Cable protection pipe resistant to tension and compression

A cable protection tube and protection tube technology, applied in the direction of electrical components, etc., can solve the problems of inconvenient use of protection tubes, difficult to use cables, and inability to thread

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

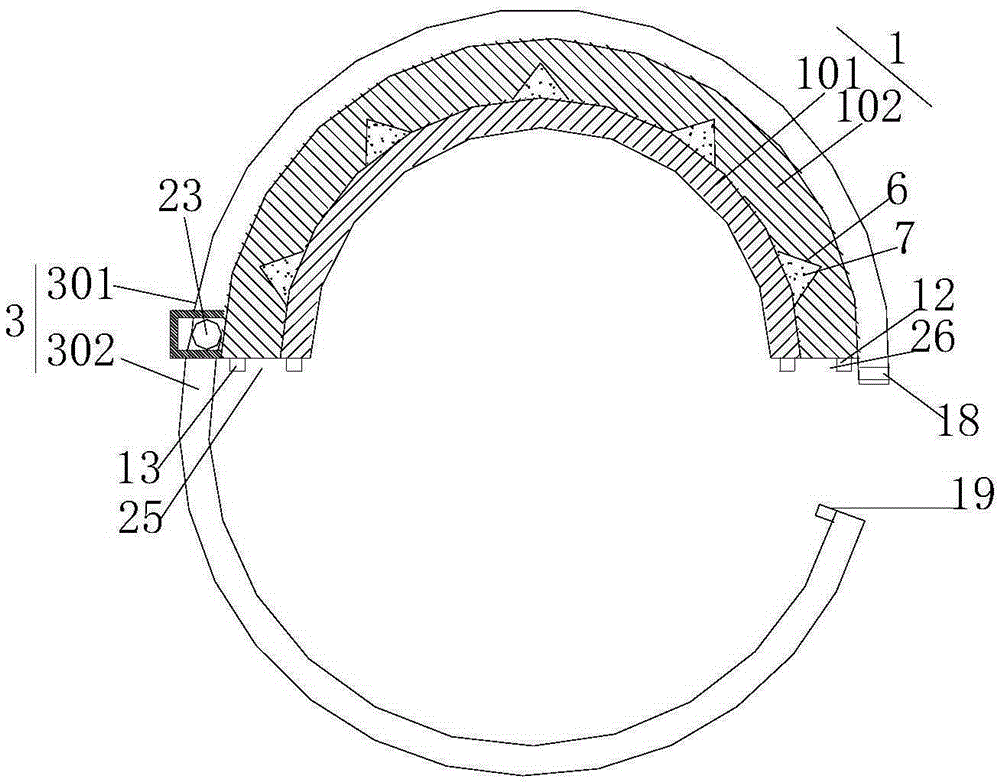

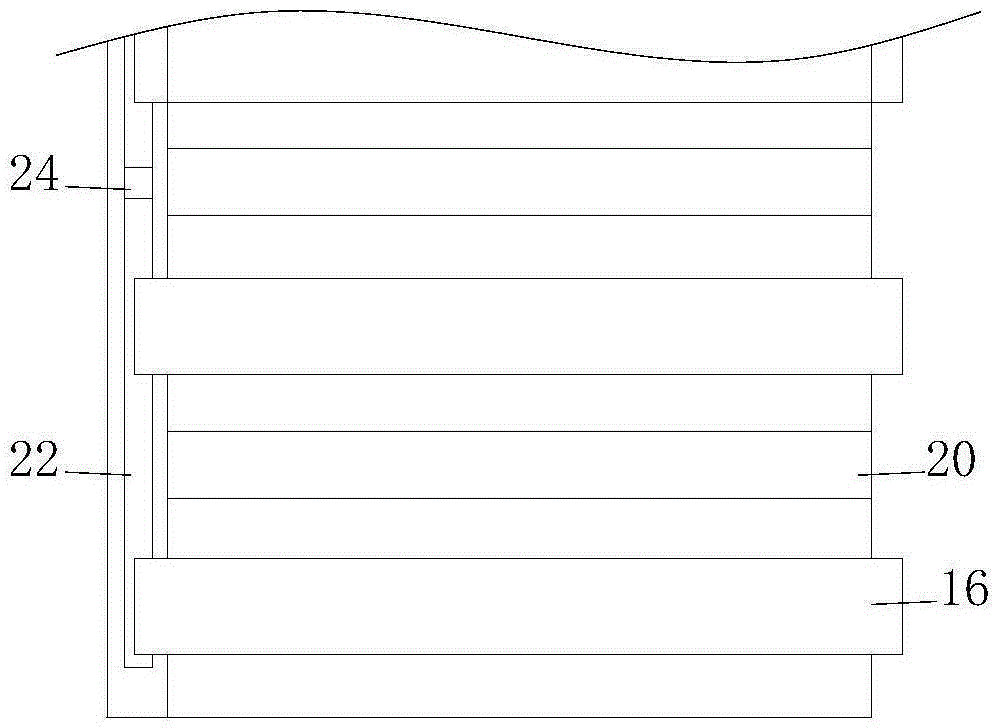

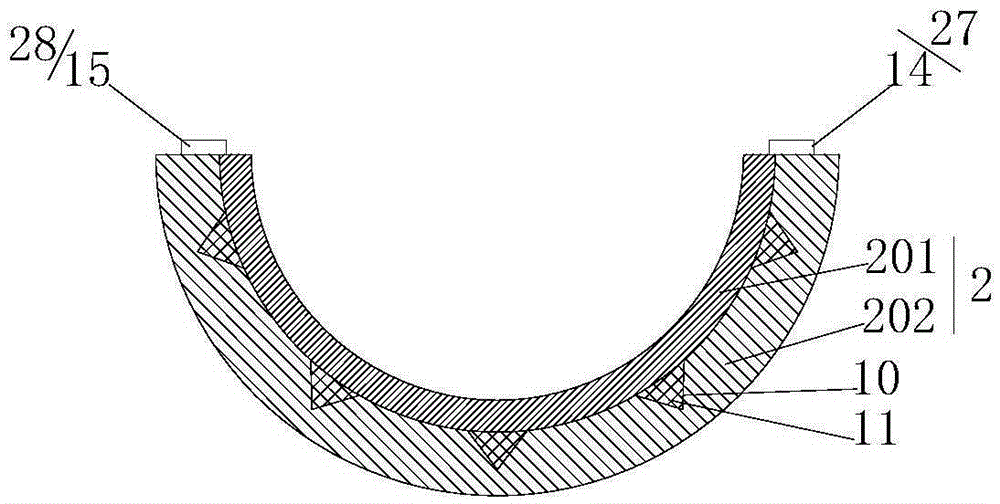

[0020] Such as Figure 1 to Figure 4 as shown, figure 1 It is a schematic diagram of the assembly of the first opening protection tube and the fixing device in a tensile and compression cable protection tube proposed by the present invention; figure 2 for figure 1 The schematic diagram of the top view; image 3 It is a structural schematic diagram of the second opening protective tube in a tensile and compressive cable protective tube proposed by the present invention; Figure 4 for image 3 Schematic diagram of looking up.

[0021] refer to Figure 1-Figure 4 , a tensile and compressive cable protection tube proposed by the present invention includes a first opening protection tube 1, a second opening protection tube 2 and a fixing device 3, and the fixing device 3 is used to fit the first opening protection tube 1 and the The second opening protection tube 2 is fixed.

[0022] Both the first opening protection tube 1 and the second opening protection tube 2 have a se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com