enameled wire is reduced, cost is saved, the installation positions of the Hall grooves and the winding mode are optimized, the production efficiency is improved, and the installation accuracy is enhanced.

Owner:TAIZHOU JINYU ELECTROMECHANICAL

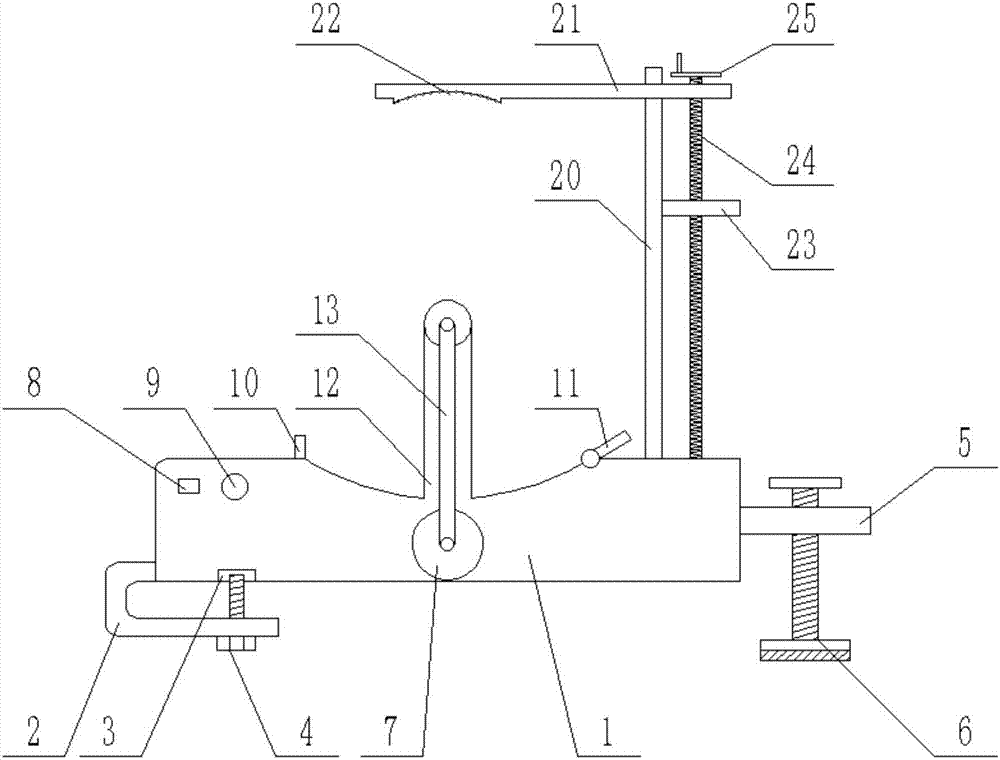

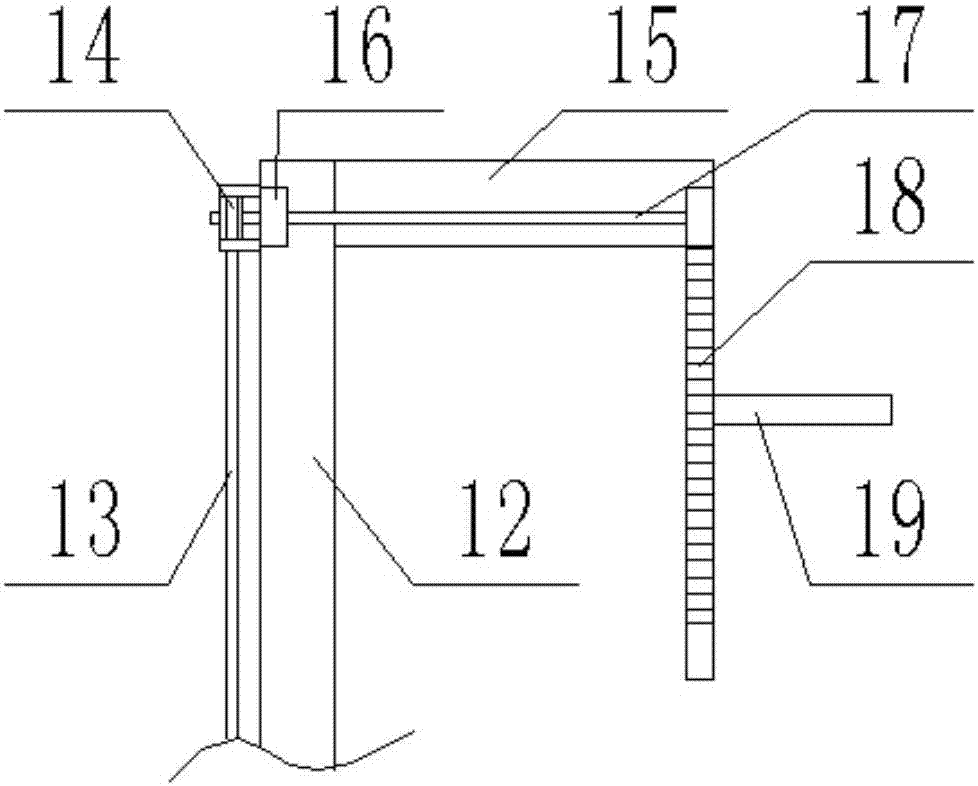

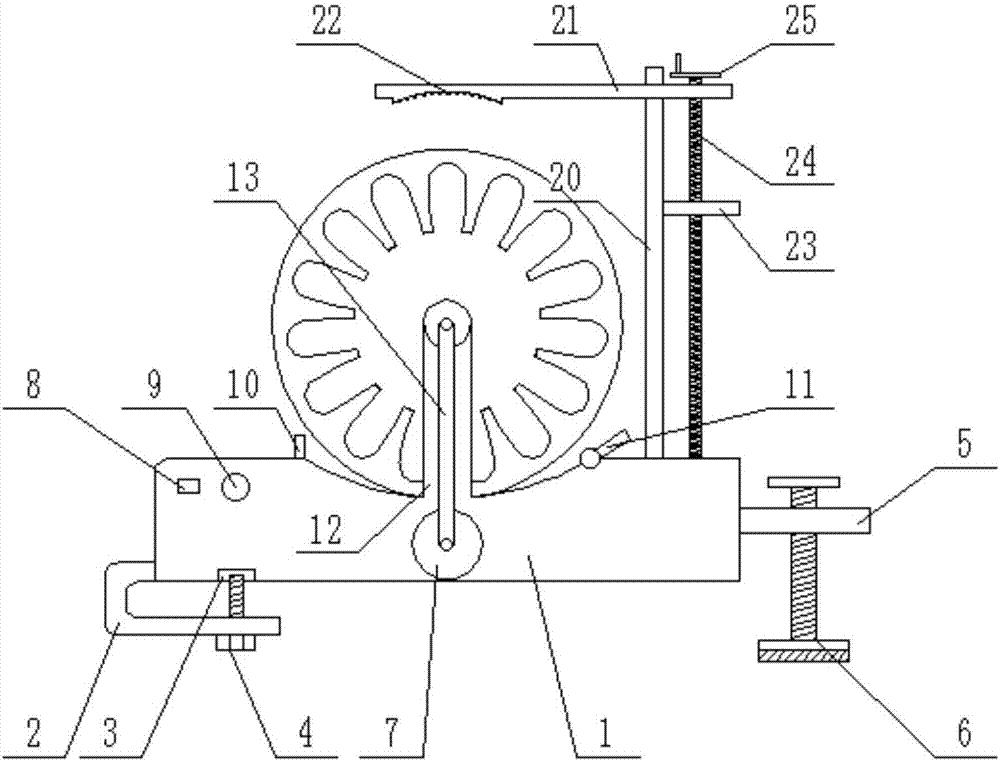

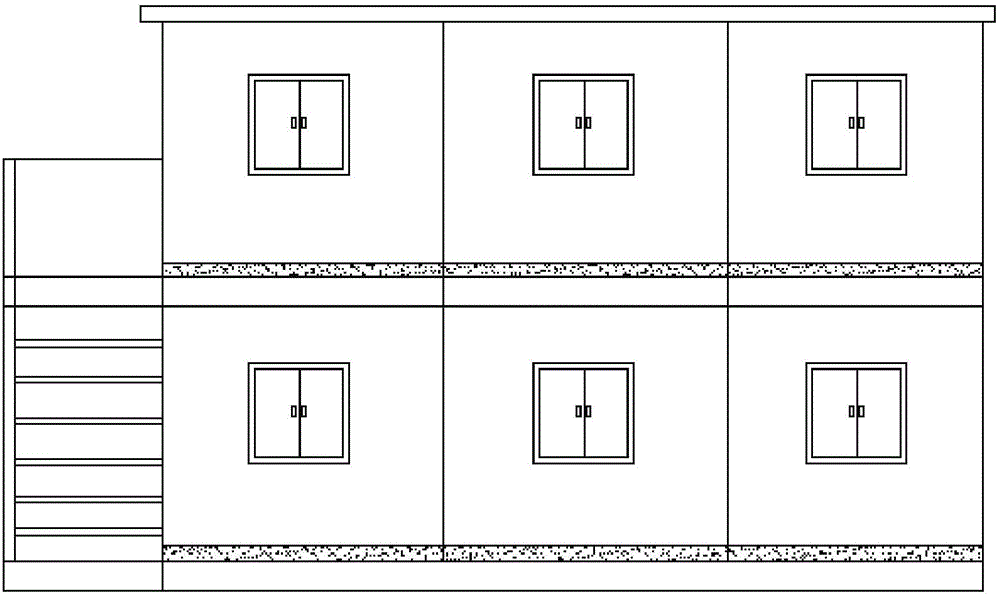

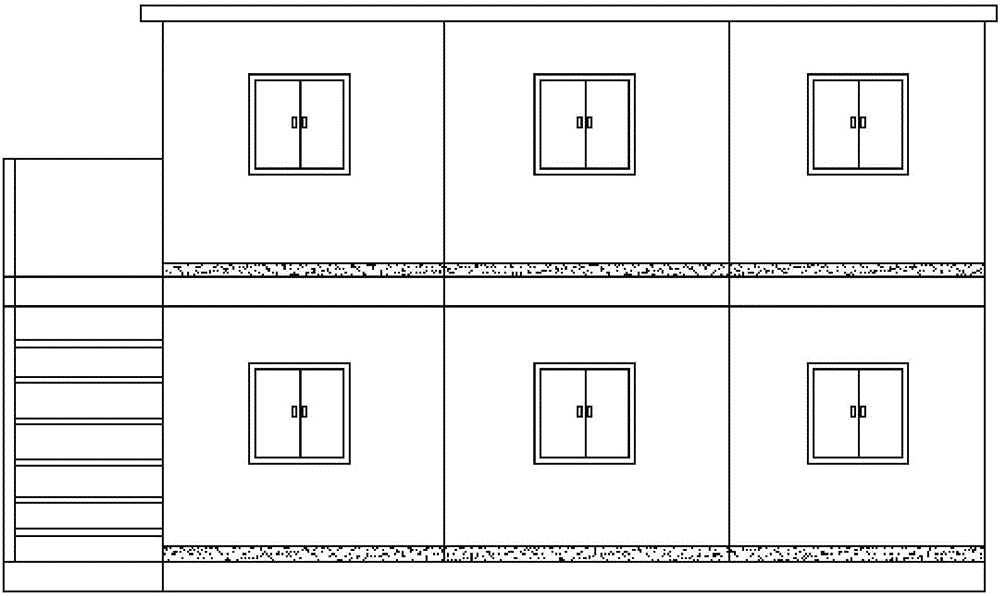

Winding installation device for production of motor of cutter for clearing up road hedges

InactiveCN107498460AEasy offlineReduce labor intensityGrinding machinesGrinding feedersElectric machineryEngineering

The invention discloses a cutting machine motor production off-line device for road hedge cleaning, which comprises a device body, a base is arranged at the bottom of the device body, a fixed block is arranged on the right side of the base, and a rotating pressing block is arranged on the fixed block , an off-line structure is set above the base, a stepping motor is set inside the base, a jog button and a speed control knob are set on the base, a limit support rod is set on the upper right of the base, and a limit support rod is set on the limit support rod. Pressing plate, the end of the limiting pressing plate is provided with an arc-shaped groove, the right side of the limiting supporting rod is provided with a screw rod, and the top of the limiting pressing plate is provided with a rocking wheel; the present invention is simple in structure, easy to use, and reduces work The labor intensity of personnel, fast off-line speed, high work efficiency, and less damage to the paint film, and the stator with a high slot full rate is also very convenient to off-line, avoiding waste, saving a lot of resources and reducing costs.

Owner:景学良

Low Rare Earth Wide Speed Hybrid Permanent Magnet Flux Switching Double Stator Motor

ActiveCN105375715BSolve the problem of mutual limitation of dosageImprove cooling effectMagnetic circuit stationary partsMagnetic circuit characterised by magnetic materialsMagnetizationTorque density

