Patents

Literature

1197results about How to "Guaranteed assembly accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

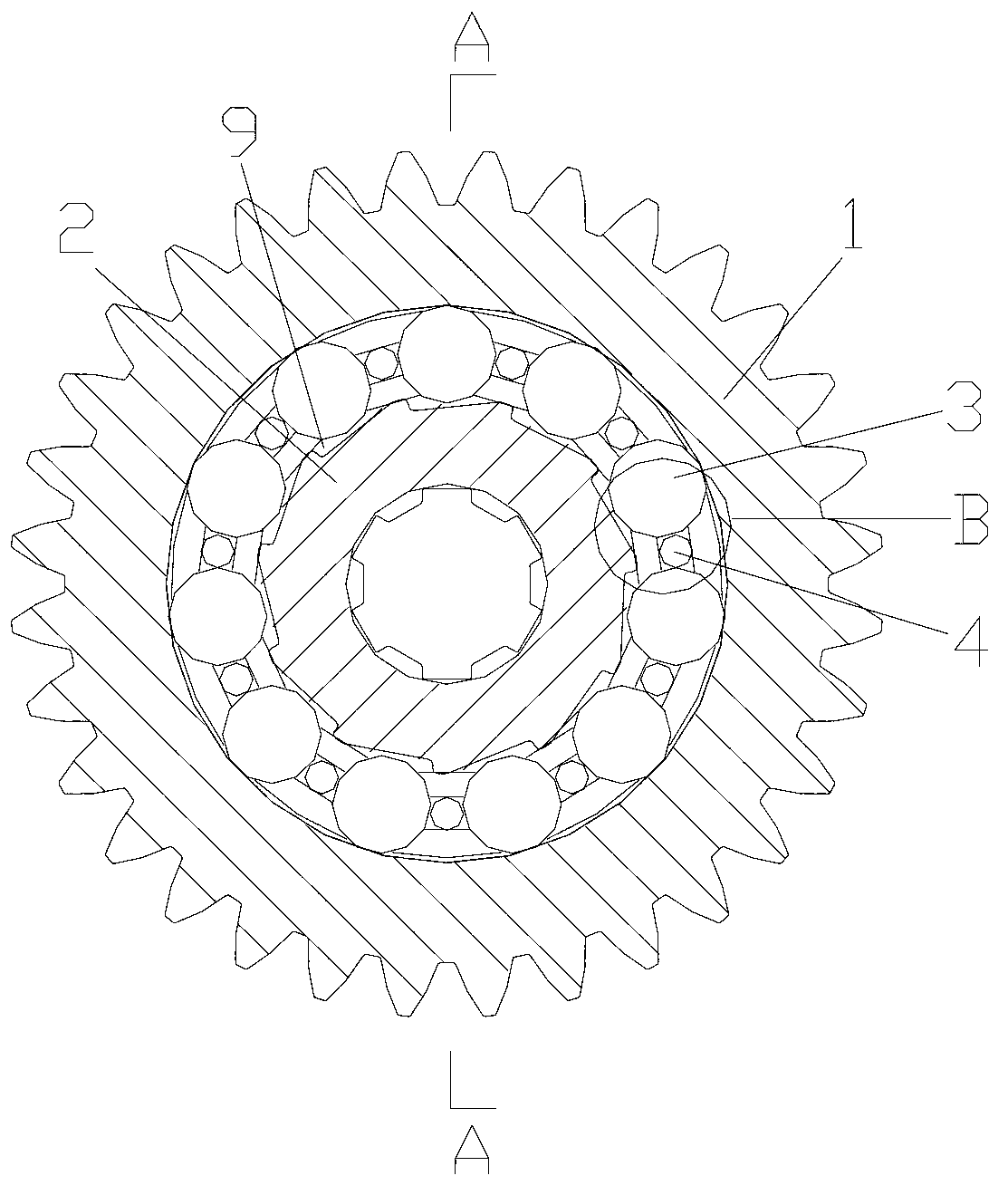

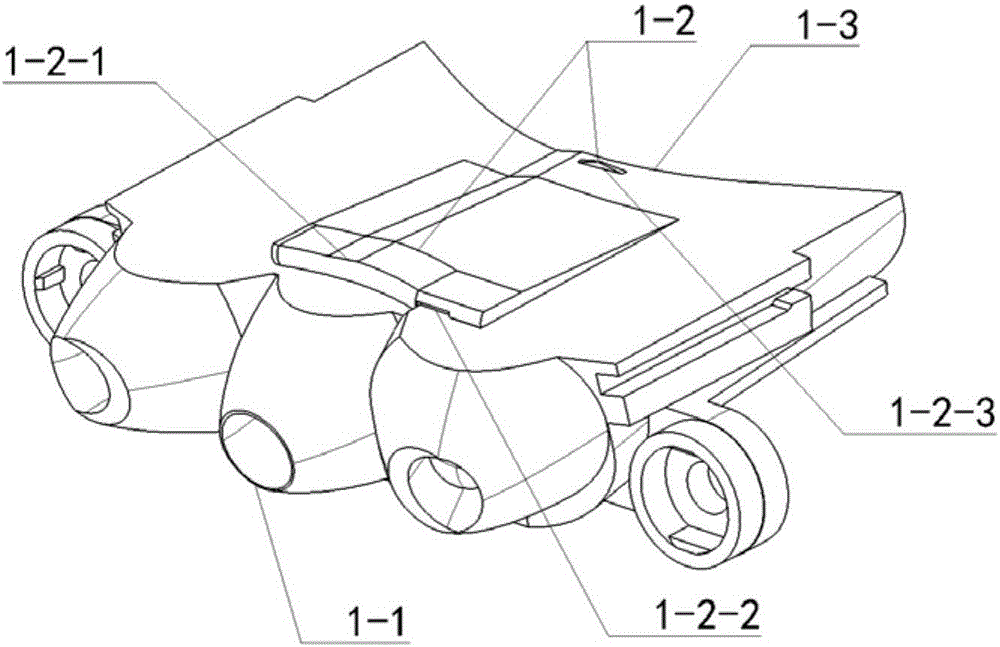

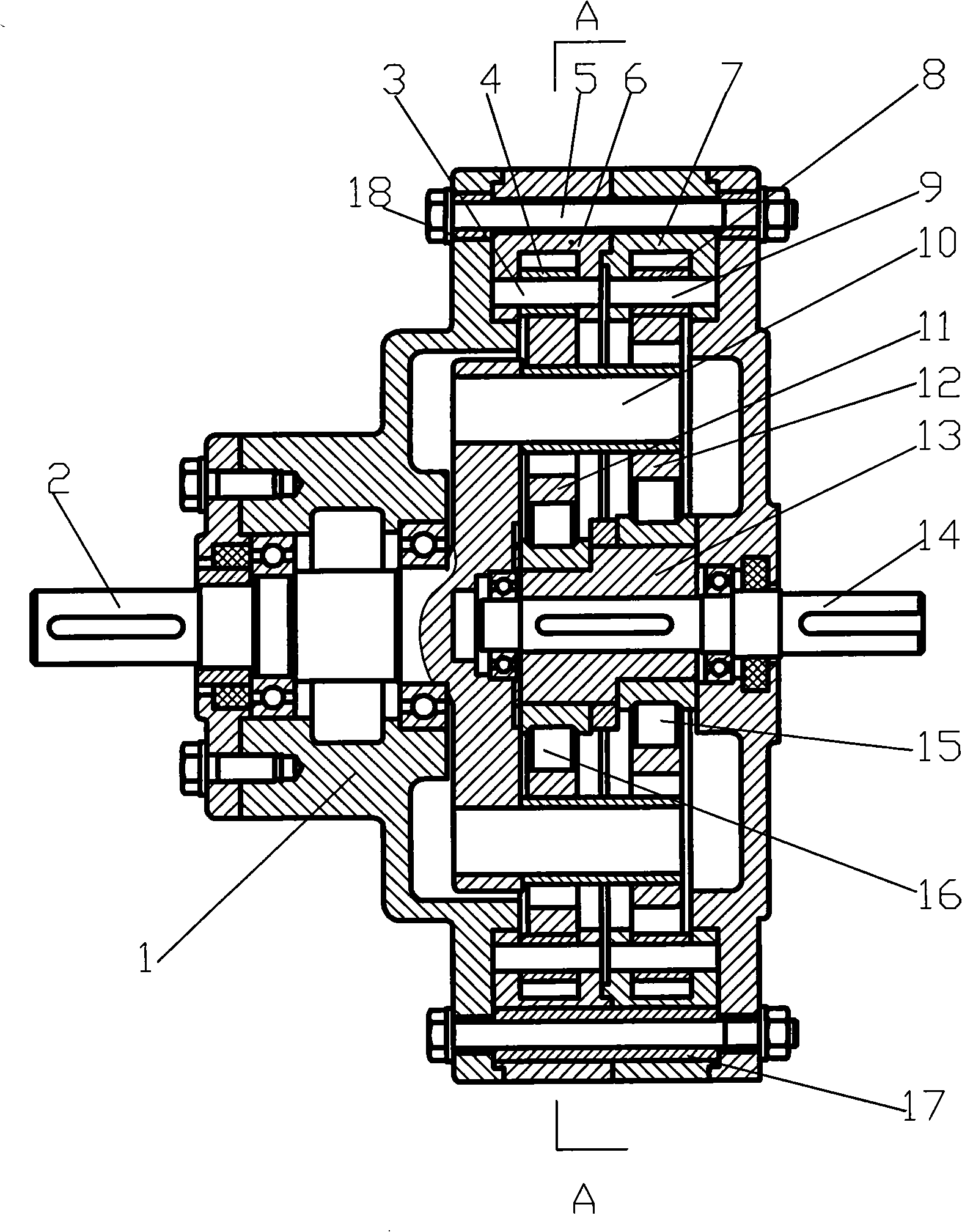

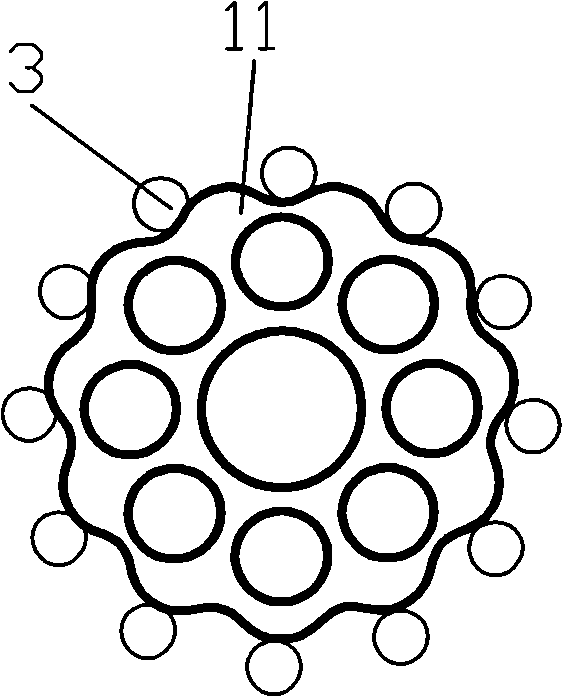

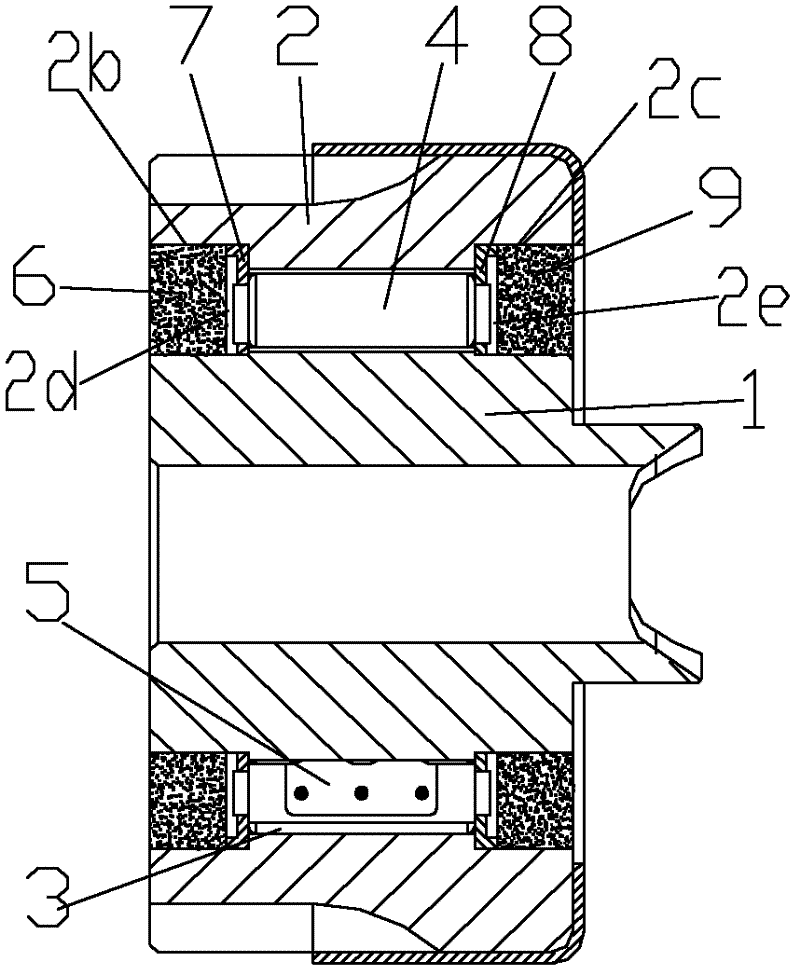

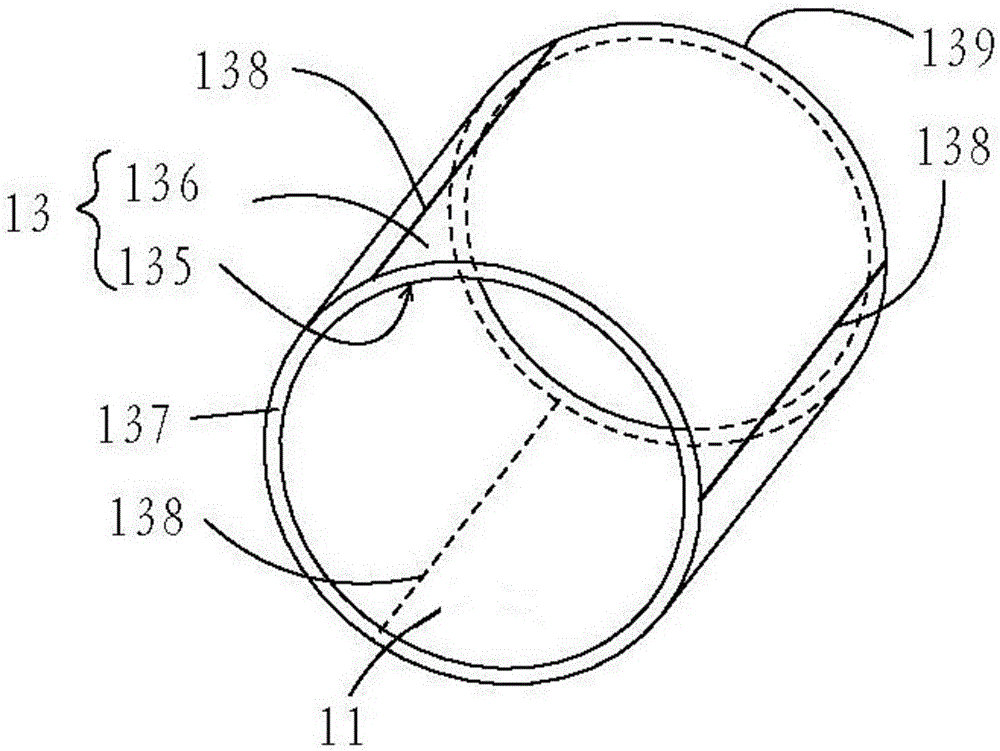

Floating auxiliary roller type overrun clutch

InactiveCN103307140AIncrease axial lengthIncrease the lengthFreewheel clutchesEngineeringMachining process

The invention discloses a floating auxiliary roller type overrun clutch which comprises an outer ring, an inner ring, rolling bodies and auxiliary rollers, wherein engagement spaces used for being engaged with or separated from the rolling bodies are formed between the outer ring and the inner ring; the auxiliary rollers are parallel to an axial line of the overrun clutch and are spaced from the rolling bodies; and the auxiliary rollers are arranged between the rolling bodies in such a way that the auxiliary rollers can move in a circumferential direction of the overrun clutch. According to the floating auxiliary roller type overrun clutch, the processing of a limiting seat is avoided, the processing process is simplified, the working efficiency is improved, and the processing cost is reduced; as the auxiliary roller structure is adopted, the axial length of the overrun clutch and the rolling bodies can be theoretically infinitely prolonged, the engagement length is prolonged, the bearing capacity of the overrun clutch is increased, the radial size of the overrun clutch under higher bearing capacity is reduced, and the service life of the overrun clutch is prolonged; and meanwhile, the probability of imbalance caused by application of a pretension force to point contact of each roller in the prior art is removed, thereby enabling each roller to keep parallel to the axial line of the inner ring.

