Vitrified microbead thermal insulation mortar and preparation method thereof

A technology of vitrified microbeads and thermal insulation mortar is applied in the field of thermal insulation mortar, which can solve the problems of high tensile and compressive strength, cracking, etc., and achieve the effects of improved thermal insulation and sound insulation, high strength and simple preparation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

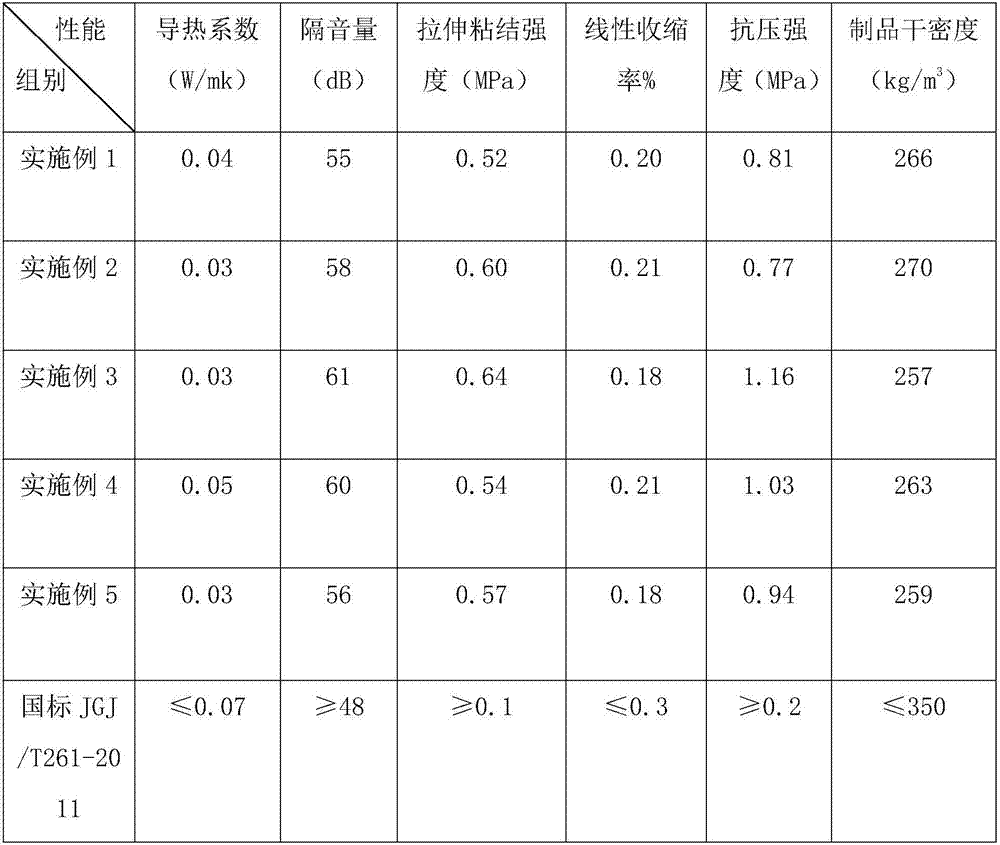

Examples

Embodiment 1

[0024] 1. Raw material composition and weight

[0025] A vitrified microbead thermal insulation mortar, including the following raw materials: 280kg of slag portland cement, 10kg of lime paste, 10kg of river sand, 10kg of vitrified microbeads, 5kg of sugar calcium, 5kg of calcium carbonate, 5kg of white latex, and modified attapulgite Clay powder 10kg, sodium lignosulfonate 1kg, barium stearate 5kg, polyester fiber 1kg, hydroxypropyl methylcellulose 4kg, polyvinyl alcohol 2kg, silicone waterproofing agent 5kg and water 10kg.

[0026] Wherein, the above-mentioned vitrified microbeads are pulverized by a grinder until the particle size is 0.5-1mm, and the modified attapulgite clay powder is obtained through the following steps:

[0027] (1) Pulverize the attapulgite clay mineral to a particle size of 40 mesh, then immerse it in clean water, stir it with an electric mixer for 1 hour, and set the speed to 800r / min, then filter, and immerse the filter residue to a concentration of ...

Embodiment 2

[0035] 1. Raw material composition and weight

[0036] A vitrified microbead thermal insulation mortar, including the following raw materials: 300kg of slag Portland cement, 20kg of lime paste, 20kg of river sand, 15kg of vitrified microbeads, 10kg of sugar calcium, 10kg of calcium carbonate, 10kg of white latex, and modified attapulgite Clay powder 15kg, sodium lignosulfonate 5kg, barium stearate 8kg, polyester fiber 3kg, hydroxypropyl methylcellulose 6kg, polyvinyl alcohol 4kg, silicone waterproofing agent 8kg and water 20kg.

[0037] Wherein, the above-mentioned vitrified microbeads are pulverized by a grinder until the particle size is 0.5-1mm, and the modified attapulgite clay powder is obtained through the following steps:

[0038] (1) Pulverize the attapulgite clay mineral to a particle size of 45 mesh, then immerse it in clear water, stir it with an electric mixer for 1.5 hours, set the speed at 750r / min, then filter, and immerse the filter residue to a concentration o...

Embodiment 3

[0046] 1. Raw material composition and weight

[0047] A vitrified microbead thermal insulation mortar, including the following raw materials: 320kg of slag portland cement, 30kg of lime paste, 25kg of river sand, 20kg of vitrified microbeads, 15kg of sugar calcium, 15kg of calcium carbonate, 15kg of white latex, and modified attapulgite Clay powder 20kg, sodium lignosulfonate 10kg, barium stearate 10kg, polyester fiber 5kg, hydroxypropyl methylcellulose 8kg, polyvinyl alcohol 6kg, silicone waterproofing agent 10kg and water 30kg.

[0048] Wherein, the above-mentioned vitrified microbeads are pulverized by a grinder until the particle size is 0.5-1mm, and the modified attapulgite clay powder is obtained through the following steps:

[0049] (1) Pulverize the attapulgite clay mineral to a particle size of 50 mesh, then immerse it in clear water, stir it with an electric mixer for 2 hours, set the speed at 700r / min, then filter, and immerse the filter residue to a concentration ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com