Owner:JIANGSU UNIV

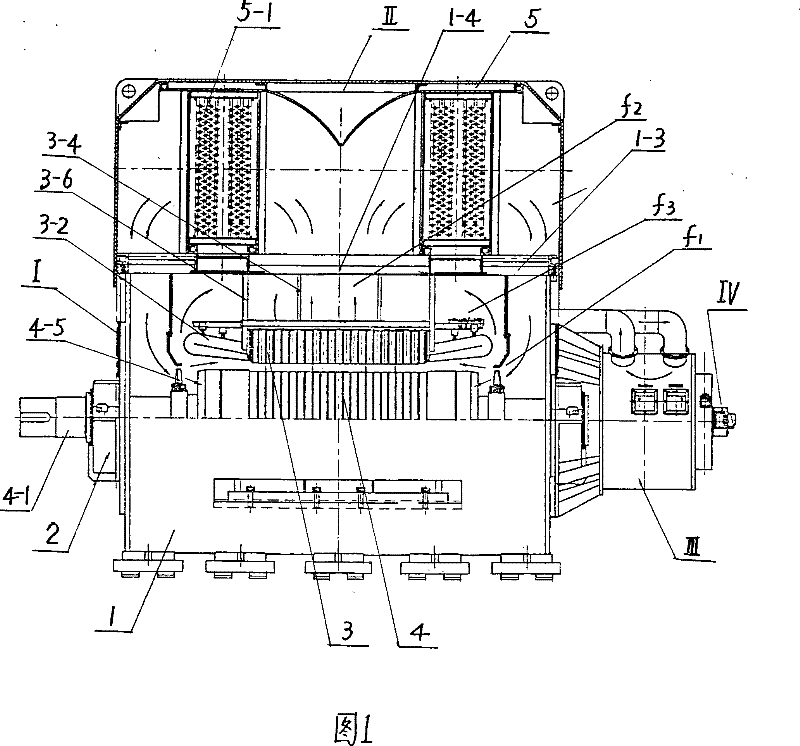

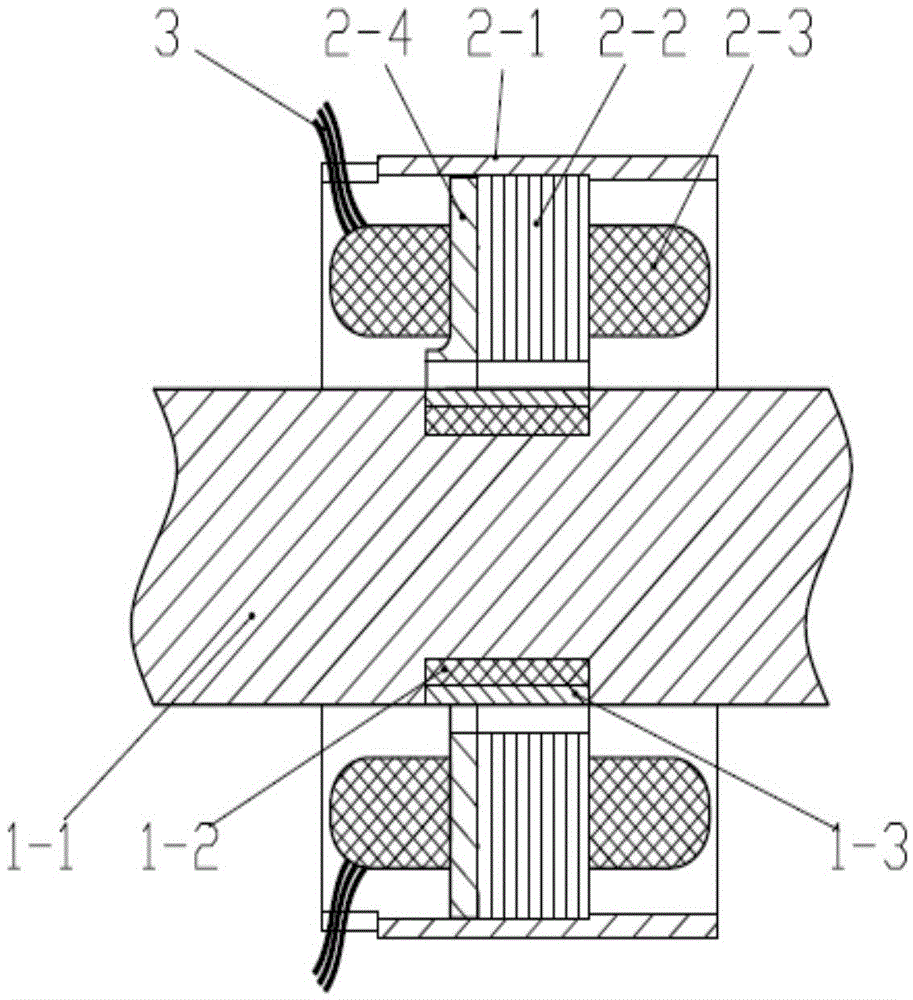

High-capacity non-salient pole nest plate type synchronous generator

ActiveCN101227129BEasy offlineGuaranteed accuracySynchronous generatorsMagnetic circuit rotating partsPower flowDynamo

The invention relates to a large capacity non-salient pole plate fine type synchronous generator, which is characterized in that a main generator is provided with a stator which is sleeved with a motor base split unit and a rotor which is connected with a motor base through an end cover bearing, an exciting end of a rotor rotating shaft is provided with a brushless excitation system with a high pole number, the tail end of the system is connected with a grounding detecting device, and a cooling system comprises a cooling device which is positioned on the main generator, four ducted cooling paths which circulate in multiply return circuits and are formed by a stator ventilating circuit, a rotor ventilating circuit, an air gas ventilating circuit and an exciting dynamo ventilating circuit of the main generator. The generator has the advantages of reasonable design of the whole system, compact structure, complete function of each portion, convenient installation and maintenance, reliableoperating property, high quality of voltage and electric current which are produced and the like, which saves manufacturing cost.

