Patents

Literature

61results about How to "Improve tensile and compressive strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

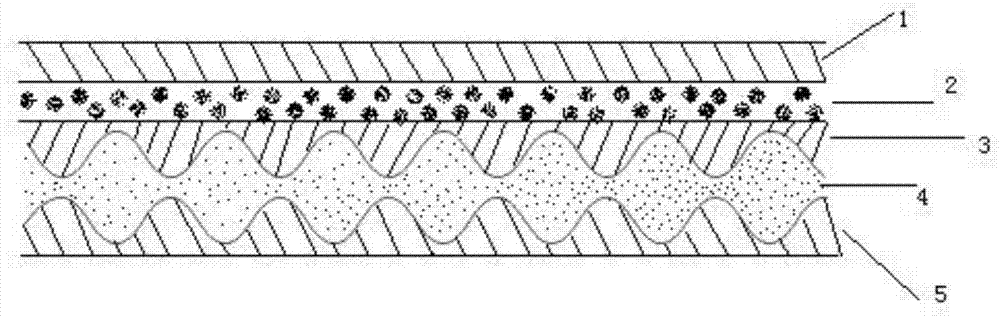

High-temperature, temperature-resisting and wear-resisting polyethylene pipe

The invention discloses a high-temperature, temperature-resisting and wear-resisting polyethylene pipe. The high-temperature, temperature-resisting and wear-resisting polyethylene pipe sequentially comprises a micron-grade modified ultra-high molecular weight polyethylene layer, a high molecular weight modified material layer of high density polyethylene and inorganic minerals and a polyethylene felt layer from inside to outside. The polyethylene felt layer is composed of the following raw materials: 100 parts of the polyethylene, 10-20 parts of nano materials, 1-3 parts of a compatilizer, 1-3 parts of a toughening agent, 1-2 parts of a coupling agent, 1-1.5 parts of a processing lubricant and 1-1.5 parts of an antioxidant. The high-temperature, temperature-resisting and wear-resisting polyethylene pipe has the advantages that nano particles are sufficiently dispersed in plastic resin so that the heat resistance, the weather resistance, the wear resistance and the like of the plastic are effectively improved.

Owner:NINGBO BOER PIPE IND DEV

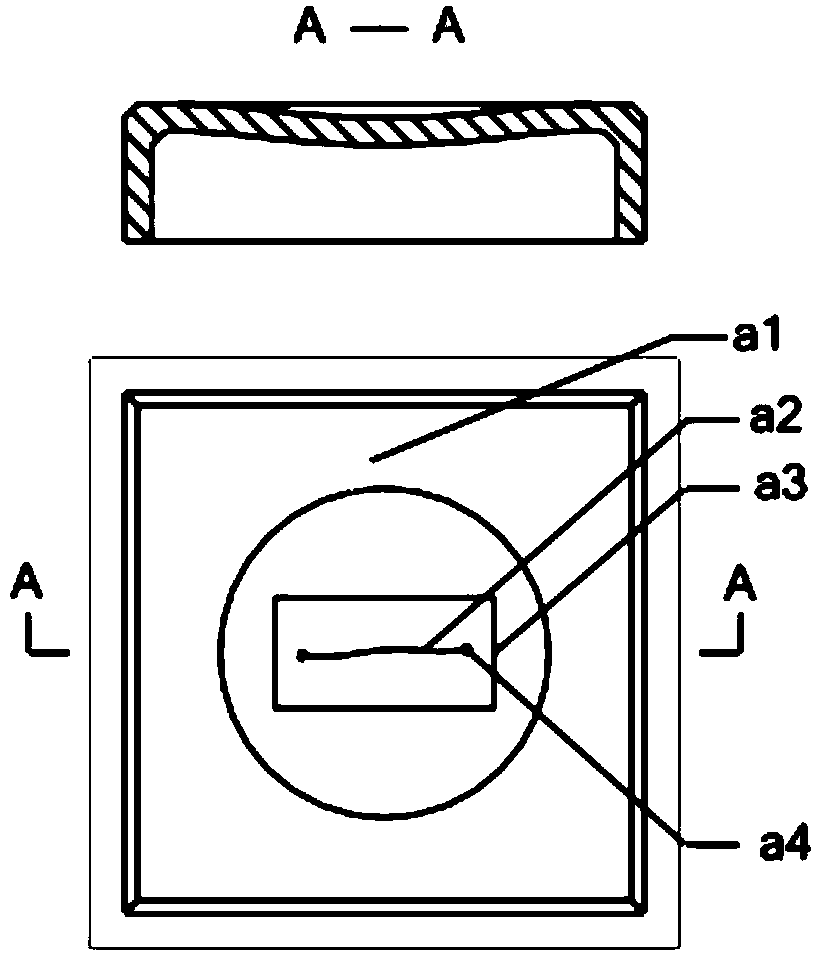

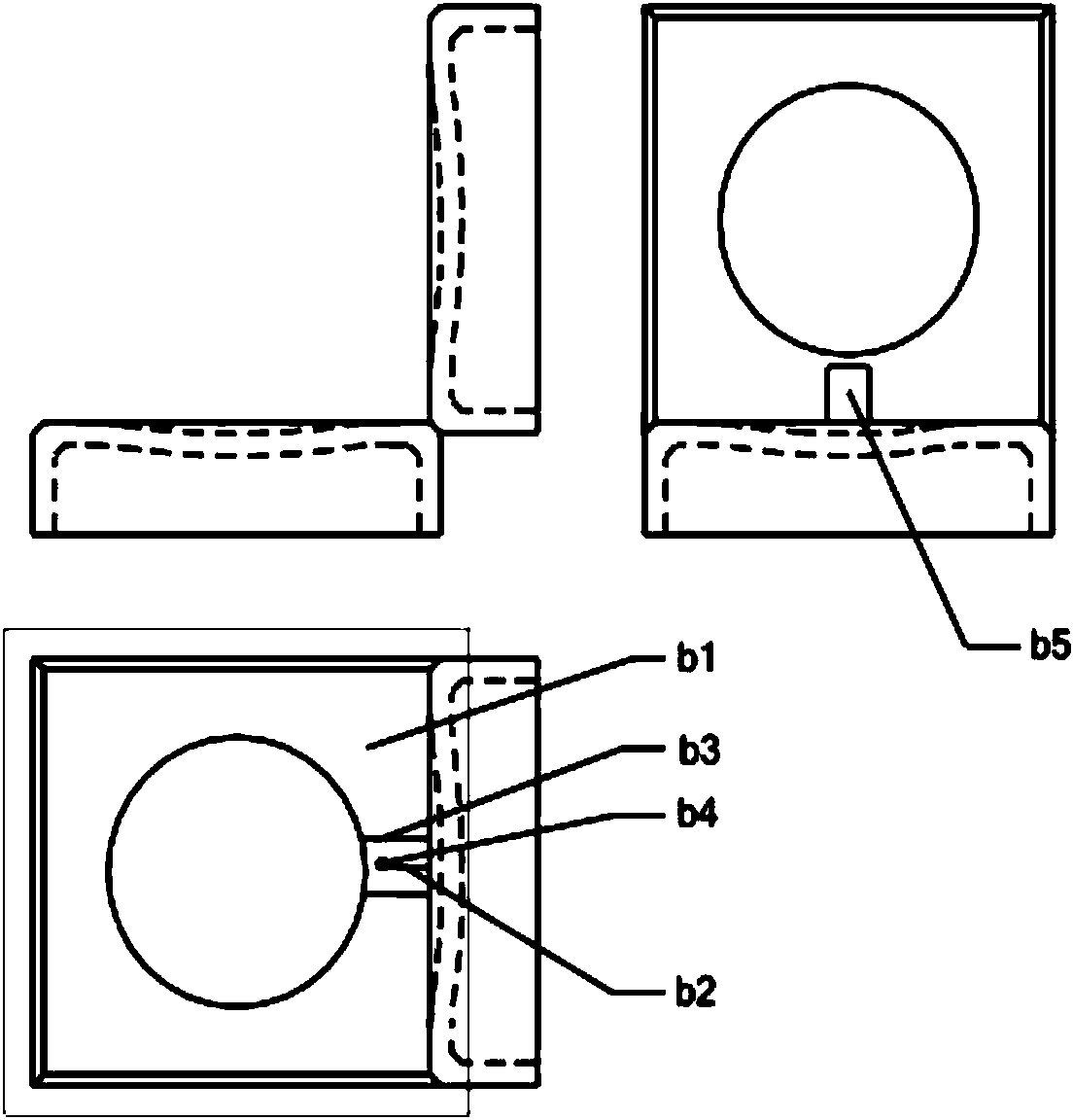

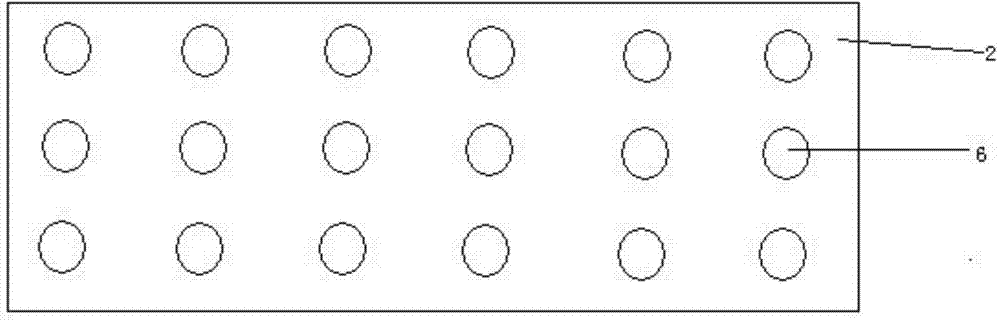

Suspending and balancing pressure type support safety vacuum glass

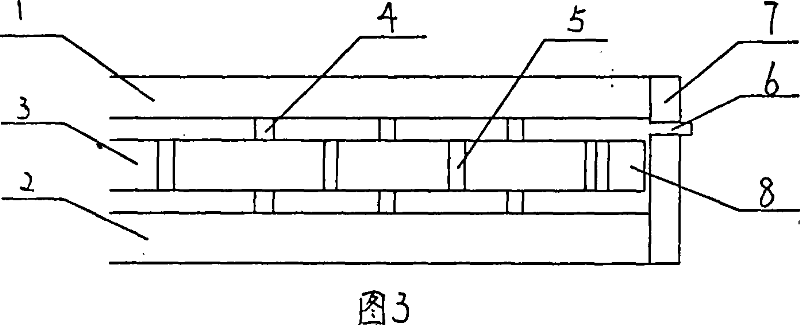

A suspended and pressure equalized support safe vacuum glass comprises closely connected up and down glass plates with sealed vitreum at four sides, a vacuum cavity in the middle which is formed by up and down glass plates and which has suspended support glass plates that has support at its six sides, corner of the suspended support glass plate having degasser. The vacuum glass has small deformation rate under pressure, high strength, free from after hollow or doubling, with simple structure, low cost, fine energy saving and noise reducing effect and higher social and economical value.

Owner:王汉清

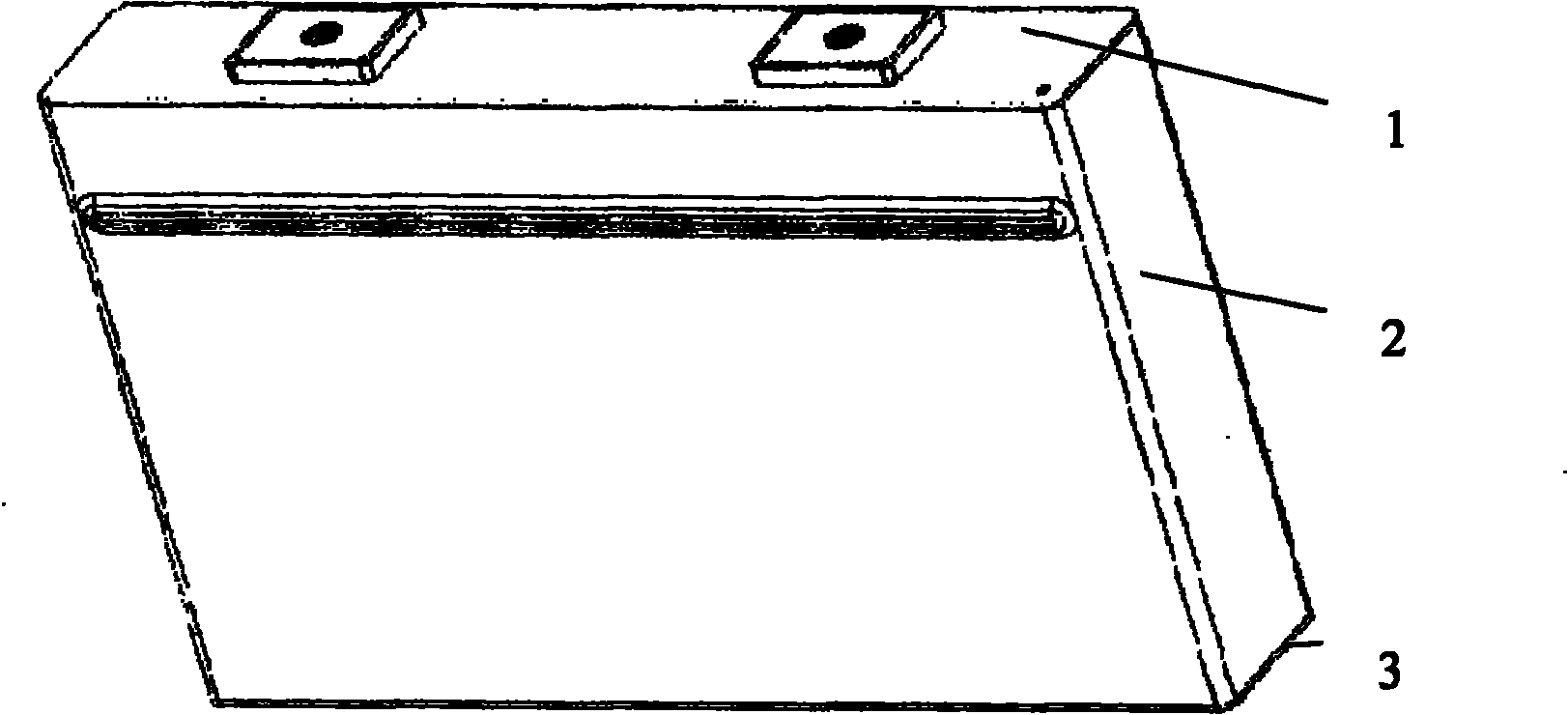

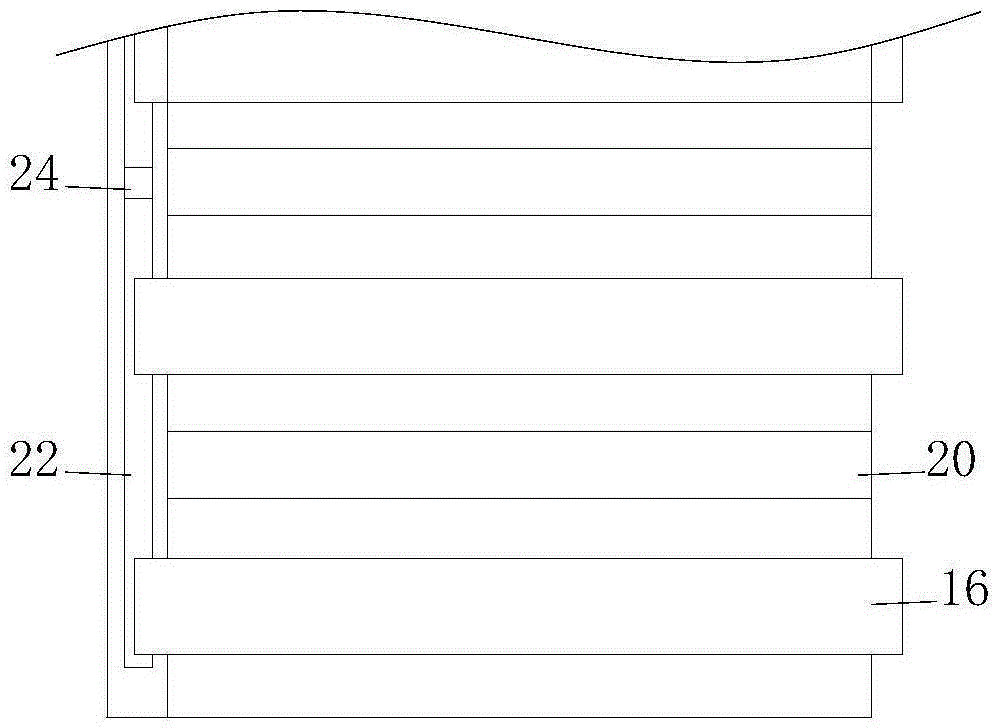

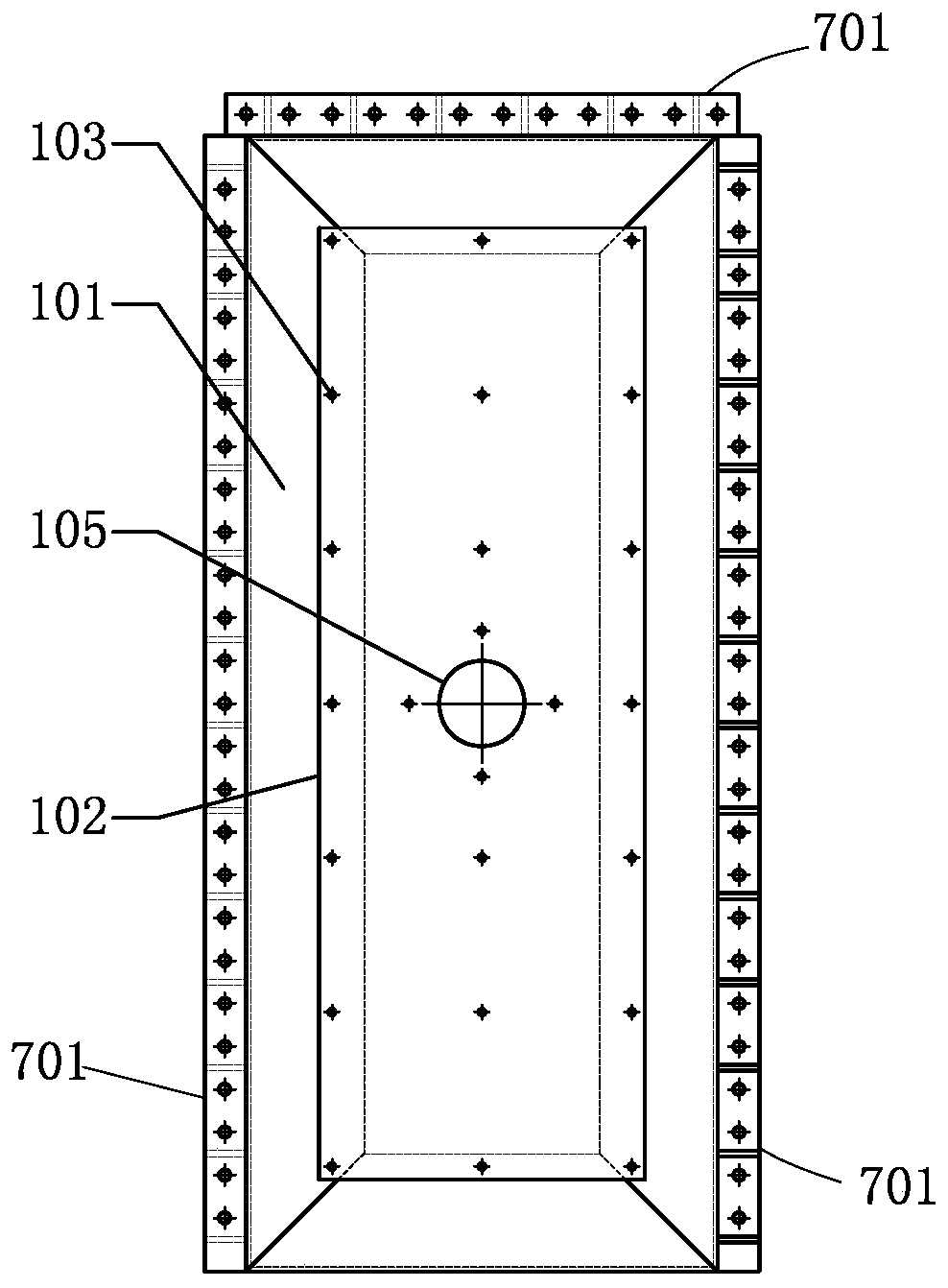

Structural heat-preservation decoration integrated large-size prefabricated outer wall-hung plate and manufacturing method thereof

