High-specific-gravity permanent magnet brushless direct-current gyro motor

A permanent magnet brushless DC, gyro motor technology, applied in the direction of electric components, electrical components, electromechanical devices, etc., to achieve the effect of stable speed, small magnetic loss and small torque change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

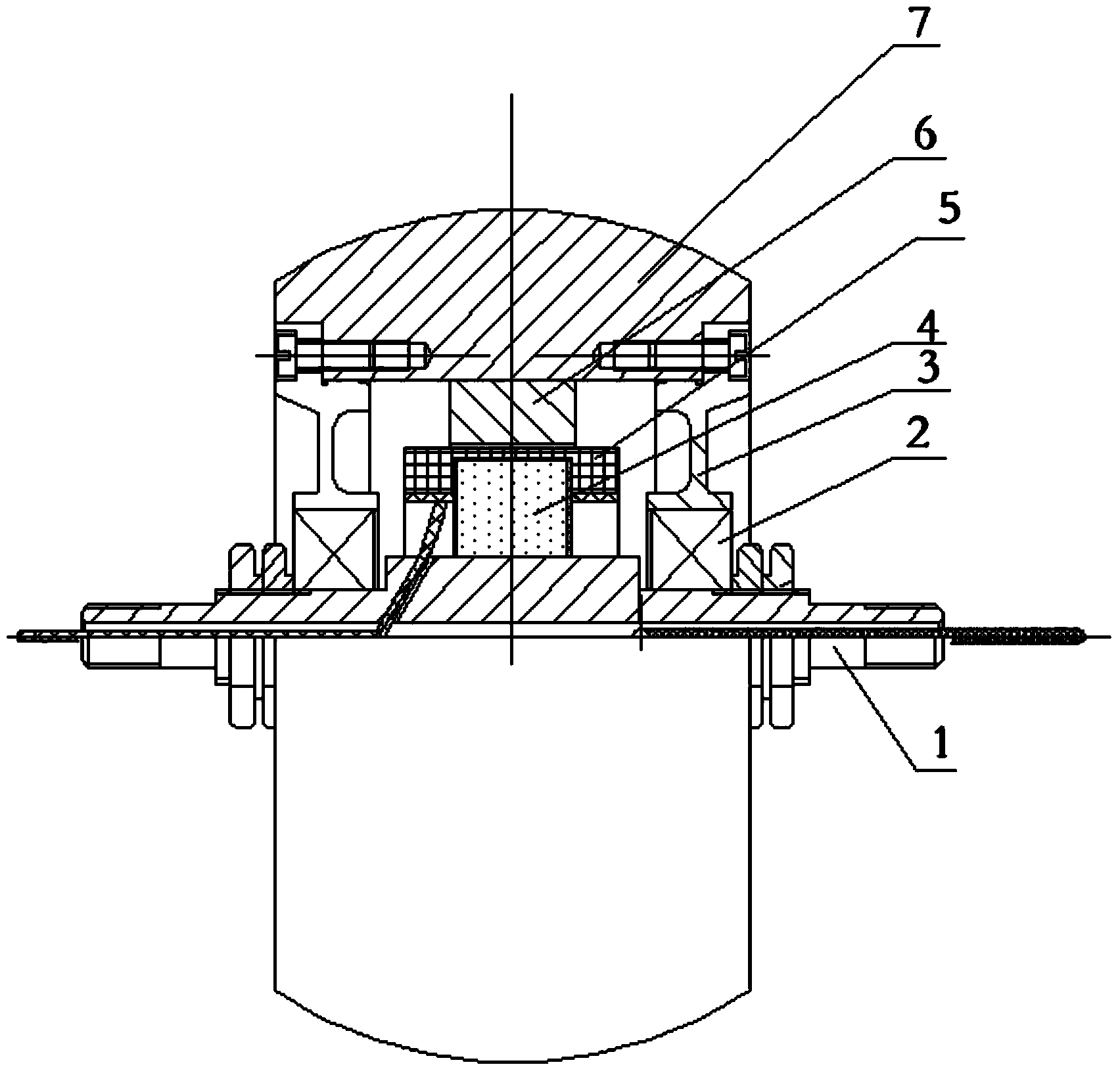

Image

Examples

Embodiment

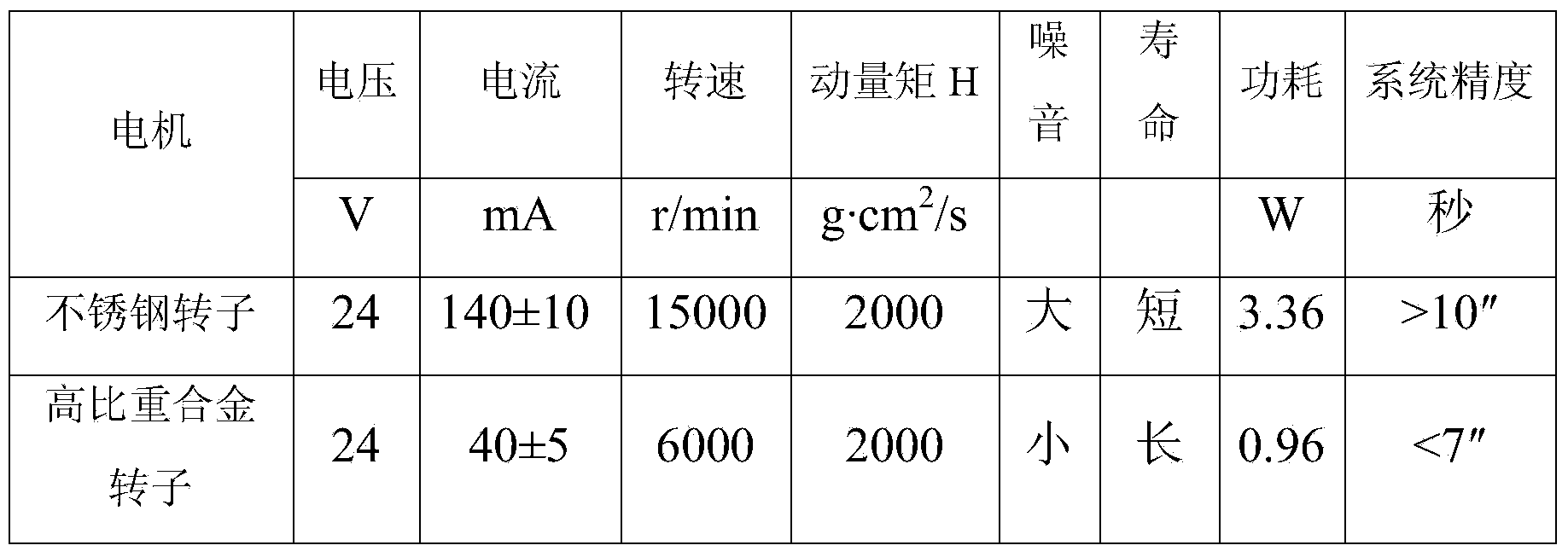

[0033] We have made two test motors. The performance requirements of this development project for gyro motors are as follows:

[0034] ①The size is controlled at inside the ball

[0035] ②Momentum H>2000g·cm 2 / s

[0036] ③It can work normally under the ambient temperature of -40℃~+55℃

[0037] ④Speed stability over 1×10 -4

[0038] ⑤ Power consumption <2 watts (rated voltage 24V, normal temperature)

[0039] ⑥ The motor runs smoothly and has low noise

[0040] ⑦The service life is not less than 2000 hours

[0041] One uses a tungsten-based high-density alloy as the rotor ring 7, and the other uses stainless steel as the rotor ring 7. The rest of the motor is the same. The measured performance of these two motors is listed in Table 1.

[0042] Table 1 The measured performance of the two motors (normal temperature)

[0043]

[0044] As can be seen from the above table, in order to obtain 2000g·cm 2 / s momentum moment, when the rotor is made of stainless steel,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com