Special joint filling mortar for light partition wallboards

A light-weight partition board and mortar technology, applied in the field of building materials, can solve the problems of cumbersome preparation of additives, complex components of caulking mortar, and increased production cost of mortar, so as to achieve good water retention effect, good slippage, and improved water retention Effects on Sex and Adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

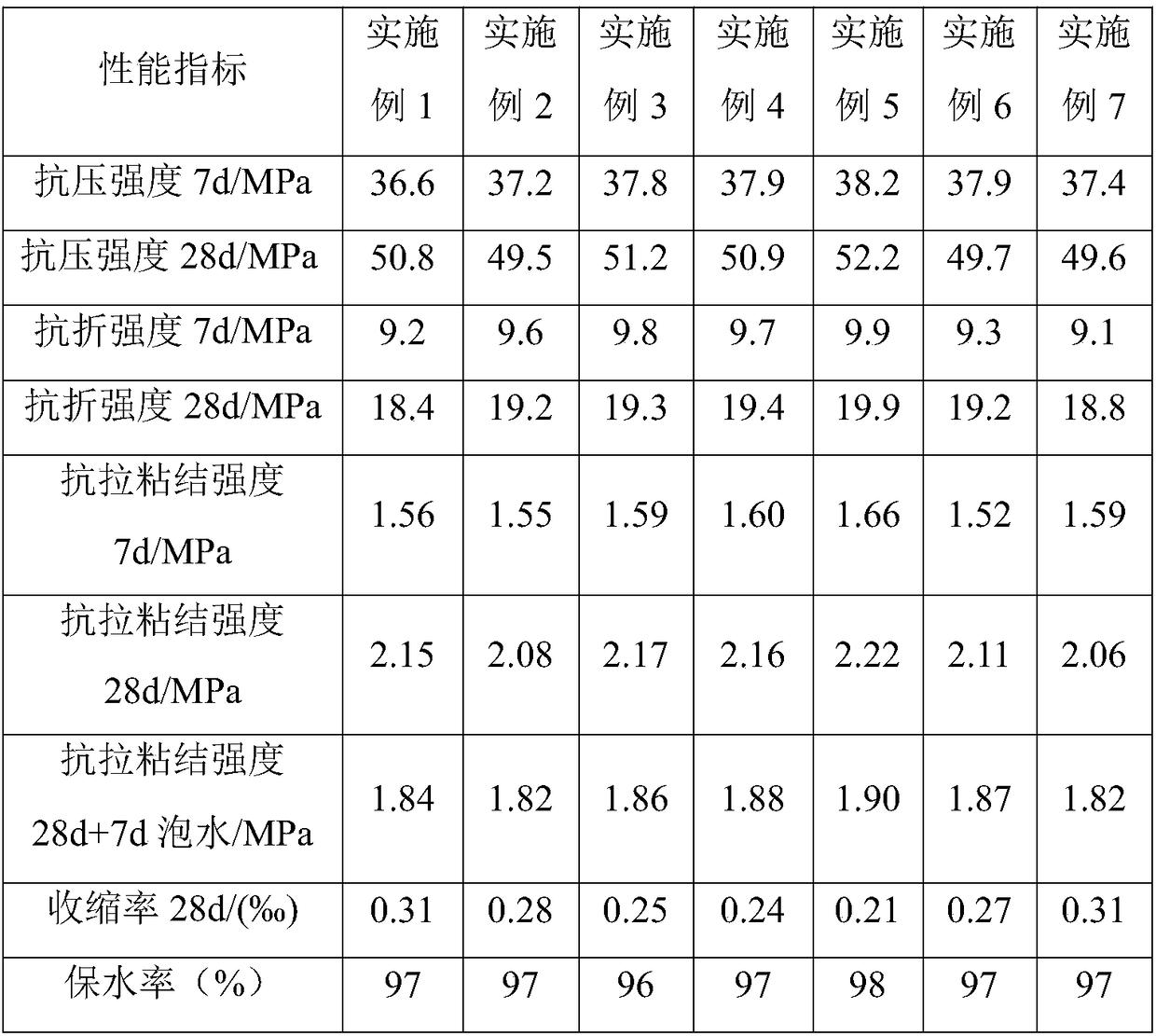

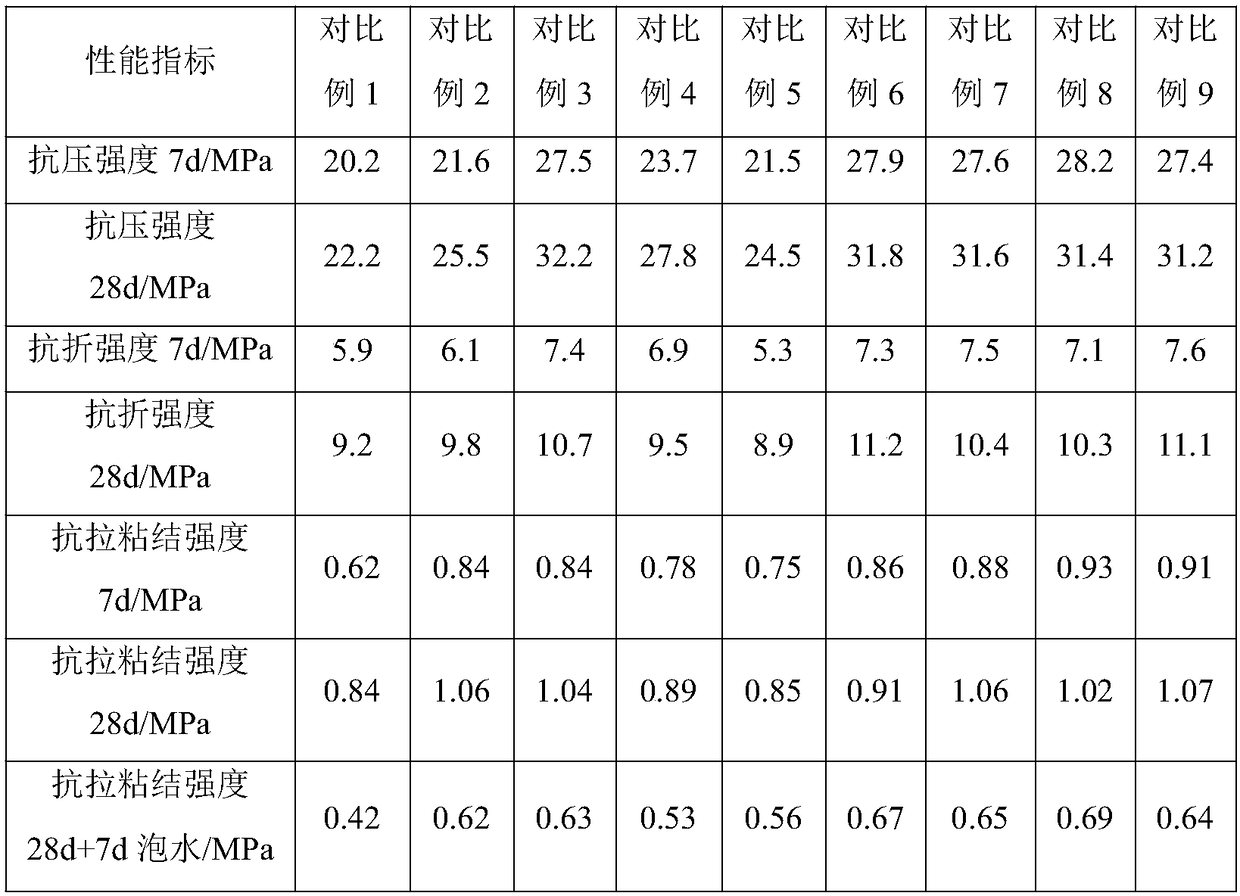

Examples

Embodiment 1

[0053]Weigh 300Kg of cement, 100Kg of fly ash, 400Kg of fine sand, and mix evenly, then add 2Kg of polymer xanthan gum powder, 1Kg of redispersible latex powder, 1Kg of starch ether, 1Kg of cellulose ether, 1Kg of retarder, oxidation Graphene modified carbon fiber (mass ratio of graphene oxide to carbon fiber is 0.05:1) 2Kg, water repellent 1Kg, fully stir and mix evenly, then add Paris plaster powder 30Kg, expansion agent (calcium sulfoaluminate expansion agent) 40Kg , after mixing evenly, add tap water accounting for 15%-25% of the dry powder weight, and stir for 3-5 minutes to obtain.

Embodiment 2