Owner:WOLONG ELECTRIC NANYANG EXPLOSION PROTECTION GRP CO LTD

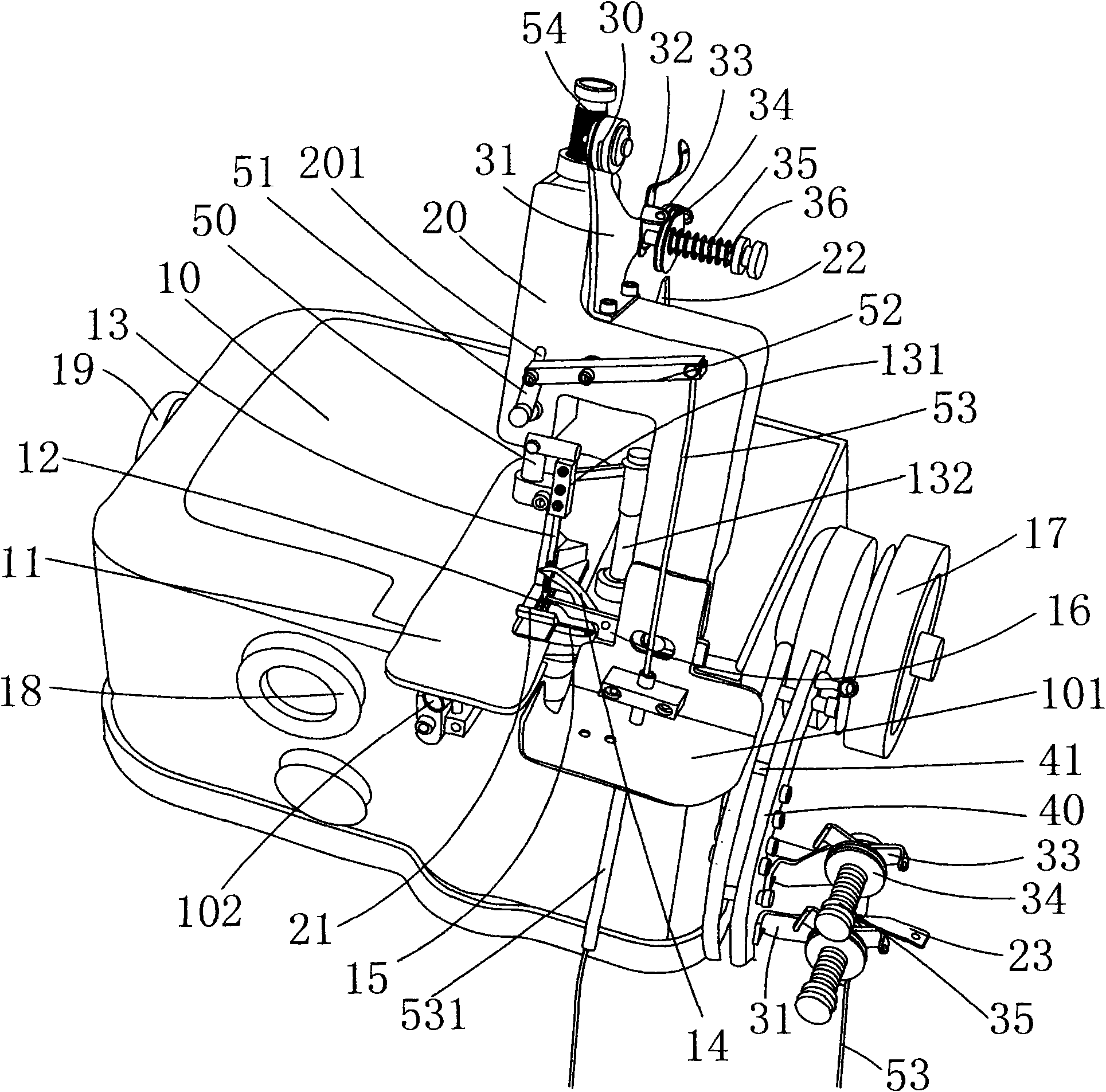

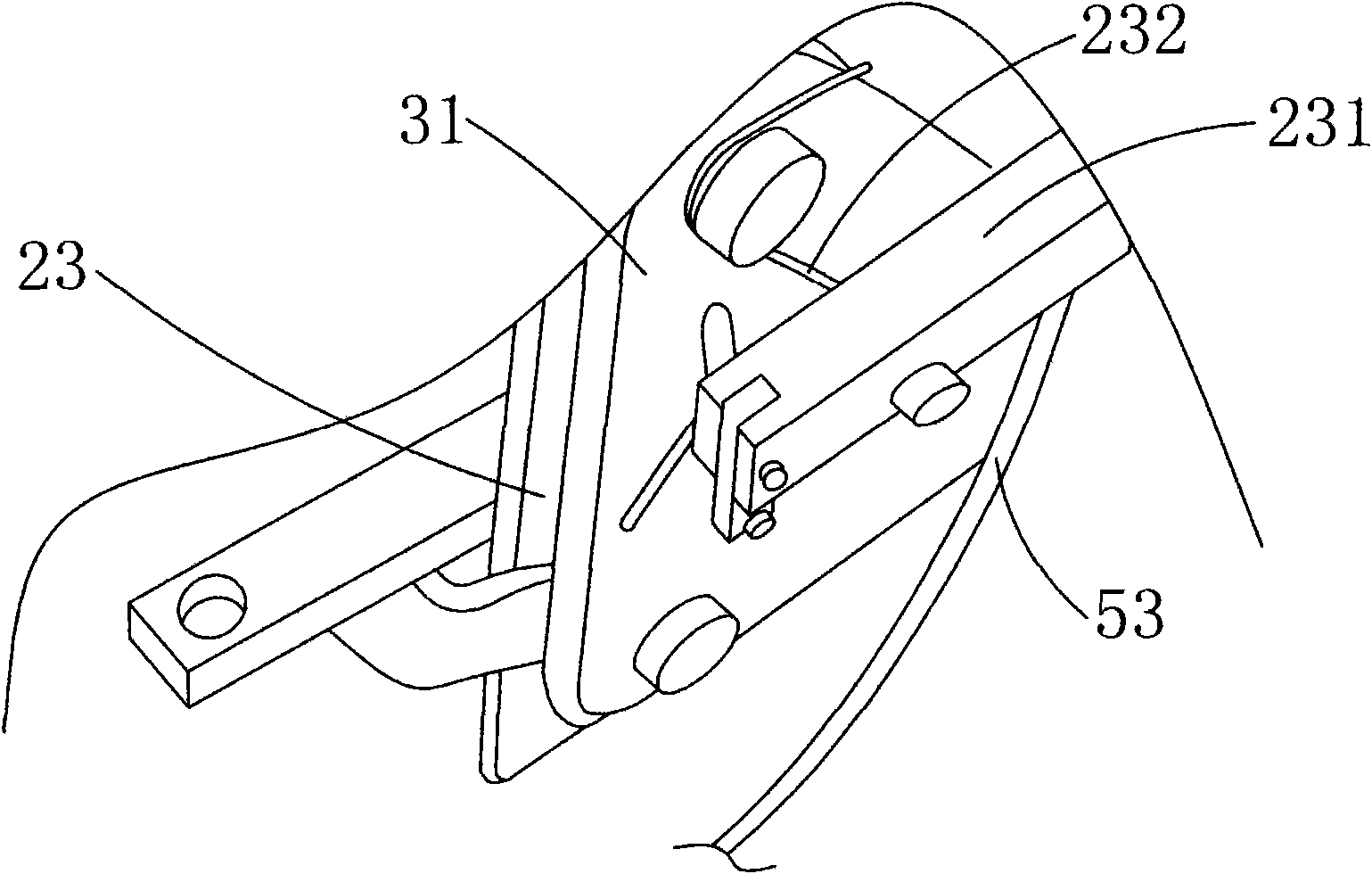

Carpet overedge machine head

InactiveCN102011273ASmall footprintSolve the lack of spaceSewing-machine control devicesPressersBiomedical engineeringCrankshaft

The invention discloses a carpet overedge machine head, which comprises a cabinet, a base, a transmission crankshaft, a needle plate, cloth feeding teeth, a needle, an upper bent needle, a lower bent needle, an upper threading device and a lower threading device. A baffle capable of adjusting the edge width is arranged on the cabinet; a belt pulley matched with the transmission crankshaft, an oil inlet, a needle pitch adjuster and the lower threading device are arranged on a side surface of the cabinet; the needle plate and the cloth feeding teeth are arranged on an upper end face of the cabinet; the cloth feeding teeth are matched with the needle plate; the needle is matched with the transmission crankshaft through a needle clamp and a telescopic rod; the upper and lower bent needles are connected with the transmission crankshaft respectively and are in synchronous cross motion; the upper threading device, a presser foot lifter device and a presser foot are arranged on the base; and the presser foot is matched with the needle plate and the cloth feeding teeth. The invention has the advantages that: the carpet overedge machine head is simple in structure, the base occupies small space, and radian leathers and thread fabrics have an enough movable space in the process of sewing the radian leathers and thread fabrics; and the upper and lower threading devices are provided with matched thread releasing devices so as to be convenient to use.