Owner:SOUTHWEST UNIVERSITY

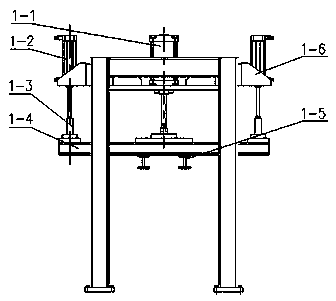

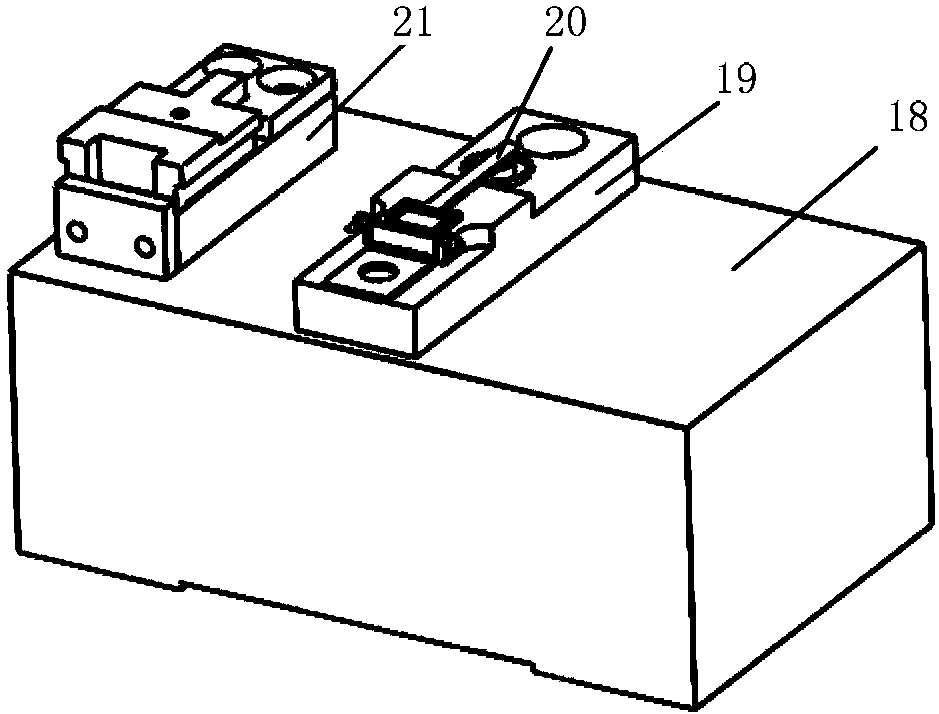

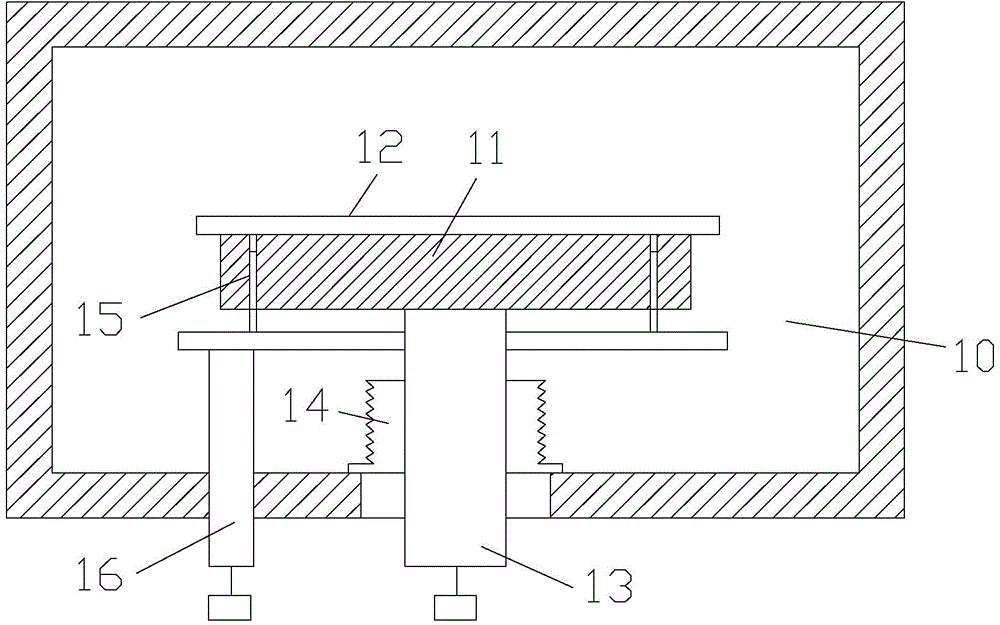

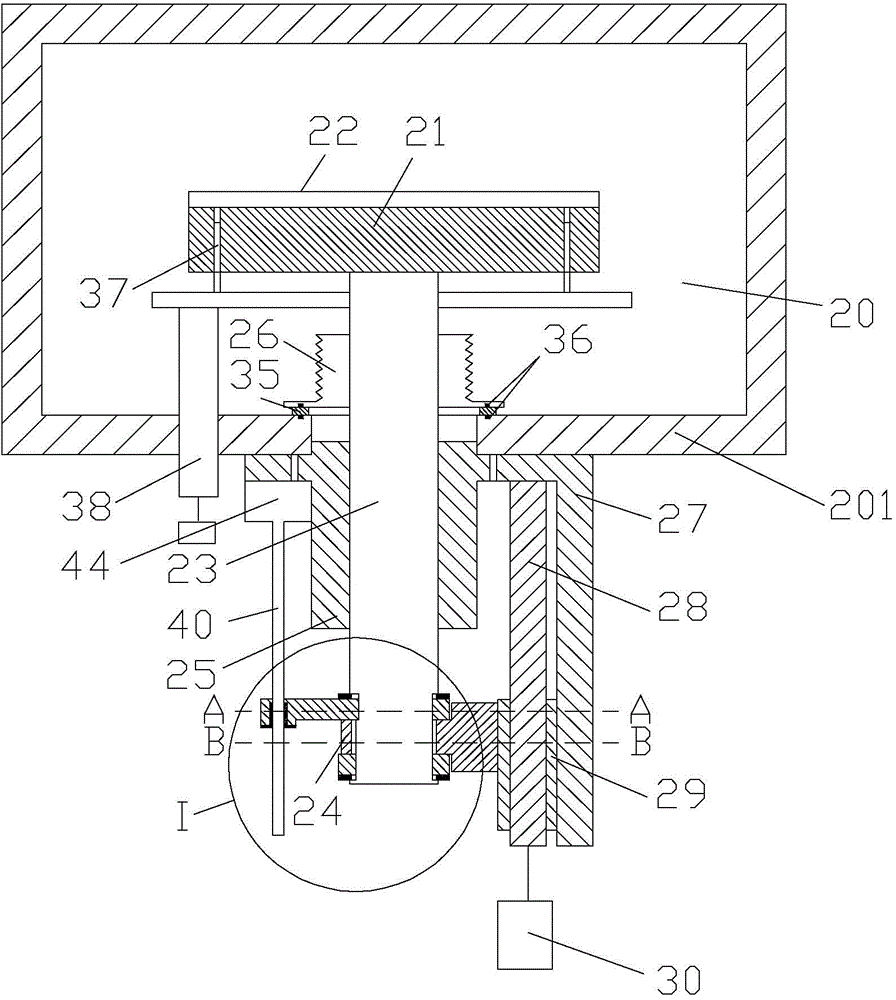

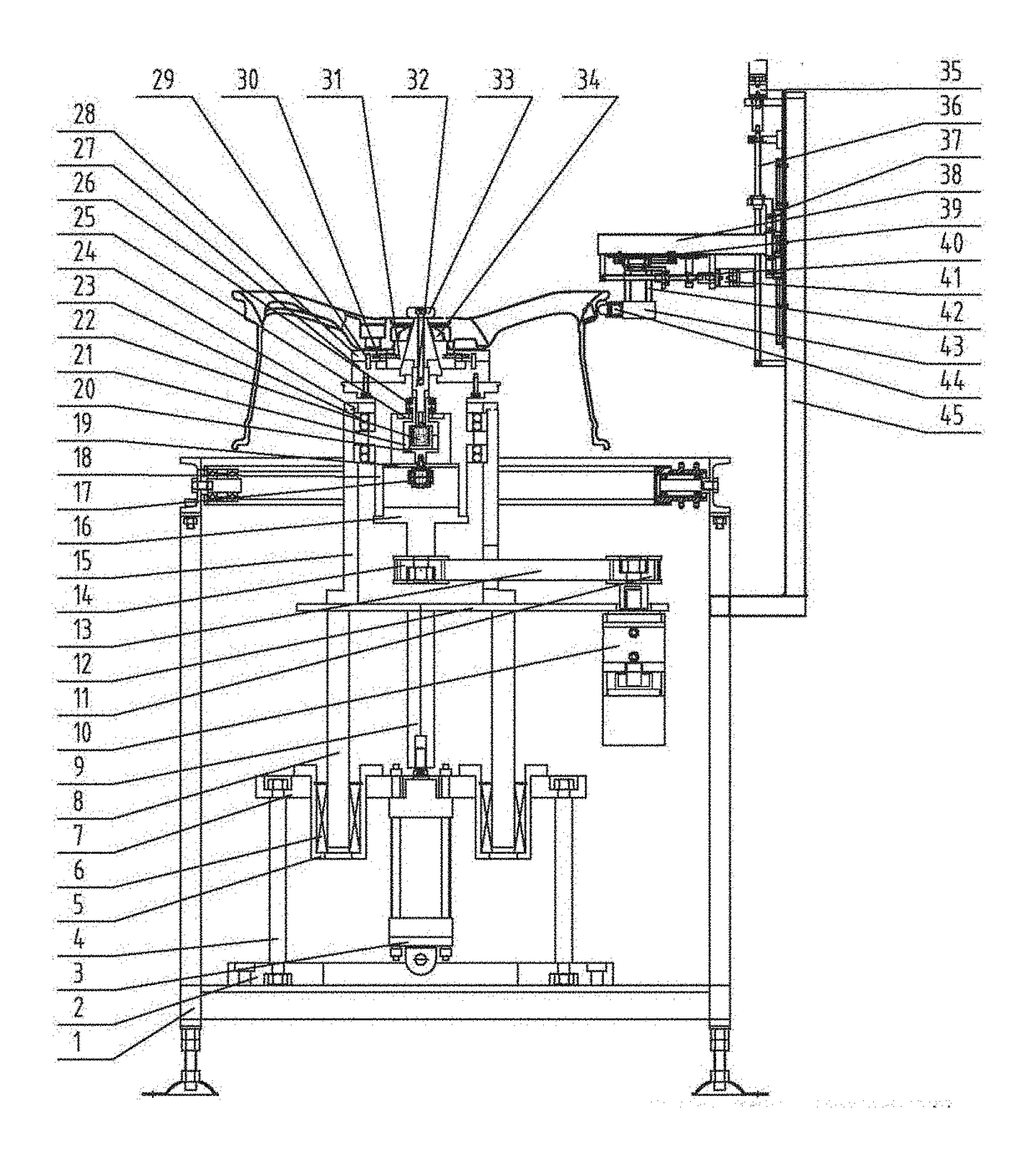

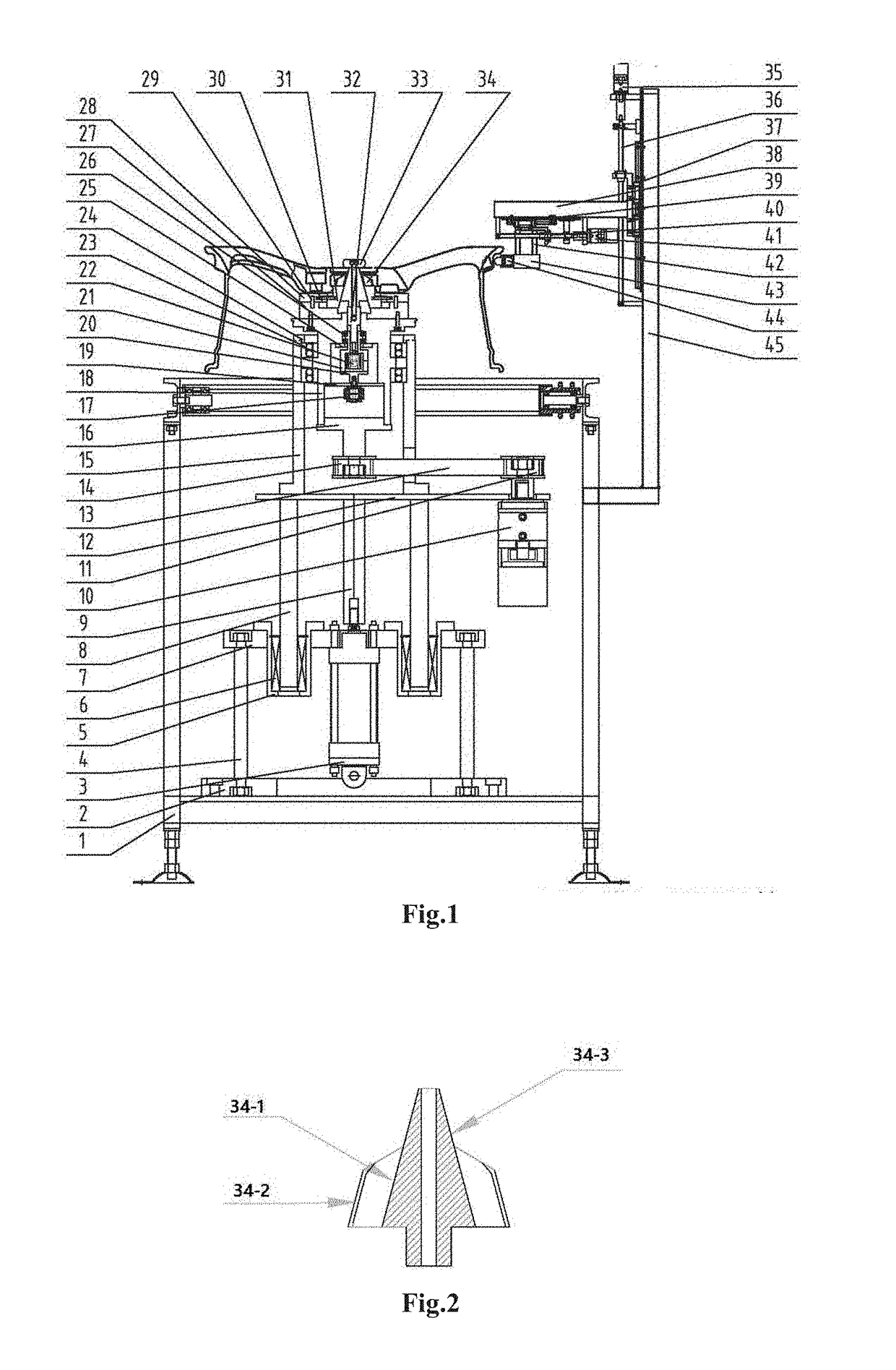

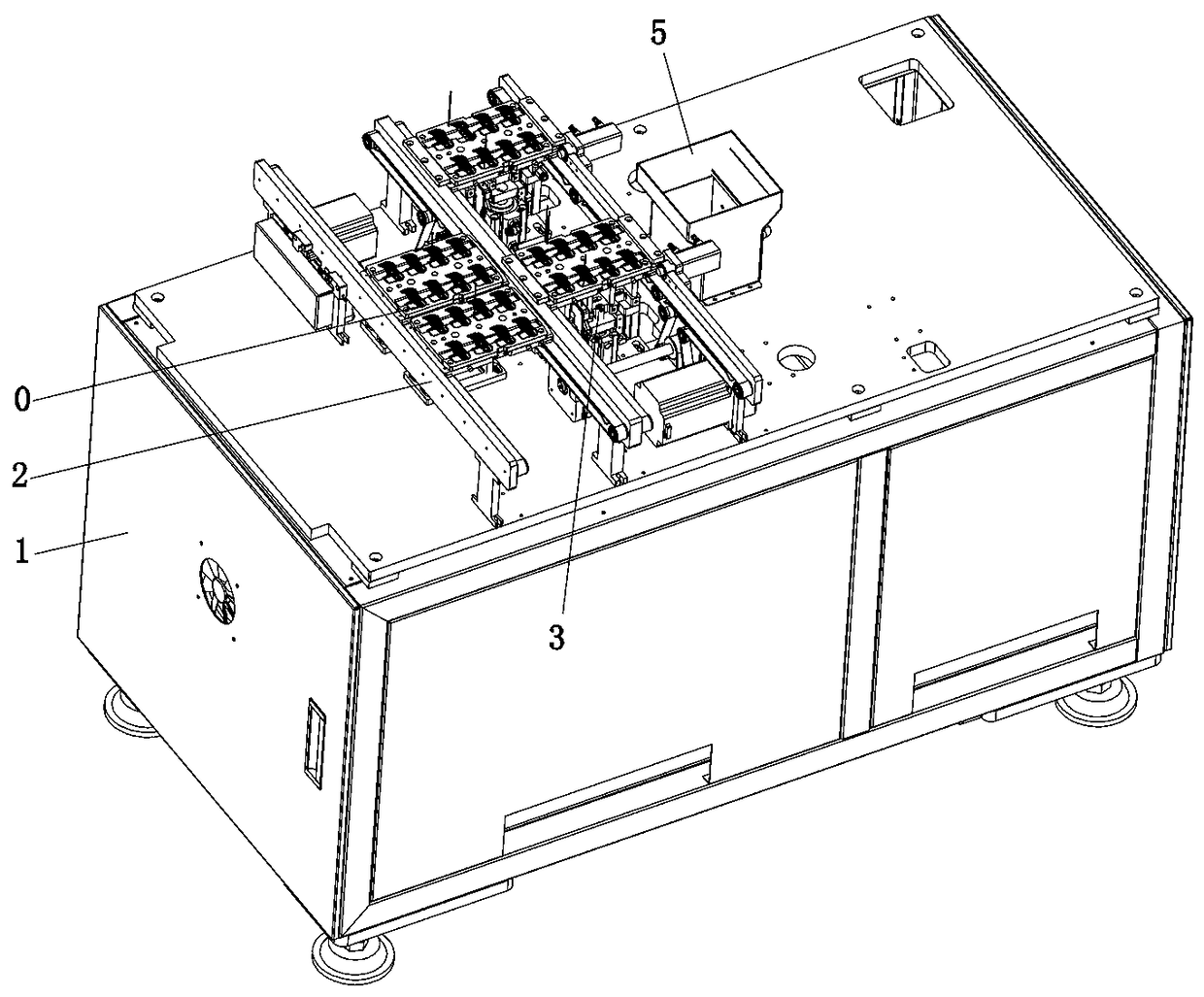

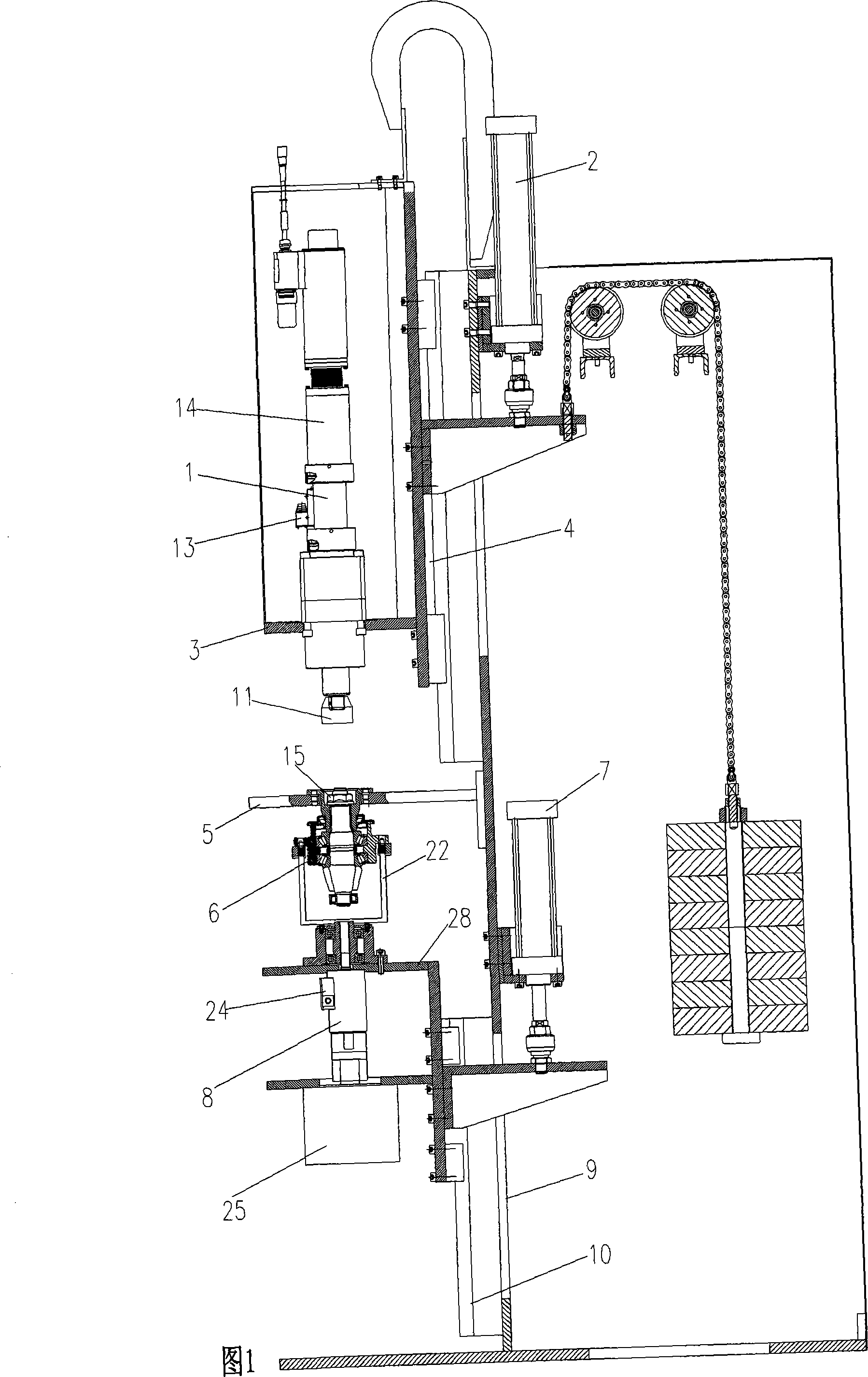

Pressing machine for liner

ActiveCN104028999APrevent slippingAvoid violent collisionsMetal working apparatusControl systemProgrammable logic controller

A pressing machine for a liner comprises a programmable logic controller (PLC) control system, a frame, a clamping mechanism, a plugging mechanism, a feeding mechanism, a pushing mechanism and a pressing mechanism. The clamping mechanism is arranged on the upper portion of the frame. A working platform is arranged on the lower portion of the frame. The plugging mechanism is fixedly arranged on the lower end surface of the working platform and corresponding to a positioning hole of the working platform. The pushing mechanism is arranged on a pressing plate of the clamping mechanism. The pressing plate is provided with a transversal linear slide. The feeding mechanism and the pressing mechanism are matched and respectively connected with the pushing mechanism through a mounting plate. The clamping mechanism, the plugging mechanism, the feeding mechanism, the pushing mechanism and the pressing mechanism are all controlled by the PLC control system. The pressing machine is adaptable to assembling of the liner of an oil pump cylinder body of an engine, and capable of realizing automatic operation, improving working efficiency, reducing labor intensity and improving products quality.

Owner:长城汽车股份有限公司平湖分公司

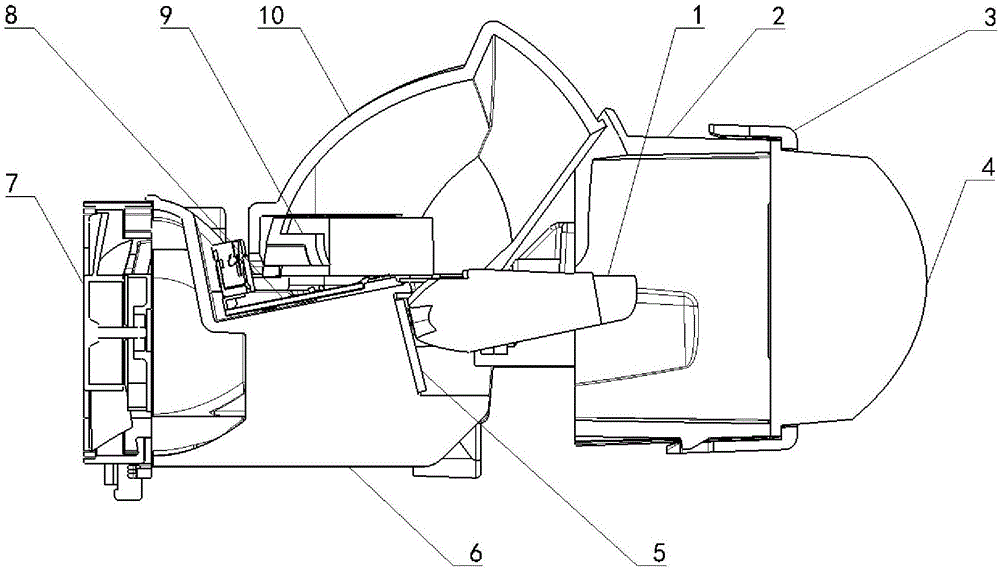

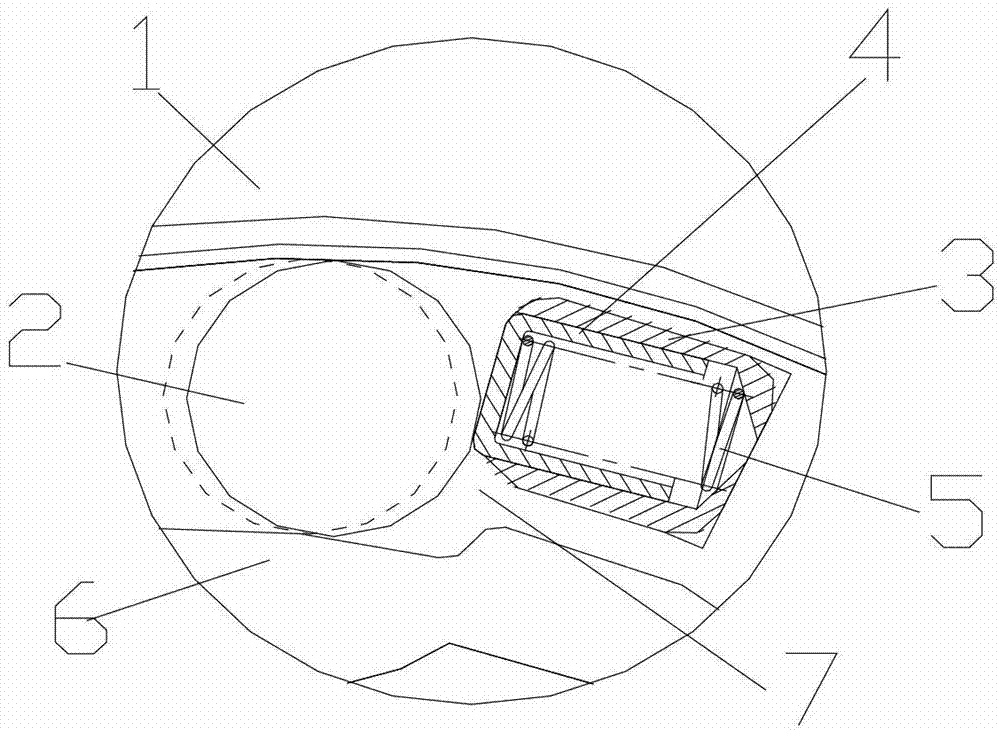

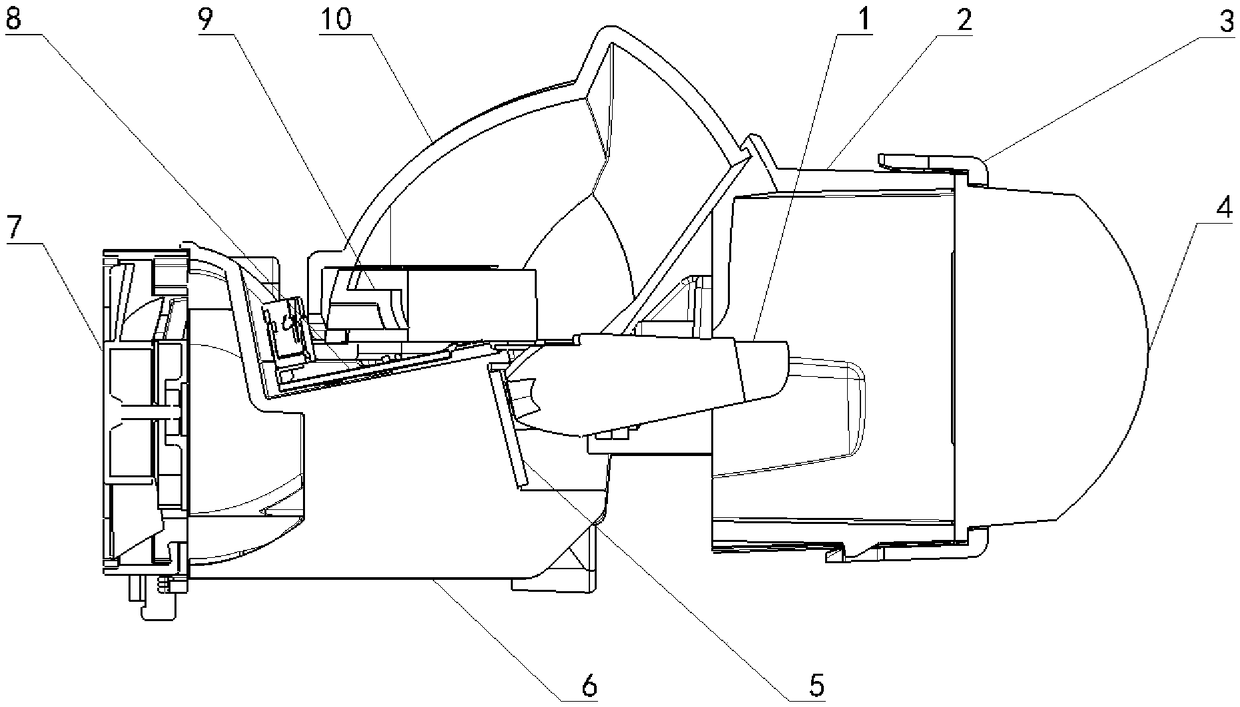

LED (light-emitting diode) light source upper beam and lower beam integrated automobile lamp module

ActiveCN106122870AReduce space footprintImprove space utilization efficiencySignalling/lighting devicesSemiconductor devices for light sourcesLED circuitLight-emitting diode

An LED (light-emitting diode) light source upper beam and lower beam integrated automobile lamp module is characterized in that an upper beam LED circuit board (5) and a lower beam LED circuit board (8) are arranged behind a condenser 1 respectively, and a reflection mirror comprises a first grade reflection mirror (10) and a second grade reflection mirror (9), which are used for forming a lower beam light shape. The first grade reflection mirror (10) can form the spreading width of the lower beam light shape independently, the second grade reflection mirror (9) increases the number of ray of light forming the lower beam light shape, and part of reflected light is used for forming a III region of the lower beam light shape. The ray of light emitted from an LED light source on the lower beam LED circuit board (8) is reflected by the first grade reflection mirror and the second grade reflection mirror, most ray of light therein is emitted after refracted by a lens (4) and forms a spreading width (5-1) of the lower beam light shape on a screen, the other part of ray of light is emitted from the lens (4) after reflected and refracted by the condenser to form a stop line (5-2) of the lower beam light shape and the III region (5-3). According to the invention, a square aluminizing surface does not need to be made on a radiator or other parts, the parts are simple to machine, and the cost is lower; the volume of the automobile lamp module is smaller, and the switching between the upper beam and lower beam has no noise.

