Suspending and balancing pressure type support safety vacuum glass

A vacuum glass and balanced pressure technology, applied in the field of structural mechanics, can solve the problems of difficulty in placing getters, damage to glass performance, and low tensile strength, and achieve the effects of improving strength and safety performance, increasing beauty, and increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

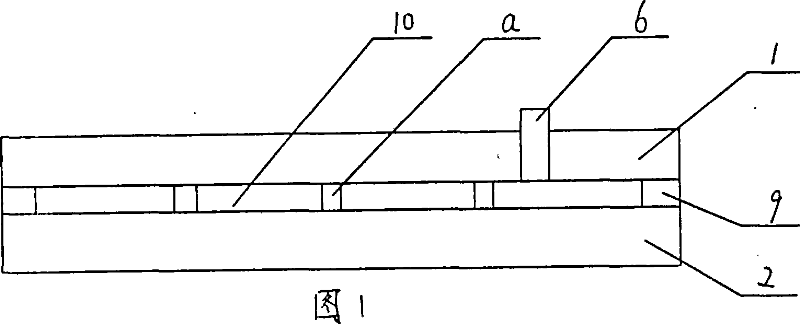

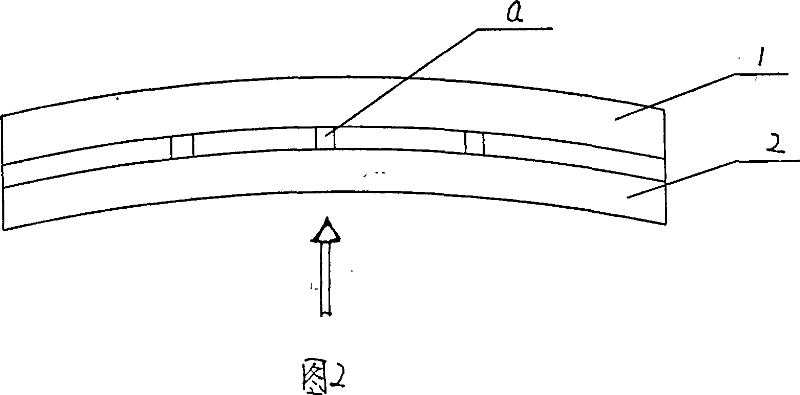

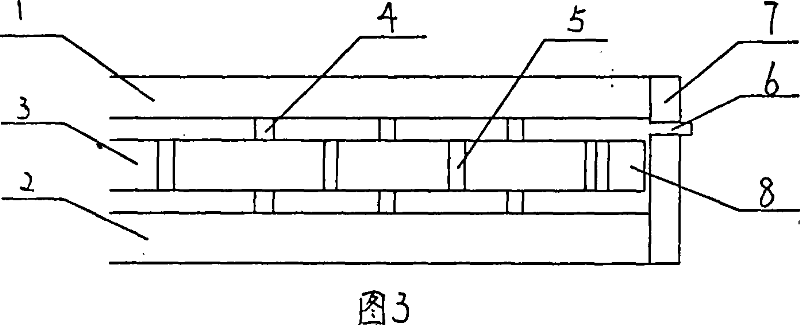

[0025]Embodiment 1, referring to Fig. 3, 5, 6, 8 (a)-(d), at first cut three glass plates according to the required size, be the upper glass plate 1, the lower glass plate 2 and the suspended support glass plate 3, the upper glass plate The size of the plate 1 and the lower glass plate 2 are the same, for example, 1500×1000mm. The three pieces of glass are ground and pre-cleaned, and the upper glass plate 1 and the lower glass plate 2 are then tempered. Other glasses can also be used. Such as float glass, clear glass or low-reflection film glass; the suspended support glass plate 3 adopts double-sided low-reflection film glass, and can also use one of single-reflection film glass, float glass, and white glass, and the length and width are uniform. Smaller than the size of the upper glass plate 1 and the lower glass plate 2, such as 1 mm smaller, generally between 0.2-10 mm, the size is related to the thickness of the support 5, and its four corners are cut off in a triangular s...

Embodiment 2

[0026] Embodiment 2, referring to Fig. 7, is the same as Embodiment 1, except that two layers of glass plates are added above the upper glass plate 1 or below the lower glass plate 2, and the method of the embodiment is used to seal and vacuumize to form Two internal vacuum chambers, that is, double-suspension support balanced pressure vacuum glass with double vacuum chambers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com