Owner:吴新华

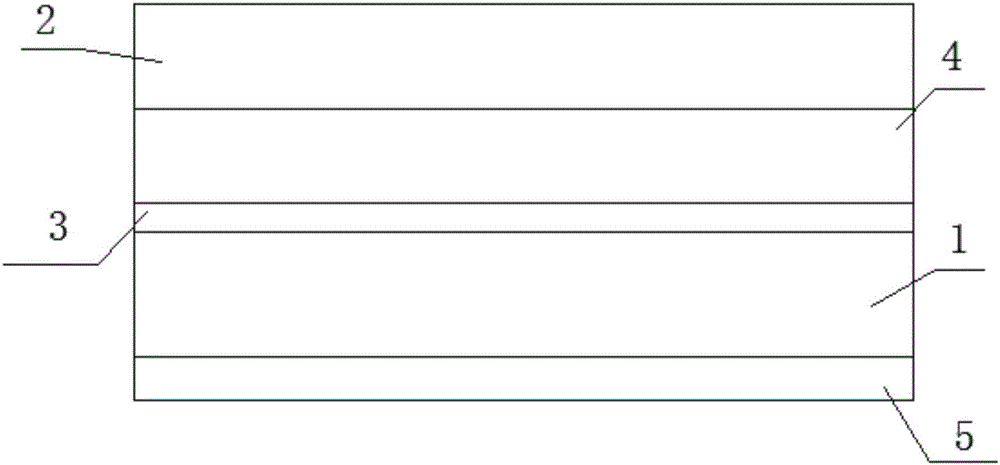

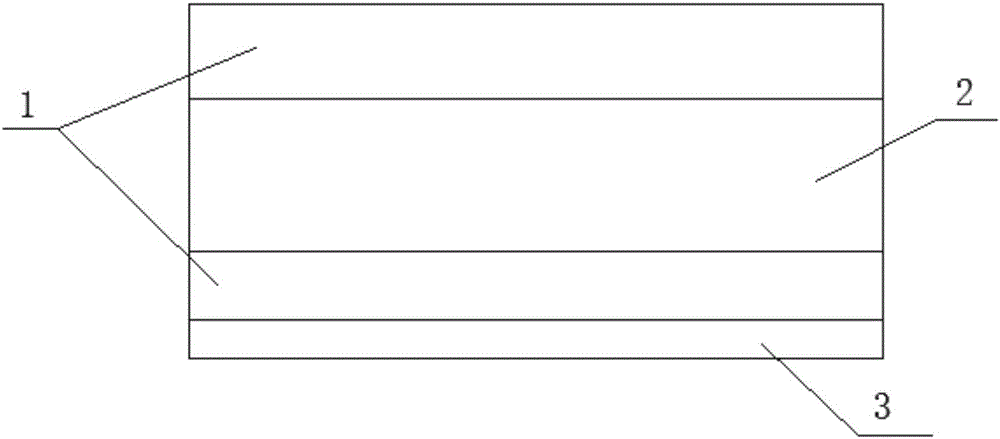

Novel container fireproof and dampproof floor

InactiveCN106639233AReduce weightHigh mechanical strengthCovering/liningsSynthetic resin layered productsEngineeringAir tightness

The invention discloses a novel container fireproof and dampproof floor. The floor comprises a middle material layer, a waterproof layer and a surface pulp layer which are sequentially connected from bottom to top, a mixing layer is arranged between the waterproof layer and the surface pulp layer, and an aluminum foil layer is arranged at the lower portion of the middle material layer. The floor is simple in overall structure and is made of light materials and formed by compositing various materials, thereby having many functions. The aluminum foil layer adopts soft aluminum foil as raw materials of an aluminum foil layer, and the soft aluminum foil has the advantages of being high in mechanical strength, low in weight, free of heat adhesion, not likely to be corroded, good in barrier property, dampproof, waterproof, high in air impermeability and the like.

Owner:张家港市盛港绿色防火建材有限公司

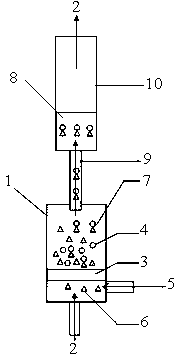

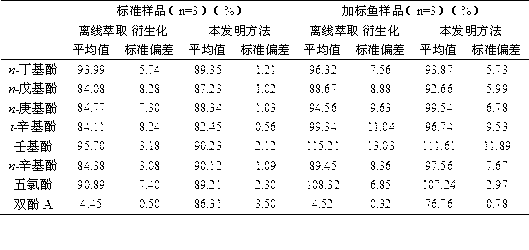

Air-flowing type dynamic liquid-phase micro-extracting method for online derivatization

InactiveCN103245544AAvoid decompositionDoes not increase extraction timePreparing sample for investigationSolventPre treatment

The invention discloses an air-flowing type dynamic liquid-phase micro-extracting method for online derivatization. The air-flowing type dynamic liquid-phase micro-extracting method comprises the following steps of: introducing a derivatization reagent to an extracting system when air-flowing type dynamic liquid-phase micro-extracting is carried out on a sample, so that a substance to be tested is quickly subjected to a derivatization reaction in an extracting process; and completing a sample pre-treatment process when a derivatization product enters an extract phase. The air-flowing type dynamic liquid-phase micro-extracting method for online derivatization is a novel sample pre-treatment method which is highly integrated on the basis of the original air-flowing type dynamic liquid-phase micro-extracting method. Compared with the original air-flowing type dynamic liquid-phase micro-extracting method, the air-flowing type dynamic liquid-phase micro-extracting method disclosed by the invention can be used for simplifying the two-step process including extraction and derivatization onto one step, and can be used for the substance which is easy to thermally decompose and is difficult to extract by adopting the original technology. Compared with other derivatization reaction, the derivatization reaction in the air-flowing type dynamic liquid-phase micro-extracting method can be carried out without an independent step and solvent condition. Moreover, the whole technology has the characteristics of being simple to operate, quick, on-line, efficient, integrated, easy to link with a chromatographic system and capable of analyzing in a quantitative manner.

Owner:YANBIAN UNIV

Dual-power brushless DC motor

PendingCN106787312ARealize powerless switchingIncrease full rateMagnetic circuit rotating partsMagnetic circuit stationary partsLow noisePermanent magnet rotor

The invention discloses a dual-power brushless DC motor comprising at least two motor drive units. Each motor drive unit comprises a stator core, a permanent-magnet rotor, a Hall sensor, a relay, a controller and a battery. Multiple teeth which are of the same structure and used for winding are arranged on the stator cores along the circumference. Windings of which the at least three phases are in same phase angle distribution relative to each other are wound on the teeth. The windings of each phase are wound in turn on the multiple stator cores to form multiple layer structures. The in-phase windings in the same layer are connected in series. The in-phase windings in two adjacent layers are connected end to end. Connectors lead out by the multi-phase windings in the last layer are connected to form a tail end. Connectors lead out by the multi-phase windings in the first layer are connected with alternating current to form an input end for driving the multi-phase windings in at least one layer to work. The torque and mileage of the dual-power brushless DC motor of the invention are 40-50% higher than those of a single-power motor. The dual-power brushless DC motor has the advantages of high torque, low temperature rise, low noise and long mileage, and is in line with the industry technical standard.

Owner:广西南宁凯得利电子科技有限公司

Integral non-hooking sparking plug for electric trolley bus

InactiveCN104325889AIncrease freedomEasy to hang up the linePower current collectorsElectrical conductorPower cable

The invention discloses an automatic hanging sparking plug for use in running of an electric trolley bus. The automatic hanging sparking plug is characterized in that an integral enclosed non-hooking design is adopted; two conducting transverse rods are taken as sparking plug conductors, and are connected through a convex insulating cap; the outer ends of the conducting transverse rods are connected with a wiring rod through insulating brackets, thereby forming an enclosed triangle; a conducting transverse rod groove of a certain width is formed between the insulating brackets extending upwards from both sides of the sparking plug and the insulating cap projecting in the middle. Wire hanging can be performed conveniently by correcting the electric trolley bus below a power cable, lifting the wiring rod and putting the insulating cap in the middle of the sparking plug between two power cables in a sleeving manner; on the contrary, the wires can be separated easily by descending the wiring rod. The integral enclosed non-hooking design is adopted for the sparking plug, so that an electric wire is prevented from being hooked even hanging fails. The automatic hanging sparking plug has the beneficial effects that once the integral automatic hanging sparking plug is arranged on the electric trolley bus, hanging and separation running can be performed conveniently without worrying about the problem of falling of the electric wire or damage to the electric wire by hooking. Therefore, the degree of freedom of running of the electric trolley bus is greatly increased, the application range is expanded, an open type electric road net is built, and various passenger cars, trucks and saloon cars can be modified into electric vehicles or hybrid power vehicles.

