Glass fiber reinforced plastic water tank crack repairing technology

A glass fiber reinforced plastic and crack technology, applied in the direction of adhesive additives, non-polymer adhesive additives, adhesives, etc., can solve the problem of incapable of repairing cracks, and achieve improved service life, prolong service life, and improve tensile and compressive strength. the effect of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

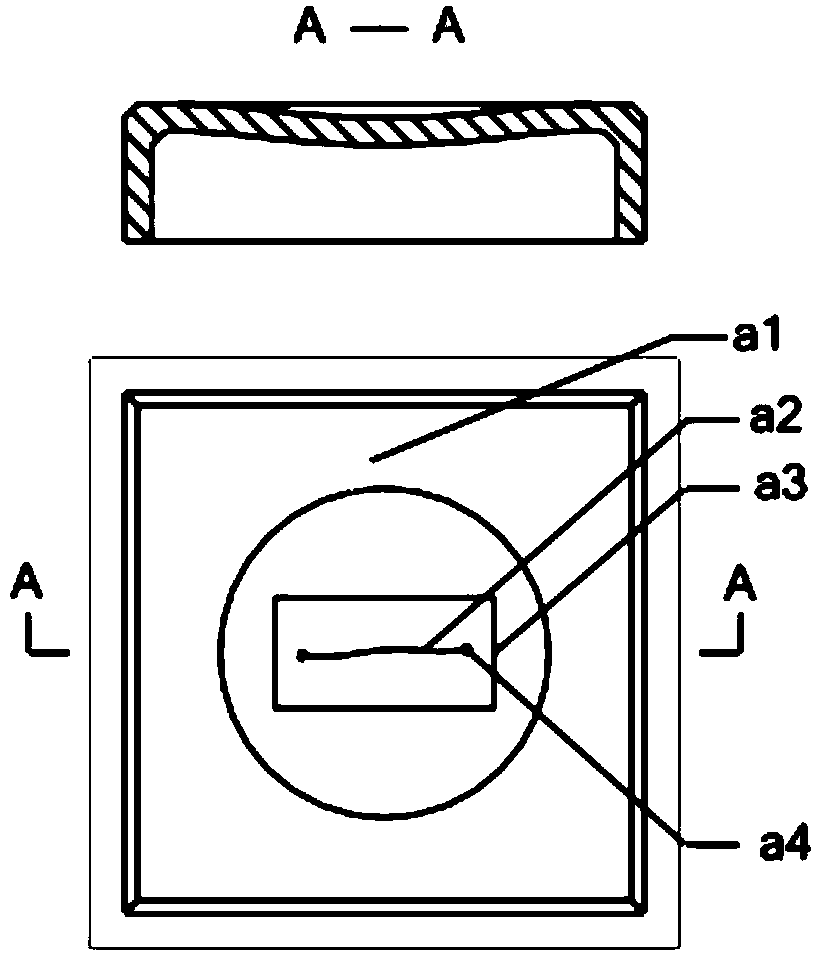

[0055] Embodiment 1, the crack of FRP water tank occurs at the bottom of the water tank, such as figure 1 As shown, the crack repair process steps are as follows:

[0056] To install a mobile lighting lamp in the water tank, first clean up the remaining water and dirt in the bottom of the FRP water tank. Find the plate a1 where the crack is generated at the bottom of the FRP water tank, and mark it. The crack width is about 0.5mm and the crack depth is 6mm. Use a steel tape to measure the area occupied by the crack a2 with a length of 200 mm and a width of 40 mm, and calculate the area occupied by the crack.

[0057] Grind the cracked part with an angle grinder holding a sand disc. The grinding area must be large enough to include the area occupied by the crack. The calendering layer must be removed until the first layer of glass fiber cloth is exposed. Drill technical holes a4 at the end points of both ends of the crack, the hole diameter is φ4mm, and wipe the polished surf...

