A method for manufacturing a collar version applied to a suit lapel collar and the suit lapel collar

A production method and a lapel collar technology, which are applied to the field of lapel collars of suits, can solve the problems of waste of materials, complexity, and difficulty in effectively determining the looseness of a collar, and achieve good looseness, a simple and convenient plate-making method, and a line drawing. Take the point quickly and accurately

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

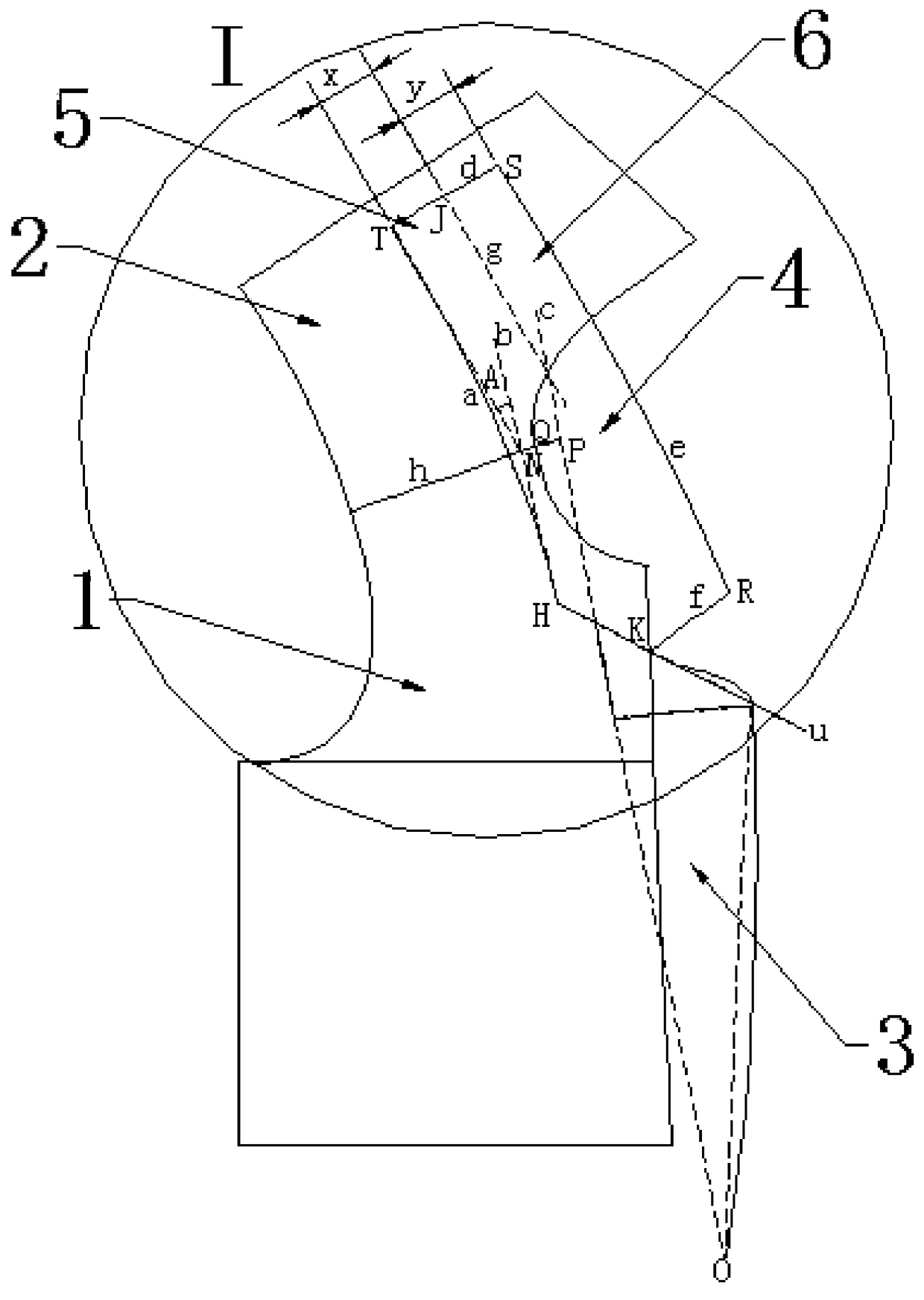

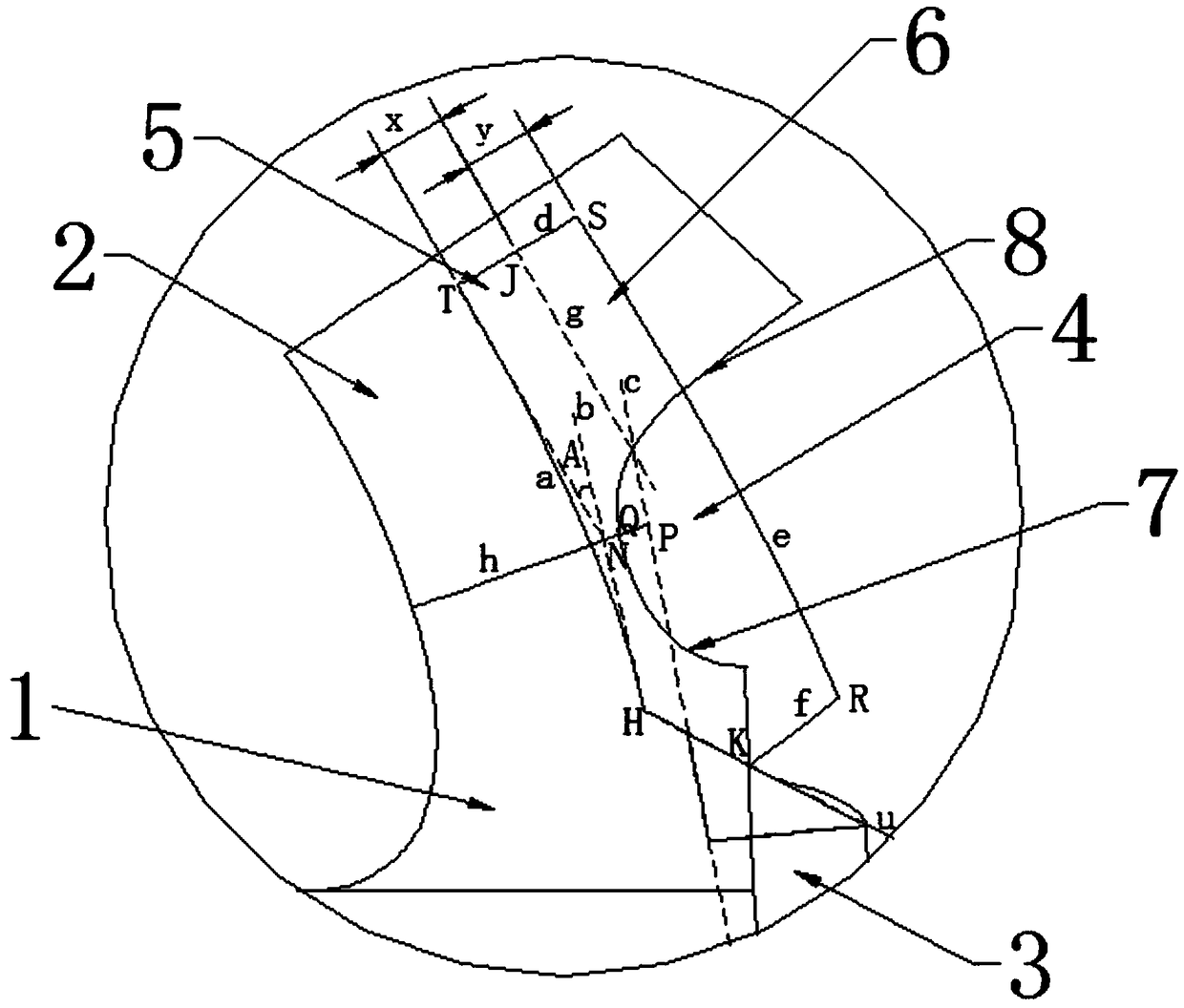

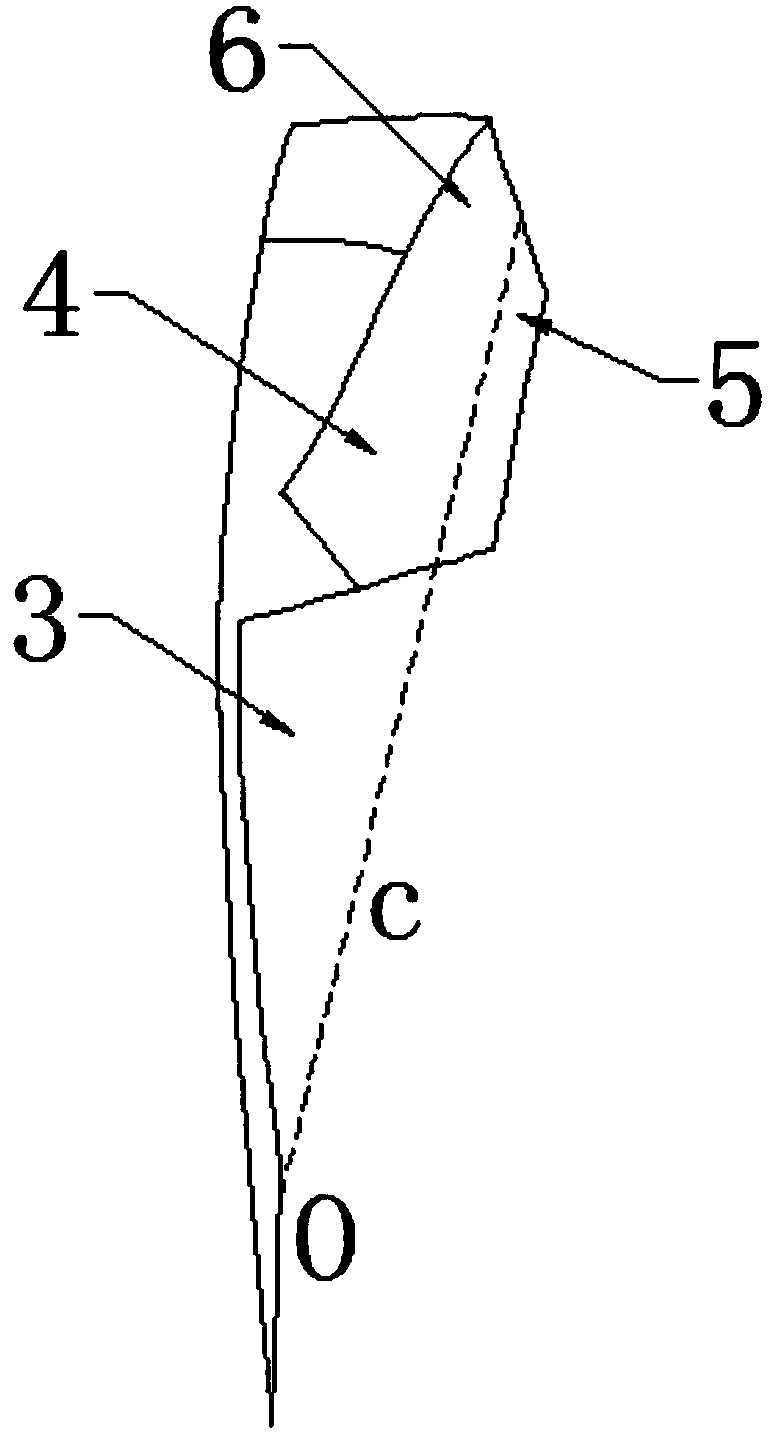

[0029] refer to figure 1 , is a structural schematic diagram of the manufacturing method of the collar version applied to the lapel collar of the suit Figure 1 , combined with figure 2 ,for figure 1 Partial enlarged view of part I in , and image 3 , is a structural schematic diagram of the manufacturing method of the collar version applied to the lapel collar of the suit Figure II , in order to clearly show the technical characteristics of the present invention, part of the structure is omitted and defined as figure 1 The paper direction shown in is the positive direction, and the up, down, left, and right directions in the illustration are the up, down, left, and right directions mentioned below. In addition, the figure only shows the structural schematic diagram of the collar on one side, and the collar on the other side of the symmetry can be It is obtained in the same way, so it will not be repeated, and the illustration will also be omitted.

[0030] Such as Fi...

Embodiment 2

[0043] The present invention also provides a suit lapel collar, which is obtained by cutting a symmetrical left collar plate and a right collar plate by the manufacturing method of the collar plate applied to the suit lapel collar given in the first embodiment above, In addition, the turned-over collar of the suit is made by auxiliary cutting cloth pieces of the left collar version and the right collar version and assembling them together. The loose slope of the collar made by the above method is better and smoother, and more beautiful.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com