Owner:朱大碌

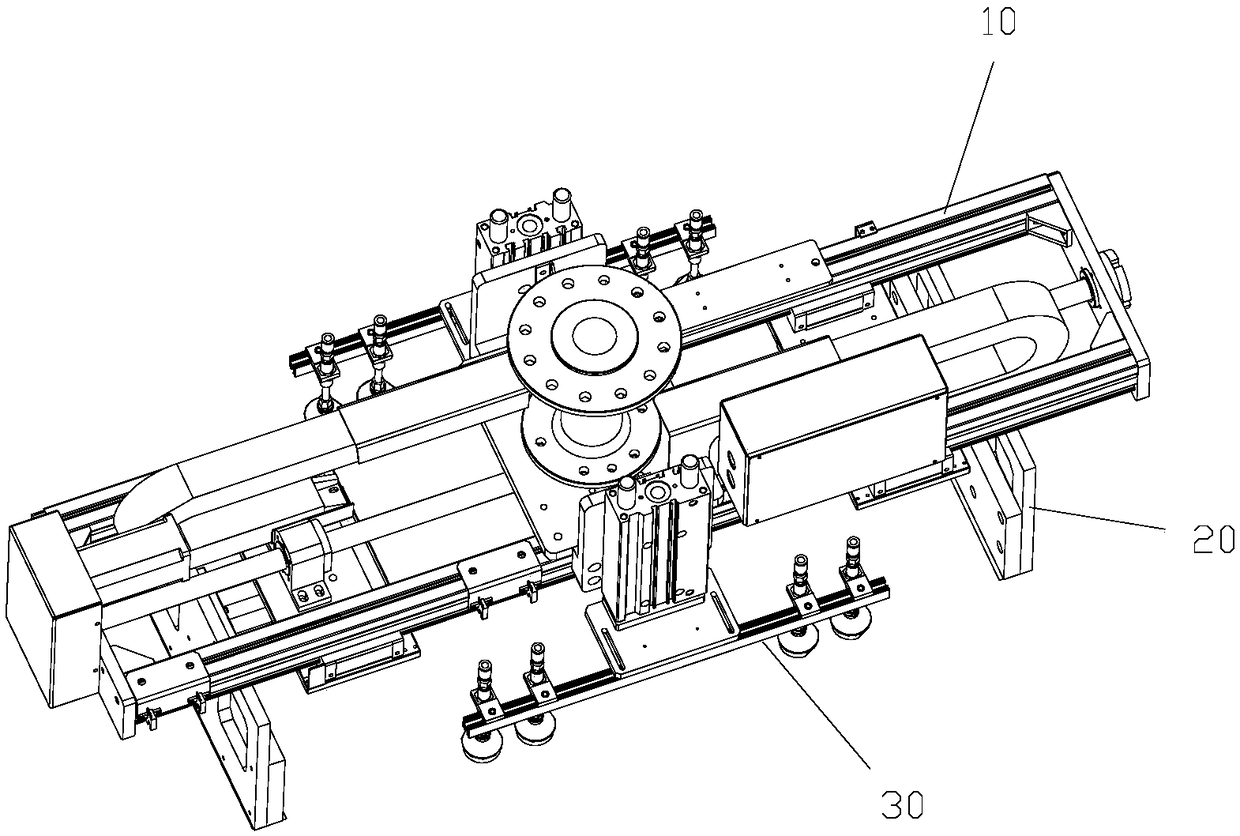

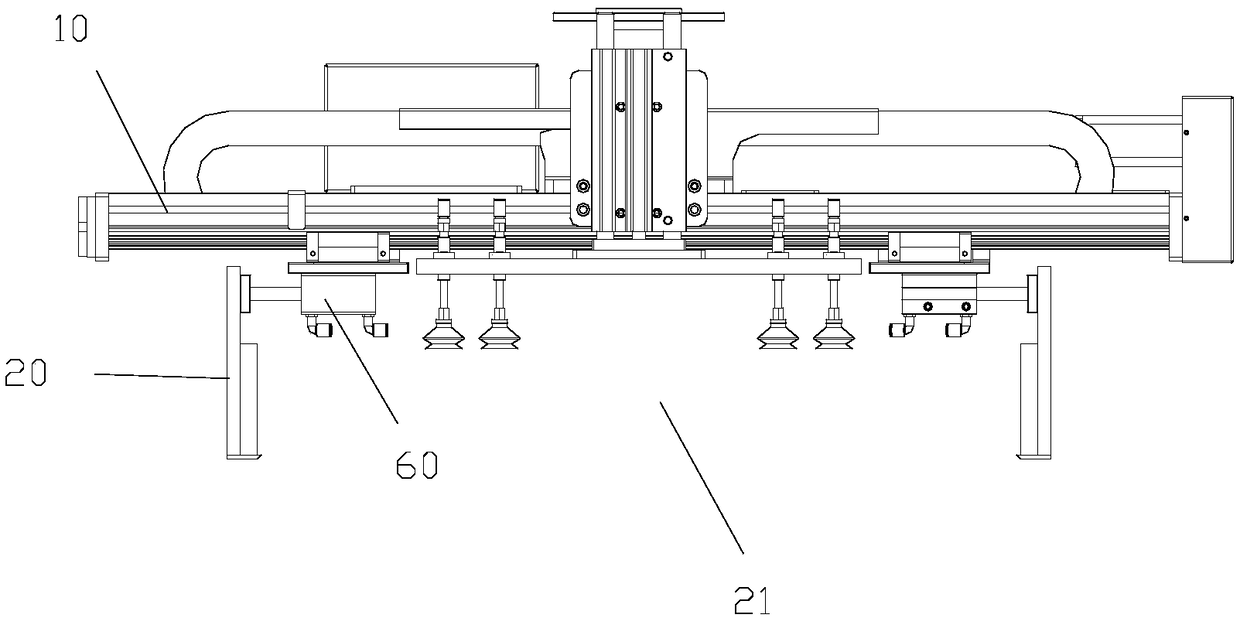

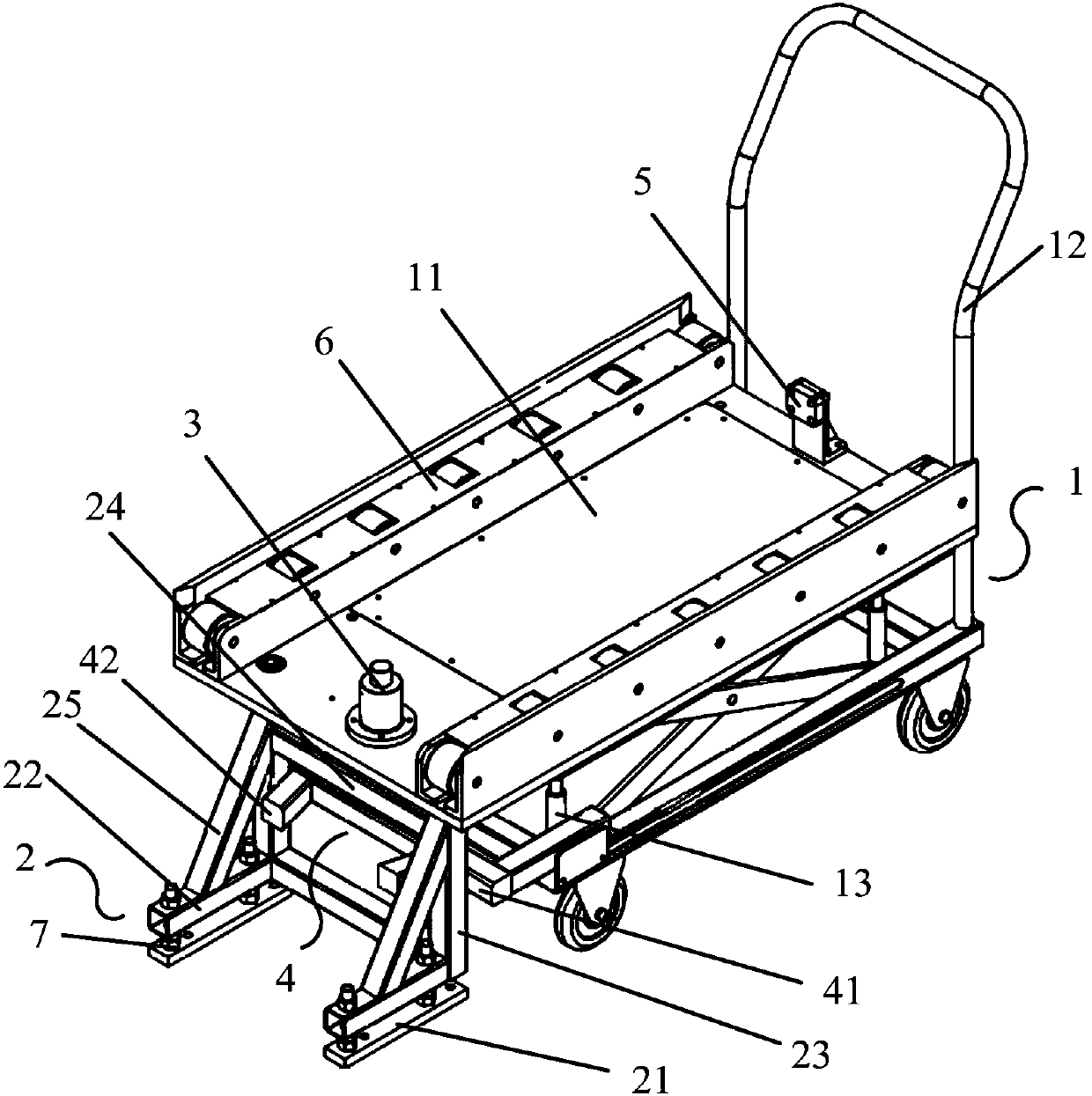

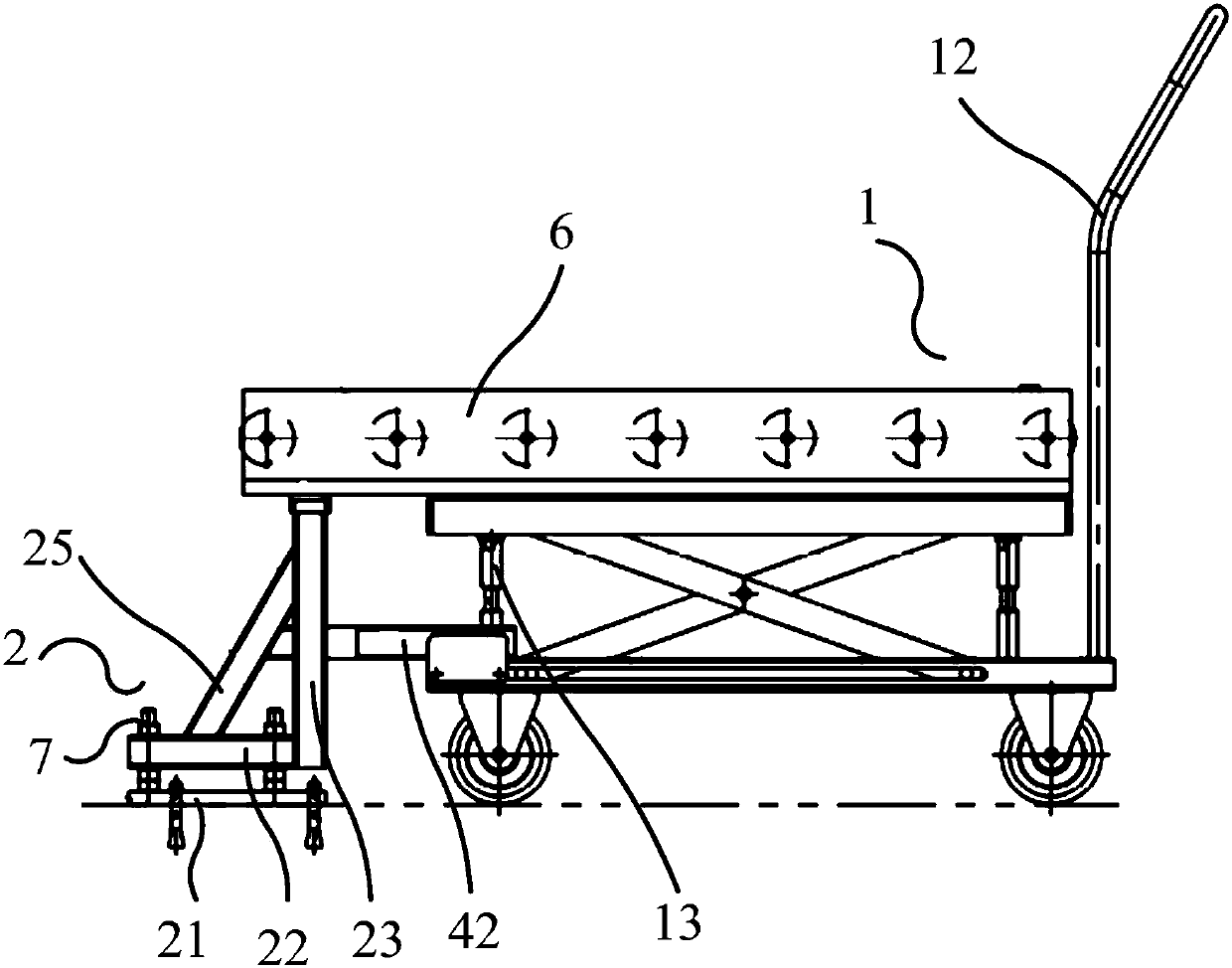

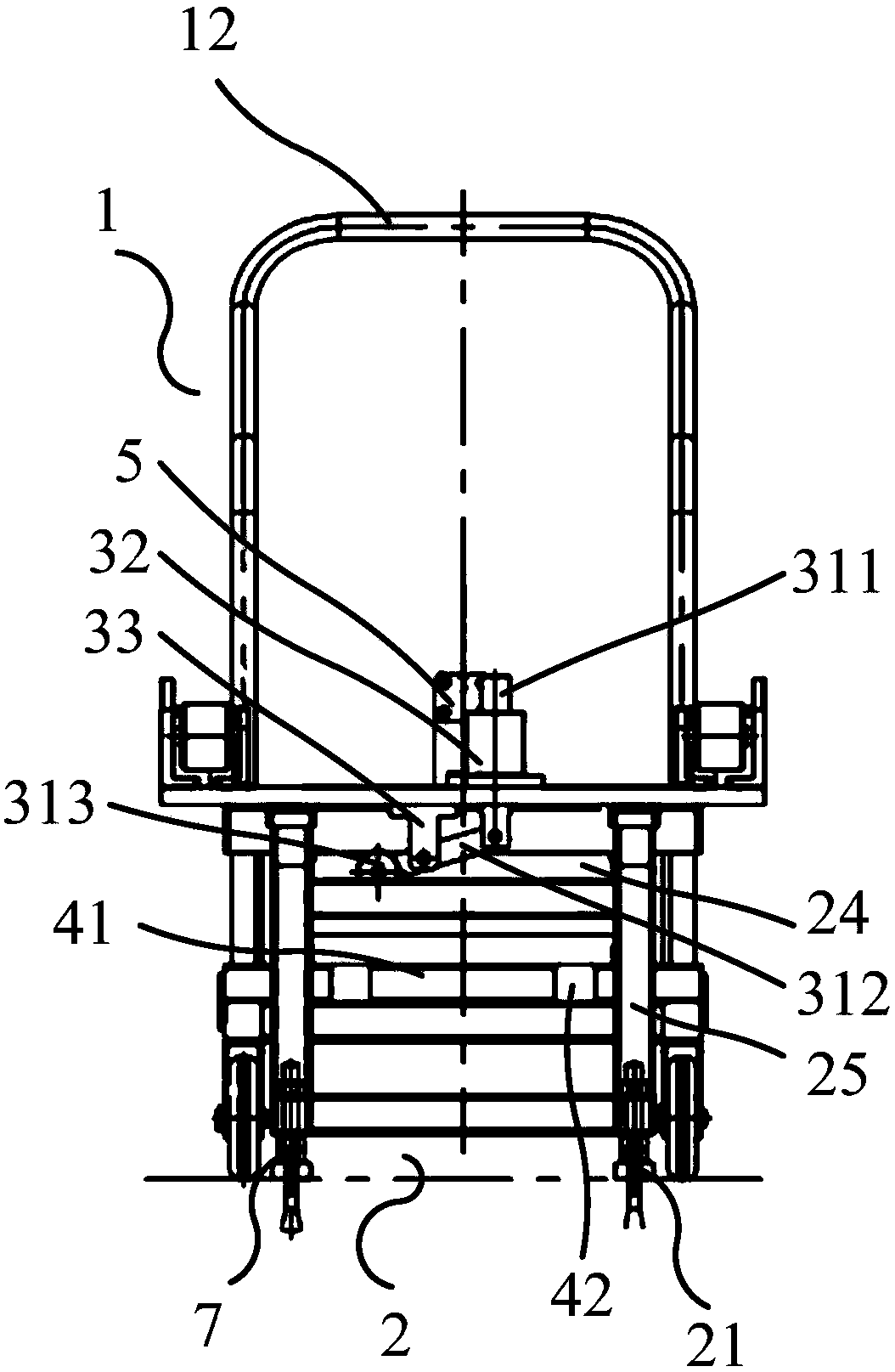

Engine rework car assembly

ActiveCN106043366BPrecise positioningWon't slide easilyHand carts with multiple axesAssembly linePositioning system

The invention discloses an engine repair car assembly. The engine repair car assembly comprises a hydraulic platform car, a positioning assembly, a blocking mechanism and a guiding assembly. During usage, the positioning assembly can be adjusted to the proper height in advance, when an engine needing to be repaired exists on an engine assembly line, an operator can hold a handle with hands to push the hydraulic platform car to a repair exit of an engine assembly workshop, the hydraulic platform car is reliably positioned through the guiding assembly and the positioning assembly and cannot slide easily, a movable assembly moves downwards when making contact with the positioning assembly, and the operator can conveniently unload the engine needing to be repaired from the line and place the engine on a car body at the moment; and in the transferring process after the engine is loaded, the blocking mechanism can further prevent the engine needing to be repaired from falling from the car body, the problem that the engine needing to be repaired needs to be loaded again in the transferring process is solved, and the working efficiency is improved.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

Permanent-magnet synchronous motor adopting concentrated winding

InactiveCN101938203AEasy to startReduce weightMagnetic circuit rotating partsSynchronous machine detailsSynchronous motorElectric machine

The invention provides a permanent-magnet synchronous motor adopting a concentrated winding, comprising a stator and a rotor. An air gap is formed between the stator and the rotor, the stator comprises a stator core and a stator winding, and the rotor comprises a rotor core, a rotating shaft and a permanent-magnet steel magnet. The permanent-magnet synchronous motor is characterized in that that stator winding is an integrated winding, the rotor is an eccentric rotor, and the air gap between the stator and the rotor is an uneven air gap. The invention has the advantages of less materials consumption, simple structure, convenient production and light weight, reduces the additional loss of motor energy and improves the utilization rate of the motor energy.

