Heavy Duty Overrunning Clutch

An overrunning clutch, heavy-duty technology, used in clutches, one-way clutches, mechanical equipment, etc., can solve the problems of reduced work efficiency, easy deflection of rollers, and fewer installations, reducing maintenance and use costs, guaranteeing Processing and assembly accuracy, the effect of increasing the bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

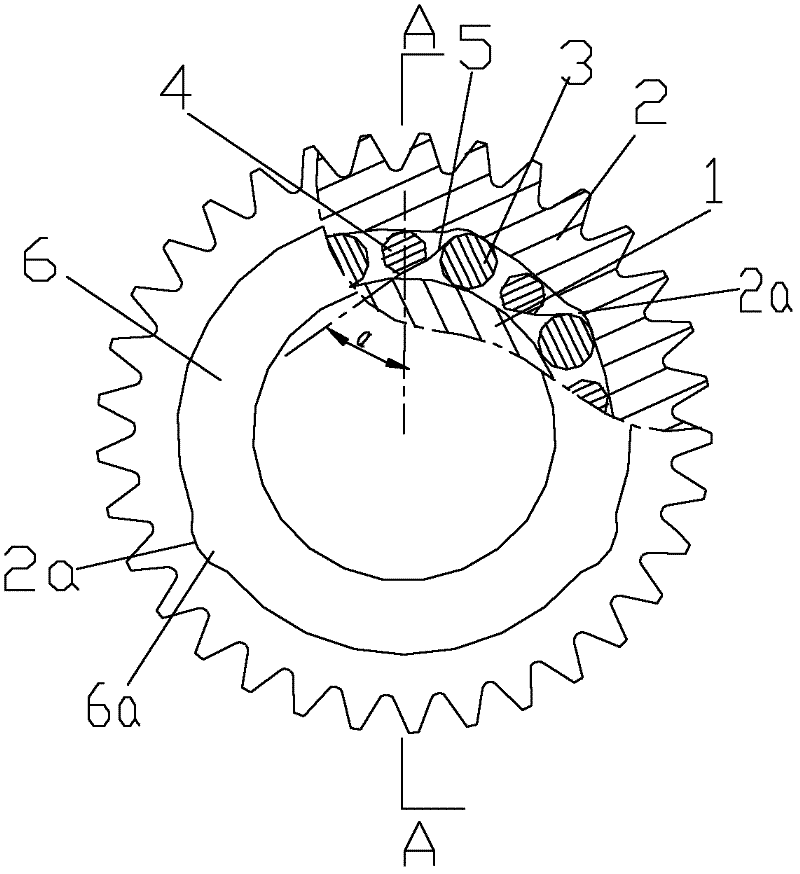

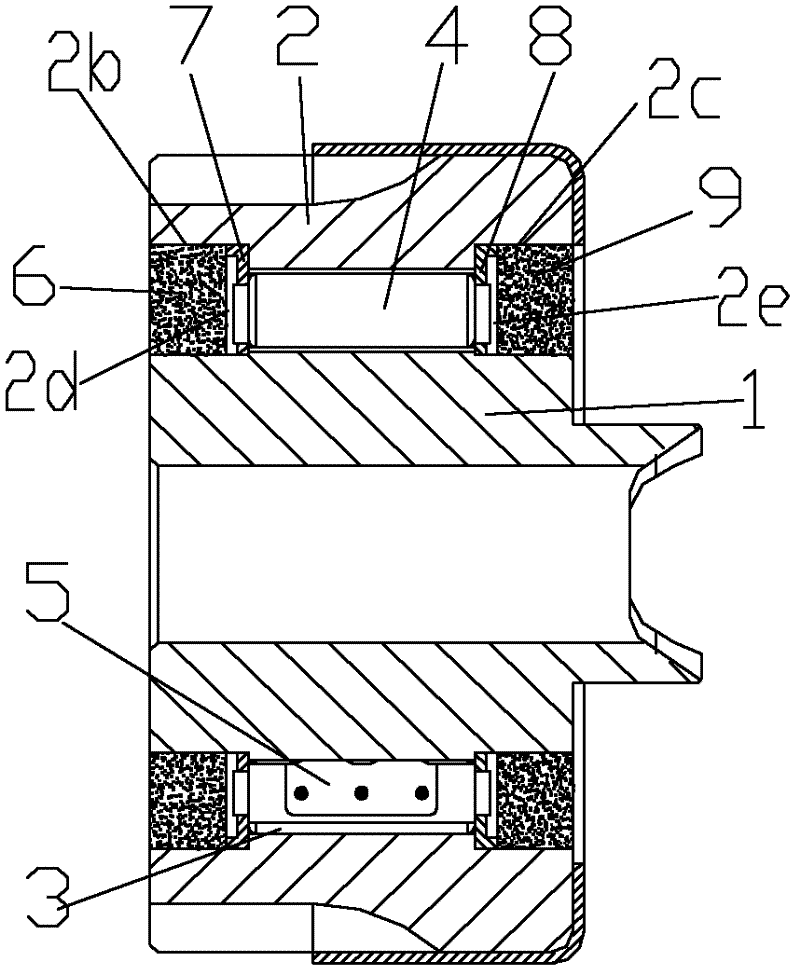

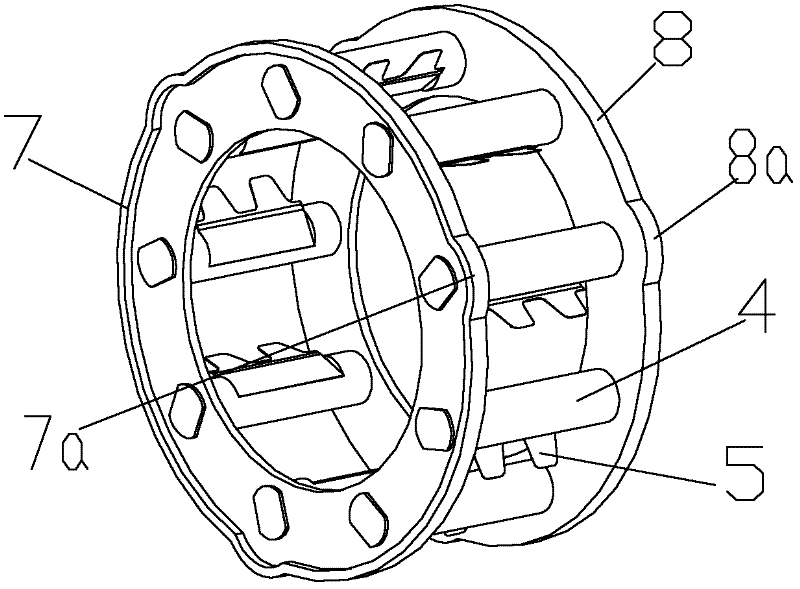

[0023] figure 1 It is a schematic diagram of the structure of the present invention, figure 2 for figure 1 Sectional view along A-A direction, image 3 It is a three-dimensional view of the cage of the present invention, Figure 4 It is a schematic diagram of the cooperation relationship between the support column and the support ring II of the present invention, as shown in the figure: the heavy-duty overrunning clutch of this embodiment includes the outer ring 2, the inner ring 1 and the roller 3, and the inner ring 1 is not limited to the annular The structure can also be a shaft-shaped structure as shown in the figure; the inner circle of the outer ring 2 forms an engaging groove 2a for engaging or separating from the roller 3. This structure tree is the same as the prior art, and the engaging groove 2a can be adopted The wedge-shaped structure or arc structure; for the present invention, the arc structure is better; it also includes a cage, which includes a support ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com