InactiveCN104563384AConstruction and transportation are convenientEasy to liftBuilding componentsProduction lineSurface layer

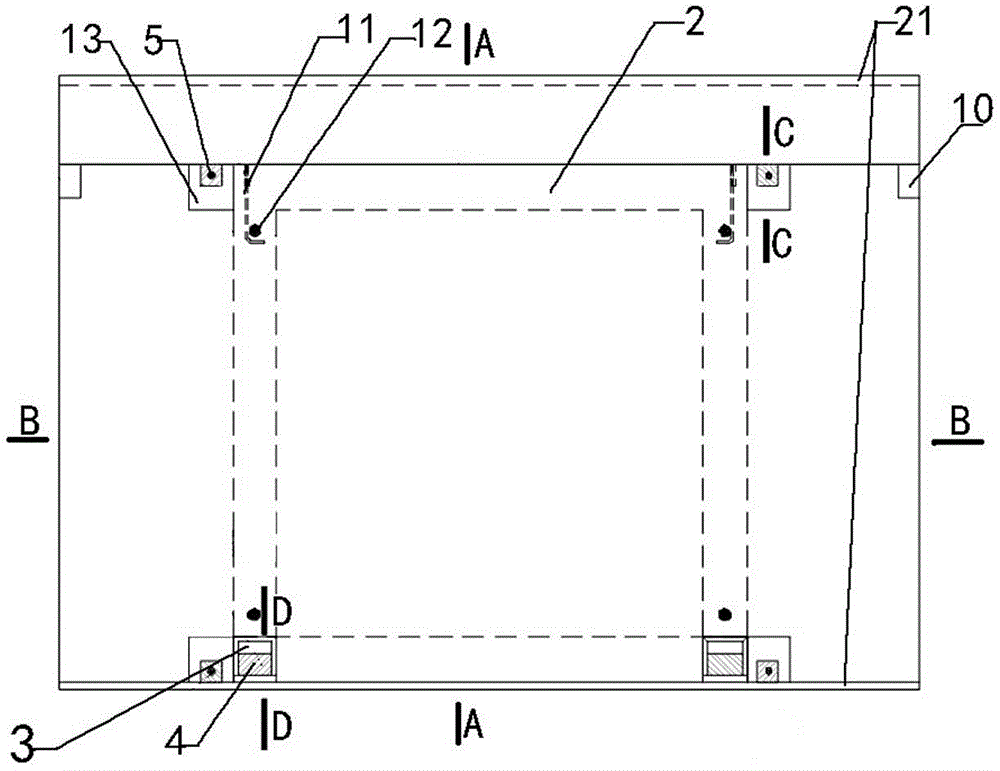

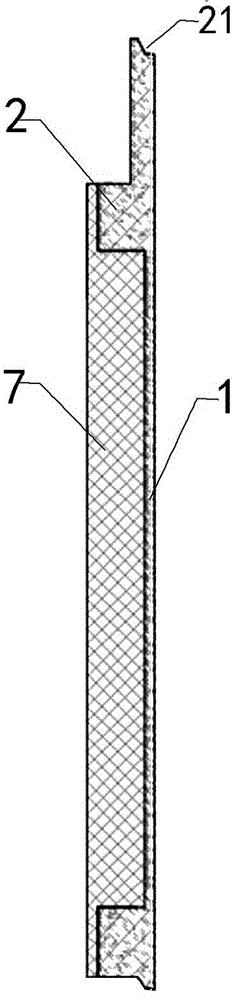

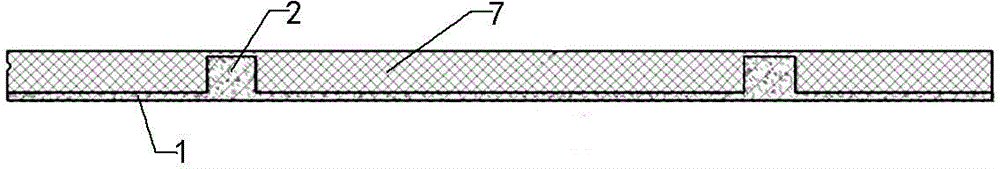

The invention discloses a structural heat-preservation decoration integrated large-size prefabricated outer wall-hung plate and a manufacturing method thereof. The structural heat-preservation decoration integrated large-size prefabricated outer wall-hung plate comprises a plate body, wherein the plate body consists of a reinforced concrete surface layer and a heat-preservation layer which are compounded together from outside to inside; embedded parts are pre-buried into the plate body; a surface layer reinforced net is paved inside the reinforced concrete surface layer; a layer of heat-preservation layer reinforced net is paved inside the heat-preservation layer; truss reinforcing steel bars are connected between the surface layer reinforced net and the heat-preservation layer reinforced net; lower chord reinforcing steel bars of the truss reinforcing steel bars are fixedly connected with the surface layer reinforced net; the upper chord reinforcing steel bars of the truss reinforcing steel bars are buried in the heat-preservation layer; grooves and tongues for matching connection are respectively formed in the upper and lower ends of the wall plate. Due to adoption of the reinforced concrete surface plates and cement-based material heat-preservation layers with self-heat-preservation property, the wall plate is simple in structure, convenient to manufacture, low in cost, light in self-weight, convenient to mount and applicable to construction of direct outer pre-hung wall plates in a whole open room, can be produced on ordinary wall plate production lines, integrates structure, heat-preservation and decoration, and can be directly hung on a construction main body structure without being assembled again or paving keels.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION

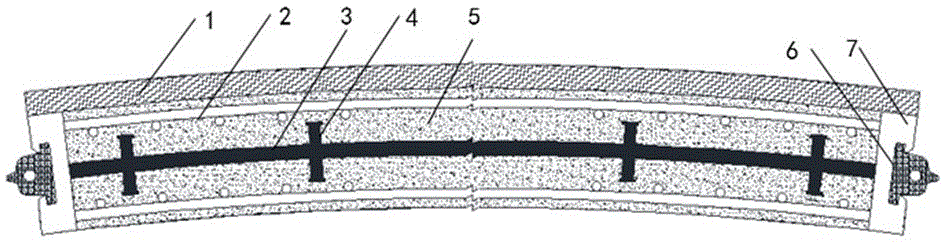

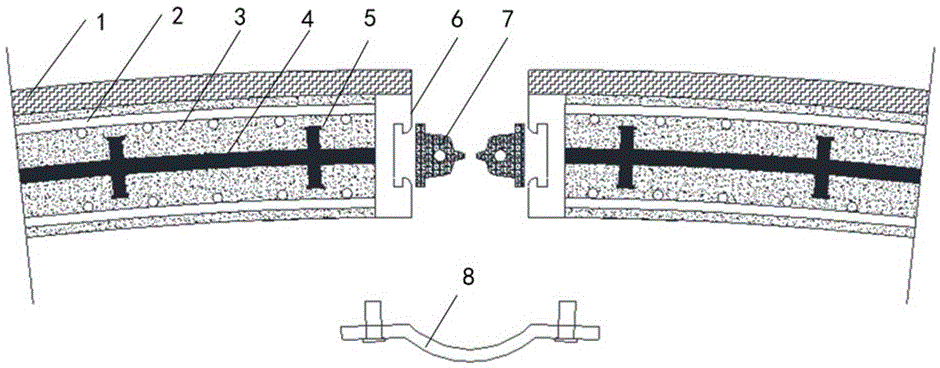

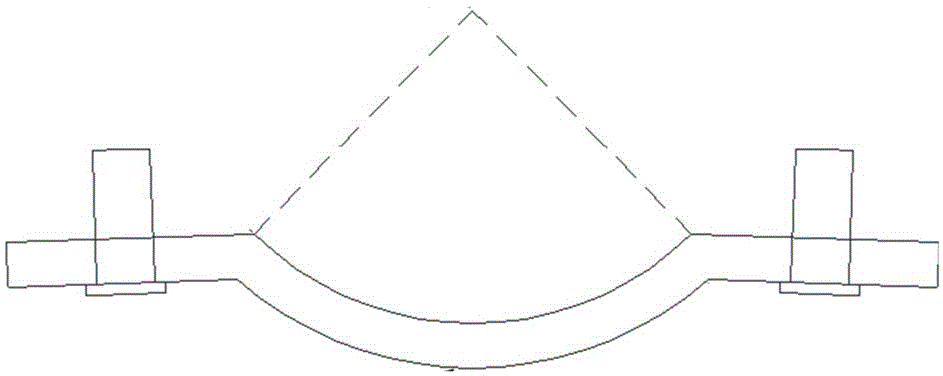

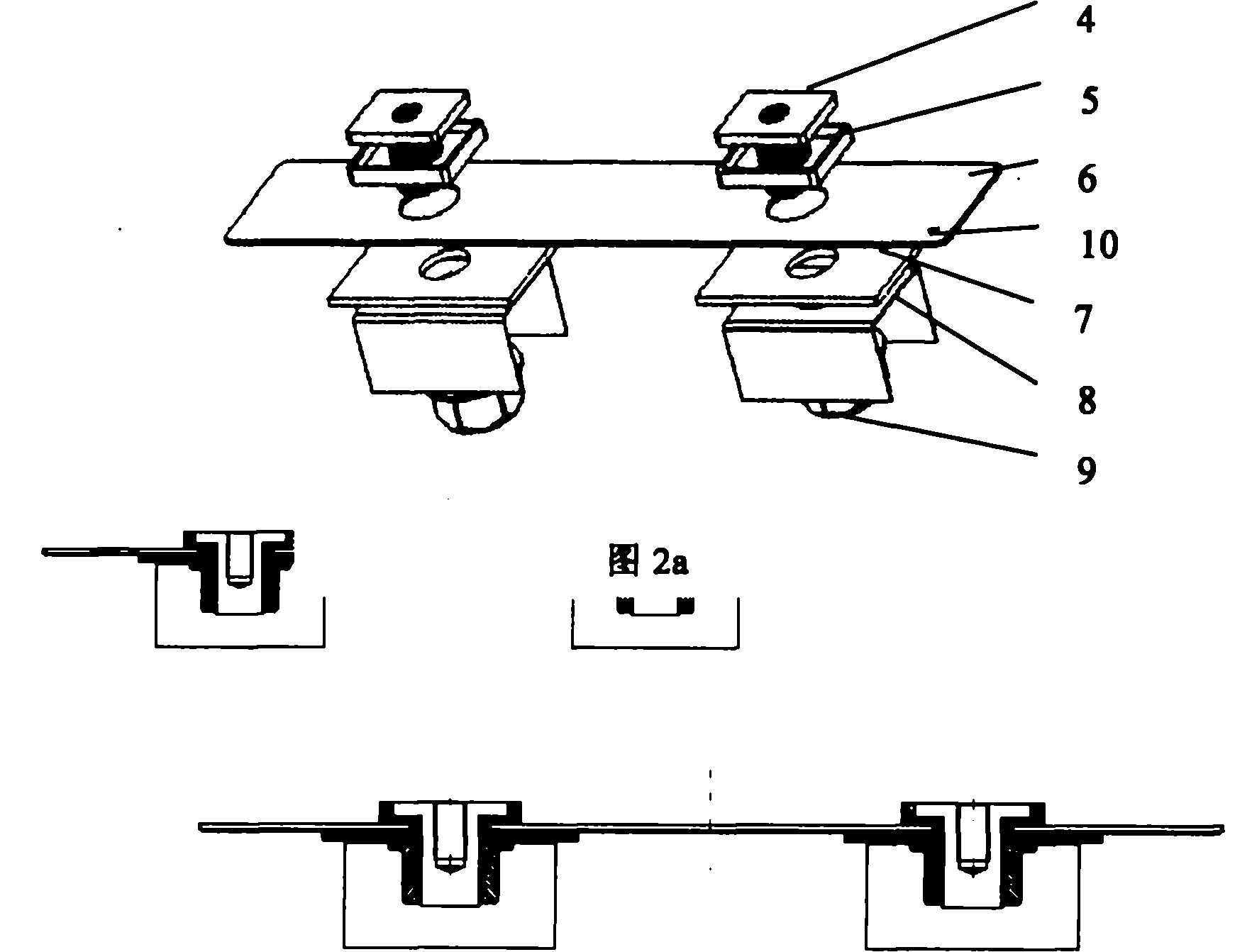

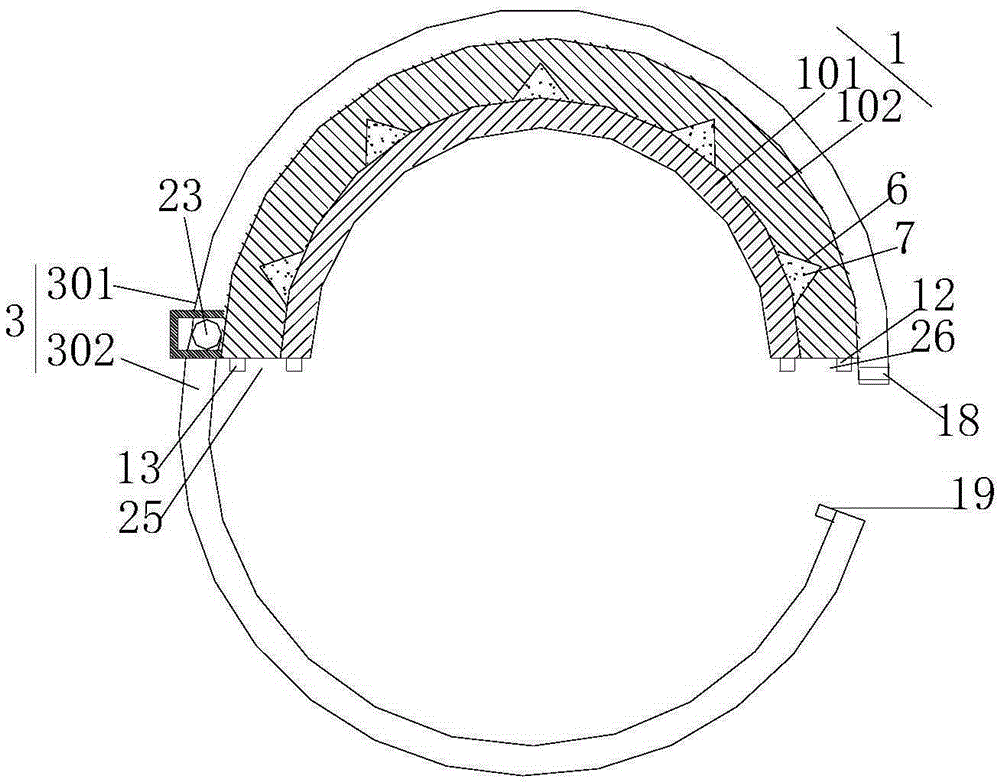

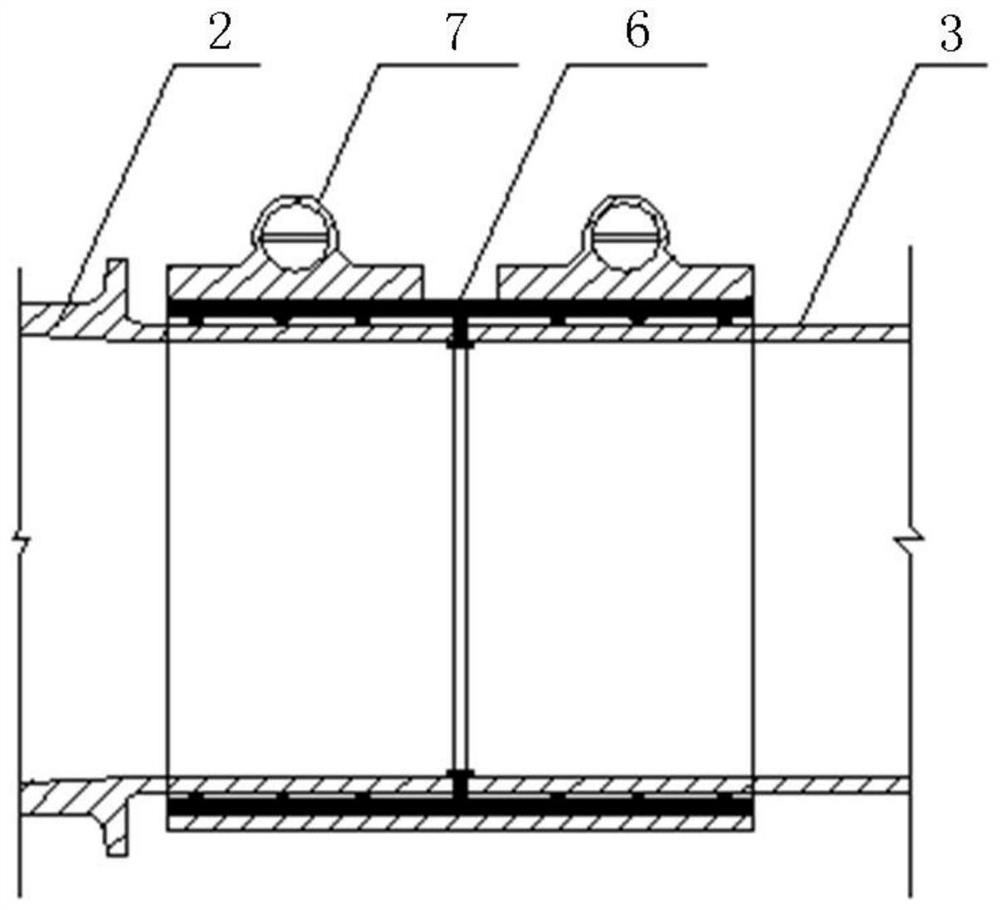

Shield tunnel segment structure and connecting structure thereof

The invention discloses a shield tunnel segment structure and a connecting structure thereof. The shield tunnel segment structure comprises a segment body and is characterized in that the segment body is mainly composed of a steel plate layer, a concrete layer wrapping the steel plate layer, and steel mesh reinforcements which are located on the two sides of the steel plate layer correspondingly and embedded in the concrete layer; the lateral edges of the segment body are fixedly provided with metal connectors, the outer sides of the metal connectors are provided with grooves for containing water stops, and the water stops are installed inside the grooves; and an outer protecting layer is arranged on the outer side of the segment body, and the outer protecting layer is a polyurea layer combined on the outer side surface of the segment body. The connecting structure is composed of two adjacently arranged shield tunnel segment structures and a connecting part for connecting the two shield tunnel segment structures. A connecting steel plate is composed of a middle arc-shaped section and flat sections on two sides. The shield tunnel segment structure and the connecting structure thereof have the characteristics that thickness is small, strength is high and the connectors are not prone to damage; and the connector deformation control effect is good, the seam waterproof effect is good, durability is high, and repairing is convenient.

Owner:SUZHOU UNIV

Glass fiber reinforced plastic water tank crack repairing technology

InactiveCN104385638AExtended service lifeSolve the leakNon-macromolecular adhesive additivesGlass fiberCrazing

The invention relates to a glass fiber reinforced plastic water tank crack repairing technology. The technology comprises the following steps of polishing inner cracks of a glass fiber reinforced plastic water tank until a first-layer glass fiber cloth is exposed, respectively drilling two technique holes at two ends of the crack, cutting a metal filter screen and glass fiber cloths, uniformly coating the cracks with a prepared resin binder, pasting the first-layer glass fiber cloth, carrying out blade coating with the resin binder, pasting the second-layer glass fiber cloth, carrying out coating with the binder, simultaneously pasting the third-layer glass fiber cloth and the metal filter screen, repeating the above binder coating and pasting processes until the 4th-6th glass fiber cloths are pasted, then carrying out blade coating on the last-layer glass fiber cloth with the resin binder and carrying out curing. The technology has simple processes and a low cost, contains the stainless steel metal filter screen sandwich, improves repaired layer tensile and compressive strength and is free of water tank replacement.

