Flat knitting machine needle

A technology of knitting needles and flat knitting machines, which is applied in knitting, textiles and papermaking, etc., and can solve problems such as the difficulty of wool to push the needle latch, defective products, waste products, and the difficulty of aligning needles with wool, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

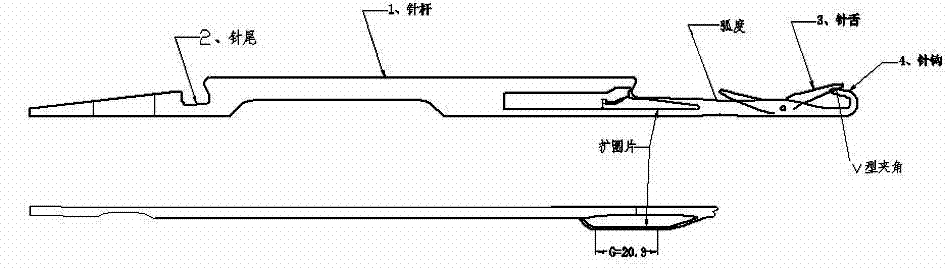

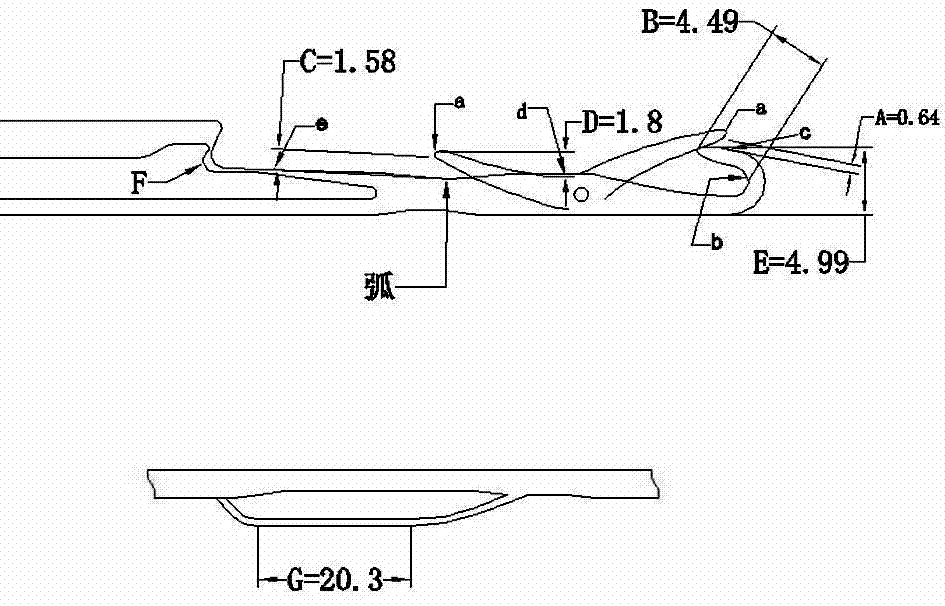

[0026] Embodiment one: see figure 1 , figure 2 .

[0027] The knitting needle of this embodiment comprises a needle bar, a needle latch, a needle bar, a needle tail, a tip of the latch a and e on the needle bar

[0028] The height of the point is 1.58, and the vertical distance between the tip a of the needle latch and the top d of the elastic pivot joint of the needle latch and the needle bar is 1.8mm. The advantage of adopting this specification is that the slope of the needle latch is smooth at this time, and it is easy to take off the thread;

[0029] When the needle latch is off-line, a certain radian is formed on the needle bar and the surface opposite to the needle latch. This radian has a larger space for the unthreaded wool, making it easier for the wool to push the needle latch and make it easier to close the needle latch;

[0030] When the needle latch and the needle hook are closed, they form a V-shaped angle with the needle hook, and the needle latch faces up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com