Owner:HASCO VISION TECHNOLOGY CO LTD

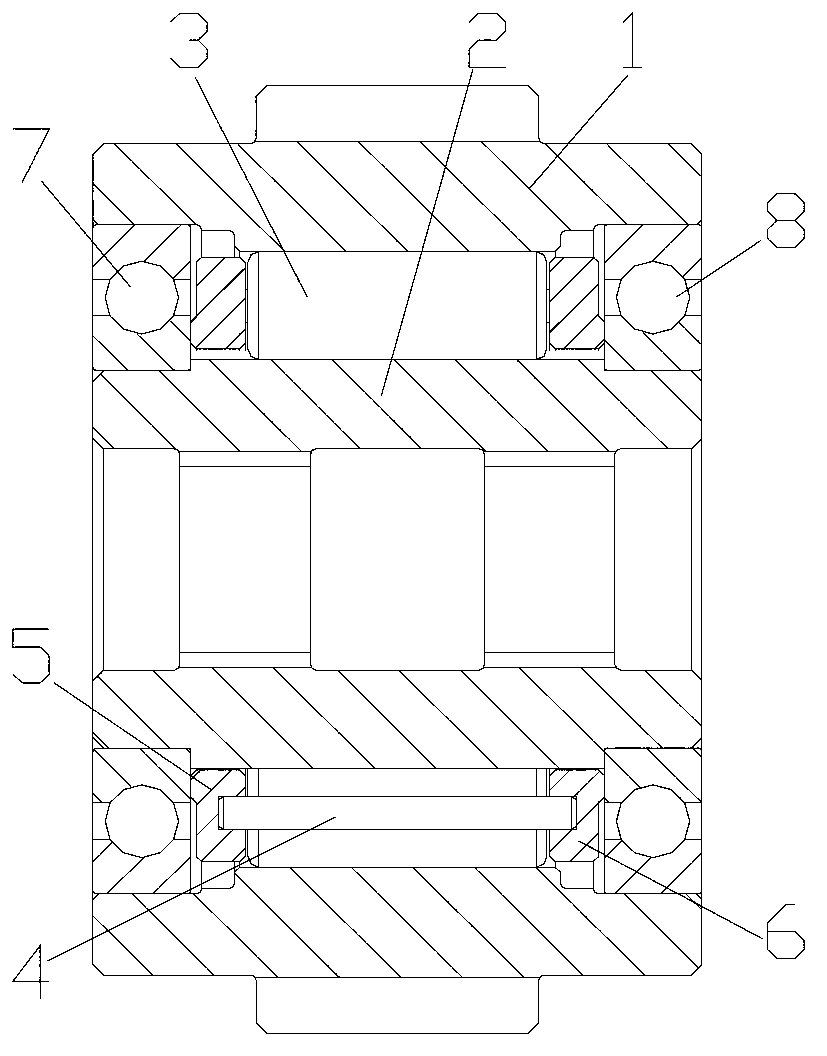

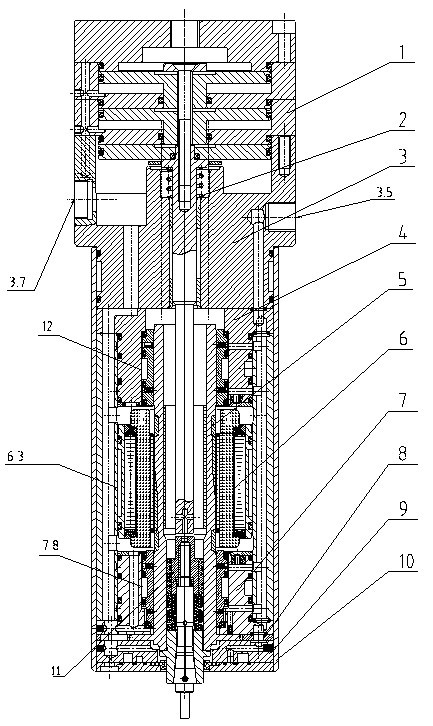

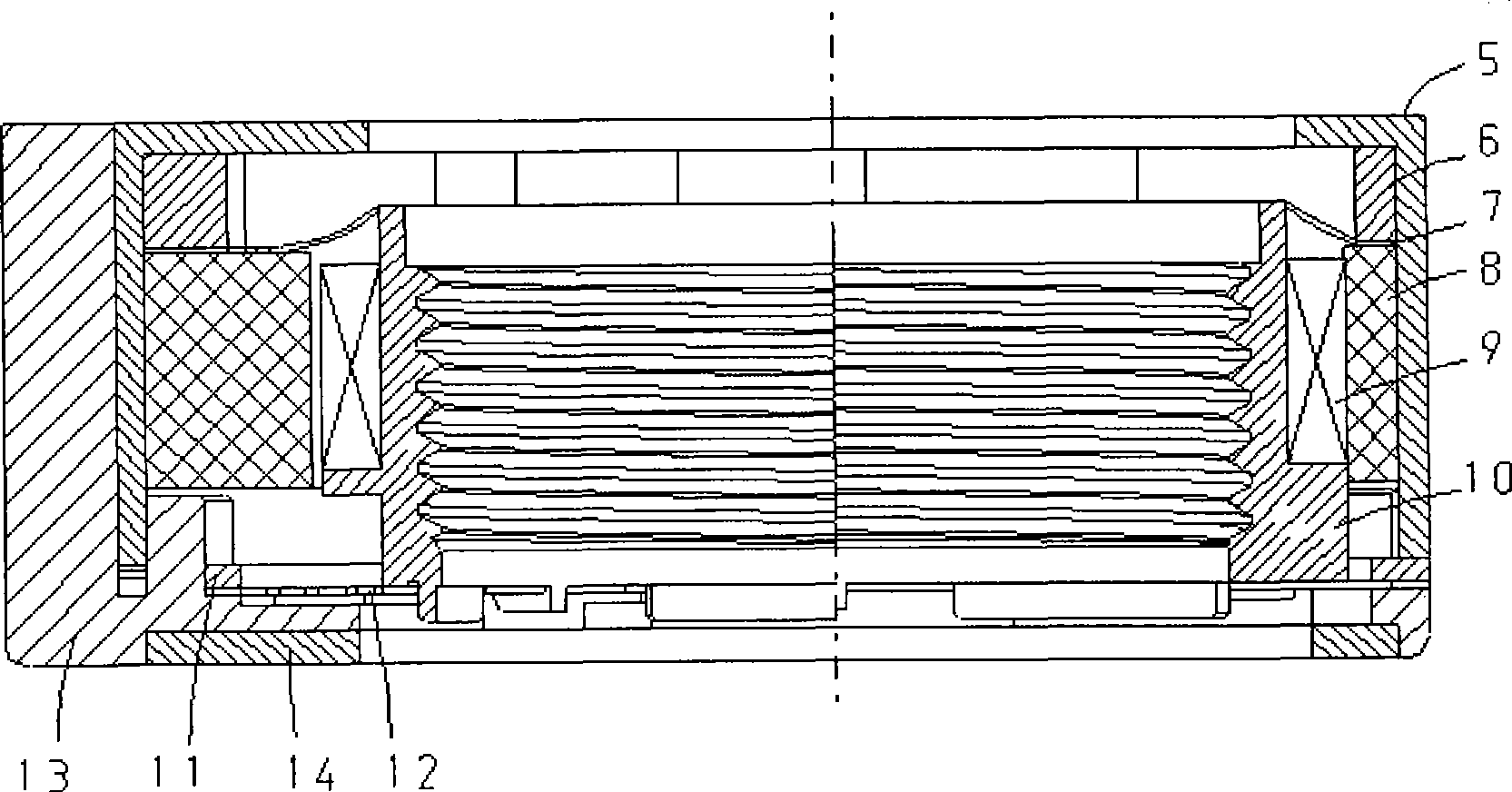

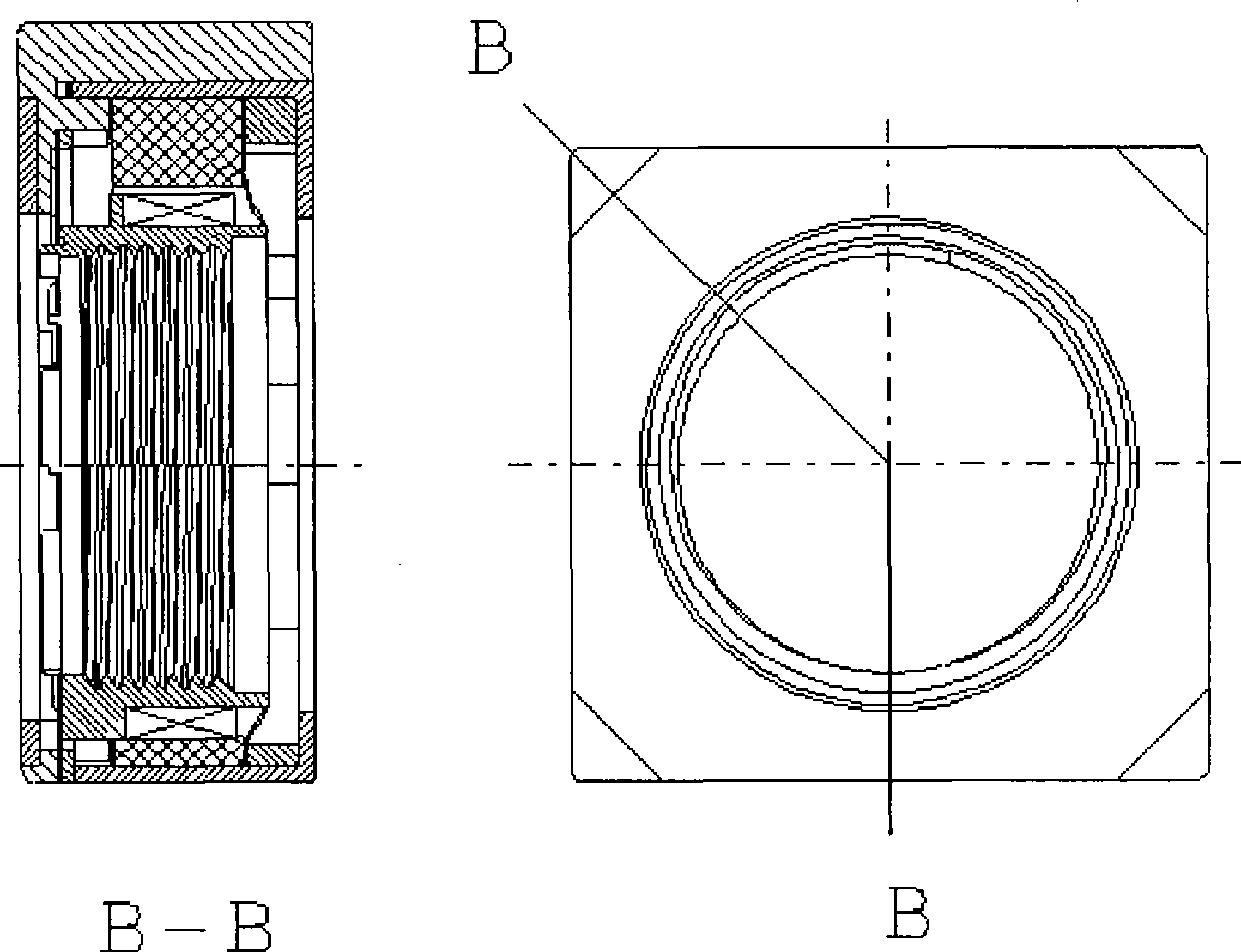

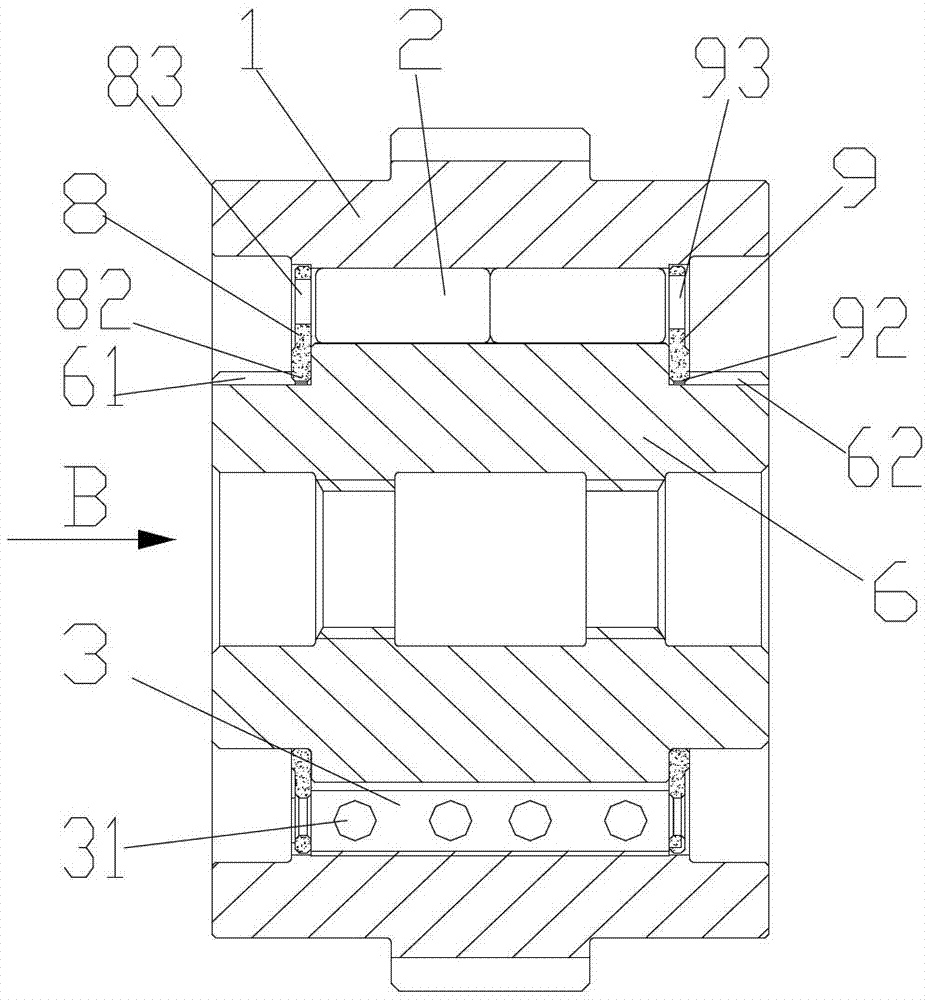

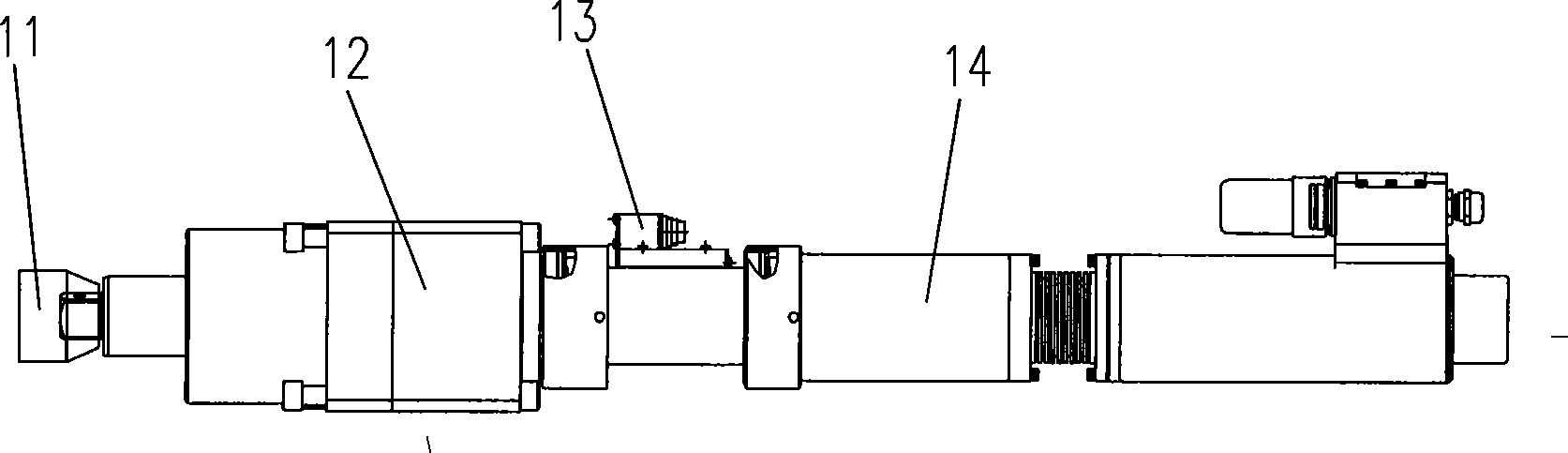

Air floatation high-speed electric main shaft

ActiveCN102078974AStable jobWork reliablyPositioning apparatusMaintainance and safety accessoriesAir bearingThrust bearing

The invention relates to an air floatation high-speed electric main shaft, in particular to an air floatation high-speed electric main shaft for a machining tool. A lower air bearing block assembly 7 is fixed on a thrust bearing 9, the upper part of the lower air bearing block assembly 7 is provided with a stator 6, the front end of a shaft core 5 is provided with a chuck accessory 11, an aluminum water jacket assembly 3 is fixed at the upper opening of a body assembly 10, and a tool changing cylinder assembly 1 is fixed on the upper part of the aluminum water jacket assembly 3; and the middle part of the shaft body of an upper air bearing 4 is provided with an upper air bearing cooling water passage 12. The main shaft is an electromechanical integrated base piece with high revolution number and high precision, has simple and compact structure, and is convenient to install, high in heat dissipation efficiency, multifunctional and convenient for popularization and application.

Owner:GUANGZHOU HAOZHI ELECTROMECHANICAL

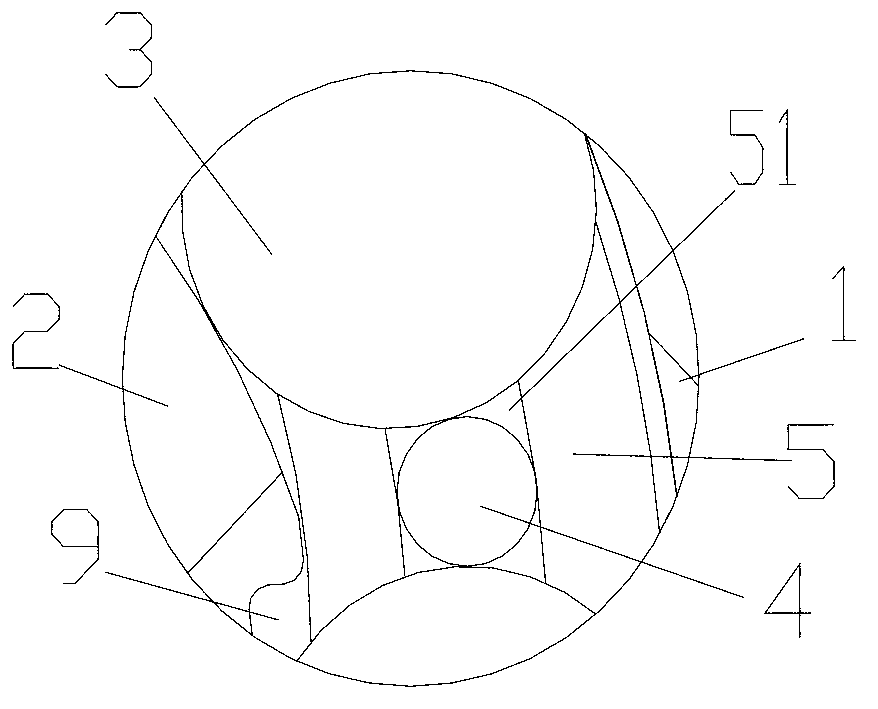

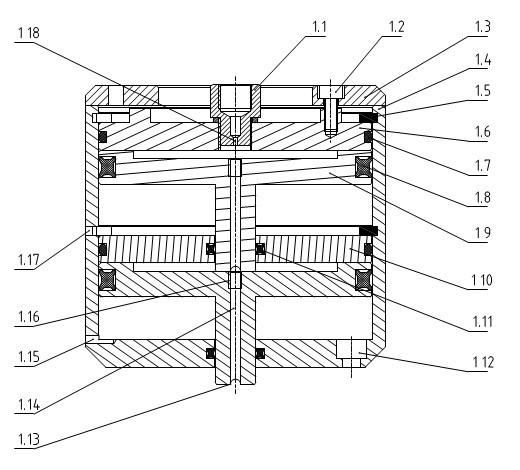

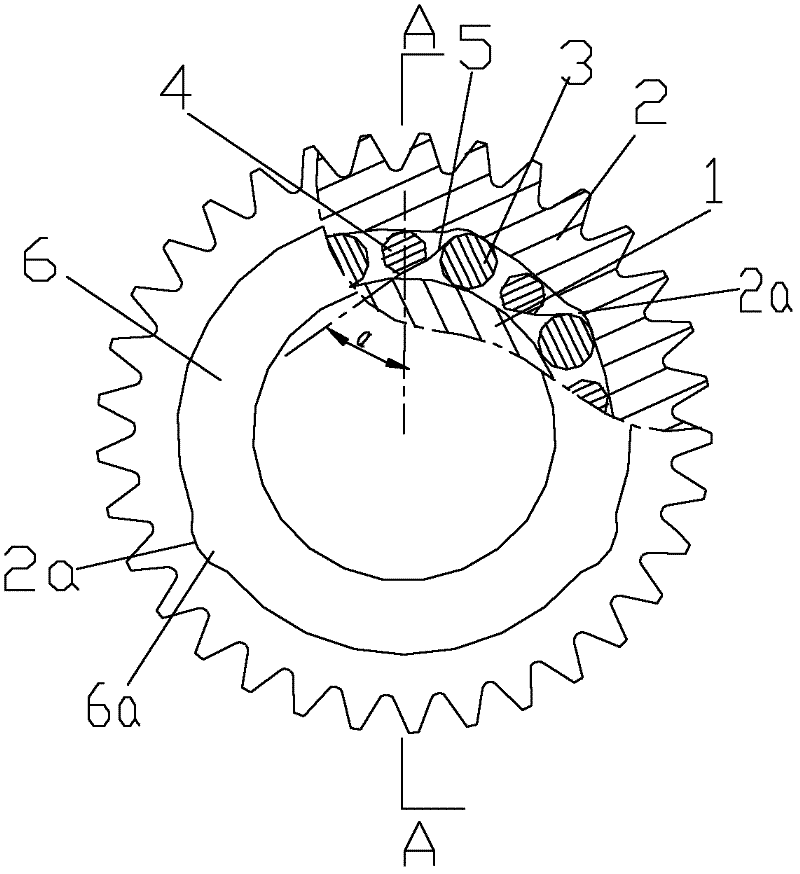

Accurate cycloid pin gear epicyclic transmission apparatus

InactiveCN101280824AEliminate or reduce hysteresisSmall hysteresisToothed gearingsEngineeringCycloid

The invention discloses a precision cycloidal-pin wheel planetary transmission device which comprises a machine base, a power input shaft, an eccentric bushing provided with two off centers, a cycloidal wheel I, a cycloidal wheel II, a dowel pin for cycloidal wheels, a power output shaft, a wheel spider I, a wheel spider II and two sets of pin gears that are respectively arranged on the wheel spider I and the wheel spider II; one end of the dowel pin for cycloidal wheels is fixedly arranged on a flange of the power output shaft and the other end is inserted into an isotonic pin hole of the cycloidal wheel I and the cycloidal wheel II to form a pin type output mechanism; the direction of a tooth outline on which the cycloidal wheel I and a pin gear I are meshed and the direction of a tooth outline on which the cycloidal wheel II and a pin gear II are meshed are reverse. The precision cycloidal-pin wheel planetary transmission device of the invention can eliminate or reduce tooth clearance during the transmission process, thereby improving transmission efficiency, reducing vibration and noise and prolonging service life; the relative position of the two wheel spiders in a circumferential direction is adjustable, so that meshed gap and return difference can be controlled effectively and more options are available when shaping the tooth outline of the teeth of the cycloidal wheels.

Owner:CHONGQING UNIV

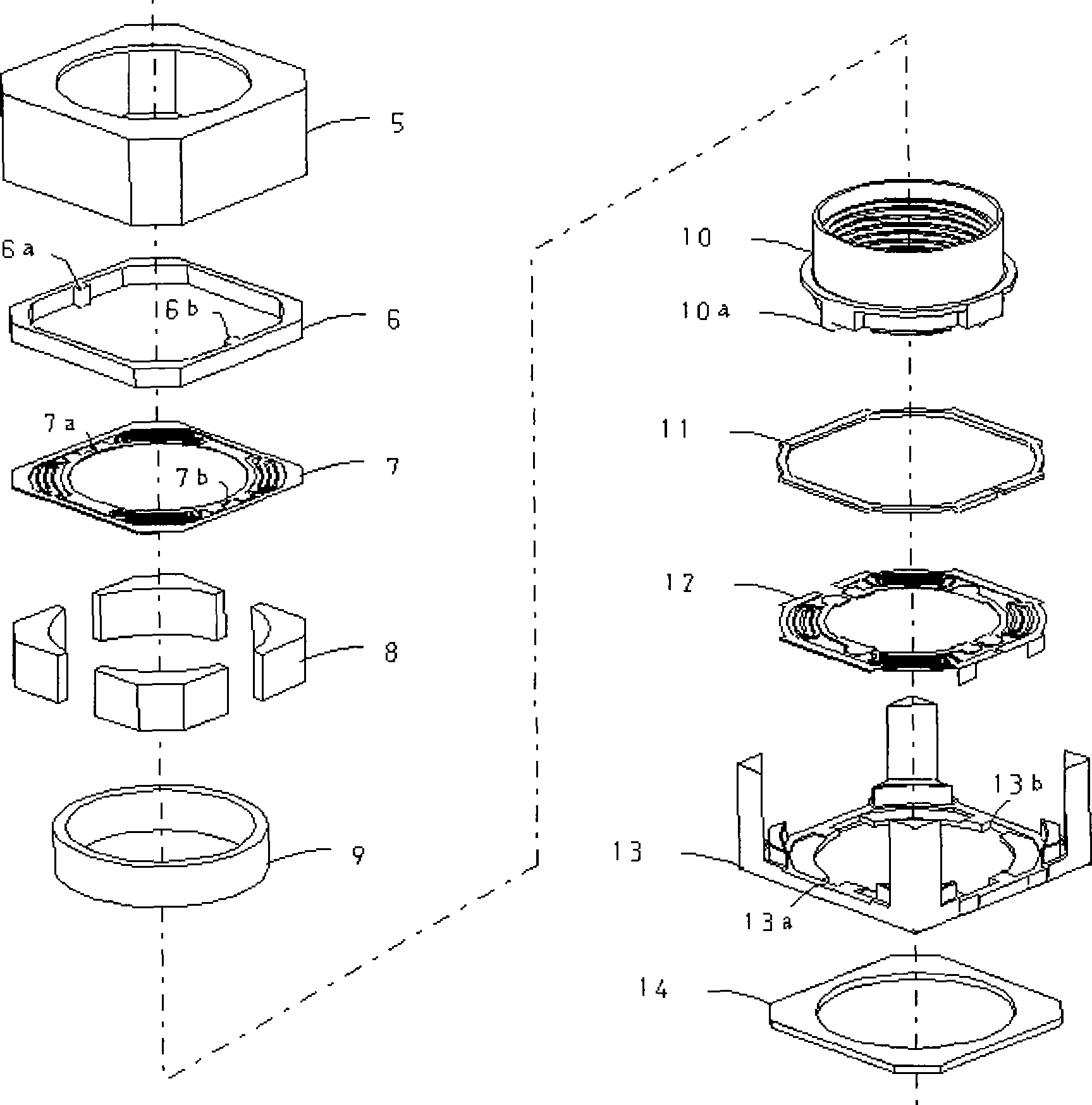

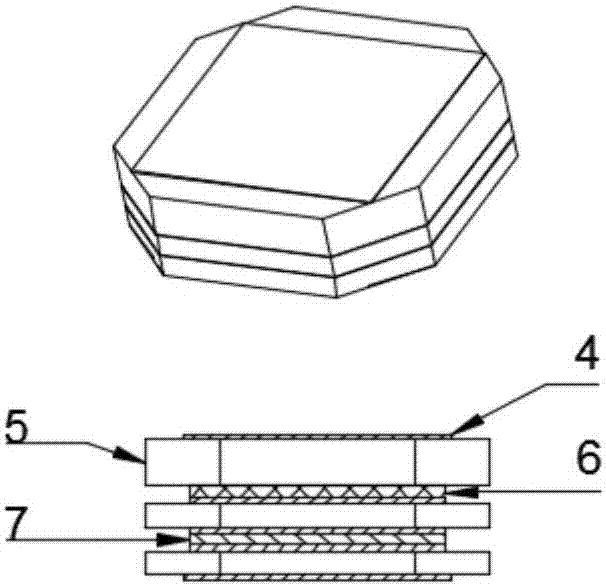

Voice coil type focus motor

InactiveCN101488698AEasy to shapeSimple processWindingsSupports/enclosures/casingsEngineeringElectromagnetic radiation

A voice coil motor comprises a stator which is a reverse L-shaped magnetic yoke and also can be taken as a shell. The voice coil motor is characterized in that one end is provided with an opening, and the other end is not completely closed and provided with a hole; magnetite is placed on the inner wall of the shell; a base plate is matched with the shell, and a lower magnetic yoke plate is arranged on the base plate; a rotor drives a coil to be wound on a lens supporting body of an outer cylindrical surface; the connecting way is that the rotor is hung inside a stator by an upper plate type shrapnel and a lower plate type shrapnel; a frame of the upper shrapnel is fixed by an upper support chip and the magnetite, and the circular arc at the inner side is bonded with the upper end part of the lens supporting body; a frame of the lower shrapnel is fixed by a lower support chip, and the circular arc at the inner side is bonded with the lower end part of the lens supporting body. By utilizing a closed magnetic circuit formed by the reverse L-shaped shell and the magnetic yoke plate, the voice coil motor improves the stability of the magnetic circuit; the closed metal space region can be used for preventing electromagnetic radiation; the shell serves as an assembled framework, and the coil is directly wound on the cylindrical surface of the lens supporting body, so that the number of air gaps among movable bodies in the magnetic circuit is reduced. Therefore, the voice coil motor has the advantages of compact structure, low processing difficulty of the parts, simple assembly technology and strong practicability.

Owner:李俊

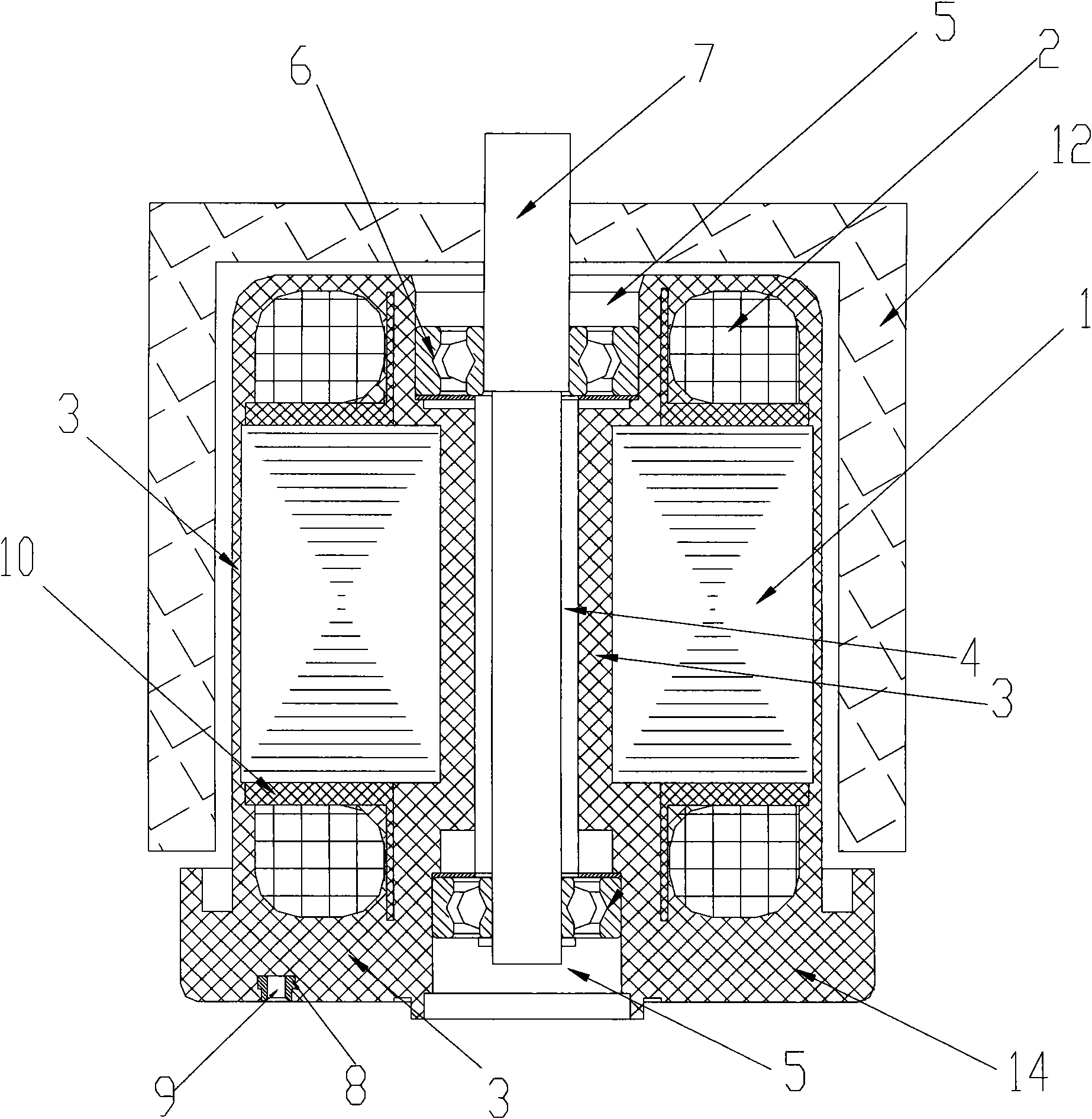

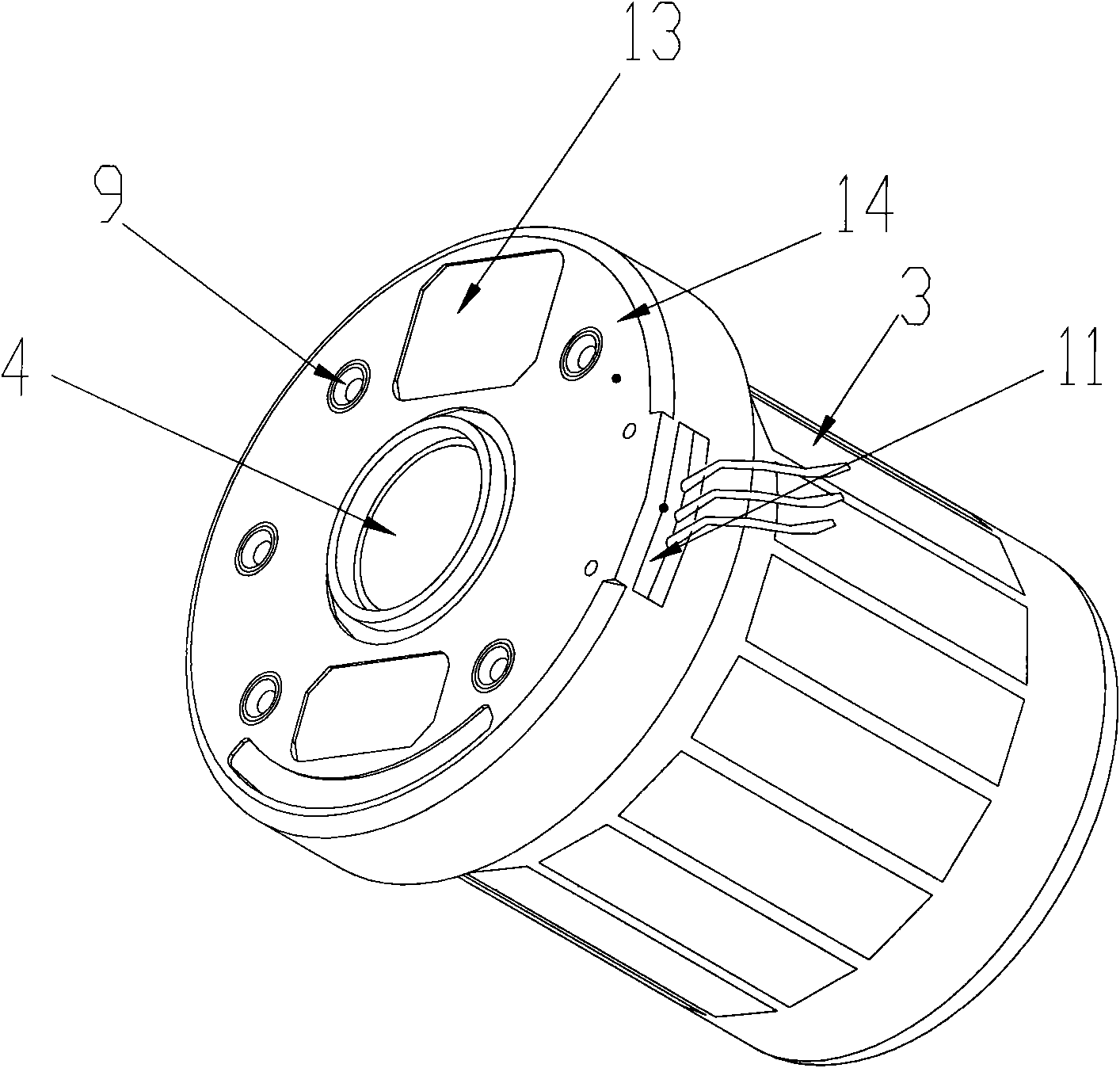

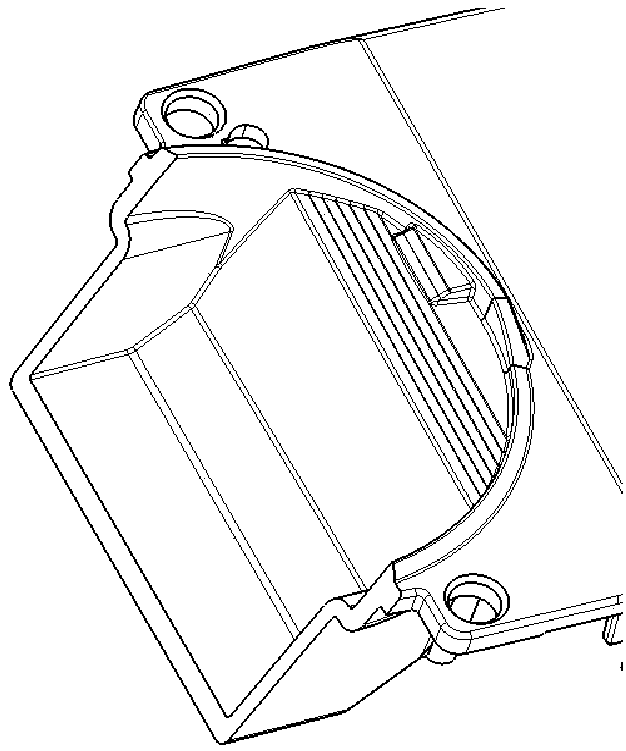

Outer rotor motor

ActiveCN101615817AImprove cooling effectReduce weightWindings insulation shape/form/constructionMagnetic circuit stationary partsNonferrous metalCooling effect

The invention discloses an outer rotor motor, which comprises a stator component, a rotor component (12) and a rotating shaft (7), wherein the rotor component (12) is sleeved outside the stator component; the rotor component (12) and the rotating shaft (7) are arranged and connected together; and the rotating shaft (7) is supported and arranged on the stator component through a bearing (6). The outer rotor motor is characterized in that the stator component comprises a stator core (1) and a coil winding (2); the coil winding (2) is wound on the stator core (1); an insulating shell (3) is injection-molded outside the stator core (1) and the coil winding (2); and the insulating shell (3) encloses the stator core (1) and the coil winding (2) to realize the isolation from the external world. The invention has good insulator performance, solves the problems of water resistance, dust prevention, corrosion resistance, the prevention of the oxidation of nonferrous metal wires, and end insulation, improves the safe reliability, reduces the weight of the motor and the cost for the motor, improves the cooling effect of a stator, reduces the temperature increase of the motor, and has more convenient motor installation and higher production efficiency.