Owner:SHANDONG IRON & STEEL CO LTD

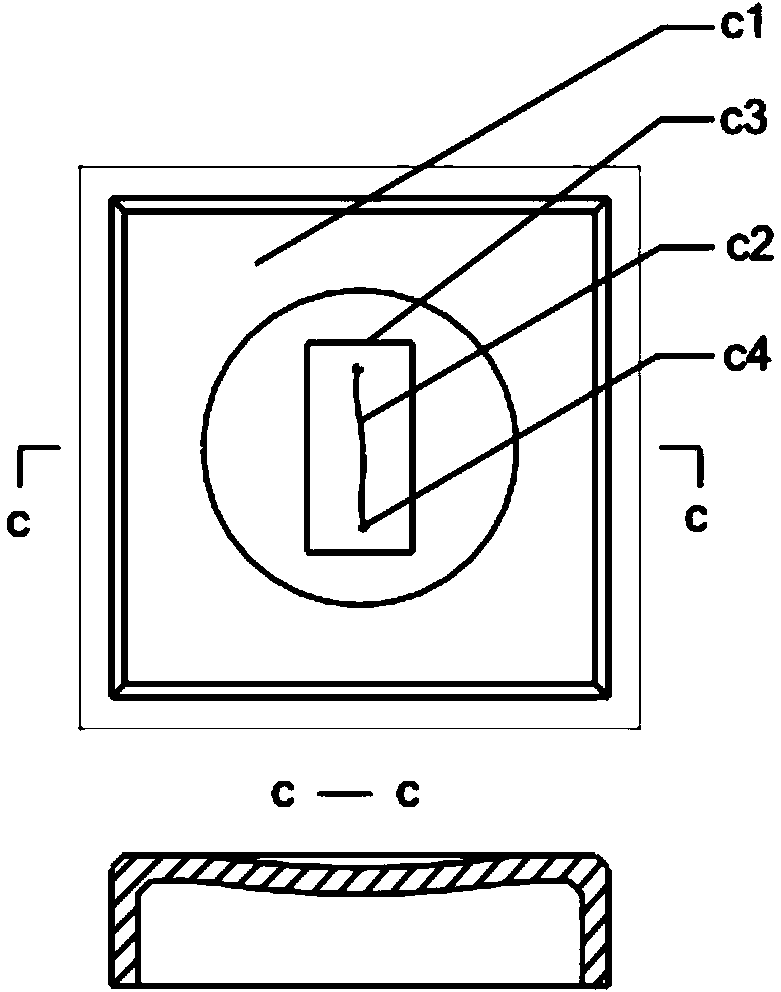

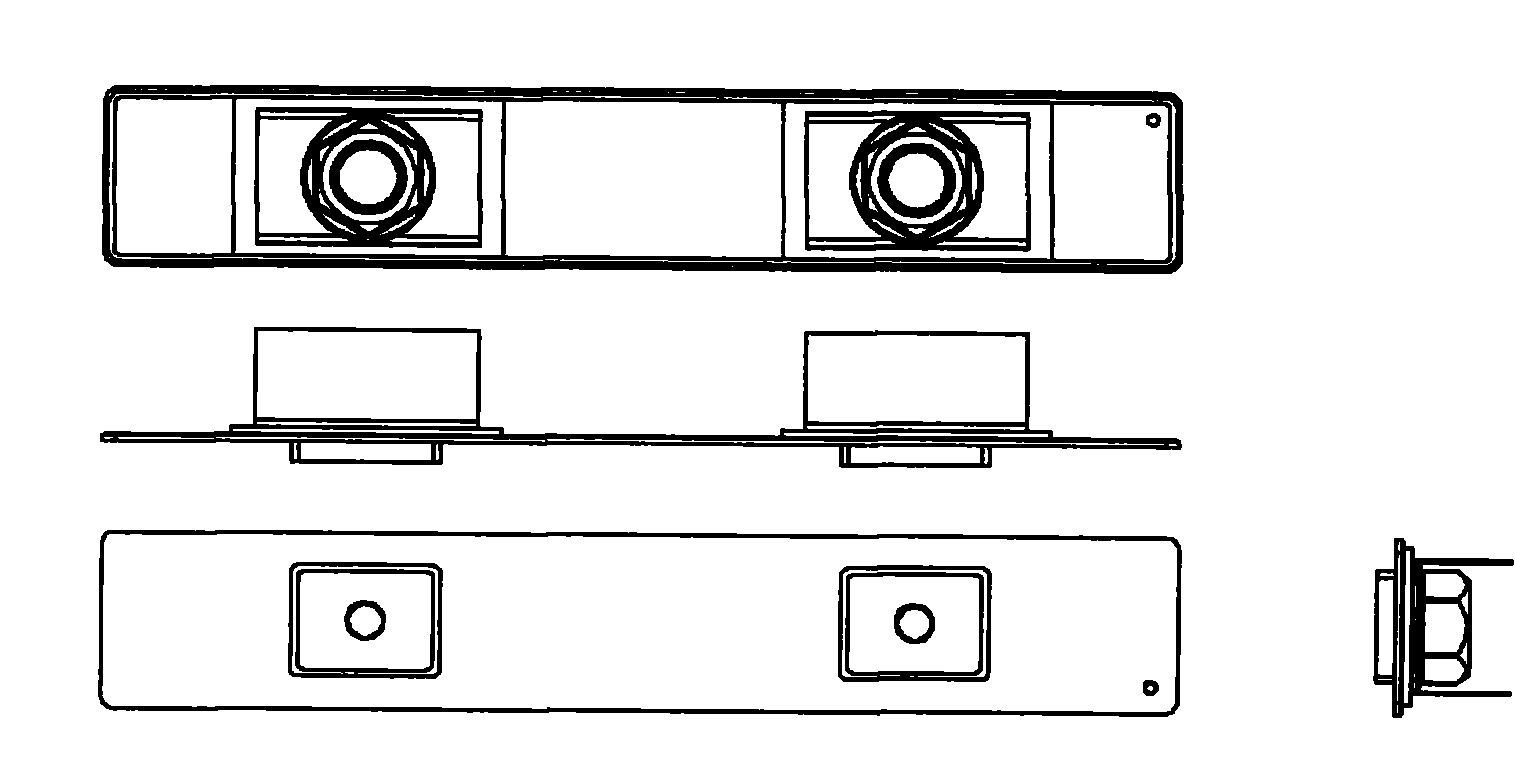

Square lithium ion battery shell and square lithium ion power battery using same

InactiveCN102315395AGood high current charge and discharge performanceImprove securityCell electrodesSecondary cellsPower batteryElectrical battery

The invention relates to the technical field of lithium ion batteries, and particularly discloses a square lithium ion battery shell. The square lithium ion battery shell comprises a shell cover, a shell body and a bottom plate; the shell body is provided with a predetermined space for accommodating the shell cover; the shell cover and the bottom plate are respectively and fixedly connected with the shell body to form a whole; the shell cover is provided with a pole post; and an internal thread and an external thread are arranged in the pole post. The invention also discloses a square lithium ion powder battery using the battery shell. The square lithium ion battery shell and the square lithium ion powder battery using the same are particularly suitable for occasions, on which massive connection in series or parallel and long-term vibration occur, such as an energy storage powder supply, a vehicle powder battery, an electric bicycle, a motorcycle and the like.

Owner:SHANGHAI AEROSPACE POWER TECH

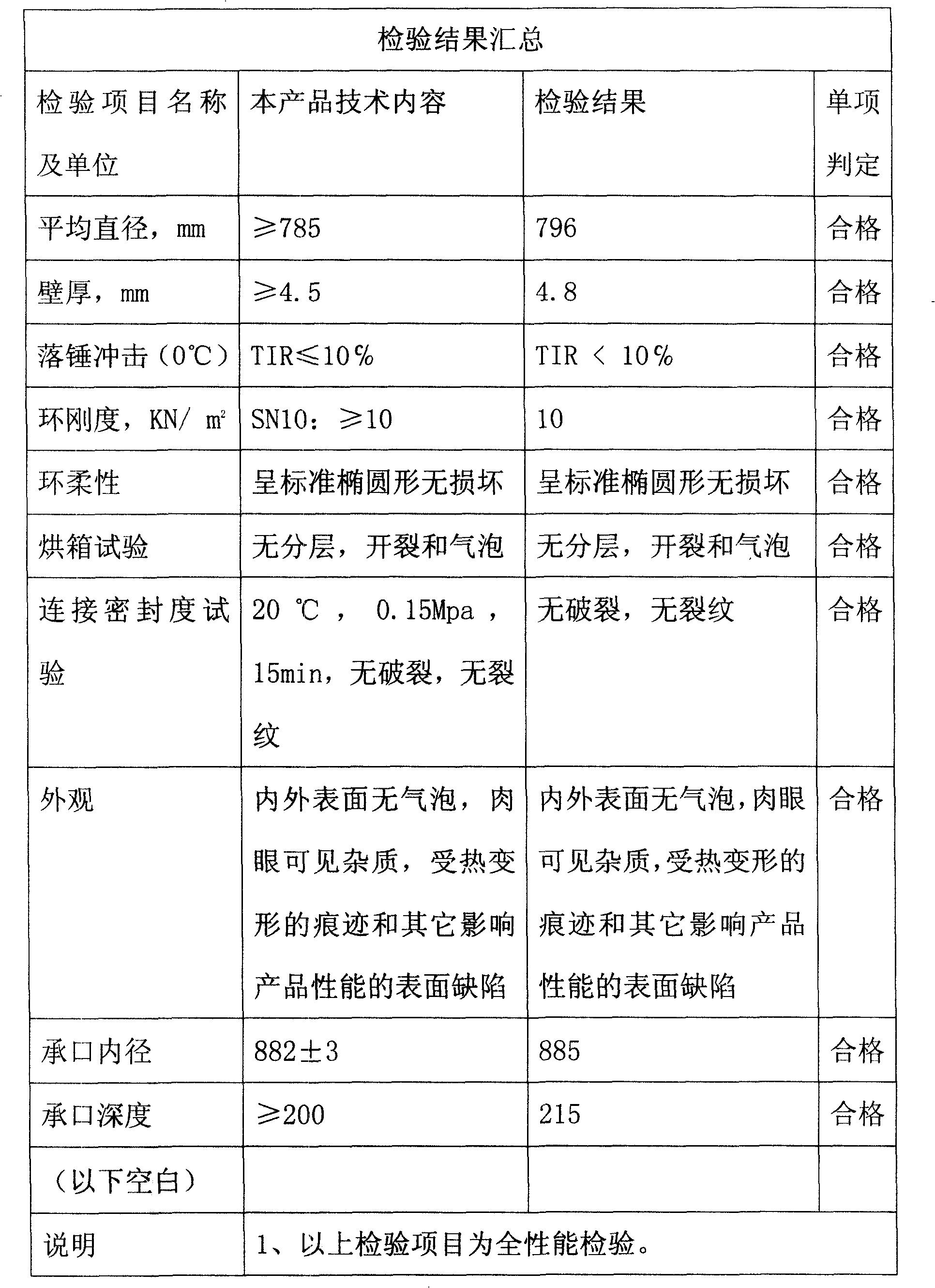

Technique for producing large diameter glass fiber reinforcement polypropylene reinforced pipe and material used for the same

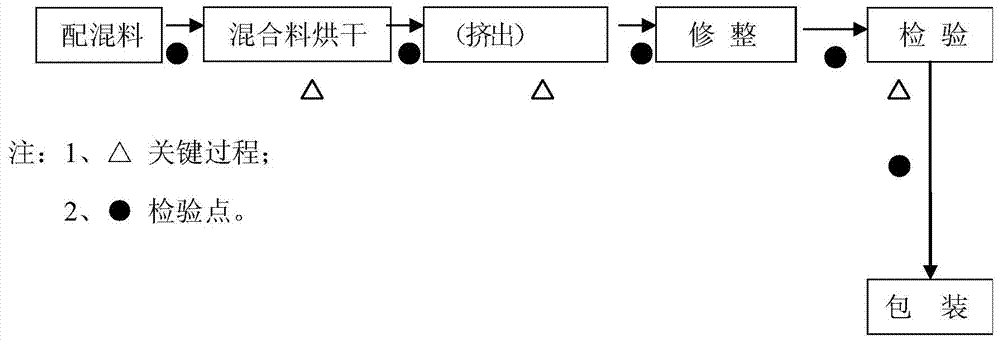

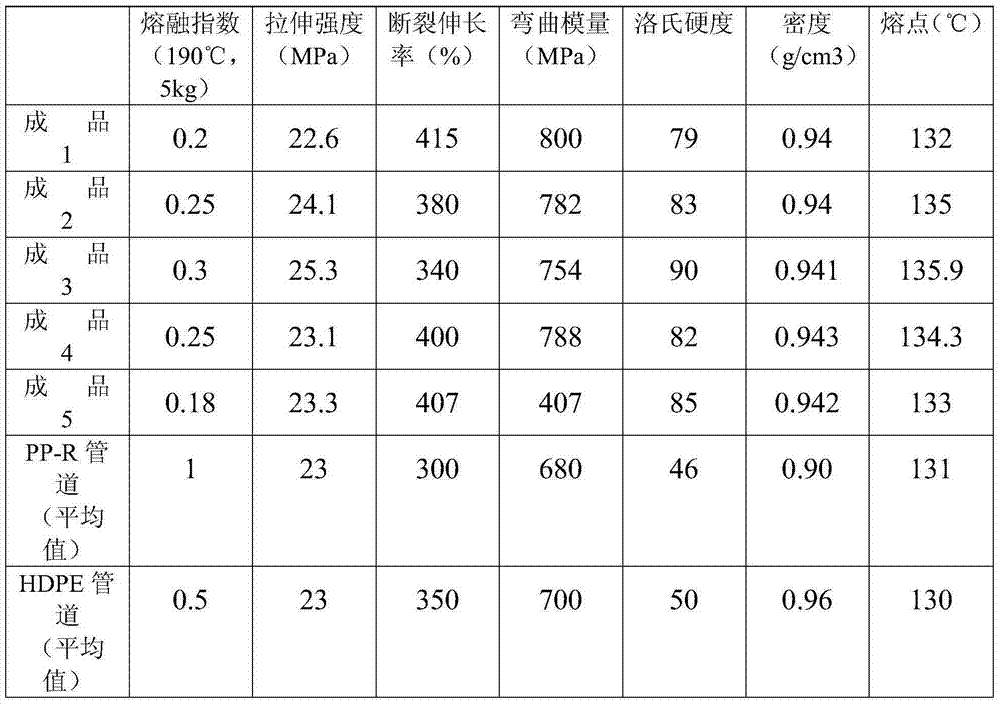

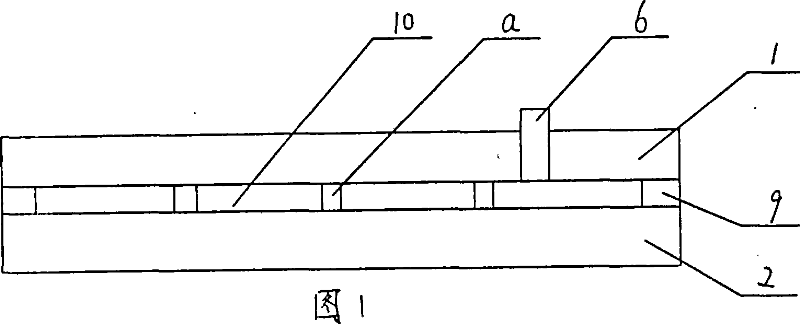

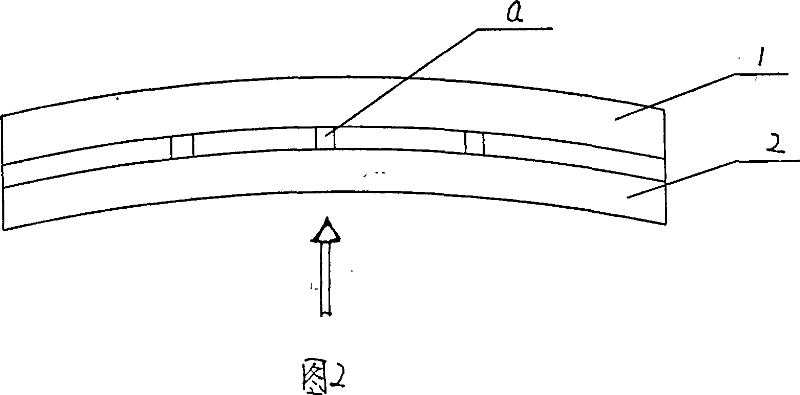

The invention discloses a material for producing a FRPP ribbed tube with large diameter and a production technology using the material to produce the FRPP ribbed tube with large diameter. The materials for producing the FRPP ribbed tube with large diameter include the following components and parts by weight: 100 parts by weight of polypropylene resin, 10-12 parts by weight of glass fiber, 15-18 parts by weight of heavy calcium carbonate, 8-9 parts by weight of toughening agent, 2-2.5 parts by weight of compatibilizer, and 0.2-0.5 parts by weight of PE wax. The production technology using the material to produce the FRPP ribbed tube with large diameter includes that firstly the raw materials are proportioned according to the definite weight ratio; then the formulations are mixed in a high-speed mixer in high speed; after that the mixed materials are introduced into an extruder for extrusion granulation; the resulting granular materials are further processed by 92 double screw extruder; and finally the resulting products are extruded and formed by a ribbed tube forming machine followed by cooling and fixed length cutting.

Owner:SHANGHAI JINSHAN YANGSHENG PIPELINE

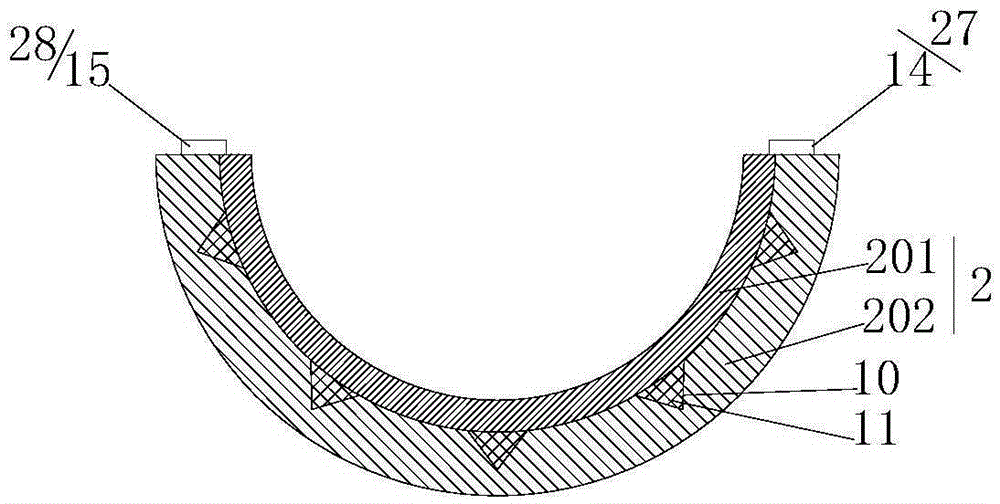

Cable protection pipe resistant to tension and compression

InactiveCN105262017AImprove tensile propertiesPlay an anti-stress roleElectrical apparatusHigh resistanceEngineering

The invention provides a cable protection pipe resistant to tension and compression. The cable protection pipe comprises a first opening protection pipe, a second opening protection pipe and a fixing device. The first and second opening protection pipes both have a semi-circular cross section. The first opening protection tube comprises a first inner protection pipe layer and a first outer protection pipe layer. The inner side of the first outer protection pipe layer is provided around the first inner protection pipe layer with a plurality of first support cavities having a triangular cross section. Each first support cavity is provided internally with a first flexible tension resistant body. The second opening protection pipe comprises a second inner protection pipe layer and a second outer protection pipe layer. The inner side of the second outer protection pipe layer is provided around the second inner protection pipe layer with a plurality of second support cavities having a triangular cross section. Each second support cavity is provided internally with a second flexible tension resistant body. The fixing device comprises a first fixing member and a second fixing member. The invention has the advantages of simple structure, high resistance to tension and compression, fixation, firmness, and good protection effect.

