Multilayer composite wooden waterproof floor

A multi-layer and composite technology, applied in insulation layers, floors, buildings, etc., can solve the problems of poor waterproof and water resistance, short floor life, troublesome maintenance and use, etc., to improve waterproof and moisture-proof performance and improve service life. , the effect of improving the barrier property

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

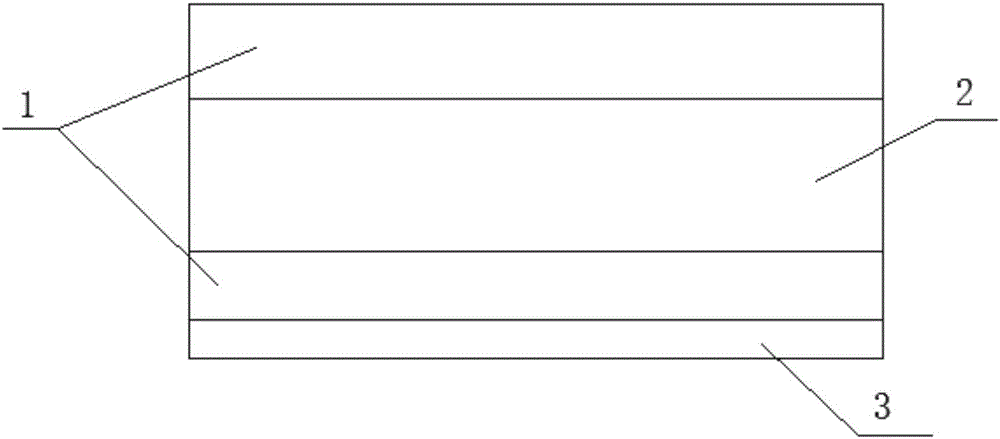

[0043] A kind of multi-layer composite wooden waterproof floor of the present embodiment, such as figure 1 As shown, it includes a board body, the board body includes a wooden layer 1 and a mixed layer 2, the wooden layer 1 is arranged on the upper and lower sides of the mixed layer 2, and a waterproof layer 3 is provided outside the wooden layer 1 on one side. In the multi-layer composite board structure of the structure of the present invention, the base material layer is a mixed layer 2, and a wooden layer 1 is provided on both upper and lower sides of the mixed layer 2, and a waterproof layer is provided on the wooden layer 1 on one side. 3 as the bottom of the entire floor. The structural strength of the entire floor is improved by providing a mixed layer 2 for bonding and strengthening between the two wooden layers 1, and the mixed layer 2 can also provide a better flame-retardant effect and has the function of preventing the spread of fire; The purpose of adding a wate...

Embodiment 2

[0045] This embodiment is further defined on the basis of the above embodiments, the mixed layer 2 includes a middle material layer and a glass fiber layer. The glass fiber layer can strengthen the tensile and compressive strength of the entire floor, and the specific number of glass fiber layers can be adjusted according to actual manufacturing and usage conditions. Other parts of this embodiment are the same as those of the foregoing embodiment, and will not be repeated here.

Embodiment 3

[0047] This embodiment is further defined on the basis of the above embodiments, a grid cloth layer is provided between the waterproof layer 3 and the wooden layer 1 . The mesh cloth adopts 5x5 purpose interwoven mesh cloth as the base material, thereby further improving the structural strength of the entire floor. Other parts of this embodiment are the same as those of the foregoing embodiment, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com