Owner:ZHONGSHAN BROAD OCEAN

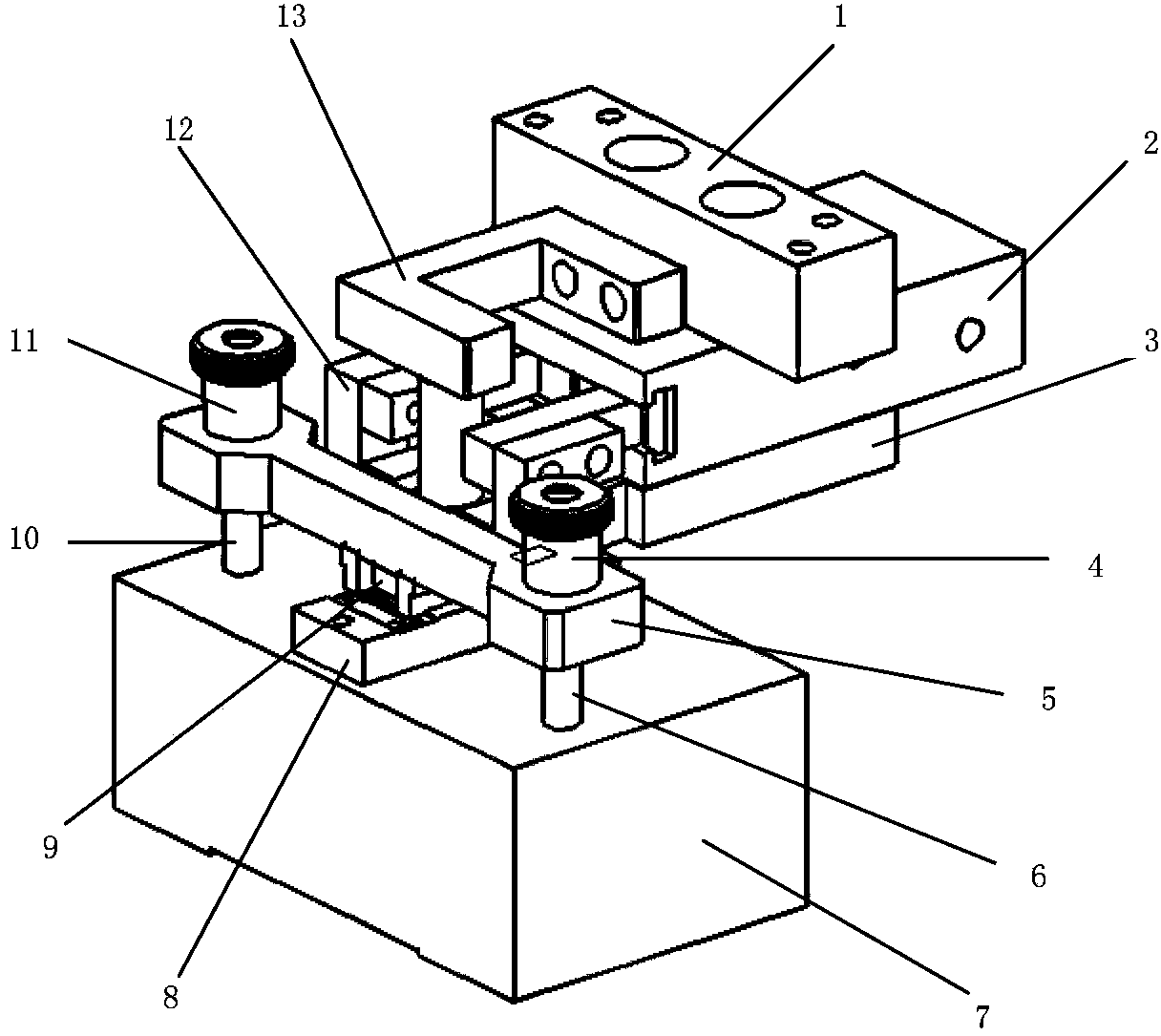

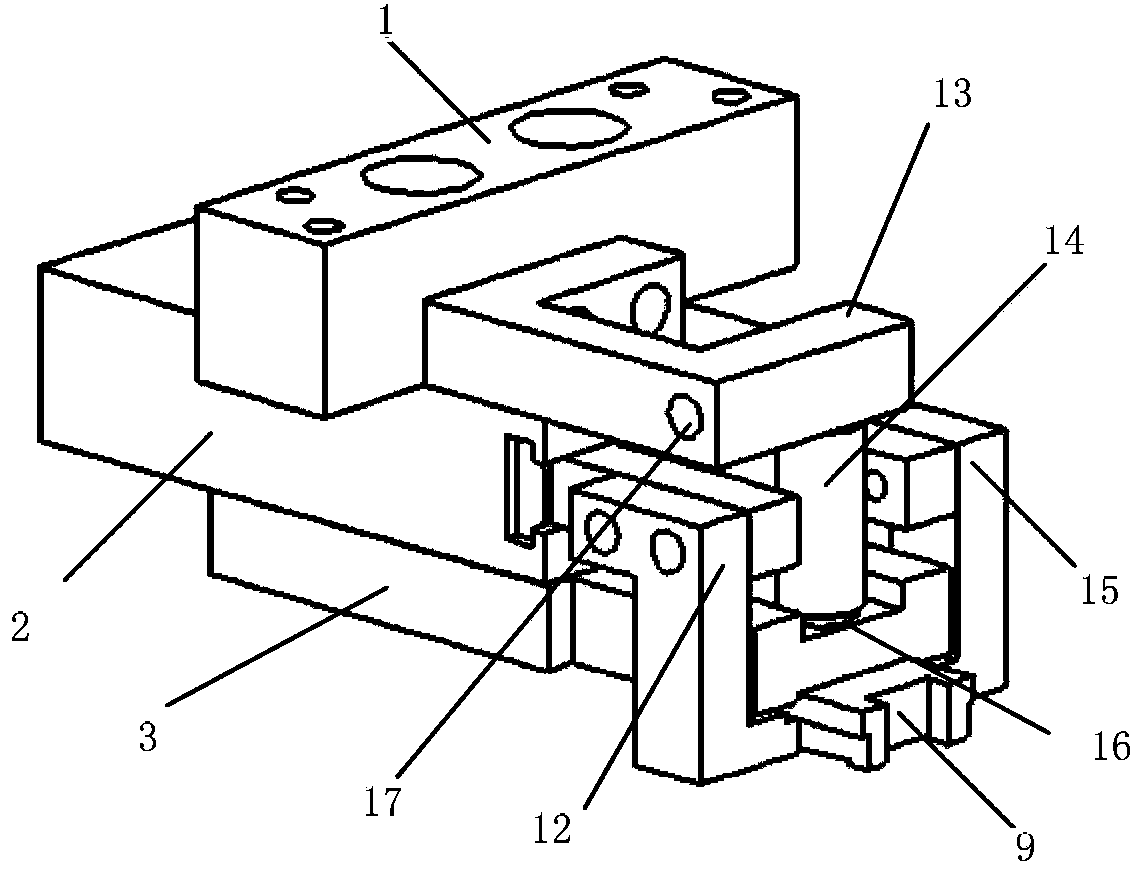

Tiny component assembling device and method

InactiveCN103350333AAchieve adsorptionRealize the assemblyMetal working apparatusMechanical componentsMechanical engineering

The invention relates to the technical field of precision assembly, in particular to a tiny component assembling device and method. The tiny component assembling device is characterized by consisting of a feeding clamp unit, combined adsorbing clamp unit and an assembling clamp unit, wherein the combined adsorbing clamp unit comprises a connecting block, a U-shaped pneumatic connecting block, a sucking disc connecting post, a left clamp finger, a right clamp finger, a sucking disc, a transitional adsorbing block, a positioning block and a pneumatic clamp; the transitional adsorbing block is designed to have a series of different sizes and structures and is used for adsorbing tiny components with various structural characteristics, so that the shift function of a clamp is achieved and the universality of the clamp is improved; the transitional adsorbing block adsorbs, moves and assembles the tiny components in the assembling process, and fixes an assembly after completion of the assembling process, thus ensuring that the assembly precision is not damaged, and achieving precision assembly of the tiny components. The tiny component assembling device and method are applicable to clamping adsorption, movement, assembly and fixation of tiny mechanical components.

Owner:DALIAN UNIV OF TECH

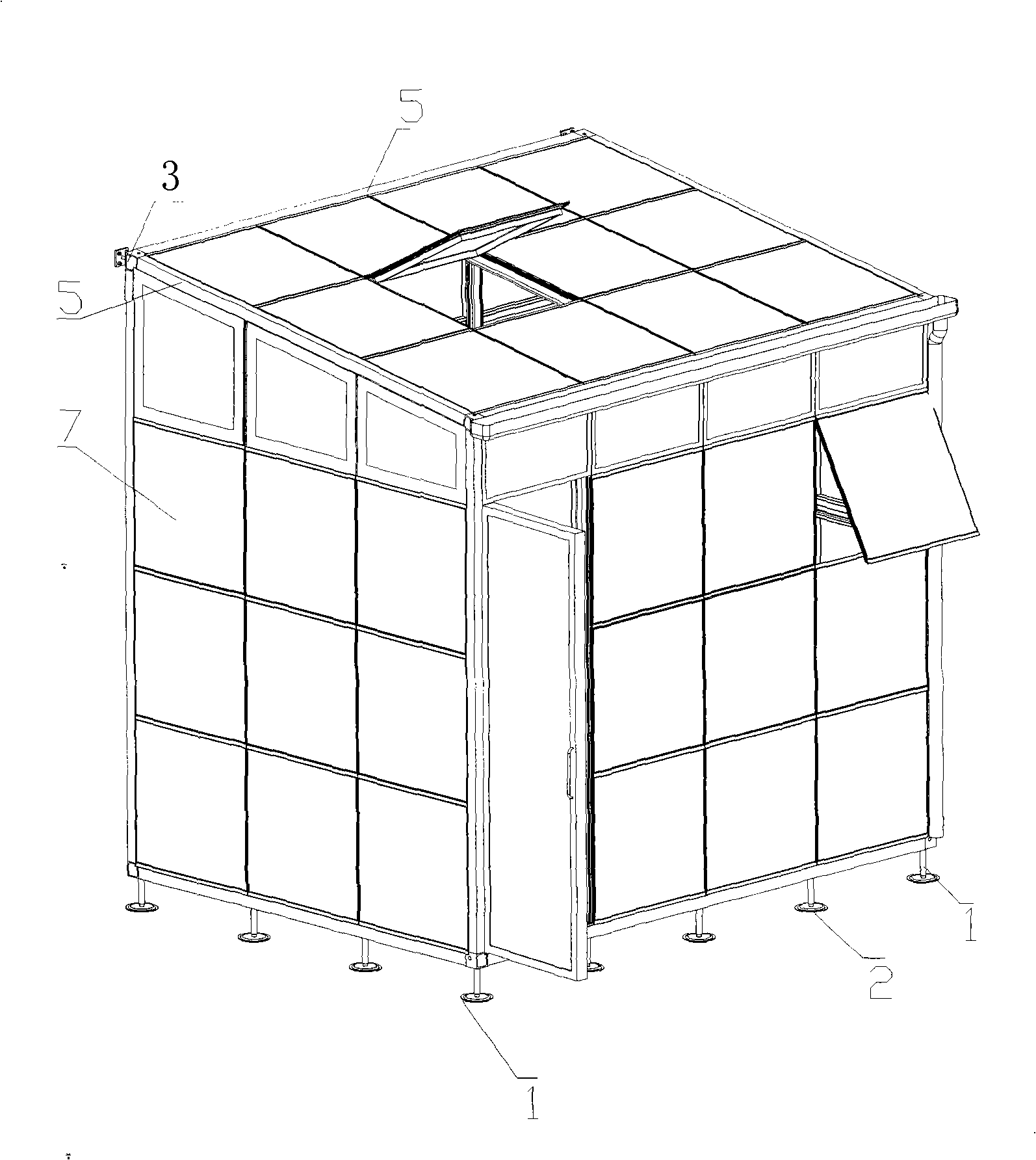

Integrated sunshine room assembly

The present invention discloses an integrated sunshine room assembly which comprises foot supporters, floor supporters, corner joint structures, auxiliary joint structures, frame beams and glass modules. Each frame beam comprises a main beam and an auxiliary beam. The foot supporters support the main beams. The floor supporters support the floor of integrated sunshine room assembly. Each corner joint structure comprises a taper sleeve which is sleeved by the main beam. The auxiliary joint structures are fixed on the main beams and comprise joints. The auxiliary beams are sleeved on the joints. The glass modules are fixed on the main beam and the auxiliary beam. The integrated sunshine room assembly of the invention can be assembled without adopting the special tool by the professional constructor, and can be installed by using the common instrument by ordinary personnel thereby greatly increasing the versatility of integrated sunshine room assembly.

Owner:ZHUHAI KING GLASS ENG

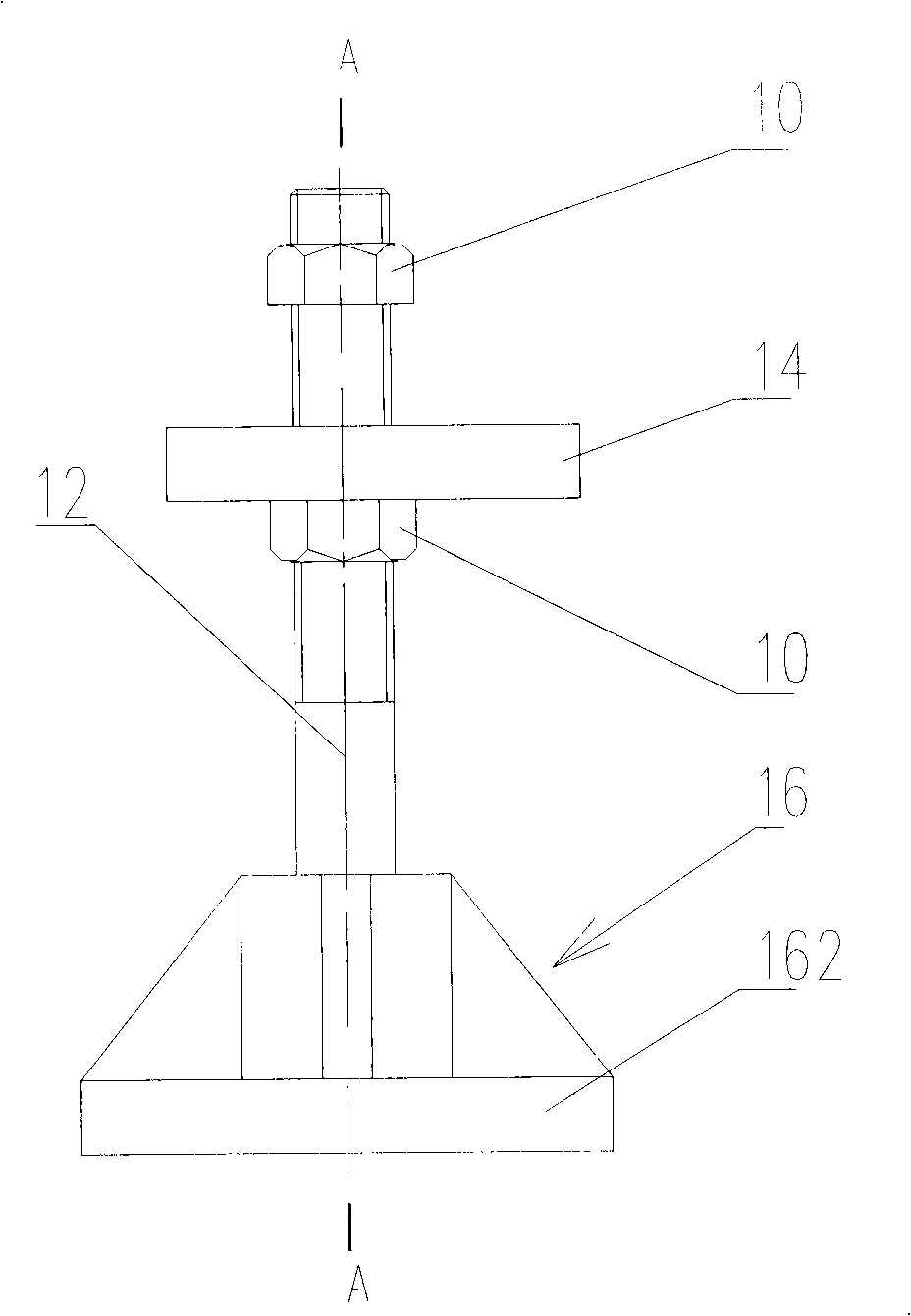

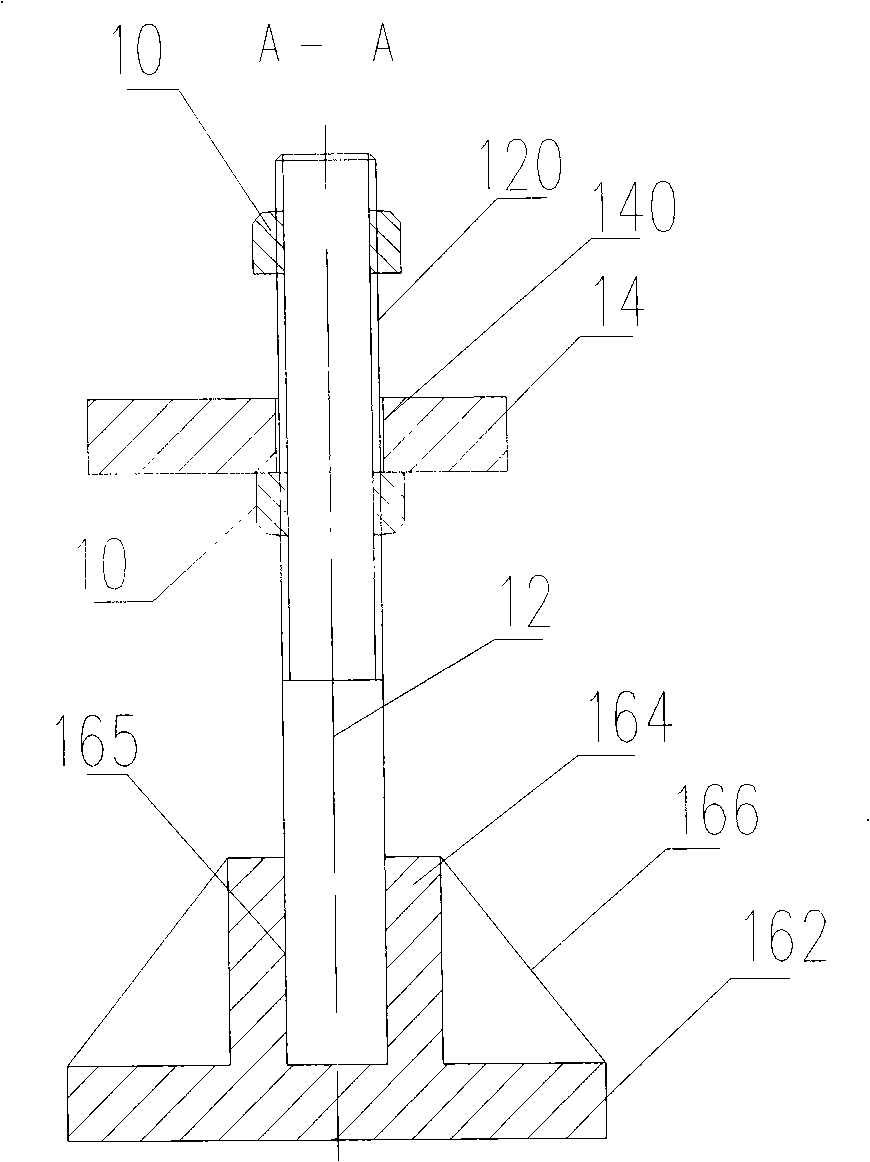

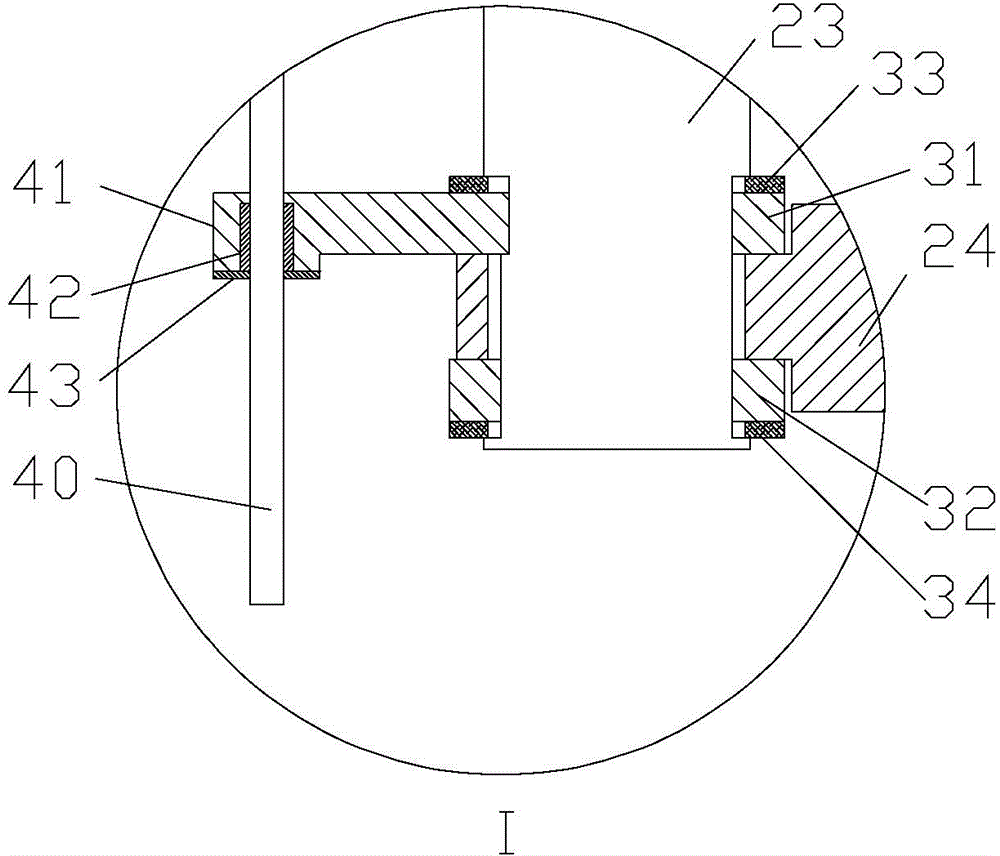

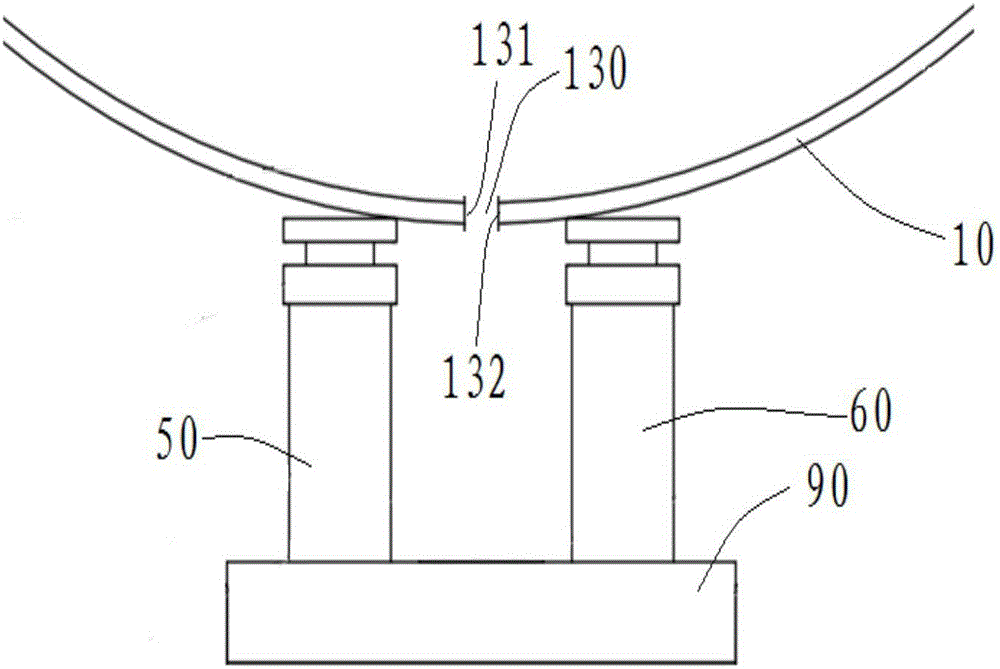

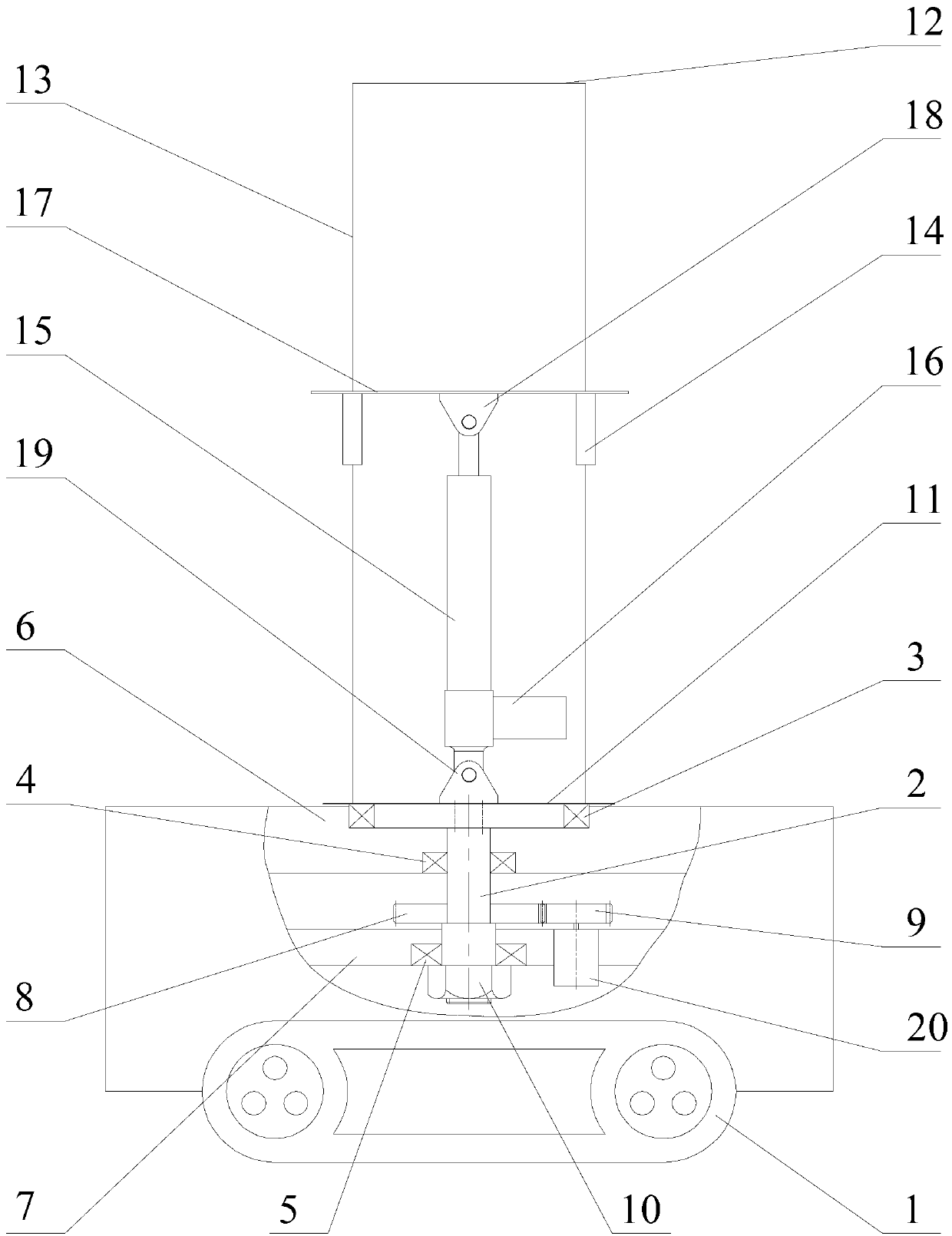

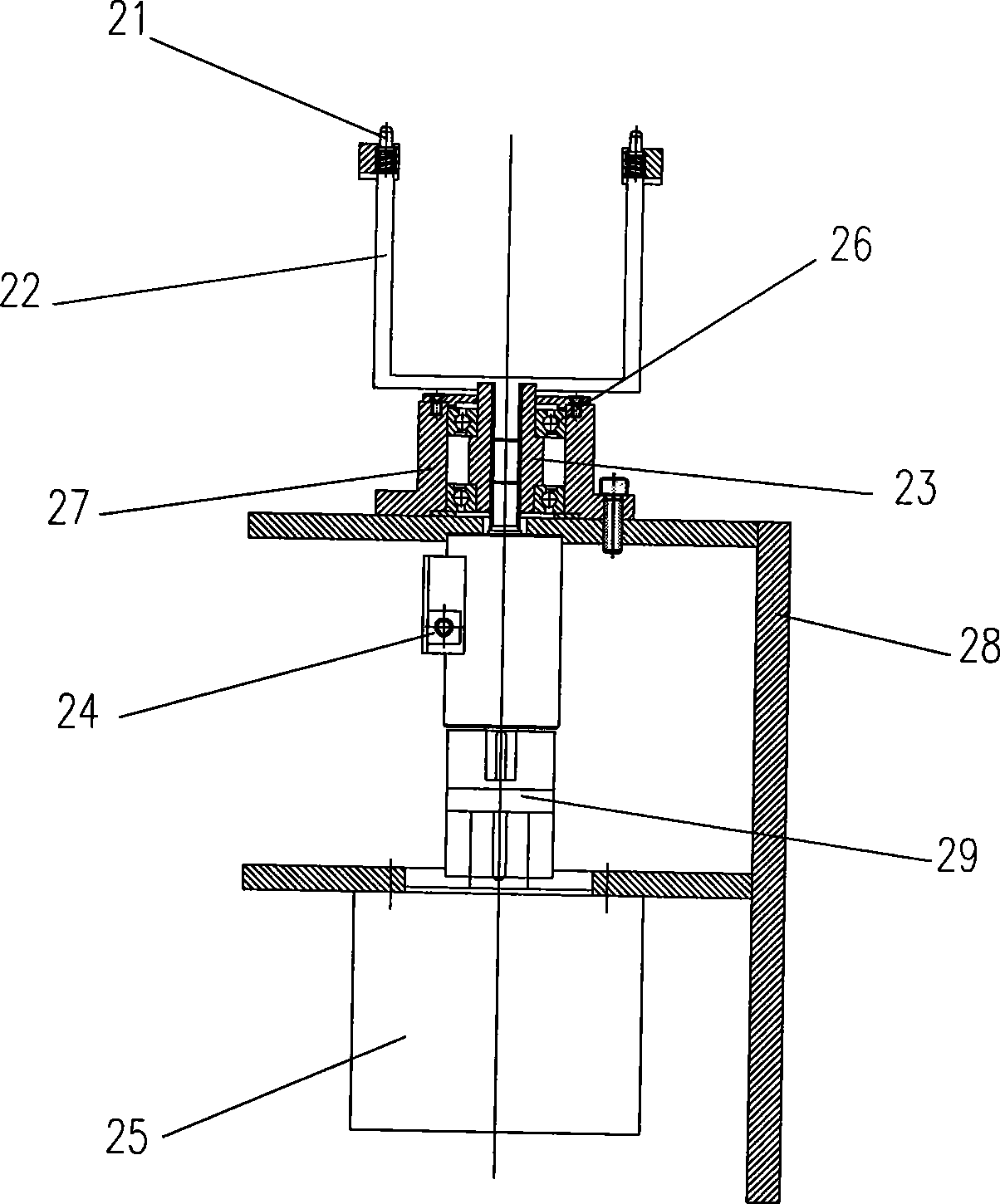

Carrying platform elevating gear, reaction cavity, and plasma processing device

ActiveCN104465447AGuaranteed levelnessEliminate redundant constraintsElectric discharge tubesVacuum evaporation coatingRotational degrees of freedomEngineering