Owner:合肥市易远新材料有限公司

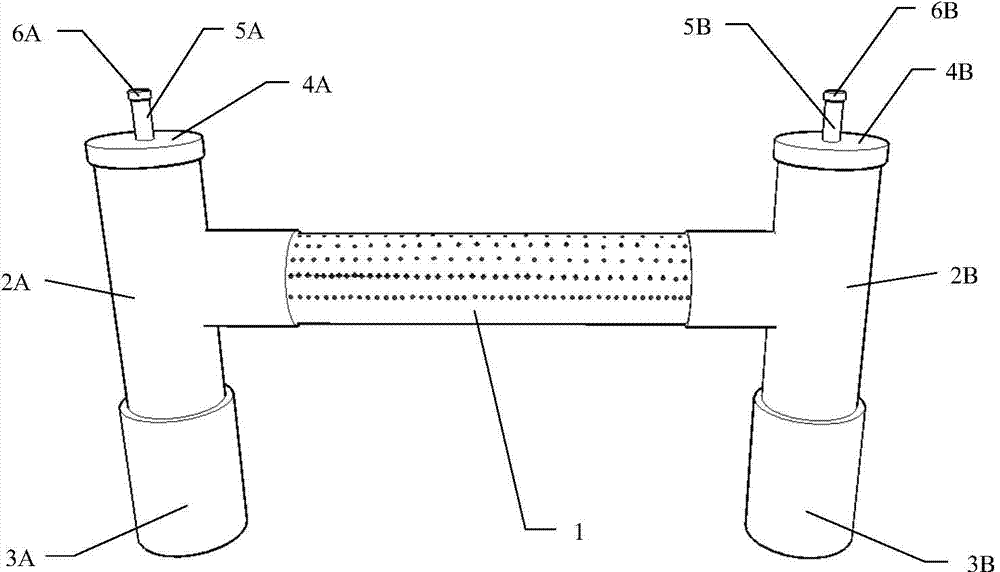

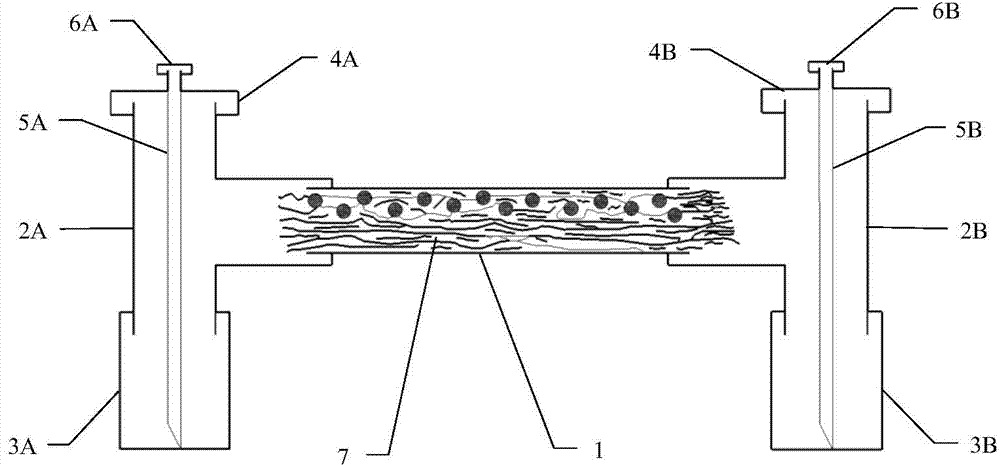

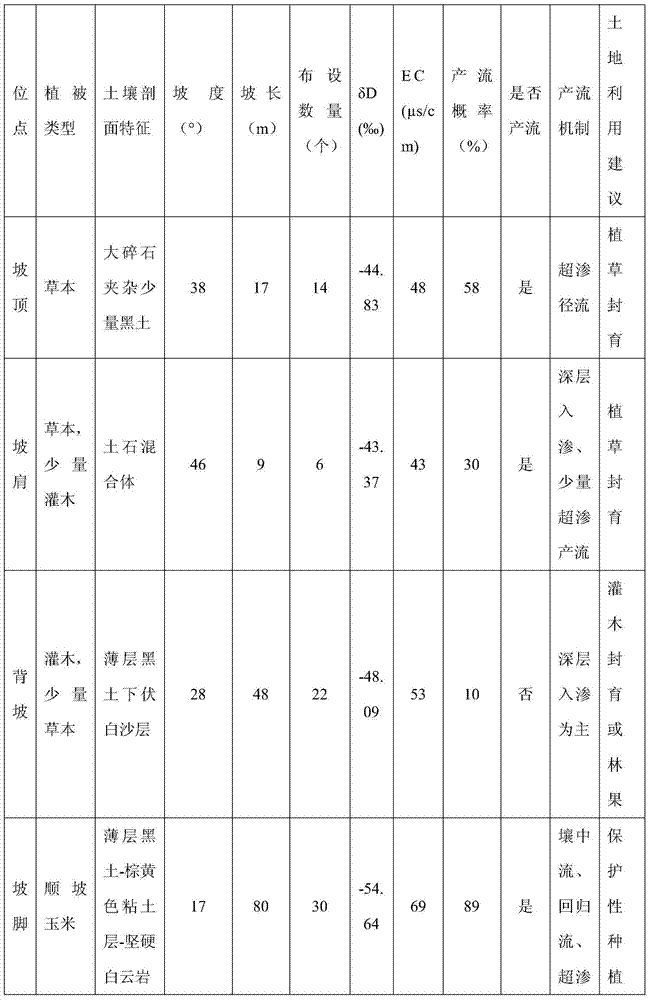

Device and method for detecting runoff producing positions on karst slope surface

InactiveCN103594020ALess adhesion lossDoes not affect concentrationEducational modelsKarstEngineering

The invention discloses a device and method for detecting runoff producing positions on a karst slope surface. The two ends of a PVC pipe are arranged in tee joints in a sleeved mode, the PVC pipe is filled with a thin gauze element, a water inlet hole is drilled in the wall of the PVC pipe, two ends of the tee joints are arranged in water storage pipes with sealed ends and pipe caps respectively in a sleeved mode, and a water guide pipe with a pipe plug at the upper end is inserted into each pipe cap and extends to the lower end of the corresponding water storage pipe. Based on slope surface point selection, the device is buried according to slope positions and types of heterogeneous ecological niches; after each rainfall, the runoff producing situation is checked, a water sample is collected, and basic water chemical indexes are measured; the runoff producing possibility of each point on the slope surface in a hydrologic year and the space-time distribution of the water chemical indexes are comprehensively analyzed, and finally judgment on the runoff producing positions on the slope surface is finished. The device for detecting the runoff producing positions on the karst slope surface is simple to manufacture, small in investment, and convenient and rapid to install, solves the problems occurring when a traditional research method is used for detecting the runoff producing positions on the karst slope surface and other areas with discontinuous earth covers, and can provide a technical means for the aspects of reasonable utilization of limited water resources, reasonable distribution of land utilization, vegetation recovery strategies and the like in the areas.

Owner:INST OF SUBTROPICAL AGRI CHINESE ACAD OF SCI

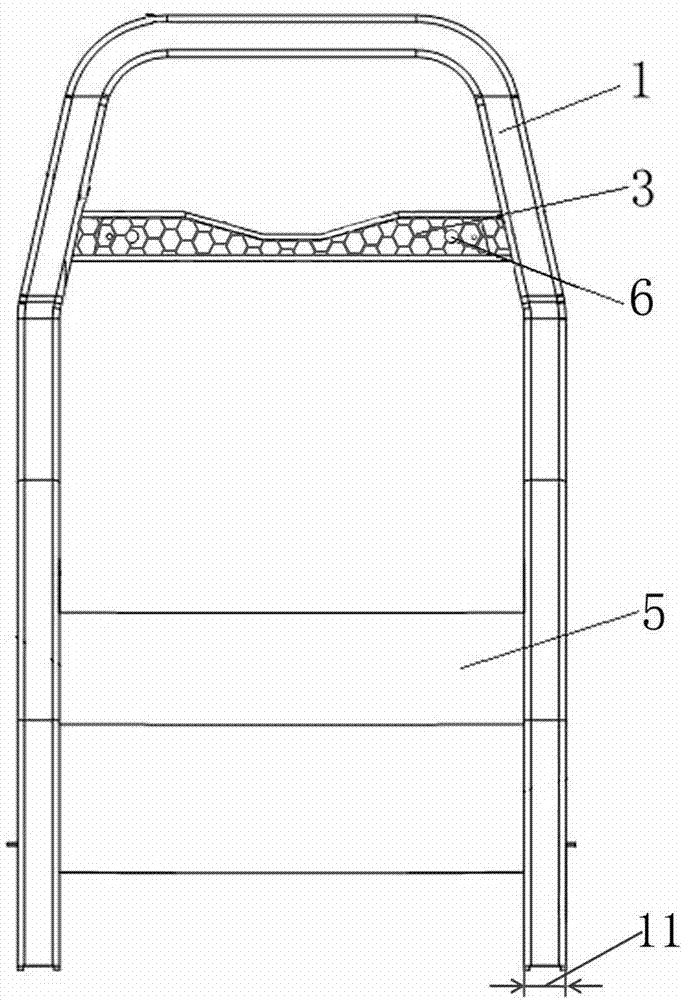

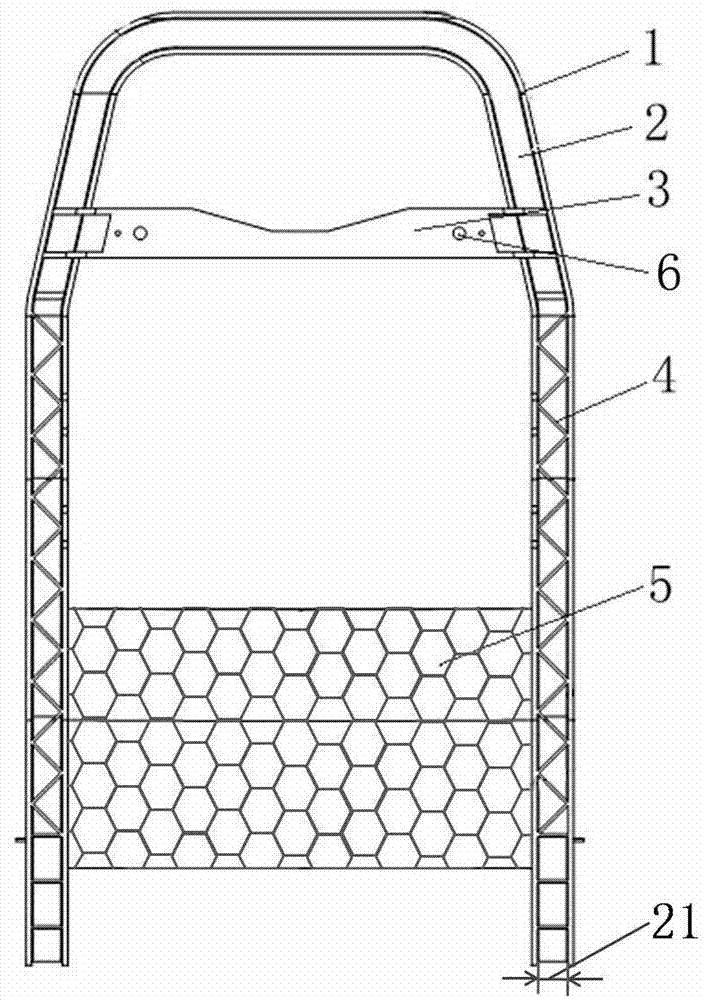

Seat backrest skeleton of intercity bus

The invention discloses a seat backrest skeleton of an intercity bus. The seat backrest skeleton comprises a door frame type skeleton integrally molded by a thermoplastic composite material, wherein the skeleton adopts a U-shaped groove structure, and is 20-40 mm wide and 25-50 mm thick; the U-shaped groove is 15-35 mm wide; and the thickness of the skeleton is greater than or equal to the width of the U-shaped groove. The structures and the sizes of a headrest part and a backrest part of the seat backrest skeleton are optimally designed, so that the whole stress condition is obviously improved. As the width of the groove is proper, the skeleton and reinforcing ribs inside are synchronously stressed when being impacted, which approximates to the case that the whole impact is borne by the seat backrest skeleton. According to the result of a finite element analysis, the seat backrest skeleton meets the safety standards of intercity buses.

Owner:ZHENGZHOU LINGYU NEW MATERIALS

Method for preparing rubber reinforcing filler by utilizing iron tailings

ActiveCN106317967AImprove tensile and compressive strengthImprove fatigue resistancePigment treatment with organosilicon compoundsPigment treatment with non-polymer organic compoundsCompressive strengthMechanical property

The invention provides a method for preparing a rubber reinforcing filler by utilizing iron tailings. The method comprises the steps of iron tailing pre-desliming, iron tailing grading and regrinding, high-purity glass sand preparation and modified quartz sand preparation. The method for preparing the rubber reinforcing filler by utilizing the iron tailings can fully utilize high-silicon iron tailing resources to prepare the high-value-added rubber reinforcing filler, the filler is small in particle diameter and regular and uniform in shape, has strong rubber interface binding power and can effectively improve the abrasion resistance, toughness, compressive strength, fatigue resistance property and other mechanical properties of rubber, and the comprehensive utilization value of the iron tailings is improved.

Owner:DALIAN DEETOP ENVIRONMENTAL TECH CO LTD

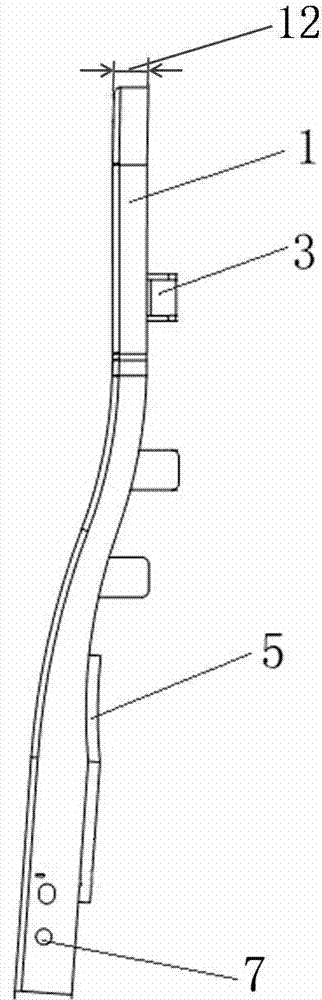

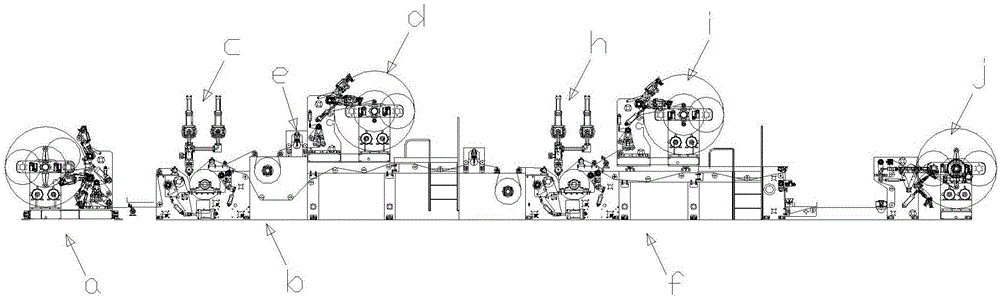

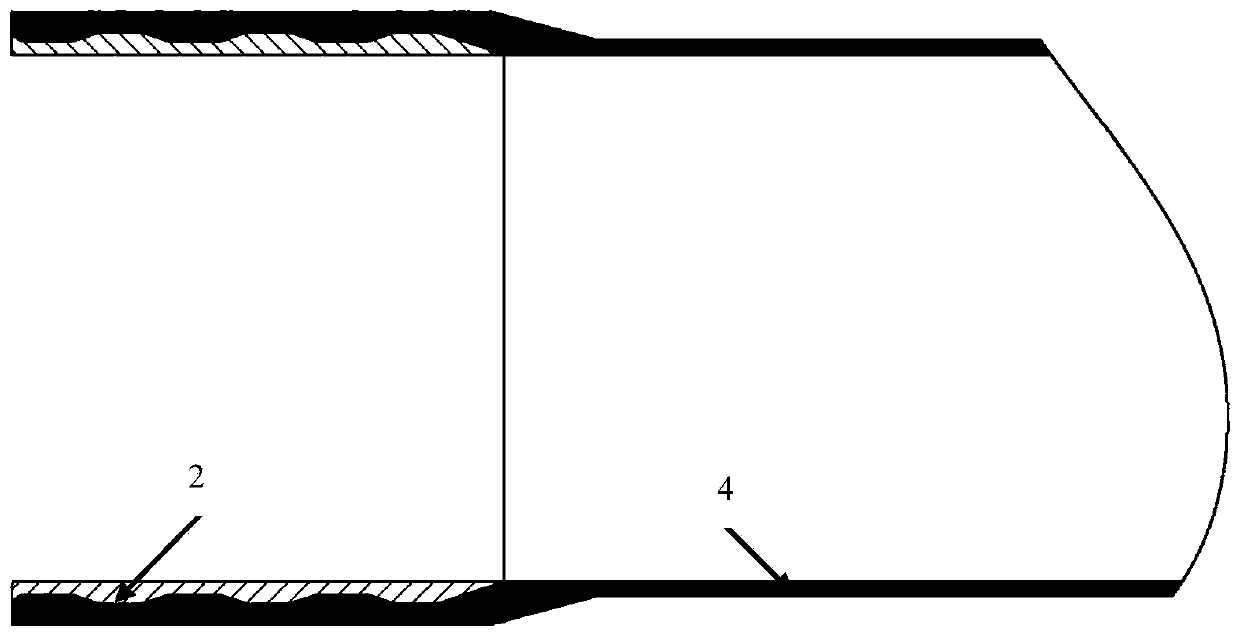

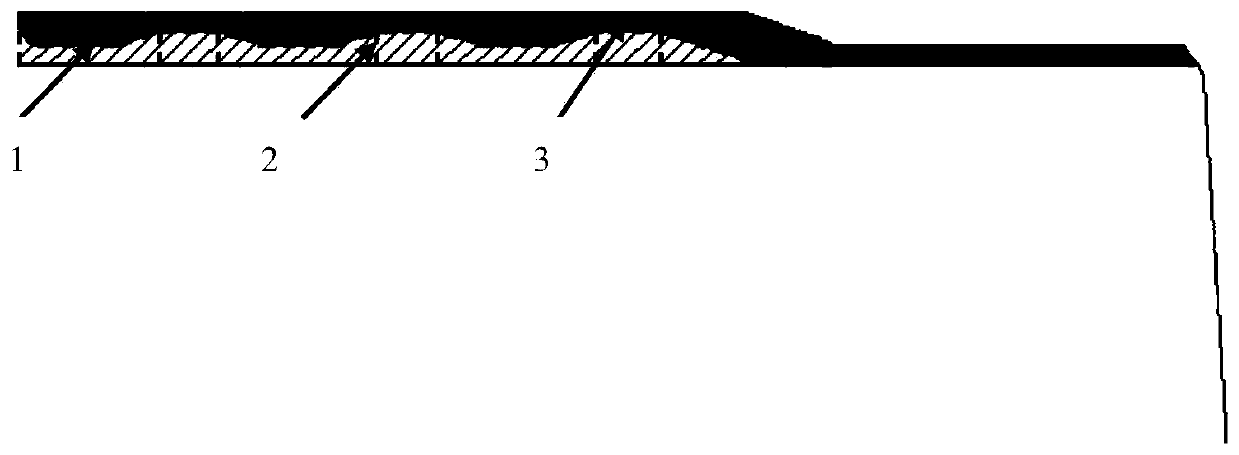

Method for preparing lithium battery aluminum-plastic composite film through coextrusion

ActiveCN107521064AImprove tensile and compressive strengthEasy to press and formElectrical equipmentFlat articlesComposite filmCompressive strength

The invention discloses a method for preparing a lithium battery aluminum-plastic composite film through coextrusion. The lithium battery aluminum-plastic composite film sequentially comprises an explosion-proof protective layer, a protective layer attaching layer, a first grafting composite layer combined with an aluminum foil, an aluminum foil layer, a second grafting composite layer combined with an aluminum foil, a heat sealing layer attaching layer and a heat sealing layer from outside to inside, wherein the protective layer attaching layer and the first grafting composite layer adopt lamination coextrusion and the second grafting composite layer and the heat sealing layer attaching layer adopt lamination coextrusion. The method disclosed by the invention has the advantages that the integral tensile strength and the compressive strength of the composite film are greatly increased; the attaching fastness of the composite film is almost 30% higher than that of like products adopting dry lamination and is up to more than 10N; and therefore, the stamping forming of the composite film is more benefitted and even the domestic aluminum foil can replace the aluminum foil imported from Japan to be applied to stamping.