Embodiment 2

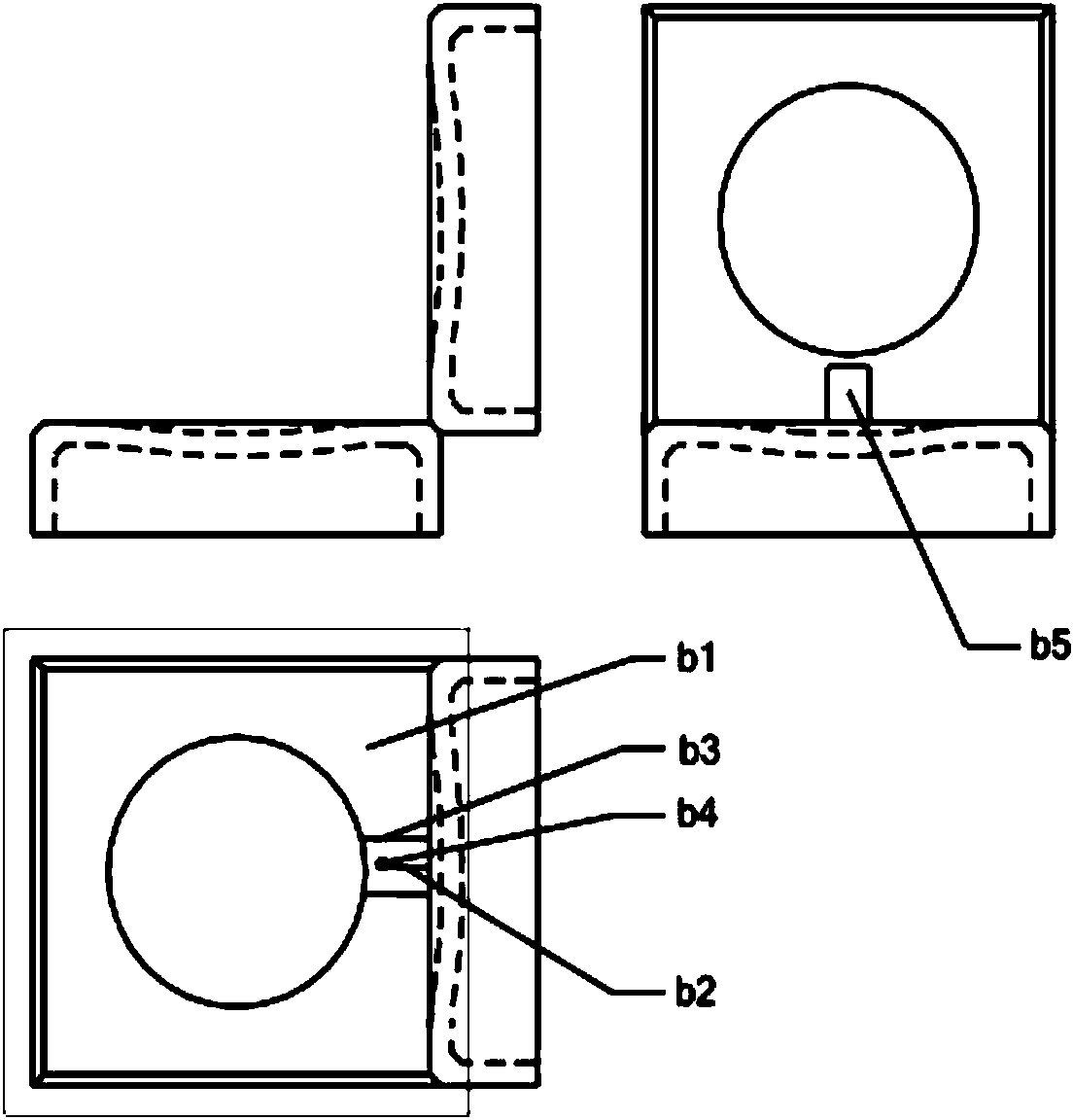

[0061] Embodiment 2, the crack of FRP water tank occurs in the corner of the water tank, such as figure 2 As shown, the crack repair process steps are as follows:

[0062] Clean up the remaining water and dirt in the FRP water tank, find the plate b1 with cracks at the corner of the FRP water tank, and mark it. The crack width is about 0.5mm and the crack depth is 6mm. Use a steel tape to measure the length of the area occupied by the crack b2 as 90mm and 30mm in width.