The invention provides a carrying platform elevating gear, a reaction cavity, and a plasma processing device. A bracket driving source drives a shaft lifting bracket to do lifting motion. A bellows shaft passes through the shaft lifting bracket and is fixedly connected with the shaft lifting bracket, so as to do lifting motion with the shaft lifting bracket in a linear bearing, thereby realizing lifting motion of the carrying platform which is fixed on the bellows shaft. In the carrying platform elevating gear, a guiding mechanism is used to limit axial rotation of the bellows shaft in a lifting process. The bellows shaft passes through the linear bearing, a guiding shaft installing assembly, and a shaft lifting bracket in sequence. The guiding shaft installing assembly tightly holds the bellows shaft. The upper end of the guiding shaft is fixed on the cavity wall of the reaction cavity. The lower end of the guiding shaft passes through the guiding shaft installing assembly, so that the guiding shaft installing assembly does lifting motion with the shaft lifting bracket along the guiding shaft. The carrying platform elevating gear can limit rotation degree of freedom of a connecting rod, so as to ensure a carrying device from deflecting.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

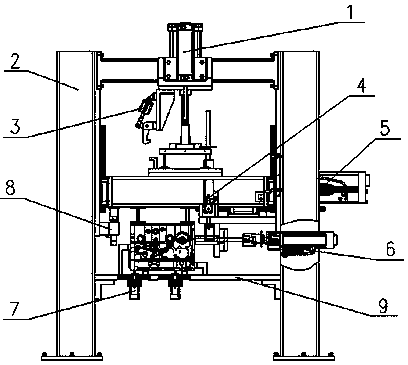

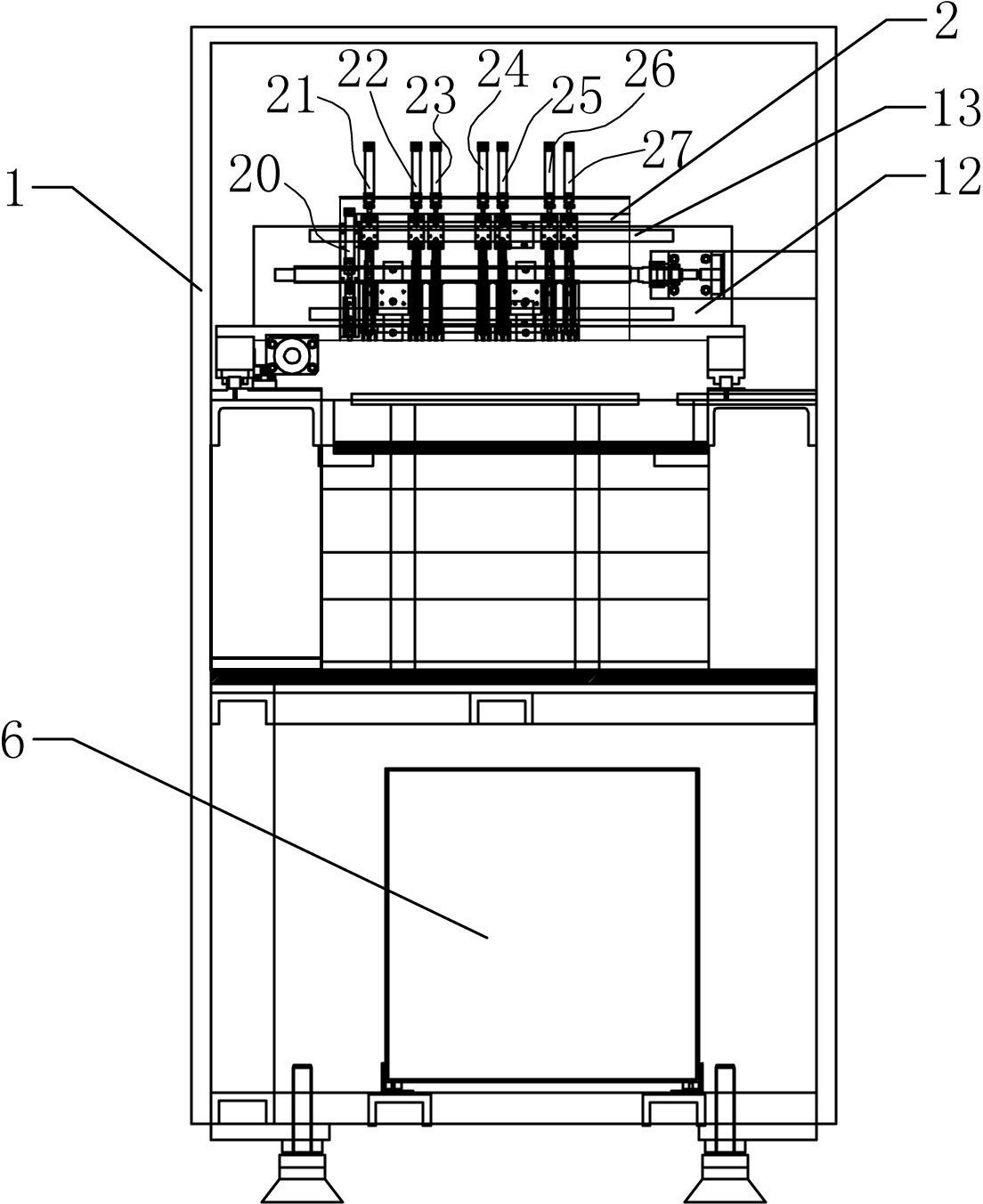

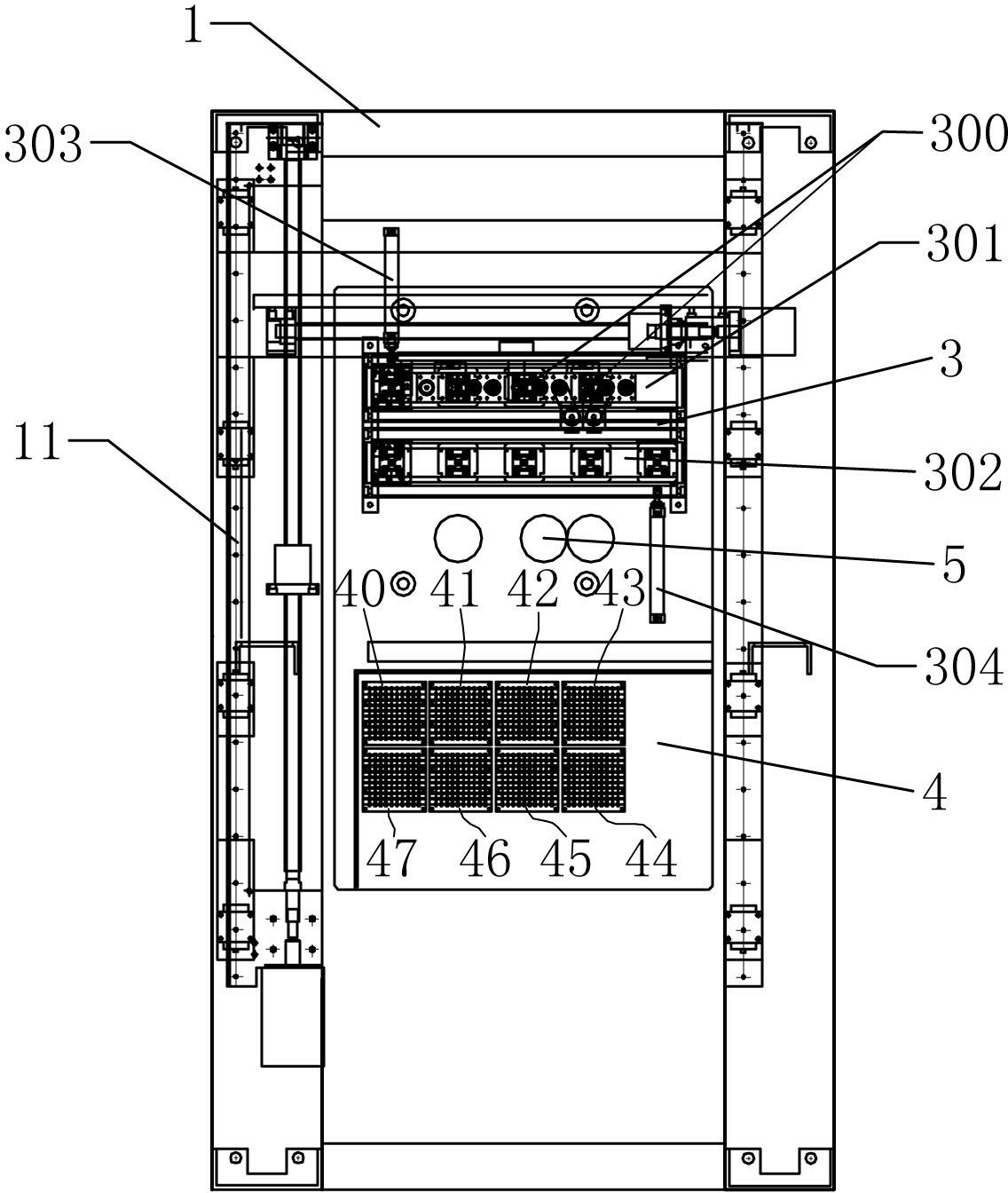

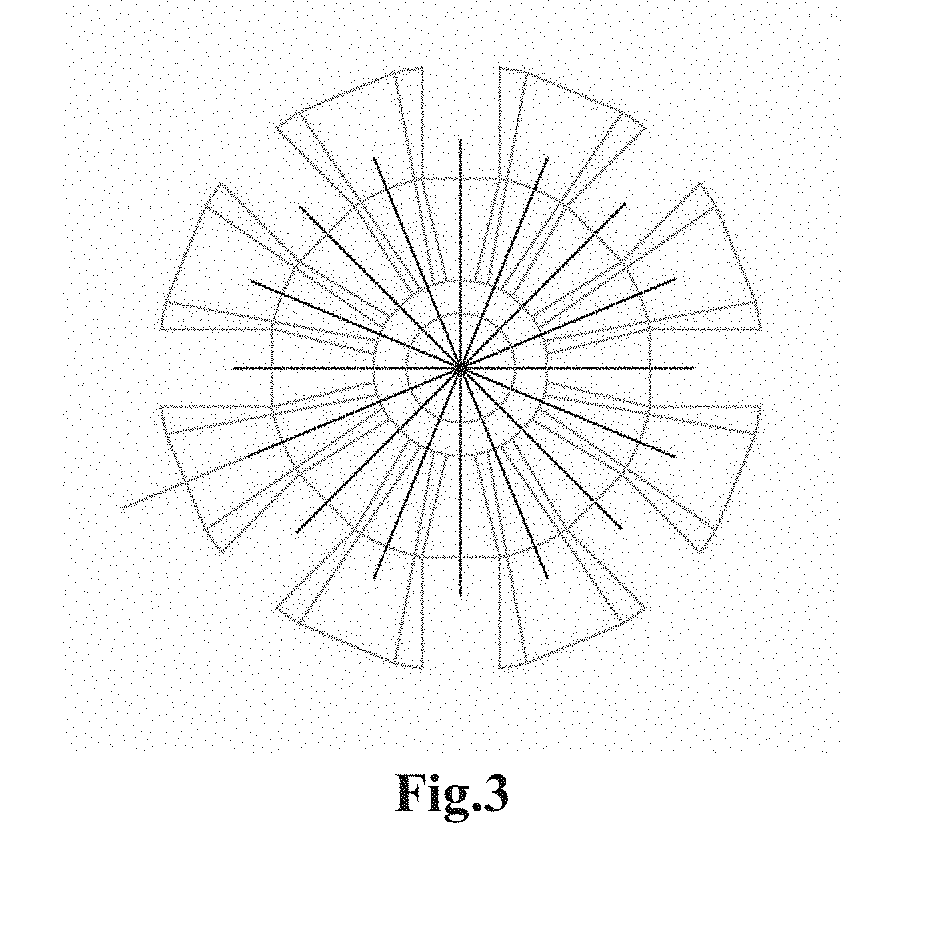

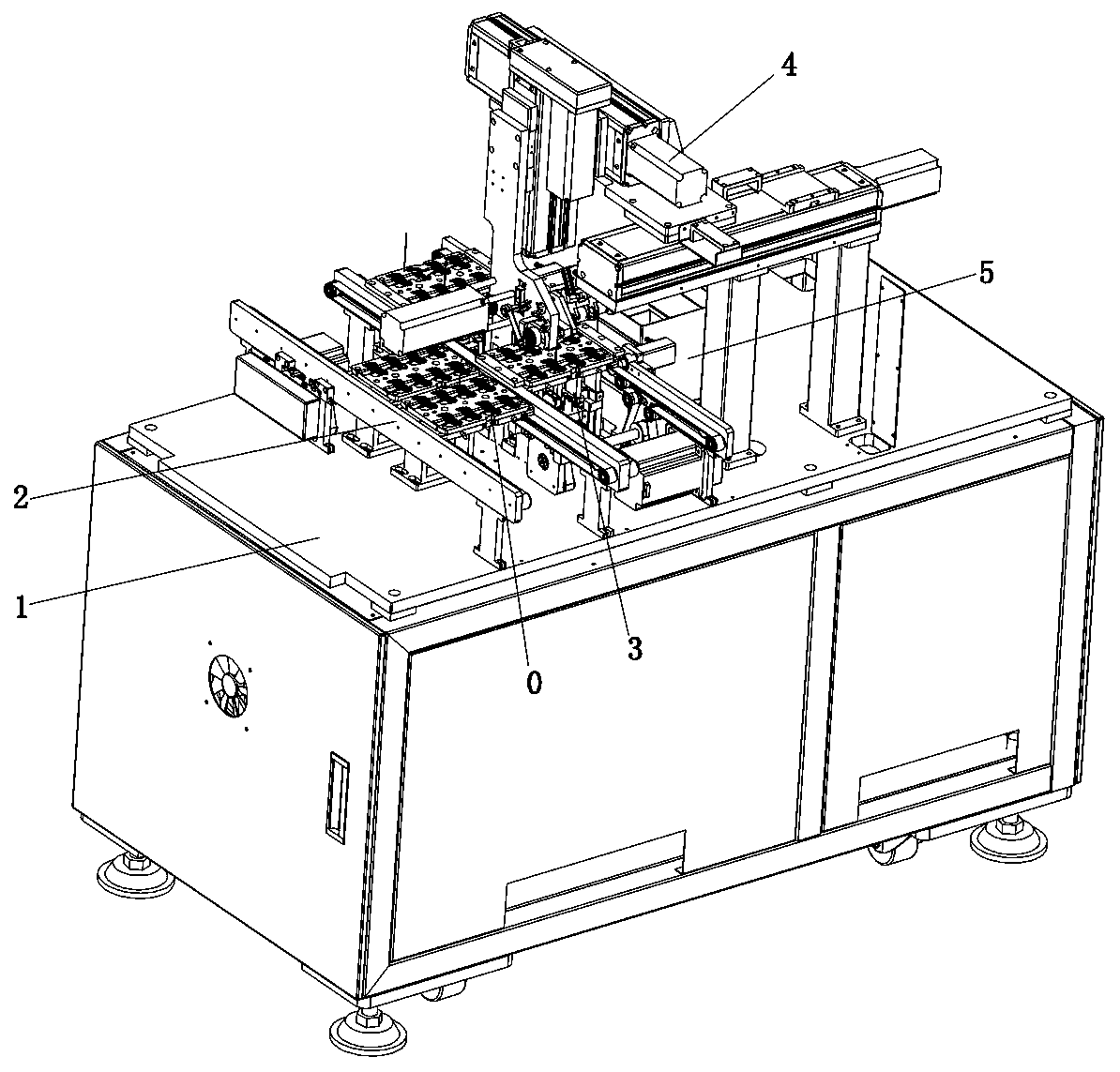

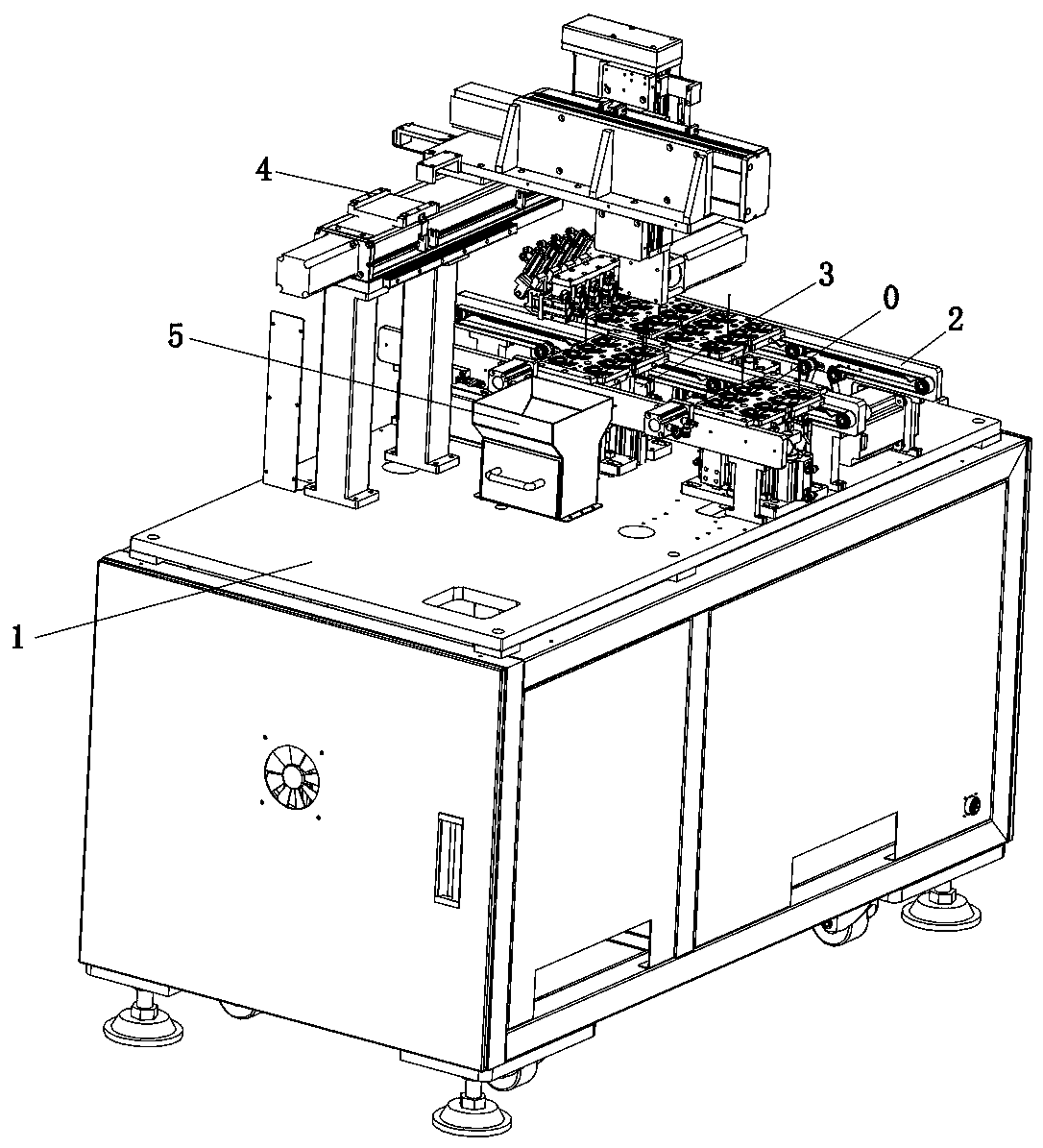

Lens assembly equipment and method of assembly lens thereof

The invention relates to the technical field of a lens assembly system, and in particular relates to lens assembly equipment and a method of using the lens assembly equipment to assemble a lens. The lens assembly equipment comprises a frame with an assembly platform and a control unit, wherein an assembly unit capable of moving on the plane parallel to the assembly platform is arranged on the frame, and comprises a plurality of suction nozzle mechanisms capable of moving along a direction vertical to the assembly platform; the assembly platform is provided with a fixture rotary platform which is provided with a plurality of clamp fixtures capable of rotary moving; the assembly platform is provided with a feed platform, and a stock tray is placed on the feed platform; and the control unit controls the assembly unit, the suction nozzle mechanisms and the clamp fixtures to move. By adopting the rotary fixture conveying platform to perform multi-process synchronous assembly, the lens assembly equipment has higher assembly efficiency and higher assembly yield.

Owner:东莞市研杰自动化设备有限公司

Online wheel run-out detecting device

ActiveUS20180003592A1Process is finishedSimple structureStatic/dynamic balance measurementVehicle wheel testingEngineeringPulley

The invention relates to an online wheel run-out detecting device. The online wheel run-out detecting device includes a frame, a chassis, a lifting cylinder, supports, bearing bases, linear bearings, mounting plates, guide shafts, a lifting shaft, a servo motor, a synchronous pulley, a connecting plate, a synchronous belt, a synchronous pulley, a base, a connecting shaft, a servo motor, a shaft sleeve, a lower end cap, a connecting shaft, a shaft sleeve, and an oil cylinder. The online wheel run-out detecting device can meet requirements of online wheel run-out detection, meanwhile it has the characteristics of simple structure, convenience in manufacturing, stable performance and capability of meeting machining requirements on precision, and can meet requirements of automatic production.

Owner:CITIC DICASTAL

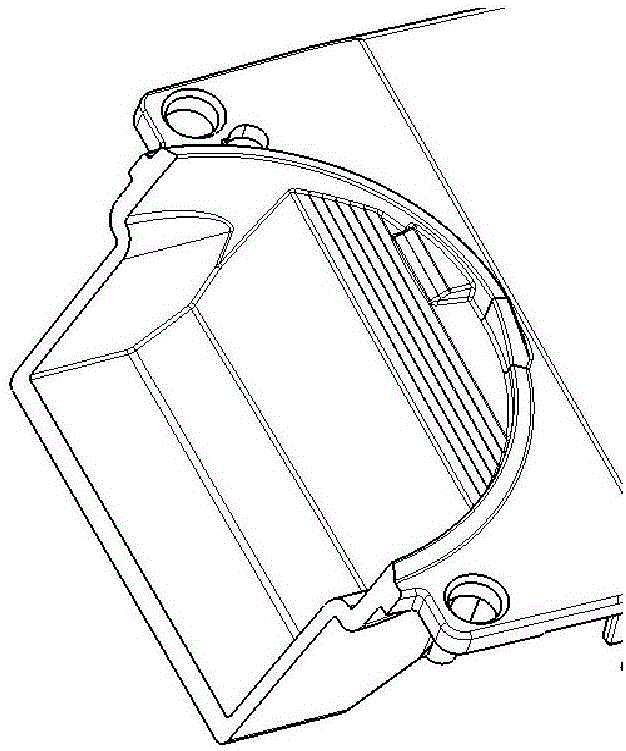

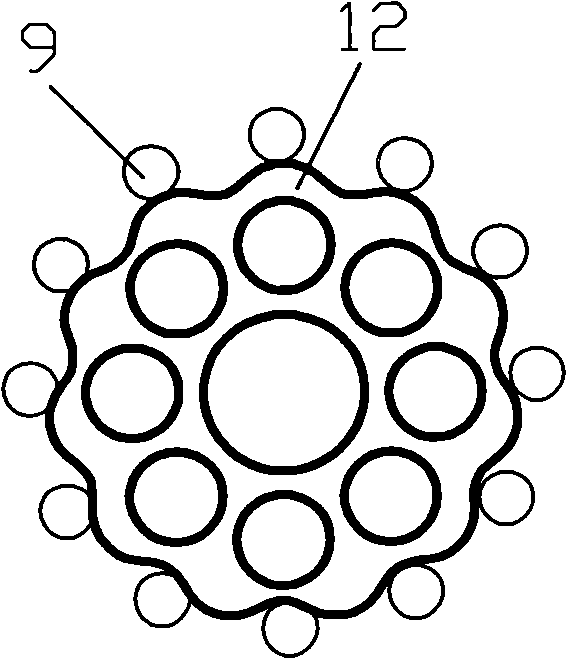

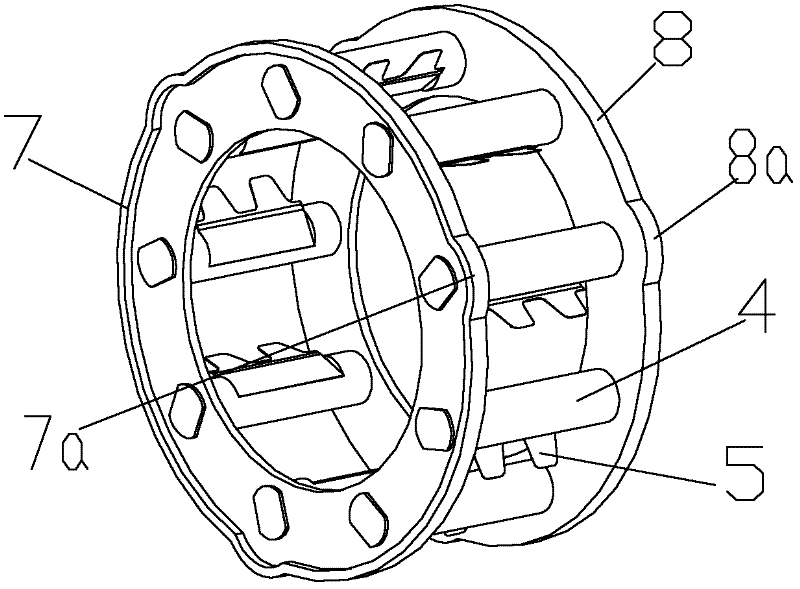

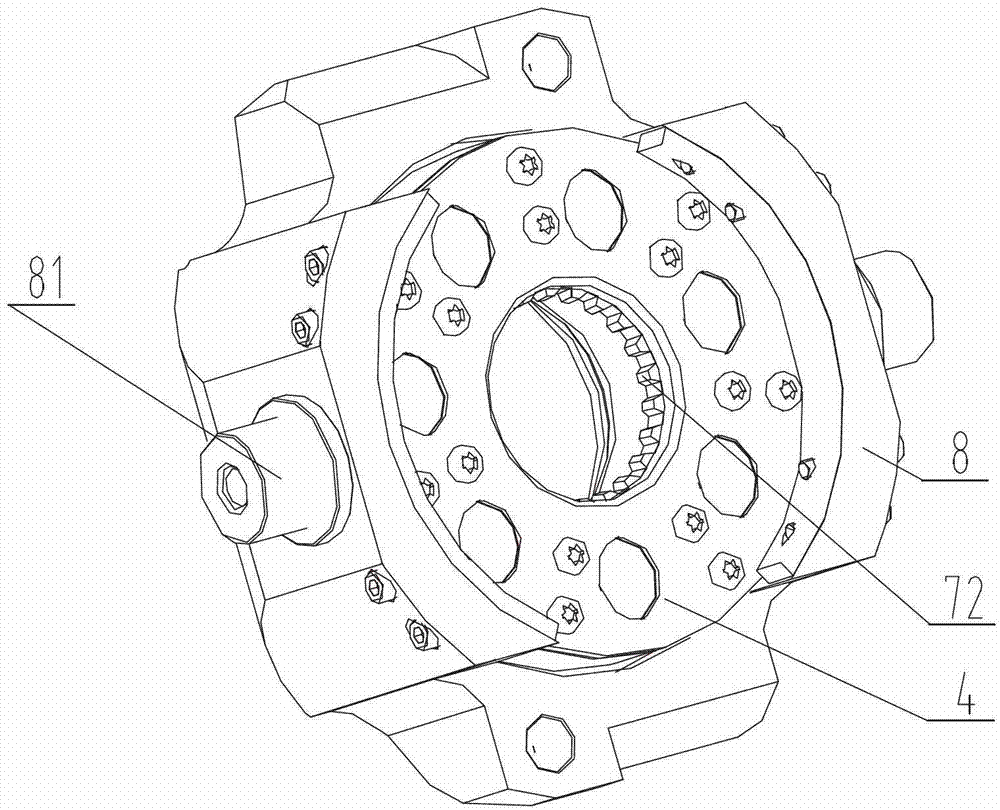

Heavy Duty Overrunning Clutch

The invention discloses a heavy-duty overrunning clutch, which comprises an outer ring, an inner ring, a plurality of rollers and a retaining frame. The retaining frame comprises a support ring I, a support ring II and a plurality of support columns corresponding to the rollers. Spring plates are fixedly arranged on the support columns along the axial direction and are used for applying pre-tightening force on the rollers along the engagement direction of an engagement slot. The direct processing of a limit seat on the outer ring can be avoided, the working efficiency can be increased, the processing cost can be reduced, the service life can be prolonged, and the transmission effect can be guaranteed. Moreover, relevant components can be replaced easily after being damaged, the outer ringneeds not to be rejected as a whole, and the cost of maintenance and use can be reduced. The axial length of the overrunning clutch and the rollers can be increased theoretically indefinitely, the engagement length can be increased, and thus the bearing capacity of the overrunning clutch can be improved. Meanwhile, the pre-tightening force can be applied at multiple points of the rollers according to needs, and the limiting balance for the rollers can be guaranteed while the axial length is ensured, so that the rollers cannot deviate from the axial line of the inner ring. Therefore, the stable operation of the overrunning clutch can be ensured, and mechanical failure can be avoided.