Owner:SHANGHAI DIANJI UNIV

Hall permanent magnet brushless high-speed direct current motor for vacuum molecular pump

InactiveCN105471216AReduce design difficultyGuaranteed assembly accuracySuppressing electromagnetic interferenceElectric machineHall element

The invention relates to a hall permanent magnet brushless high-speed direct current motor for a vacuum molecular pump. The hall permanent magnet brushless high-speed direct current motor comprises a motor rotor and a motor stator, wherein the motor rotor comprises an alloy steel mandrel, a permanent magnet and an alloy sheath; the motor stator comprises a stator core, a solenoid winding, an outgoing line, a hall element, a hall sensor, a hall circuit board, a hall mounting base, epoxy resin and an outer motor sleeve; the hall mounting base is located at one side, toward the outgoing line, of the stator core; a pin of the hall element is welded to the hall circuit board; a copper screen shielding layer coats the periphery of the hall circuit board; the opposite position of the hall sensor is rigidly fixed through the hall mounting base; a signal line of the hall sensor is arranged at one end of the outgoing line; a heavy-current motor three-phase current outgoing line is arranged at the other end of the outgoing line; a shield protection sleeves the outgoing line of the hall sensor; the motor stator is filled and sealed by the epoxy resin after being installed; and the outer motor sleeve is used for ensuring the assembly accuracy of the motor stator.

Owner:TIANJIN EMAGING TECH

Multilayer composite wooden waterproof floor

InactiveCN106677478AImprove flame retardant performanceImprove structural strengthFlooring insulationsComposite plateUltimate tensile strength

The invention discloses a multilayer composite wooden waterproof floor. The multilayer composite wooden waterproof floor comprises a plate body; the plate body comprises wooden layers and a mixed layer; the wooden layers are installed on the upper side and the lower side of the mixed layer correspondingly; and a waterproof layer is further installed outside one side of the wooden layer. According to the multilayer composite plate structure, a base material layer is the