[0055] Weigh 400Kg of cement, 140Kg of fly ash, 450Kg of fine sand, and mix evenly, then add 7Kg of polymer xanthan gum powder, 1Kg of redispersible latex powder, 3Kg of starch ether, 3Kg of cellulose ether, 3Kg of retarder, oxidation Graphene-modified carbon fiber (mass ratio of graphene oxide to carbon fiber is 0.1:1) 8Kg, water-repellent agent 5Kg, fully stir and mix evenly, then add paris plaster powder 60Kg, expansion agent (calcium sulfoaluminate expansion agent) 60Kg , after mixing evenly, add tap water accounting for 15%-25% of the dry powder weight, and stir for 3-5 minutes to obtain.

Embodiment 3

[0057] Weigh 300Kg of cement, 100Kg of fly ash, 400Kg of fine sand, and mix evenly, then add 8Kg of polymer xanthan gum powder, 3Kg of redispersible latex powder, 1Kg of starch ether, 1Kg of cellulose ether, 1Kg of retarder, oxidation Graphene modified carbon fiber (mass ratio of graphene oxide to carbon fiber is 0.06:1) 2Kg, water repellent 1Kg, fully stir and mix evenly, then add Paris plaster powder 30Kg, expansion agent (calcium oxide expansion agent) 40Kg, mix After uniformity, add tap water accounting for 15%-25% of dry powder weight, stir for 3-5 minutes, and obtain.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com