Owner:SOUTHWEST UNIVERSITY

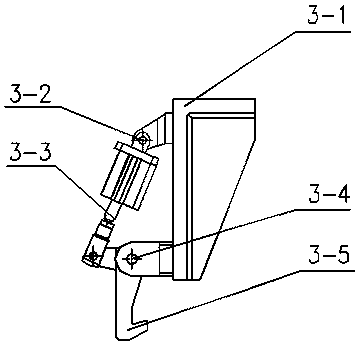

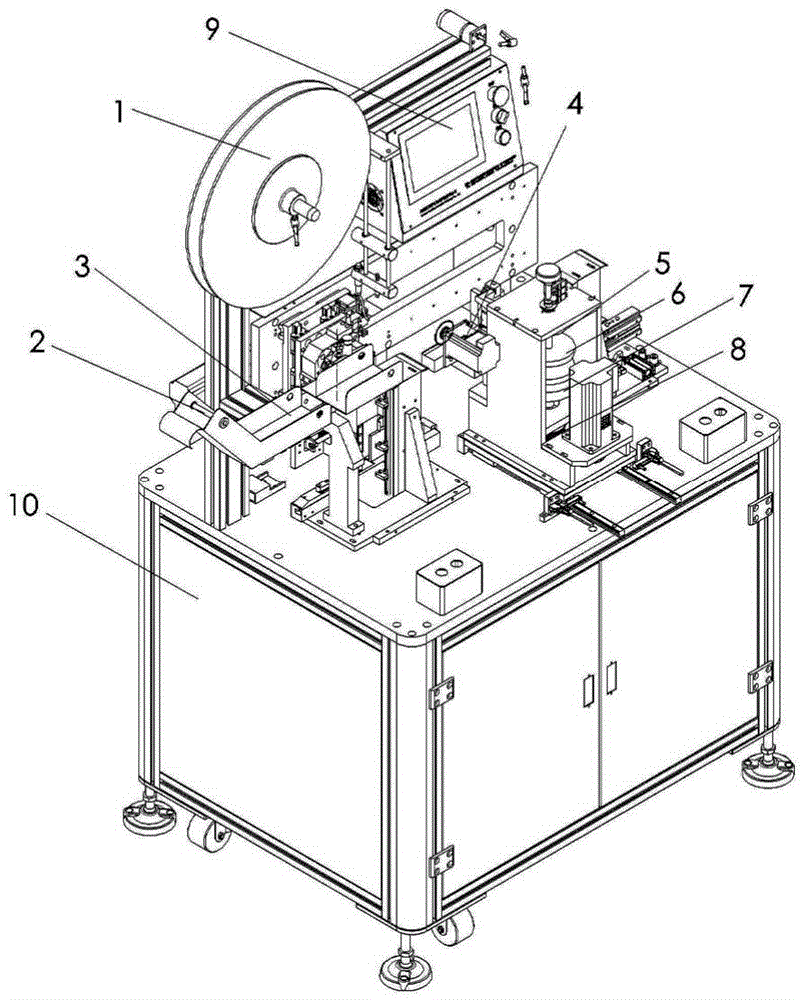

Automatic film tearing machine for accessory assembly

ActiveCN109334215AAvoid position shiftGuaranteed assembly accuracyLamination ancillary operationsLaminationTectorial membraneGlass sheet

The invention discloses an automatic film tearing machine for accessory assembly. The automatic film tearing machine comprises a transmission mechanism, a positioning and supporting mechanism, a filmtearing mechanism and a feed box, wherein the transmission mechanism is horizontally arranged on a rack; the positioning and supporting mechanism is arranged at a film-tearing station; the film tearing mechanism is arranged above the film-tearing station; the film tearing mechanism comprises a rotating component, a film clamping component and a pressing component; the film clamping component and the pressing component are respectively connected to the output end of the rotating component; the film clamping component and the pressing component comprise at least two groups, and every two groupsare arranged at an interval; the output ends of the film clamping component and the pressing component are downwards obliquely arranged opposite to each other; the feed box is arranged below the filmtearing mechanism and has an upward opening; after the protective film on gum is torn out by the film tearing mechanism, the torn protective film is put in the feed box. The automatic film tearing machine for accessory assembly disclosed by the invention is applicable to automatic whole line assembly of accessories, multiple films are torn each time, the film tearing efficiency is effectively improved, position offset of the gum or the glass sheet in the film tearing process is effectively avoided, and the assembling precision and quality are ensured.

Owner:SHENZHEN NUOFENG OPTOELECTRONICS EQUIP

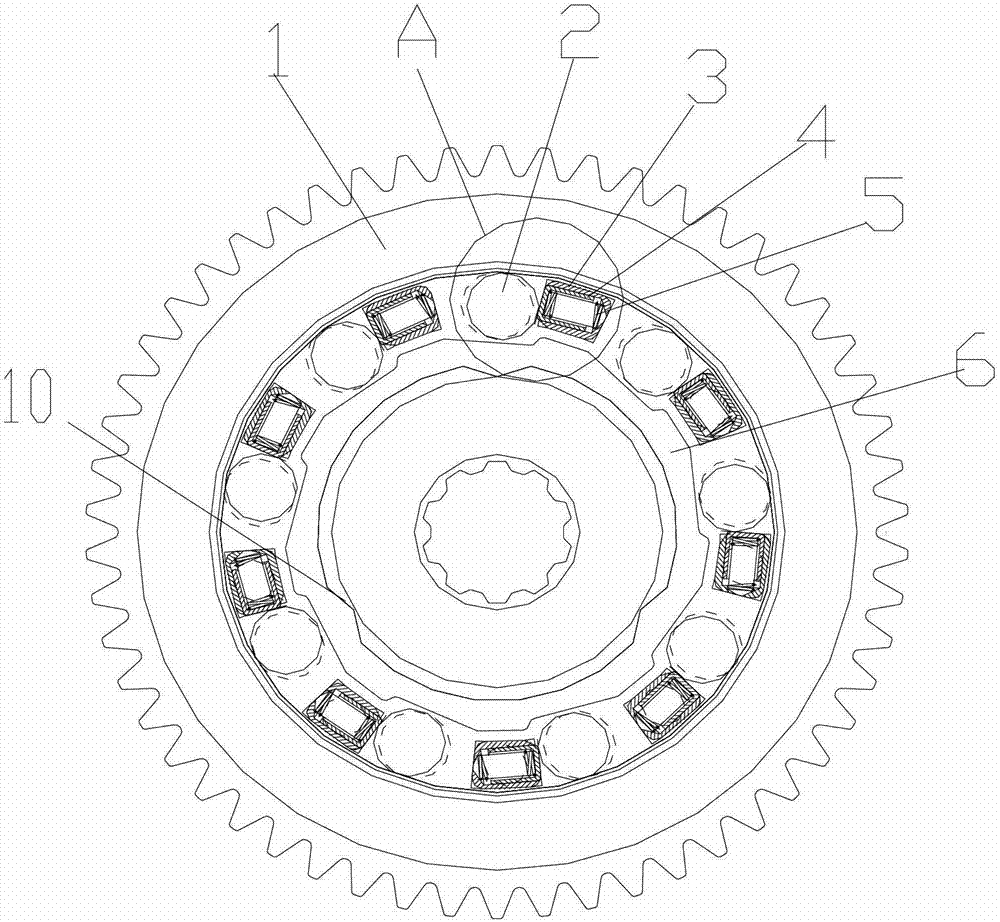

Internal star wheel overrun clutch

The invention discloses an internal star wheel overrun clutch. The internal star wheel overrun clutch comprises an outer ring, an inner ring and rolling columns, wherein wedge grooves are arranged on an outer circle of the inner ring, and meshing spaces used for meshing or separating the rolling columns are jointly formed by the wedge grooves and the inner circle of the outer ring. The internal star wheel overrun clutch further comprises supporting shafts, and the supporting shafts are arranged correspondingly to the rolling columns one by one in the circumferential direction, are detachably fixed relative to the inner ring and at least in the circumferential direction and provided with elastic pieces used for applying pretightening force towards to the meshing direction to the rolling columns. Since the supporting shafts which are detachably fixed relative to the inner ring and at least in the circumferential direction are utilized to apply the pretightening force to the rolling columns, and the wedge grooves used for forming the meshing spaces are arranged on an internal star wheel, the internal star wheel overrun clutch is directly shaped from forging, processing process is simplified, working efficiency is improved, and processing cost is lowered; adjustment to the rolling columns in the circumferential direction during processing is possible, processing and assembling accuracy is guaranteed, service life is prolonged, and transmission effect is guaranteed; and radial size of the internal star wheel overrun clutch in above structure is not limited, and bearing capability is improved.

Owner:SOUTHWEST UNIV +1

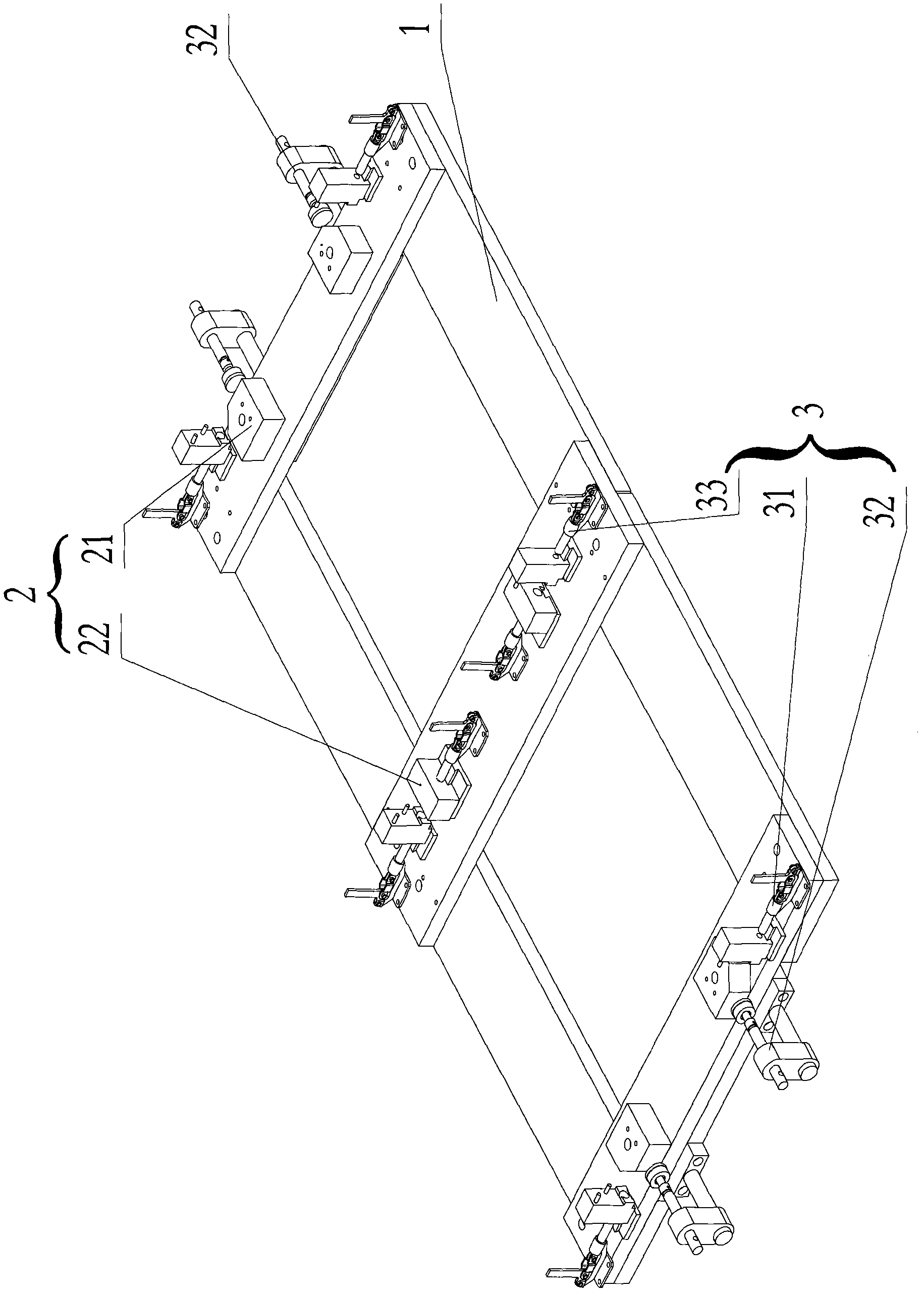

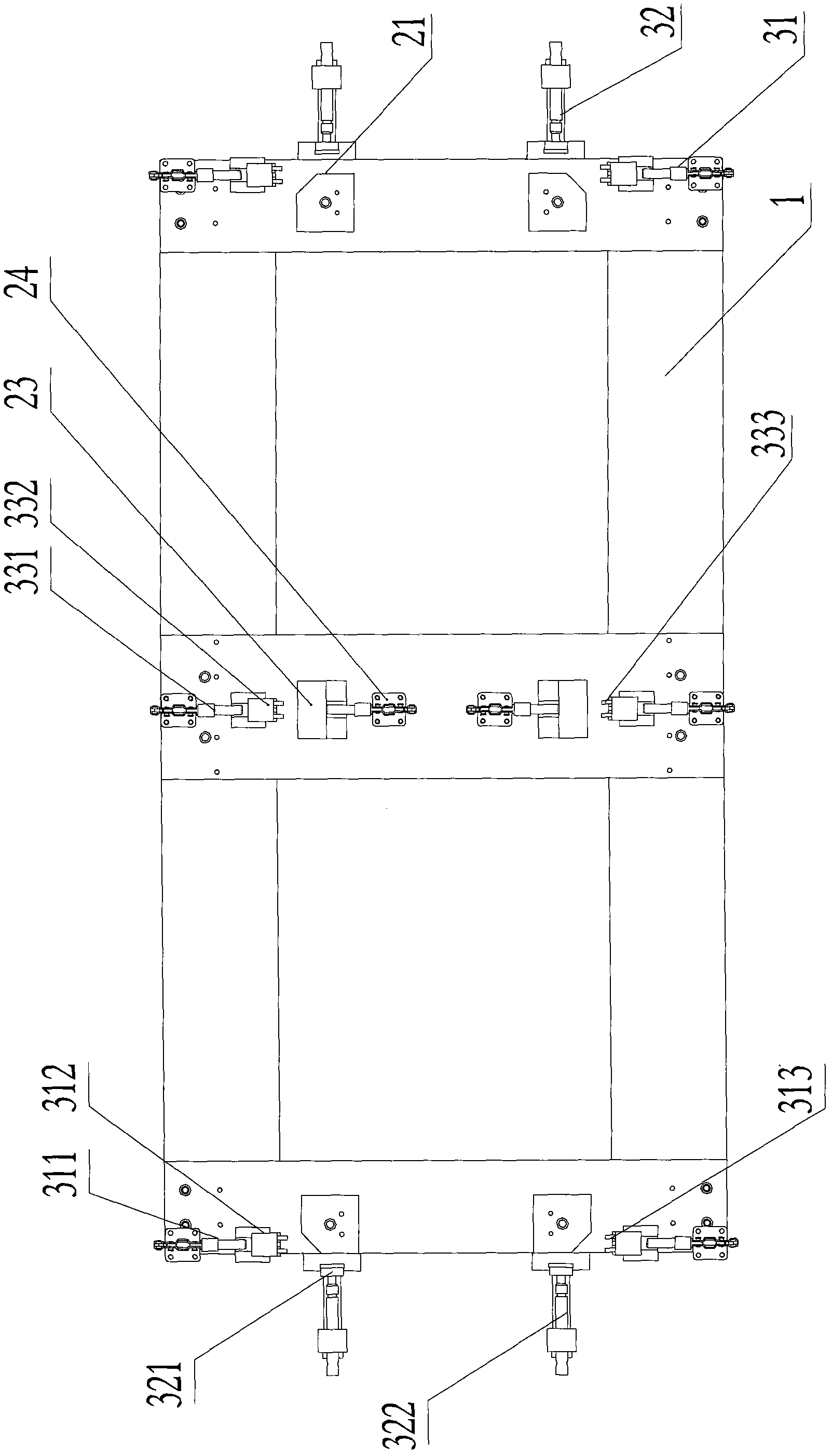

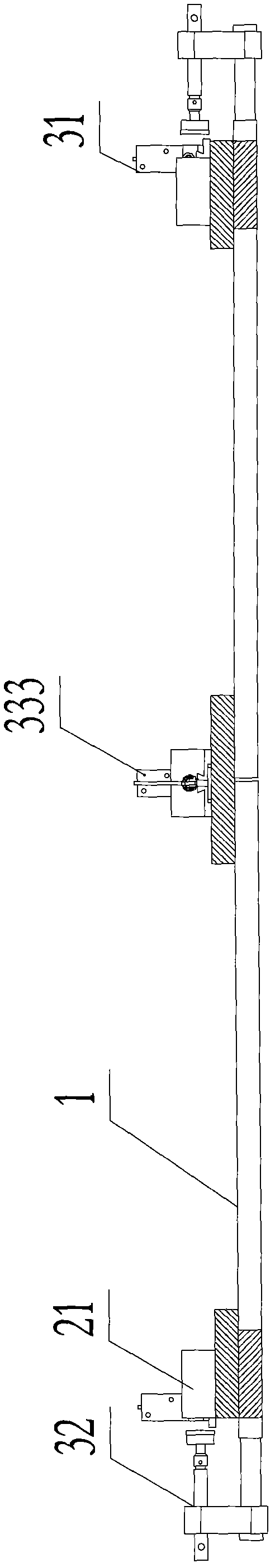

Welding tooling device for pillar frame of machine cabinet and assembly method of device

InactiveCN102029497AReduce physical laborControl or eliminate welding heat distortionWelding/cutting auxillary devicesAuxillary welding devicesInstabilityEngineering

The invention discloses a welding tooling device for a pillar frame of a machine cabinet and an assembly method of the device, wherein the device comprises a clamp body (1) and is characterized in that a positioning element (2) and a clamping device (3) are fixedly arranged on the clamp body, the positioning element (2) is used for horizontal position limitation of all parts of the pillar frame of the machine cabinet, and the clamping device (3) is matched with the positioning element (2) for clamping all the parts of the pillar frame of the machine cabinet in the horizontal direction. By adopting the device and the method disclosed by the invention, the physical labor of operation staff can be greatly reduced, and the assembly and welding efficiency can be improved; and the welding thermal deformation of a workpiece can be controlled or eliminated, and the instability of manual welding can be reduced.

Owner:Jiangsu Boamax Technologies Group Co Ltd

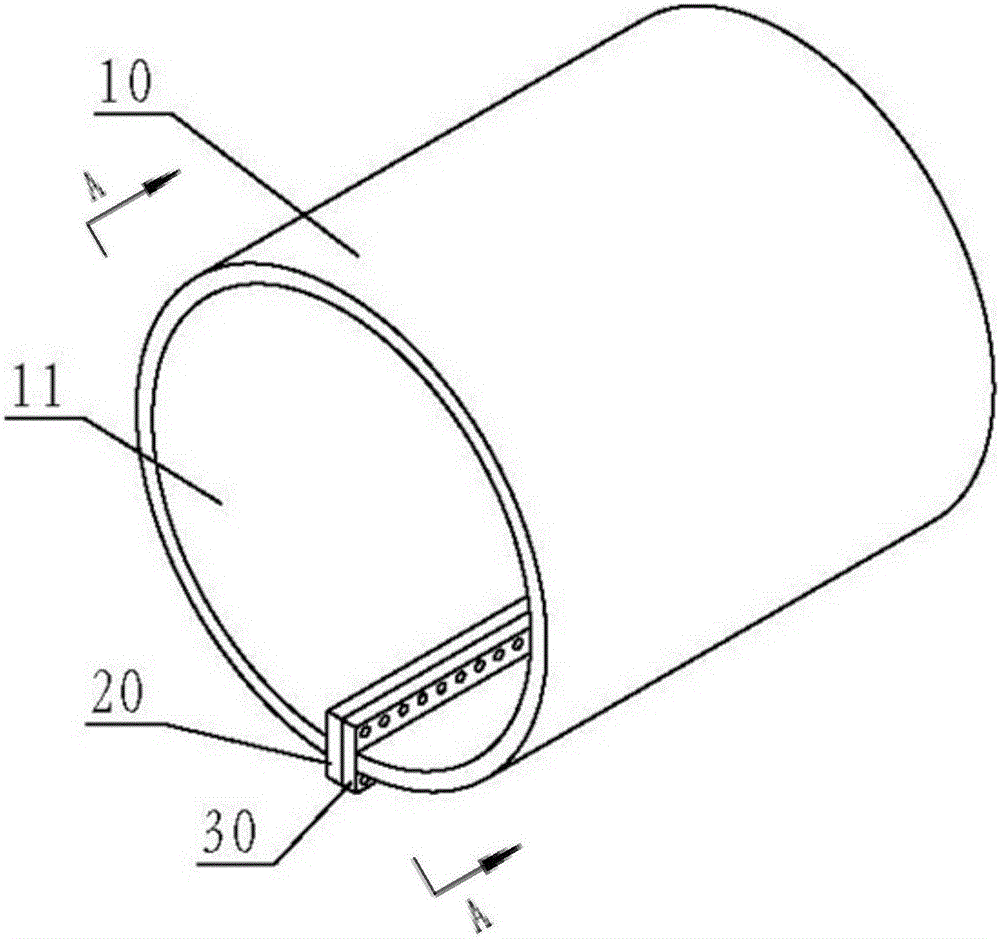

Tower piece body, tower section, tower and manufacturing method of tower piece body

ActiveCN106762444AGuaranteed roundness accuracyImprove rigidityFinal product manufactureWind motor supports/mountsPulp and paper industryTower

The invention discloses a tower piece body, a tower section, a tower and a manufacturing method of the tower piece body. The manufacturing method of the tower piece body includes the following steps that the tubular tower section is provided, and the tower section comprises a longitudinally extending through hole and a tower wall surrounding the through hole; cutting is carried out sequentially along two or more pre-cutting lines of the tower section, a seam which extends in the axial direction and penetrates through the wall thickness of the tower is formed at each cut position, and a first cutting surface and a second cutting surface are formed in the tower wall and correspond to the seams; and connecting pieces are arranged, specifically, after the seam is formed after each time of cutting, the first connecting piece and the second connecting piece are arranged on the first cutting surface and the second cutting surface correspondingly, so that the first connecting piece and the second connecting piece are made to be at least partially opposite to each other, and the opposite parts are positioned on the inner side or the outer side of the tower wall.