Owner:浙江康骏机械有限公司

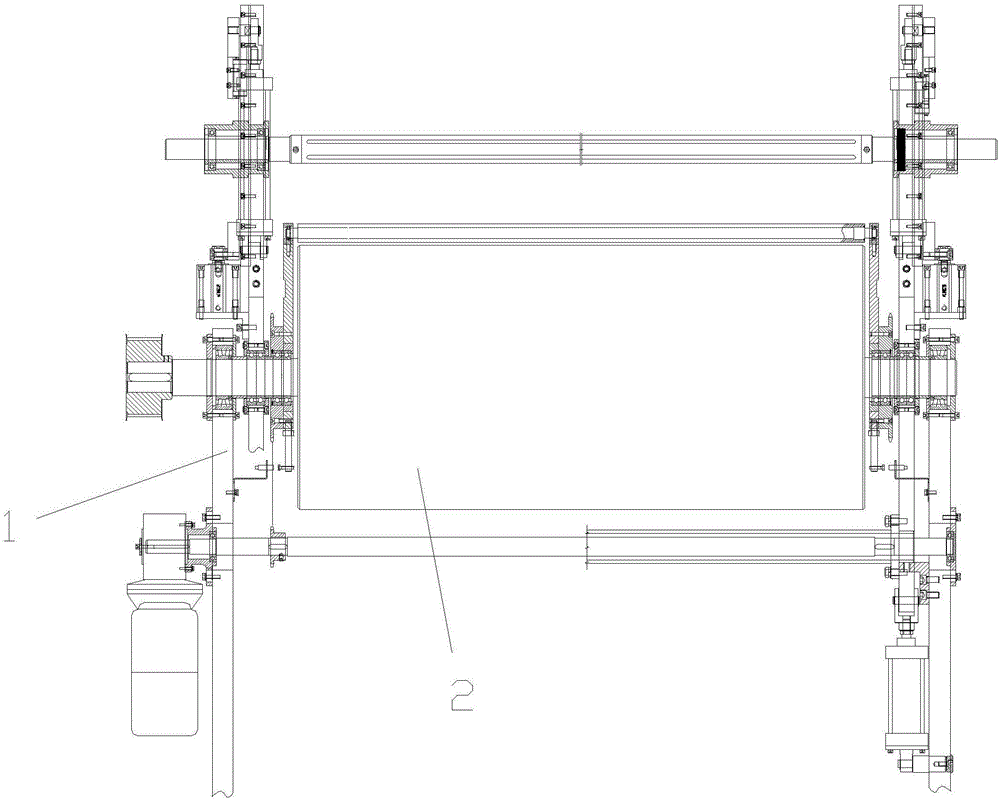

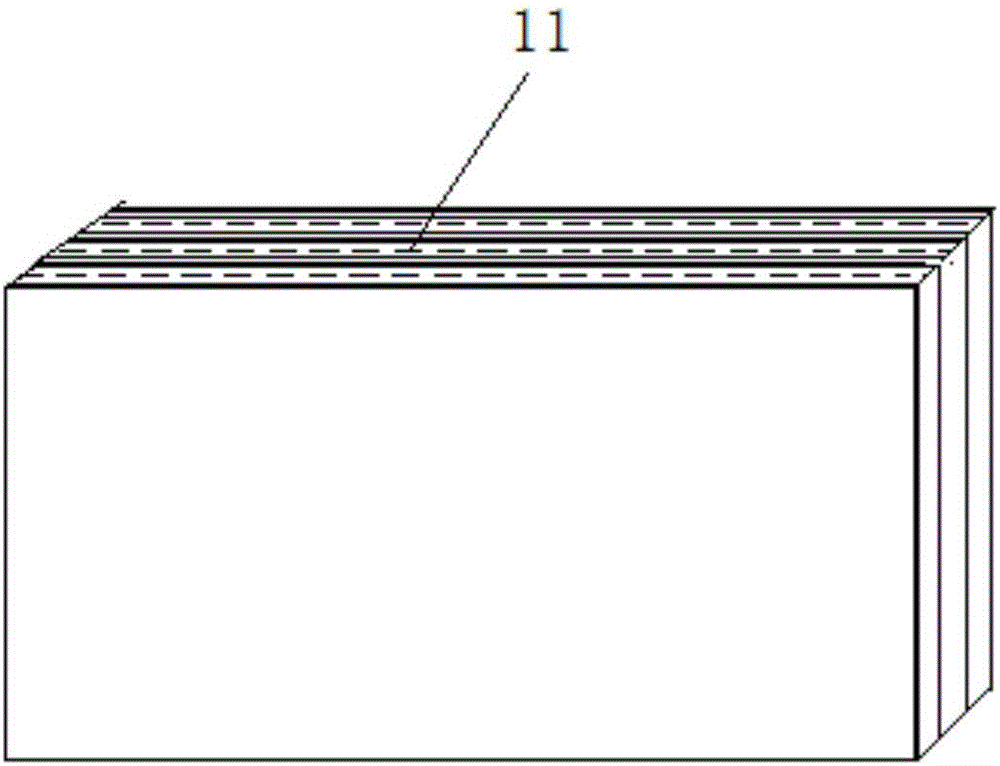

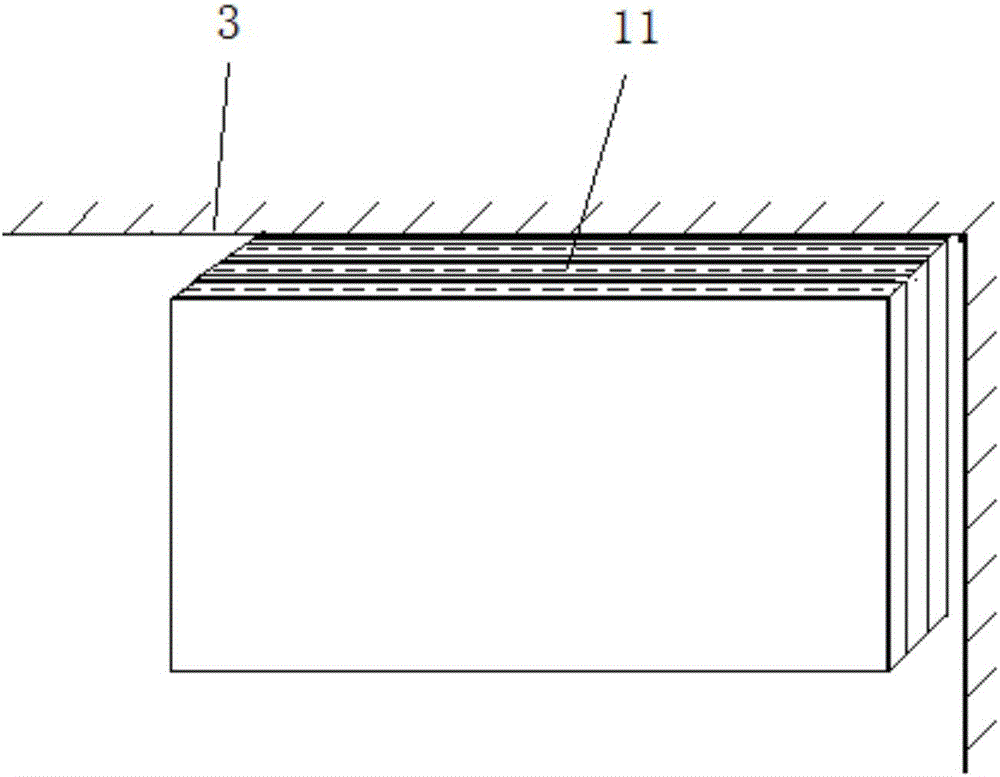

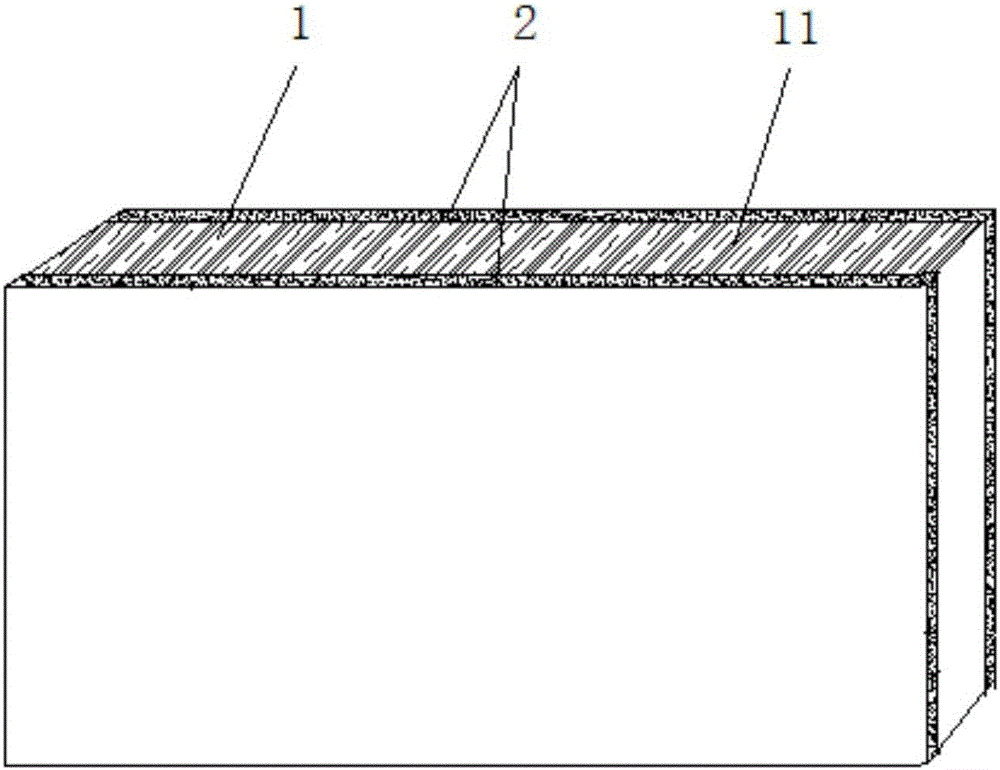

Outer wall insulating board and mounting method thereof

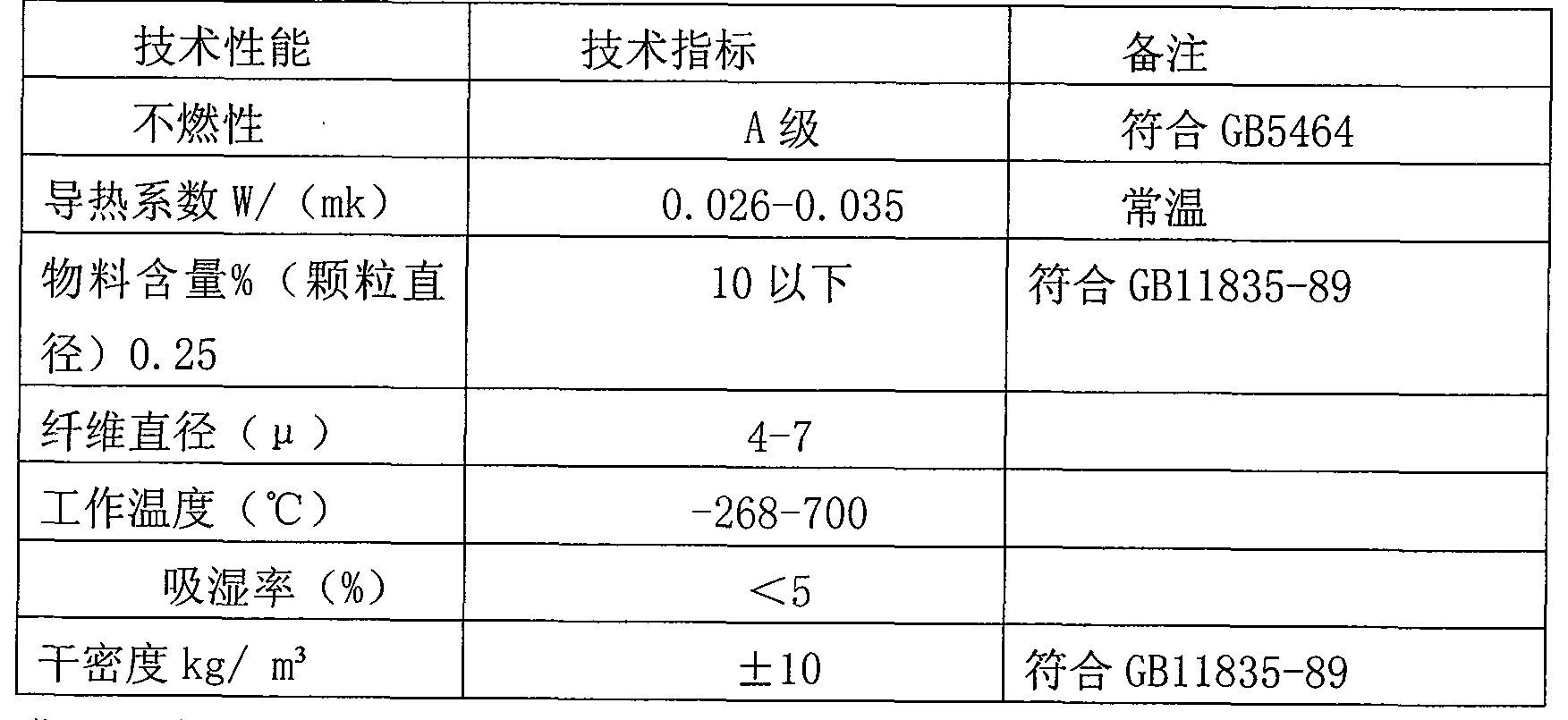

InactiveCN106836535ASuperior insulationImprove tensile and compressive strengthLaminationLamination apparatusEngineeringFiber

The invention discloses a thermal insulation board for an outer wall, which comprises a thermal insulation layer and an interface layer, and the thermal insulation layer adopts inorganic fiber cotton. The important feature of the present invention is that the fiber orientation of the inorganic fiber cotton is perpendicular to the interface layer and the wall surface. This makes the drawing direction of the inorganic fiber cotton parallel to the direction of the wind and the direction of the force after installation, which improves the tensile and compressive strength and resists the damage to the wall caused by the wind pressure.

