Light building exterior wall fireproof and heat insulating material prepared by slag rock wool

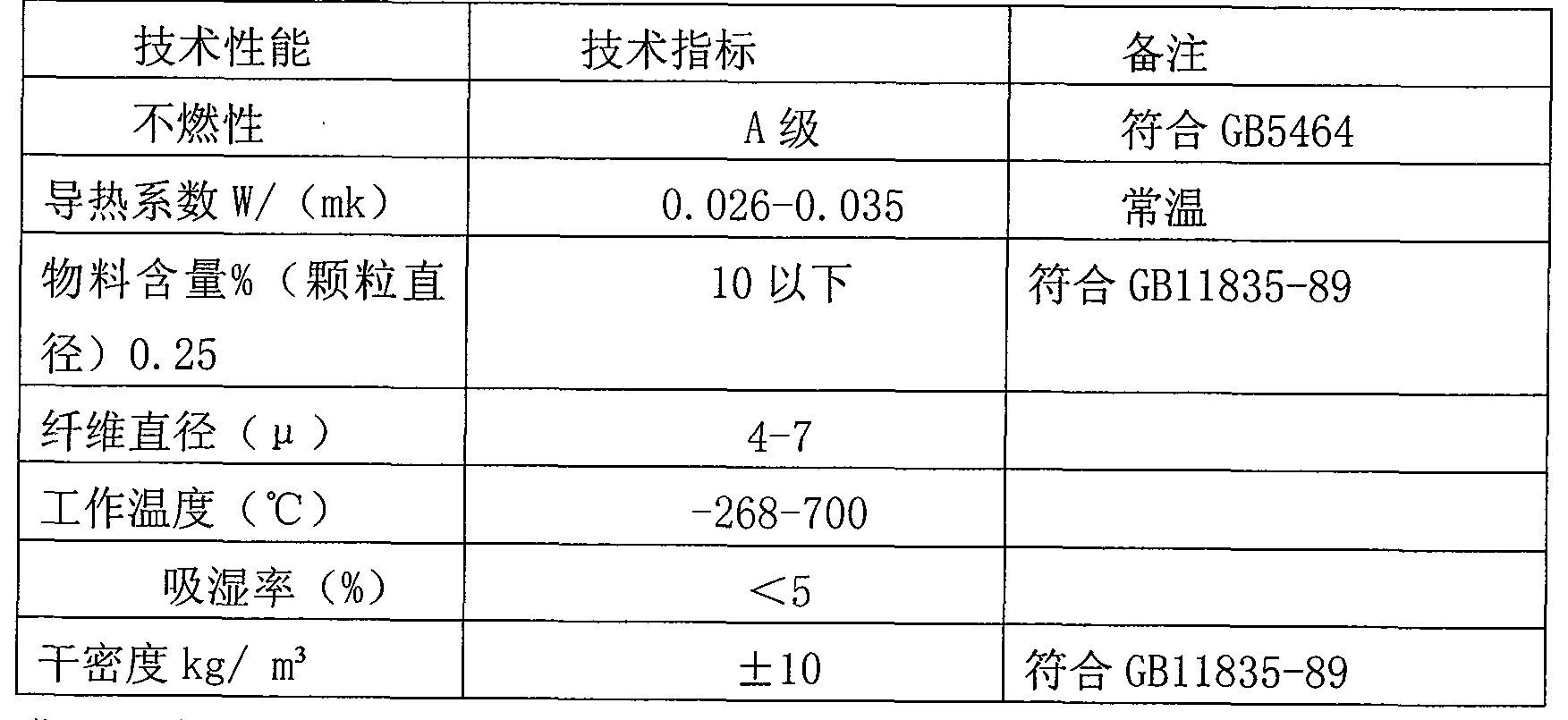

A technology of fireproofing and heat preservation, slag wool, applied in the field of fireproof and heat preservation materials for exterior walls of lightweight buildings made of slag wool, which can solve problems such as lack of heat preservation, low fireproof performance, loss of national property and people's lives, etc., to achieve Low production cost, high compressive and cracking strength, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] A light-weight building exterior wall fire-proof and heat-preservation material prepared from slag wool is characterized in that: the composition of the light-weight building exterior wall fire-proof heat preservation material prepared from slag wool is:

[0019] Slag cotton 55%, desulfurized gypsum 15%, fly ash 15%, 425# cement 15%;