Owner:BEIJING GOLDWIND SCI & CREATION WINDPOWER EQUIP

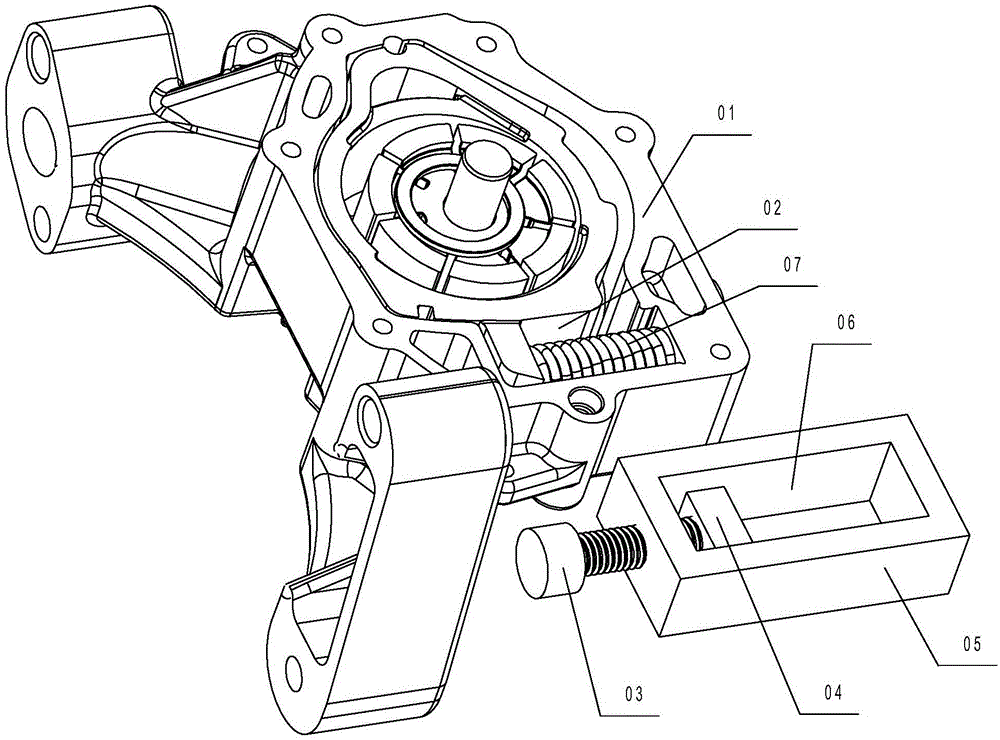

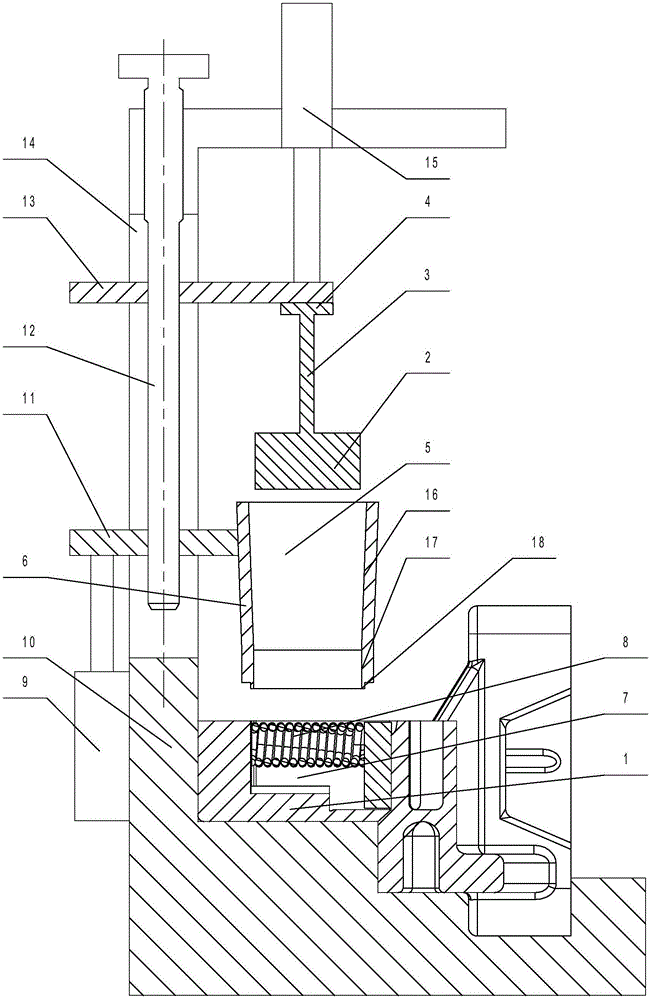

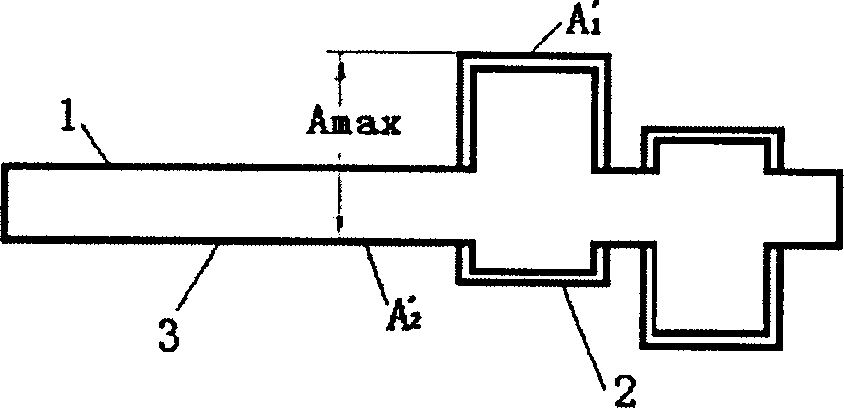

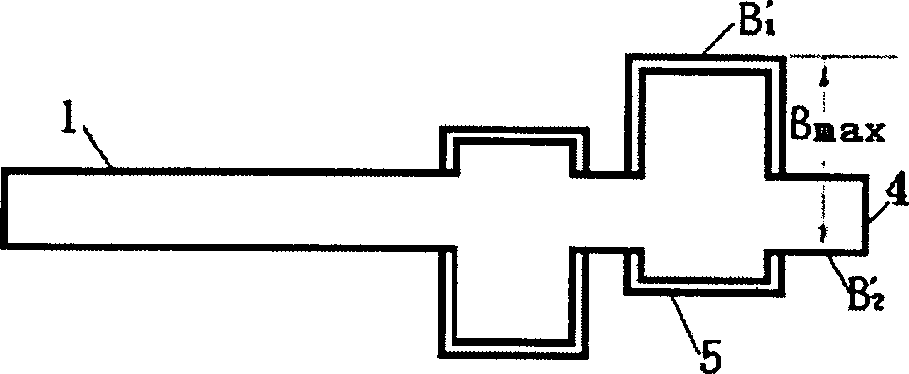

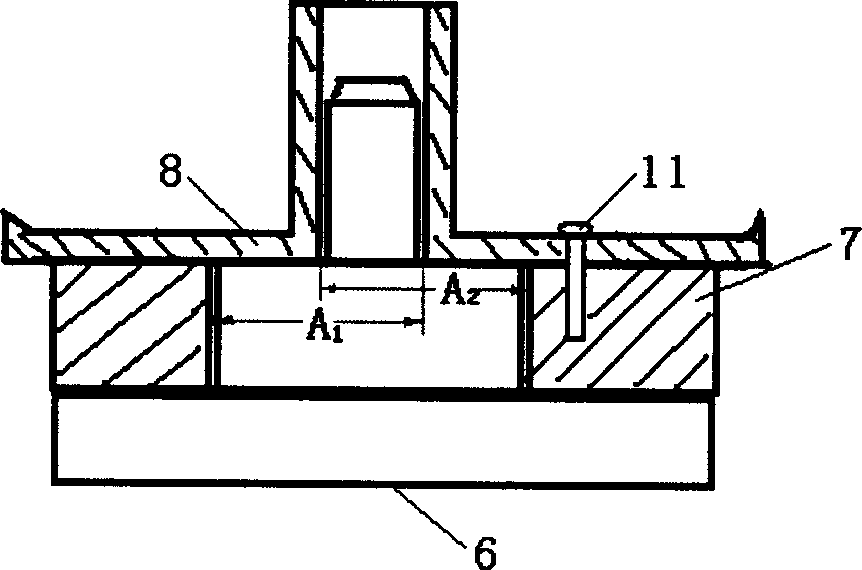

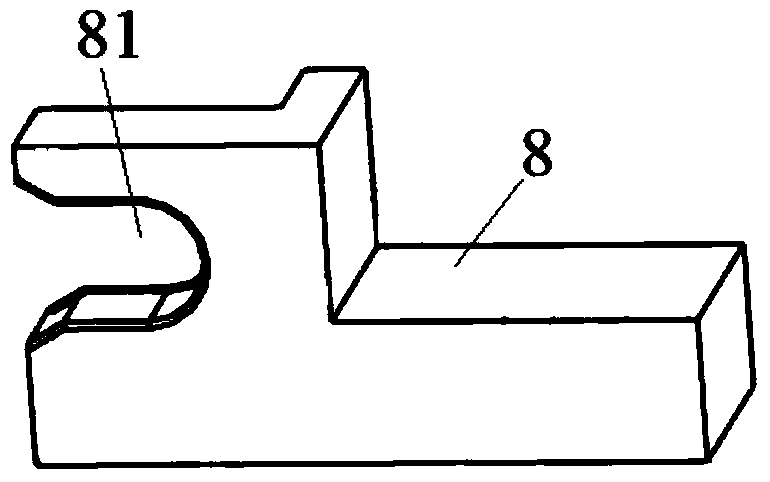

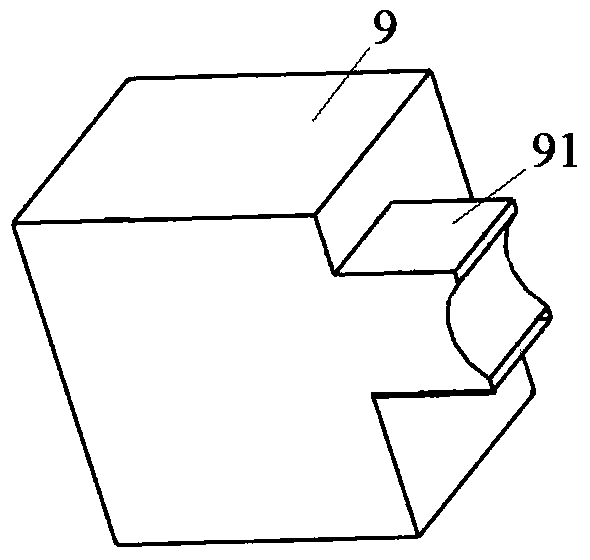

Mounting device for spring in oil pump

ActiveCN105081750AEasy to installAvoid positionMetal working apparatusEngineeringMechanical engineering

The invention discloses a mounting device for a spring in an oil pump. The device comprises a press-in seat (6), and a pressing block (2) for pressing the spring (8) into a spring mounting groove (7) in the oil pump (1); a press-in through hole (5) for storing and compressing the spring (8) is formed in the press-in seat (6); the cross section of the press-in through hole (5) is shaped like a rectangular hole; the sidewalls of two ends of the upper section of the press-in through hole (5), in the length direction of the spring (8), are bevels (16); the lower end of the press-in through hole (5) is positioned right above the spring mounting groove (7), and the space between the sidewalls of two ends of the press-in through hole is reduced from top to bottom; a driving structure for pressing in is arranged at the upper end of the pressing block (2). According to the device adopting the structure above, the position of the spring is fixed relative to the oil pump during transferring, so that the phenomena of position deviating and inaccurate positioning can be avoided, the spring can be mounted conveniently, and as a result, the assembling efficiency can be greatly improved.

Owner:NINGBO SHENGLONG AUTOMOTIVE POWERTRAIN SYSTEM CO LTD

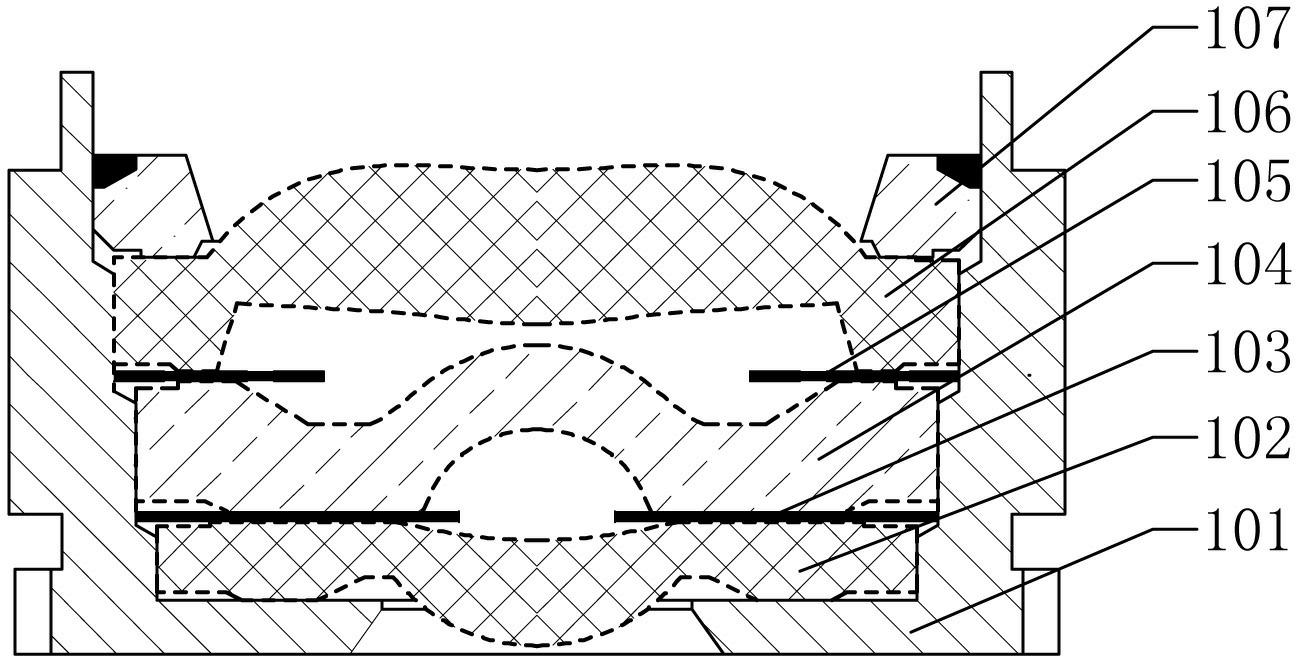

Double-cylinder rotary compressor eccentrically assembling method

InactiveCN1451864AImprove performanceGuarantee parametersRotary piston pumpsRotary piston liquid enginesControl theoryCrankshaft

An eccentrical assembling method for dual-cylinder rotary compressor includes assembling upper cylinder with its cover, assembling lower cylinder with its cover, centralizing them, fixing with screw bolts to obtain assemblies M and N, fixing M, mounting crankshaft, the first piston, intermediate plate and the second piston, putting N on it, regulating the position of upper cylinder cover, prefixing both cylinders, detaching lower cylinder cover, mounting two fixing screws, measuring the eccentrical gap between N, the second piston and crankshaft, mounting lower cylinder cover, and mounting silencer. Its advantages are high precision and high performance of compressor.

Owner:SHANGHAI HITACHI ELECTRICAL APPLIANCES CO LTD

An LED light source far and near light integrated car light module

ActiveCN106122870BReduce space footprintImprove space utilization efficiencyVehicle headlampsRoad vehiclesOptoelectronicsLED circuit

An LED light source far and near light integrated car light module, the high beam LED circuit board (5) and the low beam LED circuit board (8) are respectively arranged behind the concentrator 1, and the reflector includes a primary reflector (10) and a low beam LED circuit board (8). The secondary reflector (9) is used to form the low beam light shape. The primary reflector (10) can independently form the broadening of the low-beam light shape, and the secondary reflector (9) increases the number of rays forming the low-beam light shape, and at the same time, part of the reflected light is used to form zone III of the low-beam light shape. The light emitted by the LED light source on the low-beam LED circuit board (8) is reflected by the first and second reflectors, and most of the light is refracted by the lens (4) and then emitted to form a low-beam light on the screen. The broadening (5-1) of the shape, another small part of the light is reflected and refracted by the condenser and then emitted from the lens (4), forming the cut-off line (5-2) and zone III of the low-beam light shape (5‑3). According to the invention, there is no need to make a square aluminum-plated surface on the radiator or other parts, the parts are easy to process, and the cost is low; the volume of the lamp module is small, and the switching between the far and low beams is noiseless.

Owner:HASCO VISION TECHNOLOGY CO LTD

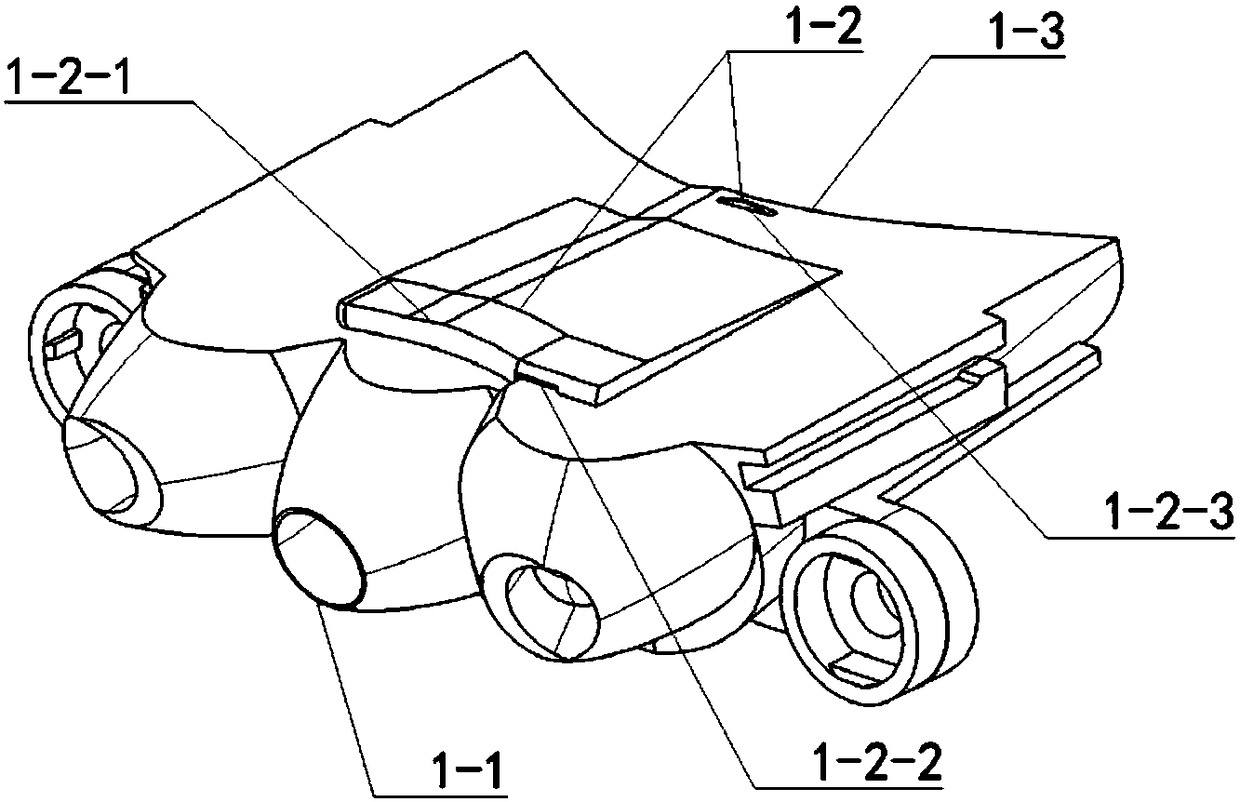

Movable and rotatable lifting platform used for picking agricultural products

ActiveCN103270849AImprove rigidityImprove general performancePicking devicesControl systemAgricultural engineering

The invention discloses a movable and rotatable lifting platform used for picking agricultural products. The movable and rotatable lifting platform comprises a walking mechanism, a rotating mechanism, a lifting platform body and a control system. The rotating mechanism comprises a rotating machine frame, a main shaft, a bearing set, a bearing seat board set, a gear set and a rotating driving motor, wherein the main shaft is connected with the bearing set in a matched mode, the bearing set is fixed on the bearing seat board set, the rotating driving motor transmits rotating power to the main shaft through the gear set, the rotating driving motor is installed on the rotating machine frame, the top end of the main shaft is fixedly connected with the lifting platform body, the bottom of the rotating machine frame is connected with the walking mechanism, and the control system is in signal connection with the rotating driving motor and the lifting platform body. The movable and rotatable lifting platform has the advantages of being capable of bearing larger loads and capsizing moment, small in motion resistance, high in motion precision, large in motion stroke, strong in universality of parts, convenient to produce and maintain, low in manufacturing cost, and the like. Large-load and mass mechanized harvesting of crops can be achieved only through that a corresponding agricultural harvesting operation device is arranged on the movable and rotatable lifting platform.

Owner:SOUTH CHINA AGRI UNIV

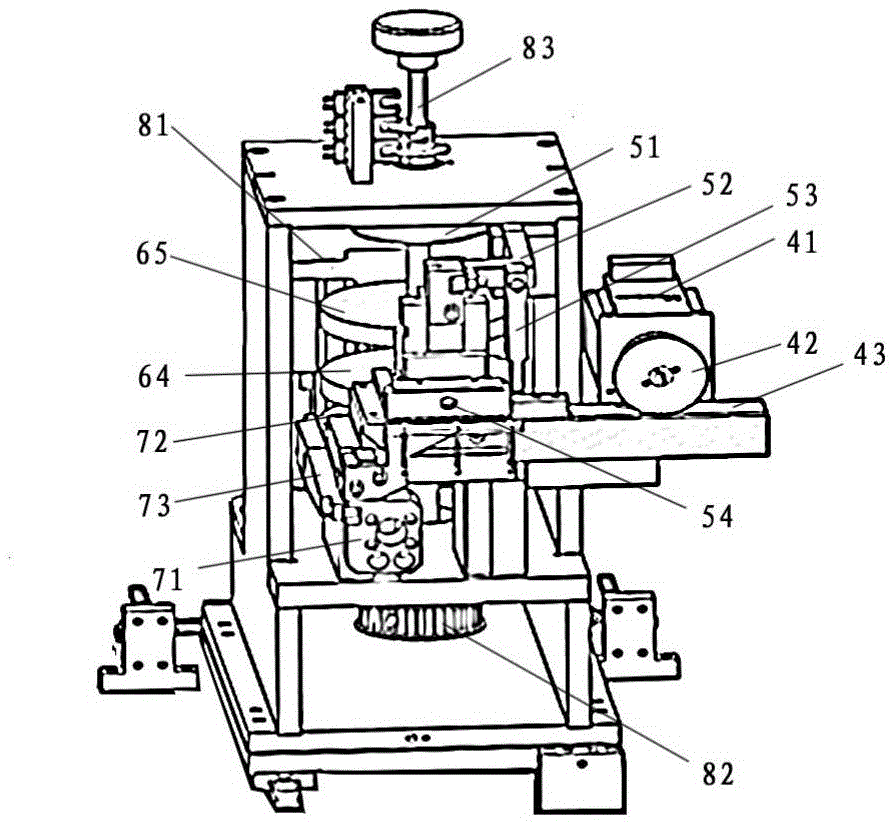

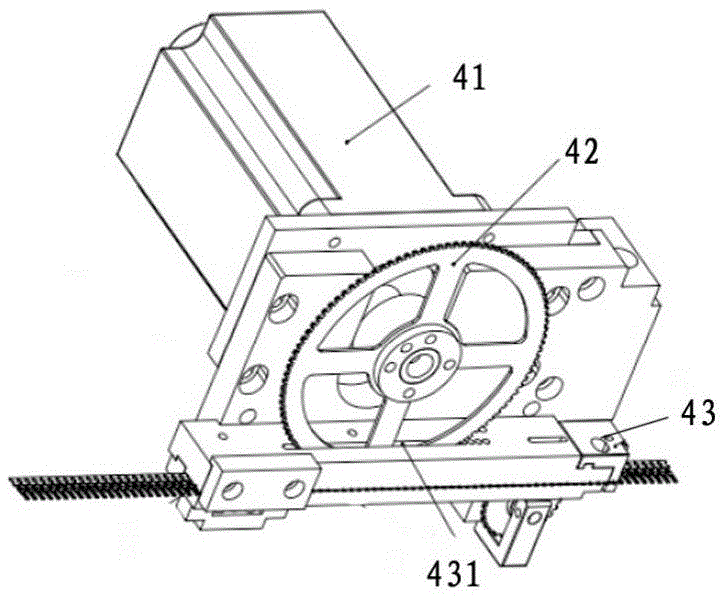

FPC cam pin inserting machine

InactiveCN105633765AImprove yield rateIncrease capacityContact member assembly/disassemblyDrive shaftEngineering

The invention relates to the field of product pin assembly for the electronic connector industry, in particular to an FPC cam pin inserting machine. The FPC cam pin inserting machine comprises a rack, a discharge plate, a feed roller, a transport track, a feeding mechanism, a pin pressing mechanism, a pin inserting mechanism, a cutting and bending mechanism, a transmission device and a control assembly, wherein the discharge plate is arranged at one side of the rack and is used for placing a to-be-inserted part of an FPC; the feed roller is arranged below the discharge plate; the transport track is arranged on the rack and is connected with the discharge plate; the feeding mechanism is arranged at one side of the transport track; the pin pressing mechanism is arranged at one side of the feeding mechanism for pressing and fixing the to-be-inserted part of the FPC; the pin inserting mechanism is arranged below the pin pressing mechanism and can take out the pin and insert the pin into the to-be-inserted part of the FPC; the control assembly controls various mechanisms to act; the transmission device comprises a drive servo motor, a cam transmission synchronizing wheel and a transmission shaft; the drive servo motor is connected with the cam transmission synchronizing wheel; the cam transmission synchronizing wheel is fixedly connected to the bottom end of the transmission shaft; the pin pressing mechanism, the pin inserting mechanism, the cutting and bending mechanism are sequentially fixed on the transmission shaft from top to bottom; and the control assembly is connected with the discharge plate, the transmission device and the feeding mechanism respectively.

Owner:DONGGUAN LITY CHUANGXI AUTOMATION TECH CO LTD

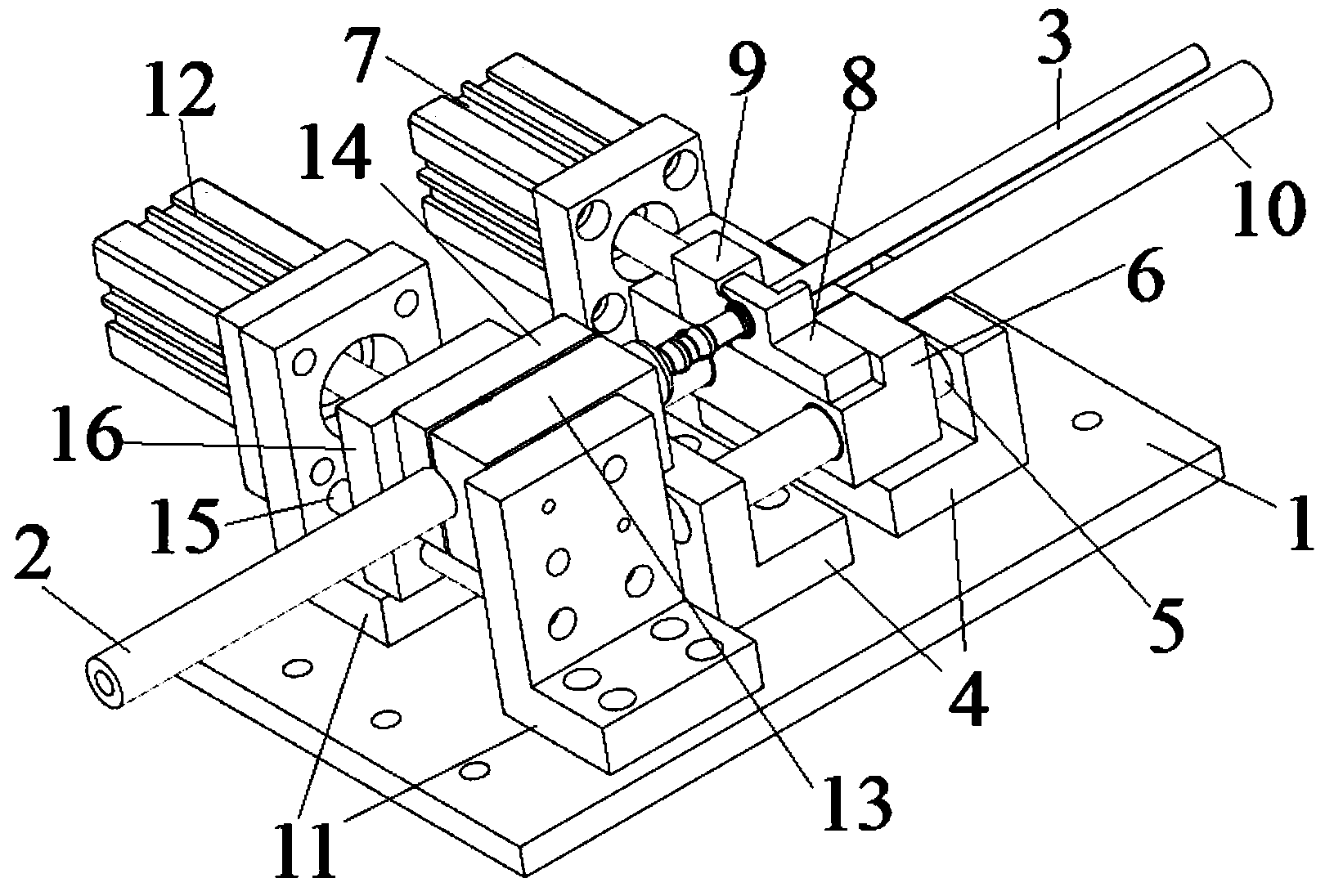

Assembling tool used for rubber pipe installation on steel pipe

InactiveCN103639974AImprove assembly efficiencySo as not to damageWork holdersMetal-working hand toolsArchitectural engineeringSteel tube

The invention discloses an assembling tool used for rubber pipe installation on a steel pipe. The assembling tool used for rubber pipe installation on the steel pipe comprises a base, a rubber pipe fixing device used for fixing a rubber pipe, a steel pipe fixing device used for fixing a steel pipe, and a steel pipe pushing device used for making the steel pipe move towards the rubber pipe fixed on the rubber pipe fixing device, wherein the rubber pipe fixing device and the steel pipe pushing device are arranged on the base, and the steel pipe fixing device is arranged on the steel pipe pushing device and moves along with the steel pipe synchronously. Compared with the prior art, the assembling tool used for rubber pipe installation on the steel pipe has the advantages that the rubber pipe is fixed through the rubber pipe fixing device on the base, the steel pipe is fixed through the steel pipe fixing device, the steel pipe fixed through the steel pipe fixing device can be made to move towards the rubber pipe fixed through the rubber pipe fixing device through the steel pipe pushing device so that the steel pipe can be inserted into the rubber pipe, and then installation of the rubber pipe on the steel pipe is achieved; operation is simple, using is convenient, steel pipe and rubber pipe assembling efficiency can be improved greatly, assembling accuracy is ensured, and the inner wall of the rubber pipe can not be damaged.

Owner:WUHU TONHE AUTOMOBILE FLUID SYST

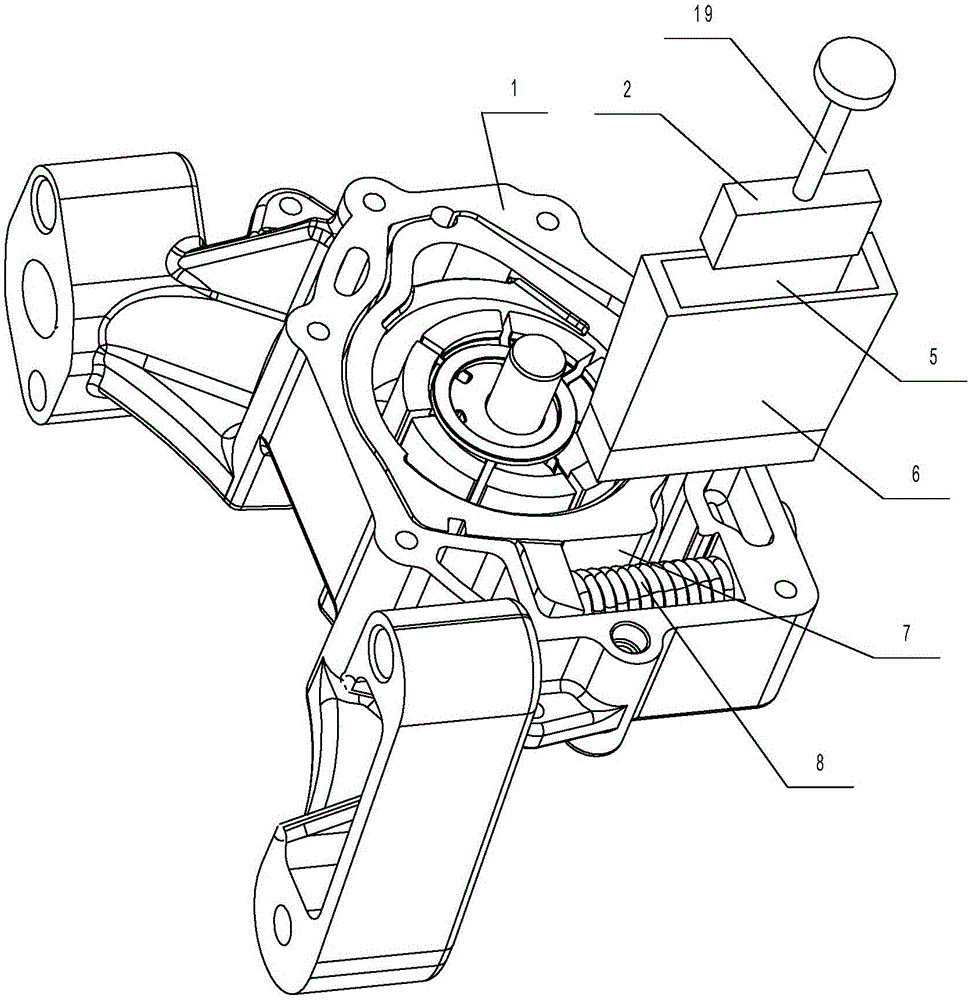

Vehicle main reducing gear pre-tighten device and pre-tighten method

InactiveCN101249608AImprove pass rateImprove work efficiencyMetal working apparatusReduction driveEngineering

The invention relates to a pre-tightening device of the automobile main reducer and a pre-tightening method of the same. The device is characterized in that a working platform is arranged for suspending the main reducer. A rotatable bearing pre-tightening torque measurement mechanism is arranged under the platform. The method is characterized in that the pre-tightening torque of a main gear bearing and the tightening torque of a main gear nut are measured while the main gear nut is tightened by a nut tightening mechanism and a main reducing bearing seat is rotated by the bearing pre-tightening torque measurement mechanism. When the pre-tightening torque of the main gear bearing and the tightening torque of the main gear nut both reach within the area of the setting value, the pre-tightening of the automobile main reducer is completed. The method can effectively improve the qualification rate of products and increase the working efficiency.