Owner:赵泊然

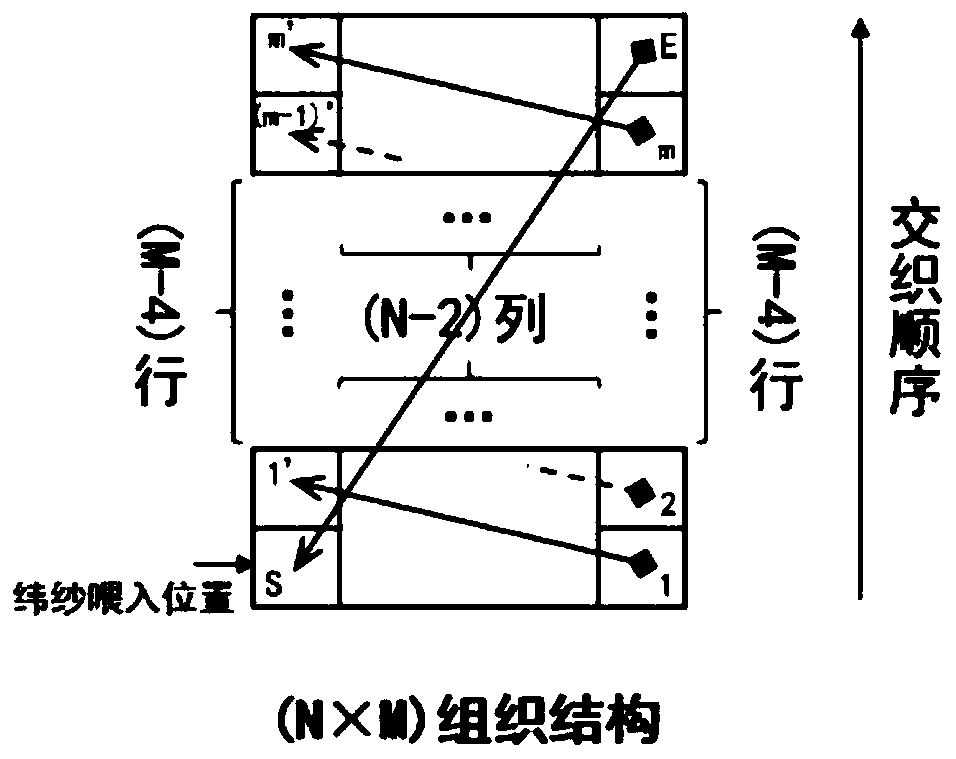

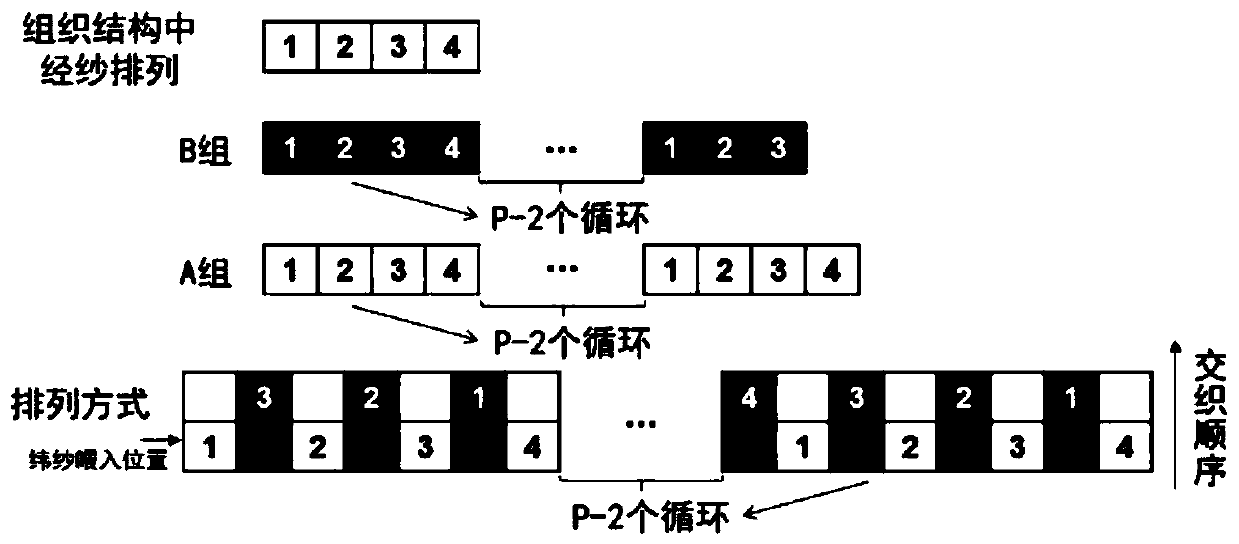

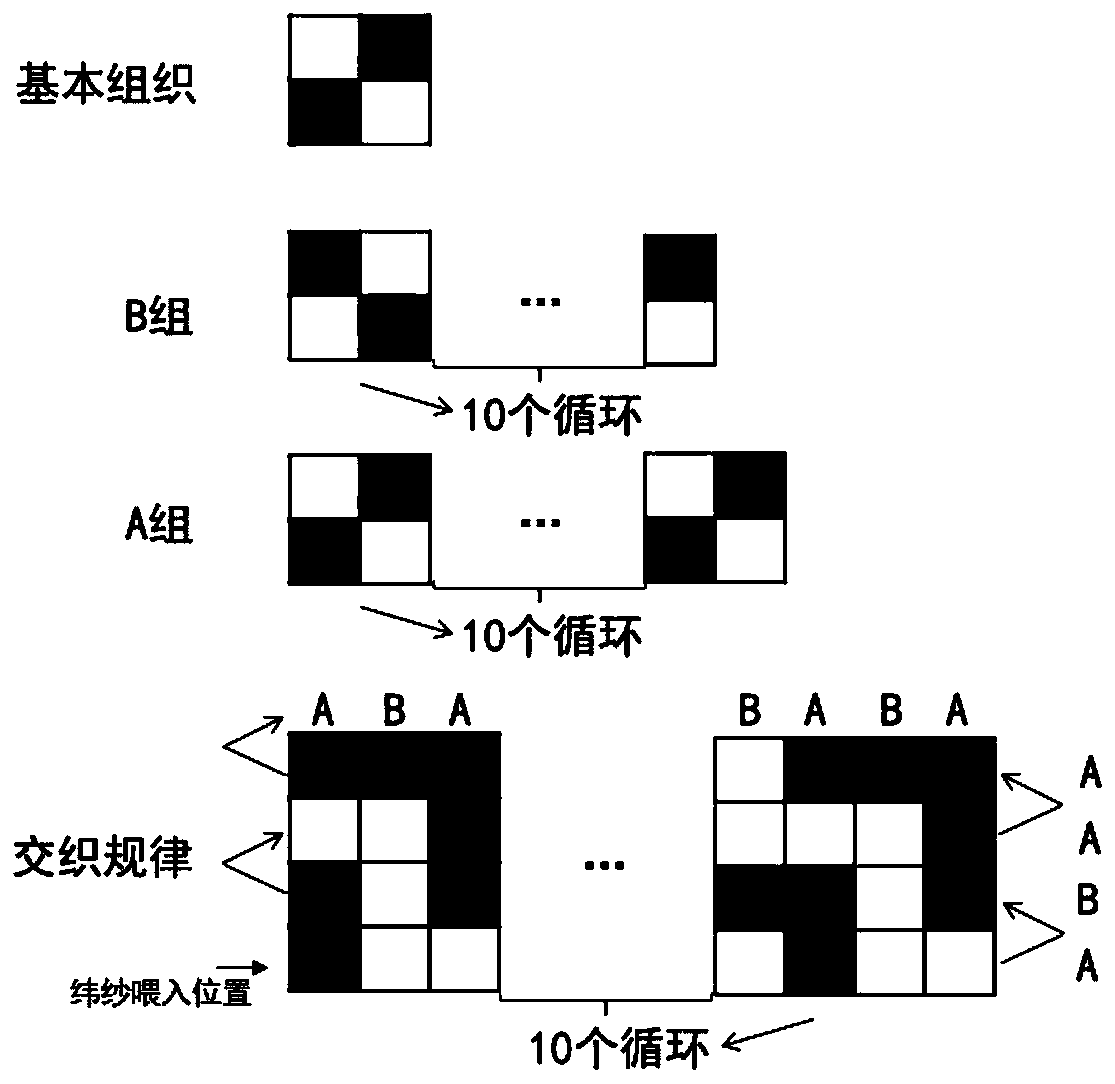

Preparation method of reinforced cement-based concrete non-splicing type woven pipe

ActiveCN111575866AAxial tensile and compressive properties of uniform structureImprove tensile and compressive strengthGeotextilesWoven fabricsFiberCompressive strength

The invention discloses a preparation method of a reinforced cement-based concrete non-splicing type woven pipe. The preparation method comprises the following steps that A, fiber raw materials for preparing the concrete woven pipe are selected; B, based on a special organization structure, warp yarns are arranged according to a specific rule, and weft yarns are continuously fed in a shuttle mode;and C, according to a specific interweaving rule, a tubular fabric with uniform axial and circumferential structures is prepared. According to the preparation method, the tubular fabric can be prepared by adopting the single weft yarns, the overall structure is uniform, the designability is high, corrosion resistance is achieved, the weight is light, the preparation method can be used for enhancing the axial tensile and compressive properties of the overall structure of cement-based concrete, the tensile and compressive strength of the cement-based concrete is improved, the compression-shearfailure is reduced, the overall sudden brittle fracture is avoided, the safety coefficient of related engineering is improved, the preparation method can be used for reducing the brittle failure of the cement-based concrete, and the preparation method can also be used for preparing cement-based concrete structural parts.

Owner:NANTONG UNIVERSITY

High-strength bend-resistant anti-corrosion adhesive tape

InactiveCN103694915AReduce usageLow costFilm/foil adhesivesCorrosion preventionWave shapeFlexural strength

The invention relates to a high-strength bend-resistant anti-corrosion adhesive tape which is sequentially compounded from five layers, namely an aluminum foil reflecting layer, a PE (Polyethylene) high-strength mesh layer, a polyolefine heat-shrinkable layer, a polytetrafluoroethylene layer and a composite bonding layer, in all to form a tape shape. The PE high-strength mesh layer is in a through hole structure, the aluminum foil reflecting layer can be connected with the polyolefine heat-shrinkable layer through a through hole, and the surface of the polytetrafluoroethylene layer is in a wave-shaped structure. The high-strength bend-resistant anti-corrosion adhesive tape disclosed by the invention has the advantages of convenience for use, ultraviolet resistance, high tensile and compressive strength and high corrosion-resistant property, achieves very high bending strength without being broken under relatively high strength bending and achieves good sealing property due to the stress action of the polyolefine heat-shrinkable layer.

Owner:TIANJIN SENTERUI ANTICORROSION MATERIAL

Thermal insulation rheological material and preparation method thereof

InactiveCN108751789AImprove thermal insulation performanceImprove tensile and compressive strengthCeramicwareEmulsionThermal insulation

The invention provides a thermal insulation rheological material and a preparation method thereof. The thermal insulation rheological material comprises, by weight, 5 to 80 parts of aerogel powder, 40to 240 parts of a reinforcement material containing kaolin, 40 to 180 parts of a latex liquid, 0 to 20 parts of a flame retardant and 90 to 150 parts of water. The thermal insulation rheological material has good thermal insulation effects and a thermal insulation rate of 0.06 W / m.K or less. The dried thermal insulation rheological material has high tensile and compressive strength and prevents dusting. A polymer network formed from the dried emulsion is located on the surface of the porous material, produces bonding effects and support skeleton effects and improves strength.

Owner:优澎(嘉兴)新材料科技有限公司

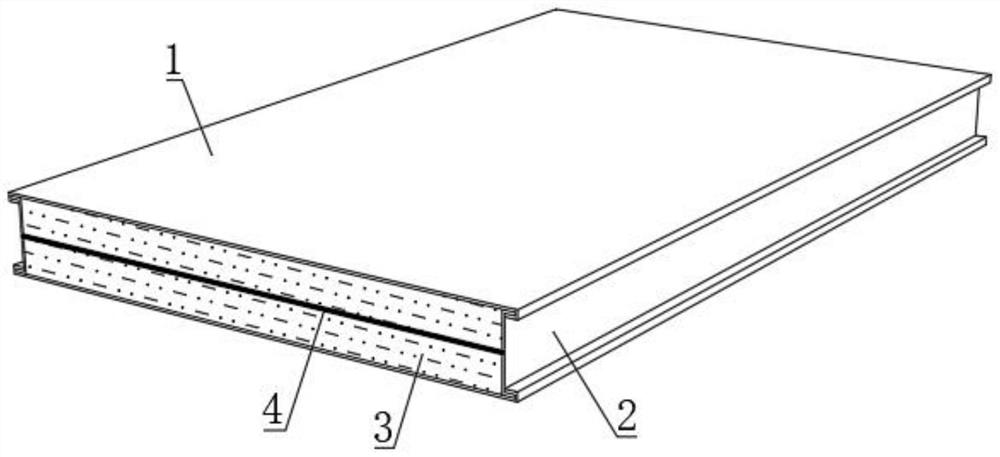

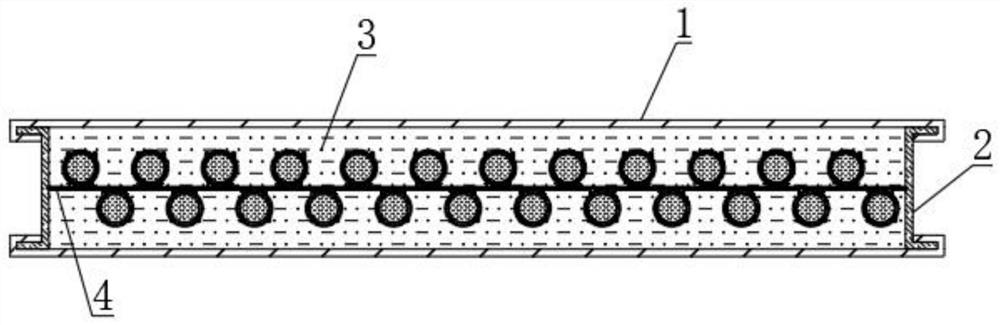

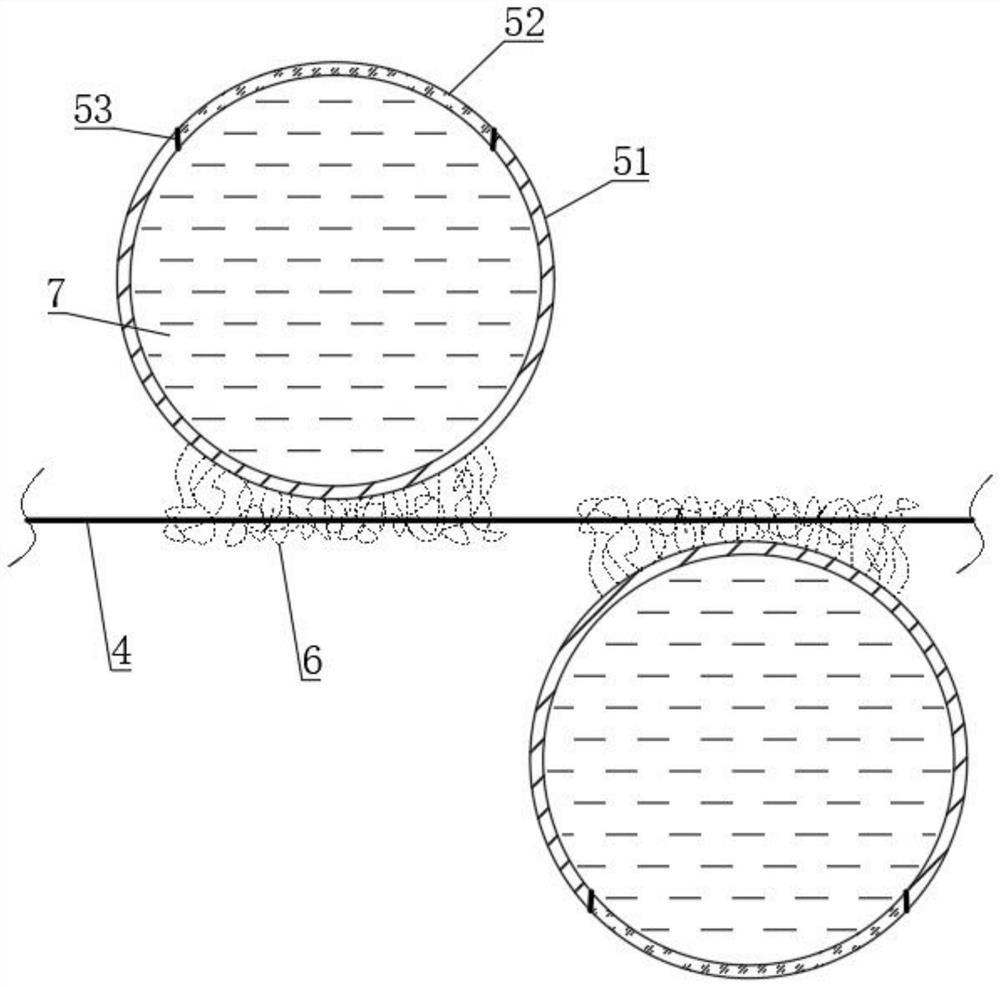

Fireproof color steel sandwich panel and preparation method thereof

ActiveCN112829396AImprove tensile and compressive strengthHigh mechanical strengthLamination ancillary operationsSynthetic resin layered productsPhenolformaldehyde foamSandwich panel

The invention discloses a fireproof color steel sandwich panel and a preparation method thereof, which belong to the field of color steel sandwich panels. Gridding cloth and anti-cracking balls A are combined and jointly formed in a phenolic foam board, and the phenolic sandwich panel with excellent heat preservation and fireproof performance is obtained; meanwhile, the tensile strength and compressive strength of the phenolic foam board are improved through the gridding cloth, the cracking and pulverization conditions of the phenolic foam board are reduced, then the overall performance is improved, cracks in the phenolic foam board with the cracking and fragmentation conditions can be repaired through the anti-cracking balls A, the fragmented phenolic foam board is bonded again, the phenolic foam board recovers a certain degree of strength performance, cracks are not prone to fragmentation, extension and expansion due to external force, the mechanical strength of the phenolic foam board is effectively enhanced, and therefore double guarantee measures are provided for the mechanical strength of the phenolic foam board.

Owner:WUJIANG HUAZHAO PURIFY EQUIP LTD

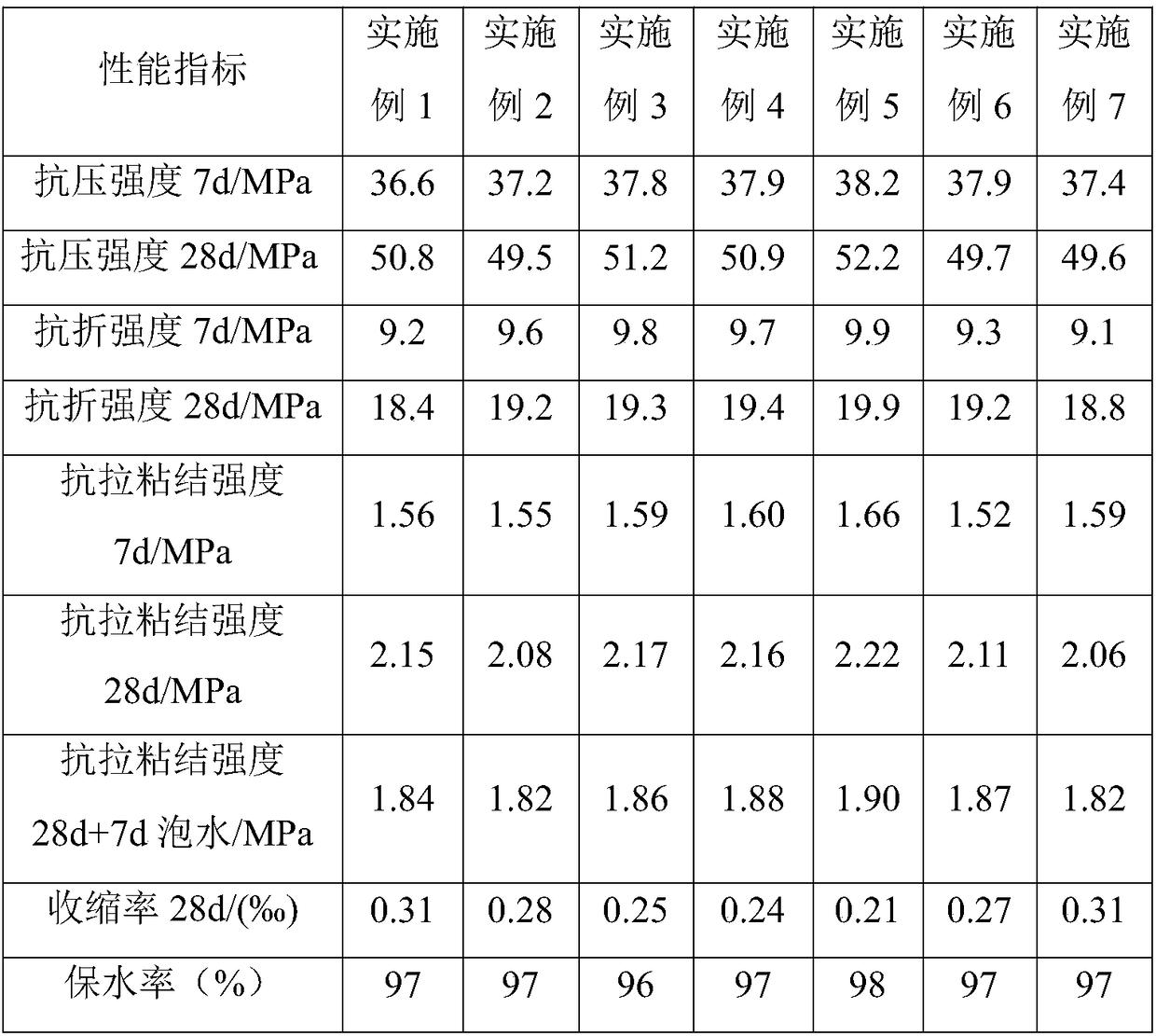

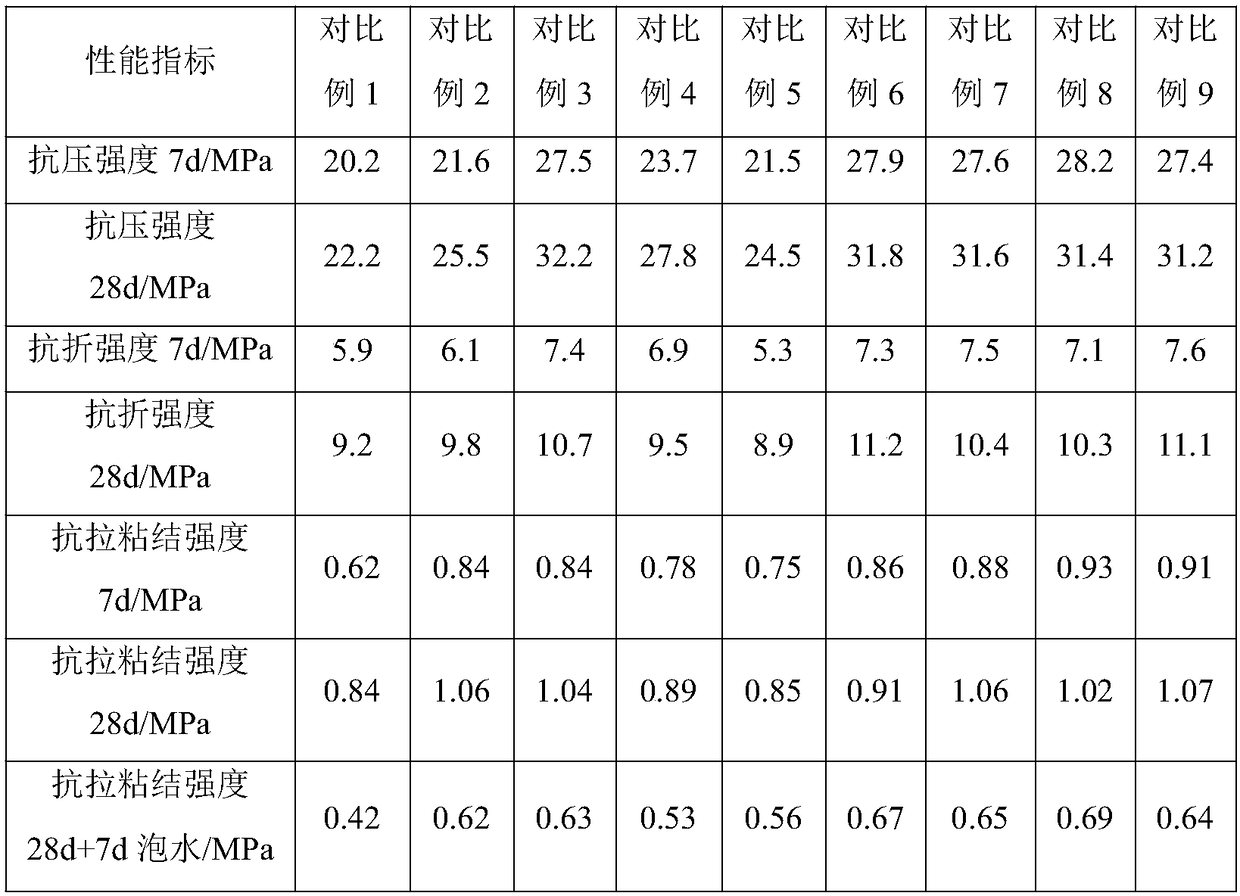

Special joint filling mortar for light partition wallboards

The invention discloses special joint filling mortar for light partition wallboards. The special joint filling mortar comprises, by weight, 300-400 parts of cement, 100-140 parts of fly ash, 400-450 parts of fine sand, 30-60 parts of calcined gypsum powder, 2-10 parts of macromolecule xanthan gum powder, 1-10 parts of redispersible latex powder, 1-3 parts of starch ether, 1-3 parts of cellulose ether, 1-3 parts of set retarders, 40-60 parts of expansive agents, 2-8 parts of graphene oxide modified carbon fibers and 1-5 parts of water repellents. A mass ratio of the macromolecule xanthan gum powder to the redispersible latex powder is 2-7:1; an expansion coefficient of the calcined gypsum powder is 120-130, and a mass ratio of graphene oxide to carbon fibers is 0.05-0.1:1. The special jointfilling mortar for the light partition wallboards has the advantages that various components of the special joint filling mortar are selected, the weights of the various components are matched with one another, respective excellent properties of the various components are comprehensively utilized, the strength of the components is drawn, and accordingly the special joint filling mortar is high inbonding strength, tensile and compressive property and water retention rate and low in shrinkage.