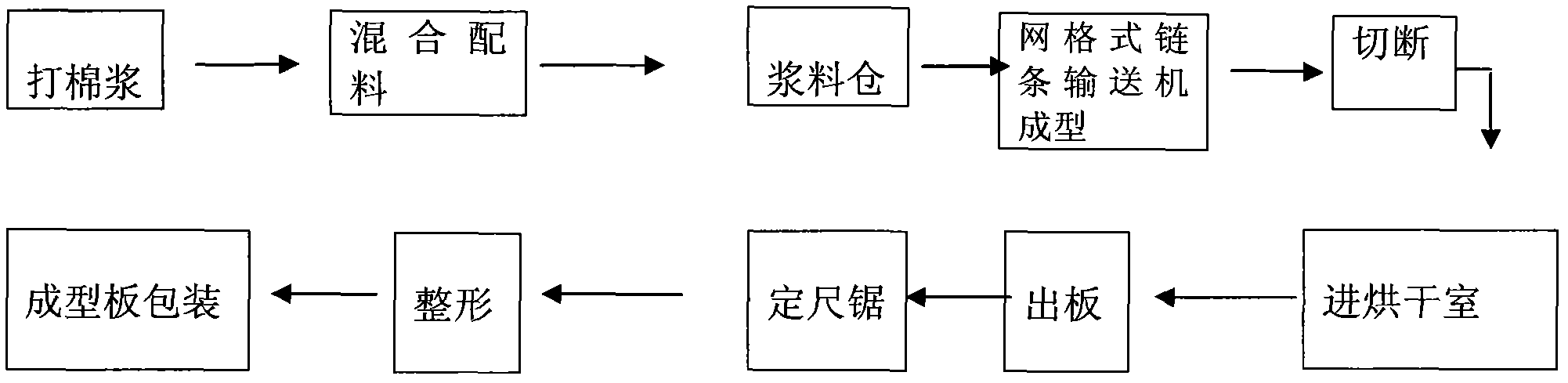

[0020] The preparation method of the light-weight building exterior wall fire-proof and thermal insulation material prepared with slag wool is as follows:

[0021] a. Put the slag cotton into the beating pool or cotton beating tank and mix it with water in a mass ratio of 1:1 to make slag cotton pulp, and pump it to the batching bin with a pump;

[0022] b. Put the desulfurized gypsum, fly ash, 425# cement and the slag cotton slurry in step a according to the mass ratio, put them into the batching bin to mix the ingredients, stir, make it evenly mixed, make the raw material slurry, and pump it to the raw material slurry bin;

[0023] c....

Embodiment 2

[0026] A light-weight building exterior wall fire-proof and heat-preservation material prepared from slag wool is characterized in that: the composition of the light-weight building exterior wall fire-proof heat preservation material prepared from slag wool is:

[0027] 45% slag wool, 20% desulfurized gypsum, 20% fly ash, 15% 425# cement;

[0028] The preparation method of the light-weight building exterior wall fire-proof and thermal insulation material prepared with slag wool is as follows:

[0029] a. Put the slag cotton into the beating pool or cotton beating tank and mix it with water in a mass ratio of 1:1 to make slag cotton pulp, and pump it to the batching bin with a pump;

[0030] b. Put the desulfurized gypsum, fly ash, 425# cement and the slag cotton slurry in step a according to the mass ratio, put them into the batching bin to mix the ingredients, stir, make it evenly mixed, make the raw material slurry, and pump it to the raw material slurry bin;

[0031] c. S...

Embodiment 3

[0034] A light-weight building exterior wall fire-proof and heat-preservation material prepared from slag wool is characterized in that: the composition of the light-weight building exterior wall fire-proof heat preservation material prepared from slag wool is:

[0035] 40% slag wool, 20% desulfurized gypsum, 25% fly ash, 15% 425# cement;

[0036] The preparation method of the light-weight building exterior wall fire-proof and thermal insulation material prepared with slag wool is as follows:

[0037] a. Put the slag cotton into the beating pool or cotton beating tank and mix it with water in a mass ratio of 1:1 to make slag cotton pulp, and pump it to the batching bin with a pump;

[0038] b. Put the desulfurized gypsum, fly ash, 425# cement and the slag cotton slurry in step a according to the mass ratio, put them into the batching bin to mix the ingredients, stir, make it evenly mixed, make the raw material slurry, and pump it to the raw material slurry bin;

[0039] c. S...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com