Owner:HEFEI UNIV OF TECH

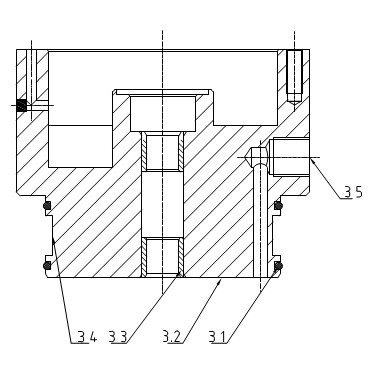

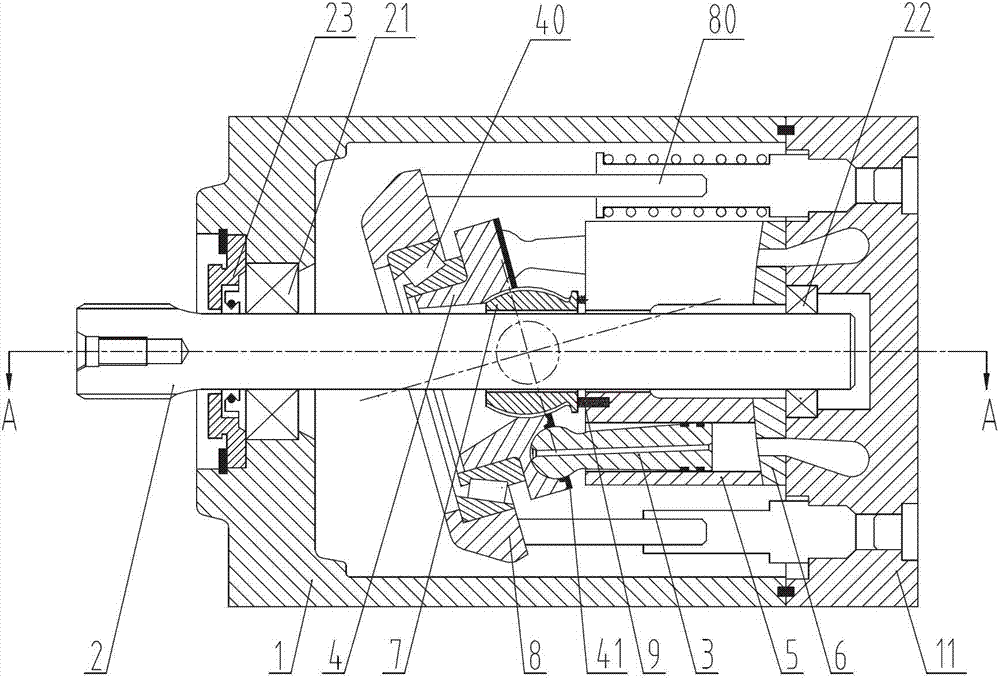

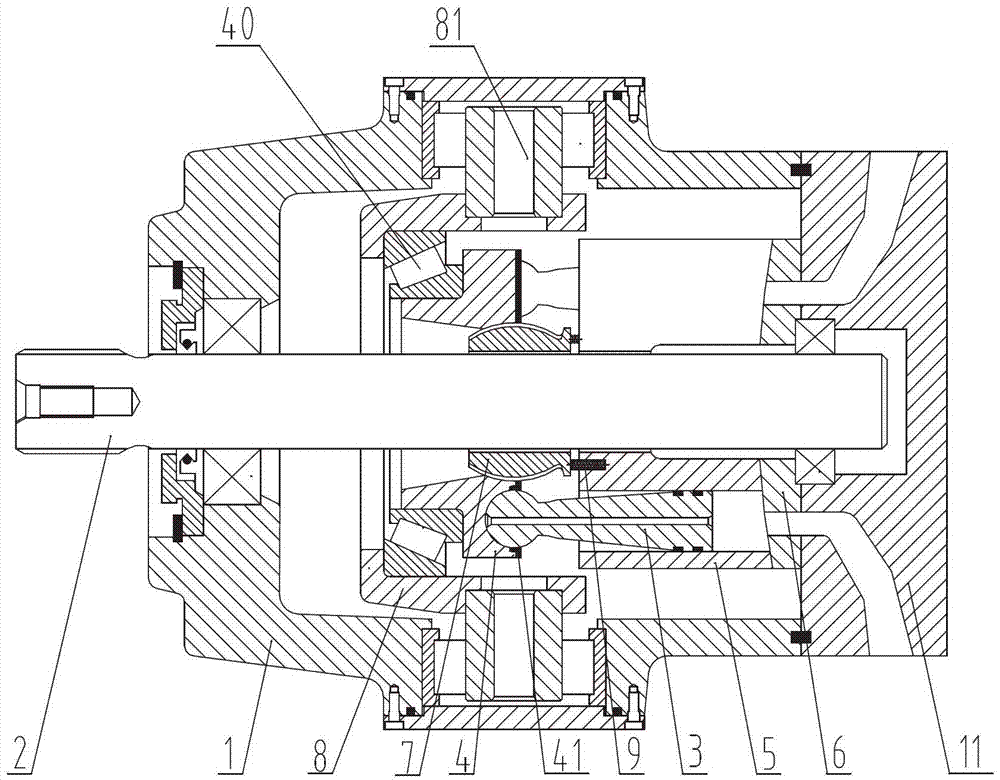

Swash plate type axial piston pump or motor

ActiveCN102926959AReduce Assembly MatesRequirements for lower machining accuracyPositive-displacement liquid enginesMulti-cylinder pumpsPlunger pumpTransmission line

The invention provides a swash plate type axial piston pump or a motor, which comprises a shell, a main shaft, a plurality of piston components, a swash plate, a cylinder, a distributive flow disk and a connecting part, wherein the connecting part comprises a first part and a second part which relatively swing, the first part is combined with the main shaft and synchronously rotates with the main shat, the swash plate is combined with the second part and synchronously rotates with the second part, a cylindrical inner hole is arranged on the center of the cylinder, the main shaft stretches into the cylindrical inner hole, the main shaft and the cylindrical inner hole are matched, and when the main shat rotates, the cylinder is driven by the piston components to rotate. The main shaft and the cylinder of the swash plate type axial piston pump can form clearance fit, the transmission line of the swash plate type axial piston pump is the main shaft, the connecting part, the swash plate, the piston components and the cylinder, and the swash plate type axial piston pump has the advantages of excellent assembly, high total efficiency and small lateral force, and can achieve the advantages of coaxial or through-shaft connection and the like.

Owner:SANY HEAVY IND CO LTD (CN)

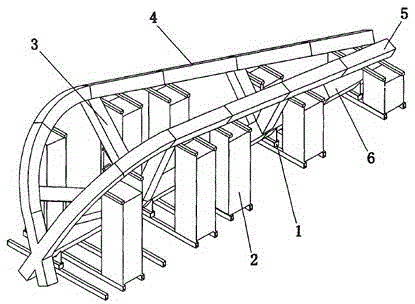

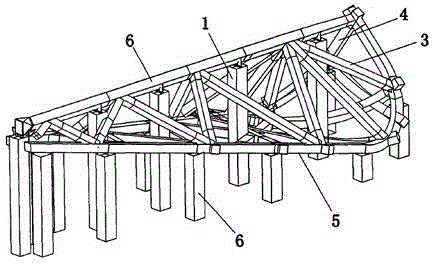

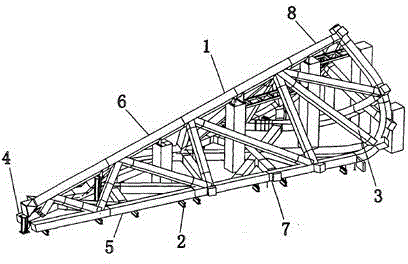

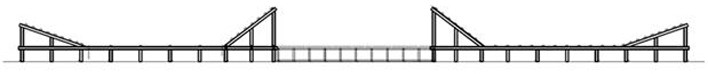

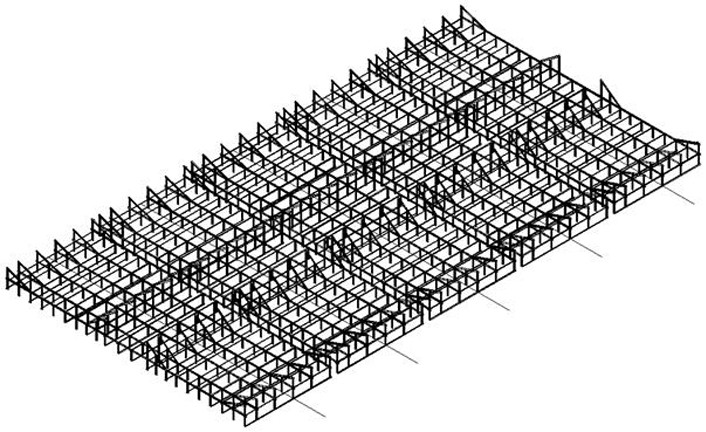

Method for establishing temporary support moulding bed system for steel structure assembly

InactiveCN105468796AGuaranteed assembly accuracyReduce operational riskSpecial data processing applicationsMechanical engineeringPredictability

The invention provides a method for establishing a temporary support moulding bed system for steel structure assembly. The method comprises the following steps: establishing a three-dimensional simulation model of unit bodies needing to be assembled of a large steel structure via three-dimensional computer modeling software at first, and determining unit body assembly postures and assembly sections of the steel structure according to the simulation model, then, optimizing and establishing an assembly coordinate system according to the assembly postures of the unit bodies, outputting three-dimensional coordinate of each feature appearance control point of the structure to be assembled in the assembly coordinate system, and finally, designing the temporary support moulding bed system generating no mutual interference with unit body members according to the three-dimensional coordinate system and the unit body assembly postures of the steel structure. The method provided by the invention can be used for solving the problems of high assembly difficulty and high control precision of large space steel structures and particularly steel structures with complex space modeling, such as box-shaped curved steel structures and the like, reducing the height of a construction working plane in assembly construction, guaranteeing the assembly precision, reducing the working risk, improving the construction efficiency and predictability and maximally reducing auxiliary construction materials.

Owner:QINGDAO BAIJIANCHENG ENVIRONMENTAL PROTECTION TECH CO LTD

Overall assembling method for ultra-wide framing steel box girder

InactiveCN111926705AReduce weld volumeShorten the manufacturing cycleBridge erection/assemblyBridge materialsWeld seamButt joint

The invention discloses an overall assembling method for an ultra-wide framing steel box girder, and relates to the technical field of steel box girder assembling. The method comprises the steps performing plate unit manufacturing and plate assembly welding, beam section matching assembly welding and pre-assembling and pre-assembling inspection; carrying out beam section assembly welding accordingto the sequence of a bottom plate, a transverse partition plate, a middle top plate, a primary positioning inner web plate, an anchor web plate, other top plates, a secondary positioning anchor web plate, a middle cross beam and a cantilever arm block, and carrying out three-dimensional stepped propelling mode section-by-section assembly and welding; and during pre-assembling, with considerationof the influence of beam section compression amount caused by welding circular seam shrinkage amount and cable force on the length, correcting the accumulated total length and error of the previous pre-assembling in the next assembly. The method has the advantages that the butt joint weld joint amount of the steel box girder on the total assembly jig frame can be reduced, and the manufacturing period is shortened; a three-dimensional step-shaped propelling mode is adopted, pre-assembling is carried out after section-by-section assembly welding, and the boundary dimension is easy to control; the assembling precision of the steel box girder can be ensured, the assembling quality is controlled, high-altitude adjustment is avoided, and the erection period is shortened.

Owner:中铁山桥(南通)有限公司

Automatic assembly mechanism for perforating bullet

ActiveCN103801930AProtection securityGuaranteed isolationMetal working apparatusProduction lineEngineering

The invention provides an automatic assembly mechanism for a perforating bullet. The automatic assembly mechanism is characterized in that a powder liner (arranged on an upper-layer conveyor belt) and a casing filled with an explosive (arranged on a lower-layer conveyor belt) are respectively taken from an dual-layer plane turning loading conveyor belt 1 by a dual-claw pneumatic loading mechanical arm 3; the casing and the powder liner are sequentially placed in a hydraulic press 4; after the casing and powder liner are compressed by the hydraulic press, a product is taken down by a pneumatic product-taking mechanical arm 6 and is placed into a die 2 of a plane turning product-taking conveyor belt 7. According to the automatic assembly mechanism disclosed by the invention, the assembly process of loading, conveying, pressing explosive and taking product is realized, the safety coefficient is improved, the work condition of a production line can be monitored by an isolating explosion-proof wall window 5 while the isolation of an operator and an explosive pressing scene is ensured, potential safety hazards are eliminated and the assembly precision and efficiency are improved. The automatic assembly mechanism is suitable for assembly and production of perforating bullets in the petroleum industry.

Owner:严格集团股份有限公司

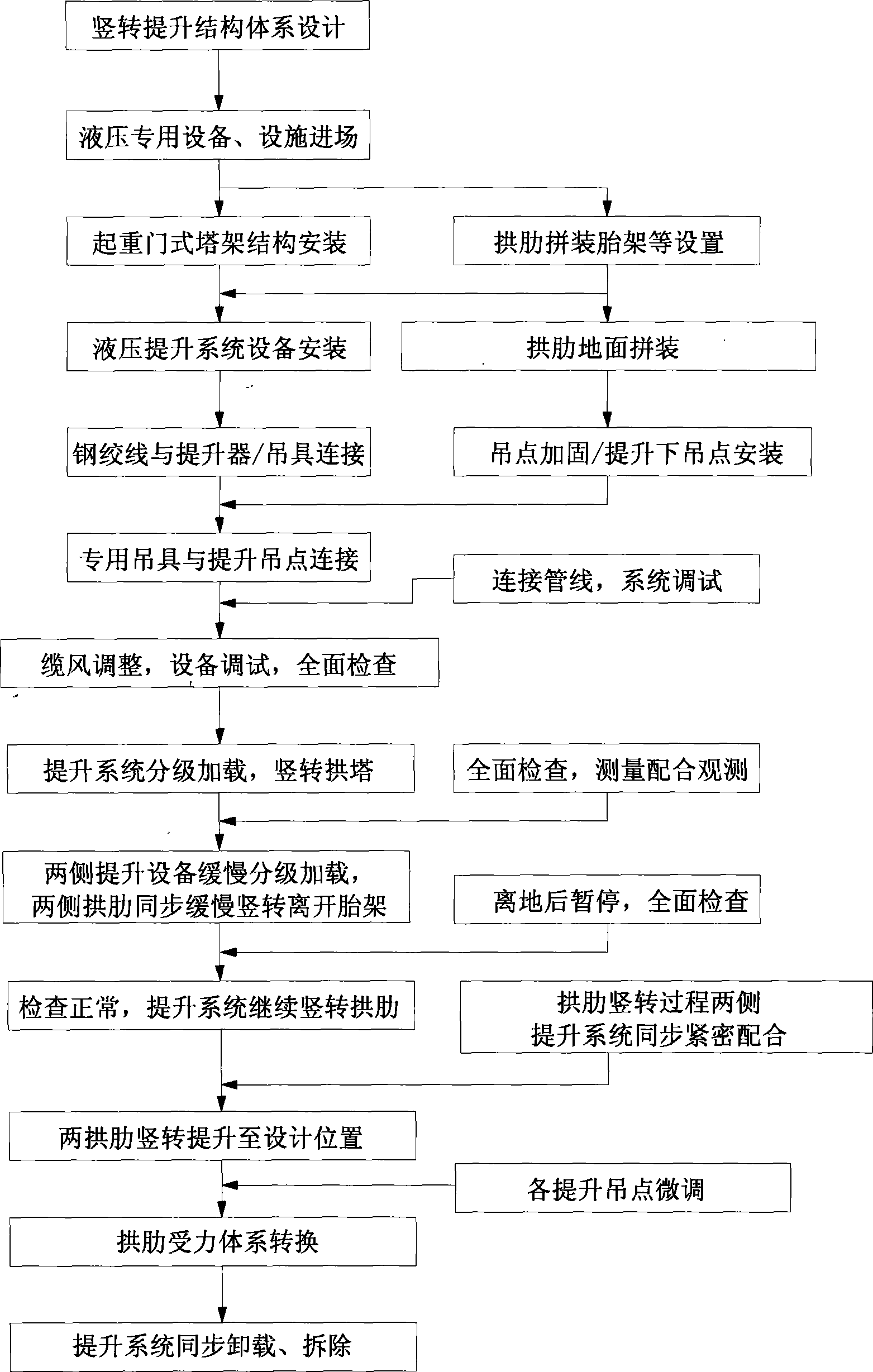

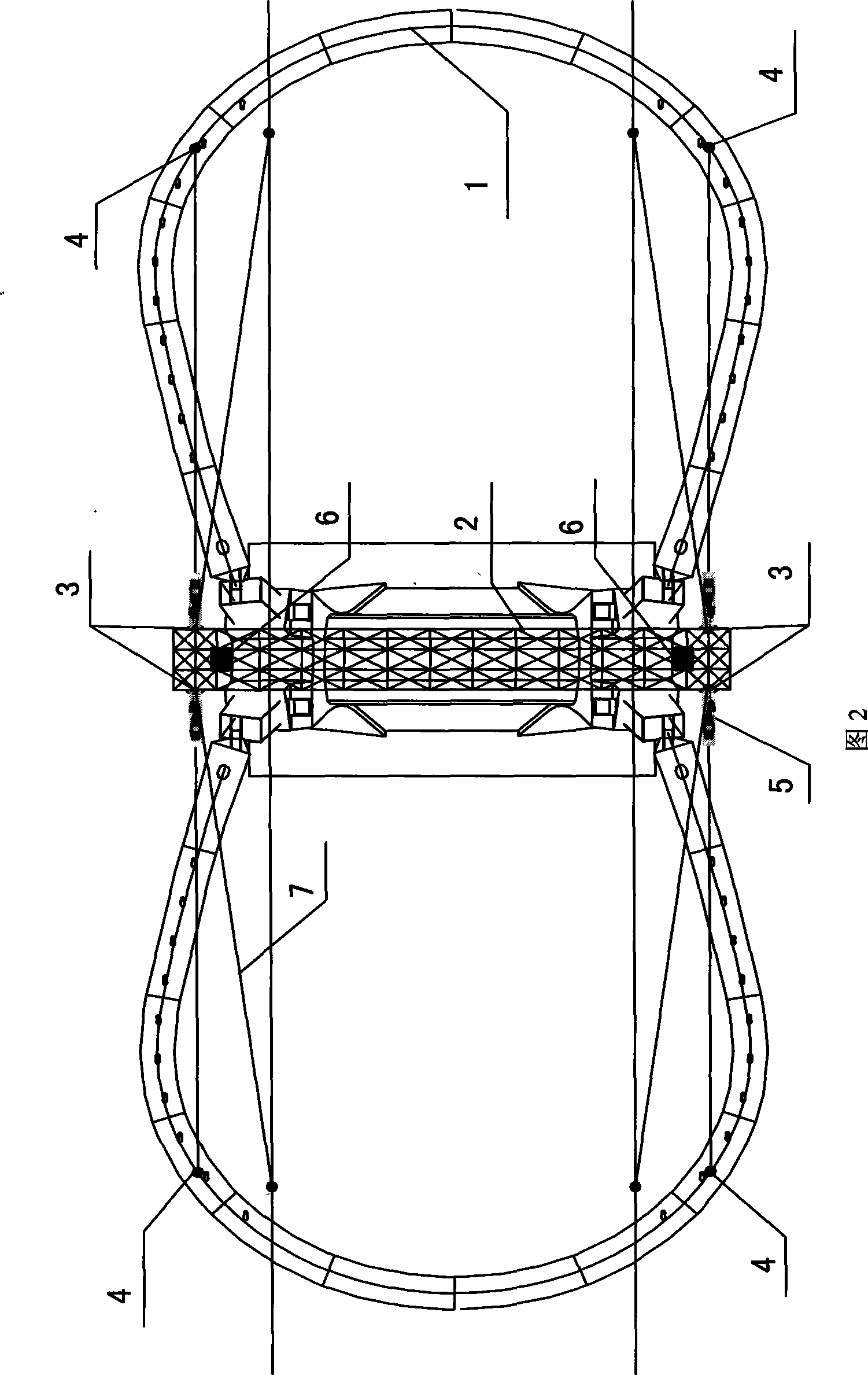

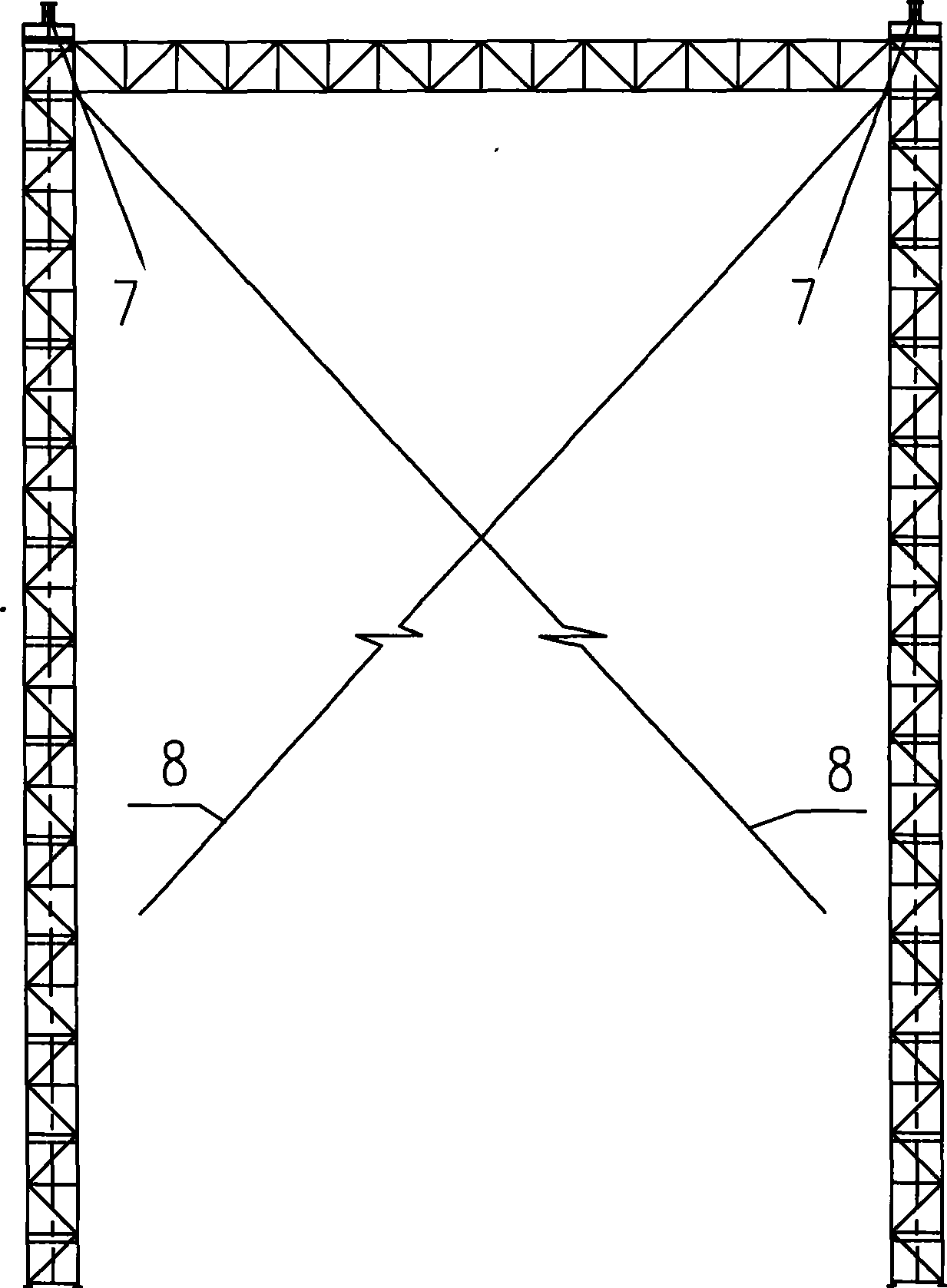

Synchronous vertical swing lift construction method for double inclination arc tower

ActiveCN101446075AIncrease the volume of the facilityReduce weightBridge erection/assemblyReinforced concreteCentral line placement

The invention discloses a synchronous vertical swing lift construction method for a double inclination arc tower. The method comprises the following steps: arranging a vertical swing winch at the combination of two gate-shaped arch ribs and reinforced concrete, arranging a bearing gate type lifting tower at the position of the symmetrical central line of the arch ribs, arranging an upper lifting sustained center and a lower lifting sustained center at the top of the tower and on the arch ribs respectively, and performing symmetrical synchronous vertical swing lift through two pairs of hydraulic lifters by utilizing the symmetry character of the double arch ribs, so as to achieve the purpose of vertically swinging the arch ribs from the planimetric position to the mounting position. The construction method has the advantages that the arc tower construction difficulty is reduced, tools and materials are saved, the construction period is shortened, and the installation of two mammoth arch rib structures can be completed with high precision and high quality; aloft work of the arch ribs is converted into ground integral assembly work, the construction efficiency is high, the safety protection work is easy to organize, and the construction quality is easy to guarantee; machines and equipment required for the construction are in a small quantity, the process is simple, and the operation is safe; the construction speed is high, the manufacture cost is low, and the investment is saved.

Owner:JIANGSU HUNING STEEL MECHANISM

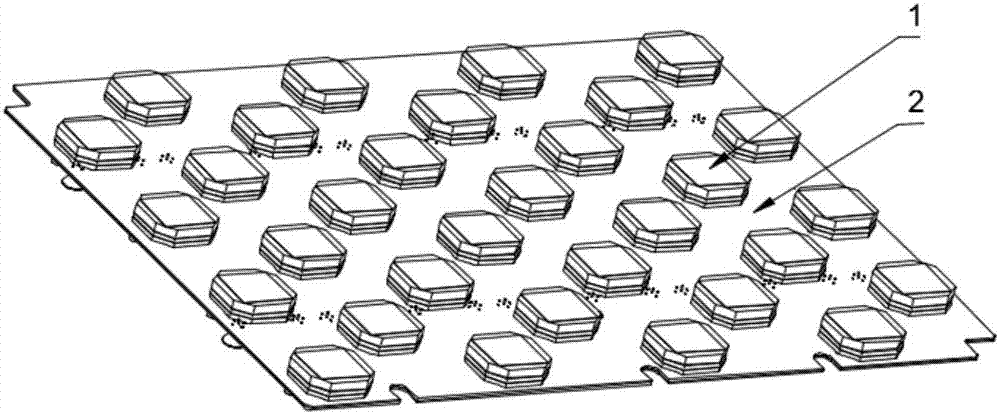

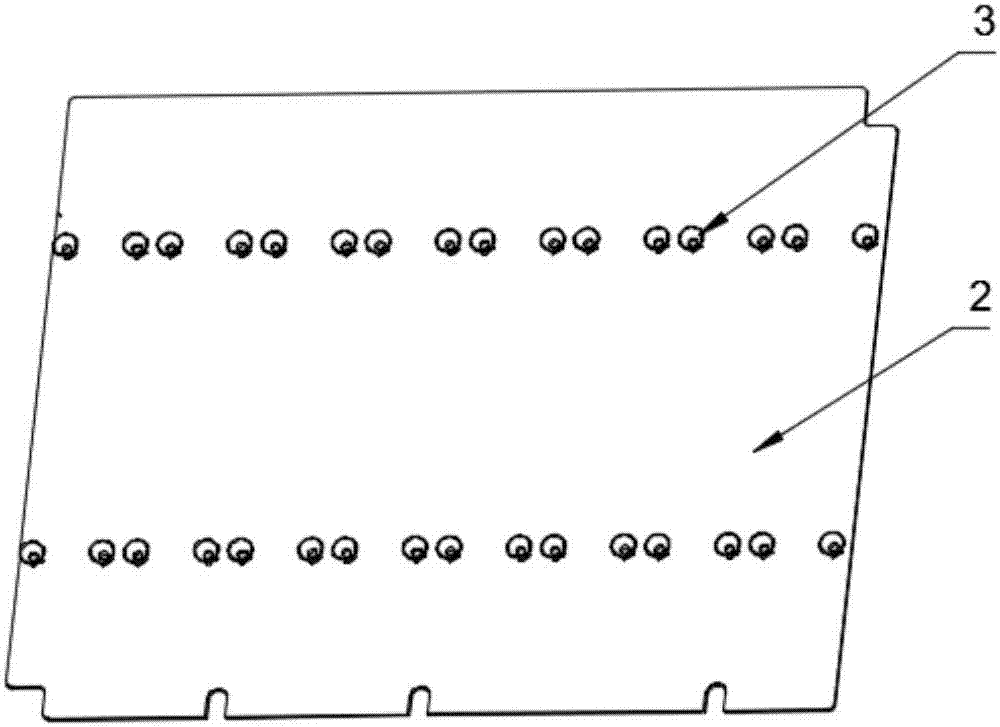

Large-scale MIMO antenna structure and manufacturing process

PendingCN107394366ASimplified assembly stepsGuaranteed assembly accuracyParticular array feeding systemsRadiating elements structural formsDielectric plateMimo antenna

The invention discloses a large-scale MIMO antenna structure and a manufacturing process. The large-scale MIMO antenna structure comprises multiple antenna units arranged in an array; each antenna unit is composed of three or more layers of dielectric plates; the PCB substrate has a structure of two layers of dielectric plates and three metal layers, a power division network and a calibration network are merged on a transmission line structure of the middle metal layer, and upper conductive metal and lower conductive metal are grounded; each antenna unit is connected with the substrate through a metal probe for feed; and the antenna adopts an SMT process to be directly welded on a corresponding antenna unit pad on the substrate, the precision is ensured through welding, and no adjustment is needed. The profile is low, the structure is compact, the integration is high, the weight is light, only few assembly steps are needed, the production efficiency is high, and high consistency and stability can be ensured.

Owner:ZHONGTIAN BROADBAND TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com