Owner:GUANGDONG FUTE NEW MATERIALS TECH CO LTD

Silicon carbide fiber cable material and preparation method thereof

The invention discloses a silicon carbide fiber cable material and a preparation method thereof. The silicon carbide fiber cable material is prepared from the following raw materials in parts by weight: 30 to 50 parts of organic silicon modified acrylate, 35 to 45 parts of epoxy resin, 20 to 30 parts of BNDB, 5 to 15 parts of styrene, 10 to 20 parts of No. 800 paraffin base rubber oil, 9 to 15 parts of pentaerythritol, 10 to 20 parts of chlorinated polyethylene, 10 to 20 parts of ethylene-octene copolymer elastomer, 8 to 12 parts of silicon carbide fiber, 4 to 8 parts of active magnesium oxide, 4 to 8 parts of active zinc oxide, 6 to 12 parts of calcium carbonate, 3 to 7 parts of microcrystalline wax, 1 to 5 parts of plasticizer, 1 to 5 parts of fire retardant, 1 to 5 parts of antioxidant and 1 to 3 parts of stabilizer. The preparation method of the silicon carbide fiber cable material comprises the steps of performing crushing, inductive heat treatment, mixing, pelleting and the like on the raw materials. The silicon carbide fiber cable material provided by the invention is simple in preparation, excellent in flame retardant property, and good in waterproofness and corrosion resistance, does not easy to age, is high in tensile strength and compressive strength and long in service life, can be widely applied in various fields, and has a good market prospect.

Owner:合肥博创机械制造有限公司

Technique for producing large diameter glass fiber reinforcement polypropylene reinforced pipe and material used for the same

The invention discloses a material for producing a FRPP ribbed tube with large diameter and a production technology using the material to produce the FRPP ribbed tube with large diameter. The materials for producing the FRPP ribbed tube with large diameter include the following components and parts by weight: 100 parts by weight of polypropylene resin, 10-12 parts by weight of glass fiber, 15-18 parts by weight of heavy calcium carbonate, 8-9 parts by weight of toughening agent, 2-2.5 parts by weight of compatibilizer, and 0.2-0.5 parts by weight of PE wax. The production technology using thematerial to produce the FRPP ribbed tube with large diameter includes that firstly the raw materials are proportioned according to the definite weight ratio; then the formulations are mixed in a high-speed mixer in high speed; after that the mixed materials are introduced into an extruder for extrusion granulation; the resulting granular materials are further processed by 92 double screw extruder; and finally the resulting products are extruded and formed by a ribbed tube forming machine followed by cooling and fixed length cutting.

Owner:SHANGHAI JINSHAN YANGSHENG PIPELINE

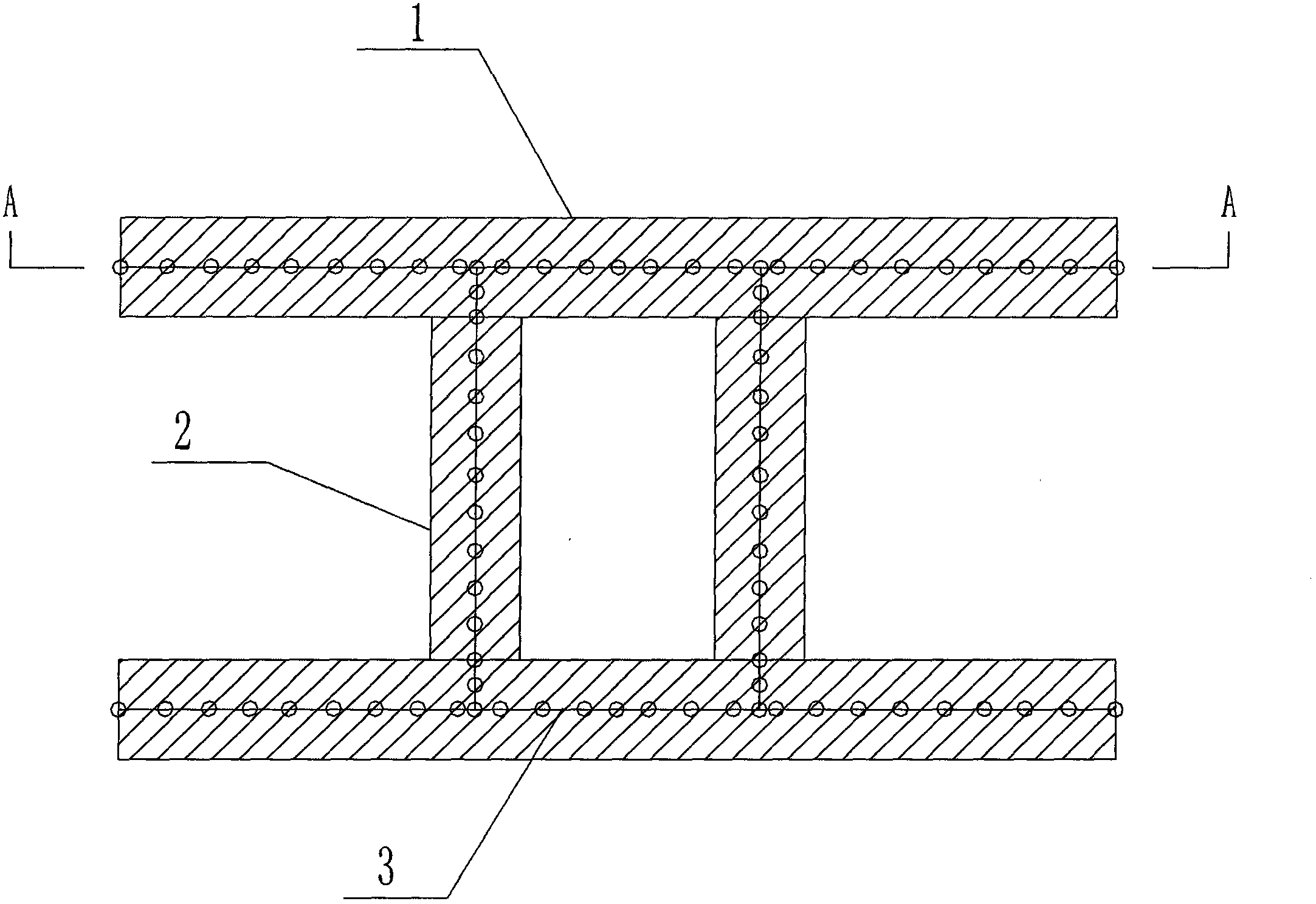

Steel-plastic composite H-beam and production method thereof

InactiveCN103423581AImprove tensile and compressive strengthSmall coefficient of thermal expansionElongated constructional elementsSurface finishBlow molding

The invention relates to a steel-plastic composite H-beam and a production method thereof. The H-beam comprises two mutually parallel transverse plates, and is characterized in that two mutually parallel vertical plates symmetrical along a center line of the transverse plates are connected between the two mutually parallel transverse plates along the length direction of the transverse plates, and all the transverse plates and the vertical plates are steel-plastic composite plates which are composed of plastic and metal nets composited in the plastic. The production method includes using metal strips as supporting materials to be connected into a framework in the shape of the H-beam, using metal wires for knitting metal wire net surfaces of the transverse plates and the vertical plates of the H-beam on the framework in the shape of the H-beam, using a mold for injection molding and blowing compressed air into the mold for blow molding, and cooling the outside of the mold by water. The steel-plastic composite H-beam has the advantages of high mechanical strength, large rigidity, no deformation, long service life, low energy consumption, low production cost, good surface smoothness and capability of completely substituting for a steel H-beam to serve as a bearing component.

Owner:索秋明

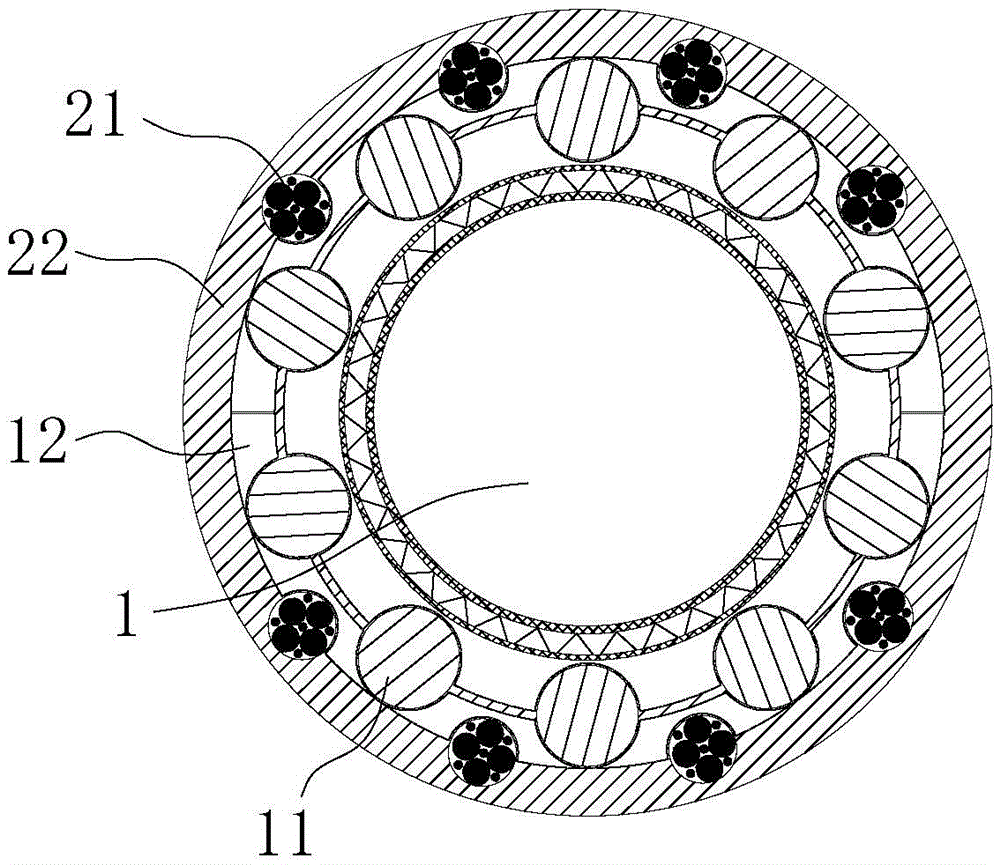

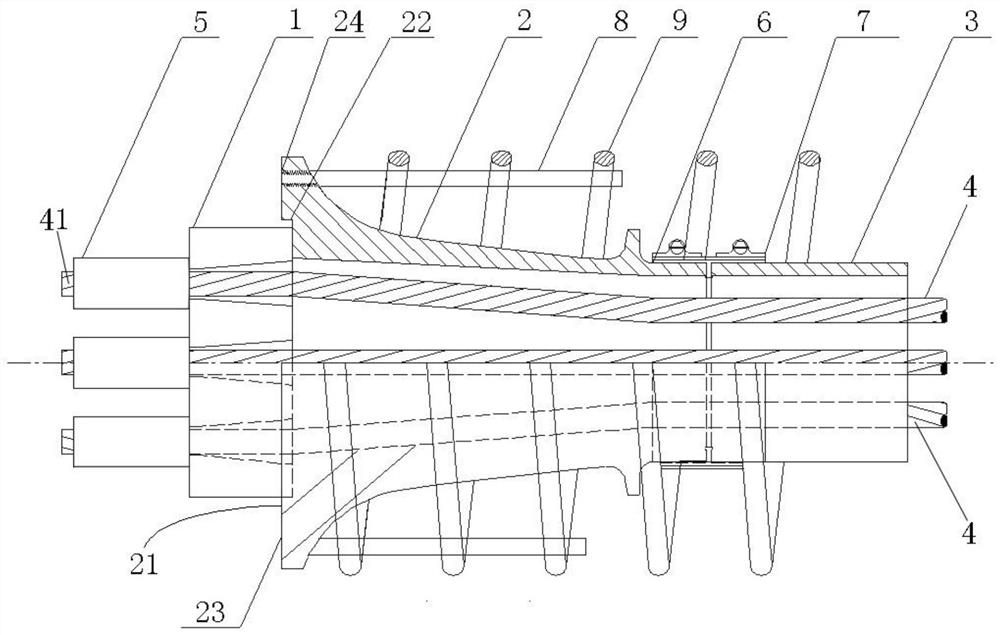

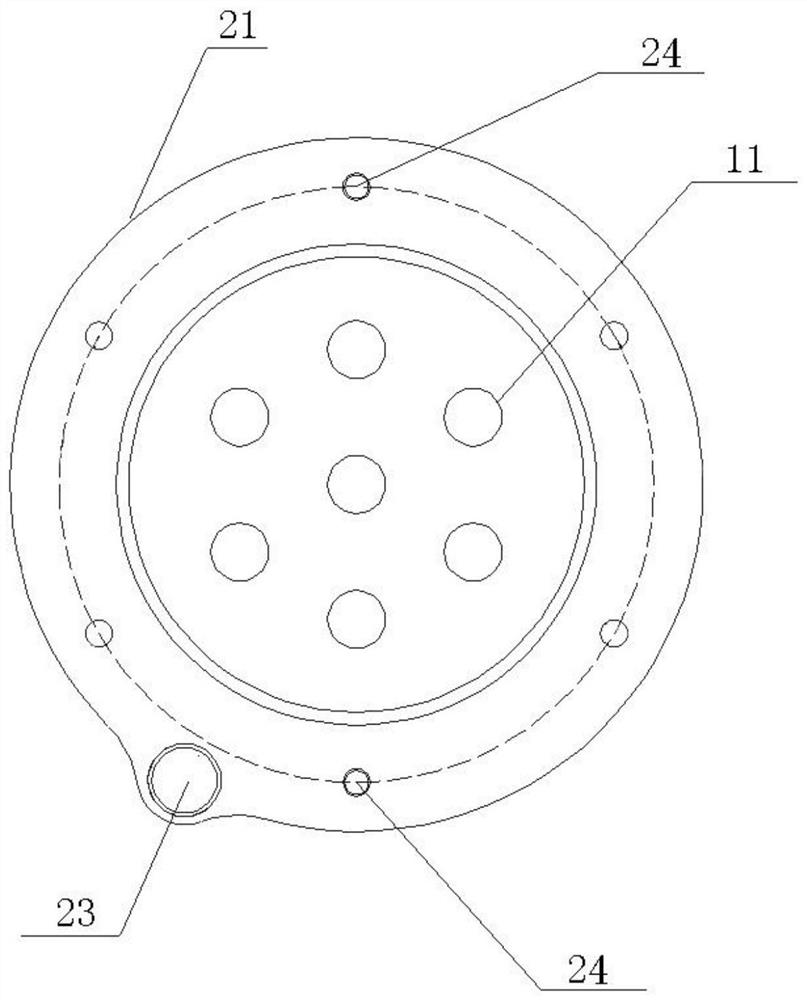

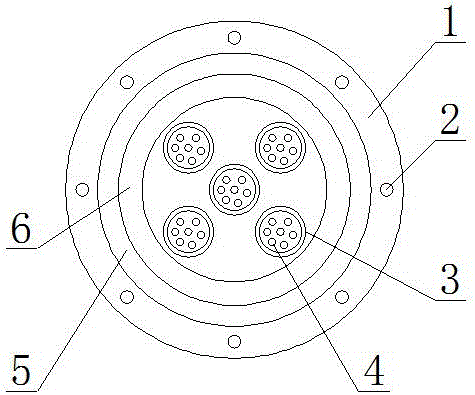

Umbilical cable for ocean engineering equipment

ActiveCN105551672AImprove tensile and compressive strengthHigh tensile strengthPower cables with screens/conductive layersSubmarine cablesCorrosionConductor Coil

The invention discloses an umbilical cable for ocean engineering equipment. The umbilical cable comprises a central air pipe, control cable cores, a first shielding coating layer, power cables and a second shielding coating layer, wherein the control cable cores are wound in a first groove in a peripheral surface of the central air pipe through screws, the first shielding coating layer is matched with the control cable cores exposed out of the peripheral surface of the central air pipe, the power cables are matched with a second groove spirally arranged in the peripheral surface of the first shielding coating layer, and the second shielding coating layer is matched with the power cables exposed out of the peripheral surface of the first shielding coating layer. In the structural design, the tensile strength, the compressive strength and the corrosion resistance of the cable can be effectively improved through spiral winding layer by layer.

Owner:GUANGZHOU JUNHE INTELLIGENT EQUIP TECH CO LTD

Forming process of composite material and metal joint

InactiveCN111319283AGuaranteed integrityImprove rigidityDomestic articlesFiberUltimate tensile strength

The invention discloses a forming process of composite material and a metal joint which can be used for a lightweight airplane traction rod structure. A connecting structure of the composite materialand the metal joint adopts a process method of manual laying and co-cementing molding of a curing oven; a physical embedding structure with a wavy section is adopted at the connecting area; and a unidirectional material is mainly laid in the design axial direction of the composite material laying layer, laying layers with + / -45 degrees direction and annular laying layers are laid at intervals, a trough position is filled with an annular fiber fabric in an area connected with the metal joint, the rigidity and strength of the connecting structure are guaranteed and improved, and finally a cylindrical appearance is formed in the connecting area. The forming process has the advantages of being simple and novel in structure, high in connection rigidity, good in structural stability, good in weight reduction effect and the like, and the forming process is particularly suitable for the design of high-rigidity composite materials and metal joints under tension and compression working conditions.