[0063] Use an angle grinder to grind the cracked part with a sand disc. The crack appears on one of the glass steel plates. When pasting, the two vertical surfaces need to be pasted at the same time. Grind the pasting surface b3 where the corner crack is located and the adjacent vertical surface. For surface b5, the polished area should be large enough, and the calendered layer should be removed until the first layer of glass fiber cloth is exposed. Drill the process hole b4 at the end of the crack far awa...

Embodiment 3

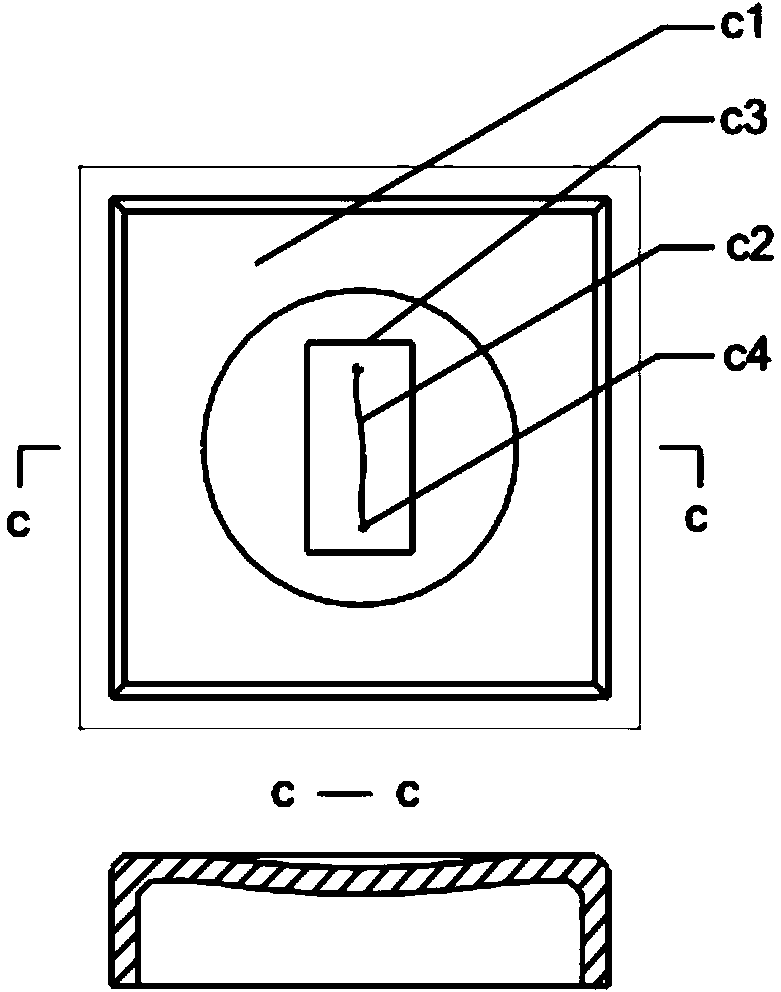

[0067] Embodiment 3, the crack of FRP water tank is produced on the side, as image 3 , the crack repair process steps are as follows:

[0068] Clean up the remaining water and dirt in the FRP water tank, and find the plate c1 with cracks on the side of the FRP water tank. The crack width is about 0.5mm and the crack depth is 6mm. Use a steel tape to measure the area occupied by the crack c2 with a length of 260 mm and a width of 60 mm, and calculate the area occupied by the crack.

[0069] Grind the inner surface c3 of the cracked FRP sheet with an angle grinder holding a sand disc. The grinding area must be large enough to include the area occupied by the crack. The calendering layer must be removed until the first layer of glass fiber cloth is exposed. until. Drill process holes c4 at both ends of the crack, and wipe the polished surface with a dry cloth.

[0070] Cut one piece of metal filter screen with the same area with iron sheets, and cut 4 pieces of glass fiber cl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com