High-temperature, temperature-resisting and wear-resisting polyethylene pipe

A high-density polyethylene and polyethylene pipe technology, applied in the field of high-strength, temperature-resistant and wear-resistant polyethylene pipes, can solve problems affecting pipe reliability, pipe damage, and inability to use hot water, so as to improve quality, economy and Social benefits, improving tensile and compressive strength, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] High-strength heat-resistant and wear-resistant polyethylene pipes, the high-strength heat-resistant and wear-resistant polyethylene pipes include: micron-sized modified ultra-high molecular weight polyethylene layer, high-density polyethylene and inorganic mineral polymers Modified material layer, polyethylene felt layer.

[0024] Wherein, the raw material composition of the polyethylene felt layer is: polyethylene 100kg; nano material 10kg; compatibilizer 1kg; toughening agent 1kg; coupling agent 1kg, processing lubricant 1kg; antioxidant 1kg.

[0025] More specifically, the polyethylene is made of high-density polyethylene, the nano-material is made of nano-carbon fiber, the compatibilizer is made of maleic anhydride, the toughening agent is made of binary ethylene-propylene rubber, and the coupling agent is made of aluminate coupling agent, the lubricant uses polyethylene wax, and the antioxidant uses antioxidant CA.

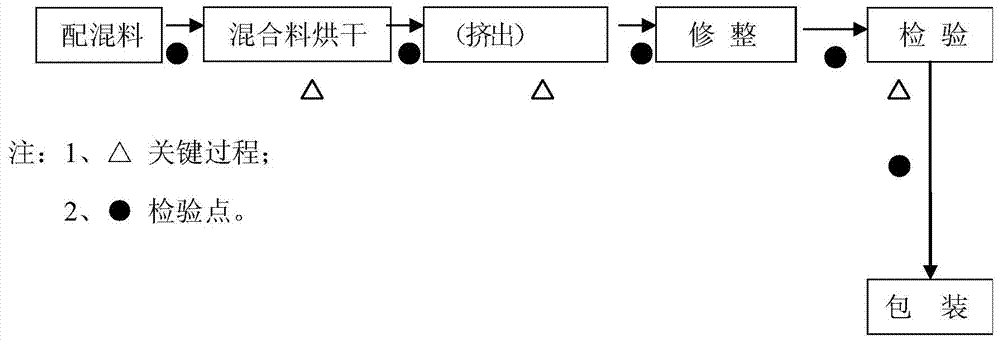

[0026] combine figure 1 As shown, the prepara...

Embodiment 2

[0043] The difference with Example 1 is: the raw material composition of this polyethylene felt layer is: polyethylene 100kg; Nano material 15kg; Compatibilizer 2kg; Toughening agent 2kg; Dose 1.2kg.

[0044] Among them, the polyethylene is medium-density polyethylene, the nano-material is nano-graphene, the compatibilizer is maleic anhydride grafted polyethylene, the toughening agent is EPDM rubber, and the coupling agent is titanic acid. Ester coupling agent, the lubricant adopts stearic acid, and the antioxidant adopts antioxidant 1010.

[0045] combine figure 1 As shown, the preparation of the outer layer polyethylene felt material in the high-strength temperature-resistant and wear-resistant polyethylene pipe can adopt the following method:

[0046] 1) Preheat the high-speed mixer to a body temperature of 80°C;

[0047] 2) Pour the nanomaterials into a high-speed mixer and stir for 18 minutes at a speed of 600 rpm;

[0048] 3) Pour the coupling agent into a high-speed...

Embodiment 3

[0062] The difference with Example 1 is: the raw material of this polyethylene felt layer consists of: polyethylene 100kg; nanometer material 20kg; compatibilizer 3kg; toughening agent 3kg; coupling agent 2kg, processing lubricant 1.5kg; 1.5kg.

[0063] Among them, the polyethylene is low-density polyethylene, the nano-material is micron ultra-high molecular weight polyethylene, the toughening agent is ethylene-vinyl acetate copolymer, the coupling agent is silane coupling agent, and the lubricant is white Oil, the antioxidant uses antioxidant 168.

[0064] to combine figure 1 As shown, the preparation of the outer layer polyethylene felt material in the high-strength temperature-resistant and wear-resistant polyethylene pipe can adopt the following method:

[0065] 1) Preheat the high-speed mixer to a body temperature of 90°C;

[0066] 2) Pour the nanomaterials into a high-speed mixer and stir for 20 minutes at a speed of 800 rpm;

[0067] 3) Pour the coupling agent into ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com