Owner:NO 54 INST OF CHINA ELECTRONICS SCI & TECH GRP

Anti-explosion anti-shock steel deck pavement structure and pavement method

PendingCN108086153AIncrease bond lengthIncreased friction and bite forceBridge structural detailsBridge erection/assemblyEngineeringFiber

The invention discloses an anti-explosion anti-shock steel deck pavement structure, and belongs to the technical field of bridge construction works. The structure comprises an orthotropic steel deck plate, an Eliminator waterproof adhesive layer, a Kevlar laminated sheet, an adhesive layer, a steel fiber concrete anti-explosion layer and an asphalt concrete wearing layer which are sequentially arranged from bottom to top. A welding stud-rubber flexible combination connector is welded on the upper surface of the orthotropic steel deck plate, and reinforcing meshes are arranged inside the steelfiber concrete anti-explosion layer. The integrity of the pavement structure is enhanced by the flexible combination connector, shear stiffness is reduced, the stress state of the steel fiber concreteanti-explosion layer is improved, applicability of the deck pavement structure is improved, the reinforcing meshes, the steel fiber concrete anti-explosion layer and the Kevlar laminated sheet form aprotection structure of the deck pavement structure, and the anti-explosion and anti-shock performances of the steel deck plate and an internal structure thereof are effectively improved.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

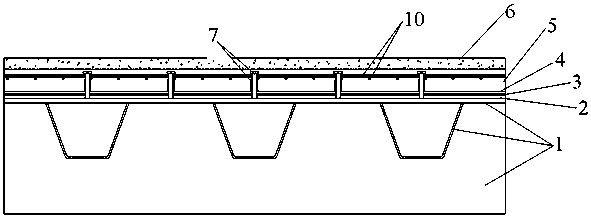

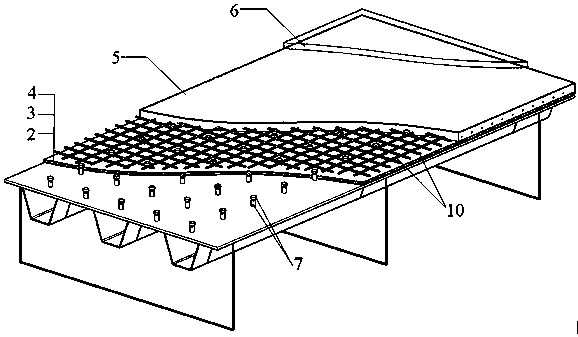

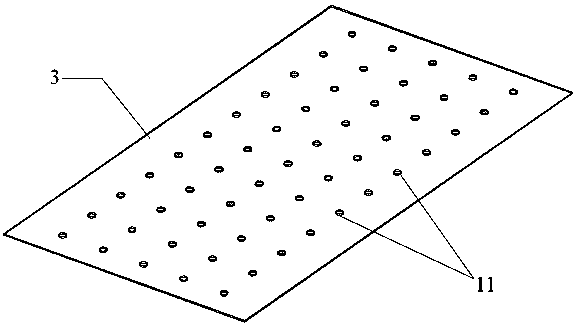

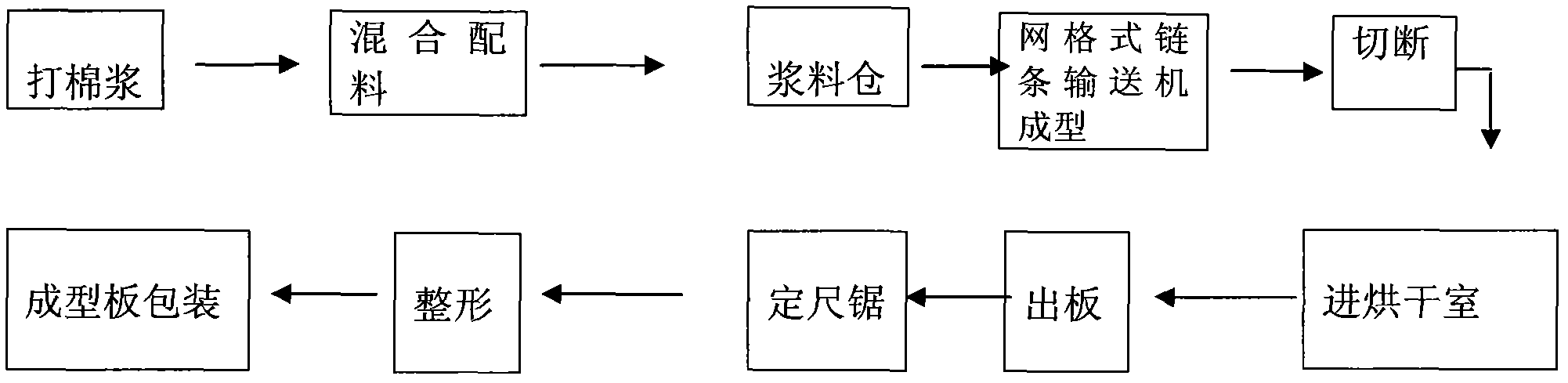

Light building exterior wall fireproof and heat insulating material prepared by slag rock wool

The invention discloses light building exterior wall fireproof and heat insulating material prepared by slag wool. The material is characterized by comprising the following components by mass percent: 30 to 60 percent of slag wool, 15 to 30 percent of desulfurized gypsum, 15 to 30 percent of fly ash, and 10 to 20 percent of No. 425 cement. The preparation method comprises the steps that the slag wool and water are mixed in mass proportion of 1:1 and stirred into slag wool slurry; the desulfurized gypsum, the fly ash and the No. 425 cement are mixed according to the mass ratio and put into a proportioning bin to be mixed, proportioned and stirred, so as to be prepared into raw material slurry; the raw material slurry is fed onto a grid type chain conveyer to be molded, so as to be manufactured into wet formed board; and the wet formed board is cut off, dried, cut and shaped, and then the light building exterior wall fireproof and heat insulating material prepared by the slag wool is obtained. The material has the advantages that the problem of poor water absorbance of a slag wool flat plate is solved, the tensile and compression strength is improved, and the phenomena of shrinkage and cracking are avoided. The material integrates light weight, fire resistance, heat insulation and moisture protection, and belongs to novel materials for building walls.

Owner:林文晖

Extrusion-type anchoring structure of prestressed concrete stretching fixing end

PendingCN111962769AAvoid contactAvoid corrosionBuilding reinforcementsPre stressArchitectural engineering

The invention discloses an extrusion-type anchoring structure for a prestressed concrete stretching fixing end. The extrusion-type anchoring structure comprises a stretching anchoring plate, an anchoring cushion cover, a corrugated pipe and a plurality of prestressed cables, wherein the anchoring cushion cover is connected with the inner end face of the stretching anchoring plate; the corrugated pipe is connected with the end face of the anchoring cushion cover; the plurality of prestressed cables are inserted into the stretching anchoring plate, the anchoring cushion cover and the corrugatedpipe in sequence; an a plurality of extrusion anchorage devices for fastening the extension ends of the prestressed cables are arranged on the outer end face of the stretching anchoring plate in orderto keep a preset length. According to the extrusion-type anchoring structure, the prestressed cables are inserted into the stretching anchoring plate, the anchoring cushion cover and the corrugated pipe in sequence, so the parts, positioned at the fixing end, of the prestressed cables are protected, the prestressed cables are prevented from being in direct contact with external concrete, and corrosion is avoided. Meanwhile, through extrusion fixing and length limitation of the extension ends of the prestressed cables by the extrusion anchorage devices, the anchoring lengths of the prestressedcables can be controlled within a proper range, and the prestress application length is prevented from getting too long or too short.

Owner:中庆建设有限责任公司

Waterproof tensile optical cable

PendingCN106154468AHigh tensile strengthEasy to wearFibre mechanical structuresMoistureOptical fiber cable

The invention discloses a waterproof tensile optical cable. The waterproof tensile optical cable comprises an outer sheath (1), a waterproof layer (5) and an inner sheath (6) which are sequentially arranged from outside to inside; the inner sheath (6) is internally provided with multiple optical fiber sheaths (3), multiple optical fibers (4) are arranged in the optical fiber sheaths (3), and multiple reinforcing ribs (2) are arranged in the outer sheath (1). The waterproof tensile optical cable has the advantages that the tensile strength of the outer sheath can be improved, the bending resistant capacity of the optical cable is improved when the optical cable is laid in a suspending mode, the deflection of the optical cable can be reduced, large shakes, caused by a strong wind, of the optical cable are avoided, therefore, reduction of abrasion of the optical cable is promoted, the optical cable can be prevented from restoring to the state before bending under the action of elasticity of the optical cable itself, and the laying precision is prevented from being destroyed; due to the fact that the waterproof layer is arranged, the waterproof and damp-proof capacities can be improved, moisture can be effectively prevented from entering the optical cable, damage, caused by dampness, of the optical cable is avoided, and the service life of the optical fiber is prolonged.

Owner:成都云士达科技有限公司

Method for producing lightweight foamed pnenolic aldehyde laminated board

InactiveCN105984197AModerate densityImprove tensile and compressive strengthSynthetic resin layered productsLaminationMicrosphereDelivery vehicle

The invention relates to a method for producing a lightweight foamed pnenolic aldehyde laminated board. The method is characterized in that glass fiber cloth is infiltrated by a mixing solution of phenolic resin and foamed microsphere, after resin on a surface layer of the glass fiber cloth is dried, the multiple layers of the infiltrated glass fiber cloth are laminated together, the temperature is controlled at 120-150 DEG C, pressurization with 1-5 MPa is carried out, and the glass fiber cloth is subjected to curing molding to obtain the lightweight foamed pnenolic aldehyde laminated board. Compared with the prior art, the mechanical strength of the lightweight foamed pnenolic aldehyde laminated board is good, and the lightweight foamed pnenolic aldehyde laminated board can be used for producing an air pipe material of a rail transit delivery vehicle.

Owner:安徽复材科技有限公司

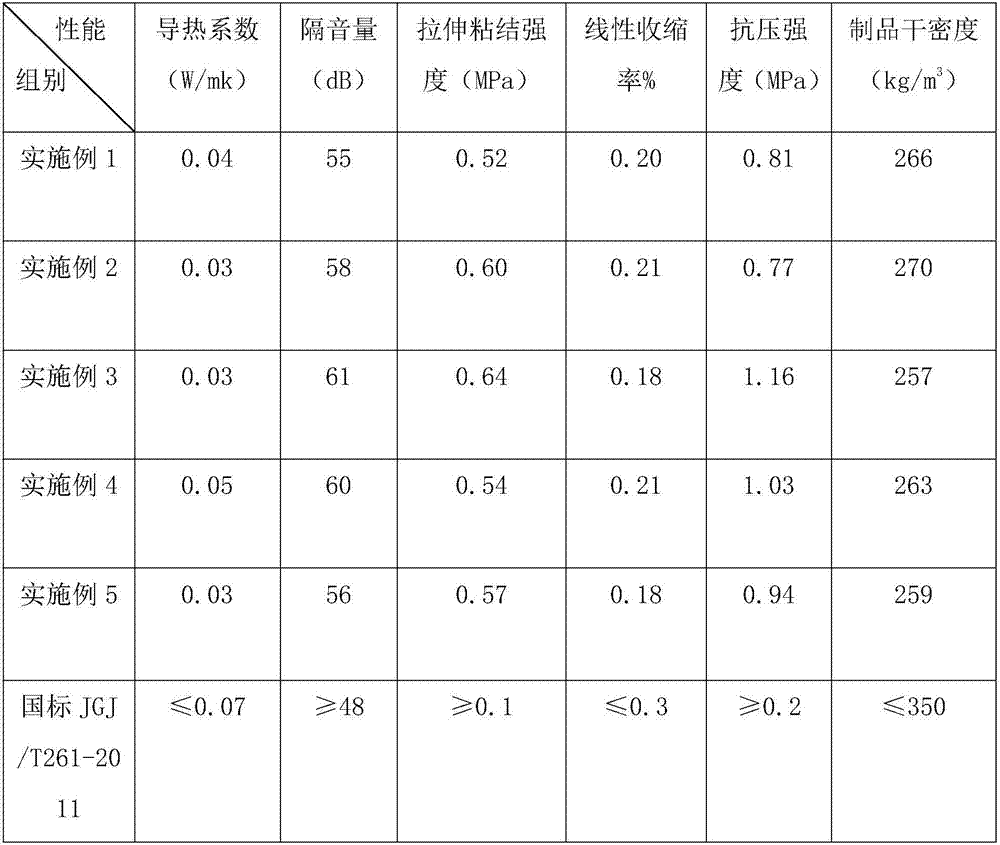

Vitrified microbead thermal insulation mortar and preparation method thereof

The invention discloses vitrified microbead thermal insulation mortar and a preparation method thereof. The thermal insulation mortar is prepared from the following raw materials: portland slag cement, lime paste, river sand, vitrified microbeads, sugar calcium, calcium carbonate, white latex, modified attapulgite clay powder, sodium lignin sulfonate, barium stearate, polyester fibers, hydroxypropyl methyl cellulose, polyvinyl alcohol, an organosilicon waterproofing agent and water. The preparation method comprises the following steps: firstly mixing the raw materials such as the vitrified microbeads and sugar calcium, and uniformly stirring, so that slurry A is obtained; then mixing the raw materials such as sodium lignin sulfonate, and uniformly stirring, so that slurry B is obtained; and finally conveying the portland slag cement, the lime paste and the river sand to a mortar stirring machine, and sequentially adding the slurry B and the slurry A, so that the vitrified microbead thermal insulation mortar finished product is obtained. The thermal insulation mortar disclosed by the invention has the advantages that tension and compression strengths and thermal insulation and sound insulation performances are further enhanced compared with the national standard and existing thermal insulation mortar, so that the problems of empty drums, cracks and drops are hardly caused when the mortar disclosed by the invention is applied to a wall body, and durability and practicability of the mortar are improved.

Owner:合肥天沃能源科技有限公司

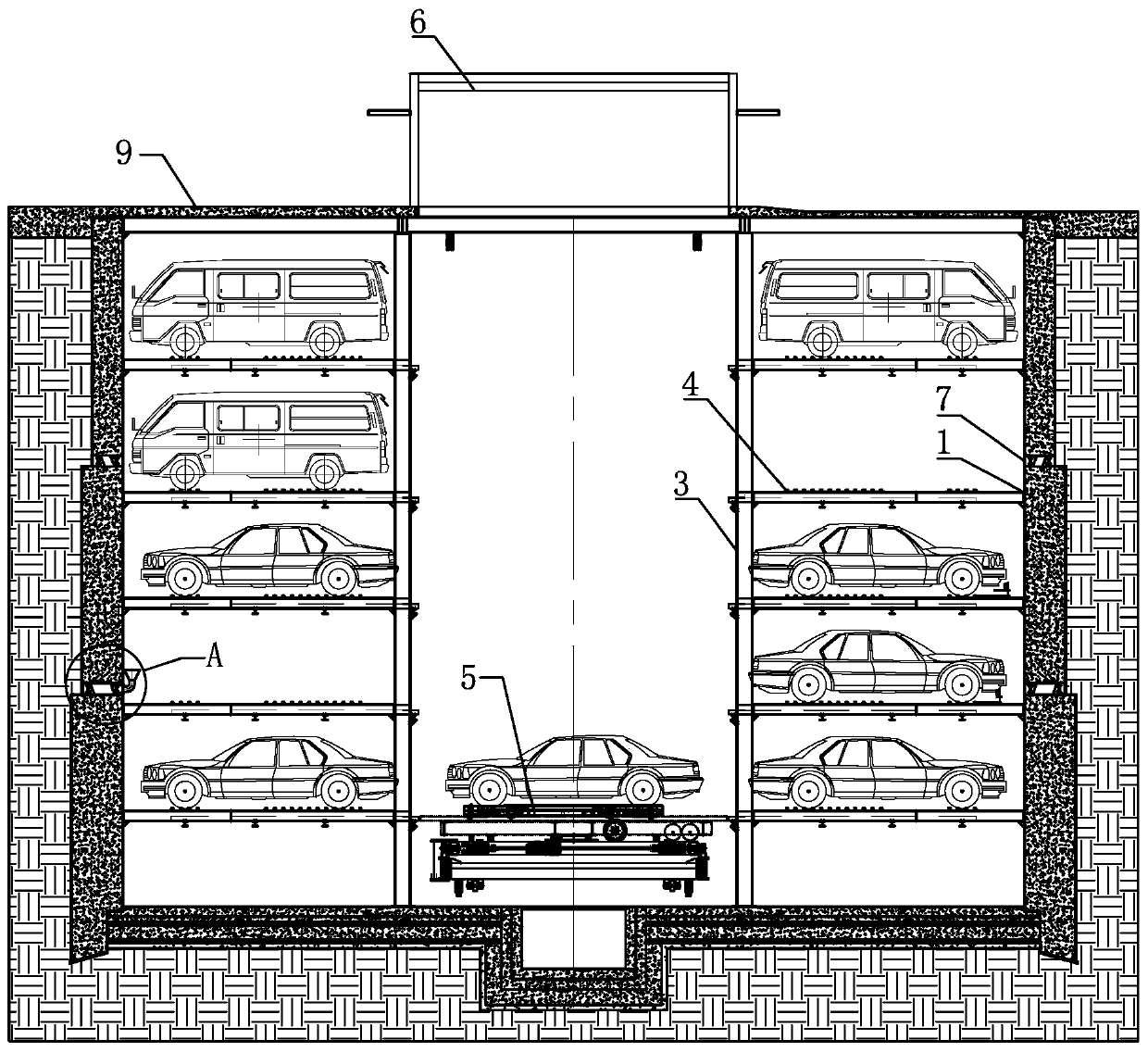

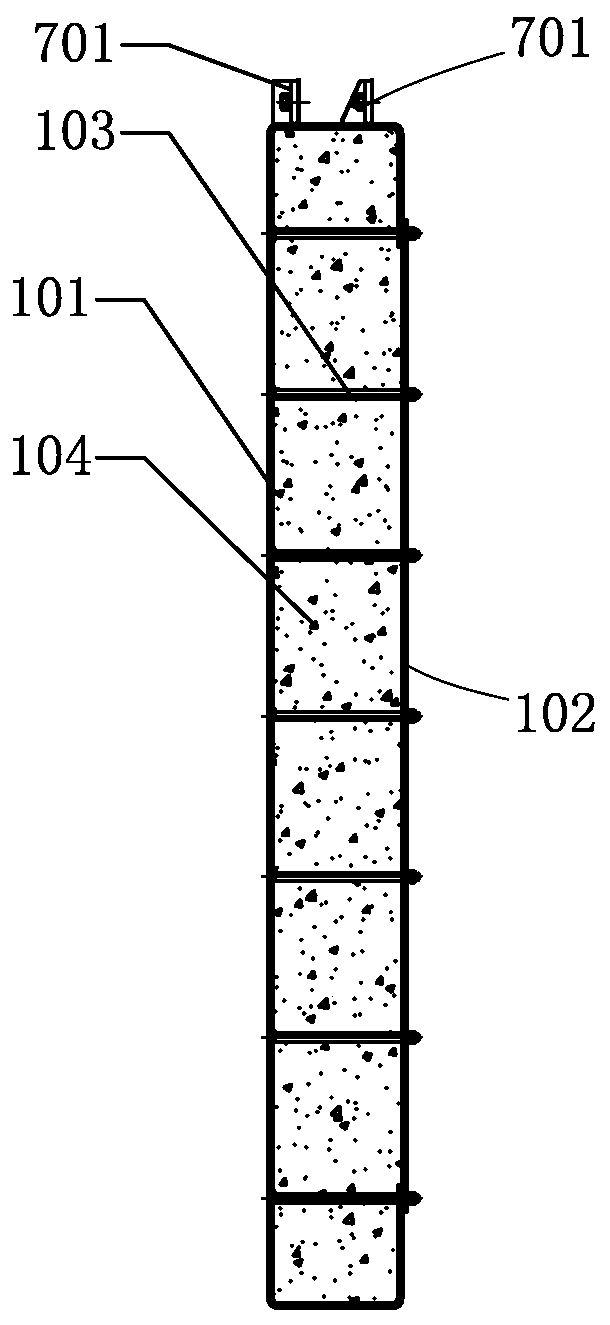

Foundation structure of open caisson stereo garage

PendingCN109736614AReduce volumeShort setting timeArtificial islandsUnderwater structuresUltimate tensile strengthBuilding construction

The invention discloses a foundation structure of an open caisson stereo garage, and belongs to the technical field of stereo garage construction. The foundation structure comprises an underground wall body, the underground wall body is divided into a plurality of upper and lower layers along the height; each layer is divided into a plurality of steel foundation units along the circumferential direction; the thickness of the steel foundation units located on the upper layer is smaller than that of the steel foundation units located on the lower layer. A connecting mechanism is arranged betweenevery two adjacent steel foundation units. Each steel foundation unit comprises a steel box body, a box body inner cavity is formed in the steel box body, a pouring gate is formed in the steel box body, and concrete is poured in the box body inner cavity. The foundation structure solves the technical problems that an underground stereo garage is long in construction period, low in structural strength and high in manufacturing cost, and is widely applied to stereo garage construction.

Owner:SHANDONG JIANZHU UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com