mixed layer, the wooden layers are installed on the upper side and the lower side of the mixed layer correspondingly, and the waterproof layer is installed on one side of the wooden layer to serve as the bottom of the whole floor. By installing the mixed layer for bonding and reinforcing between the two wooden layers, strength of the structure of the whole floor is improved; a good anti-flaming effect can be provide through the mixed layer, and a function of fire spreading prevention is achieved; and the purpose of independently and additionally installing the waterproof layer is to further improve the water-proof and moisture-proof effects of the whole floor, and problems such as wrapping caused by water invasion in the floor are avoided.

Owner:张家港市盛港绿色防火建材有限公司

A permanent magnet brushless DC hub motor for electric vehicles

ActiveCN105099111BImprove conversion efficiencyIncrease profitSynchronous machine detailsElectric machinesEngineeringElectric vehicle

A permanent-magnet brushless direct-current hub motor having high efficiency and low material loss for an electric vehicle comprises a stator assembly and a rotor assembly, wherein the stator assembly comprises a fixed support and a stacked stator steel sheet, the stacked stator steel sheet is formed by laminating a plurality of silicon steel sheets and comprises tooth parts and a tooth groove part, the tooth part comprise tooth ribs and a tooth yoke, the tooth groove part is composed of a semi-closing inner cavity formed between every two tooth parts, a single silicon steel sheet is provided with an automatic-buckling groove, the tooth groove part is of a semi-closing pear-shaped groove structure, a first Hall groove, a second Hall groove and a third Hall groove are arranged on the stacked stator steel sheet, and the stator assembly comprises a rim arranged at the periphery, a magnetic conduction ring and a plurality of magnetic steel sheets. By the permanent-magnet brushless direct-current hub motor, the pole groove ratio is optimized, the performance is improved, the usage of magnetic steel and an enameled wire is reduced, cost is saved, the installation positions of the Hall grooves and the winding mode are optimized, the production efficiency is improved, and the installation accuracy is enhanced.

Owner:TAIZHOU JINYU ELECTROMECHANICAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com