Fireproof color steel sandwich panel and preparation method thereof

A sandwich panel and color steel technology, applied in the field of color steel sandwich panels, can solve the problems of fragility, easy pulverization, low compression and bending resistance, etc. Effects of compressive strength, excellent thermal insulation and fireproof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

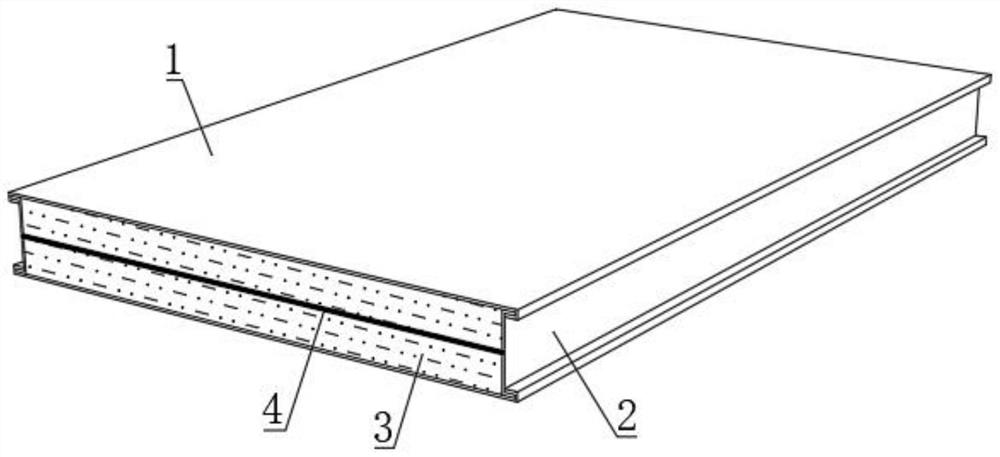

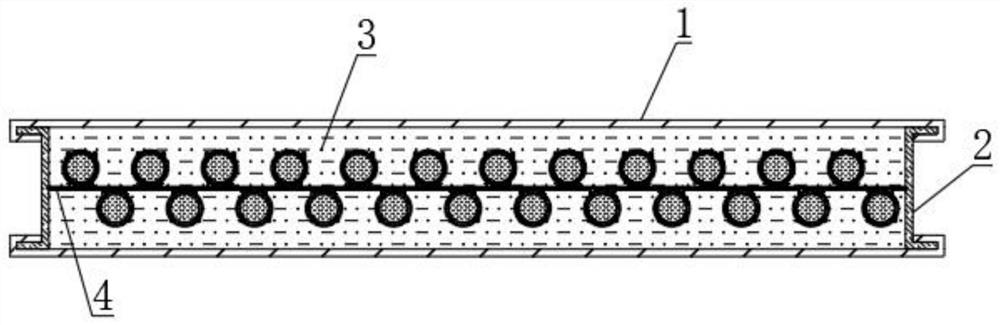

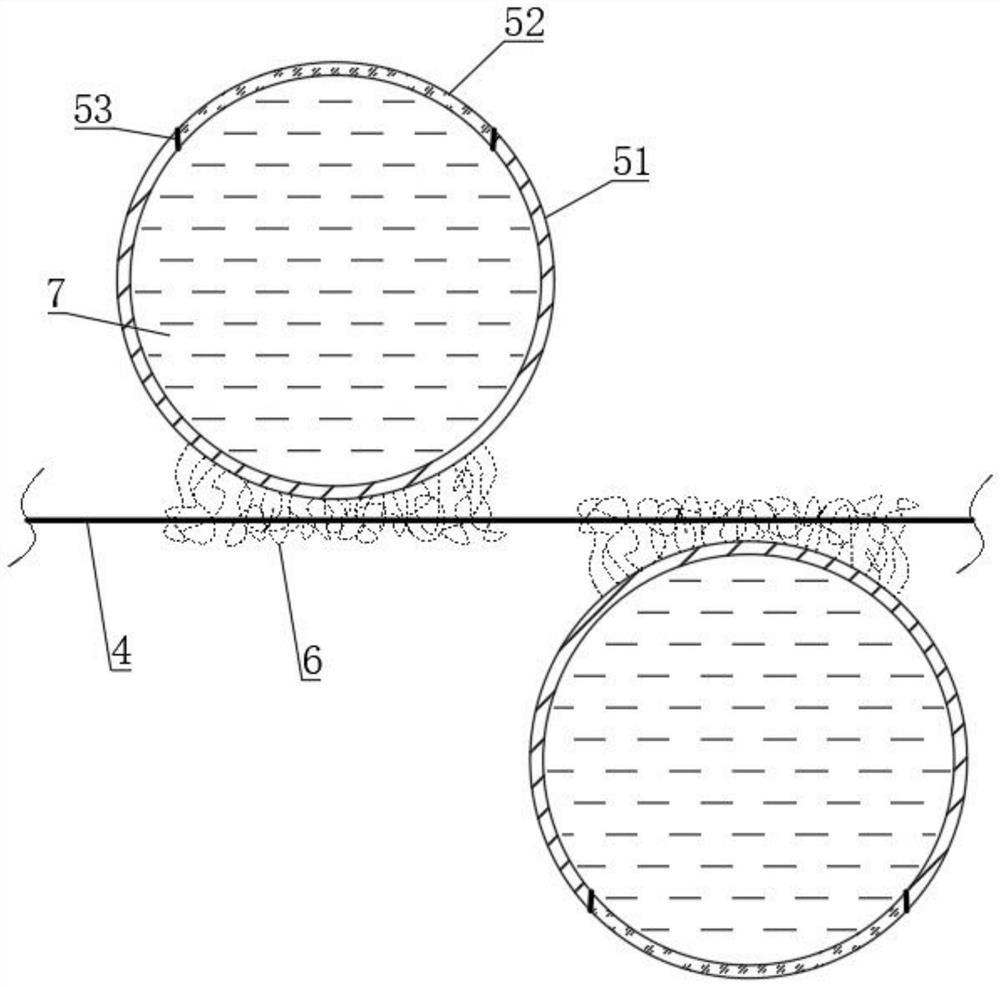

[0053] see figure 1 , figure 2 with image 3 , a fire-resistant color steel sandwich panel, including a pair of metal panels 1 distributed horizontally up and down, phenolic foam boards 3 are fixedly connected between the pair of metal panels 1, and a pair of U-shaped panels are also arranged between the pair of metal panels 1 Side plate 2, a pair of U-shaped side plates 2 are fixedly connected to the left and right ends of the phenolic foam board 3, and the inside of the phenolic foam board 3 is provided with a mesh cloth 4, and the mesh cloth 4 is fixedly connected to a pair of U-shaped side boards Between 2, the upper and lower sides of the grid cloth 4 are equipped with a plurality of evenly distributed anti-crack balls A, the anti-crack balls A on the upper and lower sides of the grid cloth 4 are distributed in a staggered manner, and the anti-crack balls A are fixedly connected to the phenolic Inside the foam board 3, the anti-crack ball A includes a main special-shap...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com